Patents

Literature

744results about How to "No movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thin-base-rock shallow coal-layer water-retaining production suitable-condition classification method

InactiveCN101070759AImprove resource recoveryHigh recovery rateUnderground miningSurface miningBedrockReturn ratio

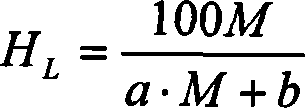

The invention discloses applicable classification method for mining under the shallow bedrock of thin seam keeping water conditions. Apply to thin seam overlying shallow bedrock aquifer water loose the protection of water resources. At first according to the feature of structure or Shallow bedrock, the height of leading water crevasse under different mining height is analyzed and calculated. The estimate formula: HL=9.29M+10.6 can be used to determine the height HL of leading crevasse water under the shallow bedrock of thin seam to the different mining height M. The mining waterproofing security coal rock pillar protector thickness of the thin bedrock shallow submersion coal bed long well working surface is 10 m. According to the classification situation of loose water-bearing stratum water body, the bedrock thickness which is needed is determined under the condition of different mining height. According to classification situation and mining height, mining is separated into reinsurance water mining according to the bedrock thickness. This method has good water resources protection effect, is safe in production, and has high coal resource returns-ratio.

Owner:CHINA UNIV OF MINING & TECH

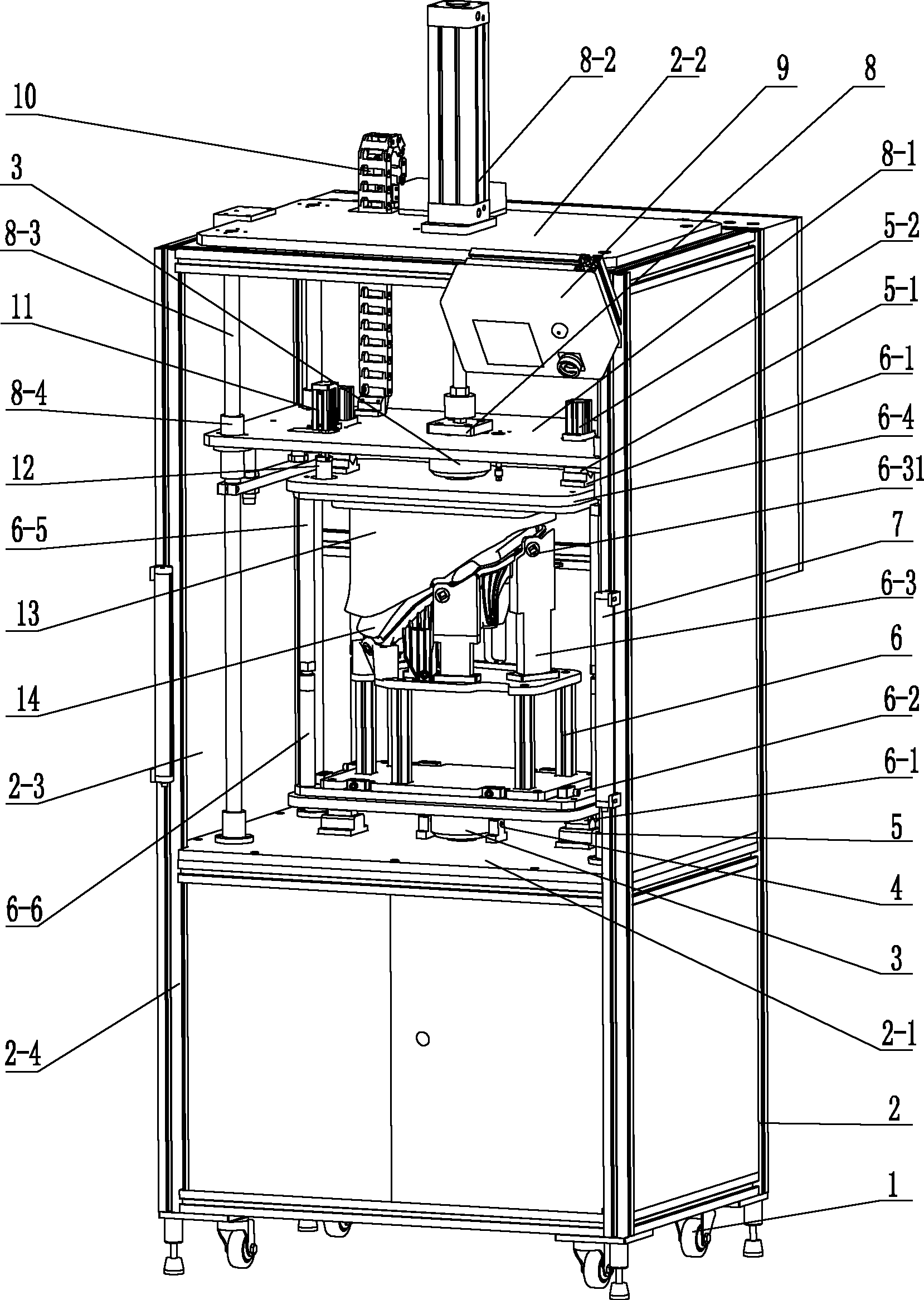

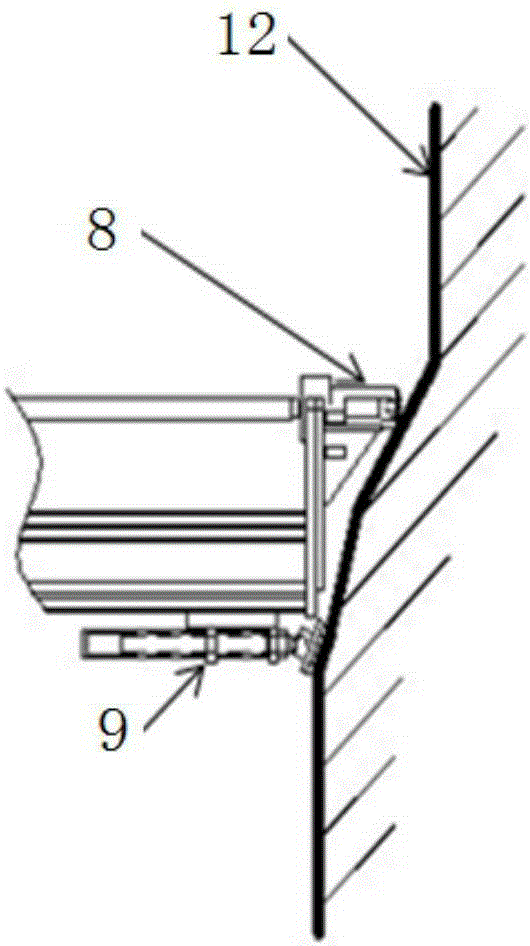

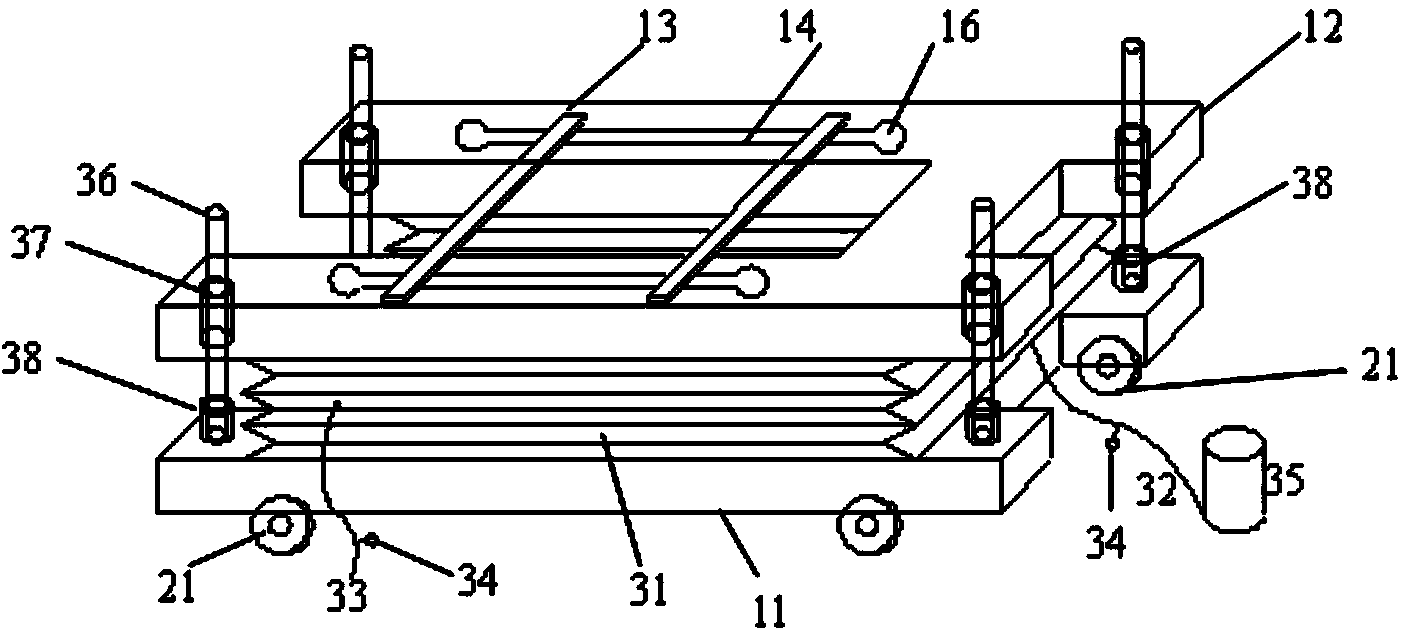

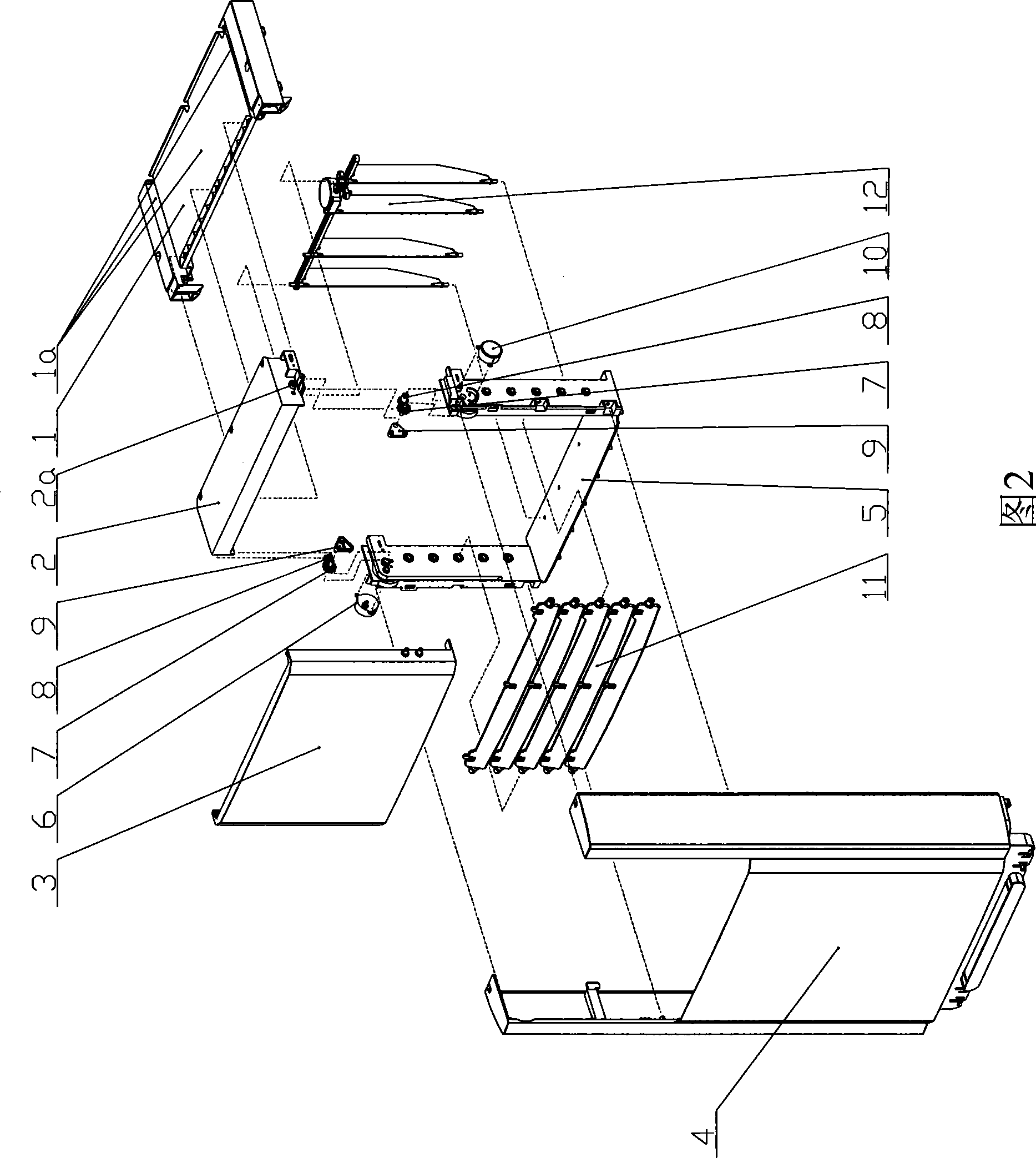

Diamond grinding material sequential arraying system and method

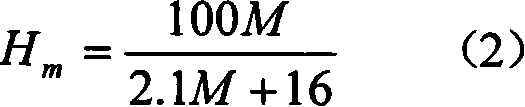

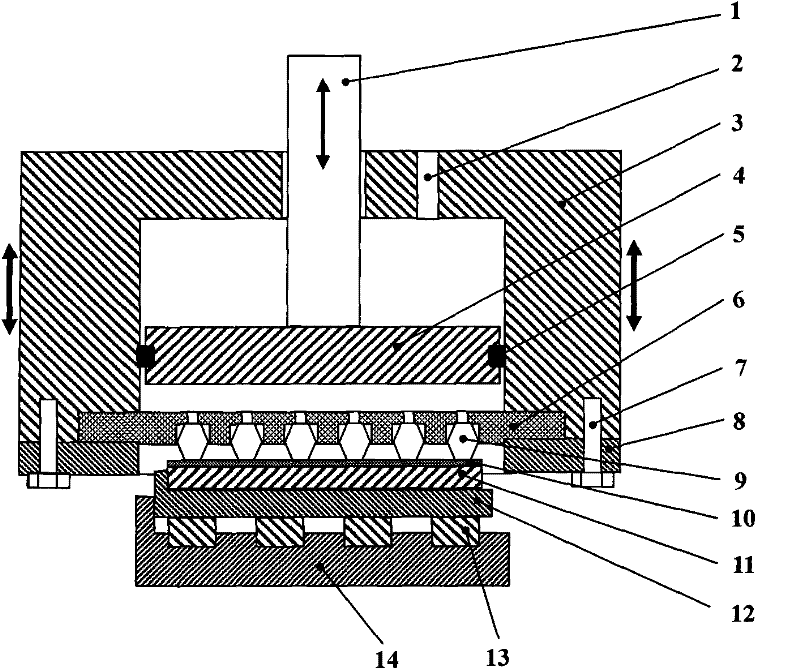

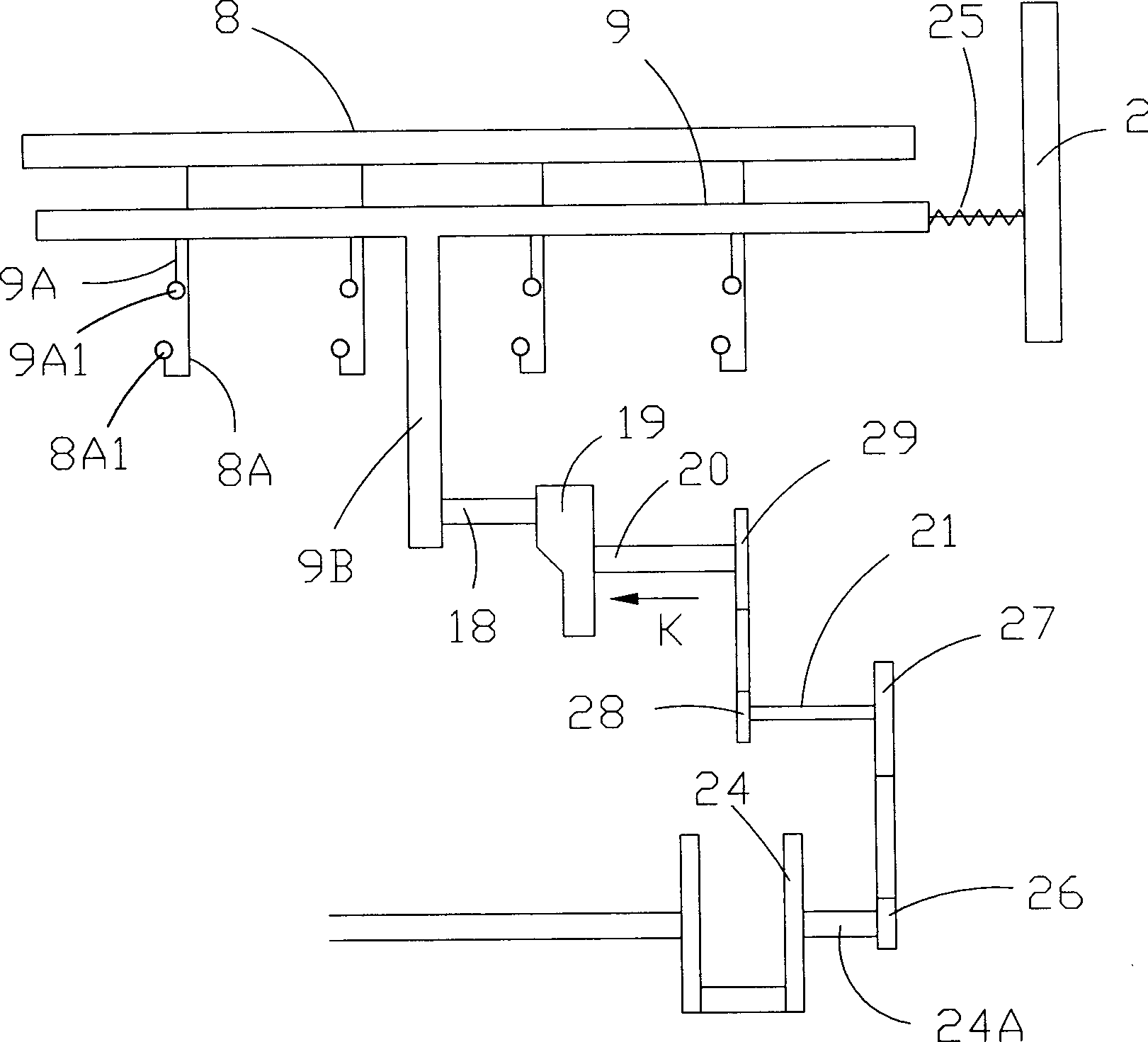

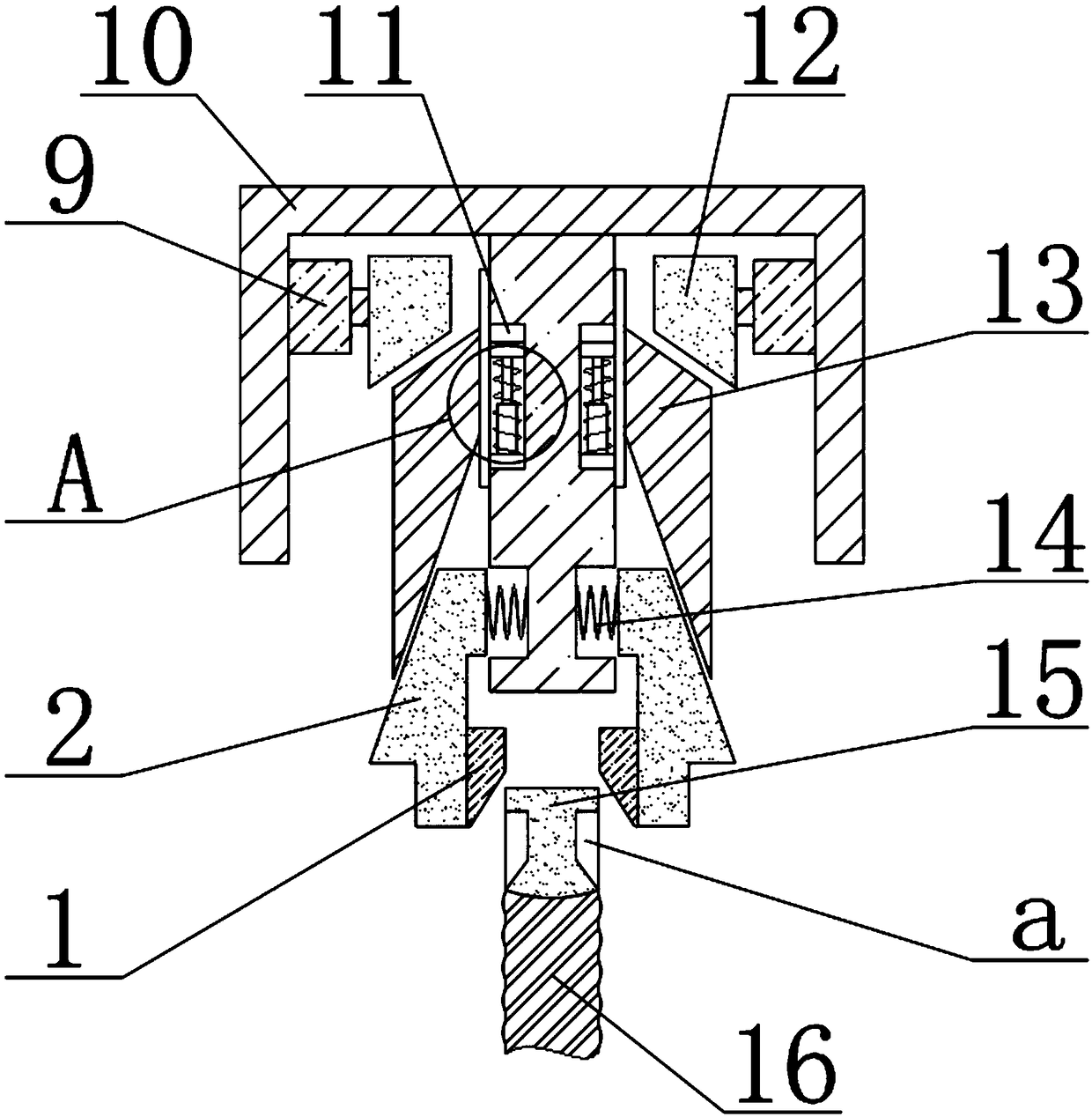

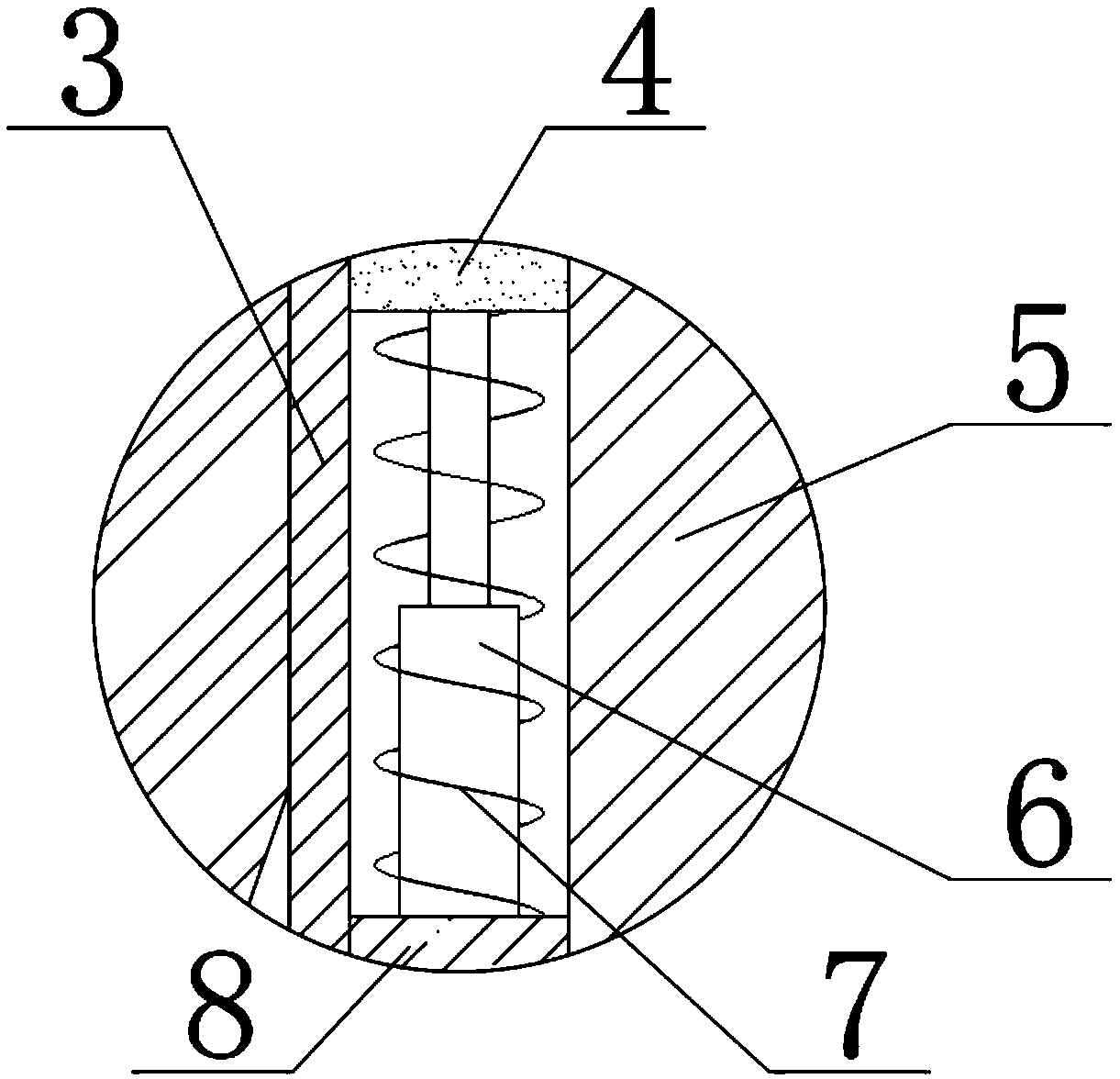

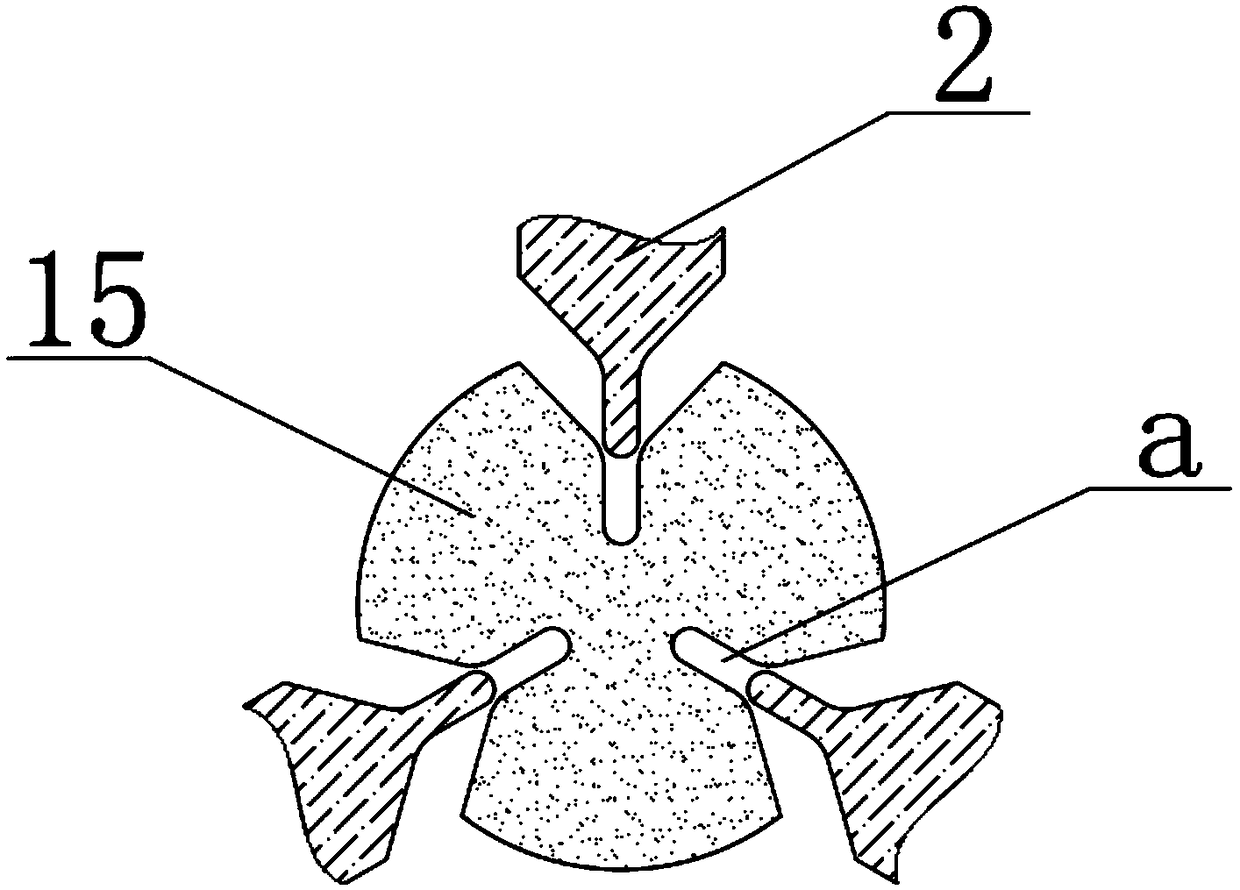

The invention relates to a diamond grinding material sequential arraying system and a method, belonging to the field of grinding material and tool manufacturing. The system comprises a cylinder sleeve (3) and a piston (4). The piston (4) which can move up and down is arranged in the cylinder sleeve by a piston rod (1), the cylinder sleeve is sealed with the piston by a sealing ring (5), an elastic plate (6) is fixed at the lower end face of the cylinder sleeve by a screw (7) and a pressing plate (8), and stepped holes are sequentially arrayed in the elastic plate. The system further comprises a worktable (14) and a supporting plate (12) arranged on the worktable (14) by a magnet block (13). With low cost and easy popularization, the system and the method can effectively, accurately and sequentially array and distribute diamond grinding materials.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

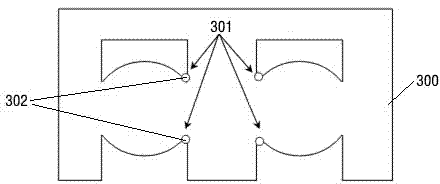

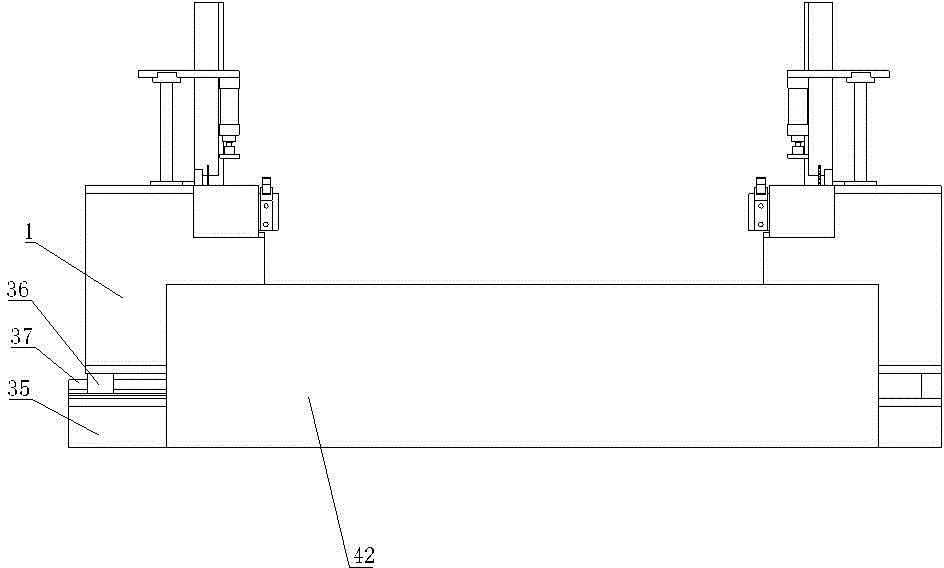

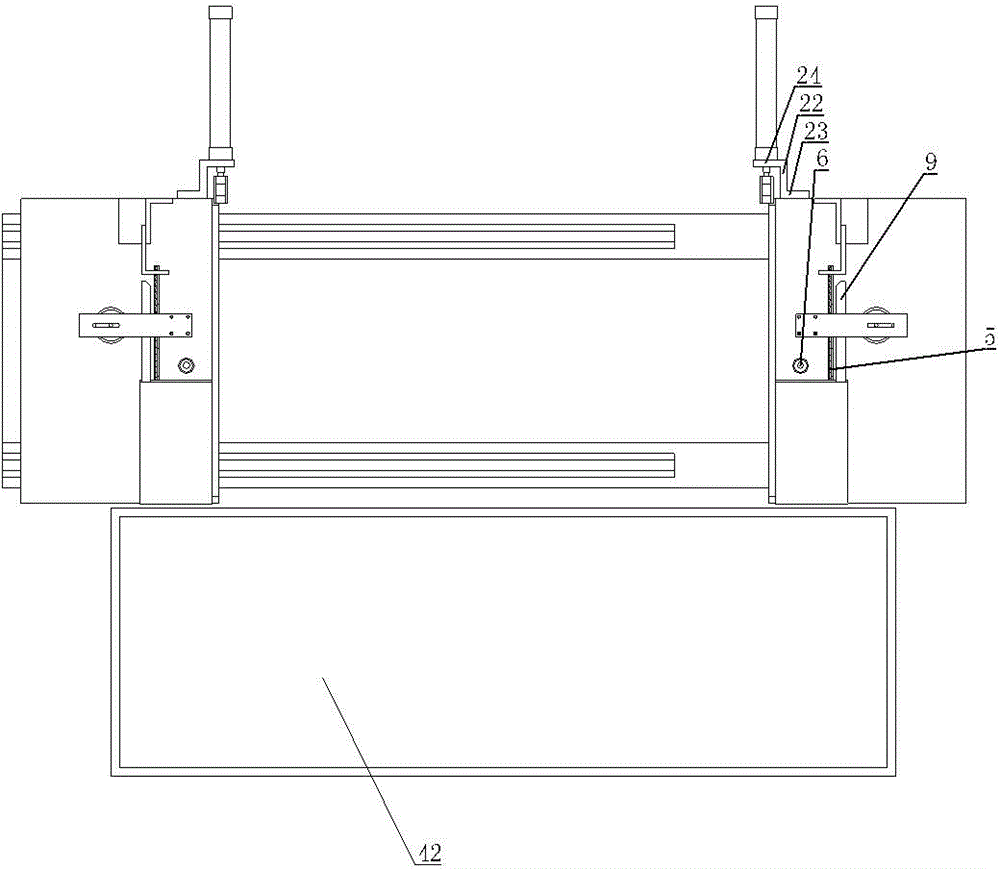

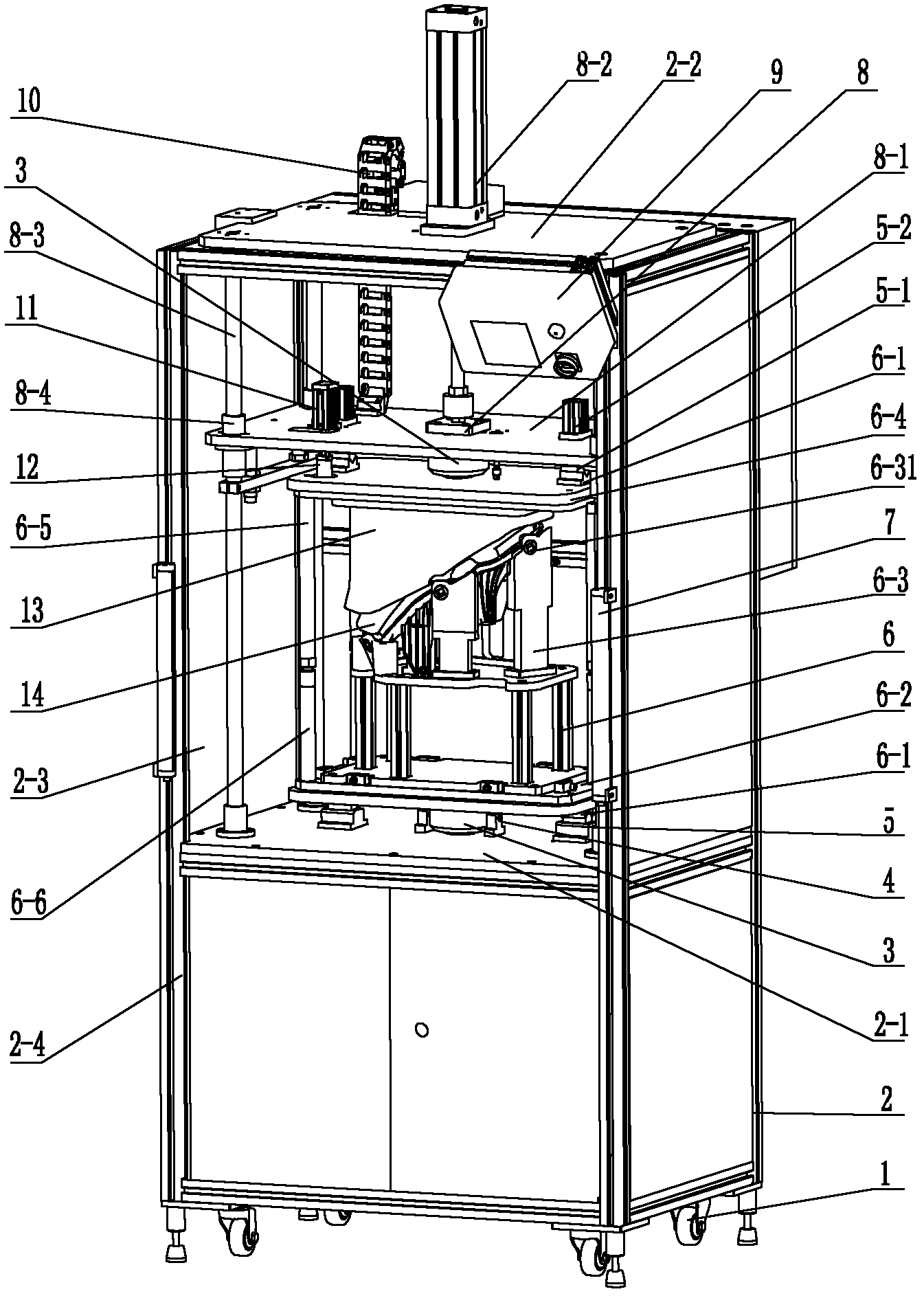

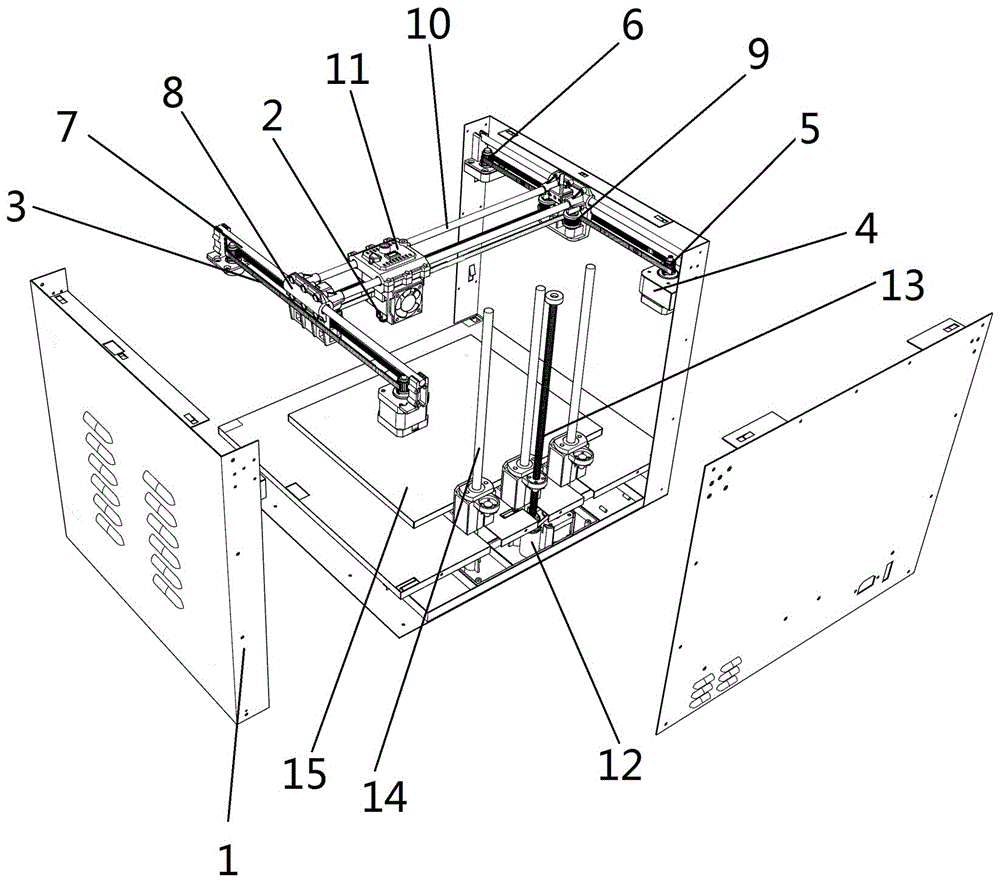

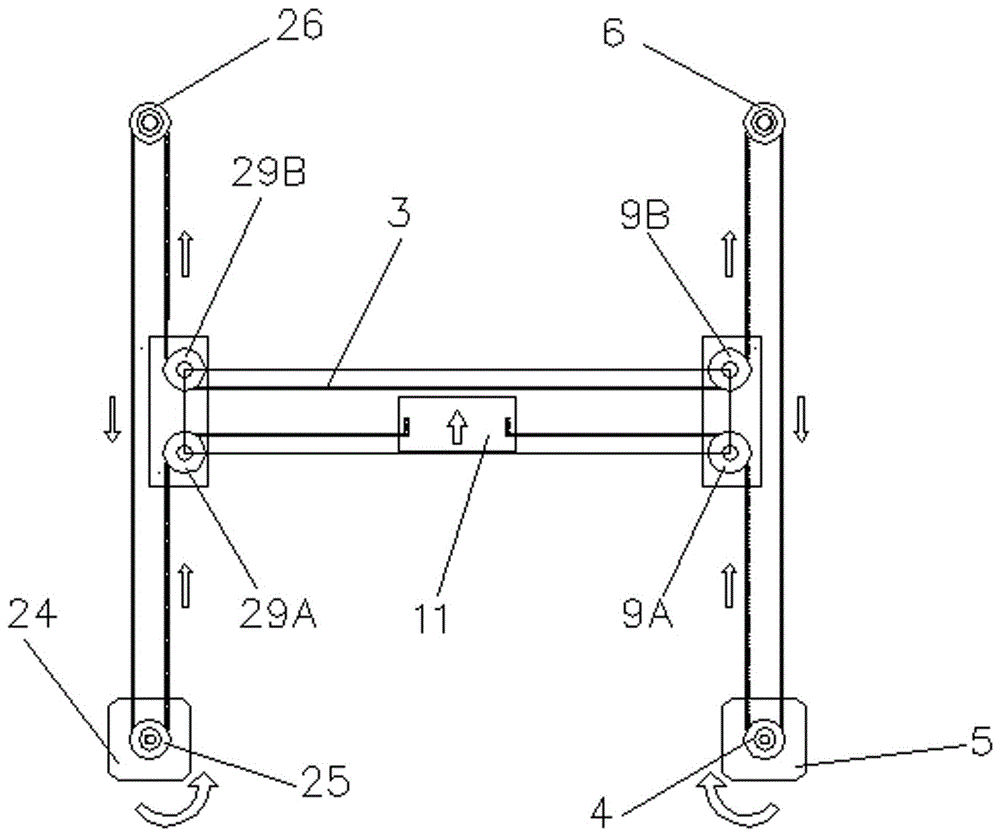

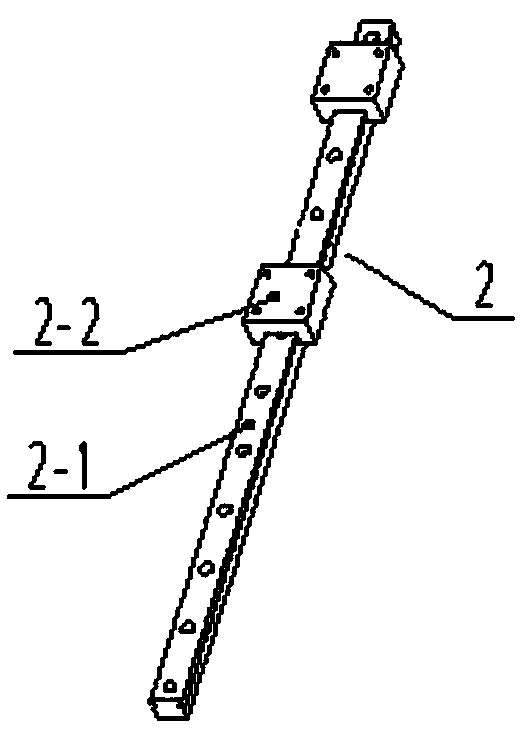

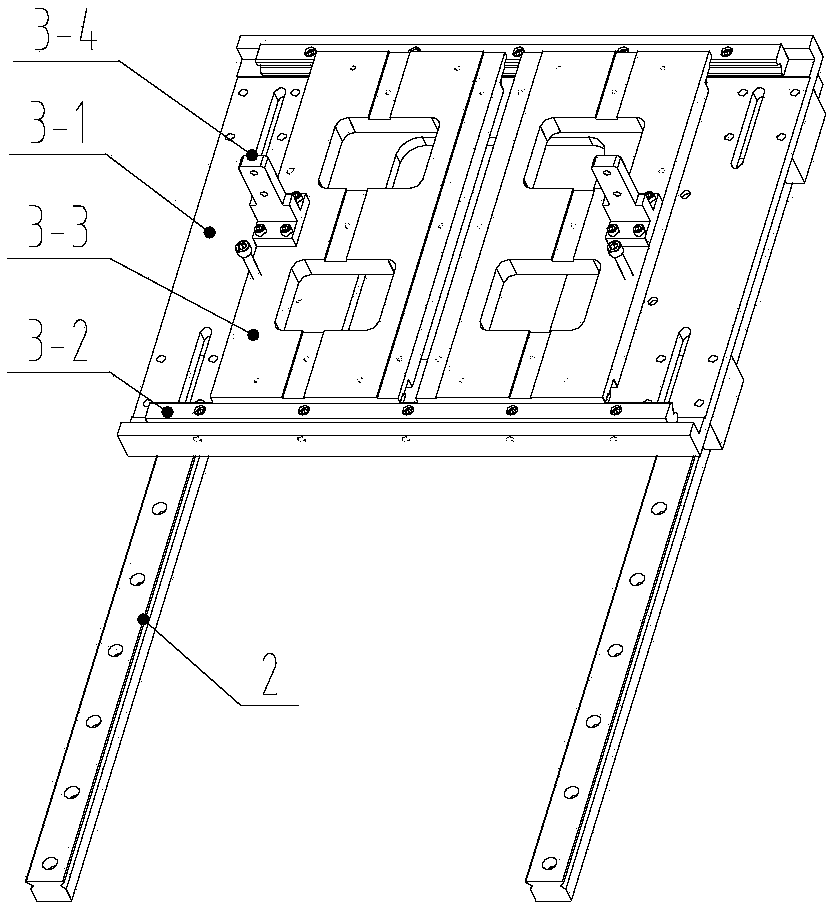

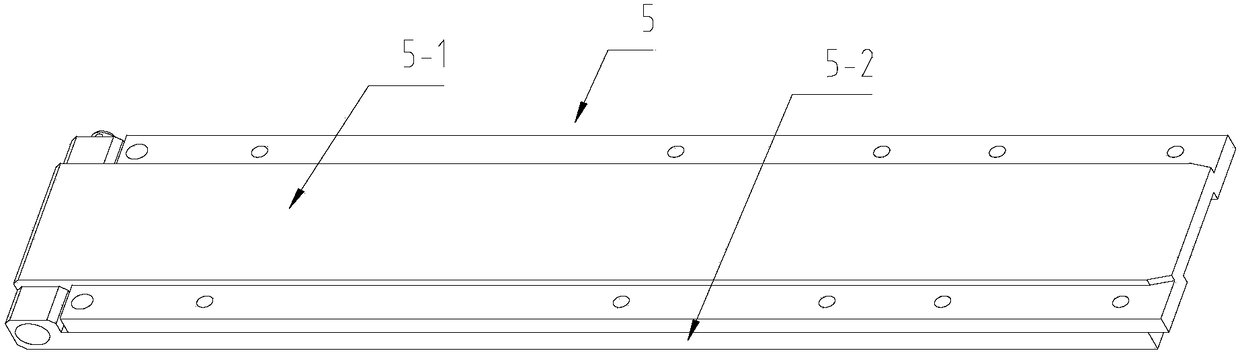

Mechanical arm for laminating transformer cores

InactiveCN105643605AAdjust poseNo movementProgramme-controlled manipulatorGripping headsTransformerEngineering

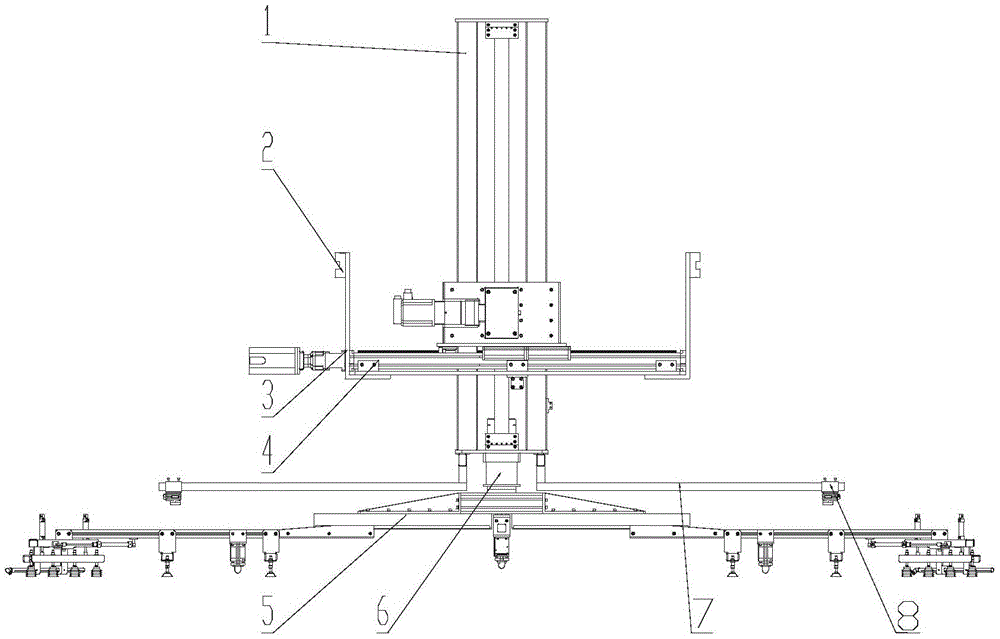

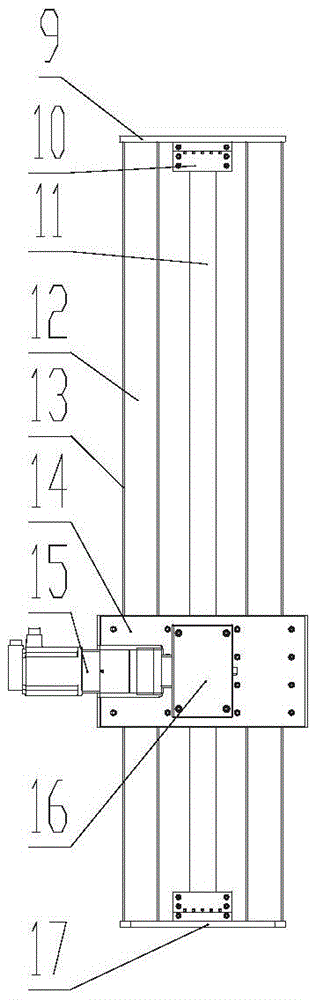

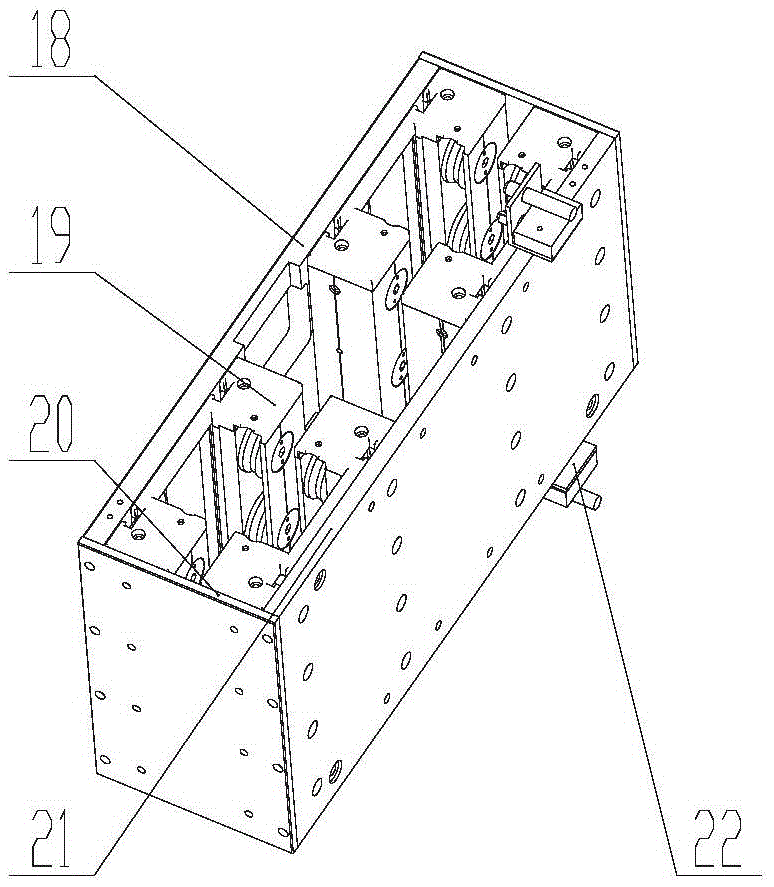

The invention belongs to the technical field of transformer core lamination processes and particularly relates to a mechanical arm for laminating transformer cores. The mechanical arm comprises a Y-direction moving assembly, slide blocks, a connecting plate, an X-direction moving assembly, an extendable-and-retractable suction disc type mechanical arm body, a rotation movement assembly, a vision camera support and vision cameras, wherein the Y-direction moving assembly is connected with the X-direction moving assembly, the rotation movement assembly is mounted at the lower end of the Y-direction moving assembly, the extendable-and-retractable suction disc type mechanical arm body is fixed to the position below the rotation movement assembly, the vision camera support is mounted at the bottom of the Y-direction moving assembly, the vision cameras are fixedly mounted on the vision camera support, the connecting plate is fixedly connected with the bottom of the X-direction moving assembly and connected with a guide rail on a gantry through the slide blocks, and in this way, the mechanical arm for laminating the transformer cores can move in the Z direction. By means of the mechanical arm, the lamination process can be automated, efficiency of the process is improved, and a transformer product can achieve high quality.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

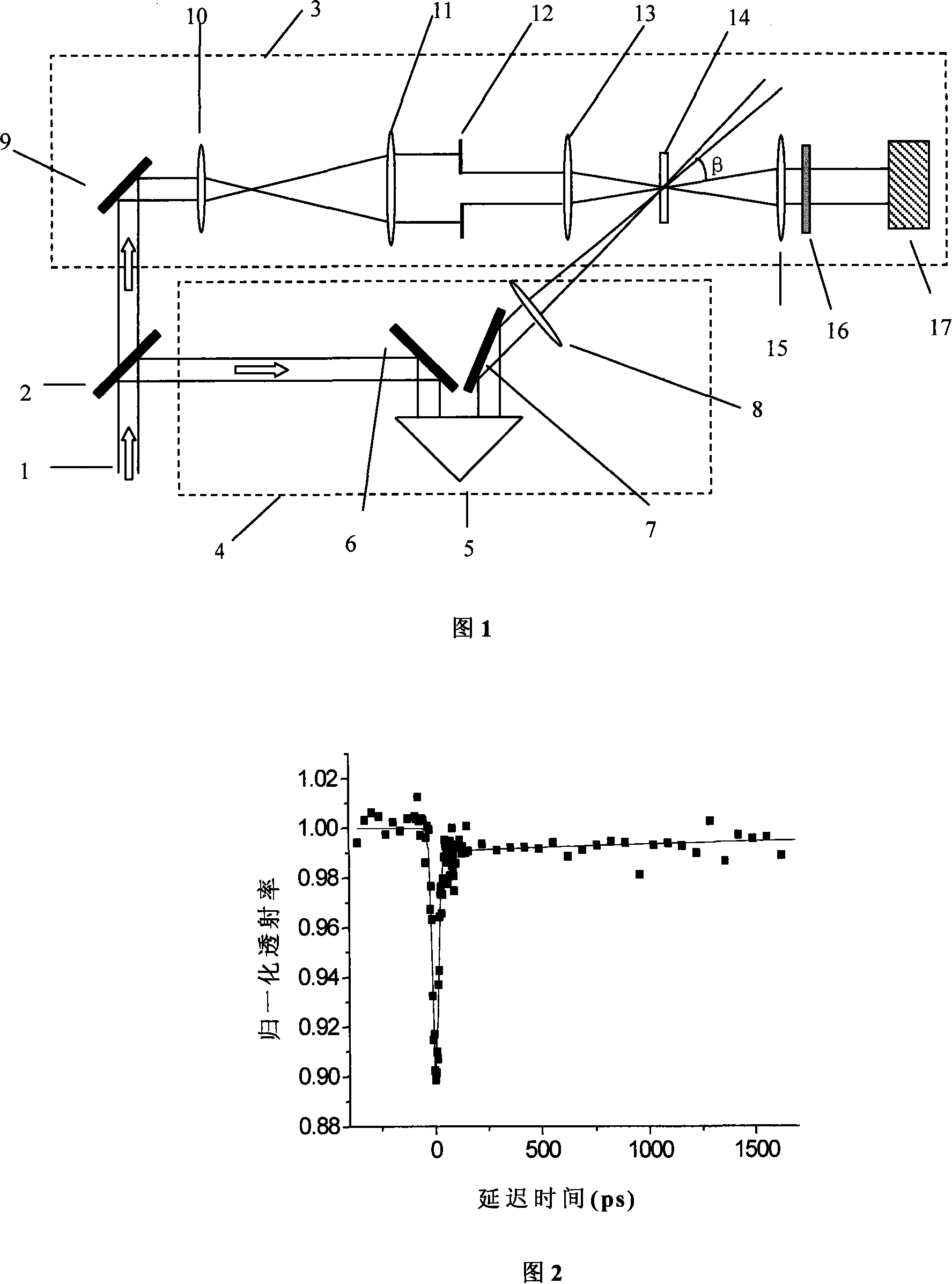

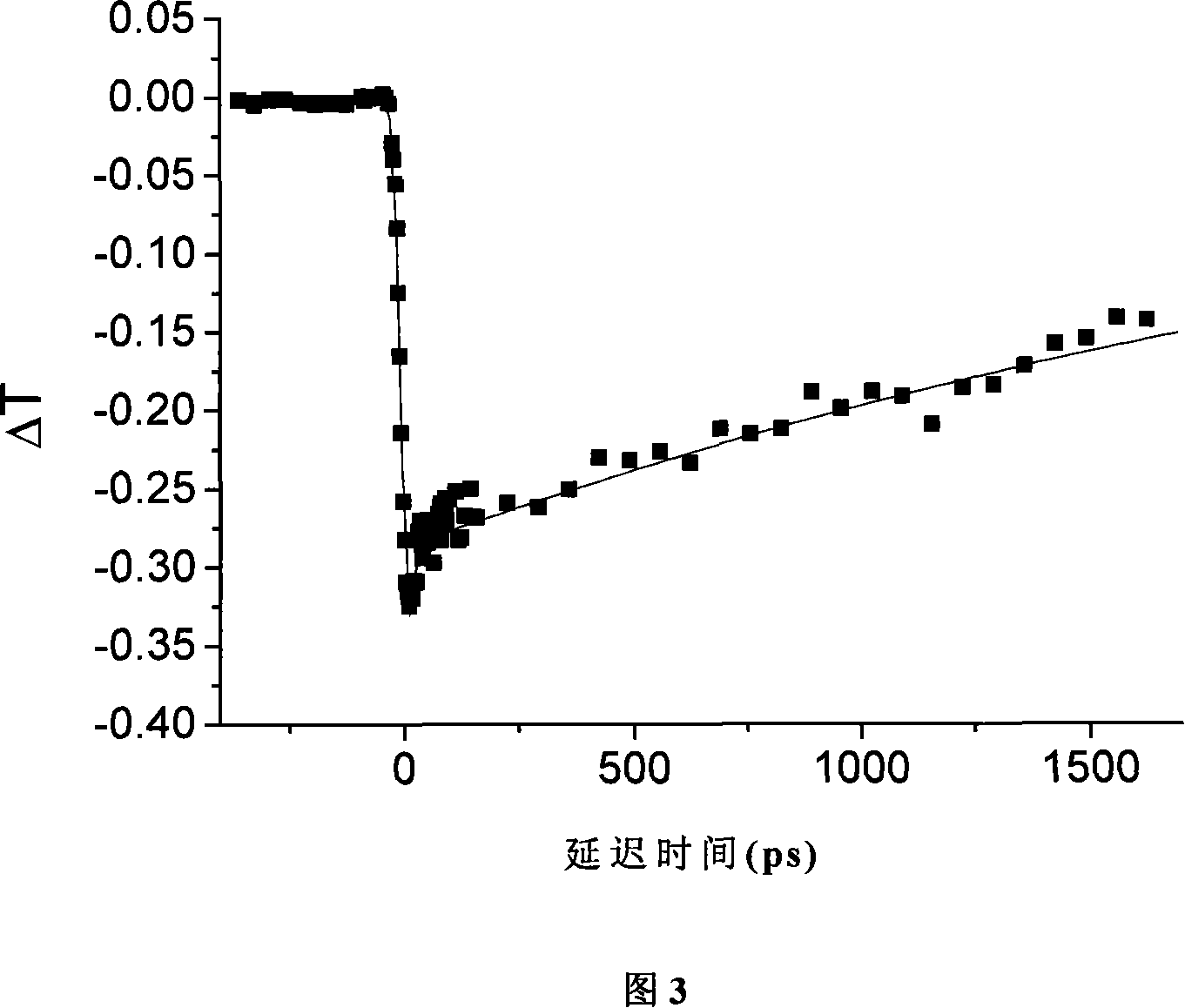

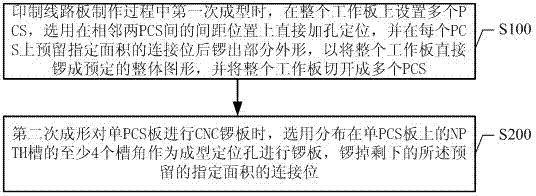

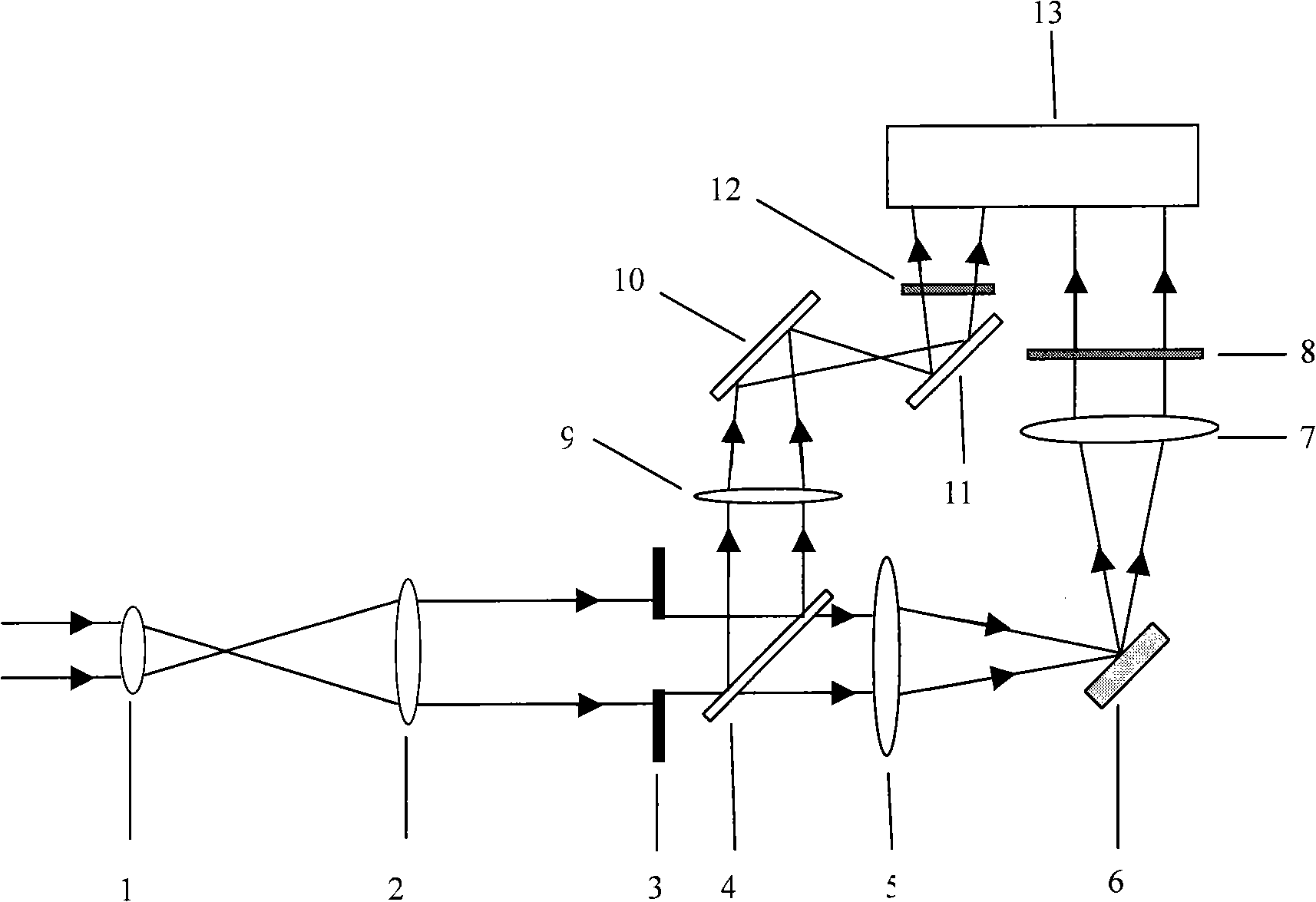

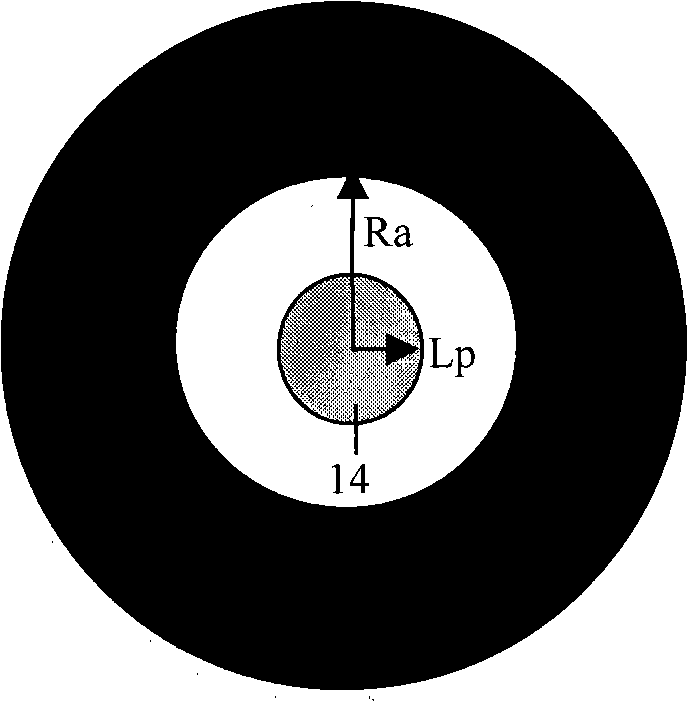

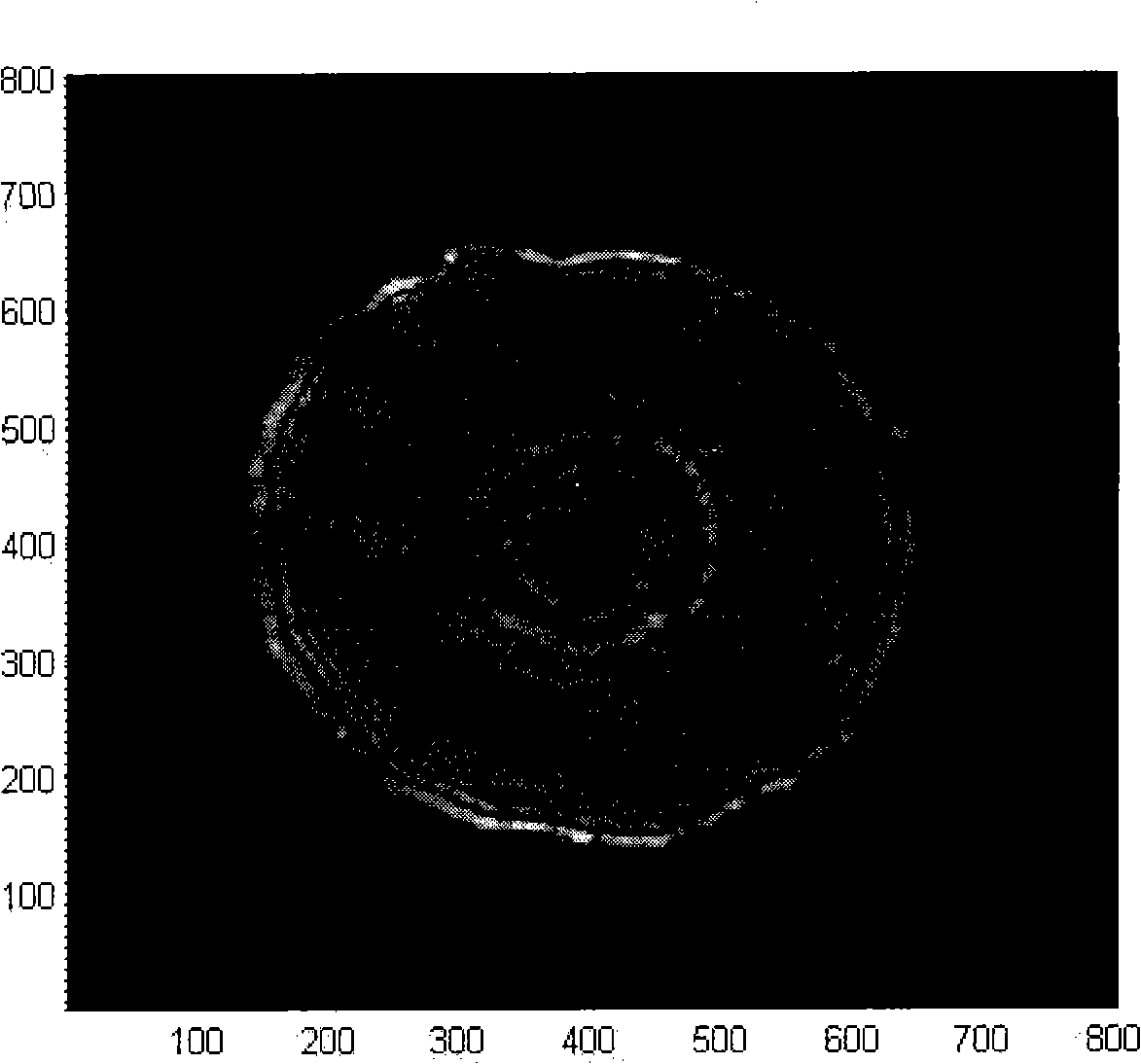

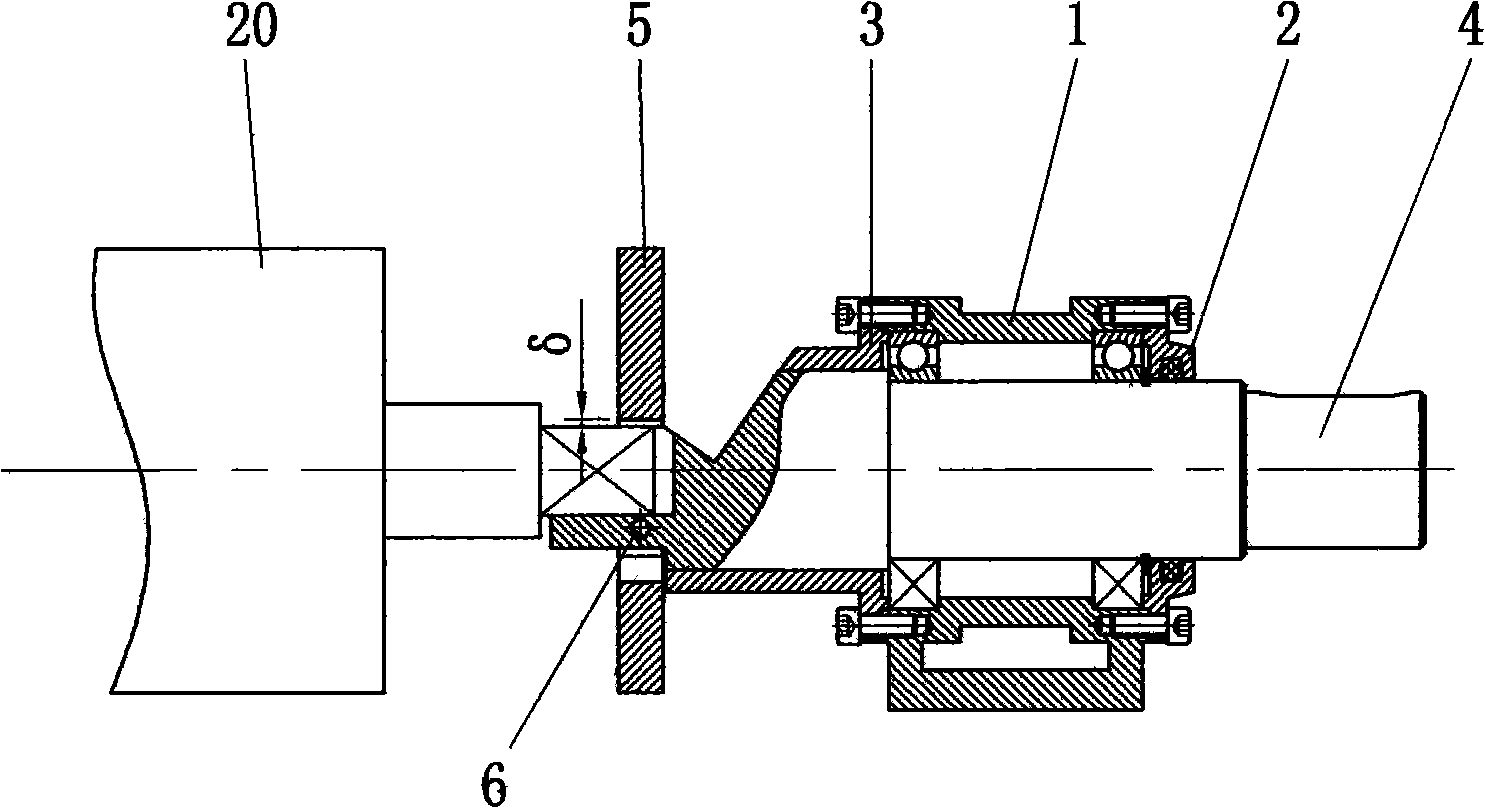

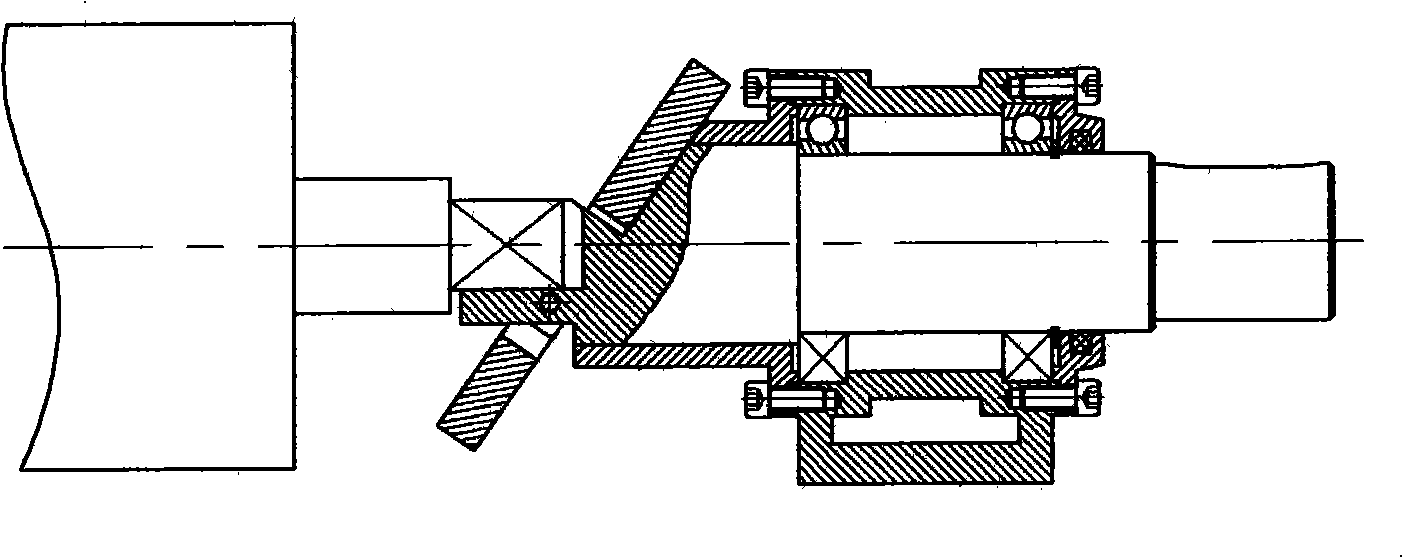

Pumping detecting method based on 4f phase coherent imaging

InactiveCN101109703ANo movementEliminate distractionsPhase-affecting property measurementsRefractive indexLaser beams

The invention discloses a pump detection method based on 4f phase coherence images. Wherein, the laser output by a laser is divided into a pumping light and detecting light; the pumping light is focused after a time-delay platform on a non-linear sample to generate non linearity; the detecting light detects the change in the pumping-light induced non-linear sample, and is recorded by a CCD. By different time delays in the pumping light, the change in the phase and strength of the detecting light emitted from the sample reflects the distribution of particles in the sample at different time periods, so that the absorption sections and service lives and refractivity volume of each energy level are determined. The invention is of simple optic path, the theoretic processing is simple, the single-phase measurement reduces the optic accumulation; the absorption and refracting pumping are completed at the same time without individual measurements, and the size and symbol of non-linear absorption and refraction can be measured concurrently, the sensitivity on the random fluctuation of the laser beam is low, and the measurement results are accurate.

Owner:SUZHOU UNIV

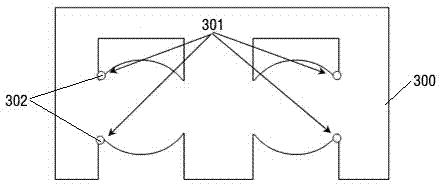

CNC (Computer Numerical Control) board splitting production method without NPTH (Non Plating Through Hole) hole positioning

ActiveCN102510667ANo movementNo problems such as breakagePrinted circuit manufactureMilling equipment detailsEngineeringSolderability

The invention discloses a CNC (Computer Numerical Control) board splitting production method without NPTH (Non Plating Through Hole) hole positioning, which is used in single PCS (pieces) shipment production in the manufacturing process of printed circuit boards, and because secondary forming is adopted, when CNC board splitting is carried out on a single PCS board, at least four groove angles of NPTH grooves distributed on the single PCS board are selected as forming positioning holes for board splitting, and remained reserved connecting positions of appointed areas are split. At least four NPTH groove angles in the PCS board are selected for positioning, PIN holes are arranged in the position tangential to the groove angles, and the PIN holes need to be distributed at four edges of the PCS board to the greatest extent so as to ensure that the PCS board does not move in four directions. The diameter of a selected pin is 0.05mm smaller than the diameter of a PIN hole drilling tool. Compared with a PTH (Plated Through Hole) hole positioning mode, the method disclosed by the invention makes a finished product do not have the problems of hole wall pull break, pad abrasion, poor solderability, hole copper fracture and the like. Compared with a gummed paper sticking positioning mode, the method disclosed by the invention makes the finished product have a more stable size and have no off tolerance, and the board splitting efficiency is effectively improved.

Owner:SHENZHEN KINWONG ELECTRONICS

Method for measuring optical non-linear 4f phase coherent imaging

InactiveCN101308091ANo movementEasy to measurePhase-affecting property measurementsInformation processingBeam splitting

The invention discloses a method which can measure the optical nonlinearity of a medium interface and apply the reflected light to measure the film optical nonlinearity, which belongs to the nonlinear photonics material and nonlinear optical information processing fields. An incident laser light is divided into two ways through a beam splitting prism, one way is a probe light which enters a measure optical path and is collected by a CCD camera after passing through a 4f phase coherent imaging system; and the other way is a reference light; and the method is characterized in that: the sample is placed on a focal plane of a first convex lens of the measure optical path in a reflection mode, a second convex lens having the same focal length with the first convex lens is positioned at the one-time focal length part along the transmission direction of the reflected light, thereby forming the reflection 4f phase coherent imaging system; and the measurements include two parts of energy calibration and optical nonlinearity measurement. The method has the advantages of convenient measurement, simple optical path, non movement of sample, single pulse measurement, being not easy to damage medium surfaces, and having low requirements to stability of light source energy and space.

Owner:SUZHOU UNIV

Dustproof electric drill

ActiveCN105081402APositioning does not affectImprove efficiencyDirt cleaningPortable power-driven toolsLinear motionEngineering

The invention provides a dustproof electric drill. The dustproof electric drill comprises a shell, a power output device including an output shaft, a drill bit, a drill bit control device arranged in the shell, and a dustproof device, wherein the drill bit is mounted on the drill bit control device; the power output device outputs power to the drill bit control device through the output shaft; the drill bit control device is suitable for converting the rotation of the output shaft to the rotation and a linear motion; the rotation and the linear motion are synchronously output to the drill bit; the dustproof device comprises a dustproof cover, an elastic cover, a shaping frame and a connecting sleeve; the connecting sleeve is mounted on the shell in a forward and backward movable manner, and has a drill bit cavity with front and back openings; the drill bit penetrates through the opening in the back end of the drill bit cavity, and extends outside the opening in the front end of the drill bit cavity; the dustproof cover, the shaping frame and the elastic cover are mounted at the front end of the connecting sleeve in sequence from outside to inside; the shaping frame comprises at least three shaping pieces; each shaping piece is rotationally mounted at the front end of the connecting sleeve in the periphery; and the dustproof cover is arranged at the front end of the connecting sleeve in a forward and backward movable manner.

Owner:皇庭雅居家具海安有限公司

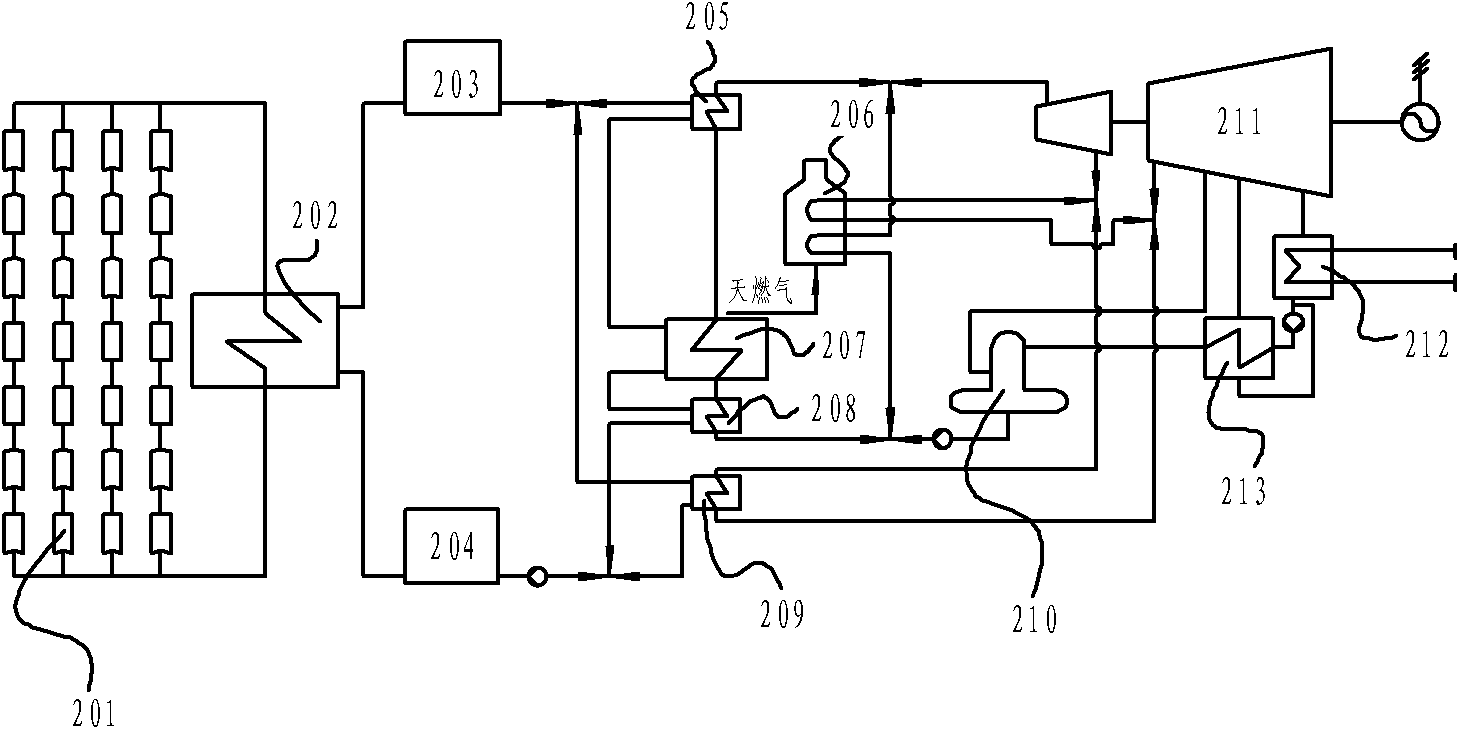

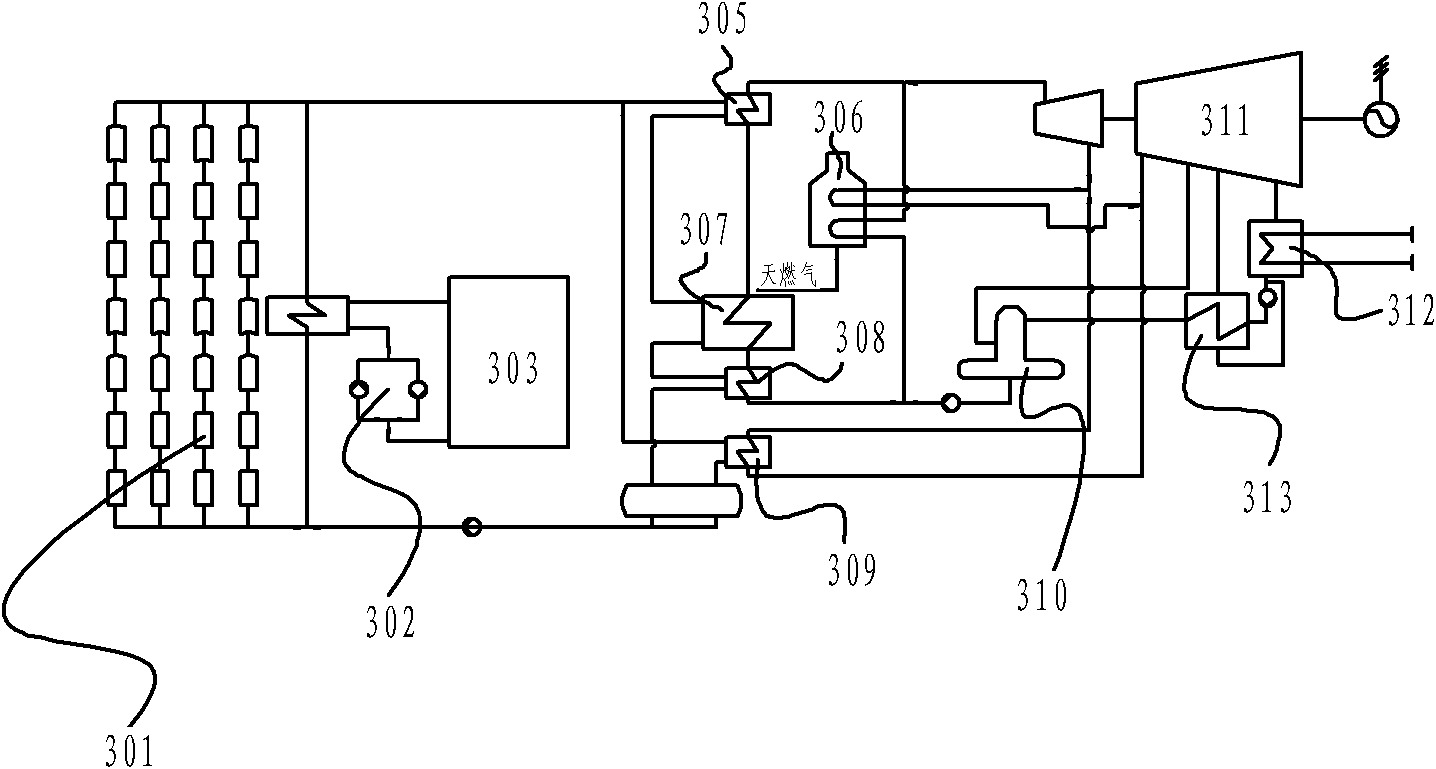

Pneumatic pipeline robot system based on pneumatic tendon

The invention provides a pneumatic pipeline robot system based on pneumatic tendon, which comprises a first supporting module, a stretching module and a second supporting module successively connected with each other, wherein the pneumatic tendon is served as the stretching module. The pneumatic pipeline robot system based on the pneumatic tendon provided by the invention is based on a bionic wriggling mode, adopts an external air source, is in a multi-section wriggling form and utilizes the simple and easy as well as practicable pneumatic pipeline robot with pneumatic element design; the structure is simple; the operation is easy; through a bending pipeline, and the matching of the corresponding operation mechanism, the monitoring and maintenance of the pipeline can be realized. The pneumatic pipeline robot system based on the pneumatic tendon provided by the invention has the advantages of high power, excellent dynamic characteristics, excellent sealing property and application to various pipeline environments.

Owner:SHENZHEN POLYTECHNIC

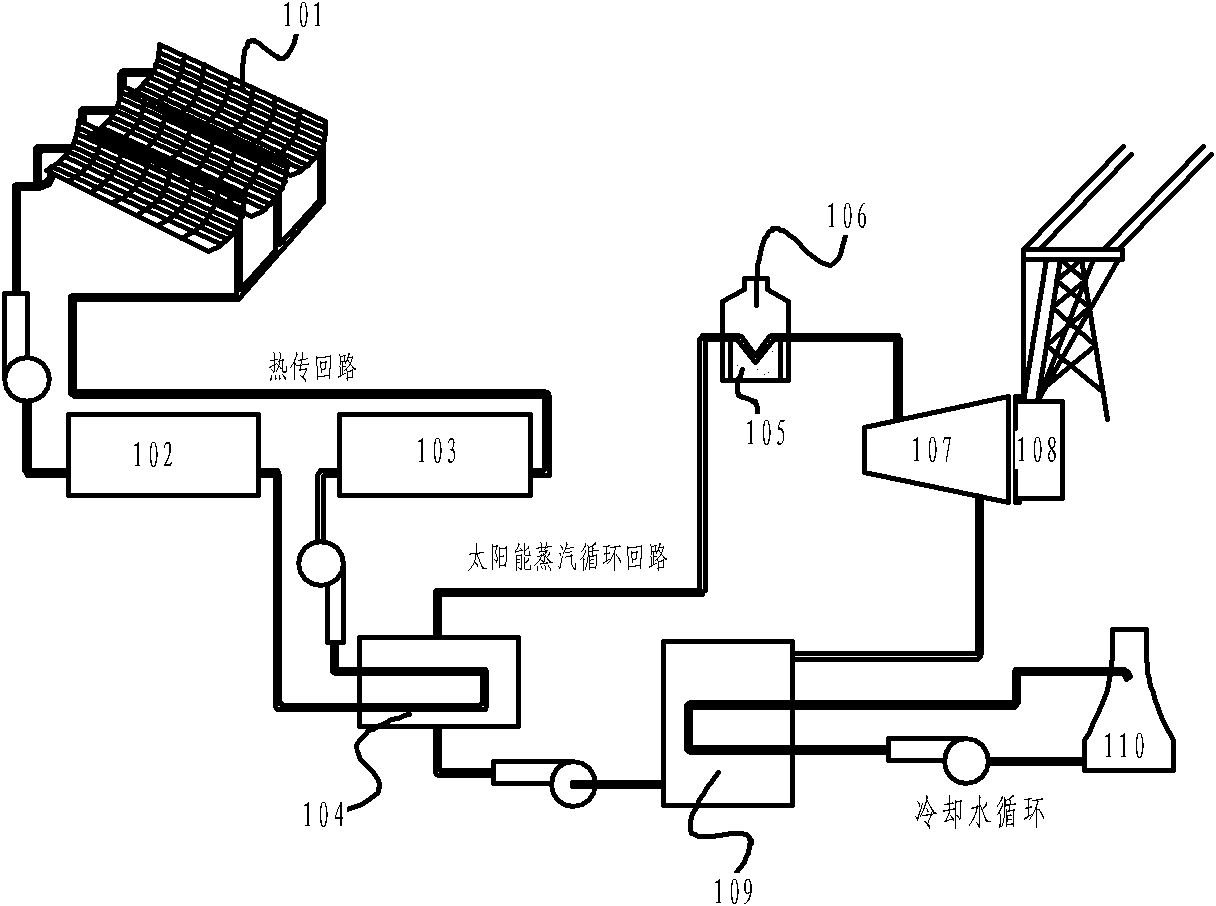

Heat accumulation device

The invention discloses a heat accumulation device comprising a heat accumulation space, a heat accumulation medium, a heat transmission input device, a heat exchange output device and a heat preservation structure wherein the heat accumulation medium, the heat transmission input device and the heat exchange output device are arranged in the heat accumulation space and the heat preservation structure is located outside the heat accumulation space; the heat accumulation space consists of a plurality of layers of serially connected heat accumulation space units and heat insulation layers between the adjacent heat accumulation space units; and the heat transmission input device and the heat exchange output device are used for carrying out heat transmission and heat exchange in the heat accumulation space, and layered input / output control is carried out on the top and the bottom of the heat accumulation device. Made of low-cost materials such as concrete, magnesia, ceramic, metal plate and the like, the heat accumulation device has low construction cost, stable performance and better performance cost ratio, and is particularly suitable for massively popularizing solar energy.

Owner:BEIJING TERASOLAR PHOTOTHERMAL TECH CO LTD

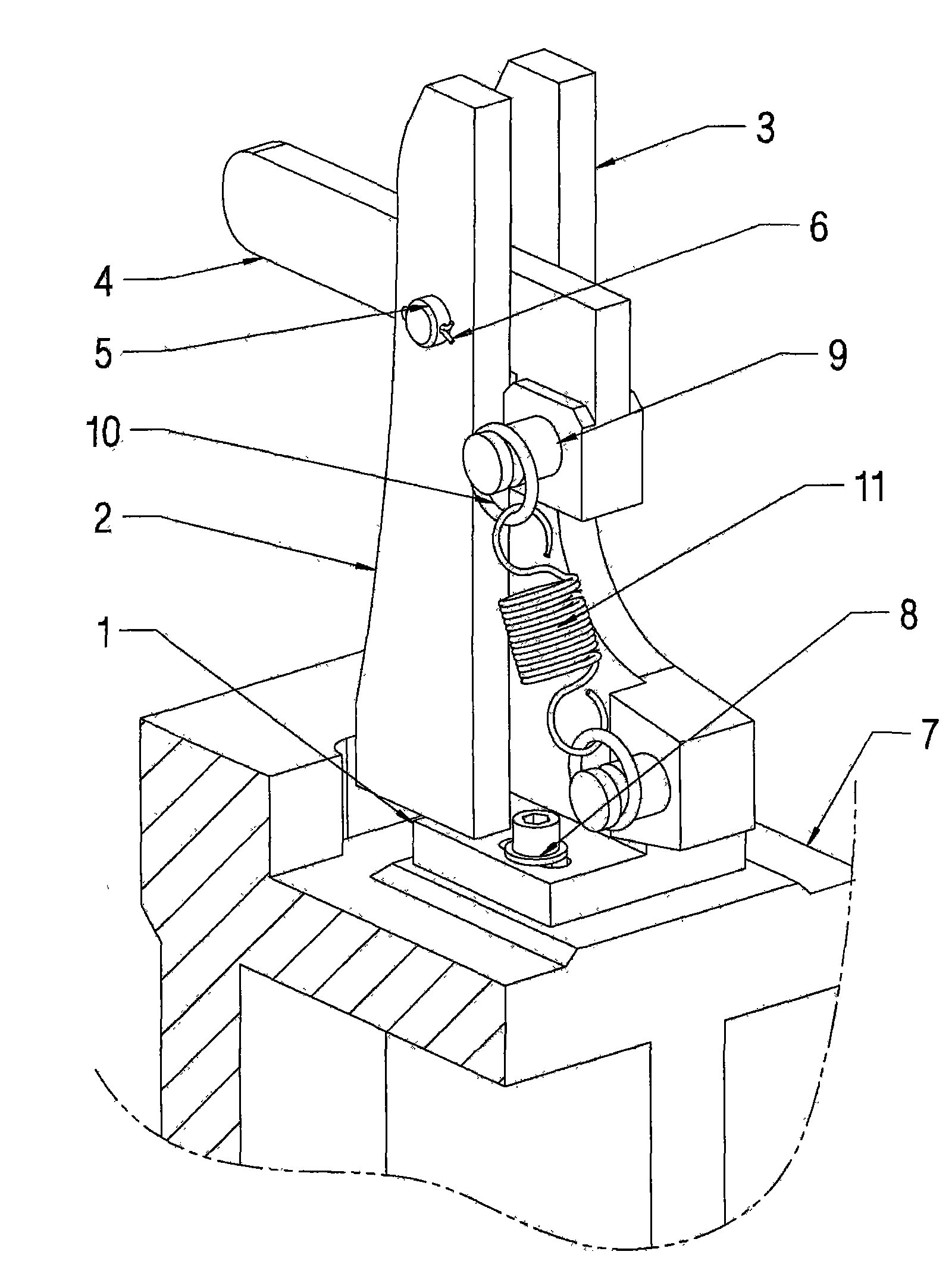

Tension spring type steel plate locating device for automobile steel plate drawing mould

ActiveCN101653808APrecise positioningNo movementShaping toolsMetal-working feeding devicesCompression moldingSheet steel

A tension spring type steel plate locating device for automobile steel plate drawing mould is composed of a pedestal, two location plates, a retainer level, a pin roll, a cotter and a tension spring;wherein the pedestal is provided with a bolt through hole fixed with the mould; the two location plates are arranged in parallel and respectively fixed with the pedestal, the location plate is provided with a pin roll hole, the charge level of the location plate is provided with inclination, and the location plate is provided with a tension spring pin; the retainer level is arranged in the middleof the two location plates, the retainer level is provided with a pin roll hole, the pin roll penetrating the two location plates and the pin roll hole on the retainer level is connected with the twolocation plates, the retainer lever rotates around the pin roll, and one end of the retainer level is provided with a tension spring pin; and the two ends of the tension spring are respectively fixedwith the location plate and the tension spring pin on the retainer level. The invention has the advantages that: structure is simple, practicability is strong, the retainer lever can ensure the steelplate to be in steady location when being placed into the mould, and the location plate can ensure the steel plate to be reliably positioned in the compression molding process, so that plates can notstir and product quality after stamping is ensured.

Owner:TIANJIN MOTOR DIES

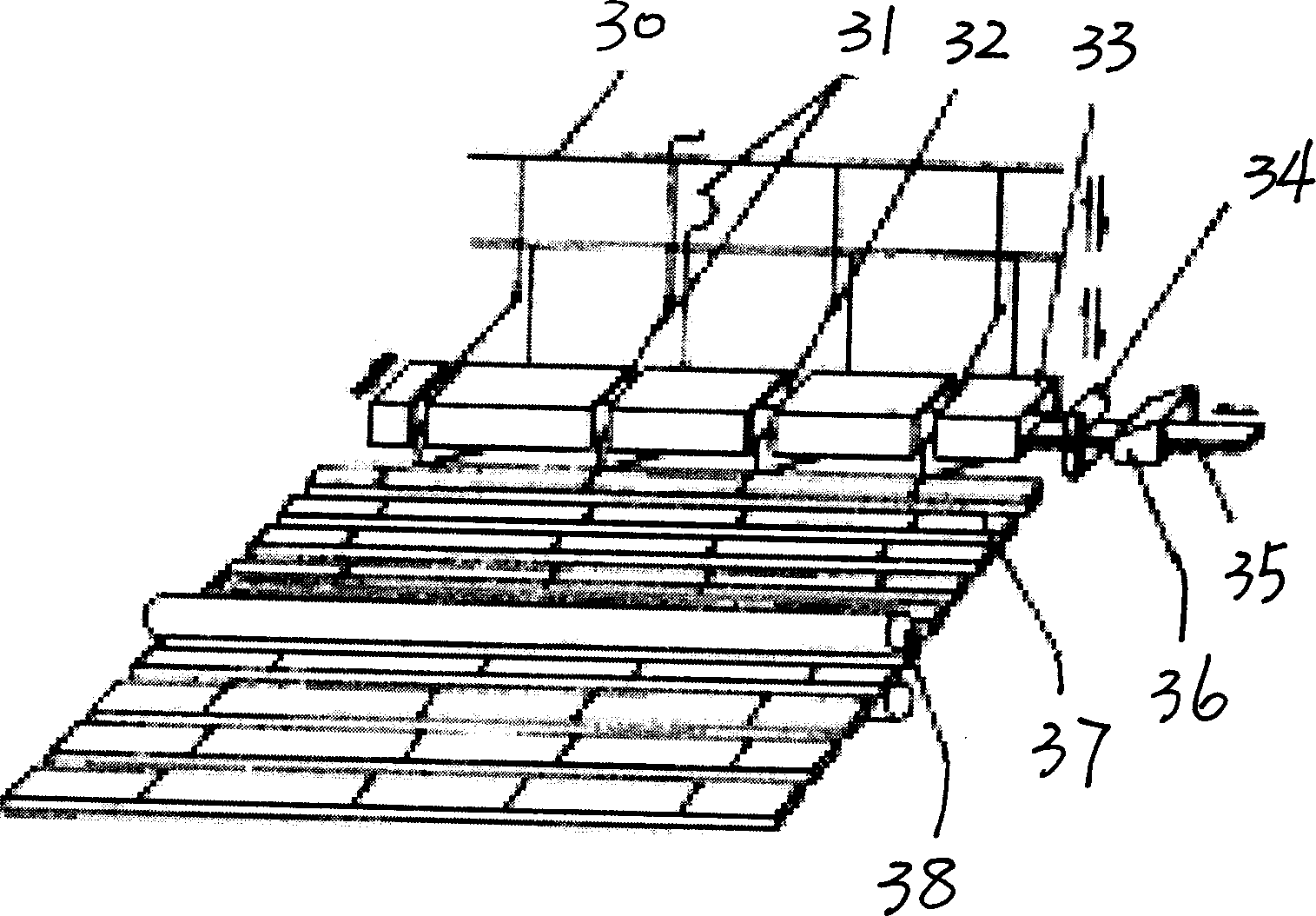

Thick-thin two-purpose automatic bamboo-curtain braiding machine

InactiveCN1850461AMake sure it's not looseModerate tightnessCane mechanical workingEngineeringSprocket

An auto bamboo curtain braider includes the pusher, the drive gear, the up-down changing thread device, the giving bamboo strip device. The drive gear includes the clutch, the bent axle and the chain wheel. Especially, the changing thread device is set between the big chain wheel and the front thread pole. So the thread can crisscross to four directions, and the bamboo strip would not be bent in the process of the braiding. It can be used for the bamboo strip of 0.8-4.2mm thickness and 1300-2600mm length. So it can assure the bamboo curtain not loosen in the production and transportation.

Owner:徐晓明 +1

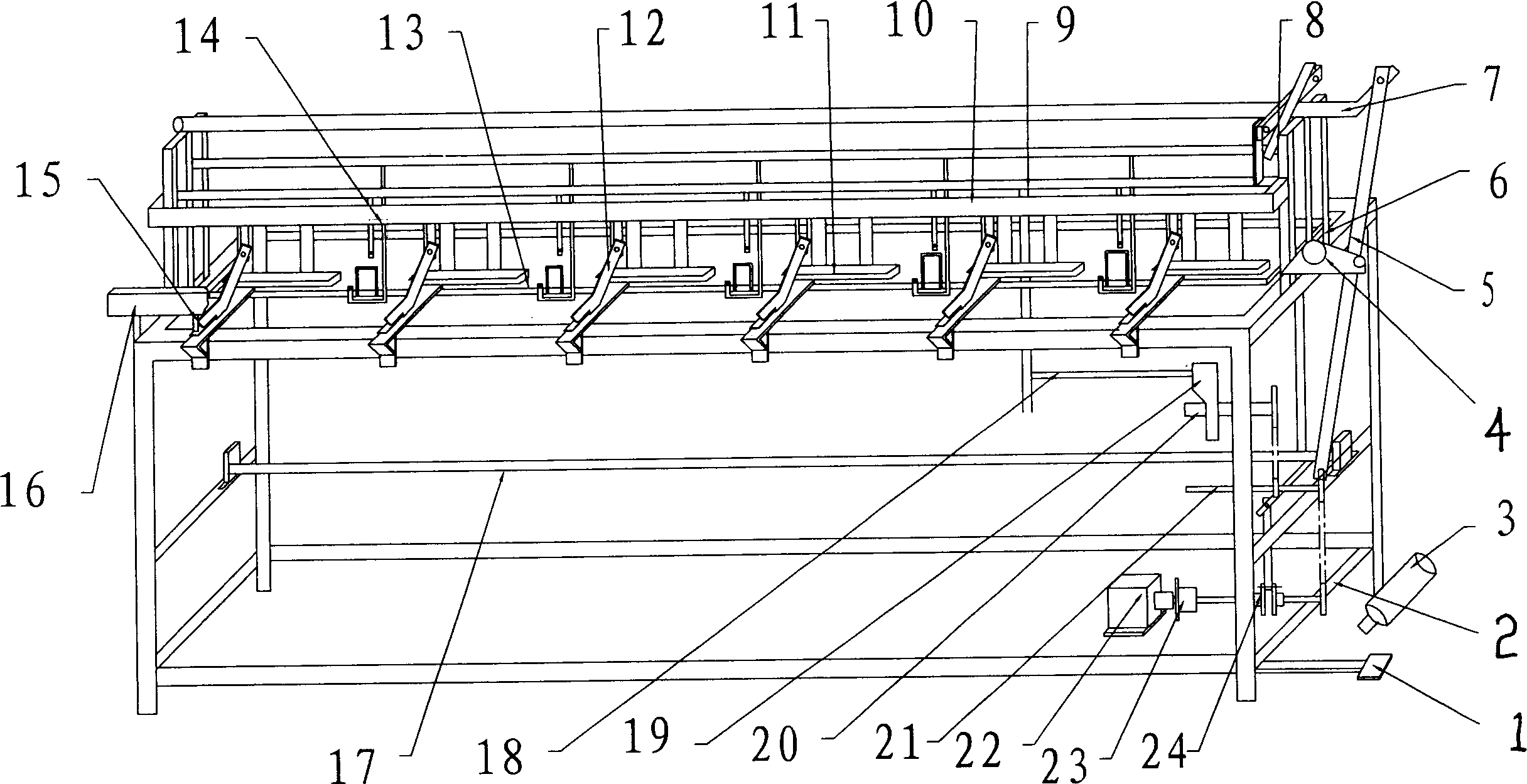

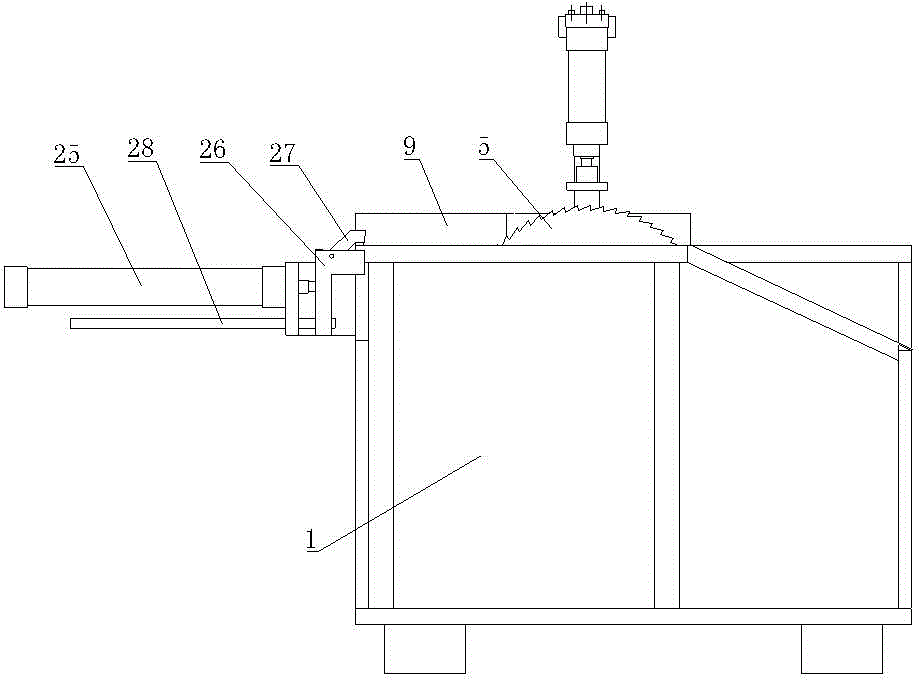

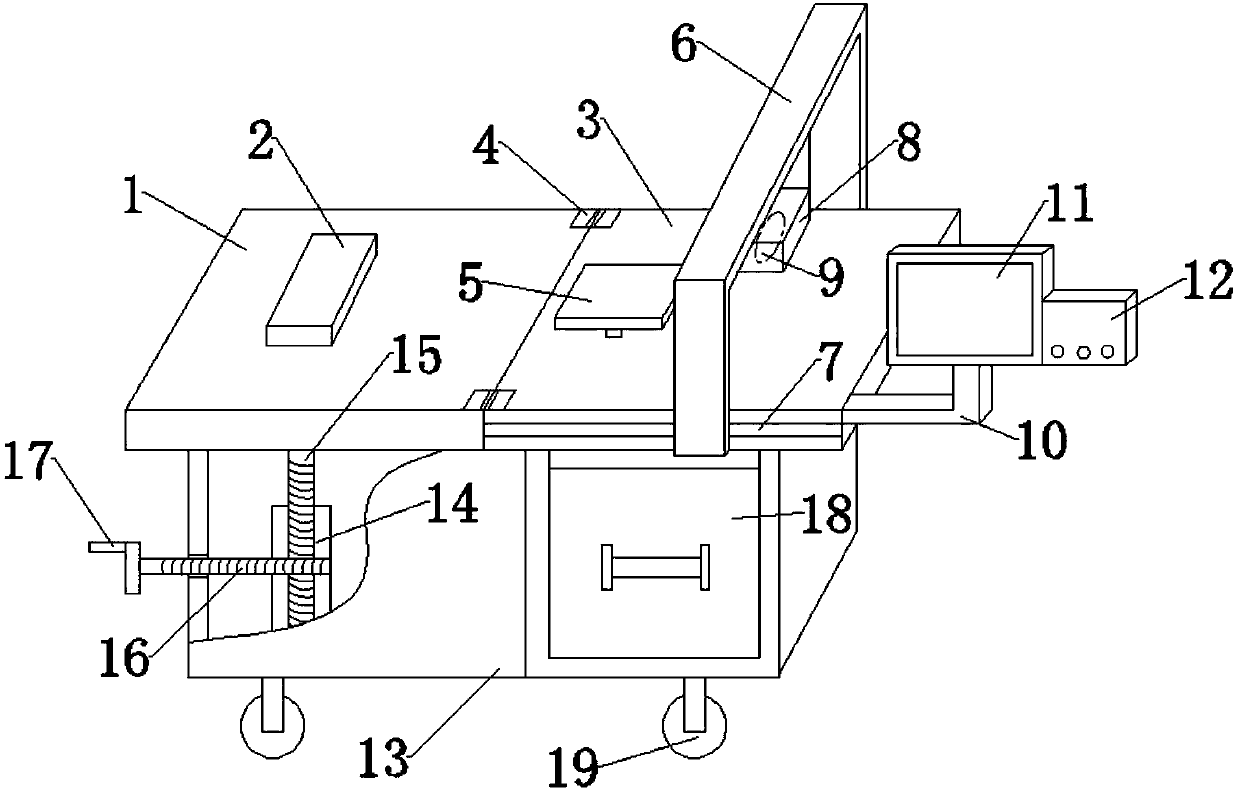

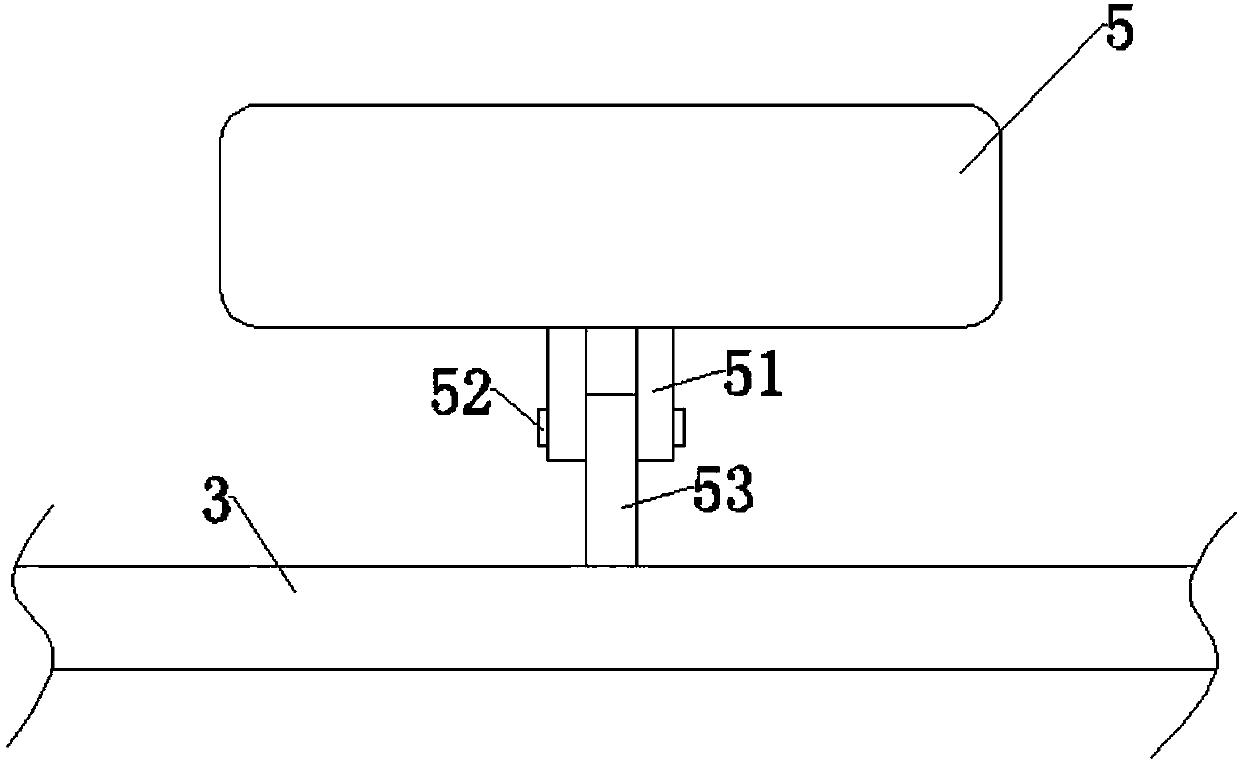

Board double-end cutting and edge aligning device

InactiveCN105690485APlay a limiting rolePush smoothFeeding devicesCircular sawsEngineeringSlide plate

The invention provides a board double-end cutting and edge aligning device. The board double-end cutting and edge aligning device is simple in structure, manual pushing is replaced, a board can be conveniently fixed and positioned, the two ends of a board are subject to cutting and edge aligning at the same time, and cut edge alignment is ensured. The board double-end cutting and edge aligning device comprises two bases arranged on a base seat, sliding blocks are arranged at the bottom of one base, sliding rails matched with the sliding blocks are arranged on the base seat, and each base comprises a mounting box; a bottom plate is arranged on each mounting box, and a discharging mechanism parallel to the cutting direction is arranged on each bottom plate; a saw blade driven by a motor, an air cylinder for lifting the saw blade and a positioning air cylinder connected with a positioning block are arranged in each mounting box; a saw groove allowing each saw blade to pass through and a positioning hole allowing each positioning block to pass through are formed in each bottom plate; a limiting plate is arranged at the position, parallel to each saw groove, of the outer side of each saw groove, and a compressing mechanism is further arranged at the position, corresponding to the outer side of each limiting plate, of each bottom plate, and a pushing mechanism is further arranged at the rear end of each bottom plate; a rear sliding plate is arranged at the position, corresponding to the rear side of each saw groove, of each base, and the rear end of each rear sliding plate inclines downwards; and a receiving box is arranged on the rear side of each base.

Owner:WUXI FORMEN TECHN

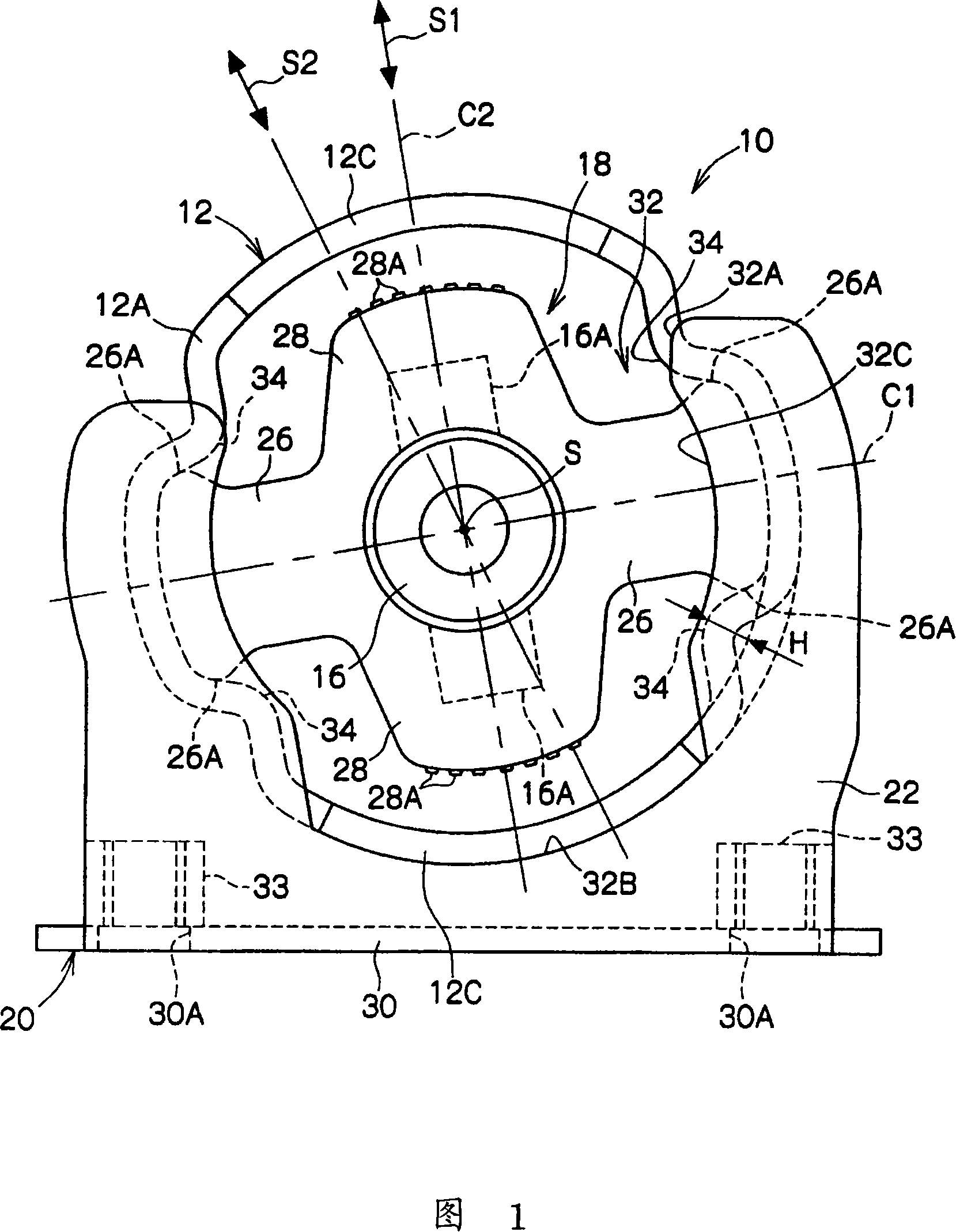

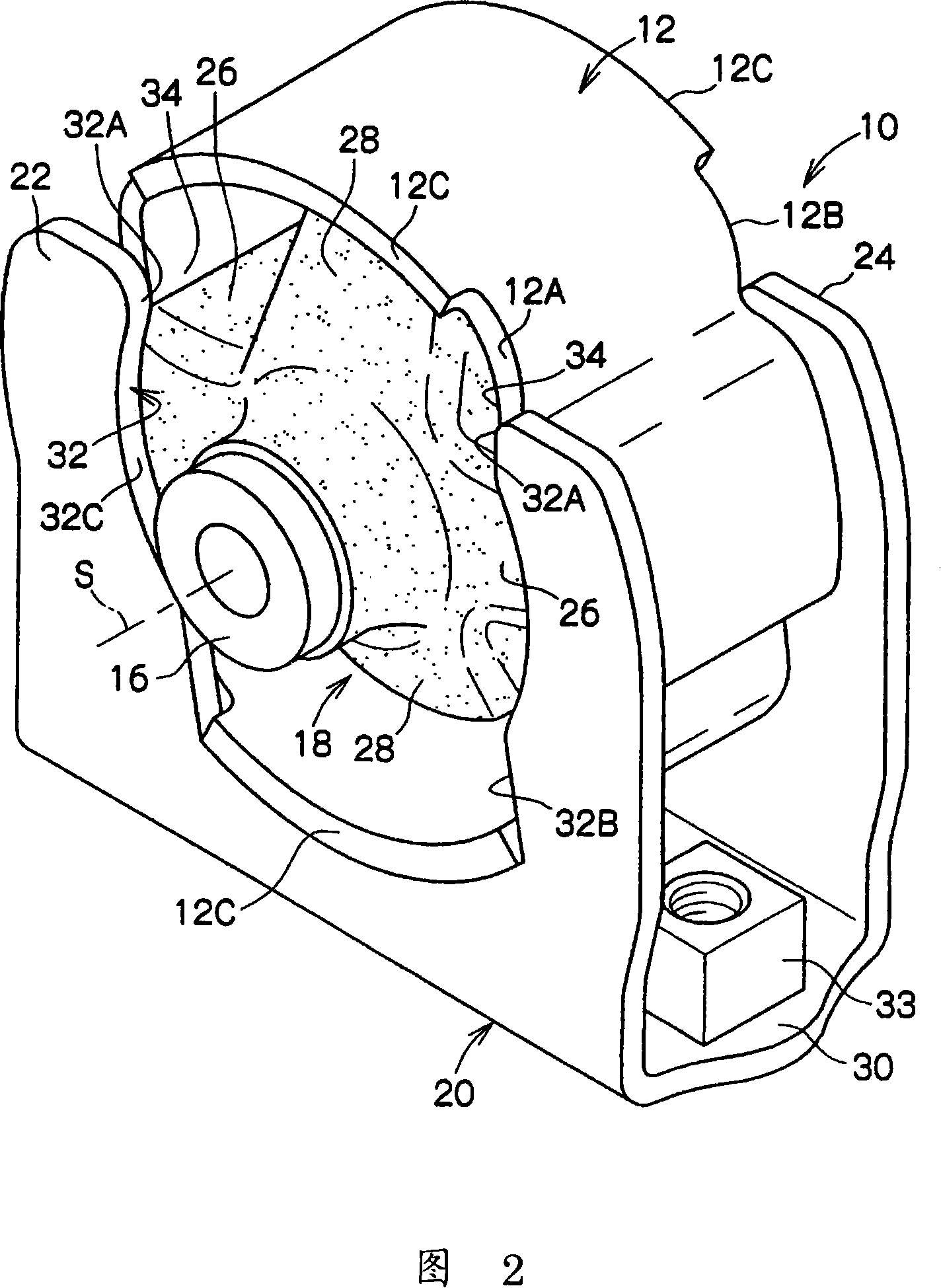

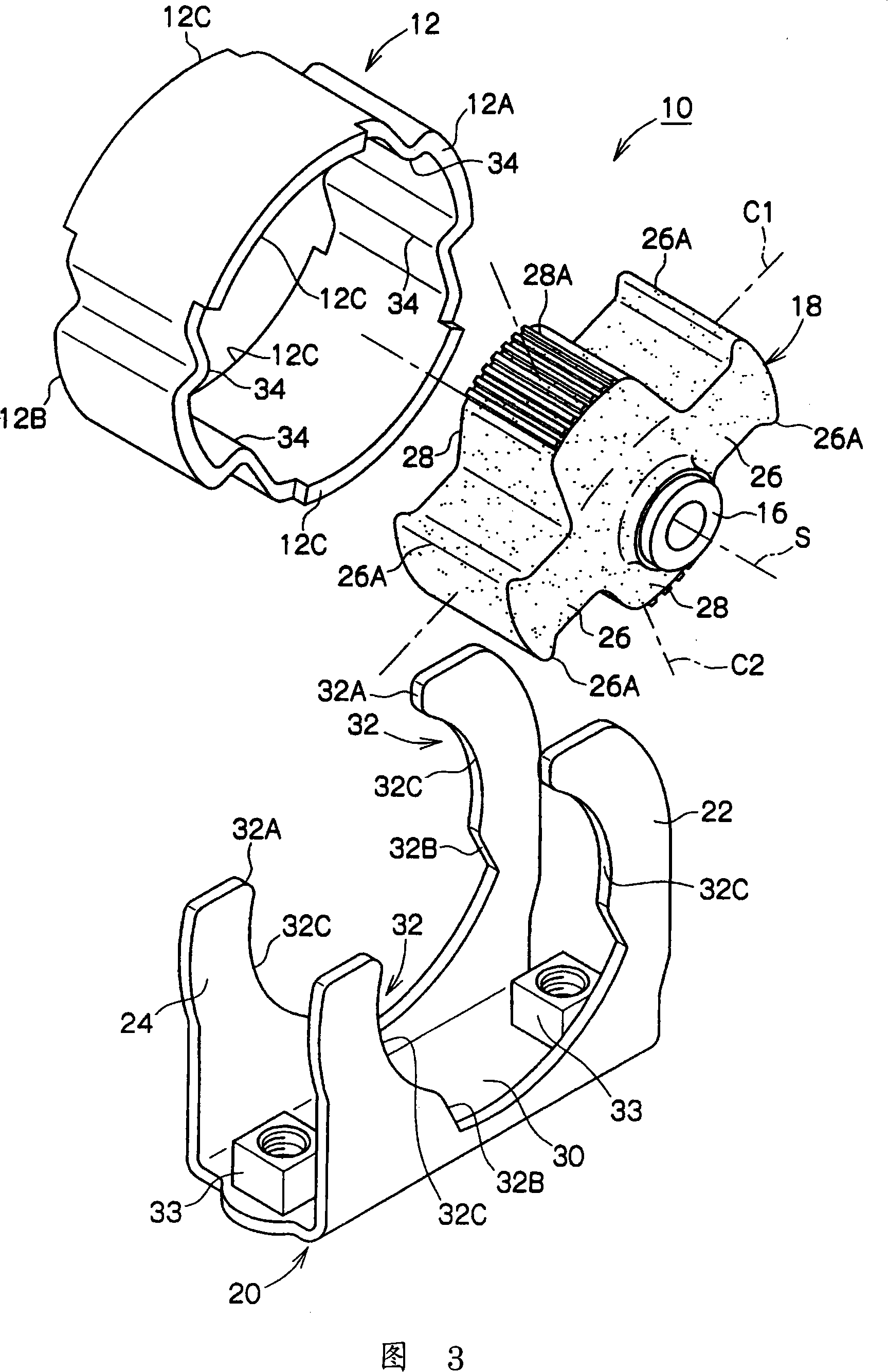

Vibration isolating device

InactiveCN101128687AGood effectImprove stop functionNon-rotating vibration suppressionRubber-like material springsElastomerEngineering

A vibration isolating device in which, even if the angular difference between a normal vibration input direction and a maximum input direction is greater, a pressure-joint section of an elastic body is not displaced from a specified position in a bracket tube section. [MEANS FOR SOLVING PROBLEMS] A rubber elastic body (18) is vulcanized and joined to the outer peripheral surface of an inner tube (16), end sections of a pair of pressure-joint sections (26) of the elastic body (18) are pressure-joined to the inner peripheral surface of a bracket tube section (12), and the elastic body (18) is pressure-fitted into a circular tube-like bracket tube section (12). Projection-like bends (34) projecting in an L shape with a height H greater than the plate thickness of the bracket tube section (12) are formed at those radially inner sections of the bracket tube section (12) that are in contact with the end sections of the pair of pressure-joint sections (26), the projection-like bends (34) being each formed in the axis direction (S), across the entire width of the bracket tube section (12).

Owner:BRIDGESTONE CORP

Press fit fixing device for vehicle lamp lampshade and lamp shell

ActiveCN102615495AImprove pass rateGuaranteed matching gapMetal working apparatusEngineeringLamp shell

The invention relates to a press fit fixing device for a vehicle lamp lampshade and a lamp shell. A rack is provided with a frame-shaped bracket, a worktable and a top plate; a lamp positioning mechanism comprises a lower template, lower supporting seats, an upper template and an upper supporting seat; each lower supporting seat is provided with a supporting surface and a nail injecting hole; rotating mechanisms arranged on the upper template and the lower template are connected with the worktable and a movable press fit platform plate; guide limiting seats are arranged on the upper template and the lower template on both sides of the rotating mechanisms; a linear bearing of a press fit mechanism is arranged on the movable press fit platform plate; guide posts arranged on the worktable and the top plate are matched with the linear bearing; a compression cylinder arranged on the top plate is connected with the upper template through the movable press fit platform plate; limiting cylinders are arranged on the movable press fit platform plate and the worktable; and limiting blocks correspond to the guide limiting seat at the bottom of the lower template and the guide limiting seat on the top of the upper template respectively. The press fit fixing device has the characteristics of lightness and convenience as well as safety in operating and capabilities of improving assembling quality and increasing production efficiency.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

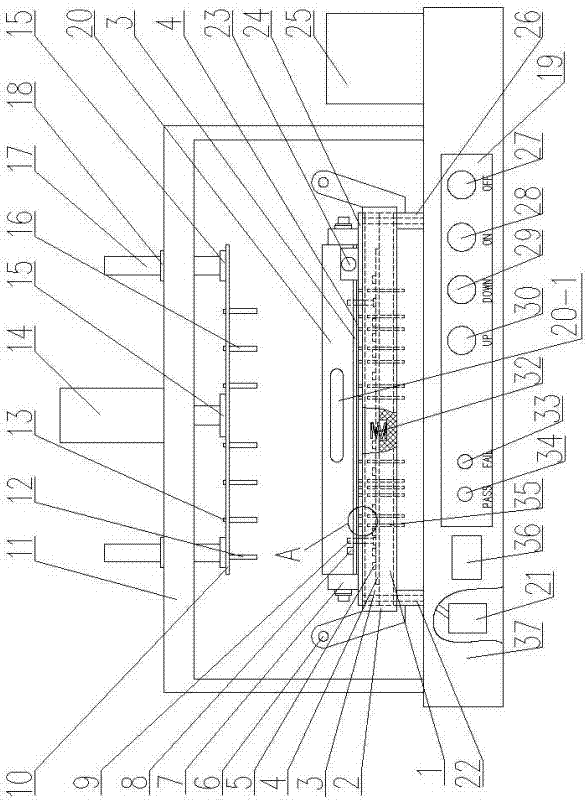

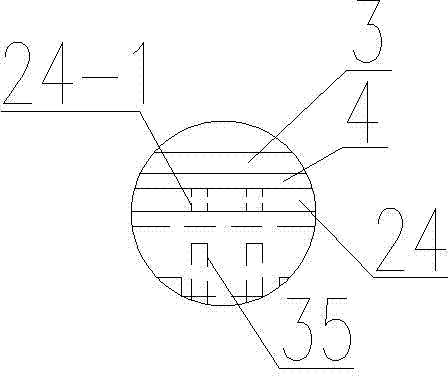

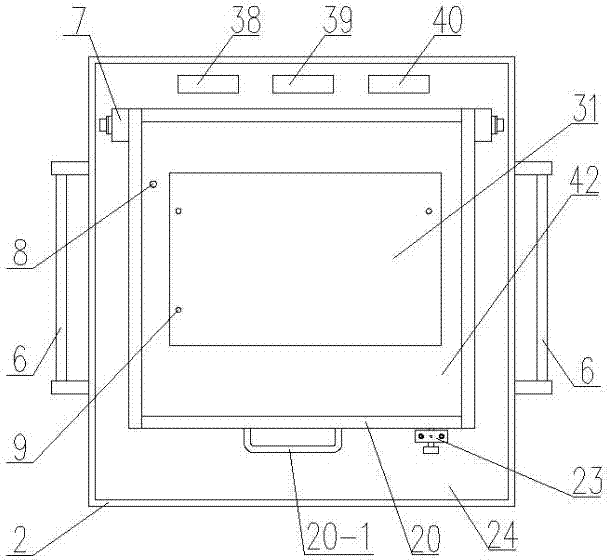

Modular PCB testing jig

InactiveCN104777417AClear structureCompact structureElectronic circuit testingVacuum extractionEngineering

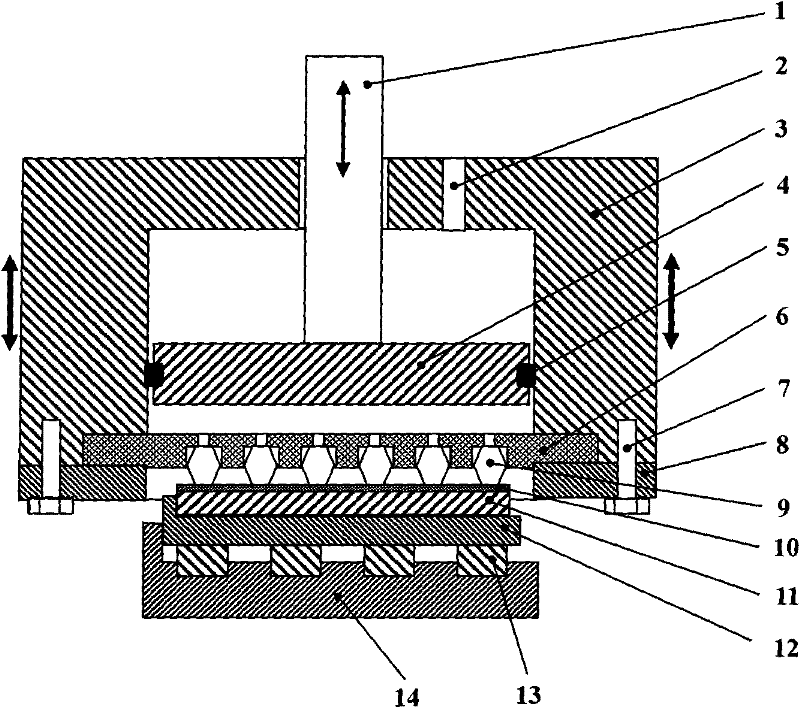

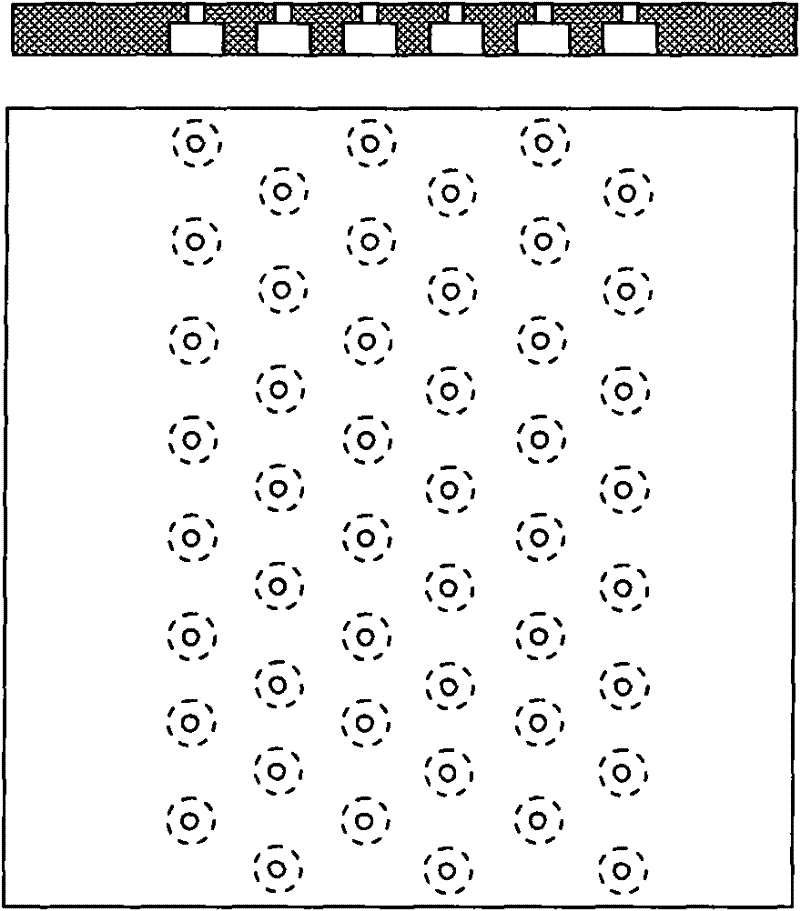

The invention relates to a modular PCB testing jig. The modular PCB testing jig comprises a testing module, a pin plate module, a supporting plate module and a covering plate module. The testing module comprises a testing platform, a support, a counter, a control board and a testing instrument. The pin plate module comprises a base, a pin plate, a sponge pad and a lower surrounding frame, wherein detection pins, spacers and springs are arranged on the pin plate, the base plate is provided with an air exhaust hole communicated with a vacuum extraction assembly, and the lower surrounding frame and the pin plate form a first containing cavity. The supporting plate module comprises a supporting plate, a sponge pad, a counter contact, an upper surrounding frame assembly, wherein the supporting plate is arranged in the first containing cavity, the upper surrounding frame assembly and the supporting plate define a second containing cavity for containing a PCB, and the supporting plate is provided with pin holes. The upper end faces of the pin plate and the supporting plate are both provided with a layer of copper foil. The covering plate module comprises an air cylinder and a cover plate fixed to a piston rod of the air cylinder, and pressing rods and a counter contact touch pin are arranged at the lower end of the cover plate. The modular PCB testing jig is compact in structure, convenient to maintain, accurate in test, high in automatic degree and capable of meeting the demand for large-scale test.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Milling cutter clamping equipment for mechanical manufacturing

The invention relates to the technical field of mechanical equipment, in particular to milling cutter clamping equipment for mechanical manufacturing. The milling cutter clamping equipment comprises aclamping block, an air cylinder, a clamping shaft, a supporting frame and a milling cutter. The clamping shaft is fixedly connected to the center inside the top end of the supporting frame, a telescopic rod is fixedly connected to the top end of a first sliding rail, the outer side of the telescopic rod is sleeved with a first spring, a pressing block is fixedly connected to the top end of the telescopic rod, a clamping barrel is fixedly connected to the outer side of the sliding block, air cylinders are fixedly connected to the tops of the inner walls of the two sides of the supporting frame, driving blocks are fixedly connected to the tail ends of main shafts of the air cylinders, the clamping block is fixedly connected to the tail end of a second spring, a clamp block is fixedly connected to the inner side of the bottom end of the clamping block, a clamping groove is formed in the outer side of a fixing block, and the milling cutter is fixedly connected to the bottom end of the fixing block. The milling cutter clamping equipment is scientific and reasonable in structure, convenient to replace and maintain, capable of ensuring axial stability and fastening of a milling cutter shaft and worthy of being popularized, and has huge economic benefits and wide market demands.

Owner:繁昌县通民机械制造有限公司

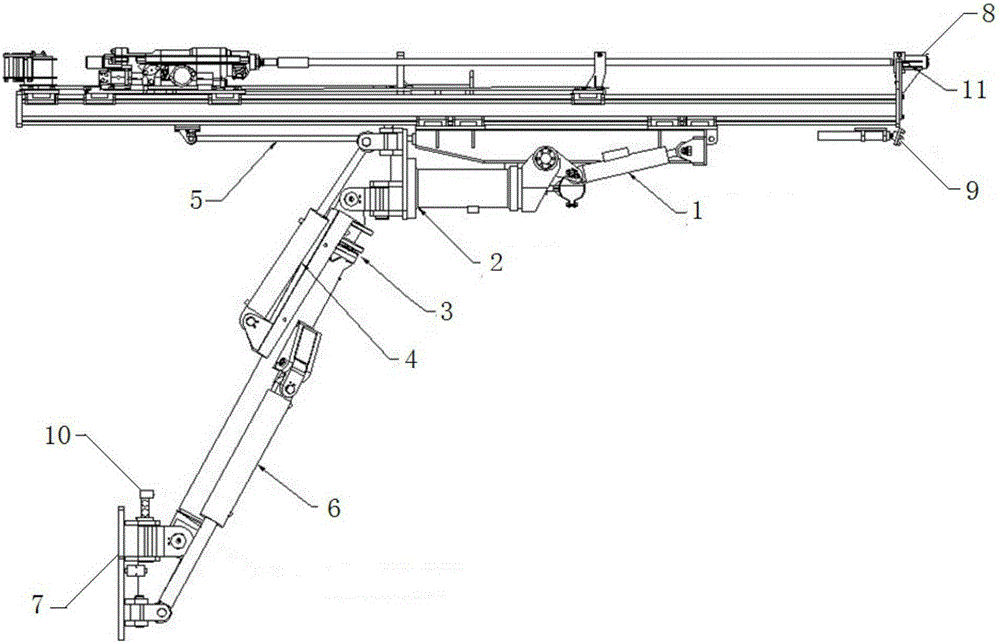

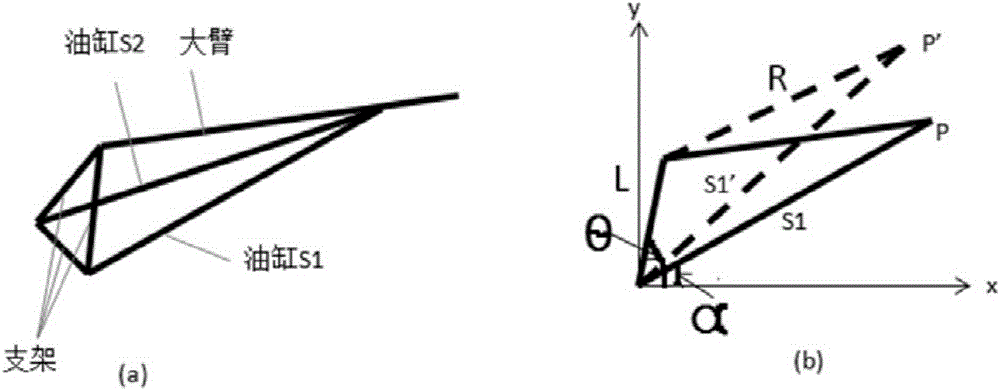

Drilling automatic positioning device and method for tunneling and drilling jumbo

ActiveCN105257274APrecise hole positionHigh degree of automationAutomatic control for drillingTelescopic cylinderDrill hole

The invention discloses a drilling automatic positioning device and method for a tunneling and drilling jumbo. The device comprises a drilling supporter, a distance measuring sensor, an advancing beam positioner, displacement sensors, an angle sensor, a laser alignment part, an interactive display terminal, a controller and a handle. The distance measuring sensor is used for determining a position relation among the tunneling and drilling jumbo, an advancing beam and an operation roadway face; the displacement sensors are respectively arranged on a near-slope oil cylinder, a telescopic oil cylinder, a pitch oil cylinder, a compensating cylinder and a lift cylinder; the angle sensor is arranged on a rotary oil cylinder; the interactive display terminal is used for the display of data and the selection and setting of a hole arrangement mode; the controller is used for receiving an instruction and driving a hydraulic valve, controlling strokes of oil cylinders, calculating the position and pose of the advancing beam by the measured data of the sensors, and finally determining the position of a drill; the handle is used for controlling the operation of the jumbo. According to the device and the method, drilling automatic positioning is realized according to the hole arrangement mode, the automation degree of the drilling jumbo is improved, the technical requirements on operators are reduced, the efficiency of tunnel operation is improved and the service lives of a drill pipe and the drill are prolonged.

Owner:上海绿钻机械有限公司 +1

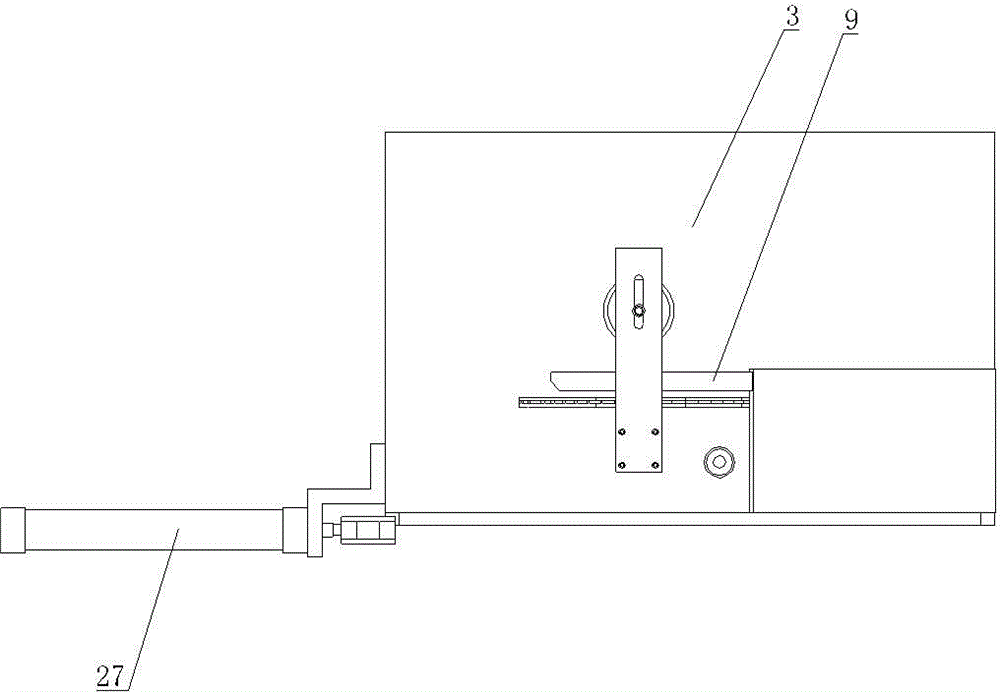

Plank cutting and edge trimming device

InactiveCN105690486AEasy to operateGood flexibilityFeeding devicesGripping devicesEngineeringSlide plate

The invention provides a plank cutting and edge trimming device. The device is simple in structure; manual pushing is replaced; and a plank can be cut, fixed and positioned conveniently, so that the cutting effect is excellent, the operation is convenient, the security coefficient is high, and cut edges are enabled to be flush. The device comprises a base, wherein the base comprises an installation box; a base plate is arranged on the installation box; a saw blade, a cylinder and a positioning cylinder are arranged inside the installation box; the saw blade is driven by an electric motor; the cylinder is used for raising the saw blade; the positioning cylinder is connected with a positioning block; a saw groove and a positioning hole which allow the saw blade and the positioning block to pass through are formed in the base plate; a limiting plate is arranged at the outer side of the saw groove and is parallel to the saw groove; a pressing mechanism is also arranged corresponding to the outer side of the limiting plate on the base plate; a pushing mechanism is also arranged at the rear end of the base plate; a rear sliding plate is arranged corresponding to the rear side of the saw groove on the base; and the rear end of the rear sliding plate inclines downwards.

Owner:WUXI FORMEN TECHN

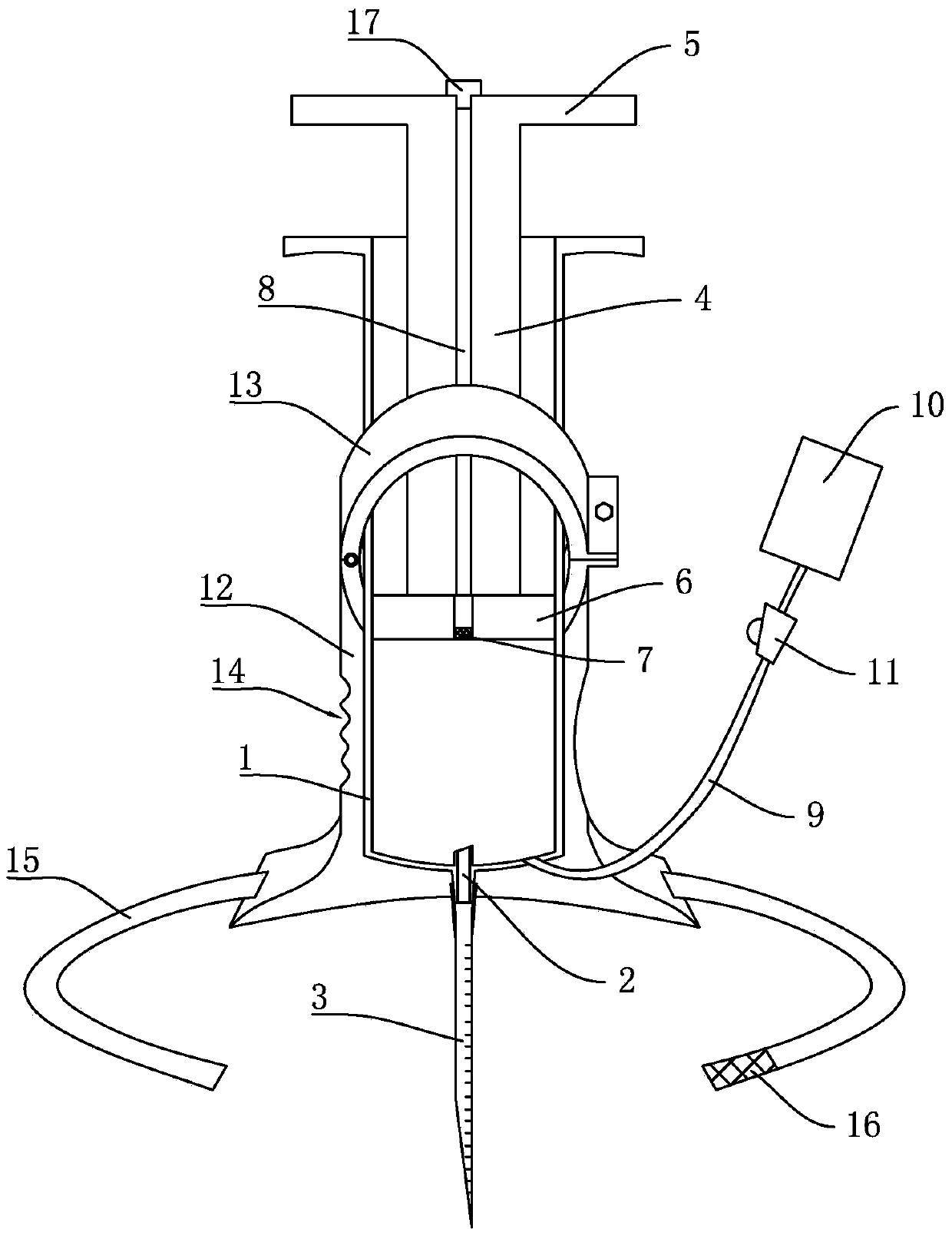

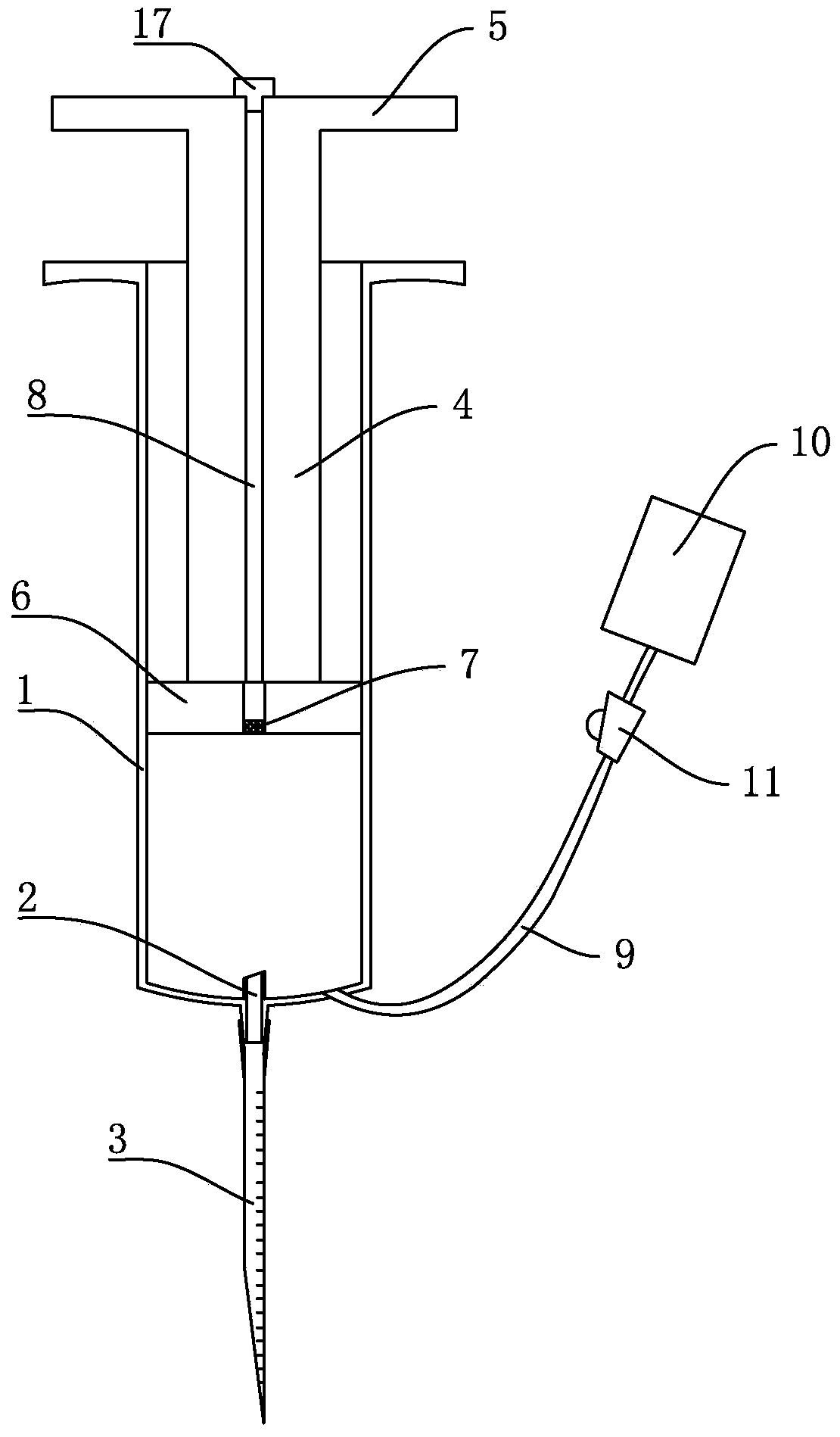

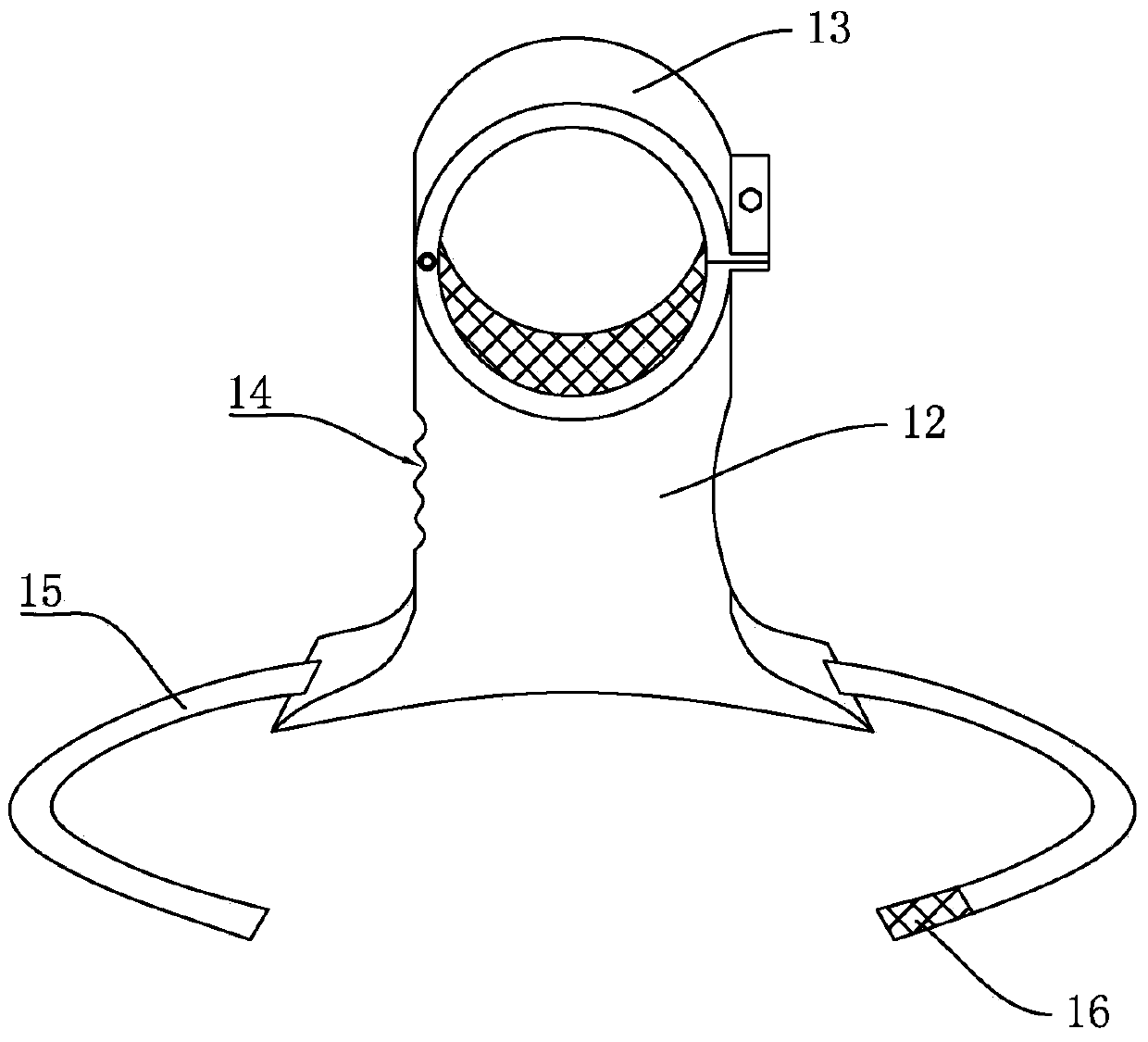

Inflatable loading positioning device and loading positioning method of columns

InactiveCN103728178AFix stability issuesSolve the need for loading and positioningMaterial strength using tensile/compressive forcesAirbag deploymentCheck valve

The invention relates to the field of structural tests, particularly a loading positioning device for compressed column tests in civil engineering, which is especially suitable for secondary loading of compressed columns under the coupled actions of load and environment. The loading positioning device comprises a vertical elevation system, a positioning auxiliary frame and a horizontal movement and fixation system, wherein the vertical elevation system is composed of an I-shaped lower bottom plate, an I-shaped upper bottom plate, an airbag with a single-side notch, an inflation tube, an eduction tube, a check valve, an inflation cylinder, a vertical guide rod, a vertical guide sleeve and a stopper. The loading positioning device can quickly, accurately and stably aim at any preset loading position at one time; and the loading positioning device can horizontally and vertically move freely to satisfy the loading demands of compressed columns in different sizes and different structures, and ensure the compressed columns to be always vertical and stable in the positioning process.

Owner:ZHEJIANG COLLEGE OF CONSTR

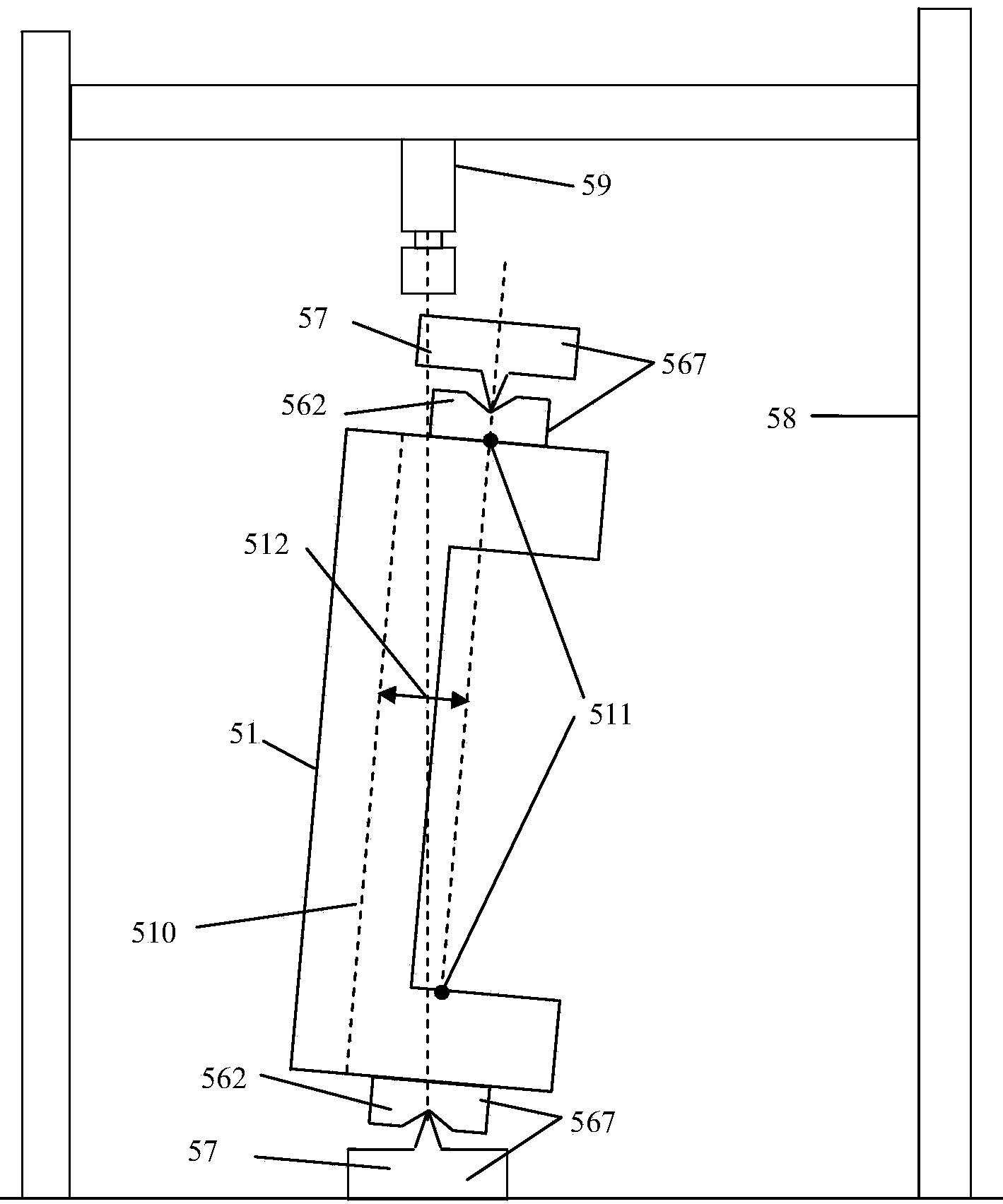

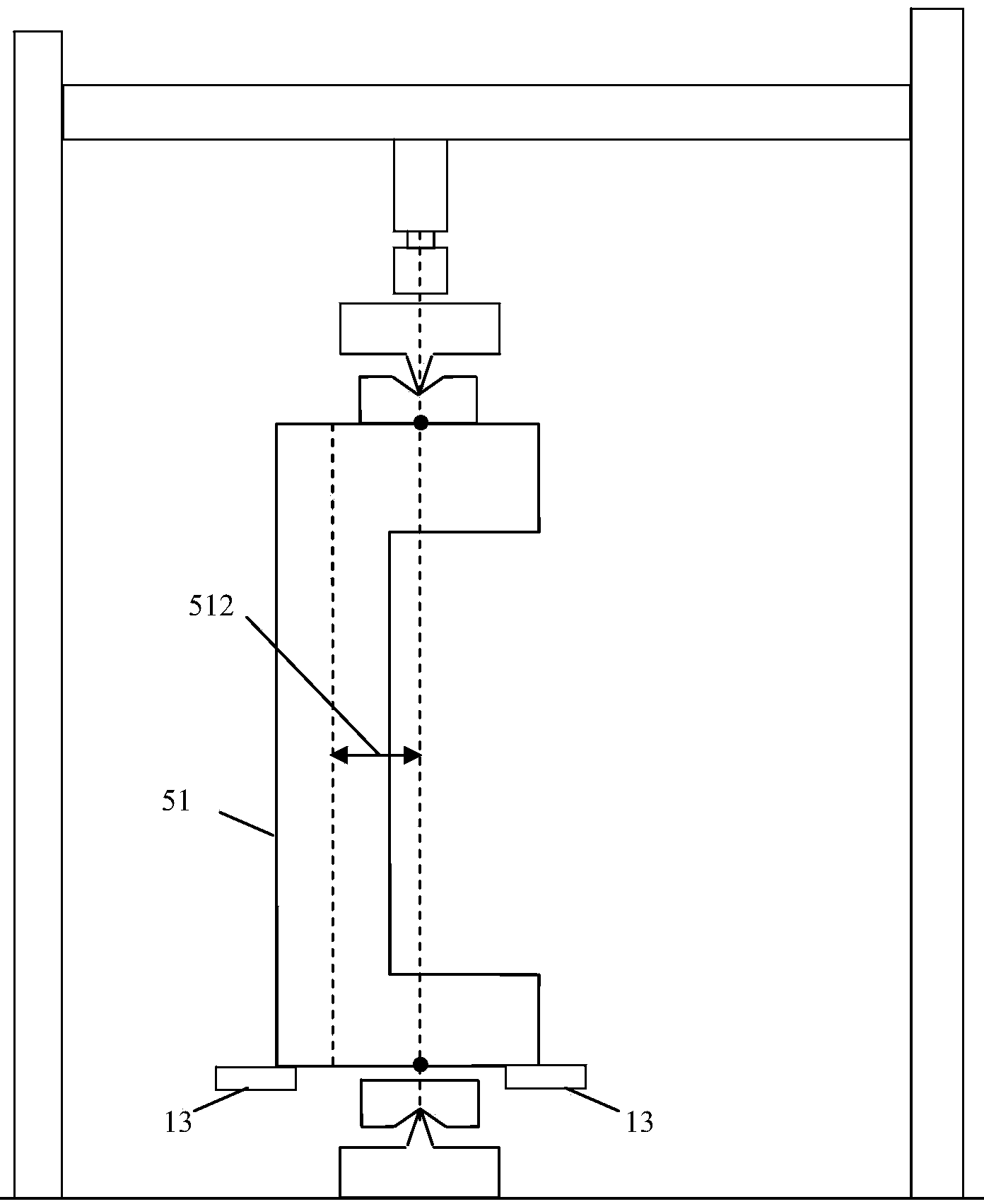

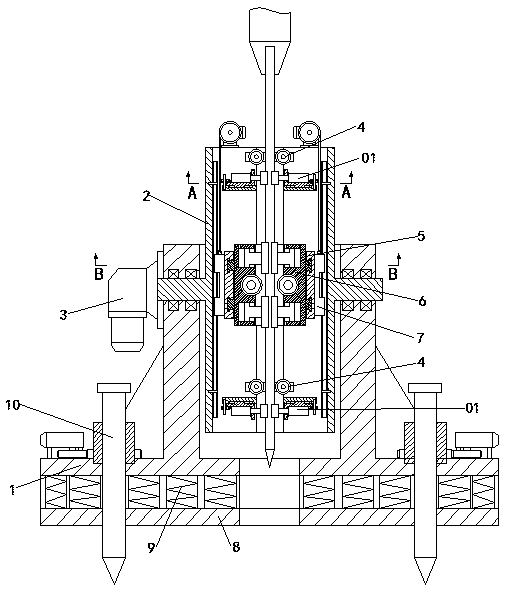

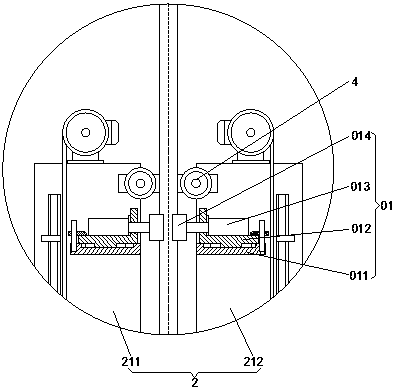

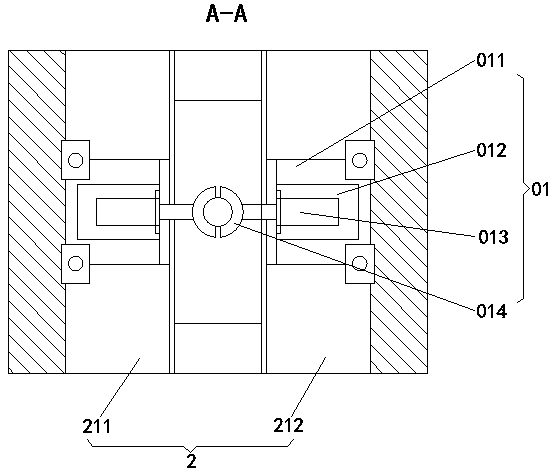

Drill rod deviation rectifying clamping device for geotechnical engineering

The invention discloses a drill rod deviation rectifying clamping device for geotechnical engineering. The device comprises a base, a deviation rectifying base is rotatably mounted on the base in thehorizontal axis direction, the base is further provided with a rotating device for driving the deviation rectifying base to rotate, a channel allowing a drill rod to pass through is formed in the deviation rectifying base in the axial direction, deviation rectifying clamping devices are mounted at two ends of the channel, drill rod guide devices are coaxially mounted on one sides of the deviationrectifying clamping devices, a locking frame is slidingly mounted at the position, between the deviation rectifying clamping devices on the two ends, of the deviation rectifying base in the axial direction, a through hole allowing the drill rod to pass through is formed in the locking frame, a drill rod clamping device is rotatably mounted in the through hole, and a sliding device for driving thelocking frame to slide is arranged at one end of the deviation rectifying base. The device has the beneficial effects that the drilling rod is convenient to dismount and mount, upper space can be effectively saved, the drilling rod is subjected to inclination angle deviation rectifying and drilling point deviation rectifying, it is effectively ensured that the drilling rod is perpendicular to theground, a drilling bit of the drilling rod is aligned with the drilling point, and the drilling process is stable.

Owner:ZUNYI NORMAL COLLEGE

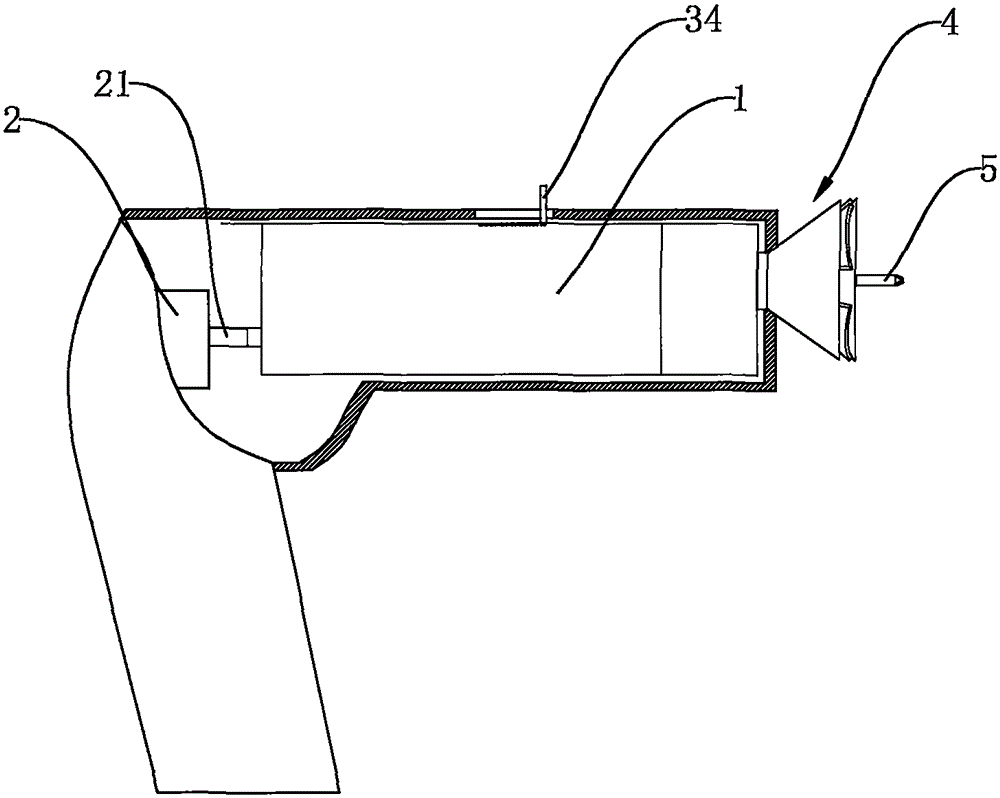

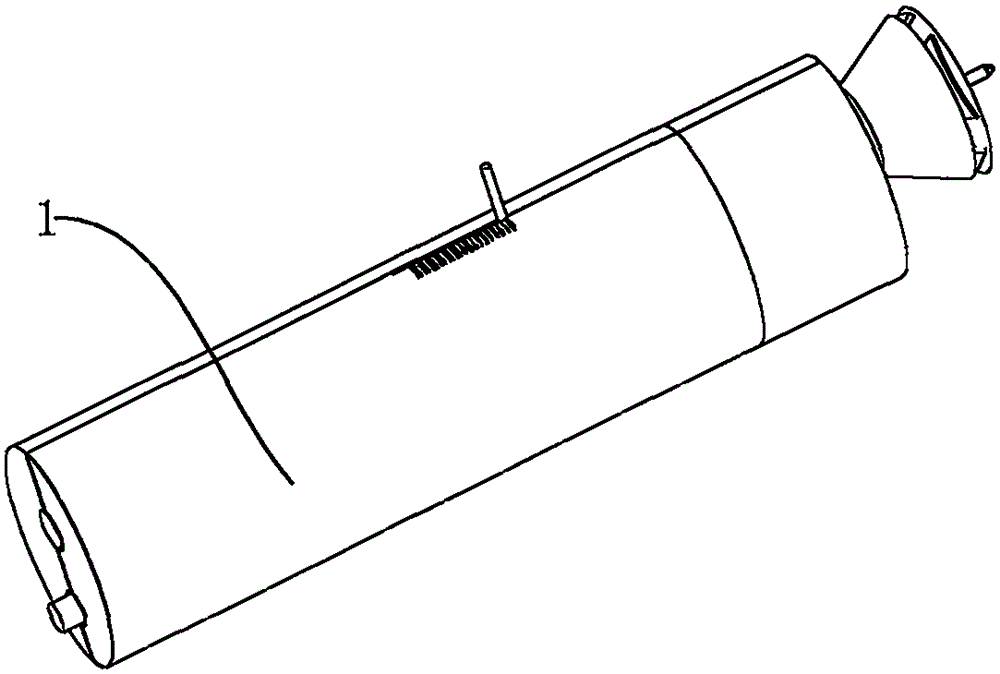

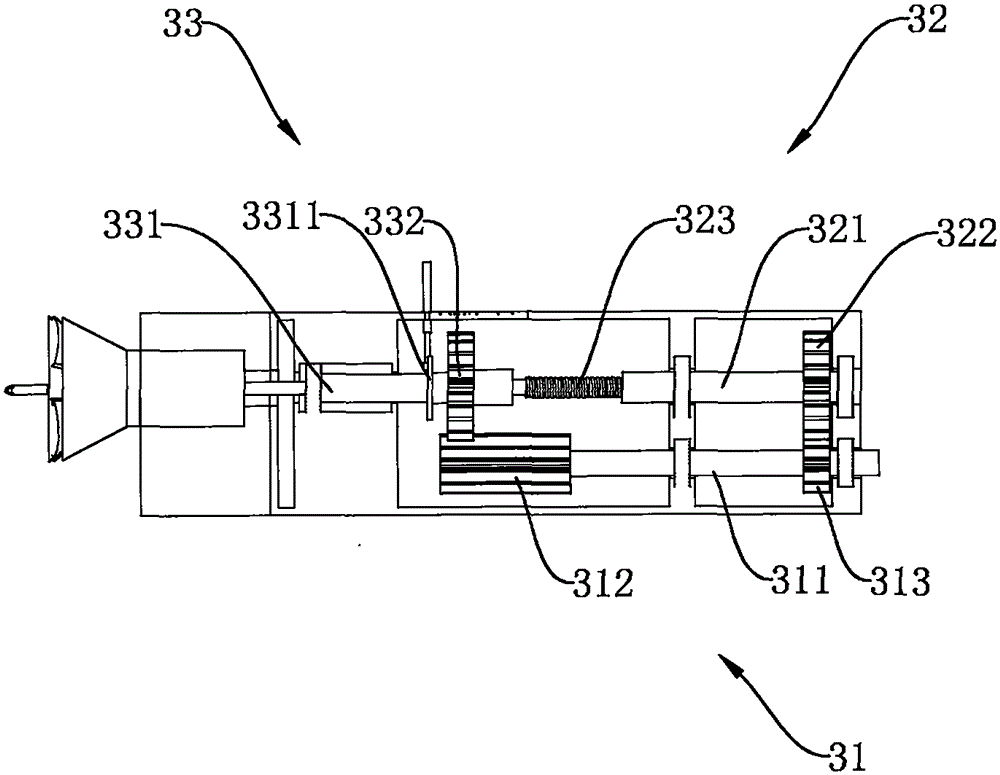

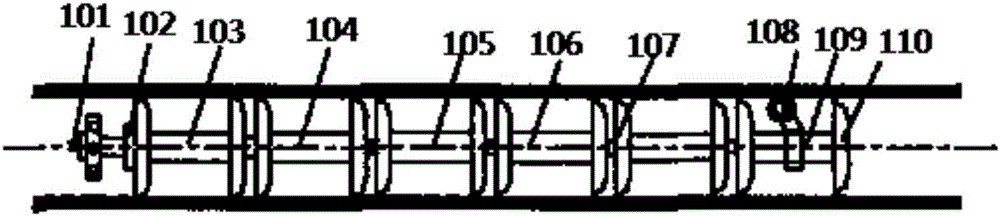

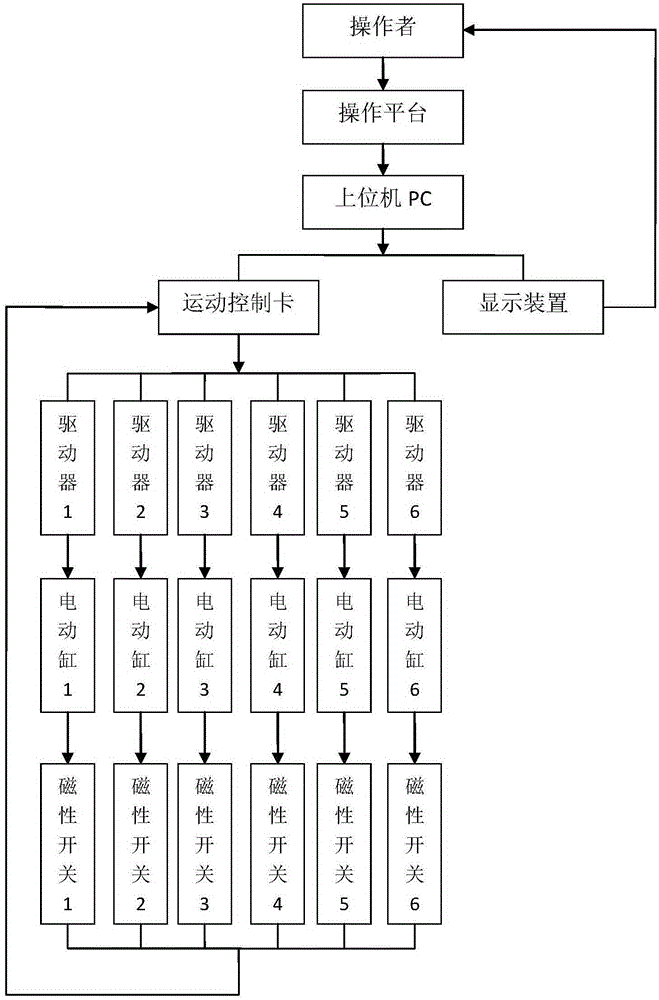

Six-degree-of-freedom parallel dynamic platform

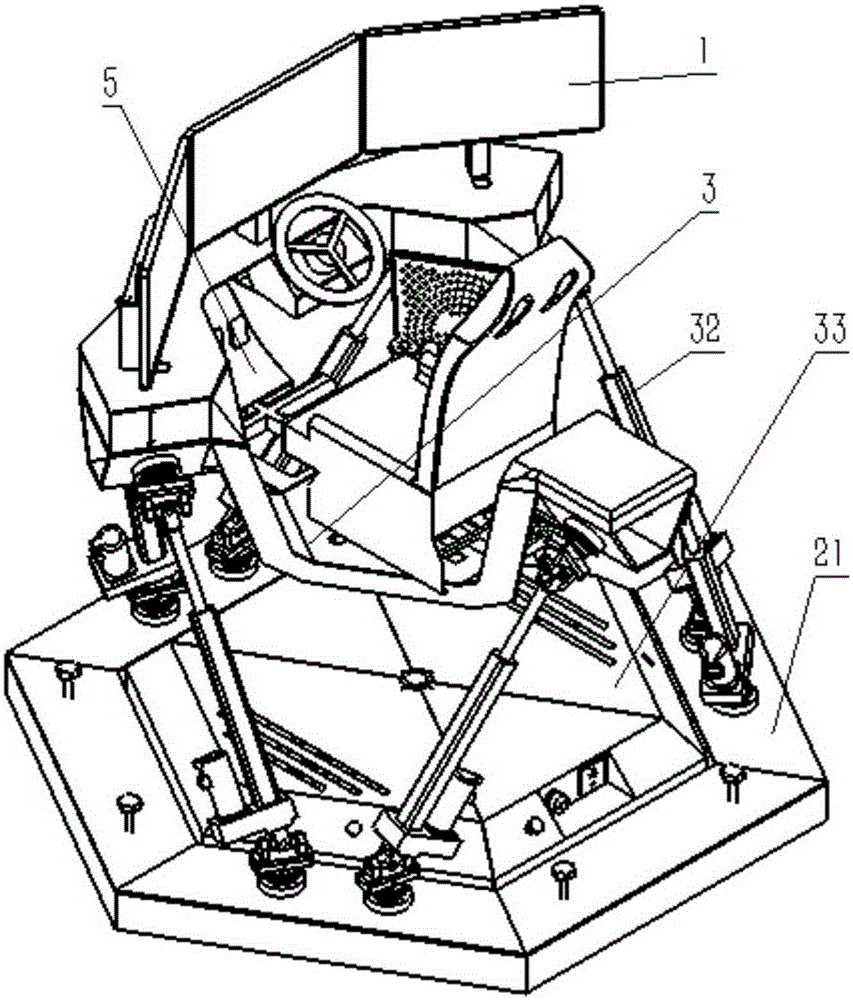

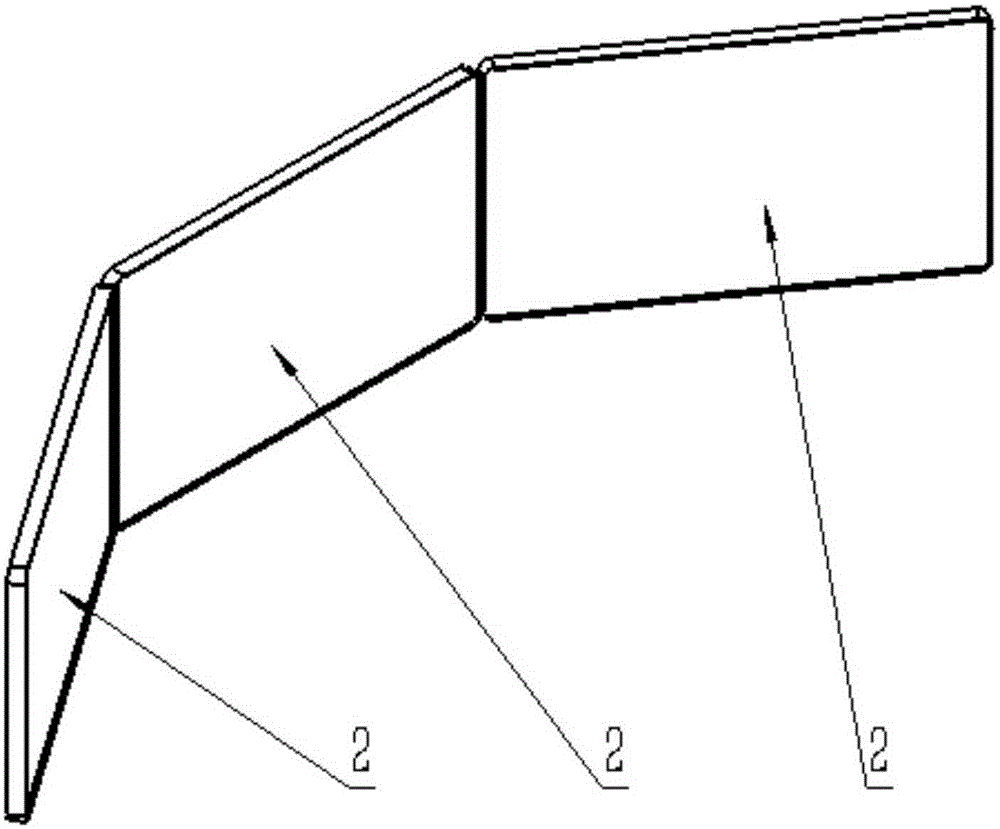

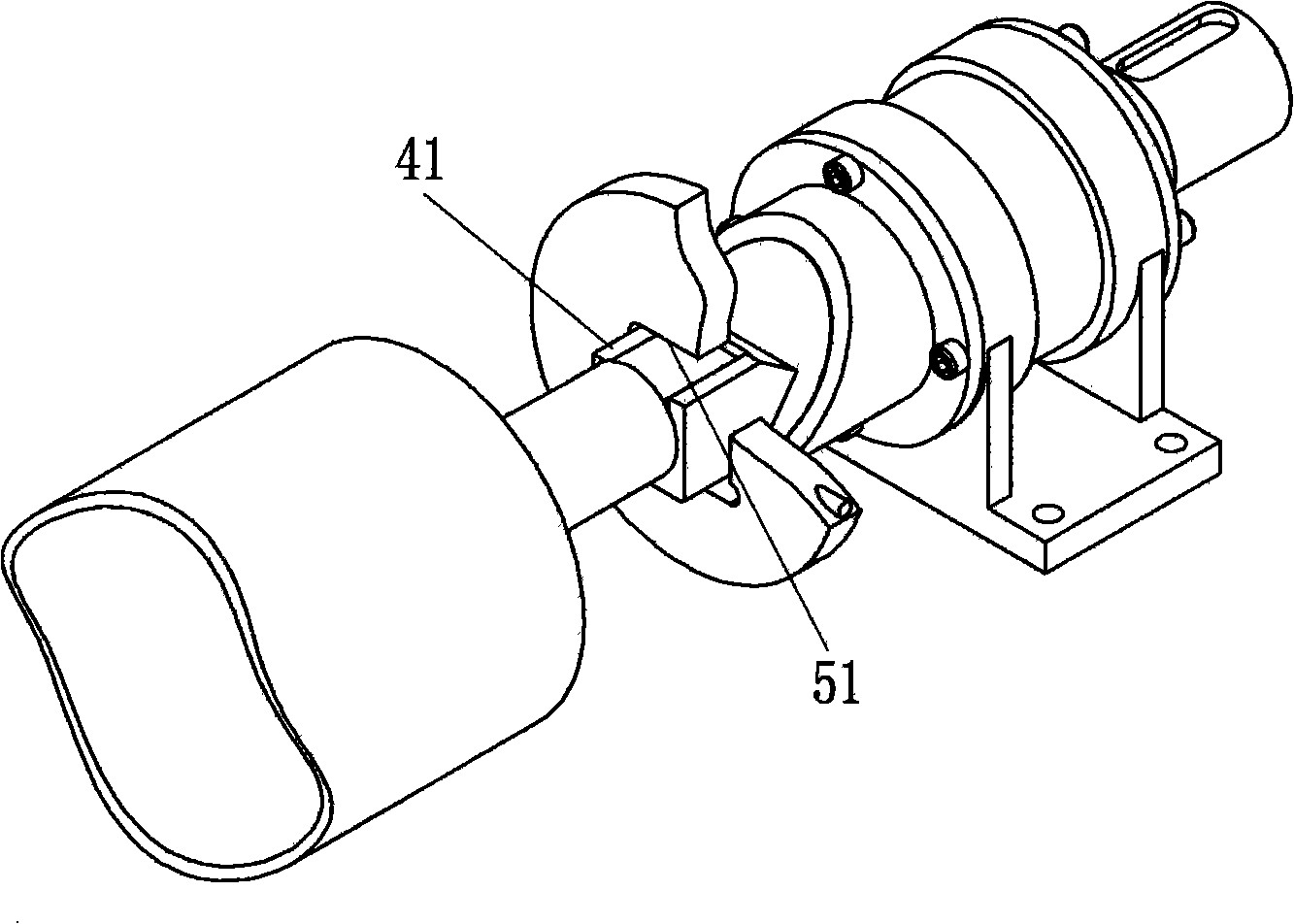

InactiveCN105185184ALower center of gravityIncrease movement speedCosmonautic condition simulationsSimulatorsParallel dynamicsControl system

The invention relates to a six-degree-of-freedom parallel dynamic platform. The six-degree-of-freedom parallel dynamic platform comprises a display device (1), an operation platform (5), an upper platform (3), an execution mechanism (32), a lower platform (21) and a control system (33); the display device (1) and the operation platform (5) are respectively arranged on the upper platform (3); two ends of the execution mechanism (32) are respectively fixed on the upper platform (3) and the lower platform (21); and the control system (33) is located in the lower platform (21). With the six-degree-of-freedom parallel dynamic platform of the invention adopted, defects in the prior art can be eliminated, and simulation experience of an operator and the reliability of the mechanism can be enhanced, and up-and-down, left-and-right and front-and-back translation and rotation can be realized. The six-degree-of-freedom parallel dynamic platform has the advantages of stable movement and convenient operation, and can bearing a large load.

Owner:北京大华旺达科技有限公司

Clamping apparatus for cloth roller

The invention relates to a clamping device of a cloth roller on a grey cloth rolling machine, comprising a support, an end cover, an inclined sleeve and a shaft; the shaft is installed on the support by a bearing; the clamping device is characterized in that: one end of the shaft is provided with a plane and a square groove and further equipped with a guide sleeve, the guide sleeve is sheathed on the shaft, the plane of an inner bore of the guide sleeve is coincident with the plane on the shaft and the cylindrical surface of the inner bore of the guide sleeve is partially coincident with the cylindrical surface of the shaft, and one end surface of the guide sleeve is an inclined plane that is not vertical to the axial line of the guide sleeve. Compared with the prior art, the clamping device of the invention has the advantages that: during the rotation of the cloth roller, a square shaft head can not shift in the square groove of the shaft and has no impact and noise; when the shaft rotates till the opening of the square groove faces downwards, the guide sleeve can bear the weight of cloth rolls and the cloth roller, therefore, parts are not easily to be damaged and are durable; the shaft and the guide sleeve are both simple in shape and easy to be processed and the whole device has convenient installation and dismantlement and easy to be maintained.

Owner:杨希霞

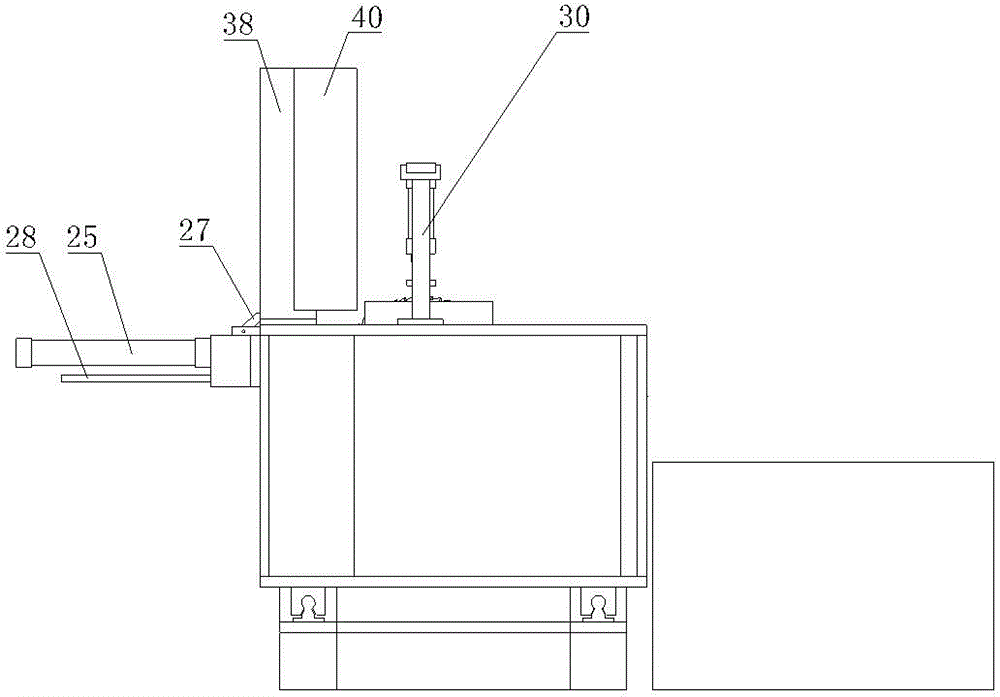

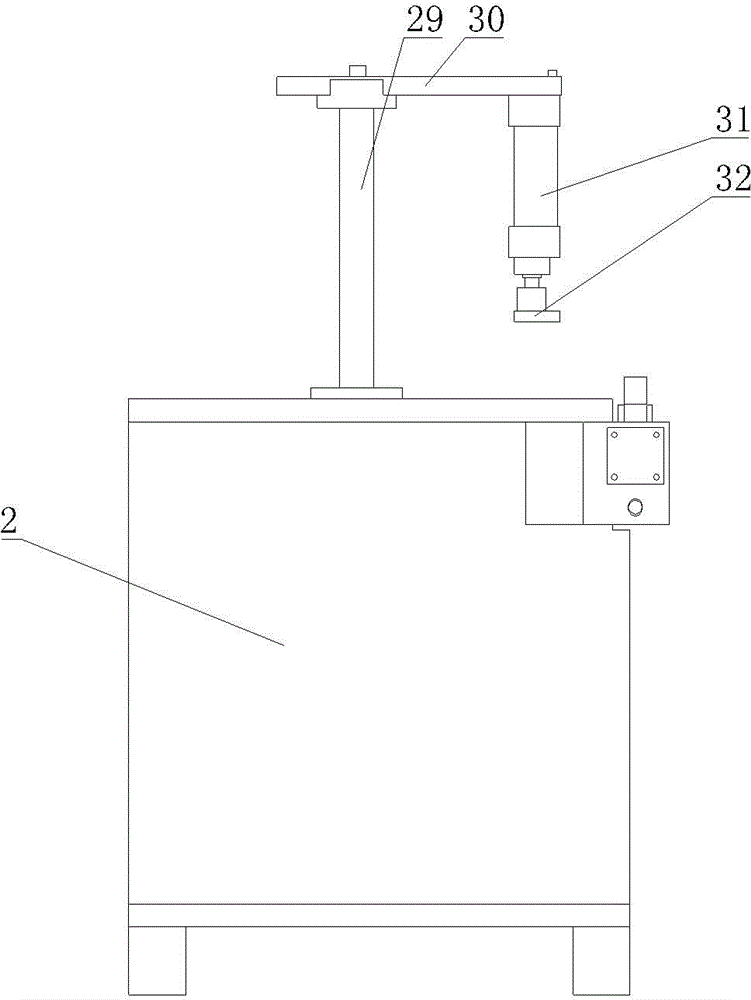

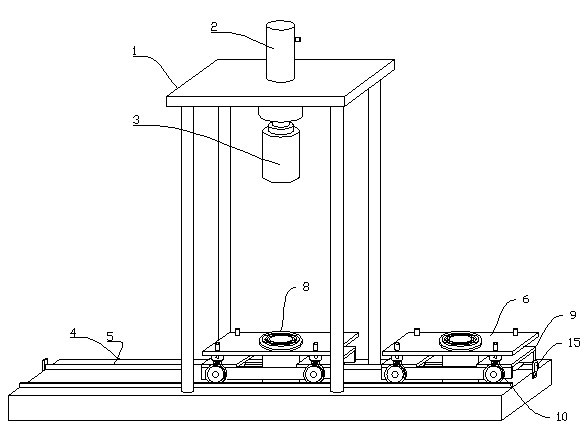

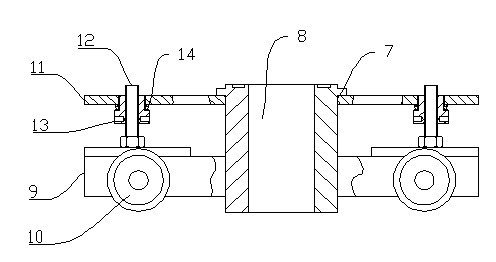

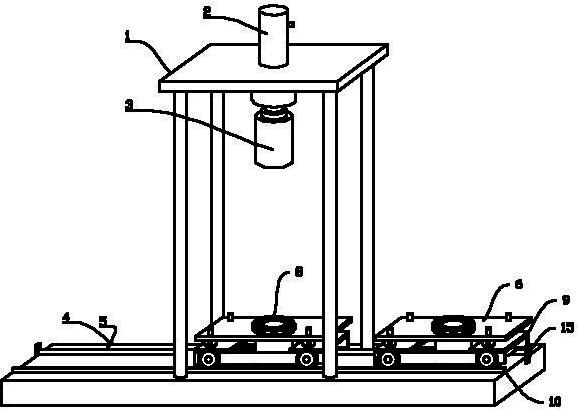

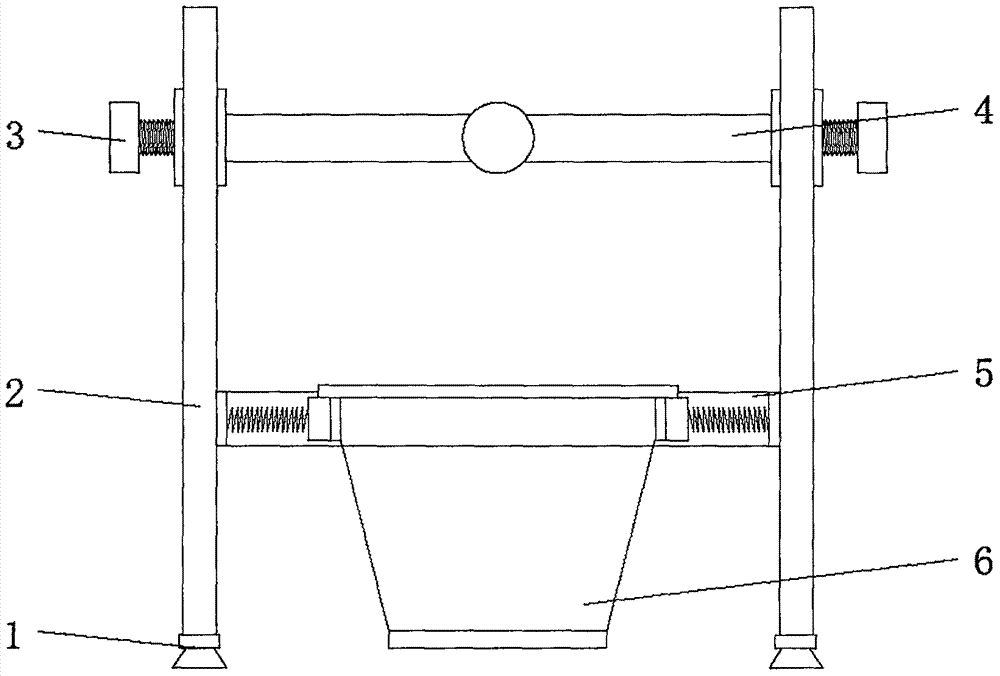

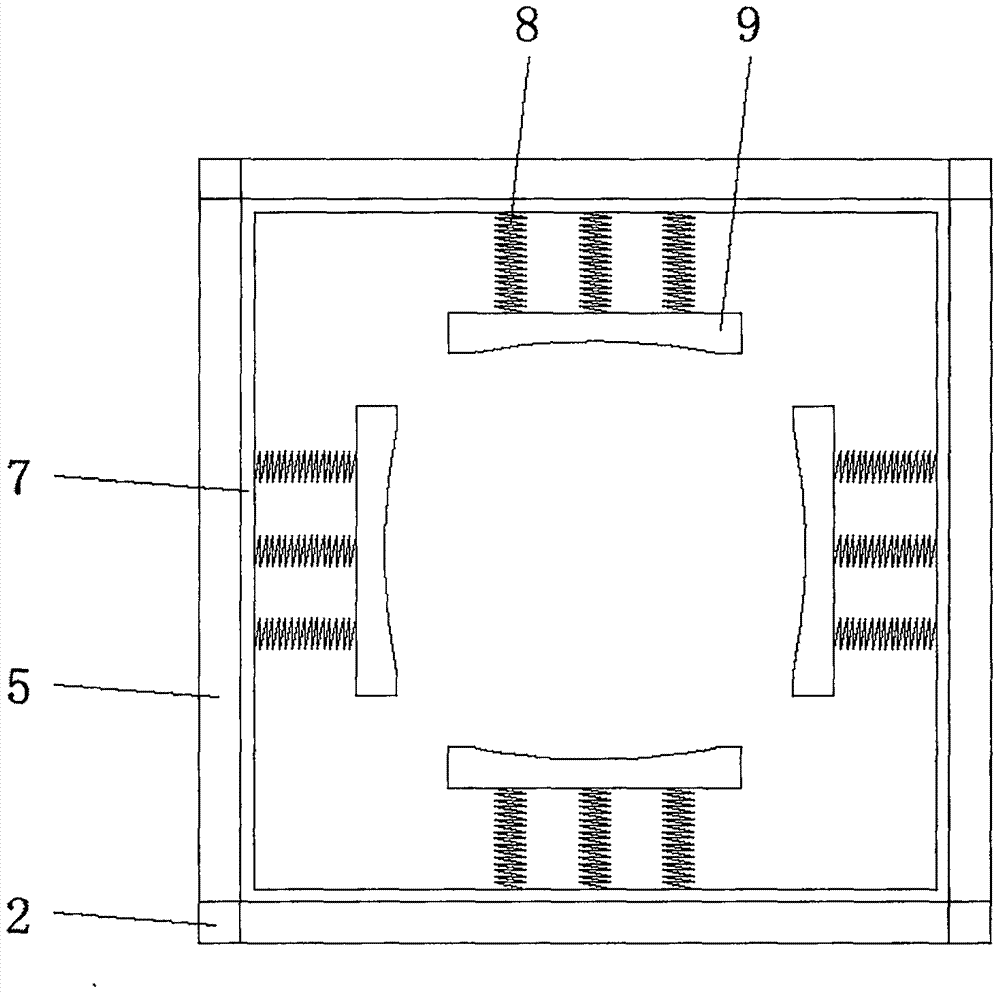

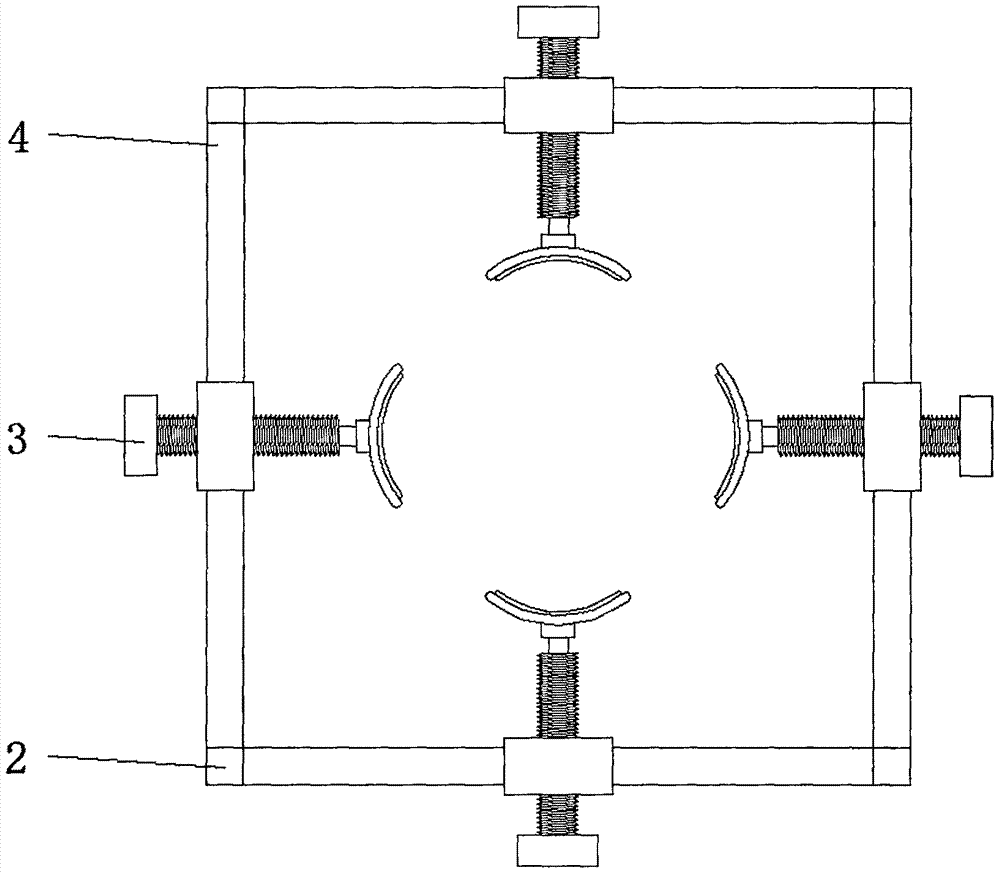

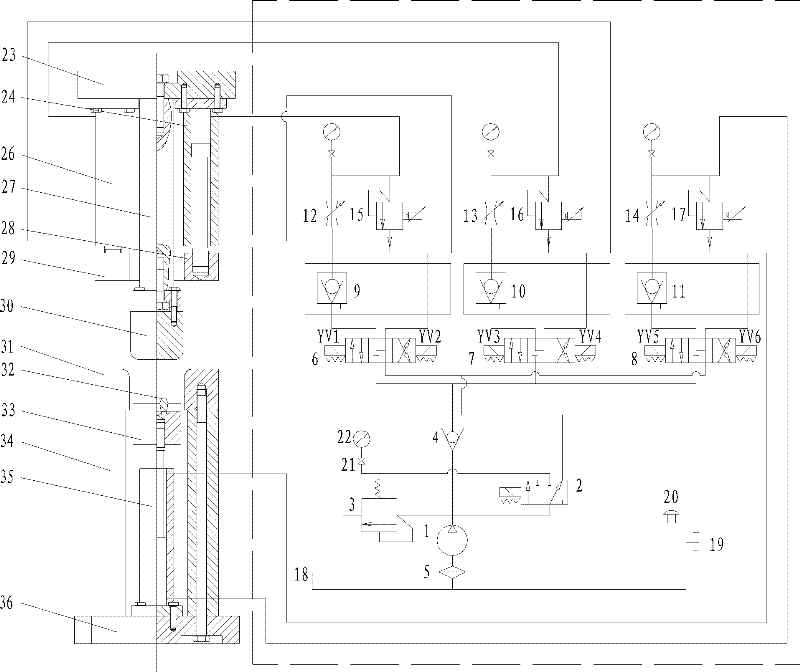

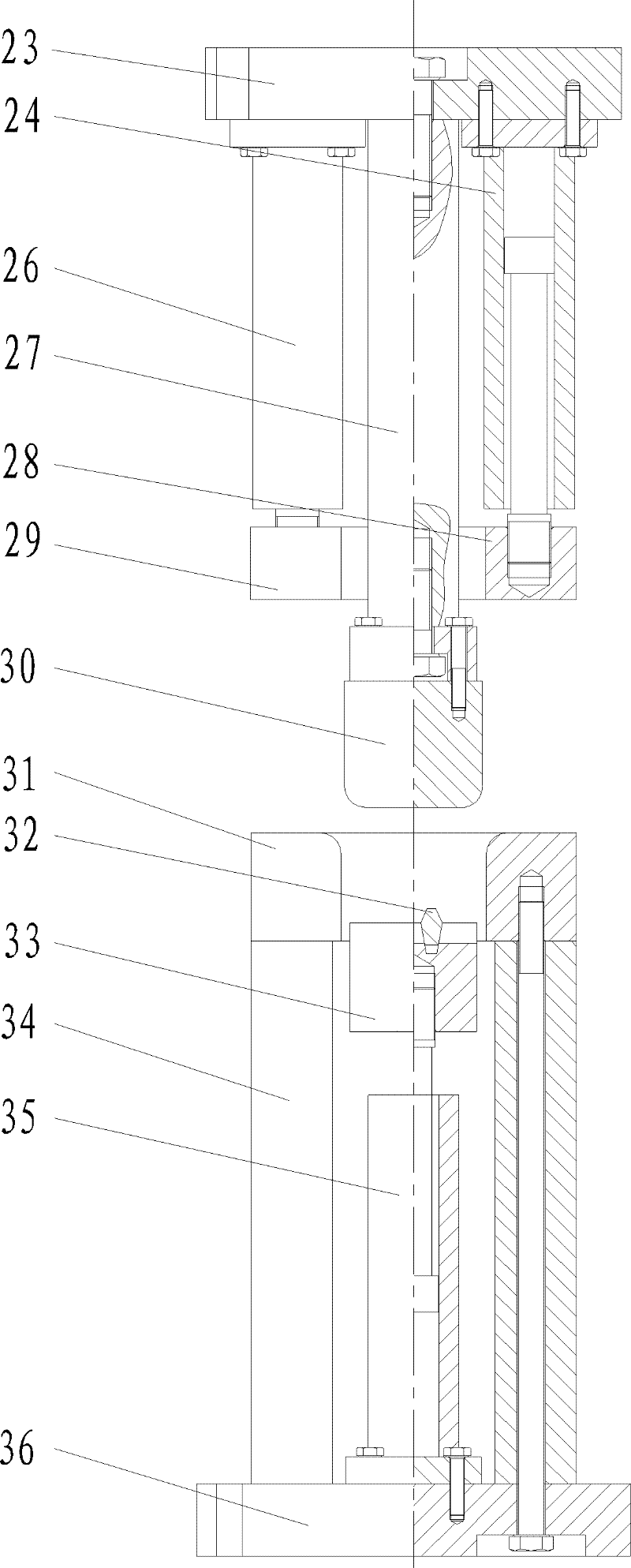

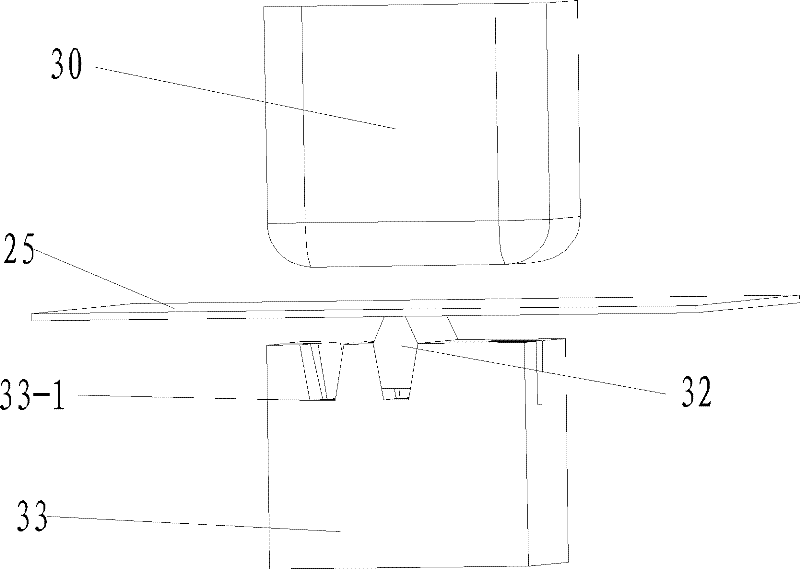

Press-mounting machine for assembling rollers of belt conveyor

InactiveCN102672456AAccurate placementSmooth connectionMetal working apparatusHydraulic cylinderBelt conveyor

The invention discloses a press-mounting machine for assembling rollers of a belt conveyor. The press-mounting machine comprises a bracket body consisting of a base, supporting posts and a top plate; a vertical hydraulic cylinder is arranged at the upper part of the bracket body; a piston rod of the hydraulic cylinder extends downwards; the rod head of the piston rod is provided with a pressing head; guide rails are arranged on the base of the bracket body; plate trailers running along the guide rails are arranged on the guide rails; and jacking heads corresponding to the pressing head are arranged on the plate trailers. The press-mounting machine is used for assembling the rollers, the plate trailers loaded with the rollers are integrally pushed into preset positions of the bracket body, the upper ends of the rollers are enabled to be aligned with the pressing head, the pressing head is driven to push fittings, such as bearings, into the rollers by using the hydraulic cylinder, and the plate trailers are pushed out of the bracket body for unloading and reloading after the press-mounting is finished. The press-mounting machine for assembling the rollers of the belt conveyor has the advantages that the operation is simple, the labor intensity is low, the working efficiency is further increased, the placement of workpieces is accurate, the migration cannot occur during press-mounting, and thus, the product quality is stable.

Owner:SHANDONG MINING MASCH GRP CO LTD

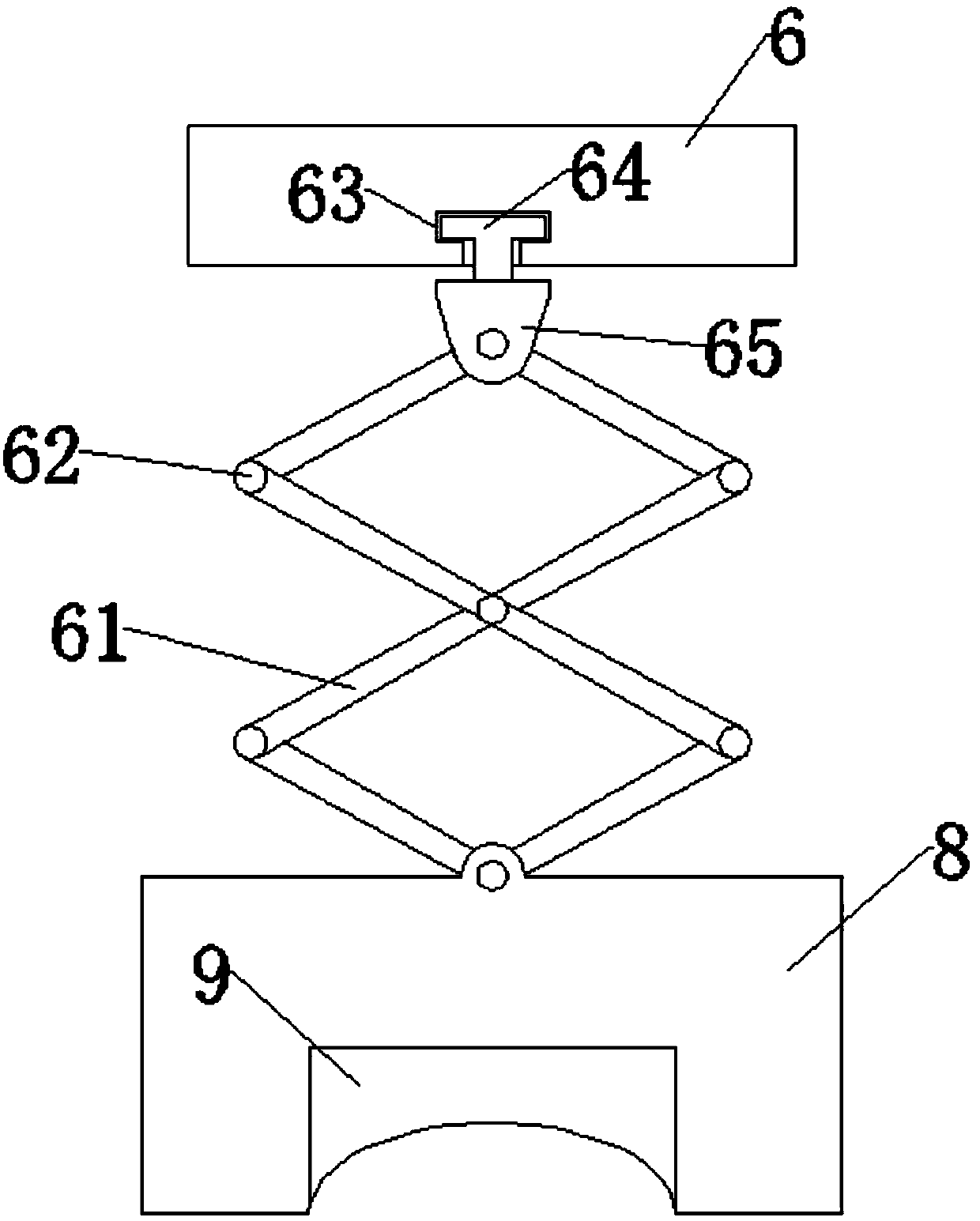

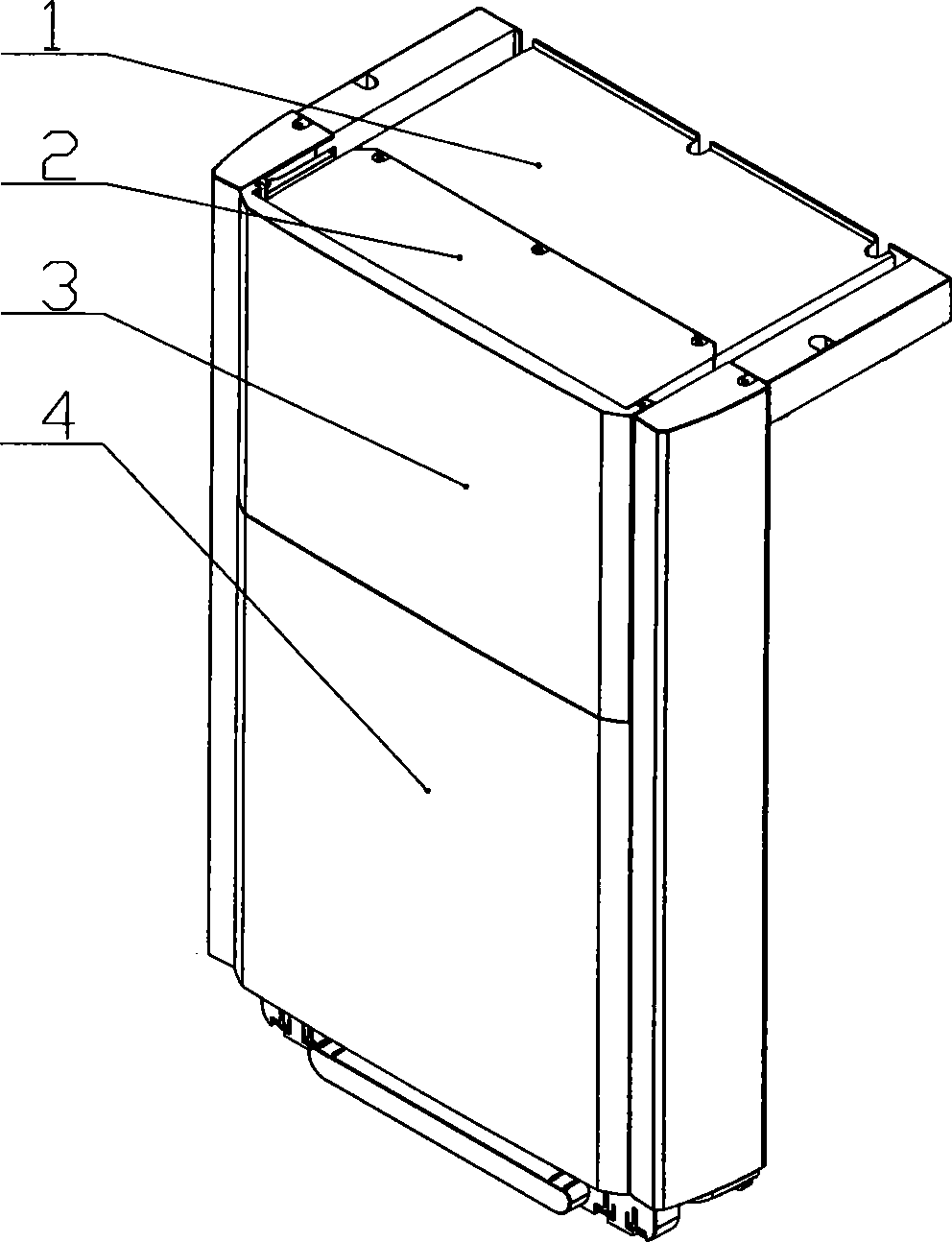

Elevating kidney stone therapeutic apparatus with supporting device

InactiveCN107854157AEasy to get up and downEasy to slapOperating tablesMedical equipmentKidney stone

The invention discloses a liftable kidney stone treatment apparatus with a support device in the technical field of medical equipment, comprising a movable plank bed, a pillow is arranged on the top of the movable plank bed, and a fixed plank bed is arranged at the right end of the movable plank bed. The movable plank bed and the fixed plank bed are connected by hinges, the top of the fixed plank bed is provided with a support device, the top of the support device is provided with a sliding support frame, the front and rear side walls of the fixed plank bed are provided with chute, the sliding support The bottom inner wall of the frame is provided with a sliding block matched with the chute. In the present invention, a movable plank bed, a limit block, a lifting screw, a rotating screw and a manual crank are arranged, and the rotating screw is driven to rotate by the manual crank, and the rotating screw and the lifting The screw is matched to make the lifting screw move up and down, and the lifting screw drives the angle adjustment of the movable plank, which is convenient for the patient to get up and down.

Owner:青岛恒科瑞新信息科技有限公司

Door opening and closing mechanism for front air outlet of cabinet air-conditioner

InactiveCN101424437ARealize opening and closing actionAchieve aestheticsAir-flow control membersGear driveEngineering

The invention provides an opening-closing mechanism for a front air outlet of a chest-type air conditioner. The mechanism adopts a structure that two gears which are connected with a stepper motor drive respective meshing driven gears to rotate, and the driven gears mesh with a rack arranged on an opening-closing door plate; two sides of the opening-closing door plate are provided with two positioning columns; the positioning columns are in close fit with copying track grooves arranged on an air-outlet inner frame; and the driven gears drive the opening-closing door plate to do corresponding movement along set copying tracks, so as to open and close the air outlet. In addition, the inner side of the opening-closing door plate is provided with guide slots parallel to the rack respectively; one end of each driven gear is sleeved with a limiting stopper; the limiting stopper can rotate around a driven gear shaft; two positioning columns are arranged on the limiting stopper; and the positioning columns are in close fit with the guide slots inside the opening-closing door plate, so as to ensure that the driven gears and the rack are in a normal meshing state when the opening-closing door plate moves to any position. When the opening-closing door plate is closed, the lower part is self locked radially through limiting columns arranged on two sides of the opening-closing door plate, and the copying track grooves arranged on two sides of an air-outlet frame, the upper part is self locked radially through a position where the gears mesh with the rack, so as to ensure that the opening-closing door plate does not move when users push the opening-closing door plate inwards with hands during abnormal operation.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

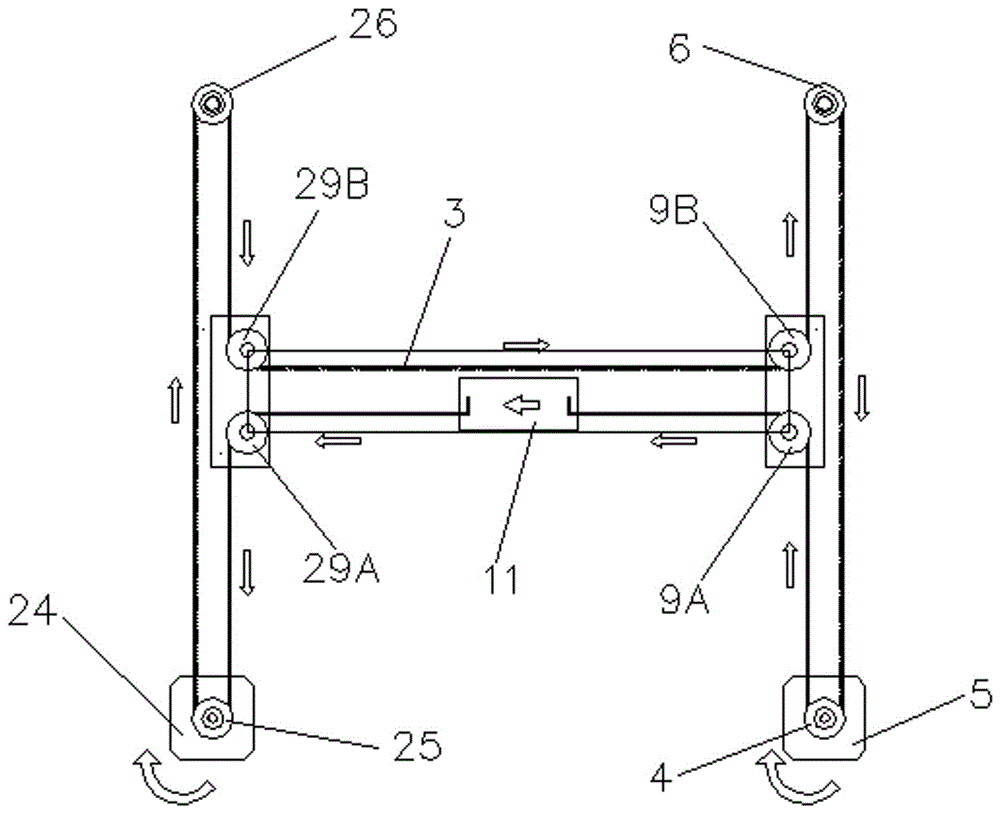

3D printer, special horizontal movement mechanism and horizontal movement method of 3D printer

InactiveCN105922599ASimple structureEasy to installAdditive manufacturing apparatusEngineering3d printer

Owner:HEBEI DAAI INTELLIGENT TECH CO LTD

Integrated driving short roller device for pulling glass

The invention provides an integrated driving short roller device for pulling glass. The integrated driving short roller device comprises a baseboard, a baseboard guide rail is arranged on the baseboard, two sliding plates are slidably arranged on the baseboard guide rail, and a clamping mechanism, a driving mechanism and an adjusting mechanism are correspondingly arranged on each sliding plate; each clamping mechanism comprises a short roller mandrel fixed to the corresponding sliding plate; a glass clamping end is arranged at one end of each short roller mandrel, and is sleeved with an asbestos roller wheel, and a driving end is arranged at the other end of the corresponding short roller mandrel and is connected with a driving shaft of the corresponding driving mechanism; the adjusting mechanisms comprise pulling rods for controlling the sliding plates to slide and weights for adjusting clamping force of the asbestos roller wheels. By means of the integrated driving short roller device for pulling the glass, multiple driving short roller devices are installed on a mounting support to form an integrated structure and are installed at the two sides of an annealing furnace. The riving short roller device is independently arranged, one set of rollers oppositely stretch into the hot end annealing furnace from the two sides of the annealing furnace and clamp and pull the substrate glass from the two sides respectively, the manufacturing cost is low, and the integrated driving short roller device is convenient and flexible to adjust, and can be quickly installed and adjusted.

Owner:IRICO

Anti-falling device for dendrobium cultivation

InactiveCN107980580AAchieve supportiveTo achieve the effect of placementAgriculture gas emission reductionCultivating equipmentsEngineeringFlowerpot

The invention discloses an anti-falling device for dendrobium cultivation. The anti-falling device for dendrobium cultivation comprises anti-sliding bases, supporting rods, rotating limiting devices,an upper installing frame and a lower installing frame, wherein spring installing plates are installed on the inner surfaces of the lower installing frame, limiting springs are installed at the ends,away from the lower installing frame, of the spring installing plates, flowerpot supporting plates are installed at the tail ends of the limiting springs, a flowerpot is arranged in the middles of theflowerpot supporting plates, and the supporting rods are installed at portions of the four corners of the lower installing frame; the anti-sliding bases are installed at the tail ends of the supporting rods, and the supporting rods at the upper portion of the lower installing frame are connected through the upper installing frame; the rotating limiting devices are installed in the middles of thefour edges of the upper installing frame, rotating bolts are installed in the middles of the rotating limiting devices, and rotating nuts are installed at one ends of the rotating bolts. By means of the anti-falling device for dendrobium cultivation, flowerpots can be conveniently placed, and through the rotating limiting devices at the upper ends, main dendrobium stems with different sizes can besupported for preventing dendrobium from falling.

Owner:容县明曦铁皮石斛种植场(微型企业)

Weld-line movement-controlled tailor-welded blank stamp-forming device

InactiveCN102303063AControl flowFlexible control of blank holder forceServomotorsHydraulic cylinderControl system

The invention discloses a weld-line movement-controlled tailor-welded blank stamp-forming device, relating to tailor-welded blank stamp-forming devices. The weld-line movement-controlled tailor-welded blank stamp-forming device aims at solving the problem that the traditional tailor-welded blank stamp-forming device cannot control a weld line to move to a correct position through regulating a blank-holding force of a blocking blank holder and regulating a holding force of the weld line and cannot flexibly control a blank-holding force on a blank at two sides of the weld line. A female die is mounted on the upper end faces of two female die cushions; a holding block can move up and down along the die cavity of the female die under the driving of a piston rod of a third hydraulic cylinder; a holding pin inserts into one of grooves; a first blank holder and a second blank holder are arranged above the female die and are used for positioning a tailor-welded blank; the upper end face of the first blank holder is connected with a piston of a first hydraulic cylinder; the upper end face of the second blank holder is connected with a piston of a second hydraulic cylinder; and a control system is used for adjusting the motion of the three hydraulic cylinders through controlling the on / off of each hydraulic valve component in a hydraulic system. According to the invention, the inflow volume of blanks at the two sides of the weld line of the tailor-welded blank can be effectively controlled.

Owner:HARBIN INST OF TECH

Cardiovascular intervention curer

InactiveCN103767775AEasy to operateReduce the difficulty of operationCannulasSurgical needlesCatheterPuncturing

The invention belongs to the technical field of medical apparatus and instruments, and discloses a cardiovascular intervention curer. The cardiovascular intervention curer comprises a puncture device and a fixing device, wherein the puncture device comprises a needle tube, a diaphragm bursting tube is arranged at the top of the needle tube, a needle head is installed at one end of the diaphragm bursting tube, which extends out of the needle tube, a push rod is installed in the needle tube, a push plate is arranged at one end of the push rod, a rubber plug is fixedly installed at the other end of the push rod, a through hole is formed in the rubber plug, an elastic seal diaphragm is arranged on the through hole, a wire guiding hole is formed in the push rod, a catheter is connected with the top of the needle tube, the catheter is connected with a collection bag, a flow control valve is arranged on the catheter, the fixing device comprises a base seat and an upper arc plate installed on the base seat, an arc-shaped groove is formed in the top of the base seat, a hand holding portion is arranged in the middle of the base seat, a fixing portion is arranged at the bottom of the base seat, and two fixing bands are respectively arranged on two sides of the fixing portion. The puncture device is fixed on the fixing device, and a doctor can hold the fixing device in hand for puncturing and then fixes the fixing device, and therefore the doctor can conveniently and accurately operate the cardiovascular intervention curer, and collects blood in the collection bag, and furthermore an operation surface of the doctor can not be polluted.

Owner:马继红

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com