Integrated driving short roller device for pulling glass

An integrated, short-roller technology, applied in the field of driving short-roller devices, can solve the problems of difficult manufacturing, high cost, and difficulty in pulling glass, and achieve the effects of quick installation and adjustment, reduced cost of replacing spare parts, and realization of installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0046] The present invention designs a driving short roller device for pulling glass, and installs a plurality of driving short roller devices on a mounting bracket 1 to form an integrated structure, which is convenient for installation and adjustment.

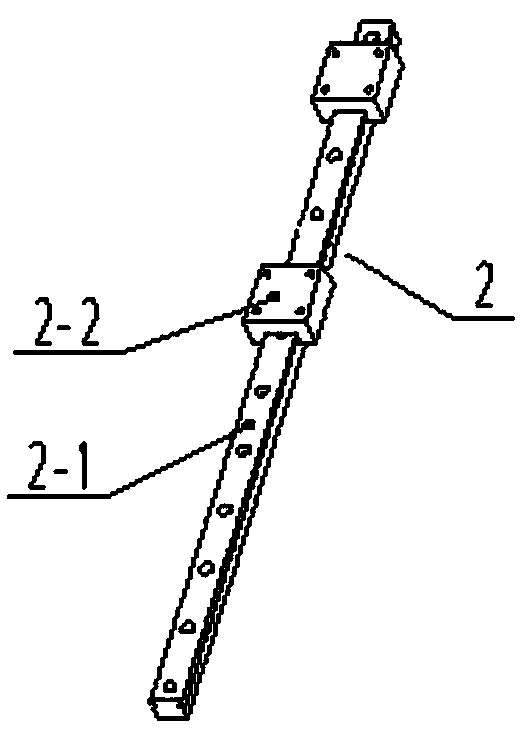

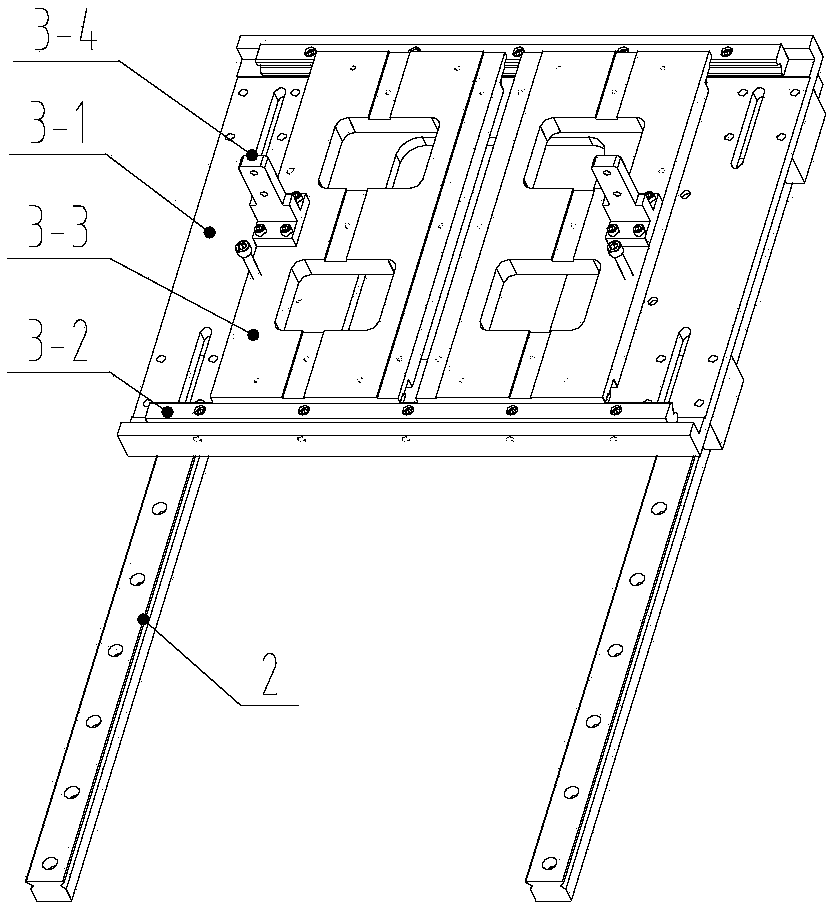

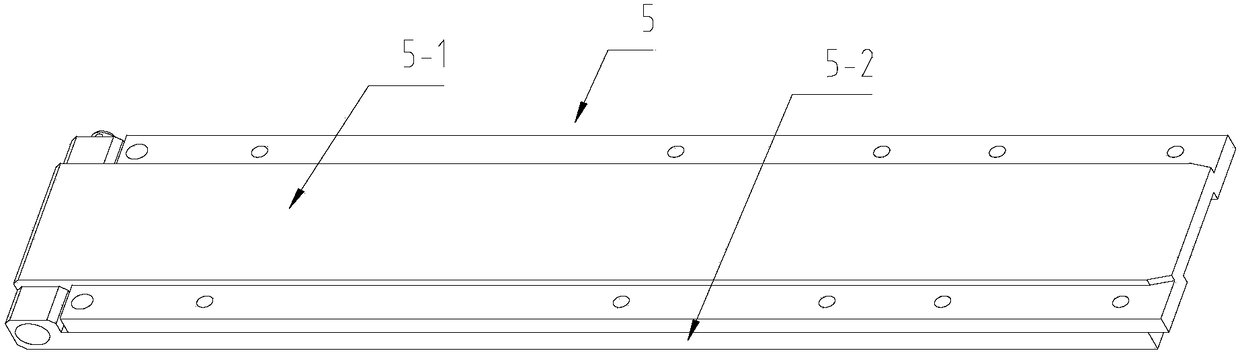

[0047] Each driving short roller device includes a horizontal sliding table mechanism 3 and two opposite linear guide rails 2; as figure 1 As shown, the linear guide 2 includes a linear guide body 2-1 and a slider 2-2 arranged on the linear guide body 2-1, and the two sliders 2-2 are connected by the second hole and the seventh hole at the proximal end. It is fixed on a linear guide rail body 2-1, and the distance between the two sliders is 400mm. The structure of the horizontal slide mechanism 3 is as follows: figure 2 As shown, the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com