Clamping apparatus for cloth roller

A cloth roll and plane technology, which is applied in the field of clamping devices, can solve the problems of the square-end connecting shaft 4 with complex shape, bad stress state, and high machining cost, and achieve good stress state, simple shape, and easy maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

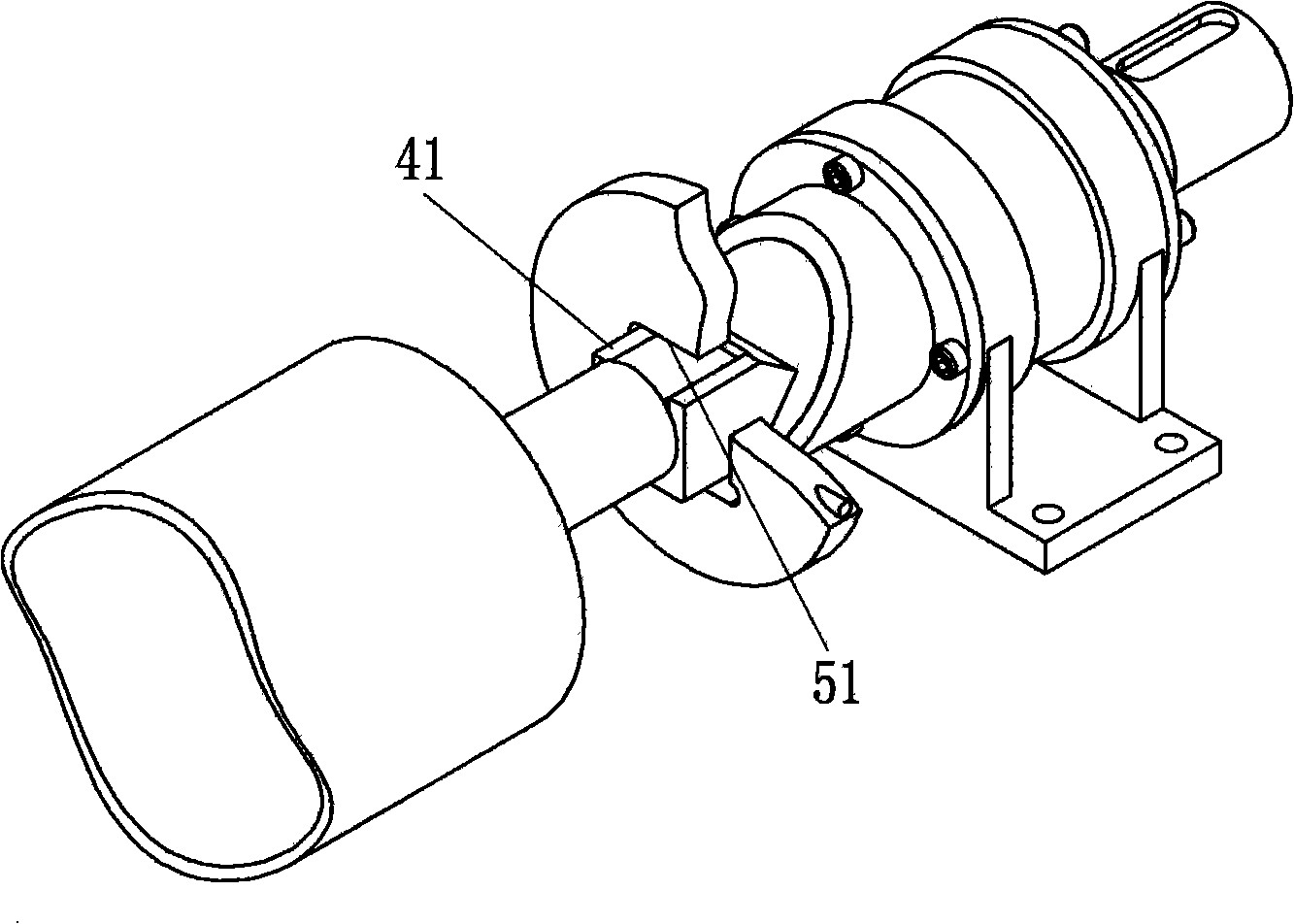

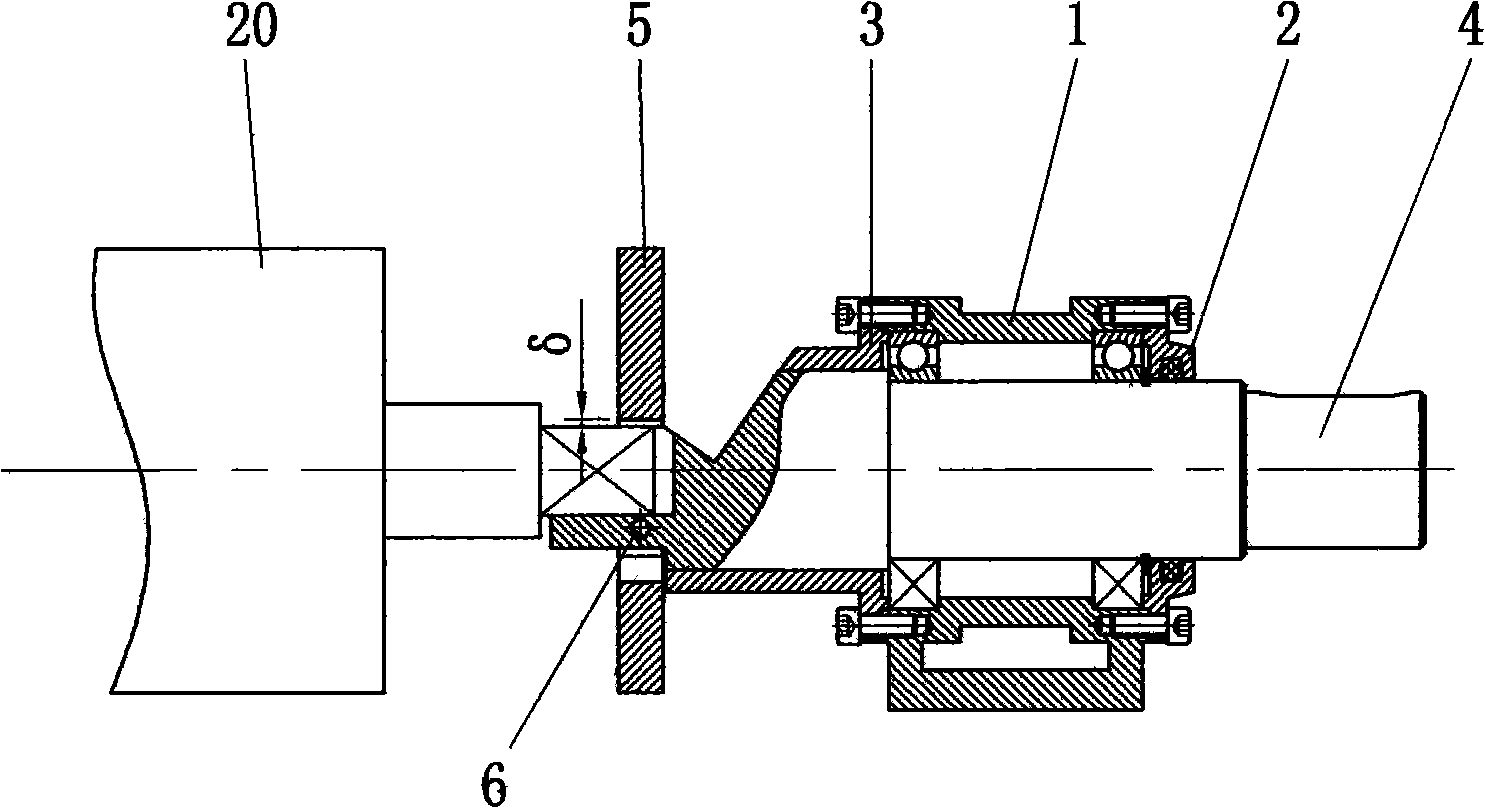

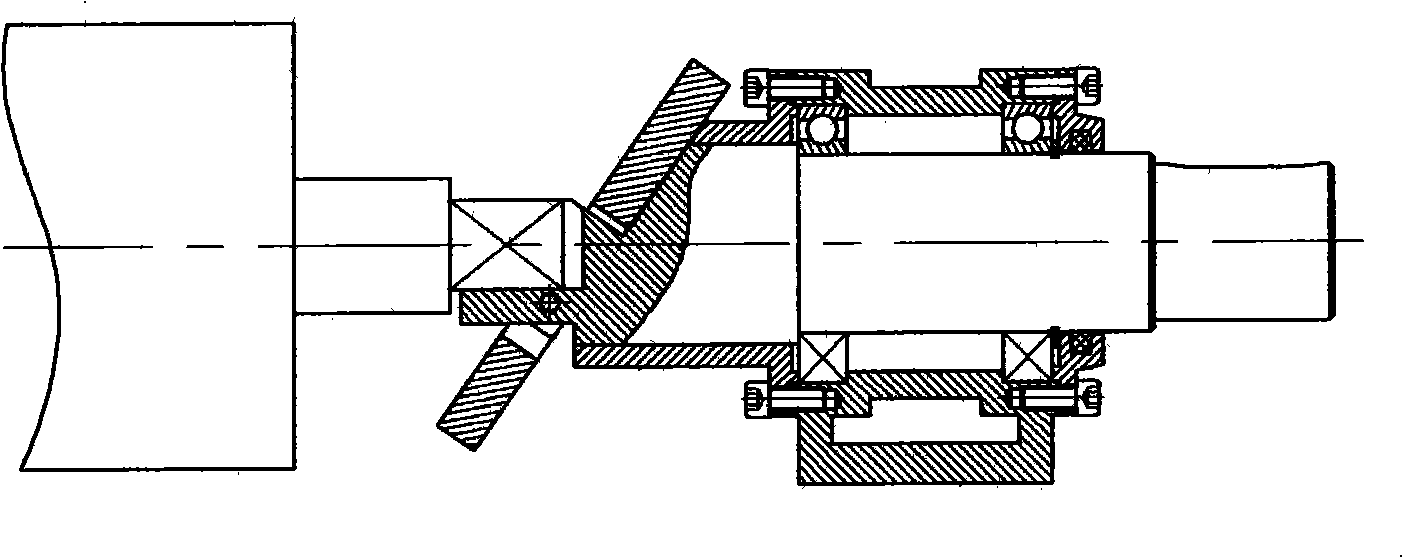

[0025] Such as Figure 5 , Image 6 , Figure 9 , Figure 10 As shown, the shaft 7 is installed on the support 1 through two bearings, a plane 701 and a square groove 702 are processed on one end of the shaft 7, the end cover 2 is installed on one end of the support 1, and the oblique sleeve 3 is installed on the bottom of the support 1. On the other end, the end of the inclined sleeve 3 not in contact with the support 1 is processed into an inclined surface 301 . The guide sleeve 8 is sleeved on the shaft 7, and the inner hole of the guide sleeve 8 has a plane 831, which coincides with the plane 701 on the shaft 7, so that the guide sleeve 8 can only slide axially relative to the shaft 7 and cannot rotate.

[0026] Such as Image 6 , Figure 10 As shown, the guide sleeve 8 is made up of three parts, specifically including an overcoat 81...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com