An integrated driving short roller device for pulling glass

An integrated, short-roller technology, applied in the field of driving short-roller devices, can solve the problems of inability to realize flexible process adjustment, high cost, and difficulty in pulling glass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0046] The present invention designs a driving short roller device for pulling glass, and installs a plurality of driving short roller devices on a mounting bracket 1 to form an integrated structure, which is convenient for installation and adjustment.

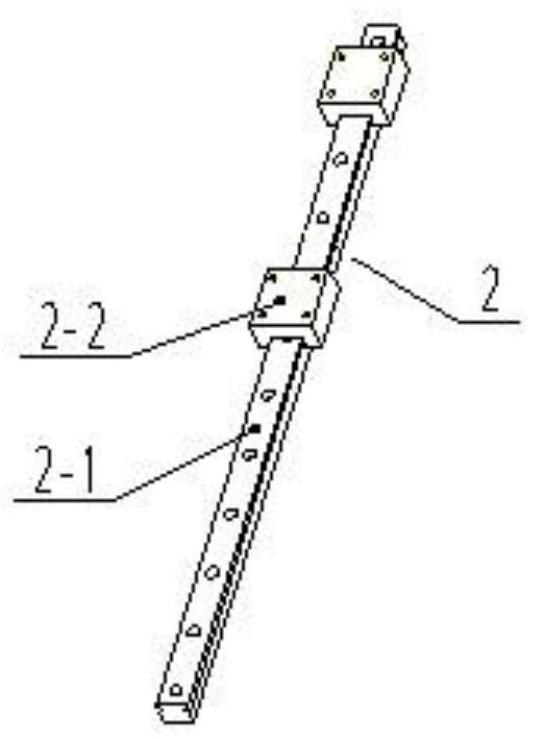

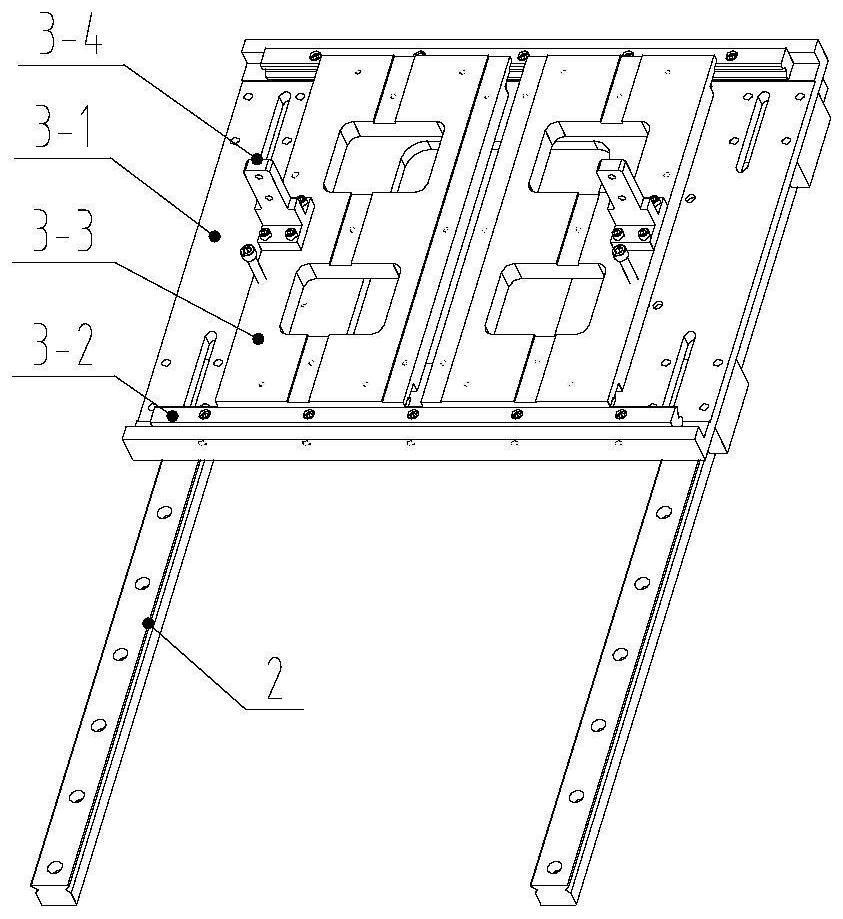

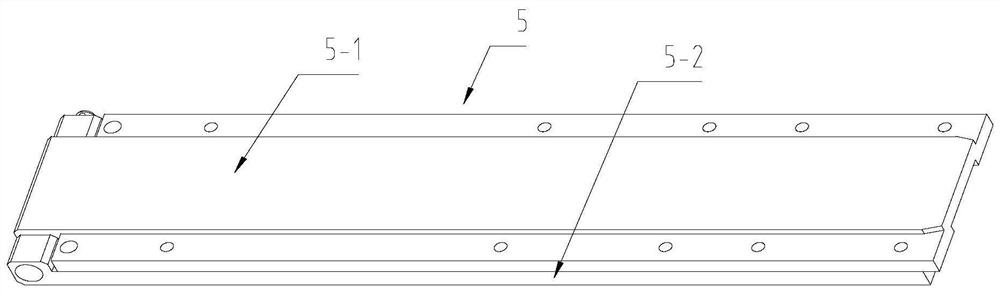

[0047] Each driving short roller device includes a horizontal sliding table mechanism 3 and two opposite linear guide rails 2; as figure 1 As shown, the linear guide 2 includes a linear guide body 2-1 and a slider 2-2 arranged on the linear guide body 2-1, and the two sliders 2-2 are connected by the second hole and the seventh hole at the proximal end. It is fixed on a linear guide rail body 2-1, and the distance between the two sliders is 400mm. The structure of the horizontal slide mechanism 3 is as follows: figure 2 As shown, the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com