Explosion-proof motor base wiring hole combined machining device and machining method

An explosion-proof motor and combined processing technology, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve problems such as the inability to guarantee the drilling accuracy, and achieve the effects of avoiding combined processing errors, improving processing efficiency, and fast milling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

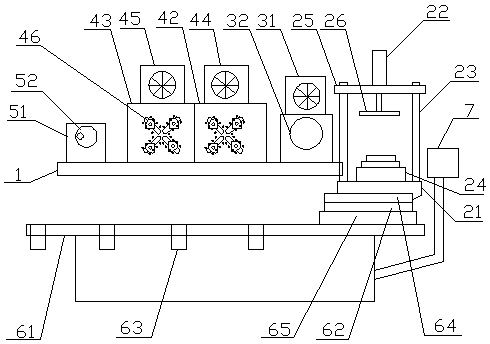

[0031] like figure 1 , figure 2 As shown, an explosion-proof motor base wiring hole combination processing device includes a bearing platform 1, on which a milling mechanism, a drilling mechanism, and a turning mechanism are arranged in sequence, and a translation mechanism is arranged in front of the bearing platform, and the translation mechanism A pressing and positioning mechanism is arranged on the mechanism, and the milling mechanism, the punching mechanism, the turning mechanism, the translation mechanism and the pressing and positioning mechanism are all connected to the controller 7, and the controller 7 is a programmable logic controller;

[0032] The pressing and positioning mechanism includes a base 21, on which a stepped eccentric pressure plate 24 is arranged, and on the base 21, support rods 23 are arranged on both sides of the stepped eccentric pressure plate 24, and the two support rods 23 A support plate 25 is fixed on the upper part, and a hydraulic telesc...

Embodiment 2

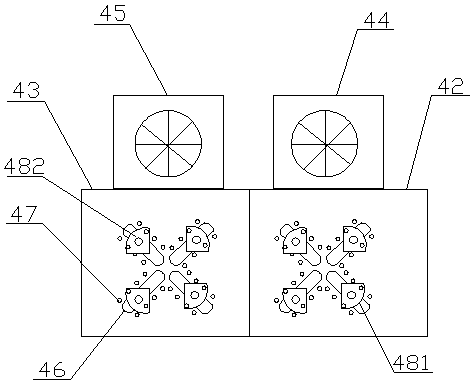

[0046] like figure 2 , image 3 As shown, an explosion-proof motor base wiring hole combination processing device includes a bearing platform 1, on which a milling mechanism, a drilling mechanism, and a turning mechanism are arranged in sequence, and a translation mechanism is arranged in front of the bearing platform, and the translation mechanism A pressing and positioning mechanism is arranged on the mechanism, and the milling mechanism, the punching mechanism, the turning mechanism, the translation mechanism and the pressing and positioning mechanism are all connected to the controller 7, and the controller 7 is a programmable logic controller;

[0047] The pressing and positioning mechanism includes a base 21, on which a stepped eccentric pressure plate 24 is arranged, and on the base 21, support rods 23 are arranged on both sides of the stepped eccentric pressure plate 24, and the two support rods 23 A support plate 25 is fixed on the upper part, and a hydraulic telesc...

Embodiment 3

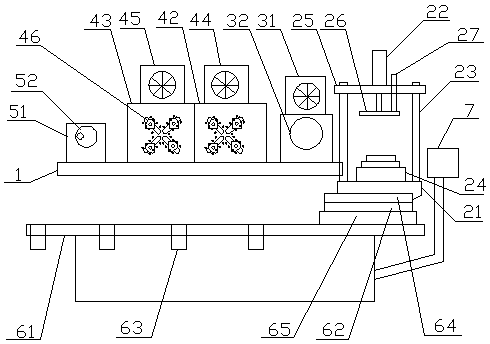

[0056] like figure 2 , Figure 4 As shown, an explosion-proof motor base wiring hole combination processing device includes a bearing platform 1, on which a milling mechanism, a drilling mechanism, and a turning mechanism are arranged in sequence, and a translation mechanism is arranged in front of the bearing platform, and the translation mechanism A pressing and positioning mechanism is arranged on the mechanism, and the milling mechanism, the punching mechanism, the turning mechanism, the translation mechanism and the pressing and positioning mechanism are all connected to the controller 7, and the controller 7 is a programmable logic controller;

[0057] The pressing and positioning mechanism includes a base 21, on which a stepped eccentric pressure plate 24 is arranged, and on the base 21, support rods 23 are arranged on both sides of the stepped eccentric pressure plate 24, and the two support rods 23 A support plate 25 is fixed on the upper part, and a hydraulic teles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com