Modular PCB testing jig

A PCB board and test fixture technology, which is applied in the field of modular PCB test fixtures, can solve the problems of unsatisfactory large-scale testing, difficult operation and maintenance, and low production efficiency, so as to eliminate the influence of electronic components and equipment , compact structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

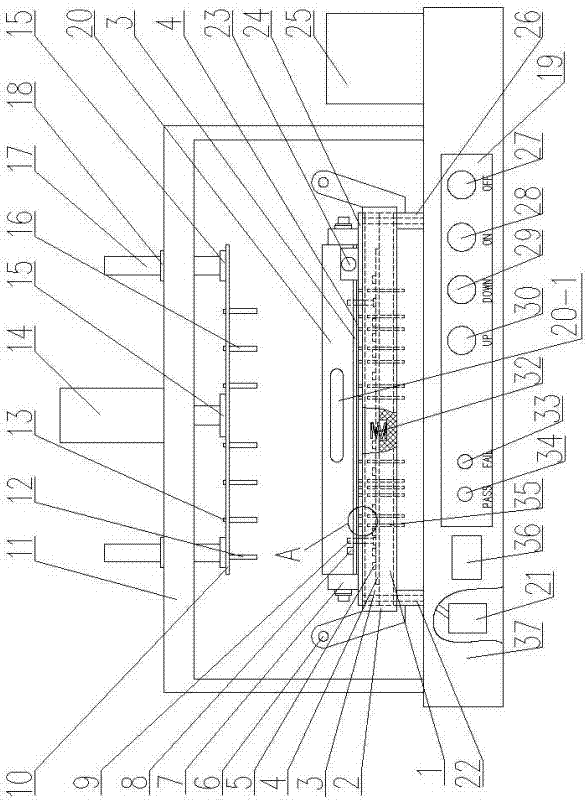

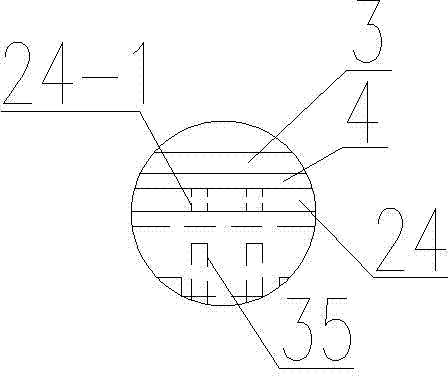

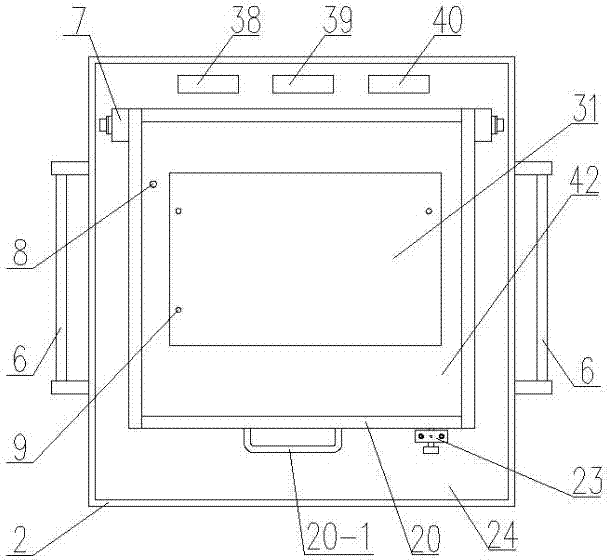

[0022] Examples, see attached figure 1 ~ attached Figure 4 , a modularized PCB board test fixture, comprising a test module, a needle board module, a carrier board module and a cover board module arranged sequentially from bottom to top.

[0023] The test module includes a test stand 37 , a bracket 11 fixed on the test stand 37 , a counter 36 on the test stand, a console 19 on the test stand 37 , and a tester 25 on the test stand 37 . The tester 25 is electrically connected to the console 19 , and a vacuum pumping assembly 21 is built inside the test bench 37 . On console 19, be provided with test and pass indicator light 34, test fail to pass indicator light 33, power off button 27, power start button 28, cylinder drop button 29, cylinder rise button 30, tester 25 and test pass indicator light 34 respectively , The test fails to pass the indica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com