Press fit fixing device for vehicle lamp lampshade and lamp shell

A technology for car lamp shades and fixing devices, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting the appearance of the car, the labor of the operator, and the high labor intensity, so as to improve the quality of combination assembly and the qualified rate of lamps High, improve the effect of assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

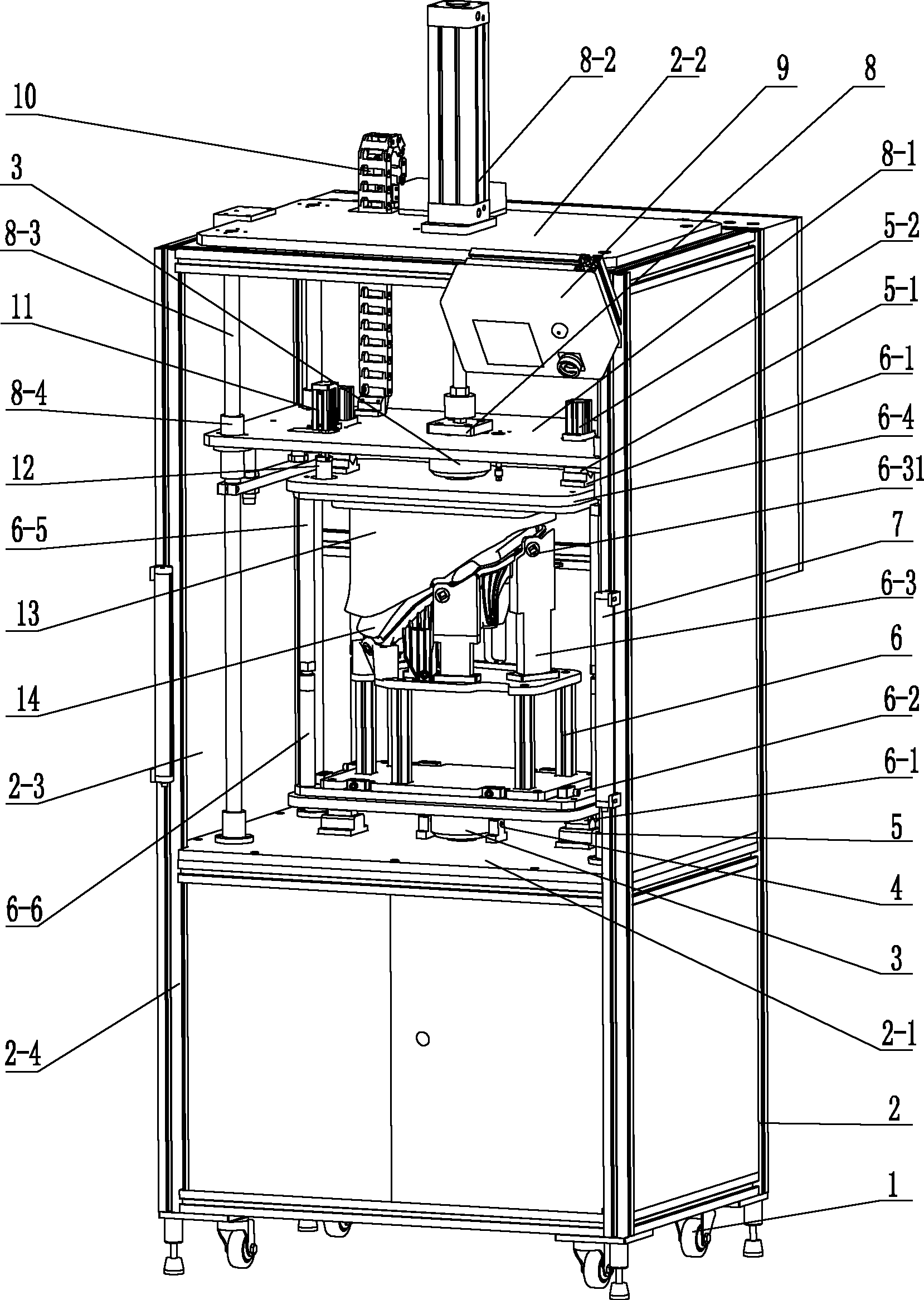

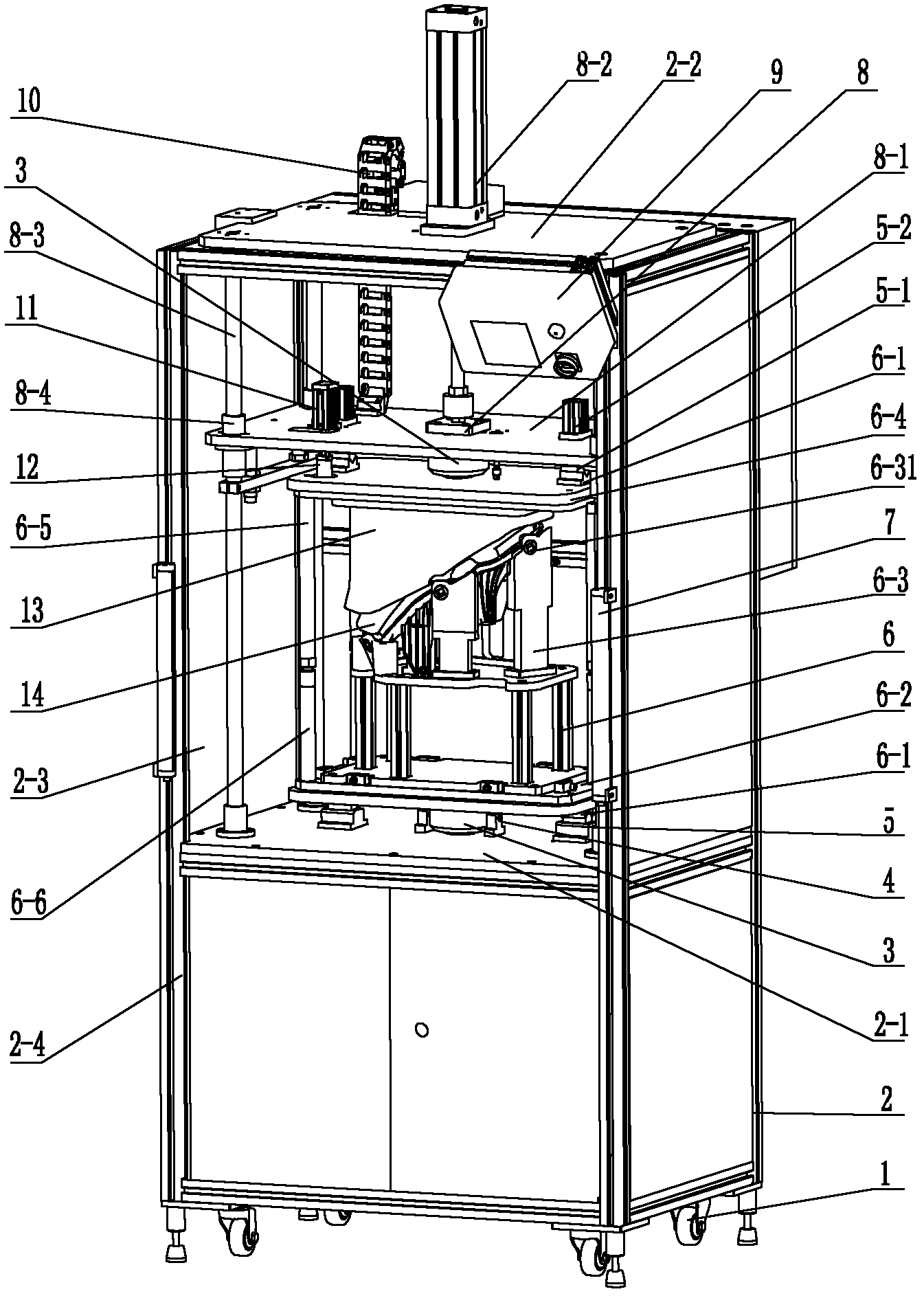

[0010] See figure 1 As shown, the pressing and fixing device of the lampshade and the lamp housing of the vehicle lamp of the present invention includes a frame 2 , a lamp positioning mechanism 6 for being installed on the lampshade and the lamp housing, a pressing mechanism 8 and a limiting mechanism 5 .

[0011] See figure 1 Shown, frame 2 of the present invention comprises frame-shaped frame 2-4 and is installed in the workbench plate 2-1 of frame-shaped frame 2-4 bottom, the top plate 2-2 of the top and surrounding casing 2-3, frame The frame 2-4 is positioned at the side of the opening and is equipped with a safety grating 7 to protect the safety of the operator during operation. The present invention is equipped with at least two walking wheels 1 at the bottom of the frame frame 2-4, which can Four traveling wheels 1, this traveling wheel 1 can adopt universal wheel, can arrange production line flexibly.

[0012] See figure 1 As shown, the lamp positioning mechanism 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com