Press-mounting machine for assembling rollers of belt conveyor

A technology of belt conveyor and press-fitting machine, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as time-consuming, labor-intensive, easily damaged parts, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

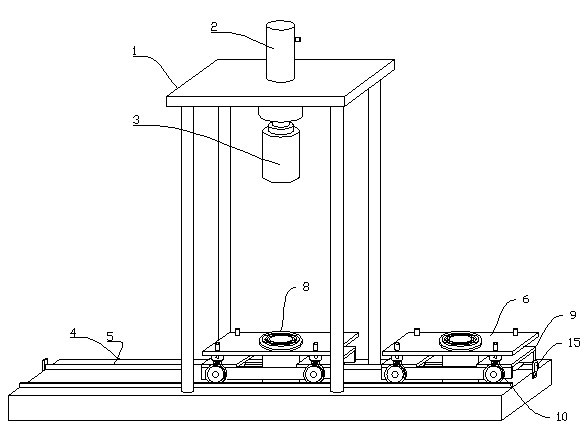

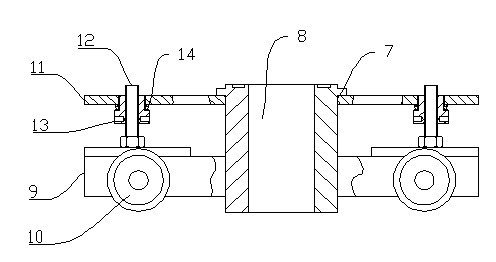

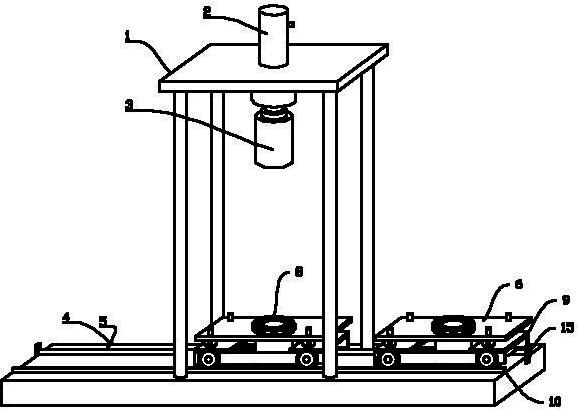

[0012] Referring to the accompanying drawings, the belt conveyor roller assembly press includes a frame body 1, the frame body 1 is composed of a fastened base 4, a pillar and a top plate, and a vertical hydraulic cylinder 2 is arranged on the top plate of the frame body 1, The piston column of the hydraulic cylinder 2 can be used for up and down telescopic movement, the piston column of the hydraulic cylinder 2 extends downward, and the cylinder head is connected with the pressure head 3 which is connected with it, and the structure of the head end of the pressure head 3 matches the structure of the head end of the idler roller . The base 4 is provided with guide rails 5, the length of which is at least the sum of the lengths of three carts 6, and the guide rails 5 extend along both longitudinal sides of the frame body 1 and are arranged symmetrically. The guide rail 5 is provided with a trolley 6 running along it, the trolley 6 includes an underframe 9 and a bracket 11, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com