Device for guaranteeing coaxiality of multiple lug piece holes

A coaxiality and lug hole technology, applied in the direction of drilling dies for workpieces, etc., can solve the problems that the coaxial hole is easy to exceed tolerance and cannot meet the coaxial hole, etc., and achieves the effect of improving efficiency, saving special tooling and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

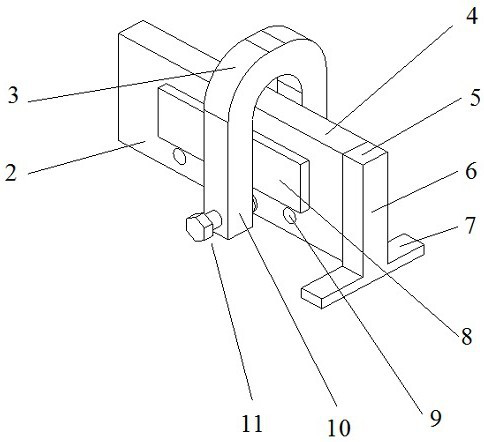

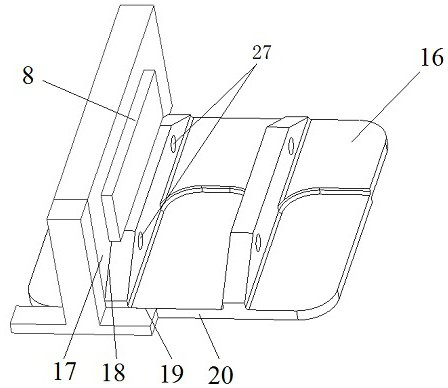

[0021] A device for ensuring the coaxiality of the multi-lug holes of the present application includes a positioning tool 2 and a U-shaped clamp 3; the positioning tool 2 is a cuboid flat plate 4 with a support 5 at one end, and the support 5 is composed of The rectangular parallelepiped strut 6 and the rectangular parallelepiped leg 7 are formed, and the strut 6 and the leg 7 are perpendicular to each other; the flat plate 4 is provided with a rectangular spacer 8 and a guide hole 9; Bolts 11 are arranged on the U-shaped body 10 and the U-shaped body 10, and the relative positions of the positioning tool 2 and the parts 16 are fixed by tightening the bolts 11. The guide hole 9 is an initial hole for guiding the tab hole 27 .

[0022] The inner surface 19 of the support is a plane and is perpendicular to the bottom plane 21 of the support.

[0023] The flat back 17 of the positioning tool 2 fits with the part lug positioning surface 18, the support inner side 19 fits with the...

Embodiment 2

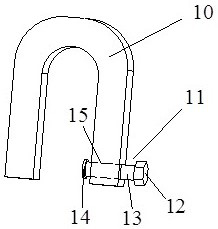

[0025] A device for ensuring the coaxiality of multi-lug holes is composed of a positioning tool 2 and a U-shaped fixture 3. The hole position of a single-lug hole is determined by fitting the positioning tool 2 with the positioning surface of the part, and the bolts on the U-shaped fixture 3 11 is made up of nut 12, screw rod 13 and nut 14, and U-shaped fixture is provided with threaded hole 15 near the bottom end. The nut 12 and the nut 14 are fixed on the screw rod 13, the parts 16 and the positioning tool 2 are clamped by the U-shaped clamp 3, the bolts 11 are fastened, the holes are fixed, and the hole is made through the guide hole 9 on the positioning tool 2. When making the coaxial hole 28 of multiple lugs, by selecting the corresponding positioning surface on the part 16, the translation device is clamped, so that the coaxial hole making of multiple lug holes can be realized.

Embodiment 3

[0027] The positioning tool 2 is a rectangular flat plate 4 with a support at one end, which is used to determine the hole position of the lug hole of the part and guide the hole making. The limit plate 8 provided on the plate 4 calibrates the bonding surface of the support 5 and the part 16 to determine the position of the lug hole 27, and the guide hole 9 provided on the plate guides the hole making. The limiting pieces 8 are symmetrically distributed on both sides of the flat plate 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com