Drilling automatic positioning device and method for tunneling and drilling jumbo

A technology for automatic positioning and rock drilling rigs, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc. It can solve the problems of restricting equipment efficiency and low drilling positioning efficiency, and achieve high efficiency and wide application. The effect of accurate hole position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

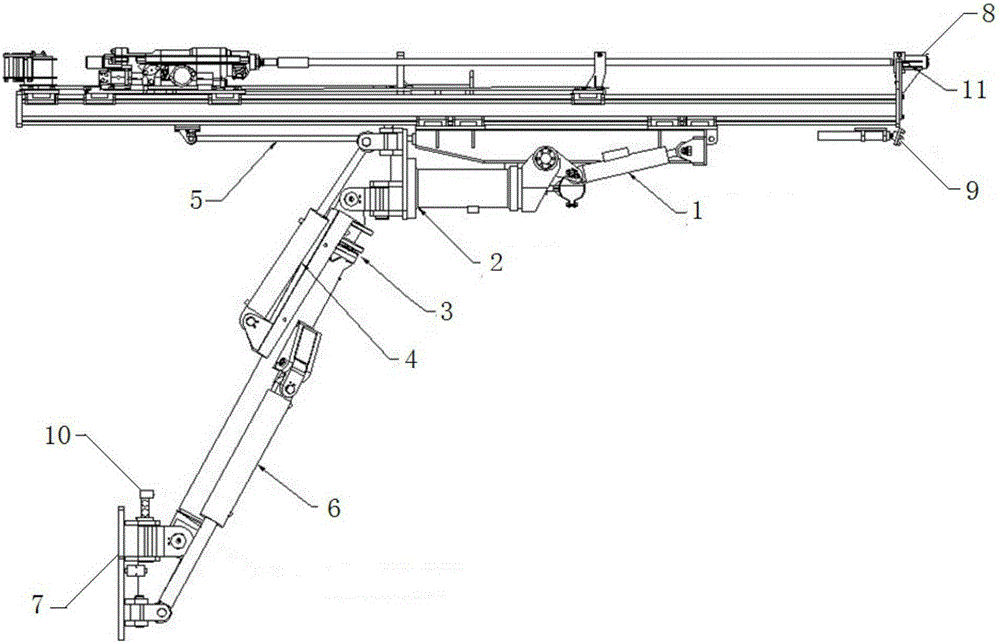

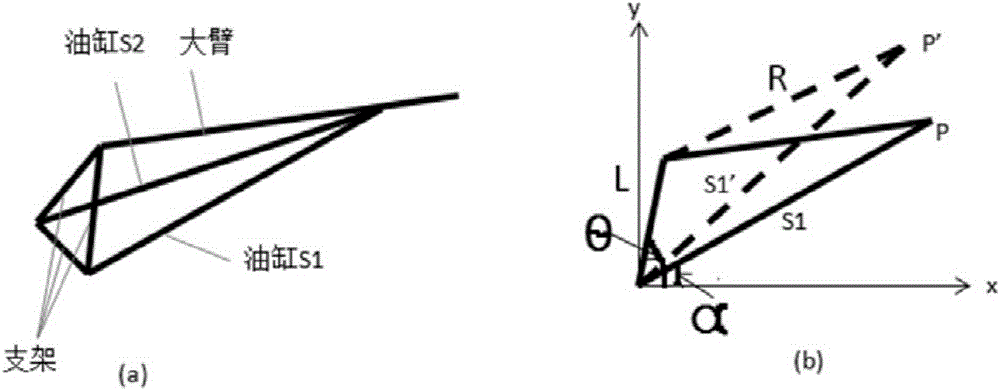

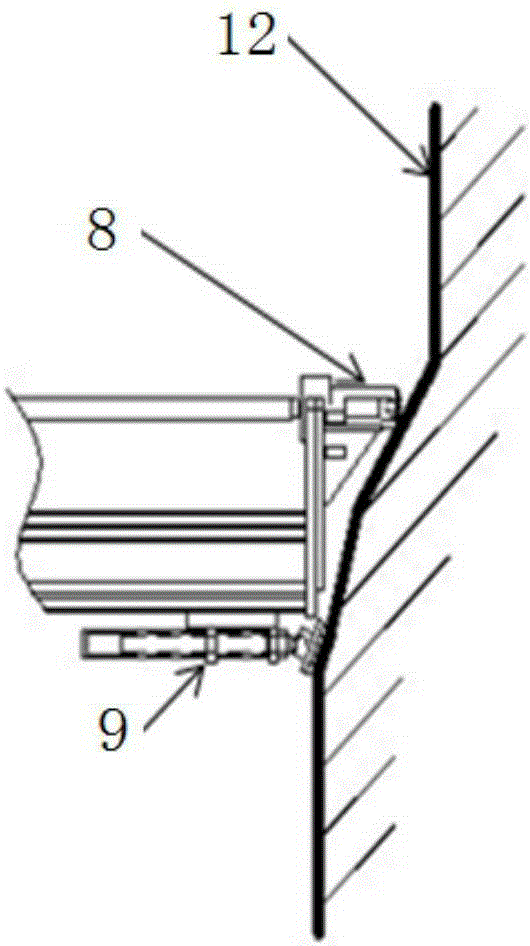

[0027] like figure 1 As shown, the automatic positioning device of the excavation rock drilling rig includes a hole supporter 8, a distance measuring sensor 11, a propulsion beam positioner 9, a lifting cylinder displacement sensor S1 and S2, a pitching cylinder displacement sensor S3 and S4, and a side cylinder displacement sensor Sensor S5. Hole supporter 8 is installed on the front end of the propelling beam and encloses the position of the drill bit. The ranging sensor 11 is installed under the opening supporter 8 and has anti-collision protection. Propelling beam positioner 9 is installed in the lower part of propelling beam front end. The displacement sensor is installed inside or outside the oil cylinder; wherein the lifting oil cylinder 6 and the pitch oil cylinder 4 are double oil cylinders, and the strokes of the two oil cylinders can be differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com