Weld-line movement-controlled tailor-welded blank stamp-forming device

A technology for stamping and tailor-welded blanks, which is applied in the direction of fluid pressure actuators, servo motors, mechanical equipment, etc., and can solve problems such as inability to flexibly control the blank-holding force of the sheets on both sides of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

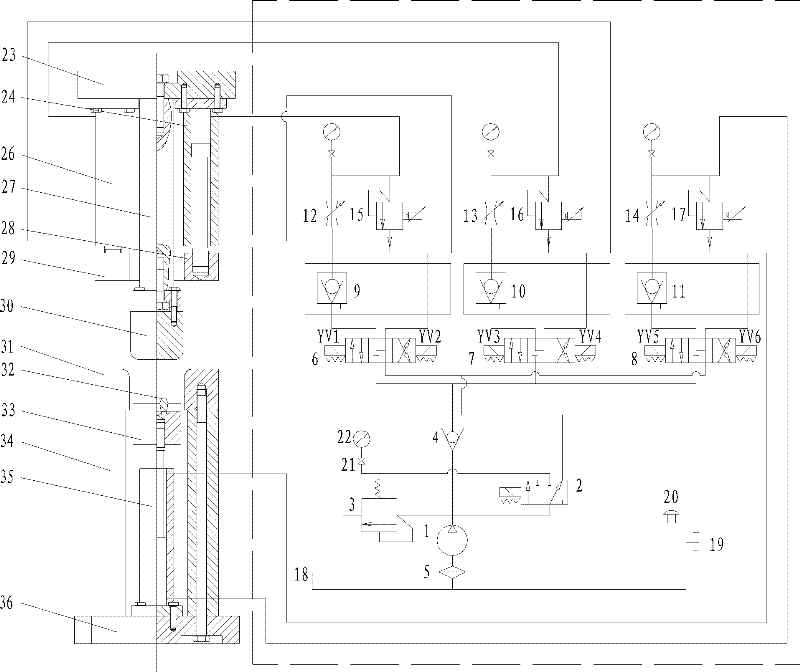

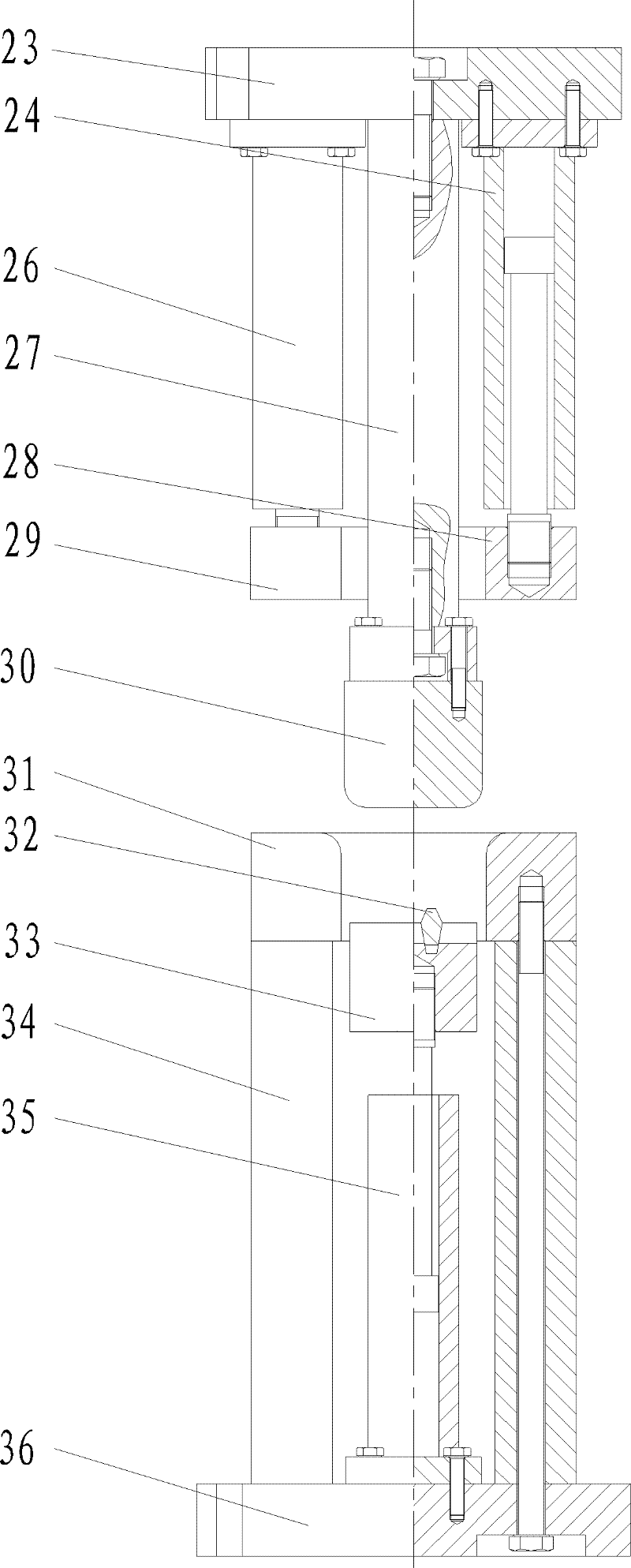

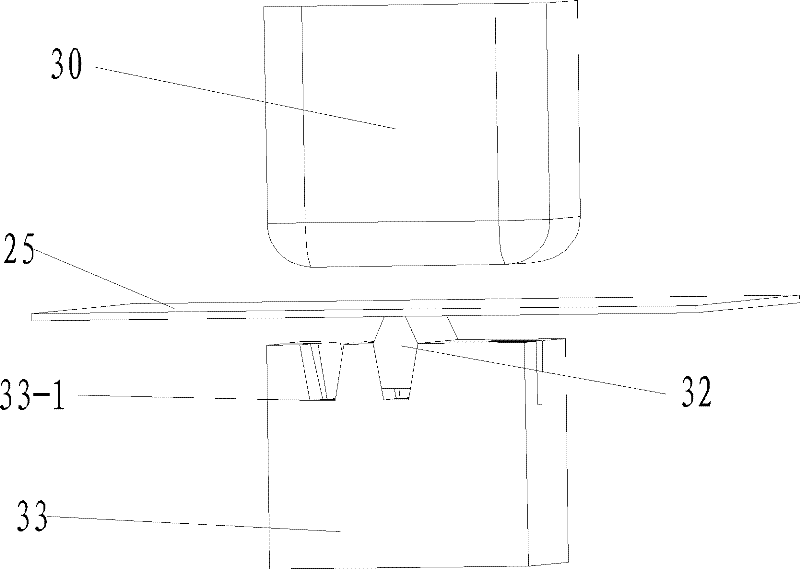

[0013] Specific implementation mode one: as Figure 1-7 As shown, the Tailored Welded Blank Stamping Device for Controlling Weld Seam Movement in this embodiment includes a die device, a hydraulic system and a control system, and the die device includes an upper template 23, a first hydraulic cylinder 24, and a second hydraulic cylinder 26 , connecting column 27, punch 30, block blank holder ring, die 31, clamping pin 32, clamp block 33, third hydraulic cylinder 35, two die pads 34 and lower template 36, block blank holder The ring is composed of a first blankholder ring 28 and a second blankholder ring 29. Two die pads 34 are respectively fixed on both sides of the upper end surface of the lower template 36. The third hydraulic cylinder 35 is located between the two die pads 34 and the second The bottom end of the cylinder body of the three hydraulic cylinders 35 is fixed on the upper end surface of the lower template 36, the die 31 is installed on the upper end surfaces of t...

specific Embodiment approach 2

[0014] Specific implementation mode two: as Figure 1~5 As shown, in this embodiment, a draw bead 42 is provided on the lower end surface of the first blank holder 28 or the second blank holder 29, and a draw bead groove 43 is provided at a corresponding position on the upper end surface of the die 31, so The drawbead 42 is matched with the drawbead groove 43 . The above technical measures can further control the flow of sheet metal on both sides of the tailor welded blank weld. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: as Figure 1~5 As shown, the hydraulic system in this embodiment includes a hydraulic pump 1, a reversing valve 2, a relief valve 3, a check valve 4, a filter 5, an oil tank 18, a first hydraulic unit, a second hydraulic unit and a third hydraulic unit. Unit; the first hydraulic unit includes the first electromagnetic reversing valve 6, the first hydraulic control check valve 9, the first throttle valve 12 and the first proportional overflow valve 15; the second hydraulic unit includes the second electromagnetic reversing valve 7. The second hydraulic control check valve 10, the second throttle valve 13 and the second proportional overflow valve 16; the third hydraulic unit includes the third electromagnetic reversing valve 8, the third hydraulic control check valve 11, the third The throttle valve 14 and the third proportional relief valve 17; the hydraulic pump 1 is installed in the oil tank 18, the relief valve 3 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com