Tapping device and multi-station drilling and tapping integrated equipment thereof

A multi-station, mounting hole technology, used in metal processing equipment, other manufacturing equipment/tools, positioning devices, etc., can solve problems such as high cost, large differences in taps, and difficulty in combining or exchanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

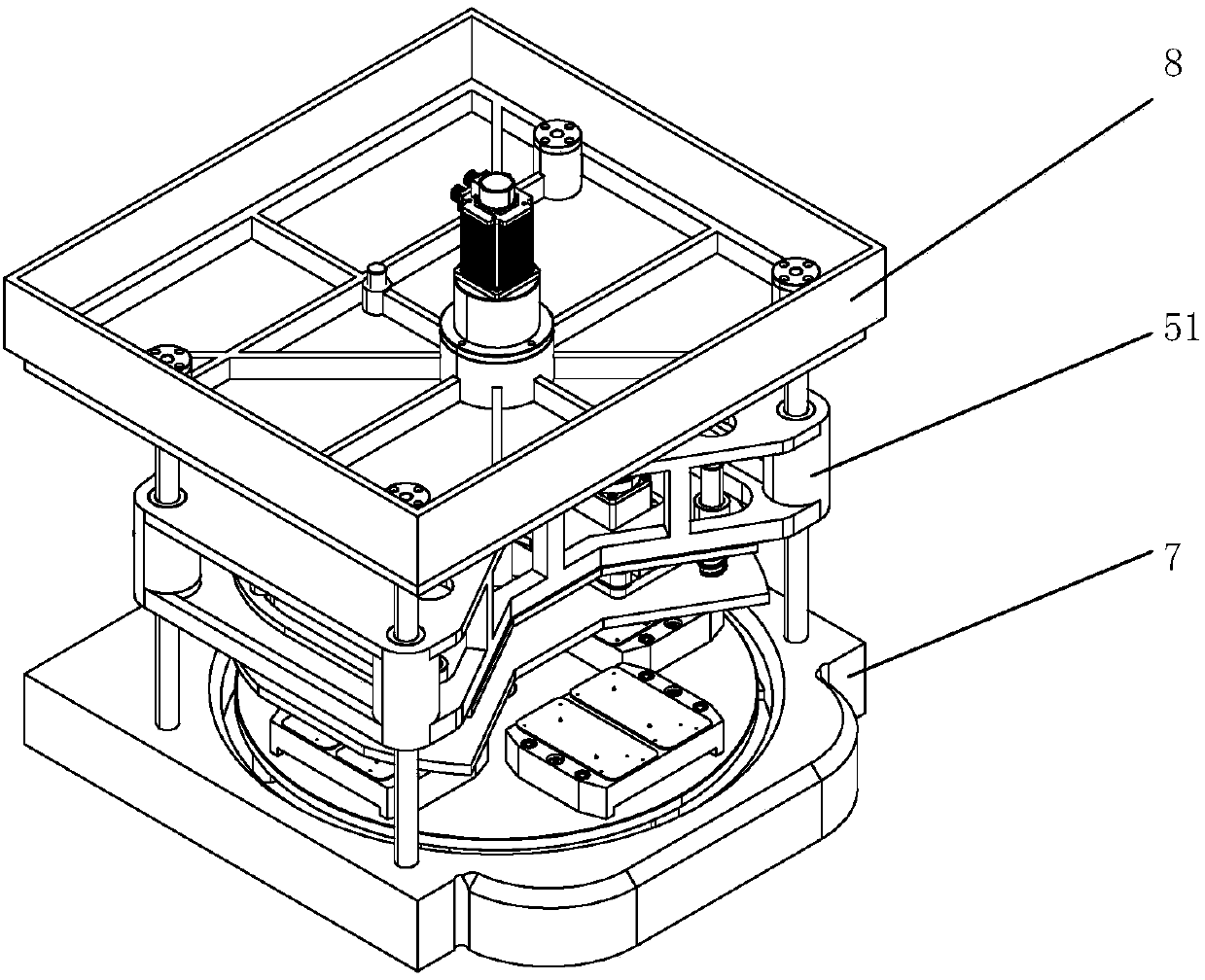

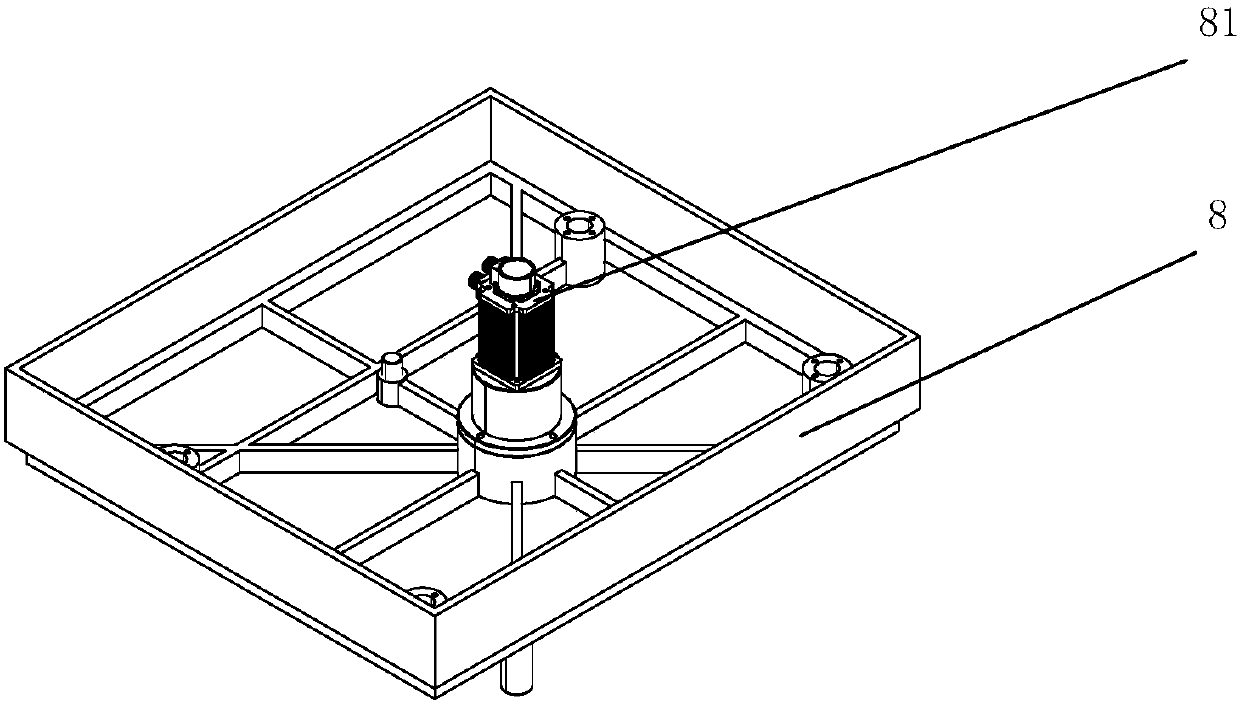

[0076] Such as Figure 1 to Figure 6 As shown, the multi-station drilling and tapping integrated equipment includes an upper frame 8, a guide post 71, a drive mechanism for moving up and down 81, an upper die base 51, an upper pressing plate 52, an upper die mounting plate 53, and a multi-station drilling Device 2, drilling drive motor 4, multi-station tapping device 1, tapping drive motor 3, lower mold rotary table 60, lower frame 7, lower mold rotary table drive mechanism 65.

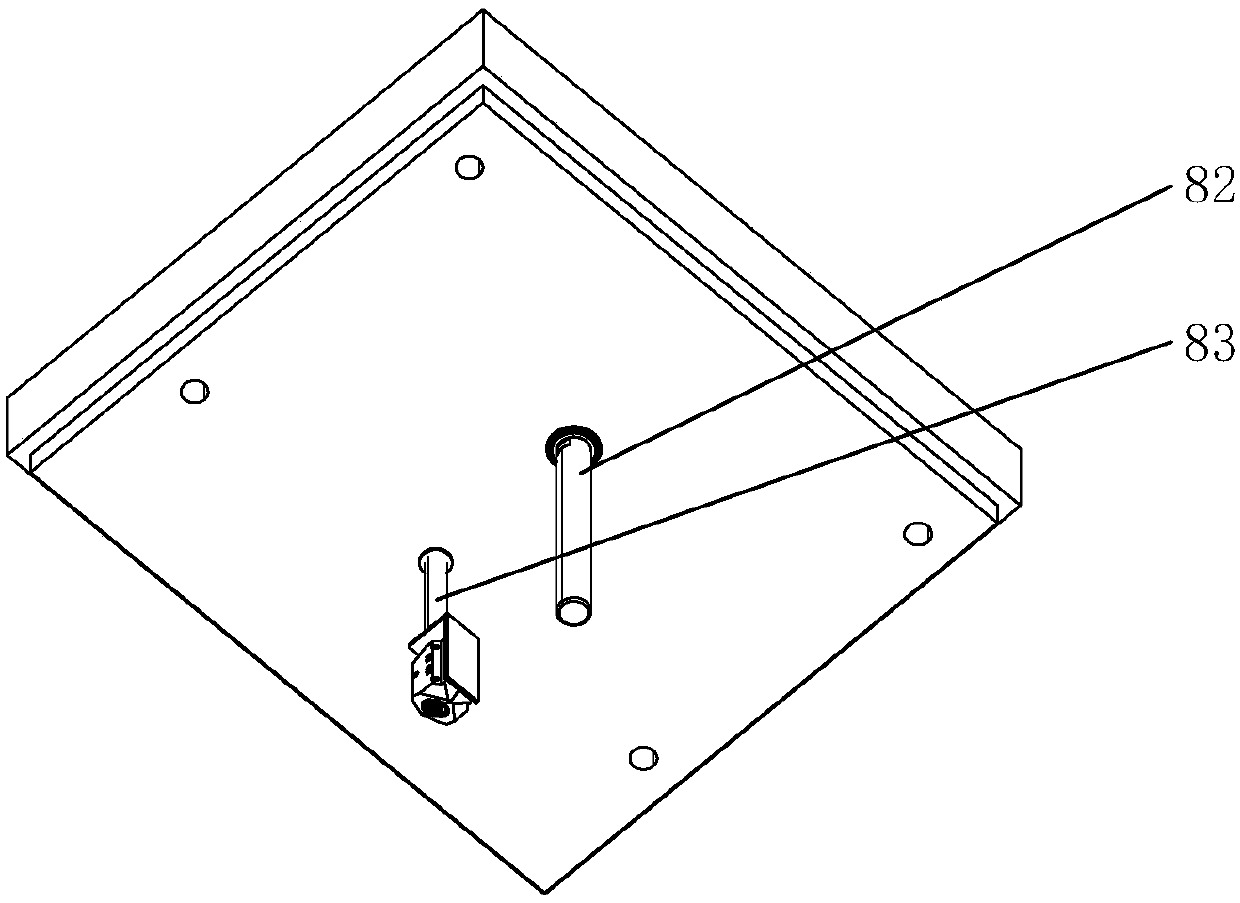

[0077] Also be provided with four lower molds 61 on the lower mold rotary table. The upper frame is also provided with a detection device 83. The lower frame 7 and the upper frame 8 are connected by four guide posts 71 . Servo motor 9 is installed in the lower frame 7, which can drive the lower mold rotary table drive mechanism 65, and drive the lower mold rotary table 60 to rotate, so that the lower mold 61 can be converted between different stations. The upper frame 8 is equipped with a servo mot...

Embodiment 2

[0100] Such as Figure 31 Shown, and embodiment 1 is different, is not the mode that adopts drill bit shank to cooperate with pilot hole. The drill spindle transmission part 22 is provided with a drill spindle transmission part guide part 2206, and the drill spindle transmission part guide part 2206 is precisely matched with the first guide hole 230212 of the drill installation hole 23021, and the drill bit 21 is provided with cooperation and guidance, so that the drill bit 21 moves along the first guide hole 230212. The axis of a guide hole 230212 is drilled downwards to ensure that the hole position does not deviate from the hole.

[0101] Such as Figure 32 Shown, and embodiment 1 is different, is not the mode that adopts screw tap shank to cooperate with guide hole. The main shaft transmission part 12 is provided with a main shaft transmission part guide part 1206, and the main shaft transmission part guide part 1206 is precisely matched with the guide hole 130212 of the...

Embodiment 3

[0103] Such as Figure 33 Shown, the difference with the drilling device in embodiment 1 is to adopt the mode of primary guide. The drill bit 2102 is precisely matched with the first guide hole 230212 to provide guidance, so that the drill bit 21 moves downward along the axis of the first guide hole 230212 to drill holes, ensuring that the hole position will not be deviated.

[0104] Such as Figure 34 As shown, the difference with the tapping device in embodiment 1 is to adopt the mode of one-level guide. Utilize tap shank 1102 and pilot hole 130212 to provide guidance precisely, make drill bit 11 move downwards along the axis of pilot hole 130212 and tap, guarantee that the thread will not deviate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com