Fixture for electro-hydraulic servo valve keeper positioning center

An electro-hydraulic servo valve and positioning center technology, applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of low precision and low processing efficiency, achieve convenient clamping, improve processing efficiency, and correct center hole position Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

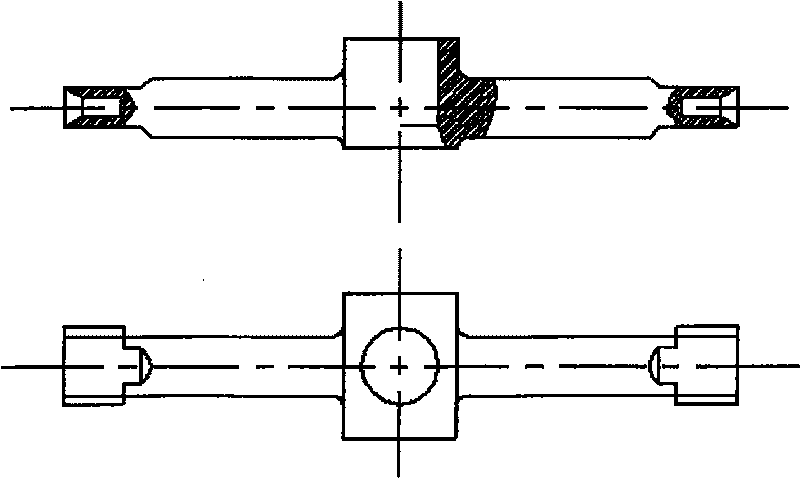

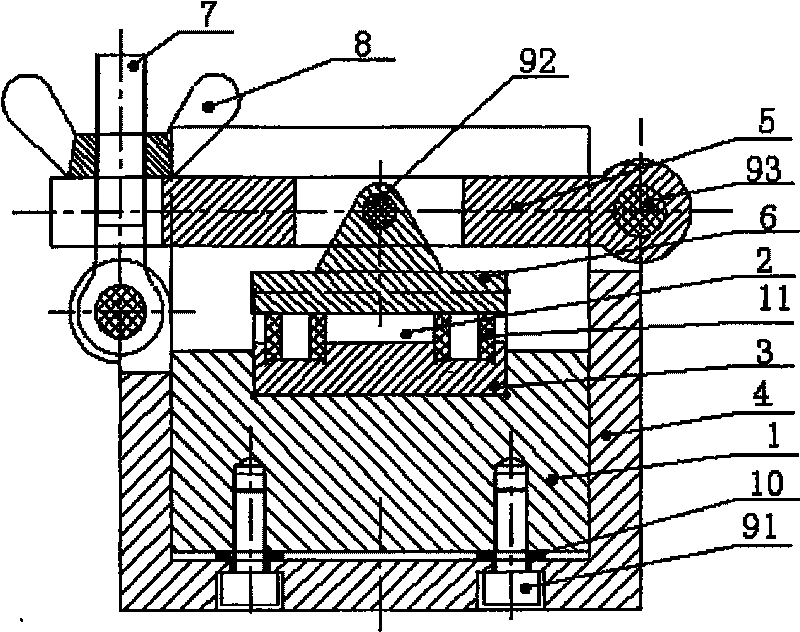

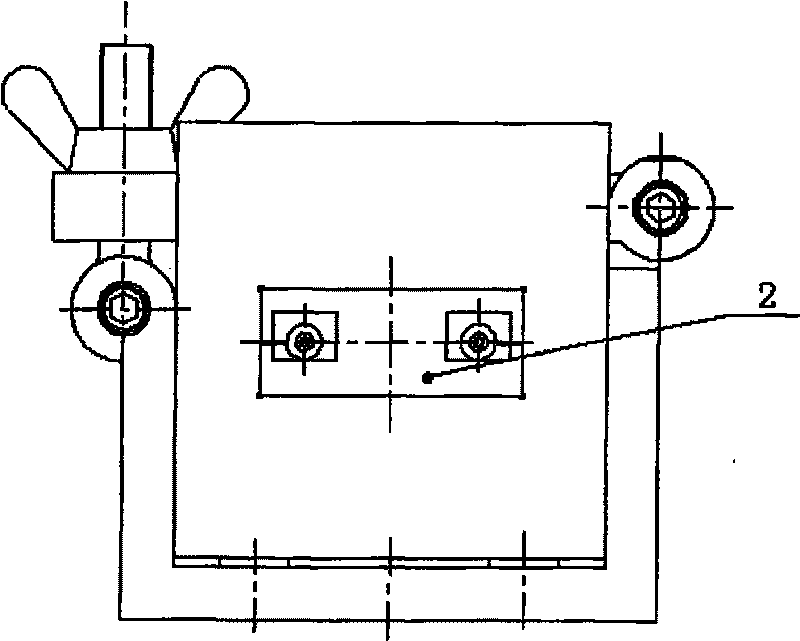

[0015] Such as figure 1 , 2 , Shown in 3, a fixture for centering the armature in an electro-hydraulic servo valve, including a jig body 1, two positioning blocks 2, a spacer 3, a support 4, a rotary plate 5, a support plate 6, and a joint bolt 7. in:

[0016] Drilling template body 1 is a "concave" structure with windows matching the two positioning blocks on both sides, and the space between the two windows is used as the placement position of cushion block 3, and the bottom of drilling template body 1 is provided with a threaded hole for fixing bracket 4; Drill template body 1 and support 4 are fixed with screw 91 and washer 10;

[0017] The positioning block 2 is installed in the windows opened on both sides of the drill body 1, and plays a centering role;

[0018] The cushion block 3 is installed in the placement position of the cushion block 3 provided between the two windows of the drill body 1, and there are two grooves for placing the armature on it, and the armatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com