Clamp for machining through hole on valve housing of electro-hydraulic servo valve

A technology of electro-hydraulic servo valves and fixtures, which is applied in the direction of drilling jigs for workpieces, etc., can solve the problems of heavy workload, achieve low cost, high efficiency, and reduce the technical level of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

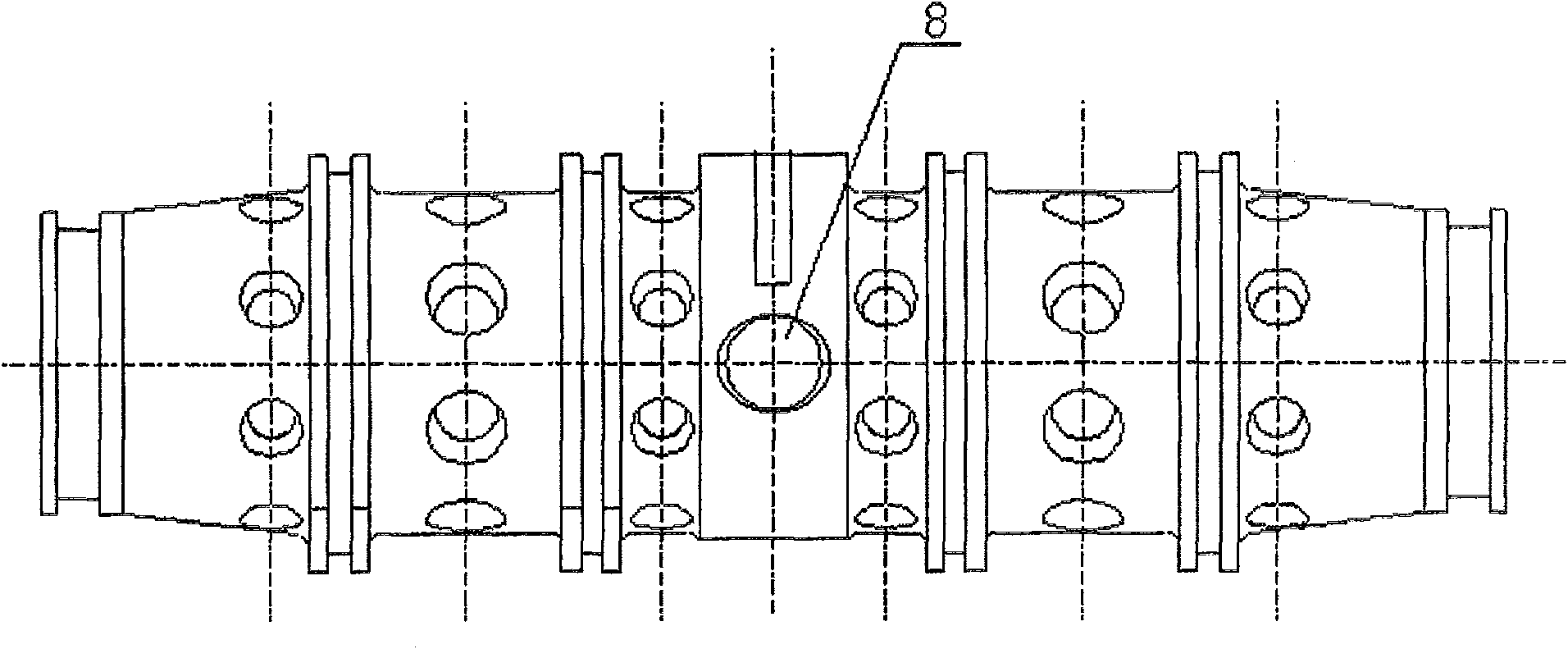

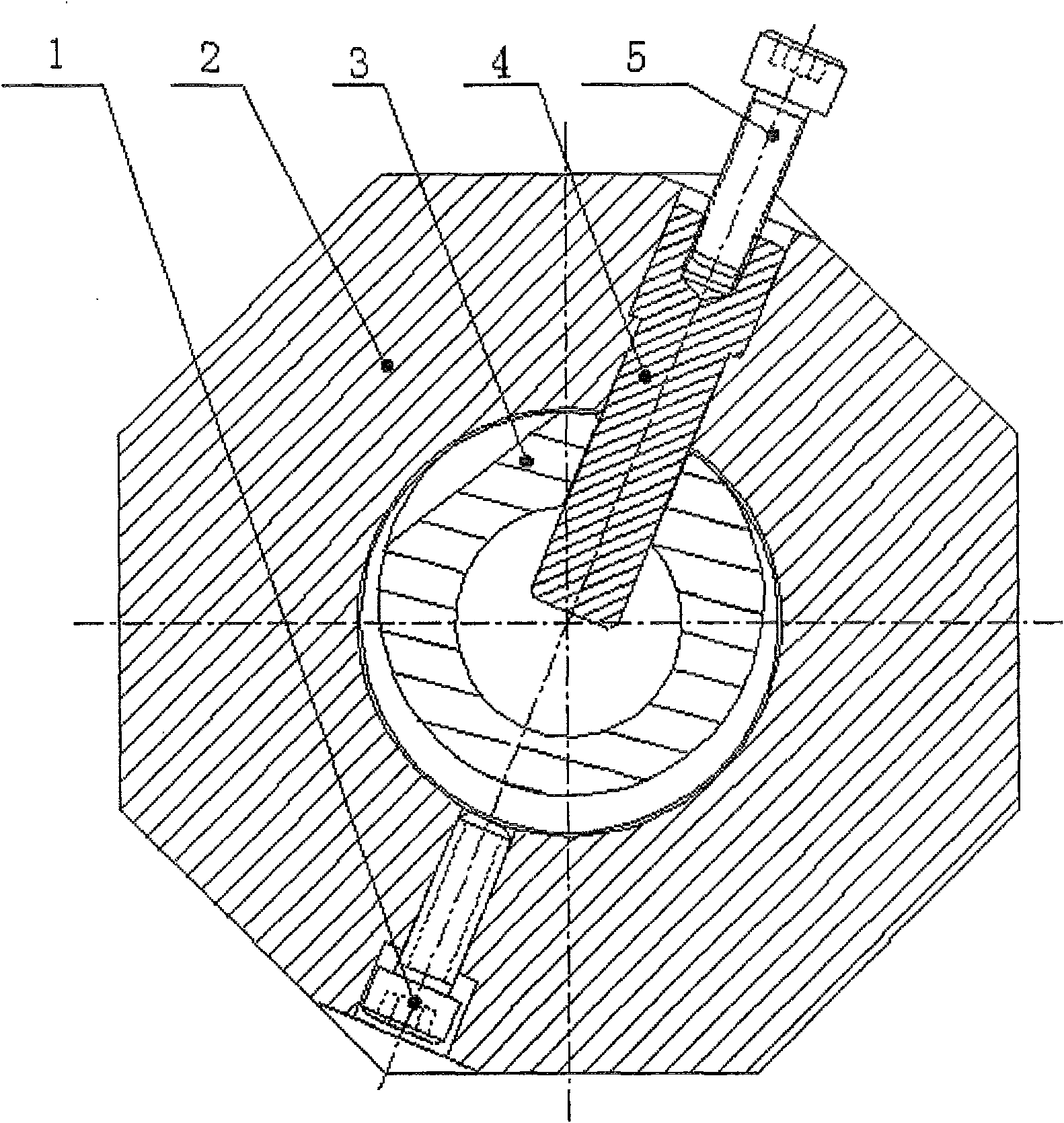

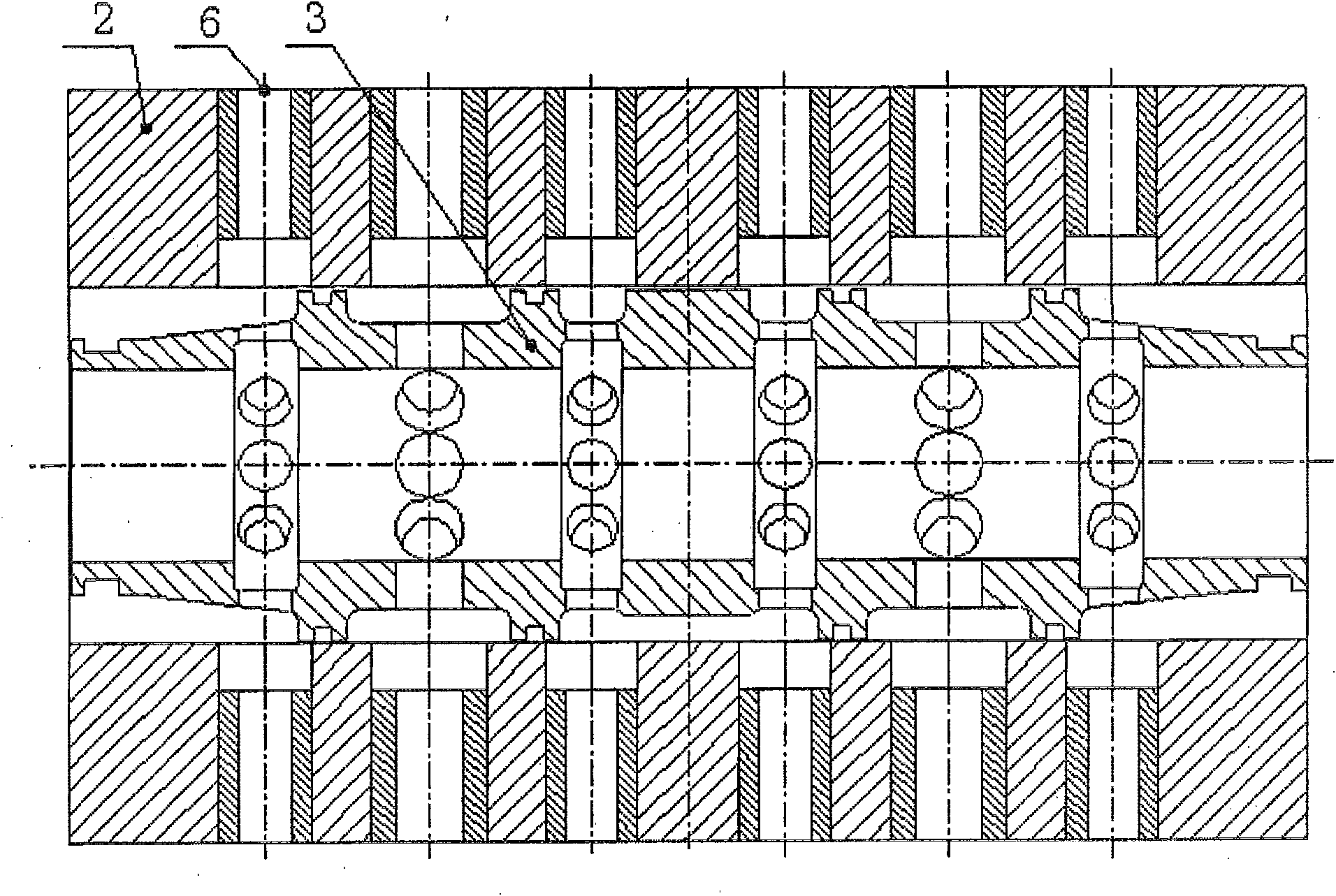

[0015] A processing fixture for the through hole on the valve sleeve in an electro-hydraulic servo valve, comprising a drill template body 2 and a drill sleeve 6, the drill template body 2 is a hollow octahedron, and holes for the drill sleeve 6 are arranged on eight sides thereof, A positioning pin placement hole 4 is arranged on one edge, and a positioning screw placement hole 1 is provided on its symmetrical edge, and the drill sleeve 6 is arranged in the placement hole provided on the surface of the drill body 2; the positioning pin and the positioning screw are placed In the placement hole; the middle part of the processing fixture also has a positioning hole, which is radially arranged on the drill body 2, and is inserted into the positioning hole in the middle of the valve sleeve 3 for positioning with a positioning pin; the positioning pin head A thread that can cooperate with the pull-up screw 5 is provided in the groove of the upper part.

[0016] The drill sleeve is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com