Flexible, simple and convenient plate processing equipment

A simple and convenient technology for plate processing, applied in metal processing, etc., can solve problems such as low efficiency, errors, troubles, etc., and achieve the effect of simple and accurate hole opening, precise hole position, and simple hole opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

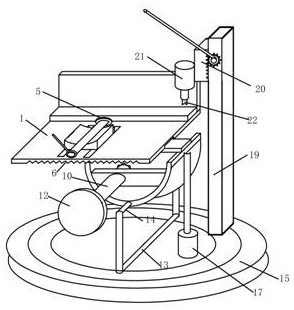

[0022] Combine below Figure 1 to Figure 4 Specific description embodiment:

[0023] Such as Figure 4 As shown, the workbench 1 is provided with an overall L-shaped workpiece rack 23, and the workbench is provided with two slideways 2 arranged parallel to each other, and the slideways are perpendicular to the vertical surface of the L-shaped workpiece rack. The bottom of the workbench is provided with an elongated chute 3 . Sliding member 4 is set on the slideway. A pressing plate 5 is arranged on the slide, and the pressing plate and the workpiece rack on the workbench form a station where the decorative plate can be placed. The bottom of the workbench is provided with a passive rack 6.

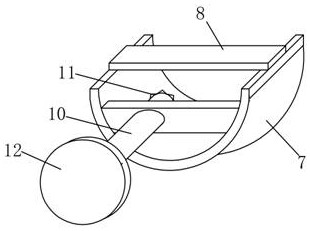

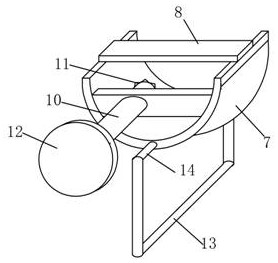

[0024] Such as figure 2 As shown, the bench 7 is arc-shaped as a whole, and a strip-shaped protrusion 8 is arranged on the top of the bench, and the strip-shaped protrusion is arranged in the strip-shaped chute 3 at the bottom of the workbench, so that the workbench can You can slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com