Patents

Literature

429 results about "Angular difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital image stabilization device and method

ActiveUS20120162454A1Improve efficiencyEfficient processingImage enhancementTelevision system detailsSorting algorithmObject based

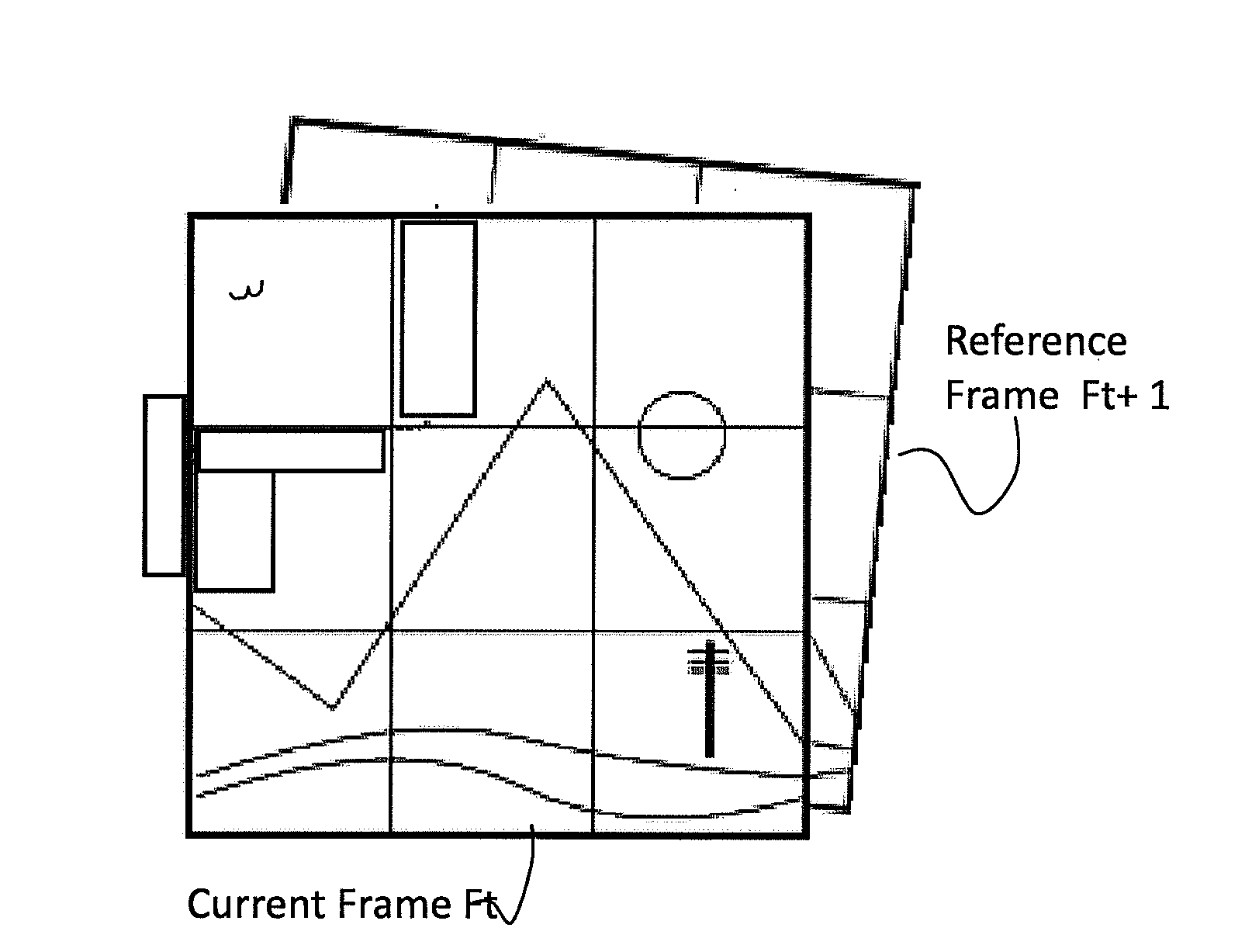

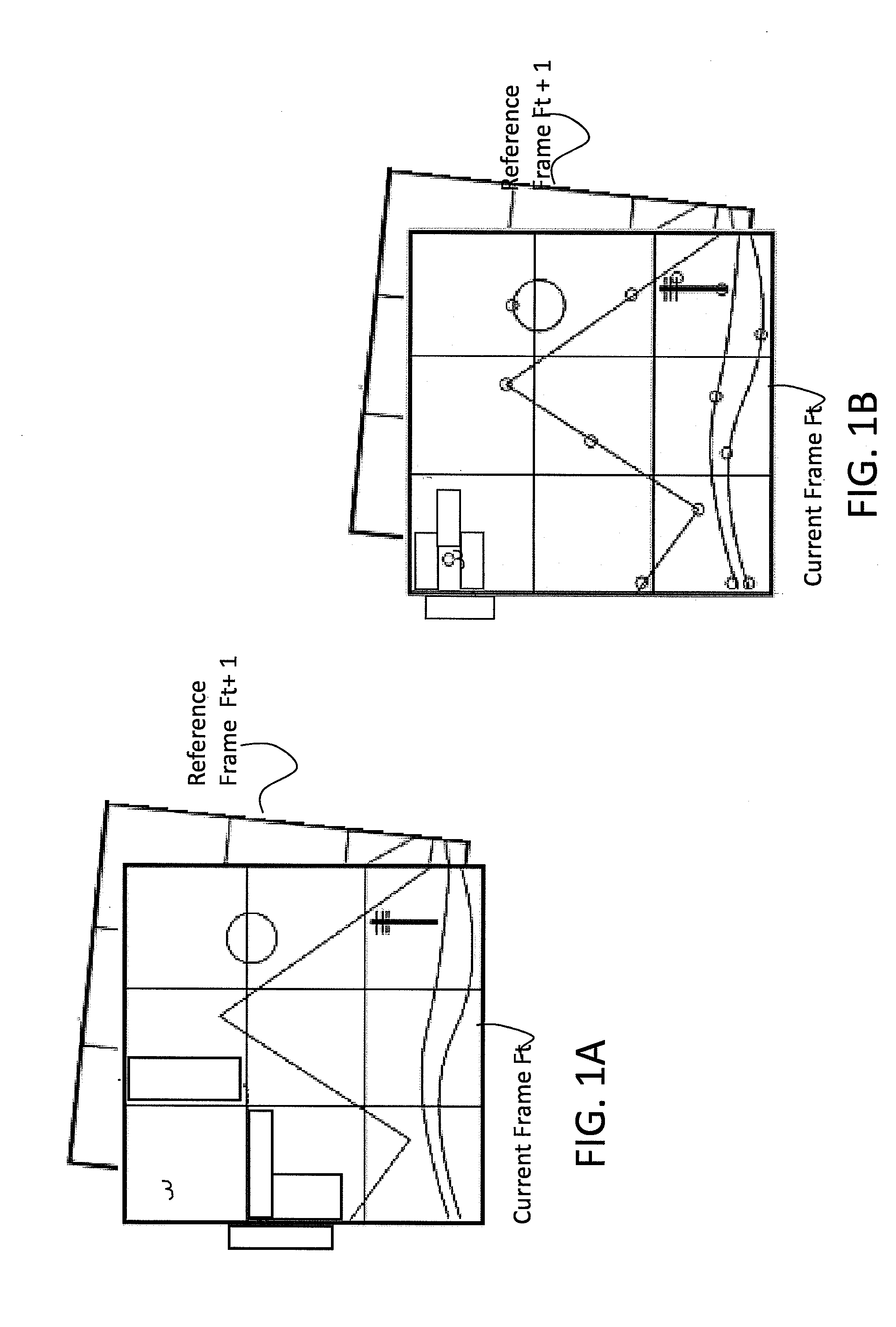

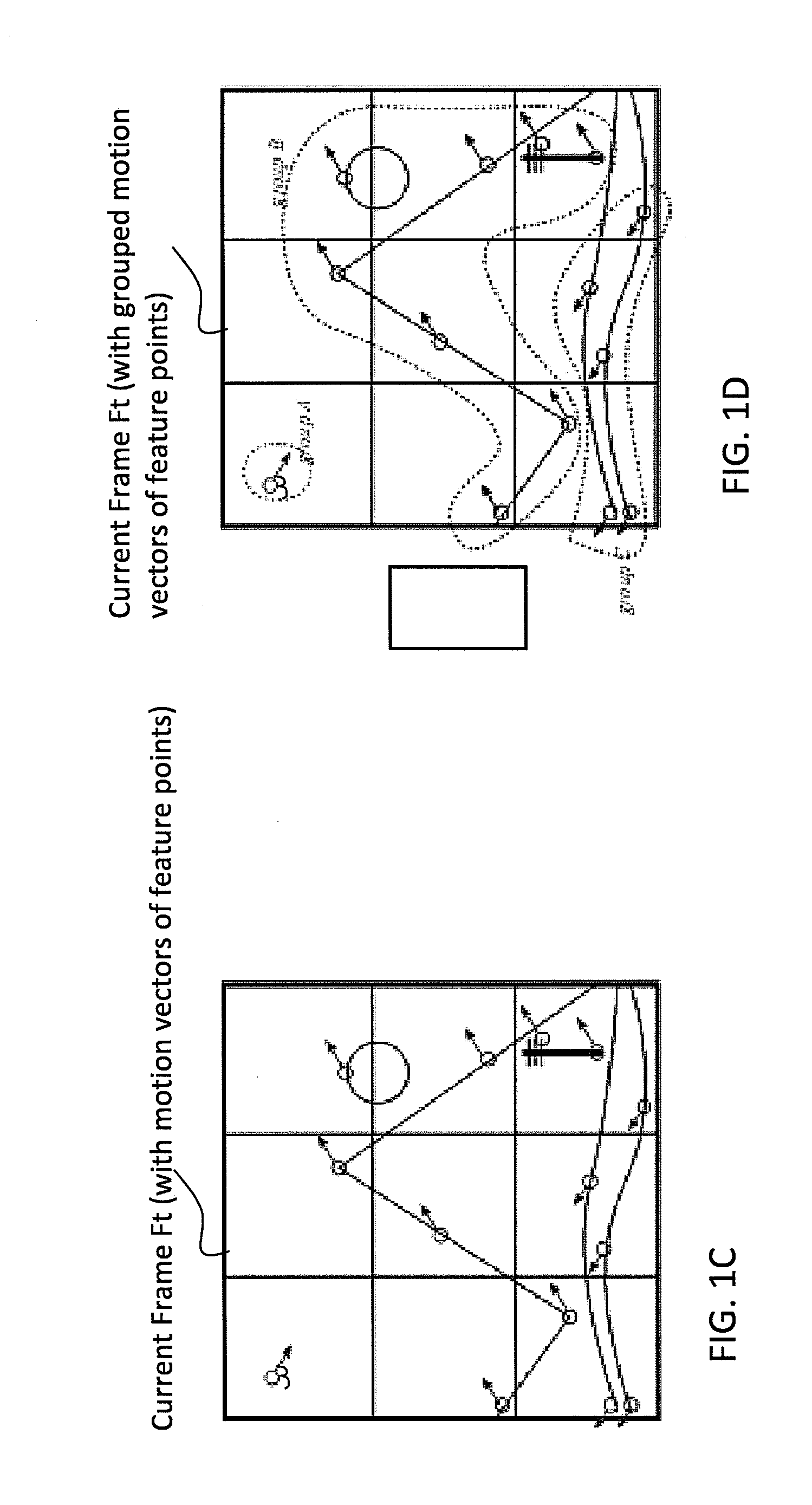

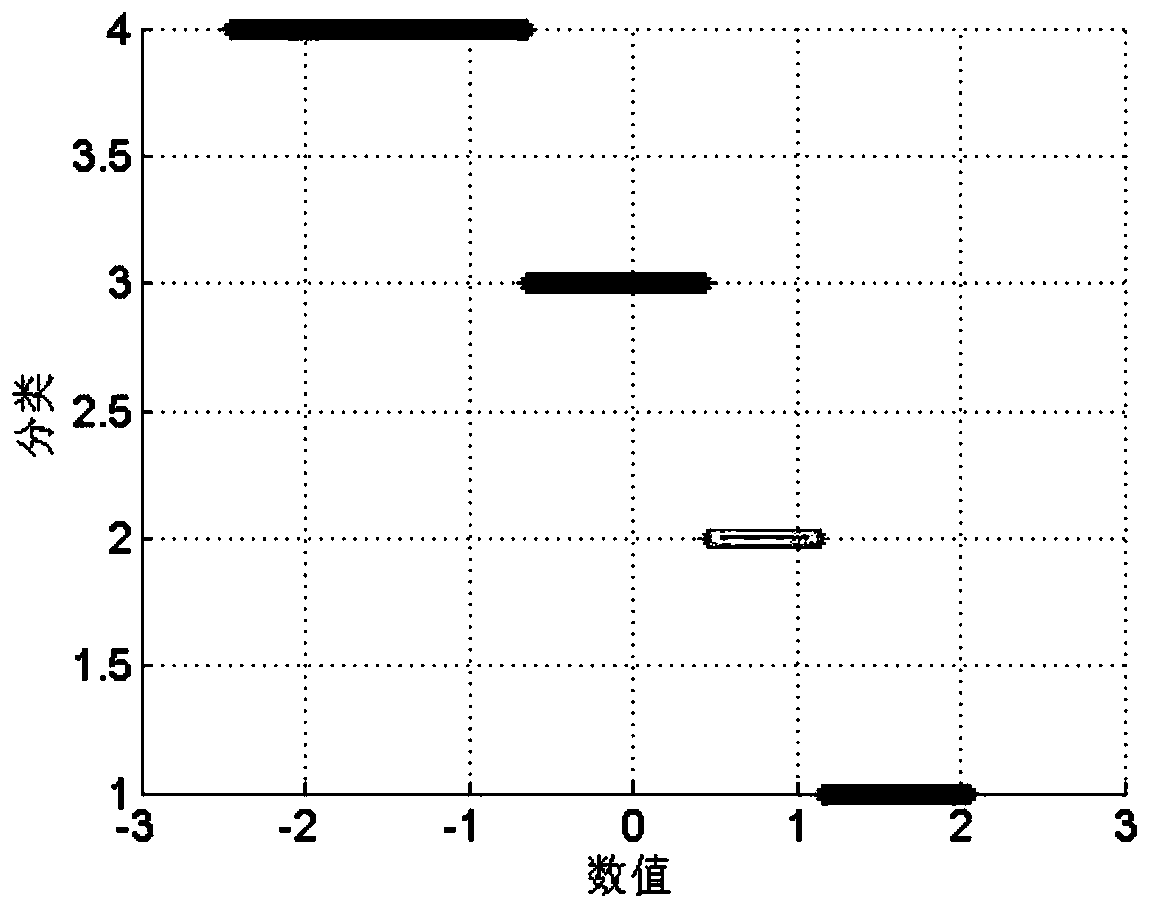

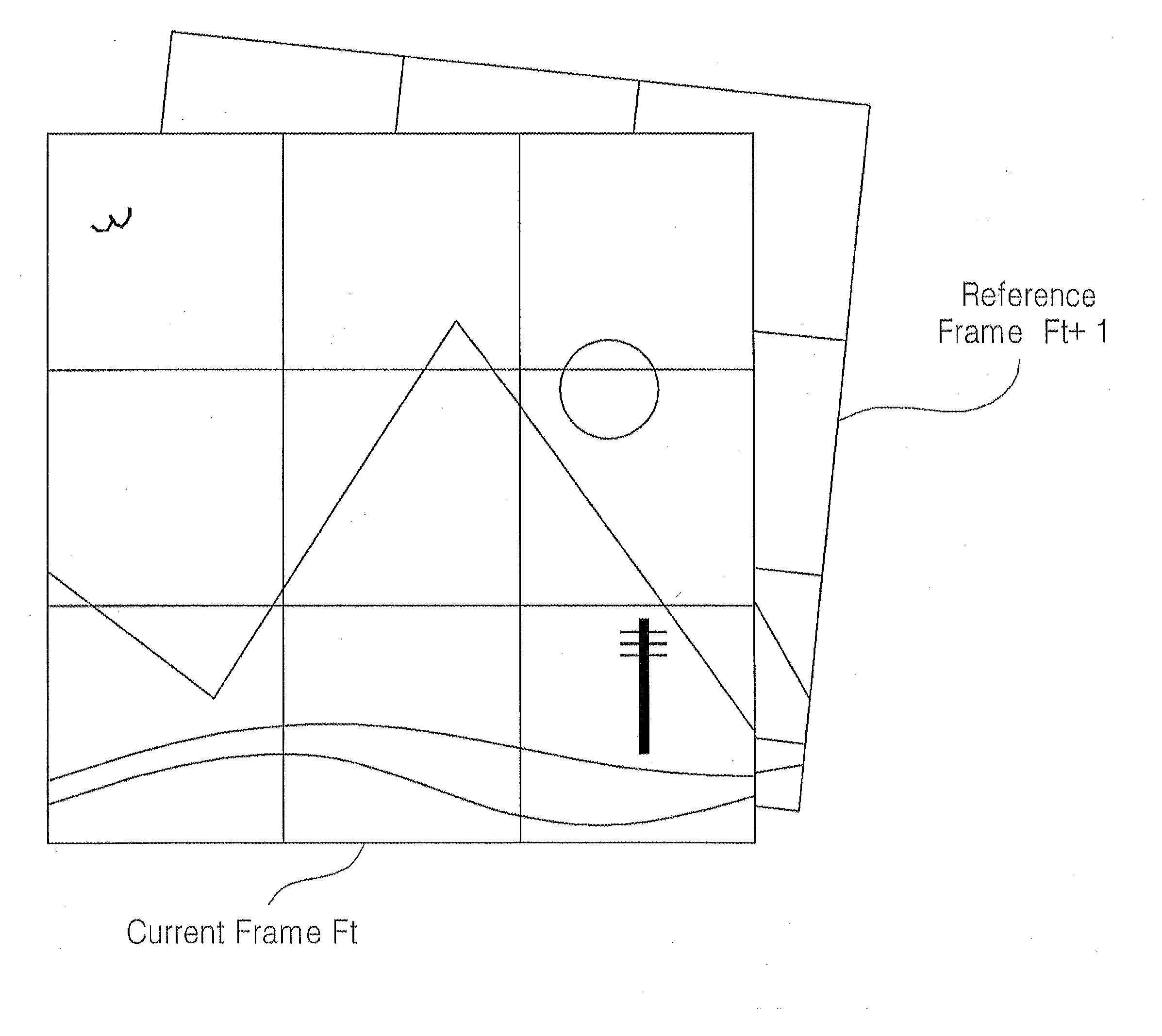

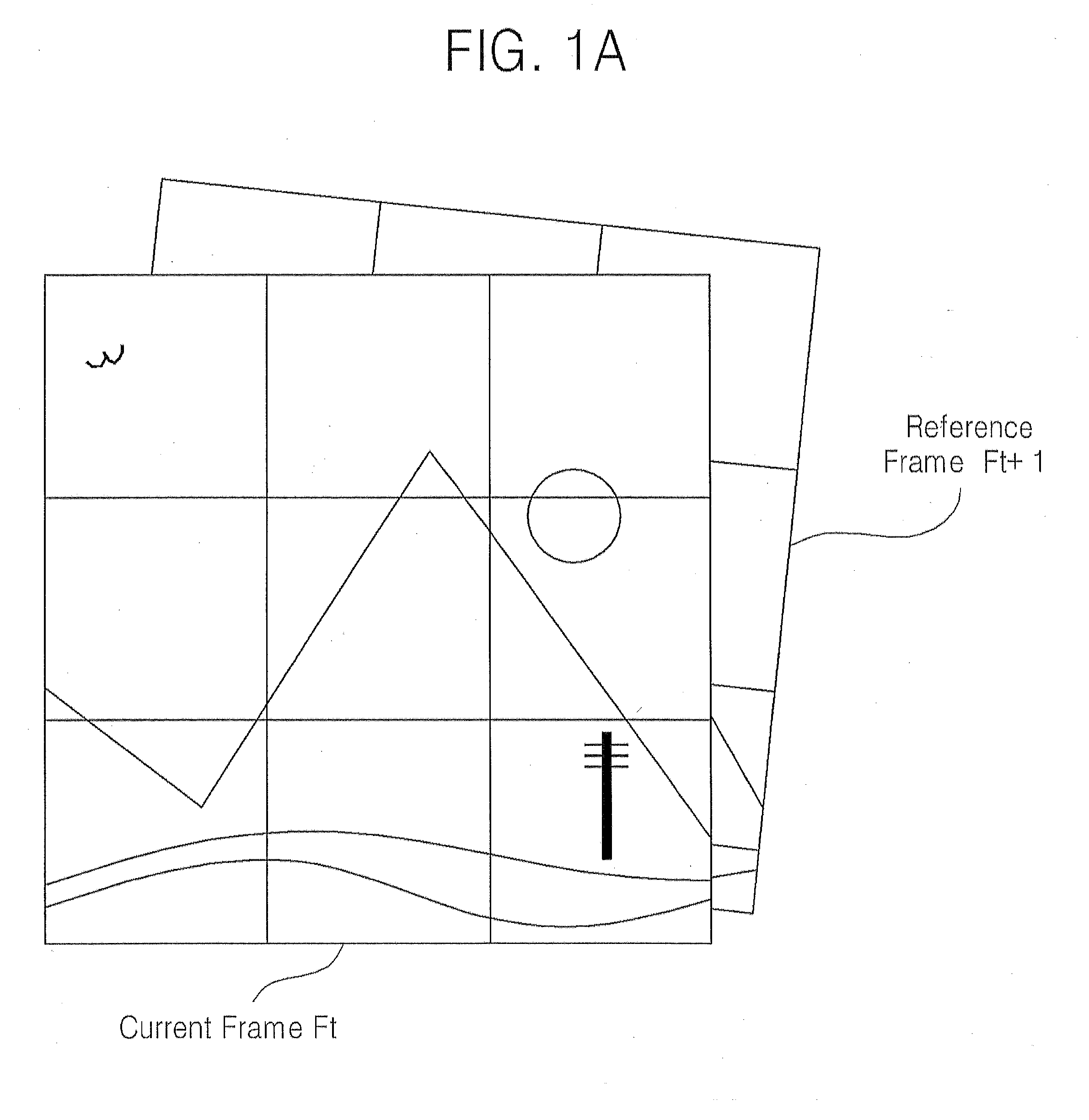

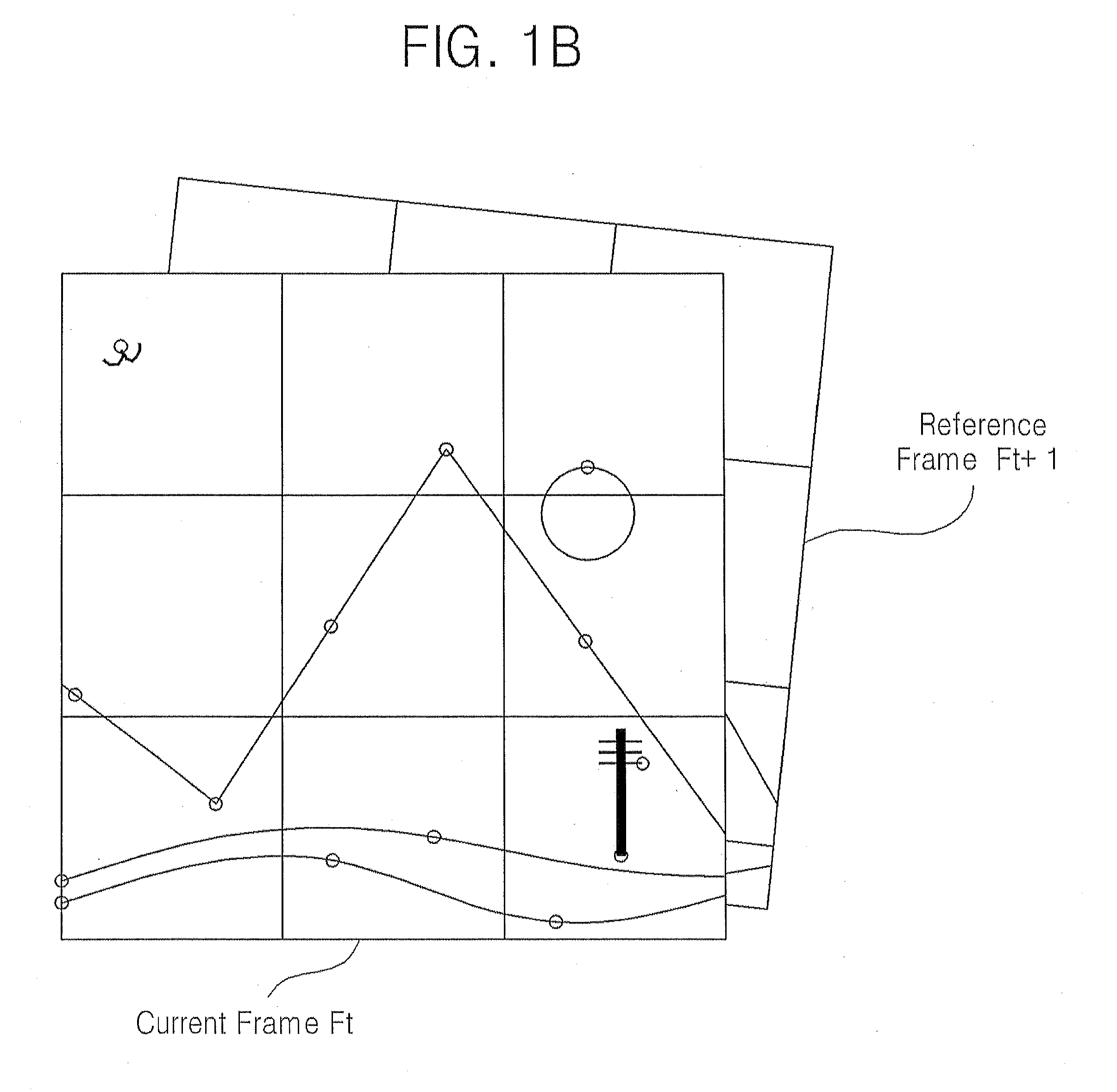

A method of Digital Image Stabilization (DIS) including a feature point sorting algorithm for selecting optimal feature points, and a computationally efficient tile-vector based search algorithm for deriving motion vectors of the selected feature points, and a feature point motion vector grouping / comparison process for grouping pairs of the selected feature points based on their vector magnitude ratio and their angular difference.A Digital Image Stabilization method including selecting a Principal transform representing a stationary / background object in the scene of a video frame, based on scoring each of a plurality of transforms of tile motion vector (Tile MV) groups and of feature point motion vector (FP MV) groups, and excluding large moving objects based on the history of the stationary (background) group and the history of each of the plurality motion vector groups.

Owner:SAMSUNG ELECTRONICS CO LTD

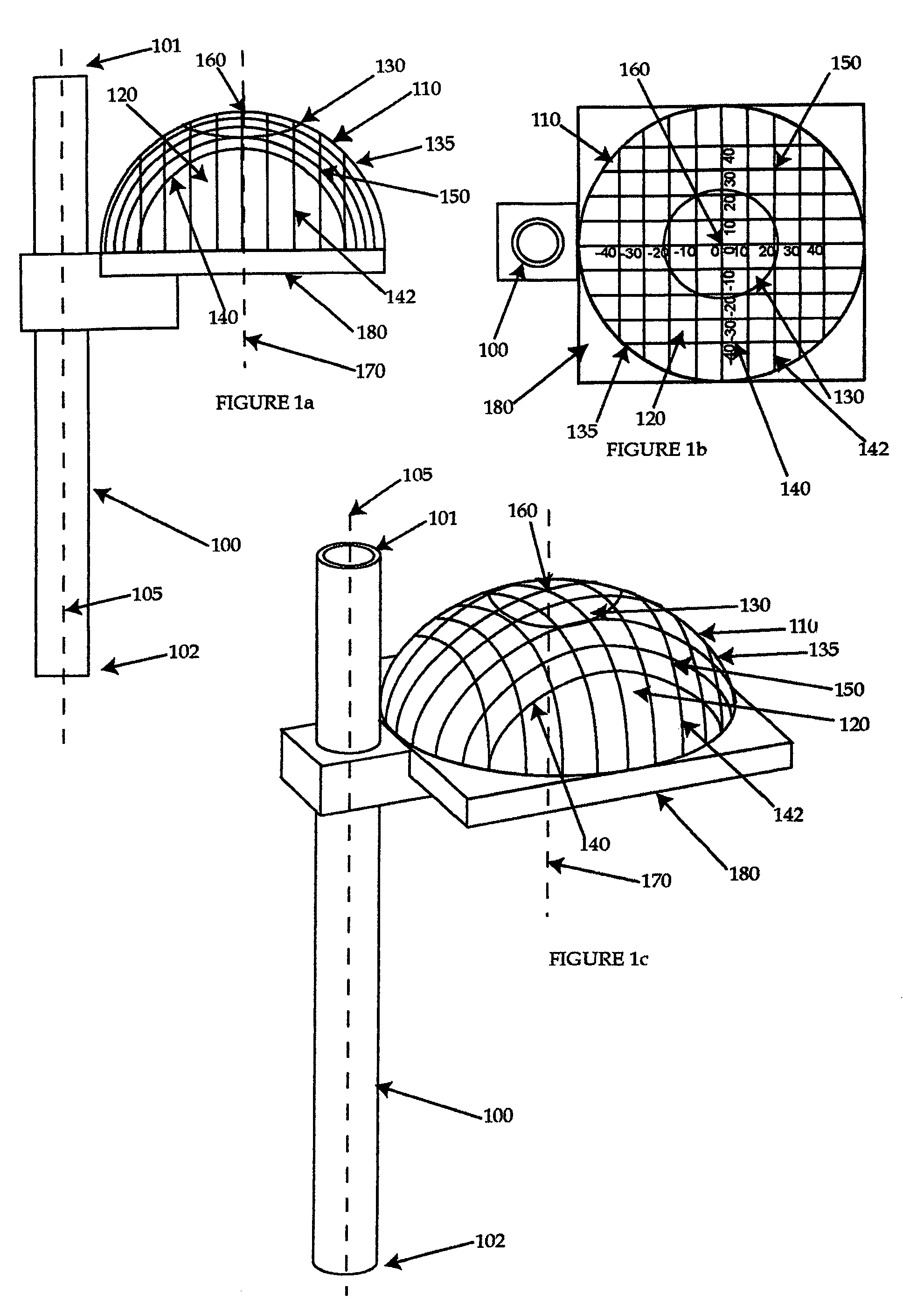

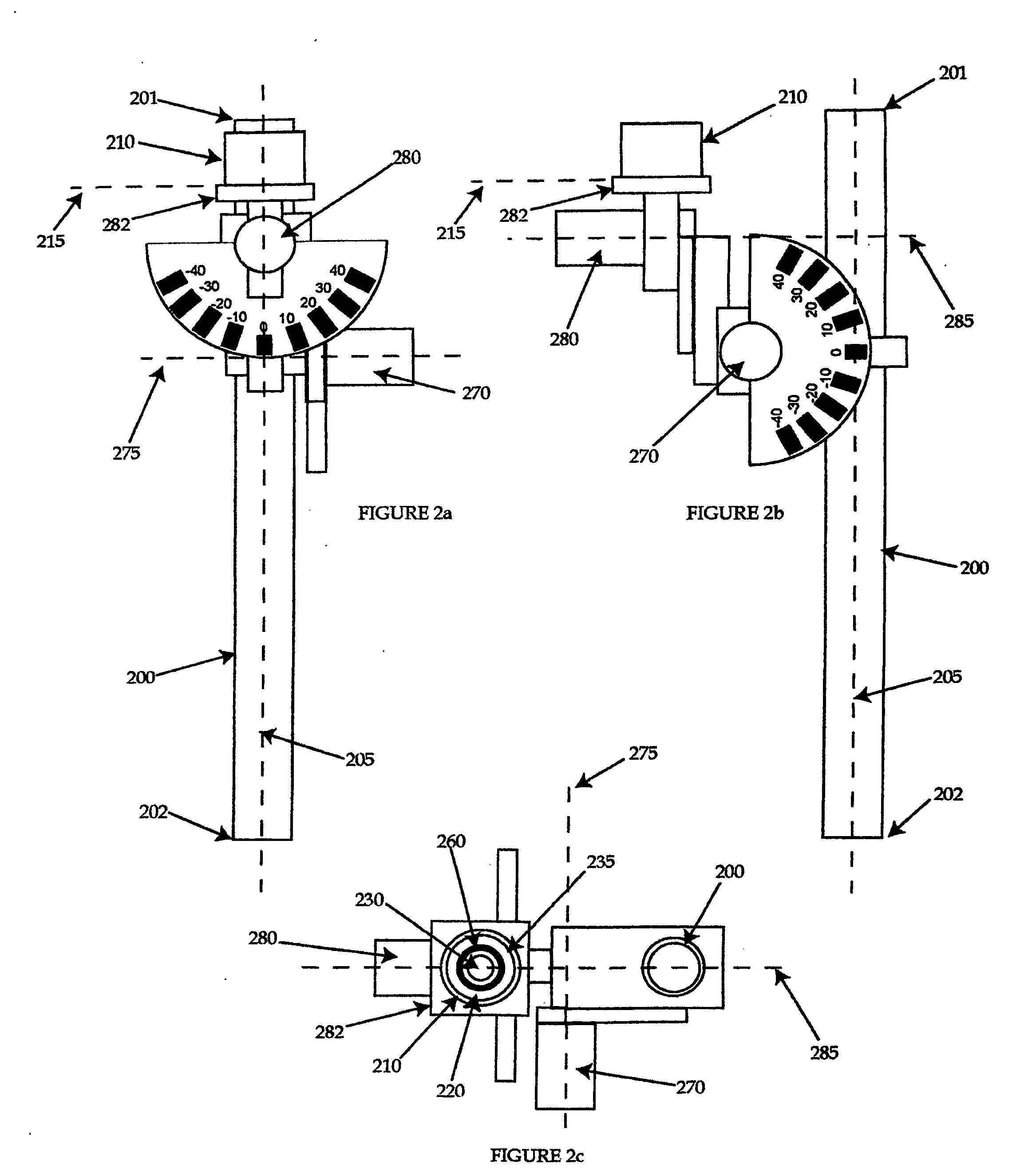

Gravity dependent pedicle screw tap hole guide and data processing device

InactiveUS7611522B2Accurate placementImprove stabilityDiagnosticsComputer-aided planning/modellingAccelerometerEngineering

Owner:NUVASIVE

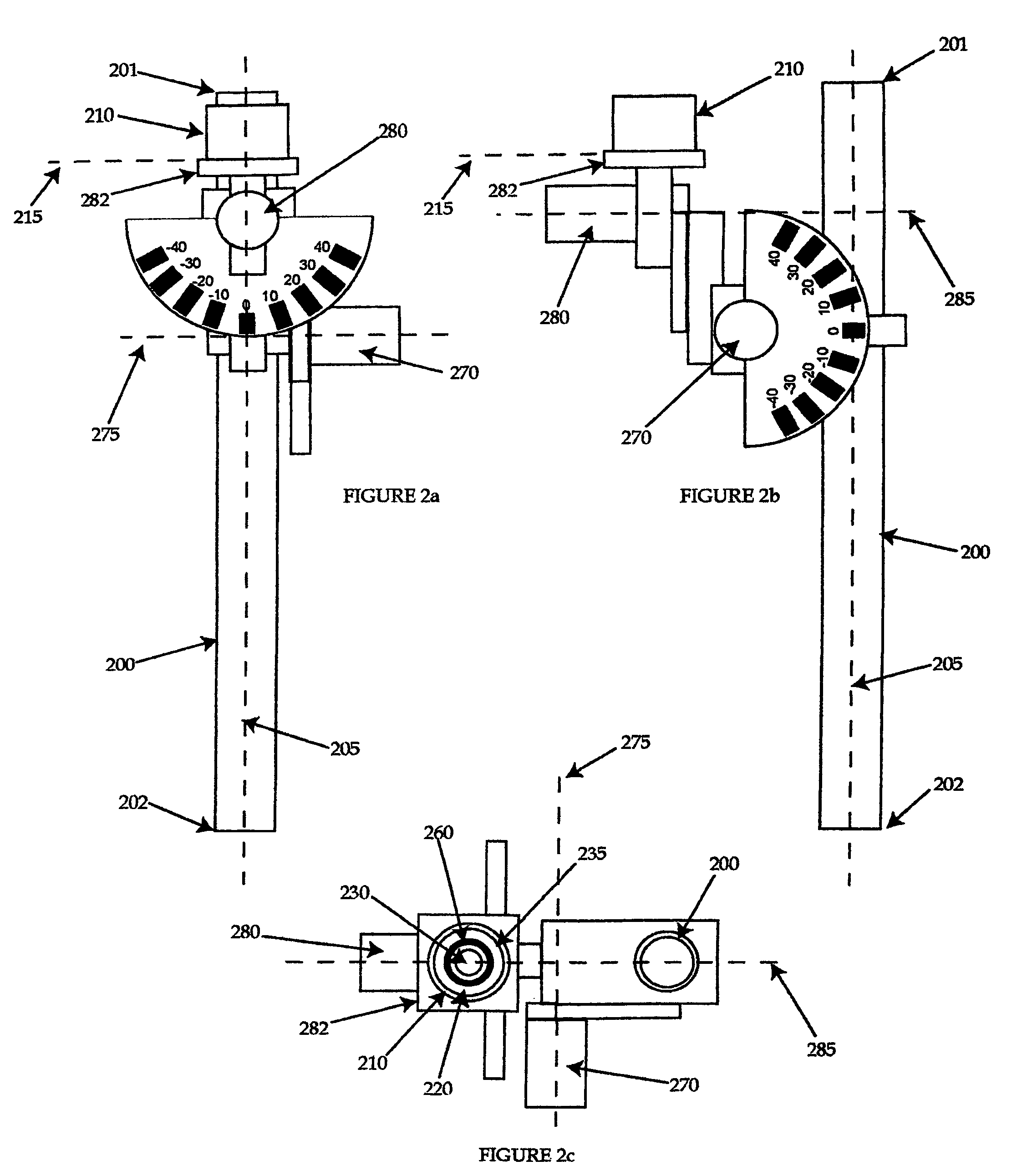

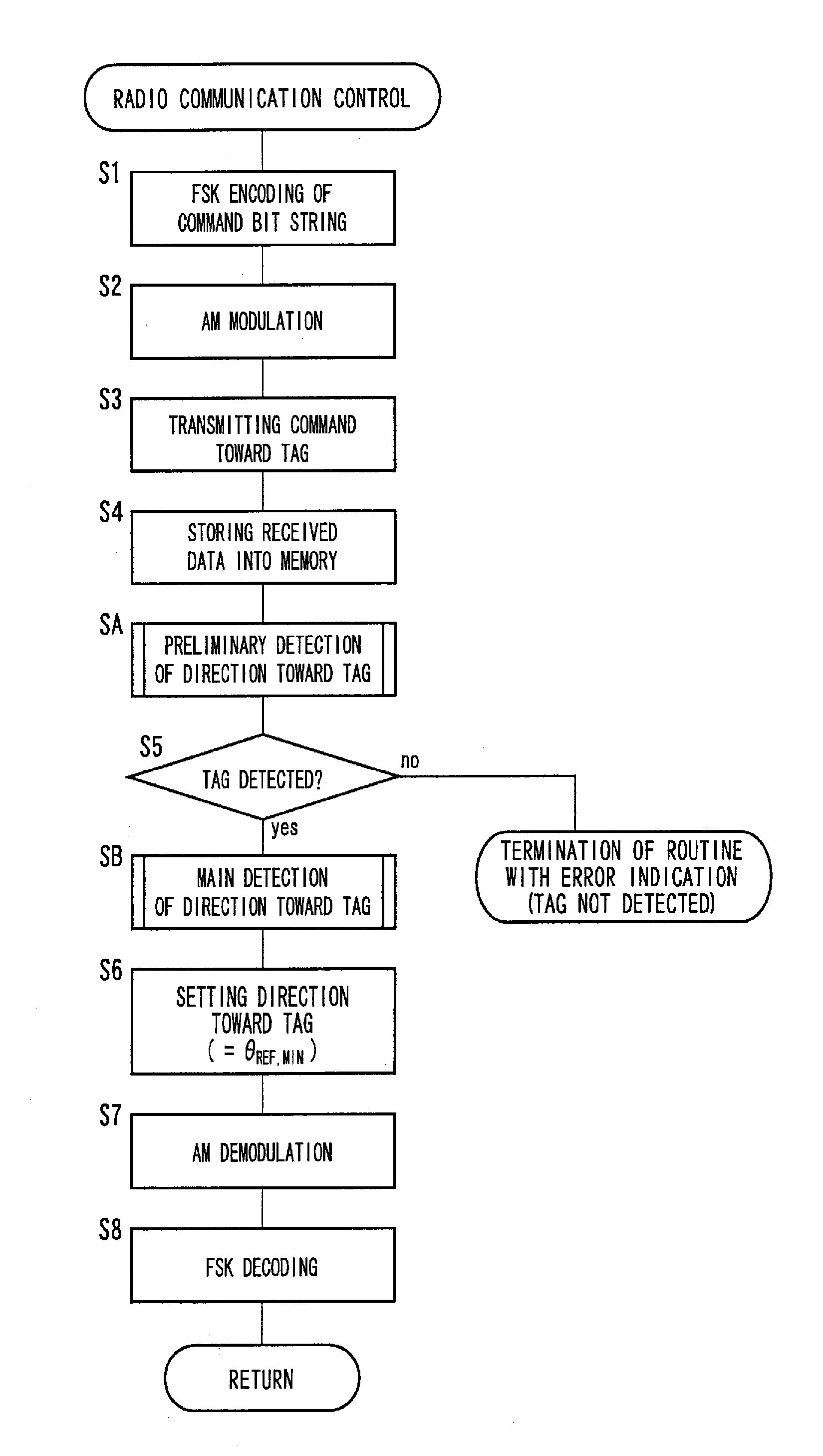

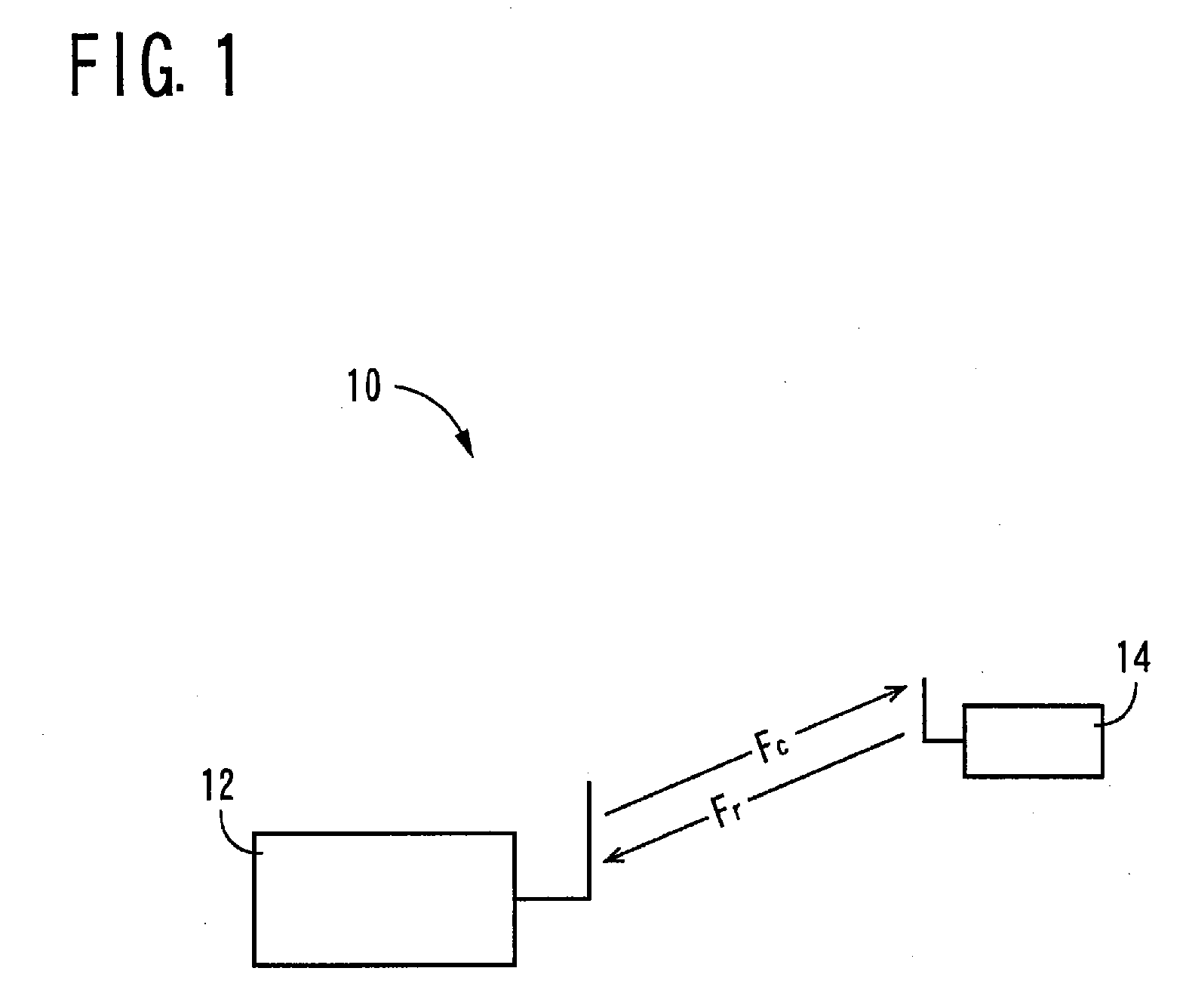

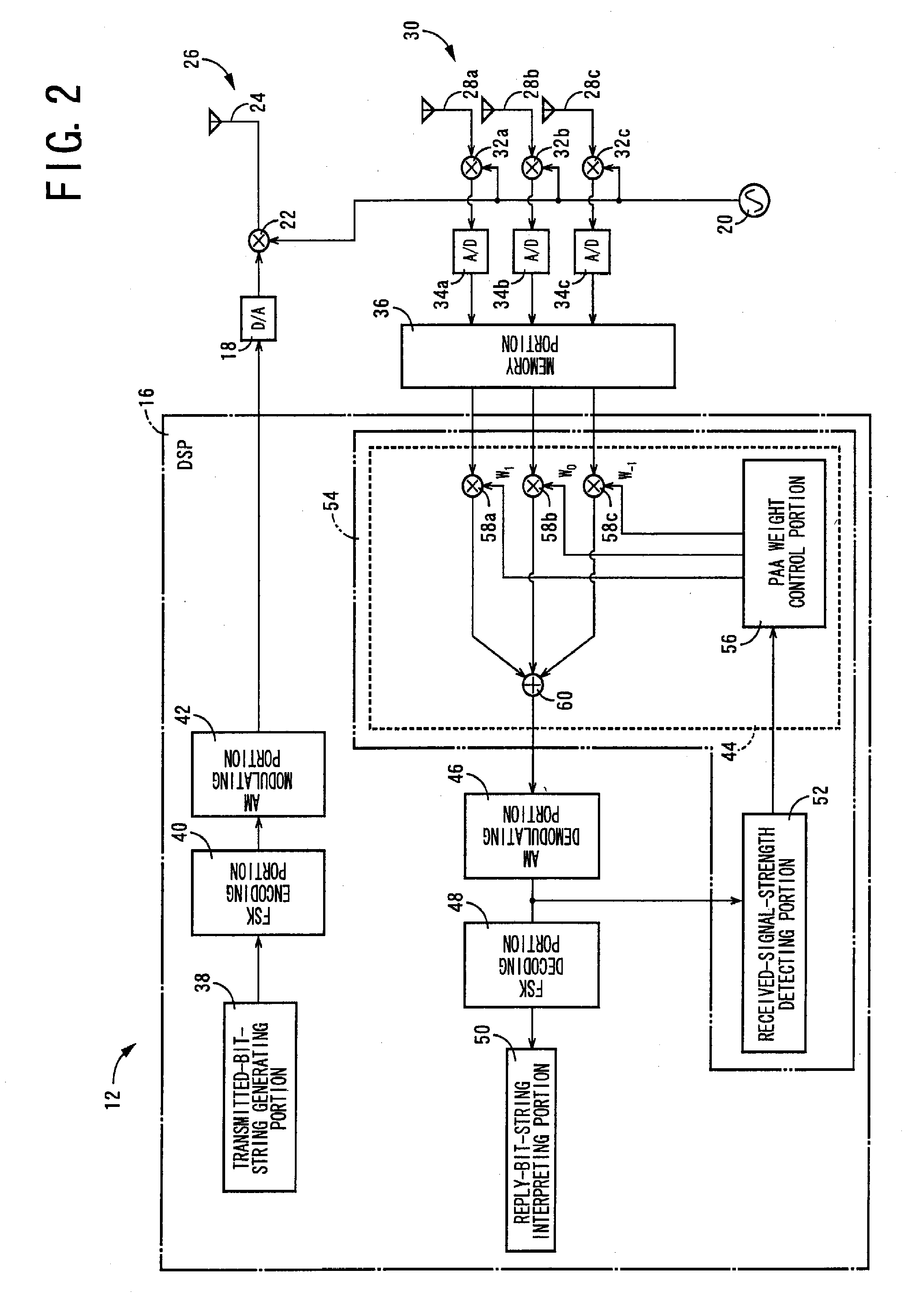

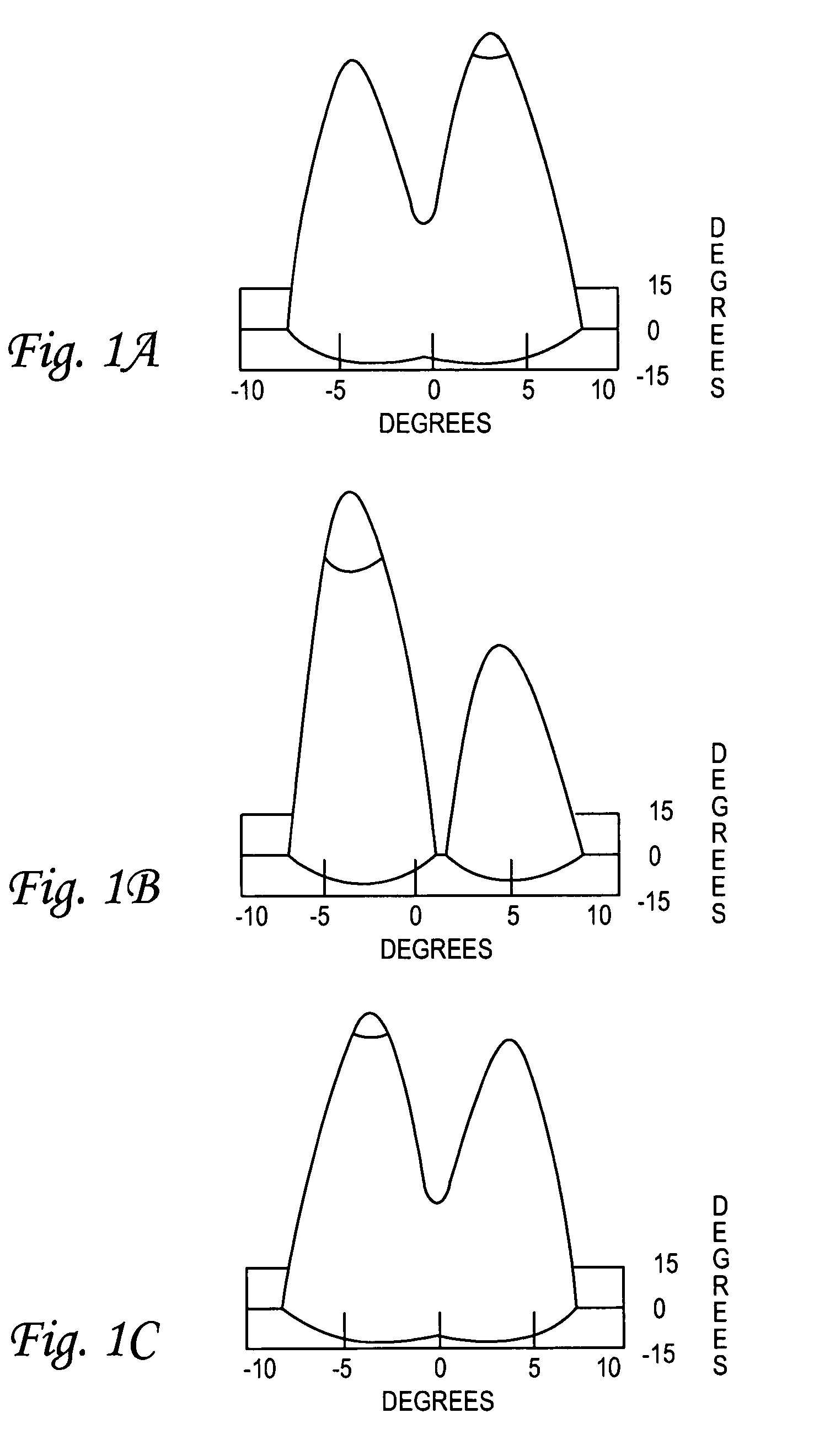

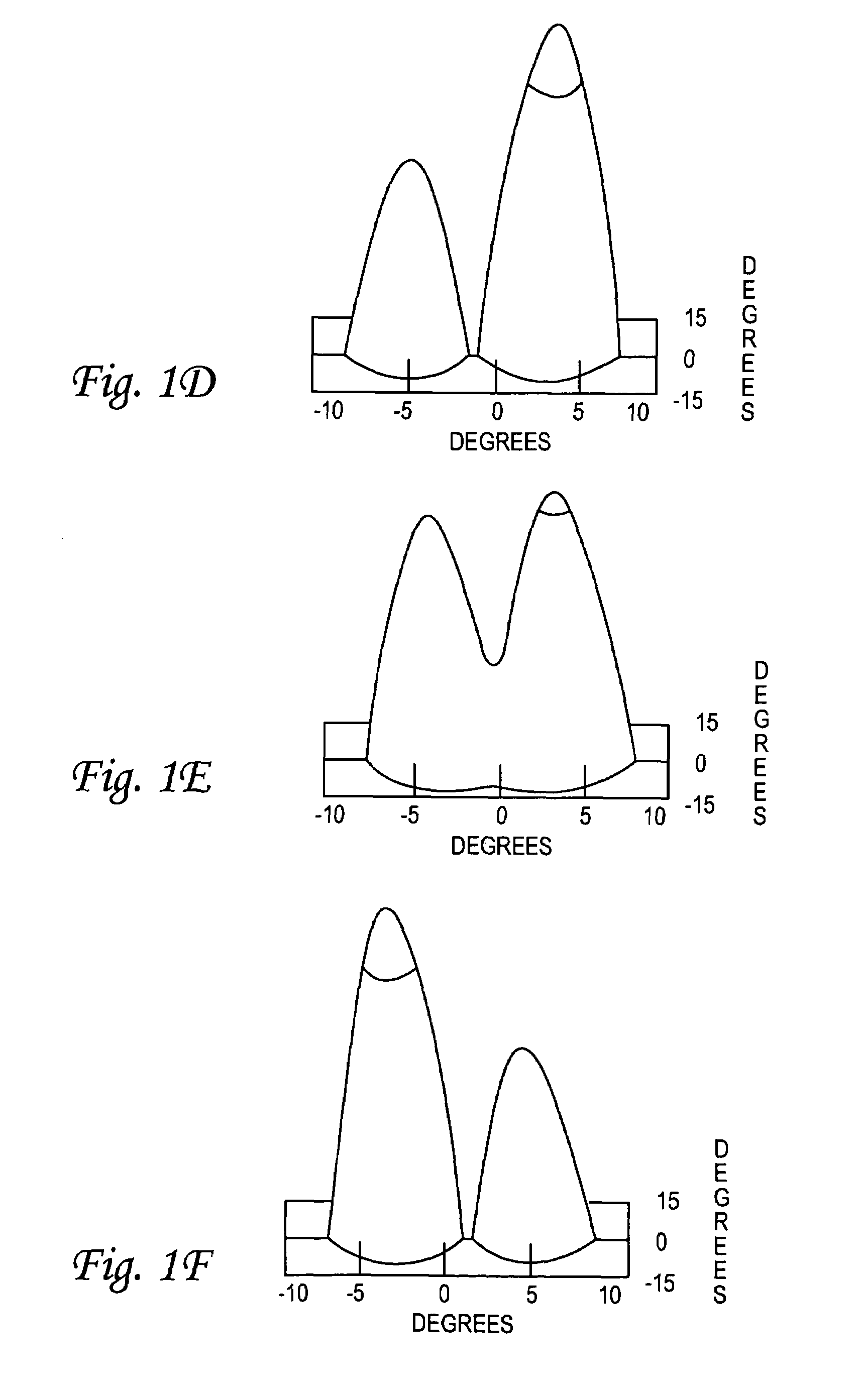

Radio-Frequency Device, And Radio-Frequency Tag Communication Device

ActiveUS20070279277A1Effective angular rangeSuitable for detectionRadio transmissionSubscribers indirect connectionImage resolutionEngineering

A radio-frequency device includes a PAA processing portion configured to control a directivity of reception of a receiver antenna device, a received-signal-strength detecting portion configured to detect a strength of the received signal received by the receiver antenna device, and a direction detecting portion configured to detect the direction toward the communication object, on the basis of a direction in which a higher one of two strength values of the received signal respectively detected in first and second maximum-reception-directivity directions of a predetermined angular difference established by the PAA processing portion is minimal. The direction detecting portion is operated based on a fact that the received signal strength is minimal at the bottom of a gain existing in an area of overlapping of two main lobes extending in the respective two directivity directions of the predetermined angular difference, so that the resolution of detection can be made higher than in the case based on the main lobe direction in which the sensitivity of communication with the radio-frequency tag is maximum. Accordingly, the direction toward the radio-frequency tag can be suitably detected.

Owner:BROTHER KOGYO KK

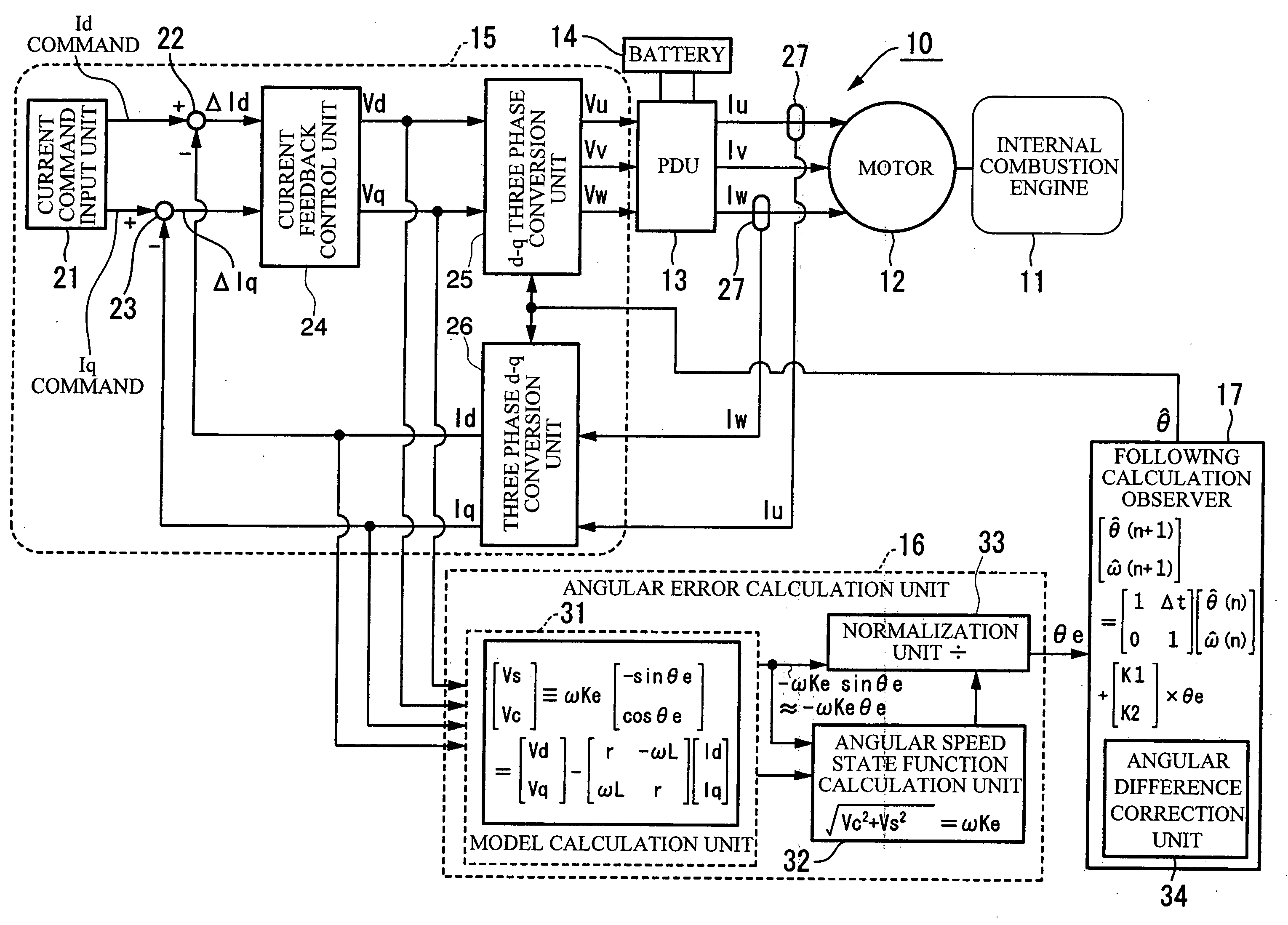

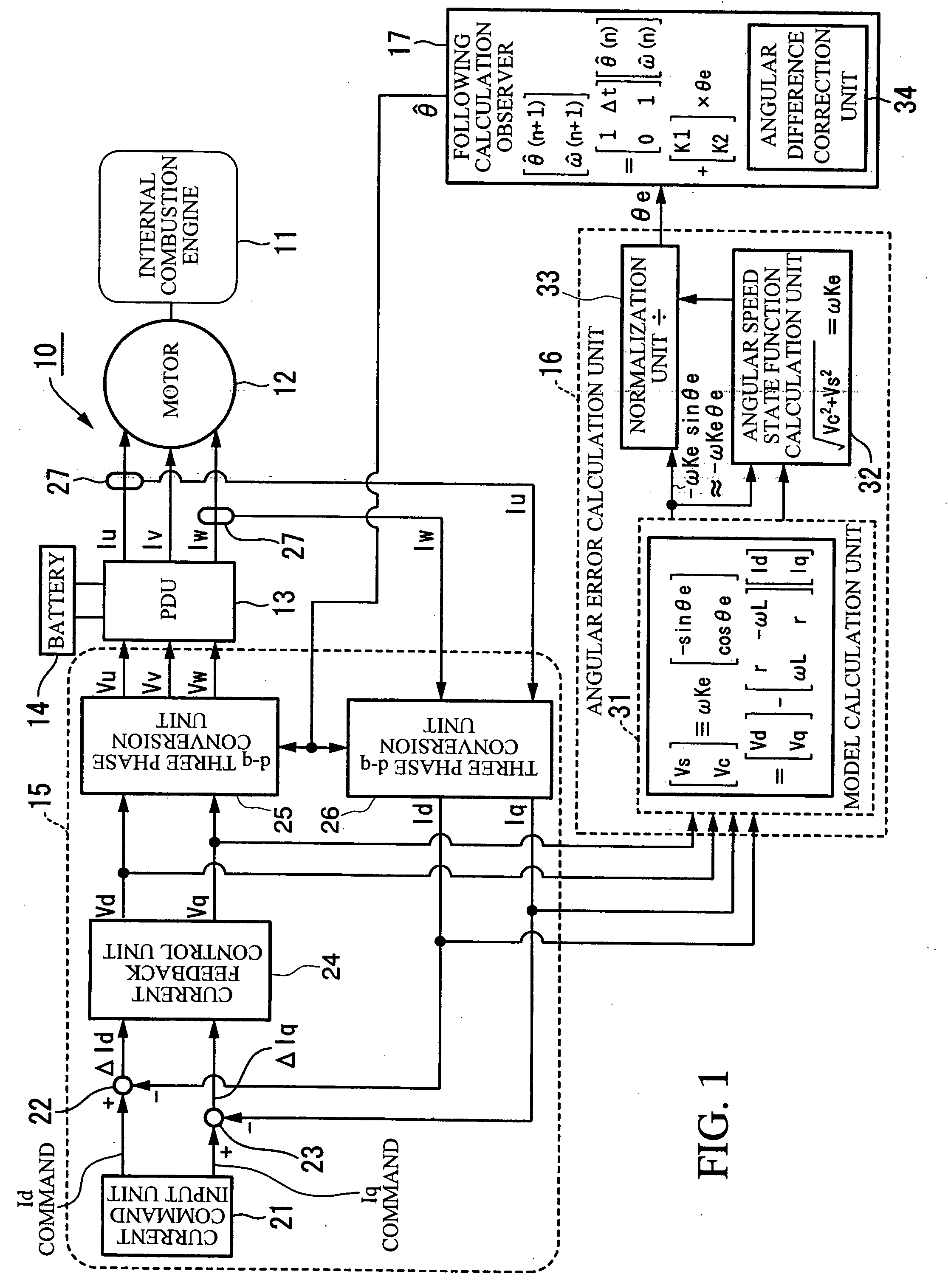

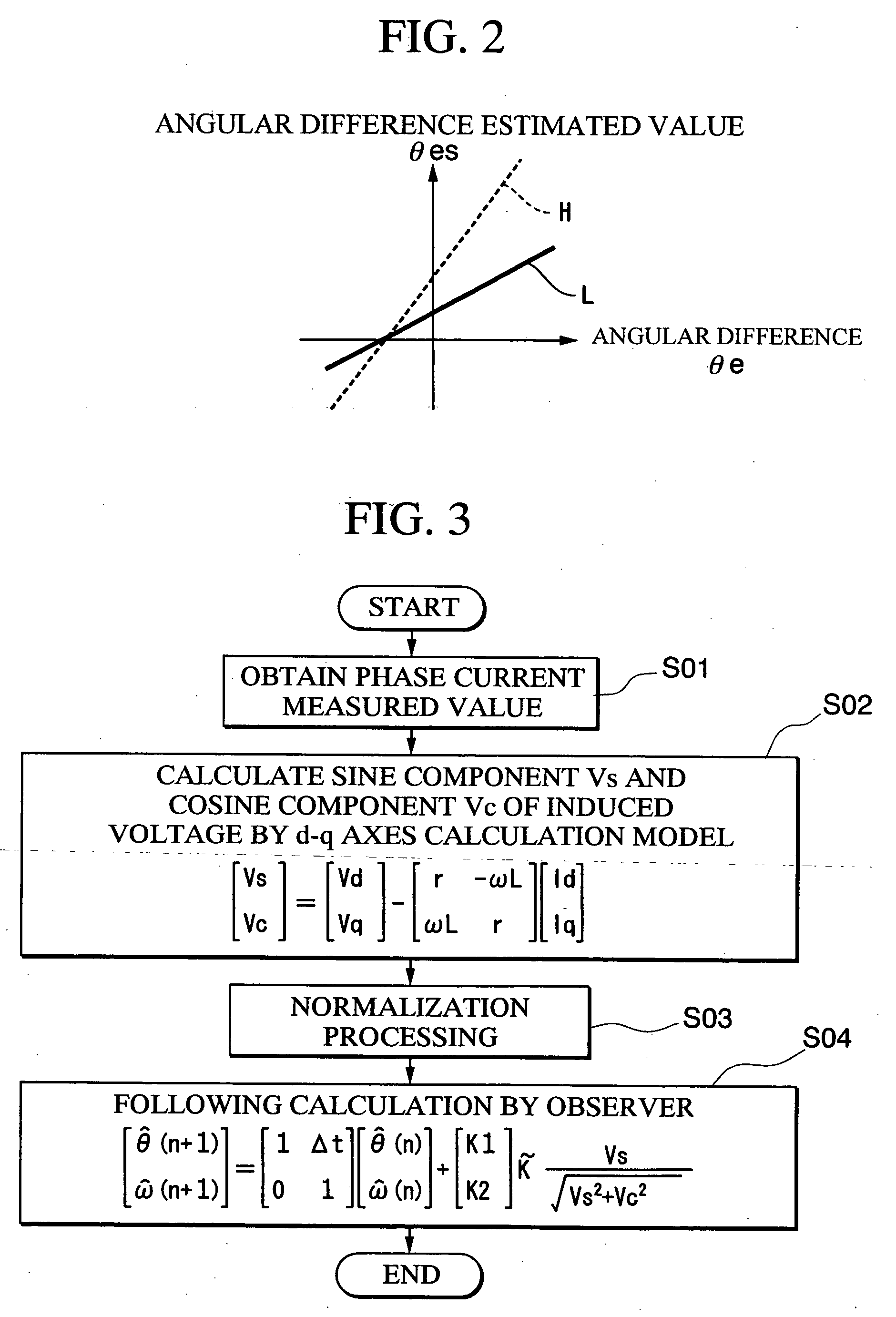

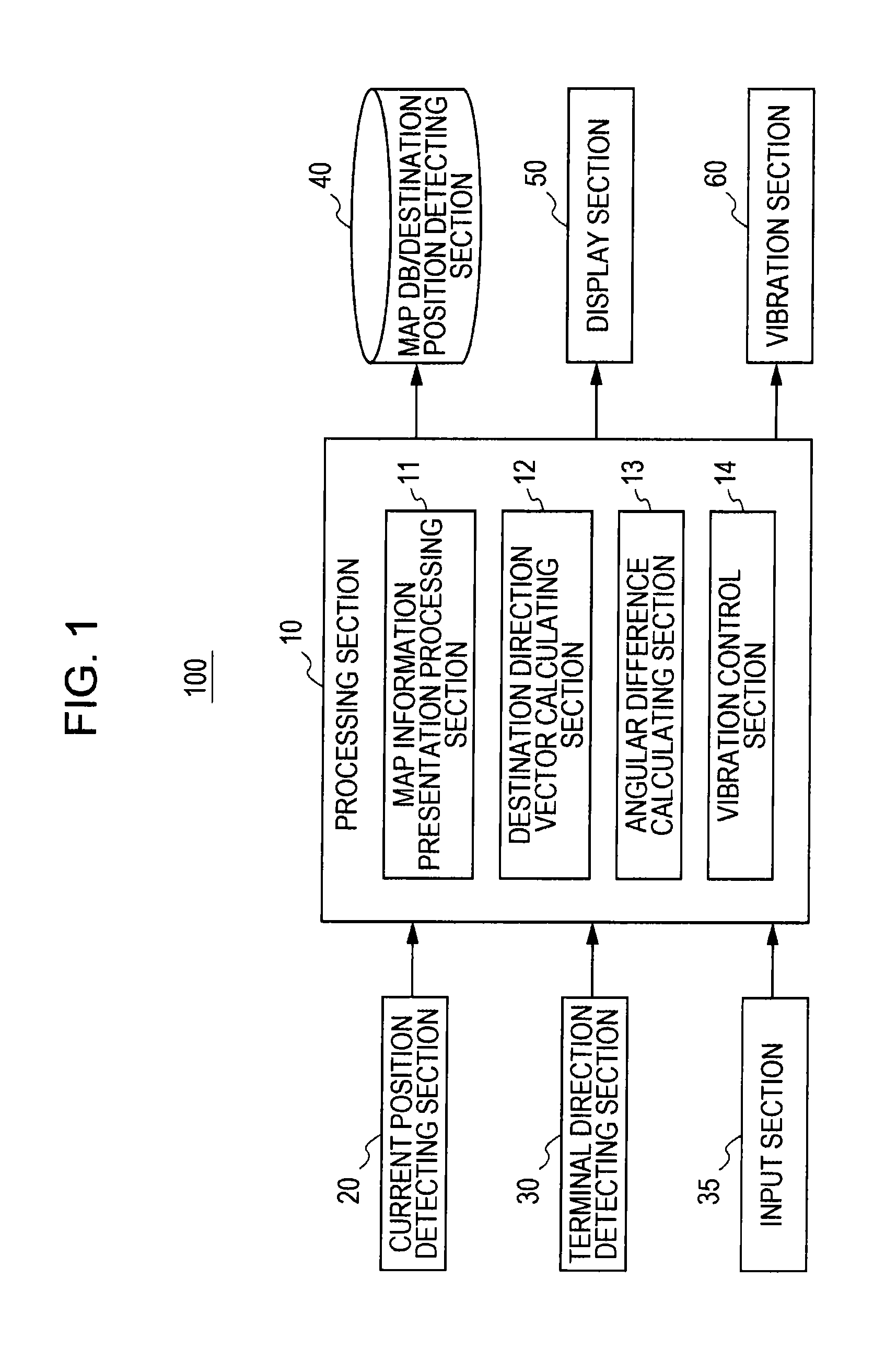

Control apparatus for brushless DC motor

ActiveUS20050029972A1Improve estimation accuracySynchronous motors startersVector control systemsPhase currentsConductor Coil

Owner:HONDA MOTOR CO LTD

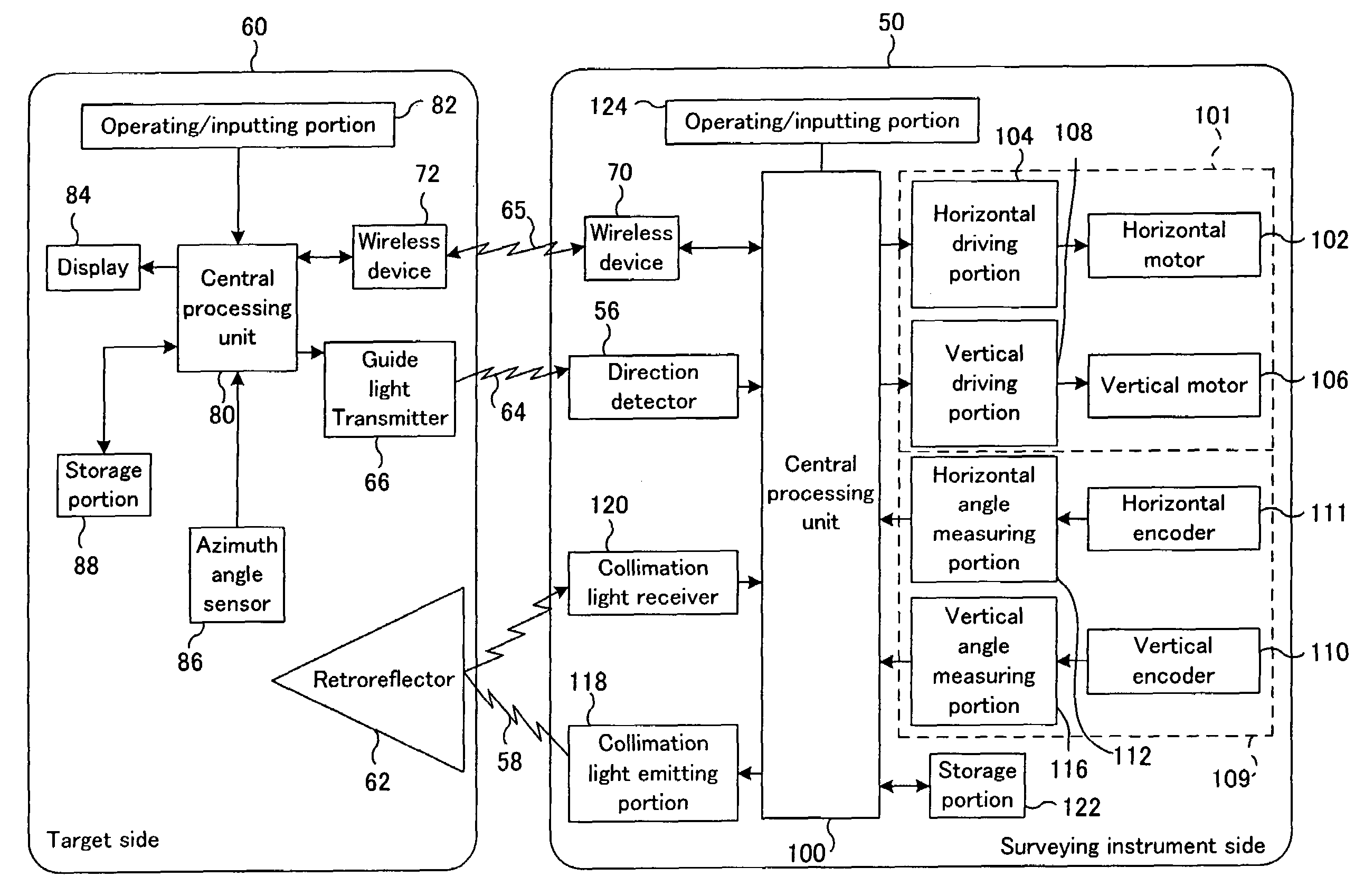

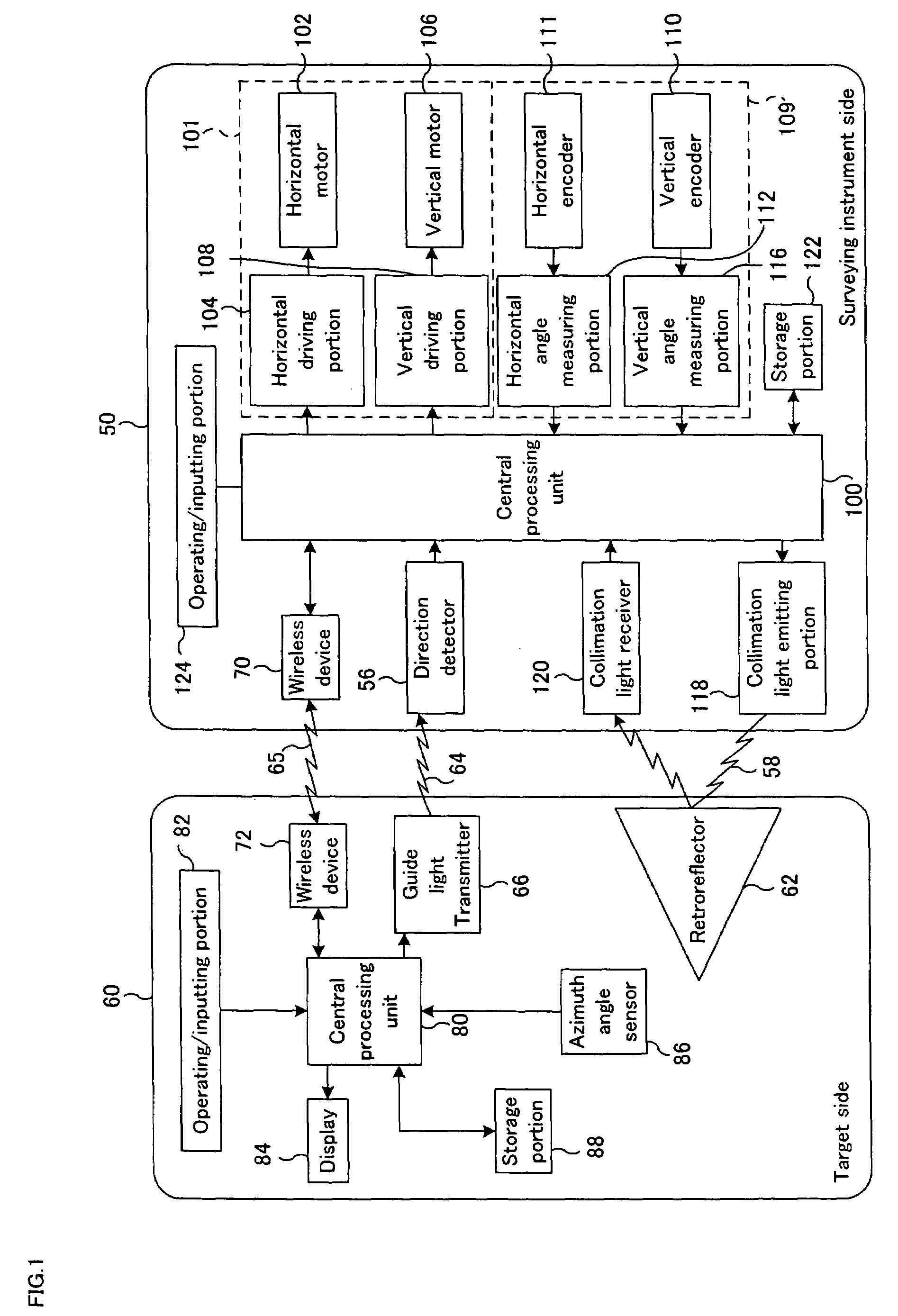

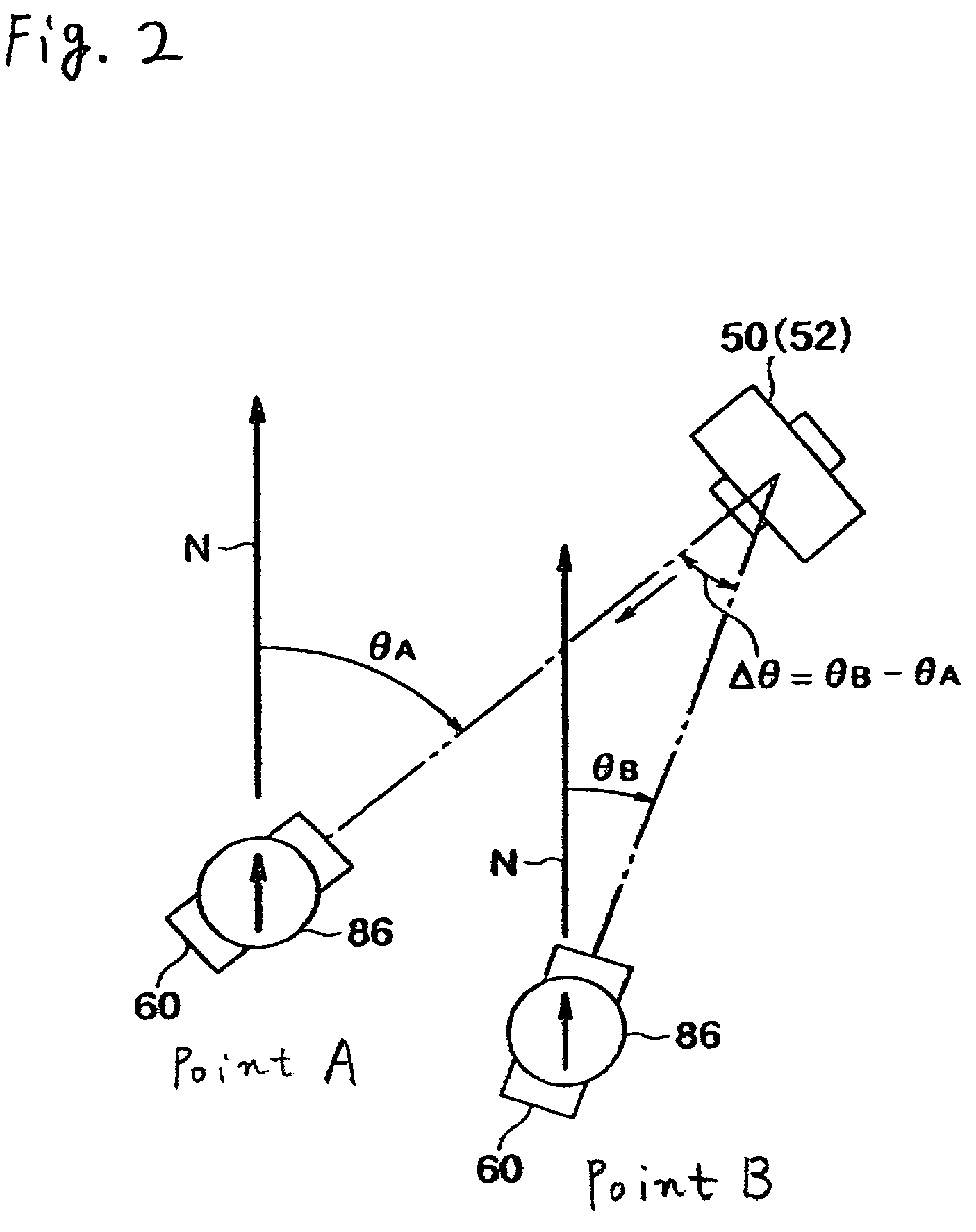

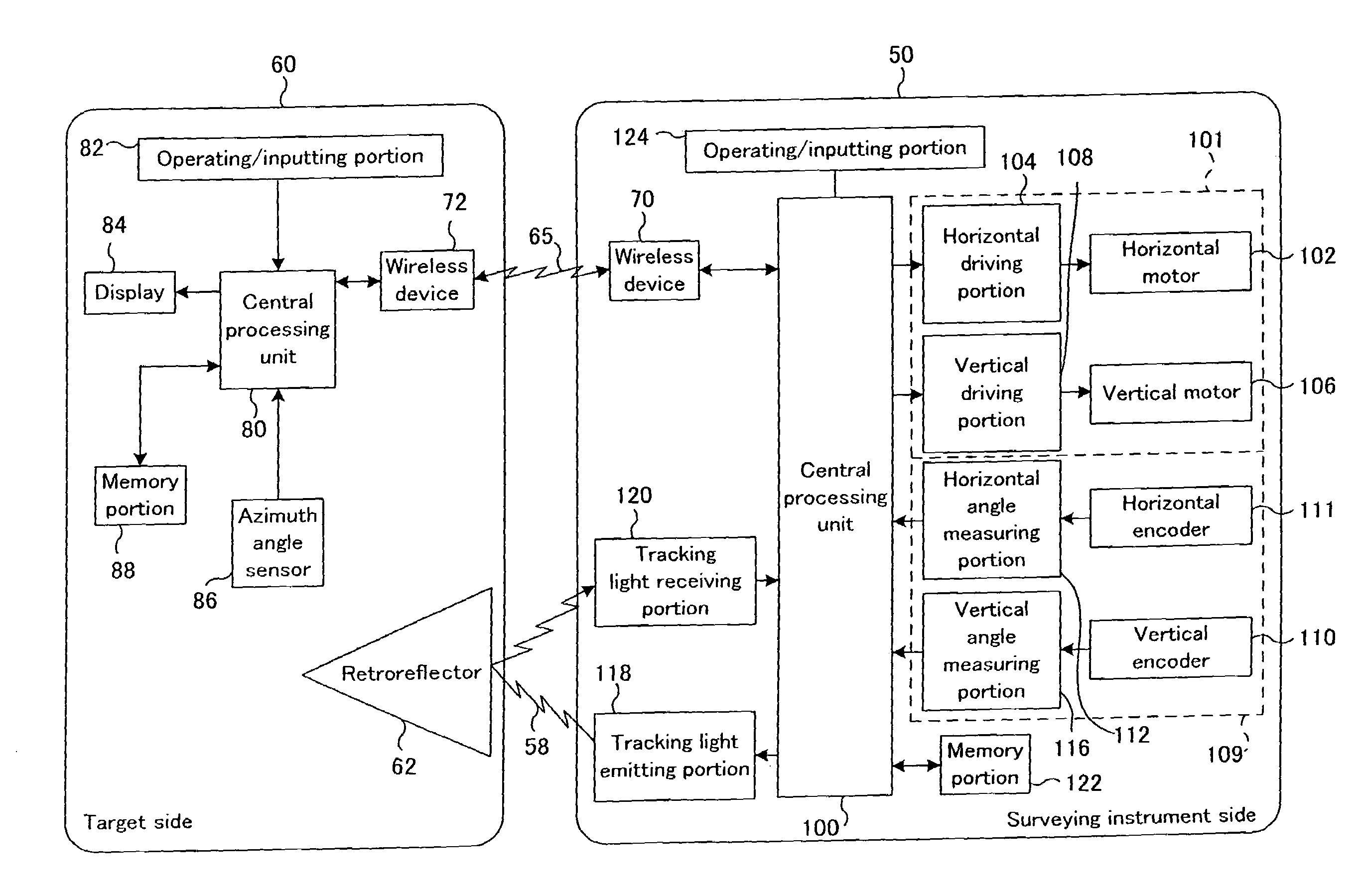

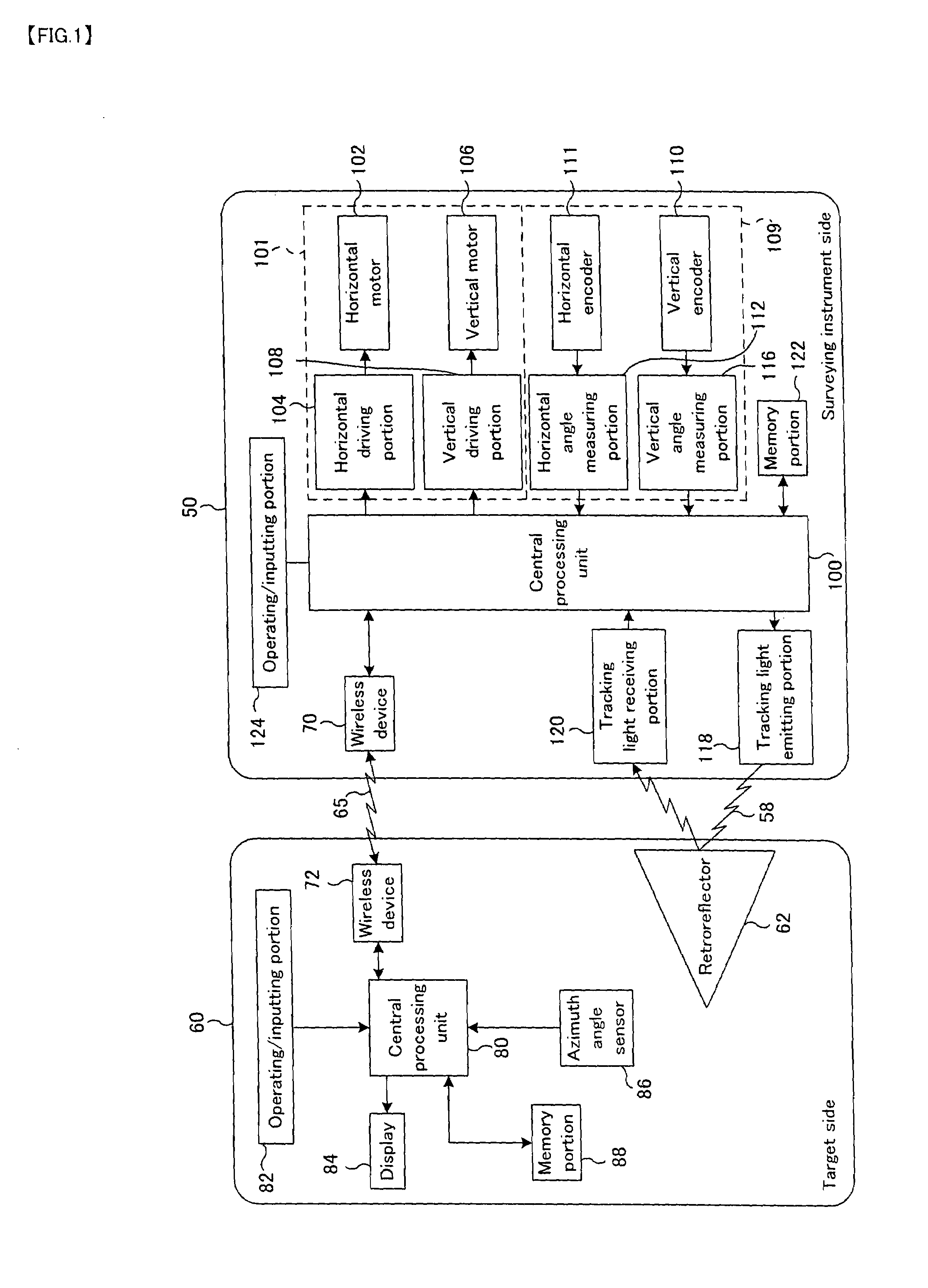

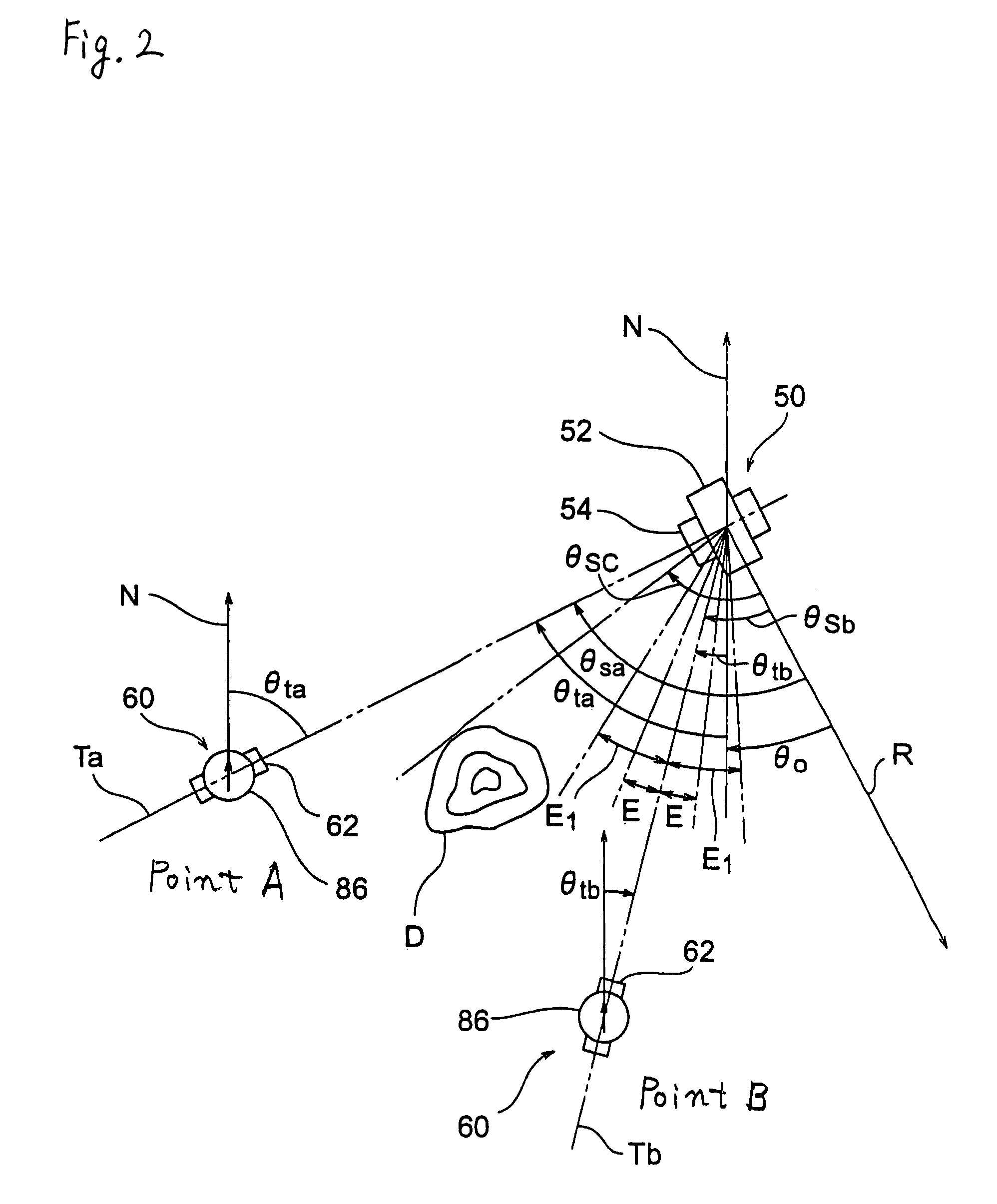

Survey system

ActiveUS7304729B2Imposing burdenShorten the timeActive open surveying meansUsing optical meansMeasuring instrumentSurvey instrument

A survey system is made up of a target and a surveying instrument provided with an automatic collimator that automatically collimates the target. The target includes a guide light transmitter that emits guide light, an azimuth angle sensor that detects a direction angle (θA, θB) at which the target is directed, and a central processing unit that sends a rotation command, which includes the rotational direction of the instrument body, to the surveying instrument. The central processing unit determines the rotational direction of the instrument body based on an angular difference (θB-θA) between a direction angle (θA) obtained when the target is caused to approximately face the surveying instrument at the last measurement and a direction angle (θB) obtained when the target is caused to approximately face the surveying instrument at the present measurement.

Owner:KK TOPCON

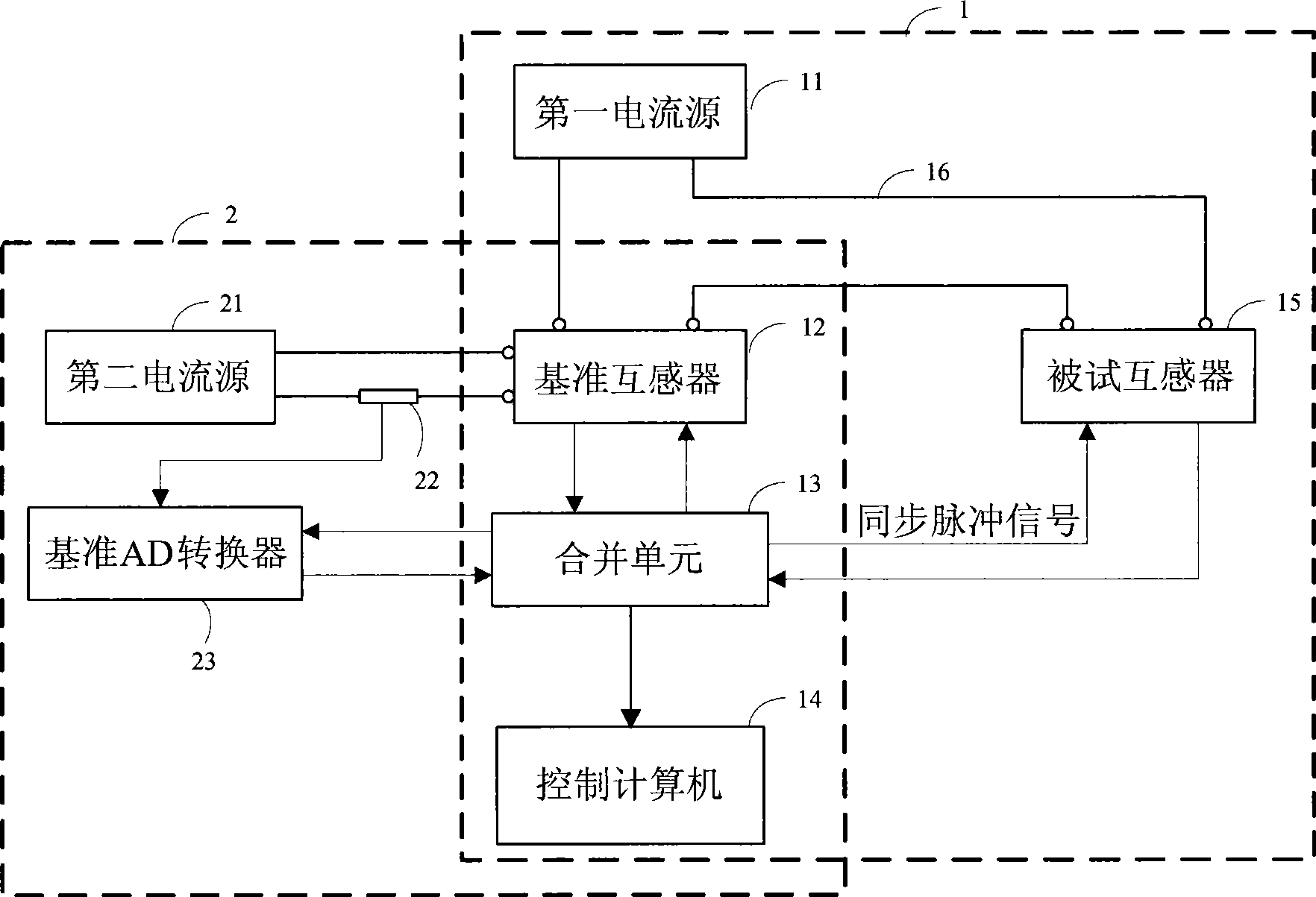

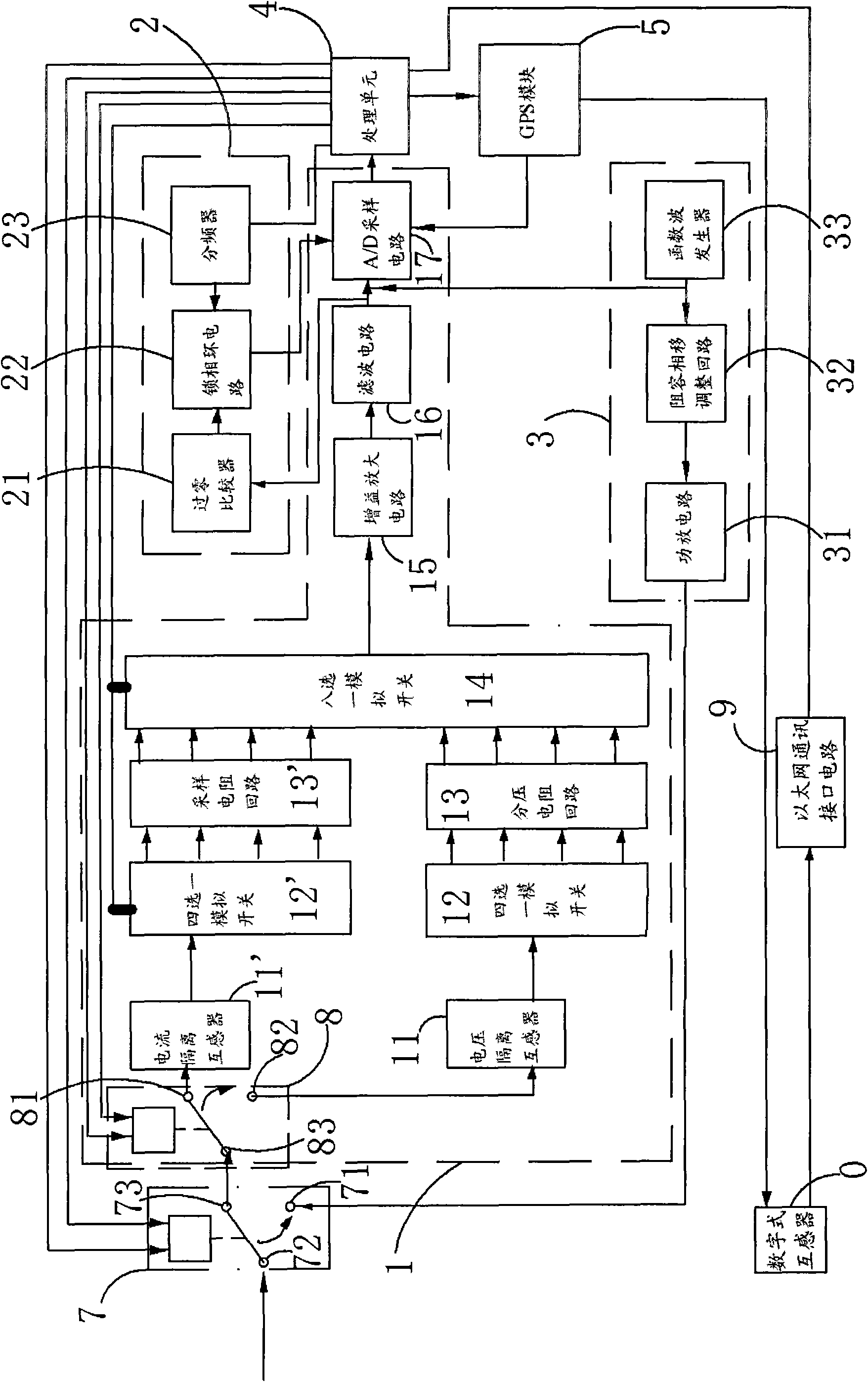

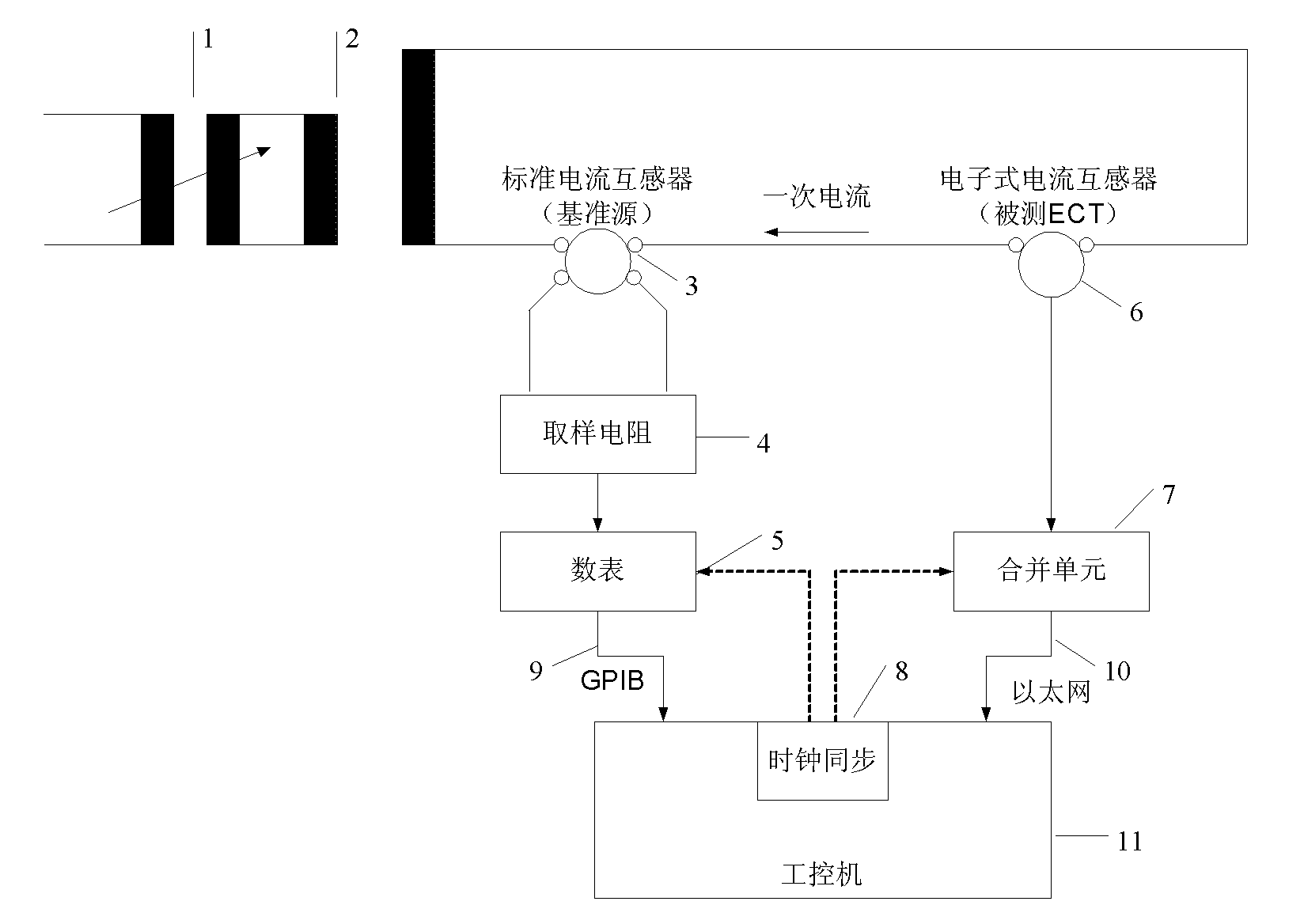

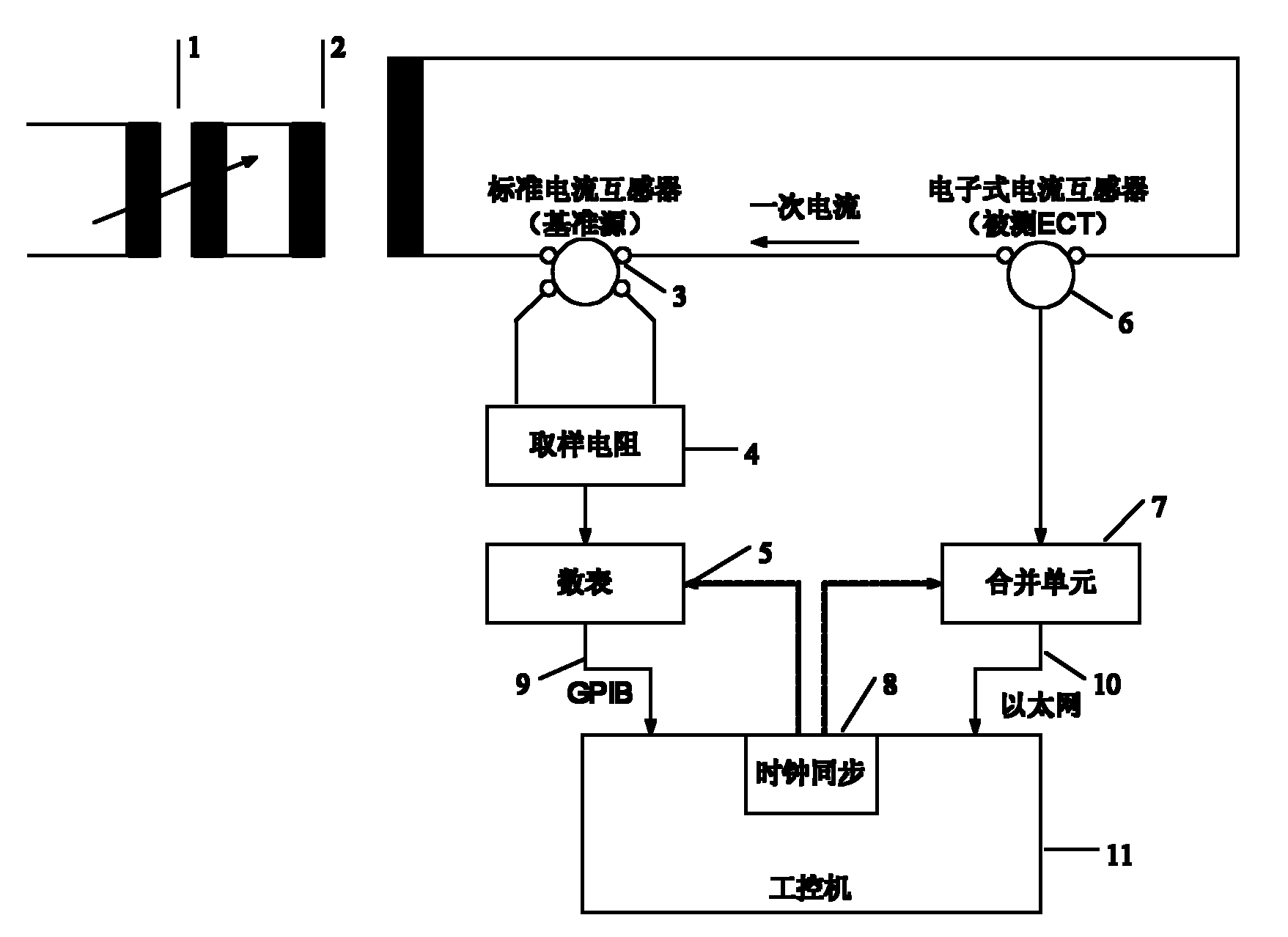

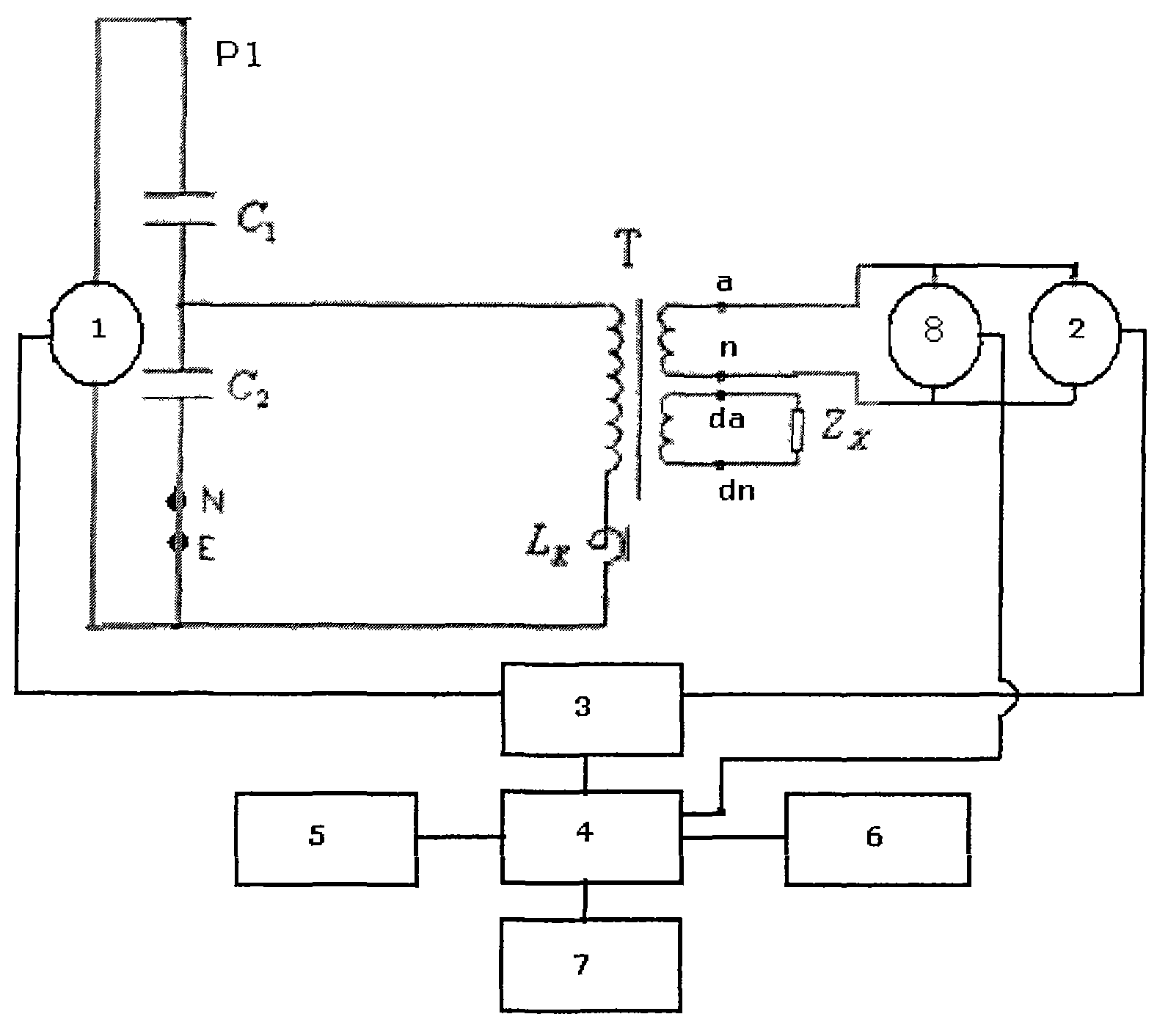

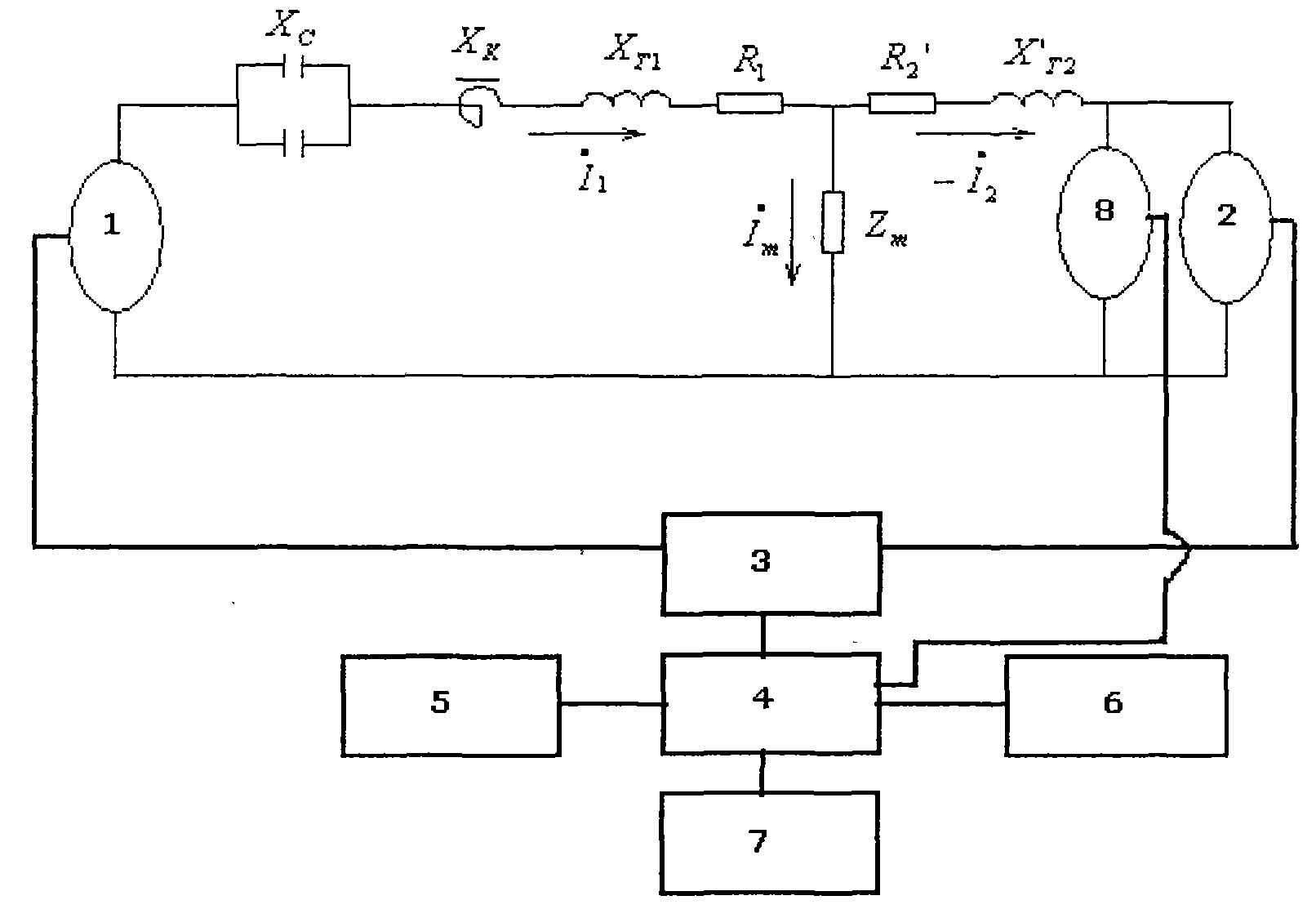

Apparatus for checking electronic type current mutual inductor

ActiveCN101413995AAchieving self-calibrationTo overcome the feature that the long-term accuracy is not high enoughElectrical measurementsElectrical resistance and conductanceEngineering

The invention discloses an electronic current transformer calibrating device. Two current sources respectively transmit current signals A1 and A2, wherein, the A1 is bigger than the A2 and has different frequency from the A2. A reference transformer senses the A1 and the A2 which is amplified by N folds simultaneously, and a tested transformer senses the A1. A merging unit transmits a synchronization pulse signal to the reference transformer, the tested transformer and an AD converter simultaneously, obtains digital quantities of current sampling values of the reference transformer and the tested transformer and the digital quantity of the voltage value at the two ends of a sampling resistor which is obtained by conversion with a reference AD converter at the falling edge of the synchronization pulse signal, and synthesizes the digital quantities into a data frame and sends the data frame to a control computer. The control computer compares the current signal which is obtained by sensing the A1 by the reference transformer with the current signal output by the tested transformer, calibrates the scale difference and the angular difference of the tested transformer, compares the current signal which is obtained by sensing NA2 by the reference transformer with the current signal which is obtained by converting the output voltage from the reference AD converter, and performs self calibration on the reference transformer.

Owner:NARI TECH CO LTD

Gravity dependent pedicle screw tap hole guide and data processing device

InactiveUS20050149054A1Accurate placementImprove stabilityDiagnosticsComputer-aided planning/modellingAccelerometerEngineering

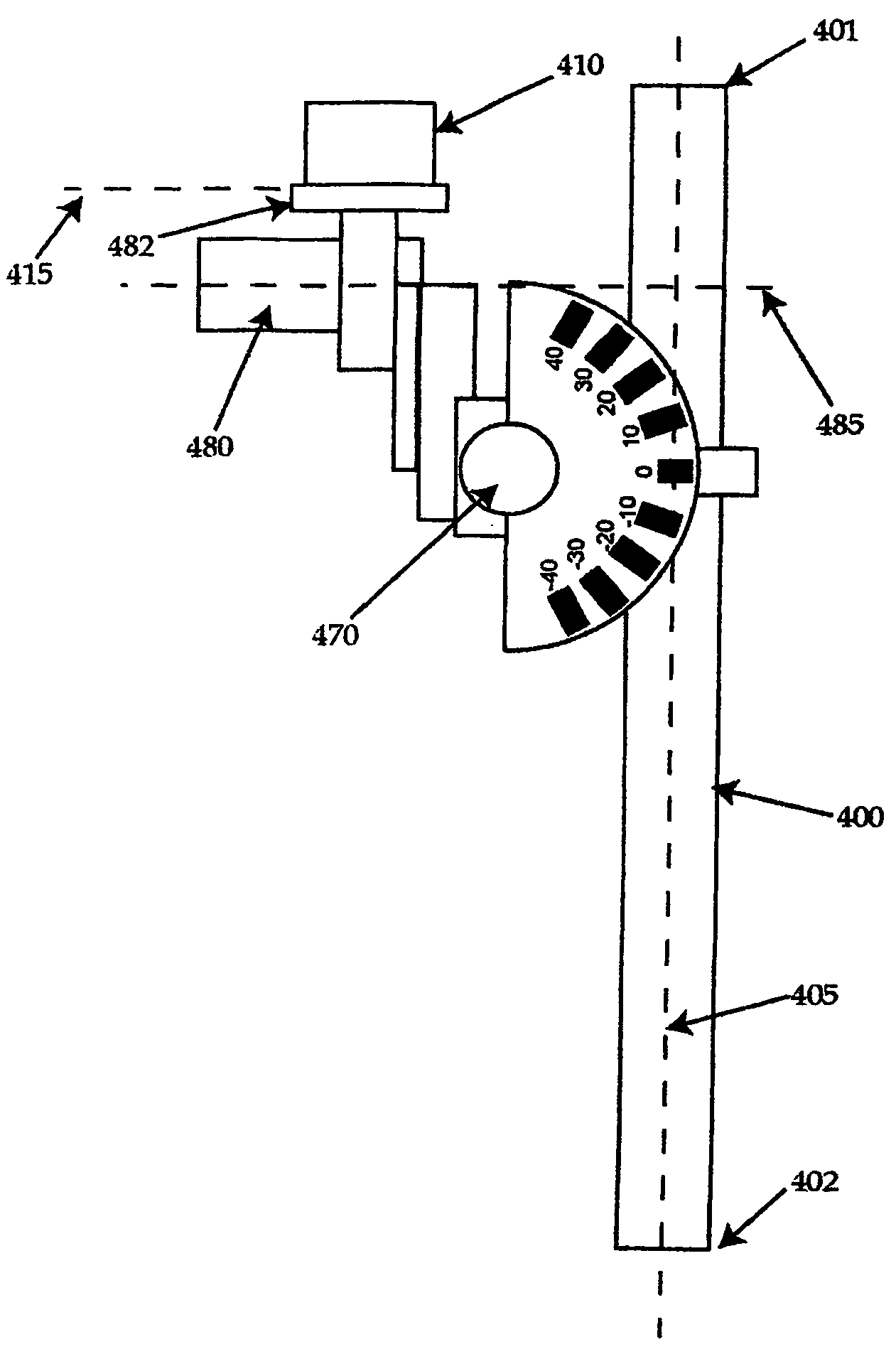

A gravity dependent pedicle screw tap hole guide comprises a guide shaft maintainable parallel to a drill bit during the drilling of a pedicle screw tap hole; an accelerometer associated with a reference direction and responsive to gravity to determine an angular difference between an acting direction of gravity and the reference direction; and a mounting attaching the accelerometer to the shaft and establishing a positional relationship between the reference direction and the longitudinal axis. The accelerometer is preferably in communication with a data processing device or system, which data processing device is able to use signals from the accelerometer to perform one or more actions, such as, for example, displaying the angular difference.

Owner:NUVASIVE

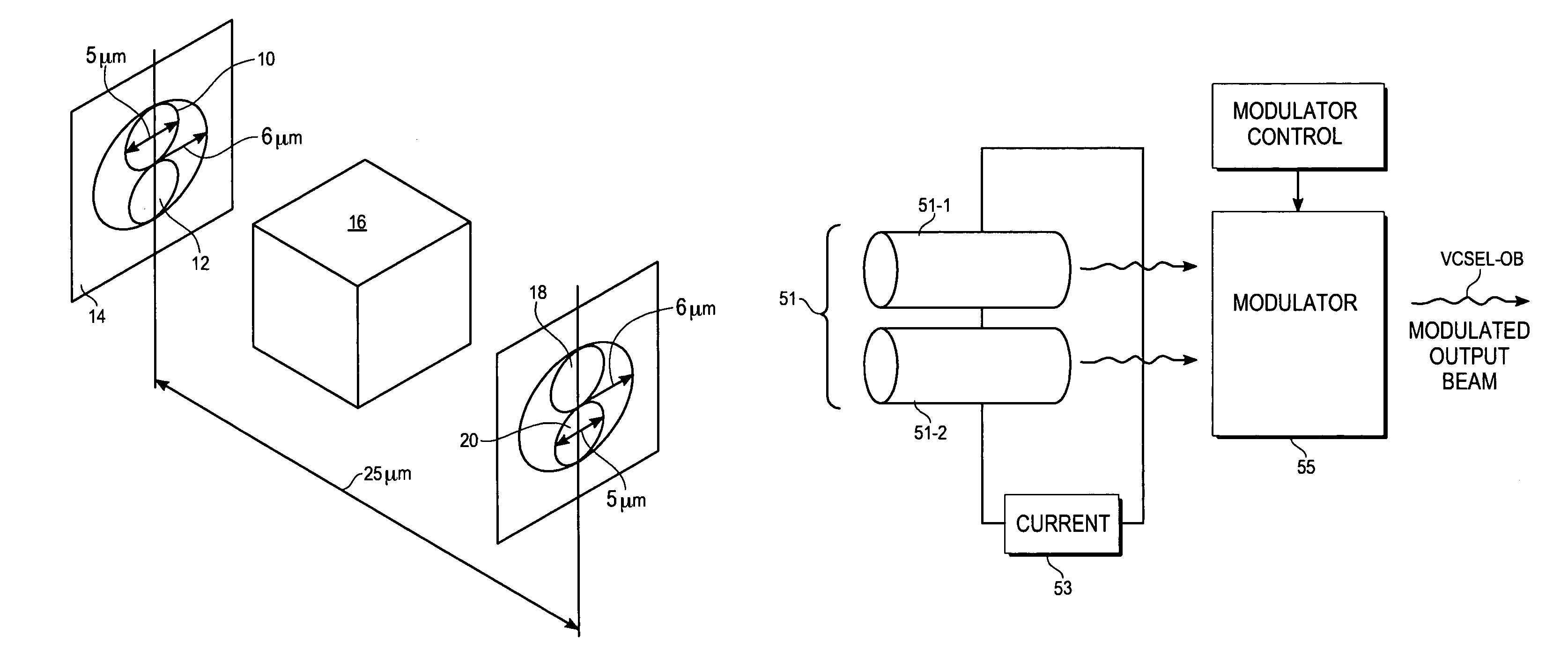

Communication using VCSEL laser array

Ultrafast directional beam switching, using coupled VCSELs is combined with a light modulator to provide information transfer at bit rates of tens of GHz. This approach is demonstrated to achieve beam switching frequencies of 32-50 GHz in some embodiments and directional beam switching with angular differences of about eight degrees. This switching scheme is likely to be useful for ultrafast optical networks at frequencies much higher than achievable with other approaches. A Mach-Zehnder interferometer, a Fabry-Peror etalon, or a semiconductor-based electro-absorption transmission channel, among others, can be used as a light modulator.

Owner:NASA

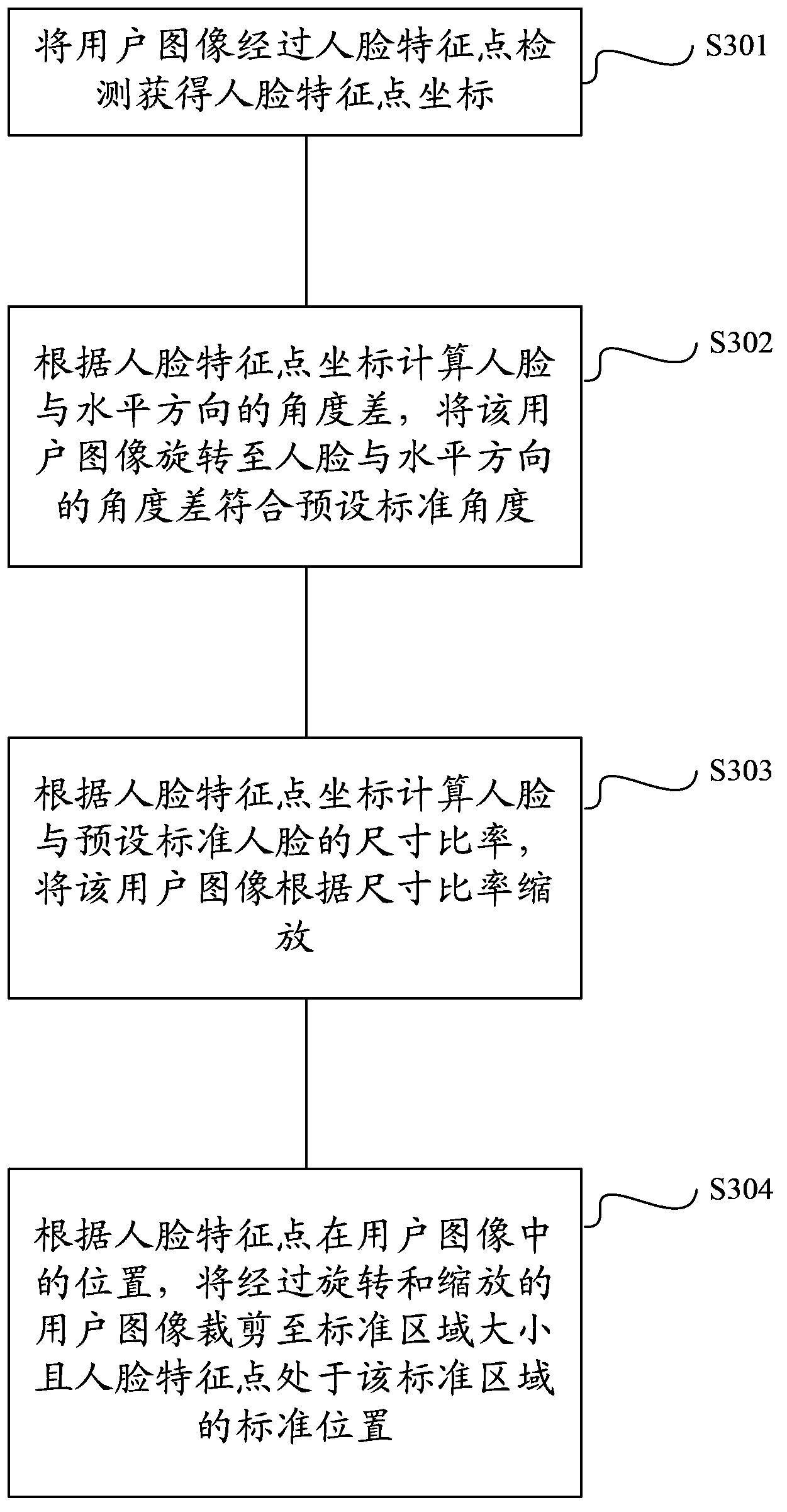

Method and apparatus for use in face recognition

ActiveCN103914676AEliminate the effects ofSame sizeCharacter and pattern recognitionPattern recognitionSize ratio

An embodiment of the invention provides a method for use in face recognition. The method includes: obtaining a coordinate of facial feature points after detection of the facial feature points of a user image; calculating the angular difference between a human face and a horizontal direction based on the coordinate of facial feature points, and rotating the user image until the angular difference between the human face and the horizontal direction matches a preset standard angle; calculating a size ratio between the human face and a preset standard human face according to the coordinate of facial feature points, and scaling the user image according to the size ratio; and according to the location of the facial feature points in the user image, cropping the user image after rotation and scaling into a standard area size so that the facial feature points are in the standard position of the standard area, and obtaining an aligned facial image of a consistent size through pre-processing of the user image so that the facial features of the same user are more consistent and the effects of low-quality images on face recognition are eliminated. In addition, the invention also provides an apparatus for use in face recognition.

Owner:杭州易现先进科技有限公司

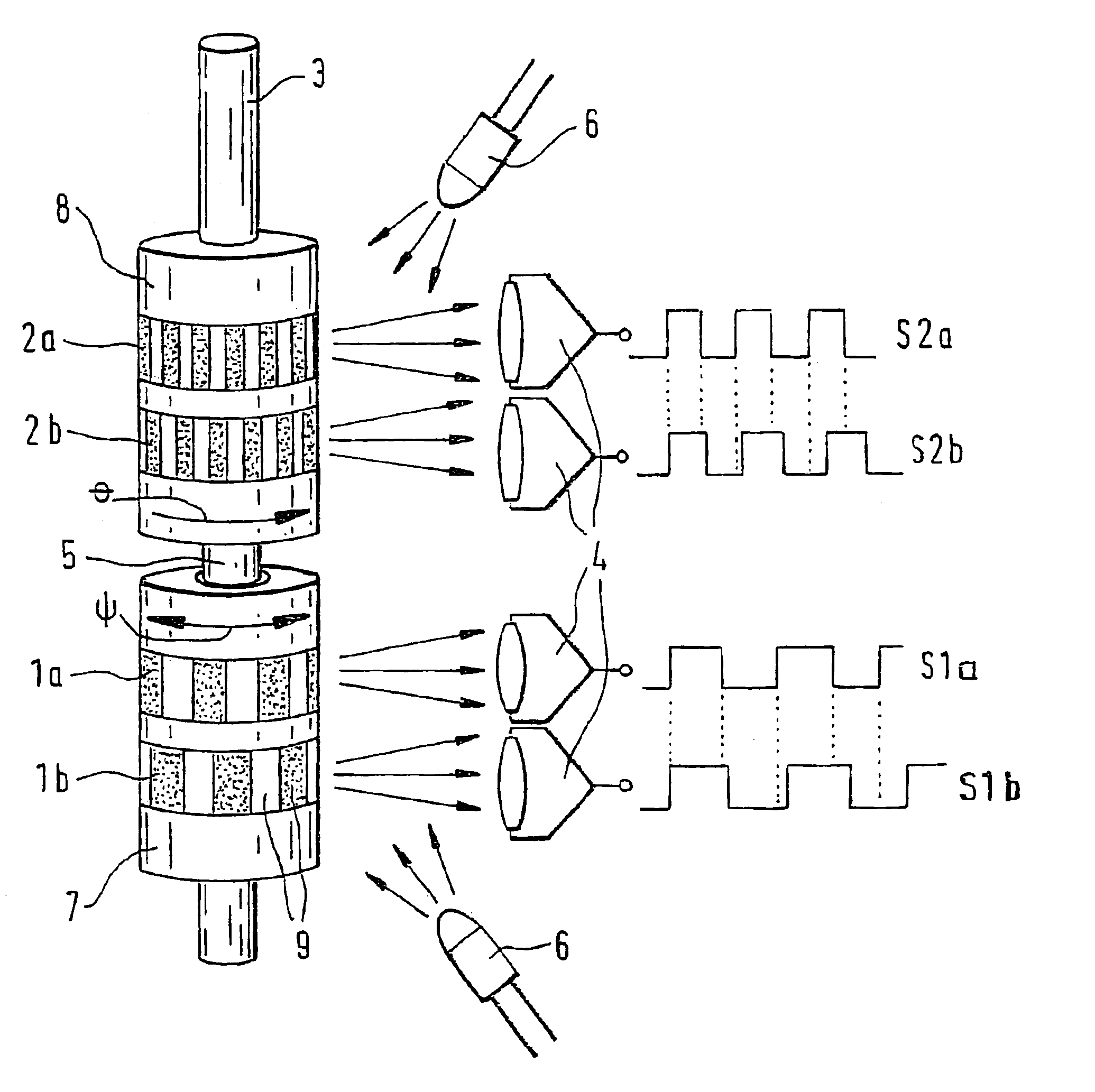

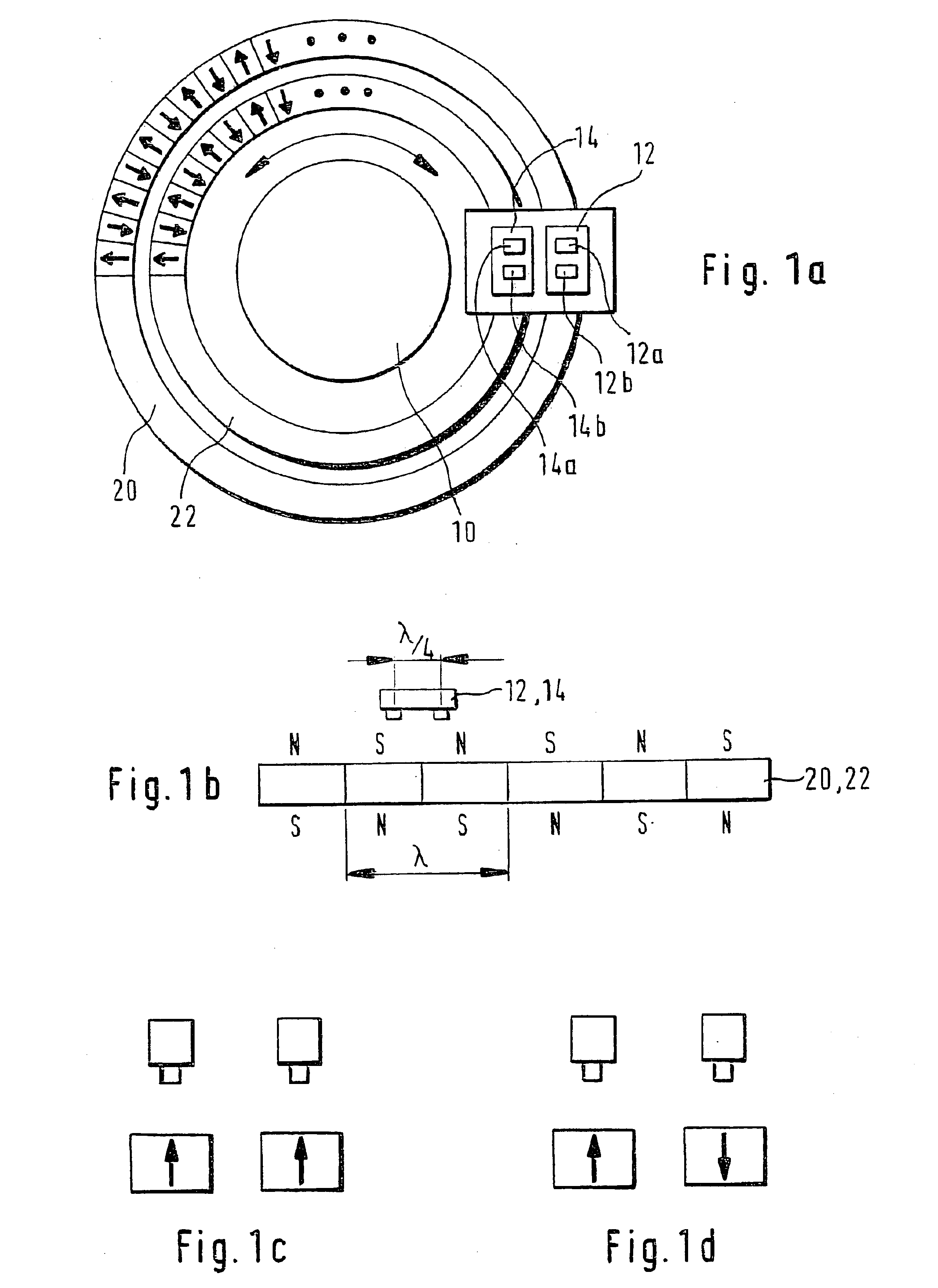

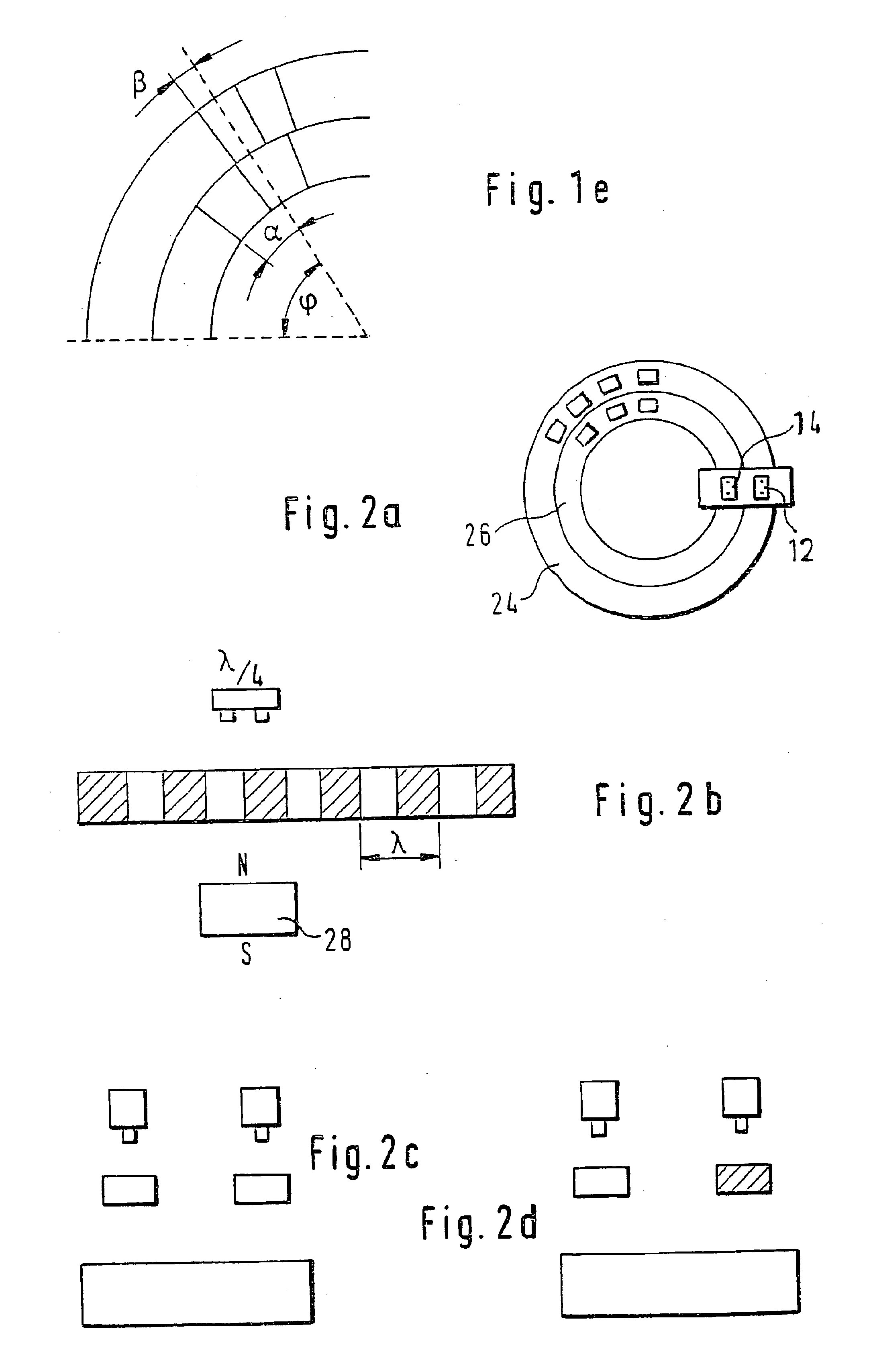

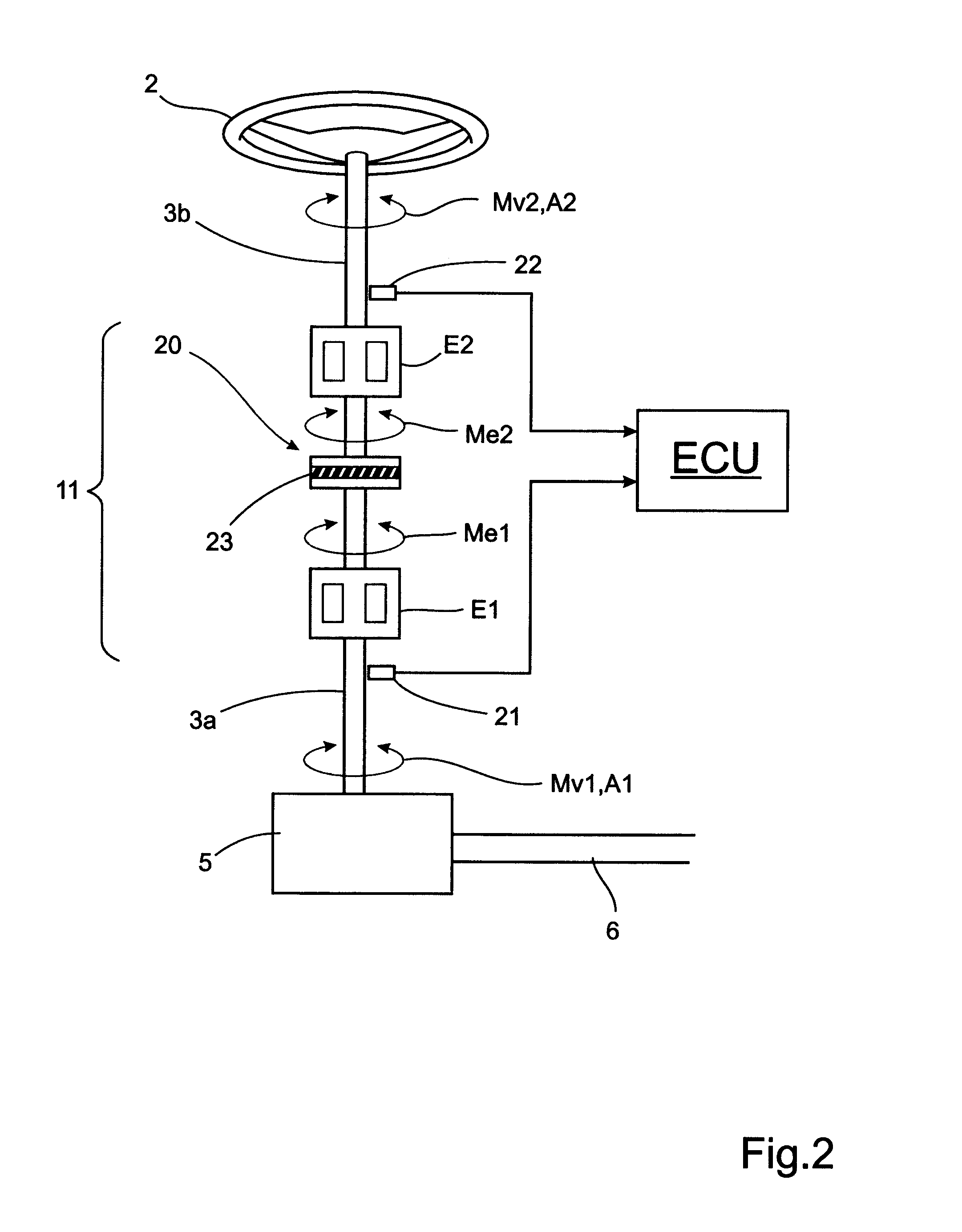

Device for measuring the angle and/or the angular velocity of a rotatable body and/or the torque acting upon said body

InactiveUS6935193B2High measurement accuracyExpand the measurement rangeSuspensionsDetection of fluid at leakage pointAngular velocityTorsion element

A device for measuring an angle and / or the torque acting on a rotatable body is proposed according to the invention, whereby the rotational angle is detected by means of magnetic or optical sensors. In particular, in a preferred exemplary embodiment, two devices (7, 8) are proposed, each of which comprises two optically readable code tracks. The two code tracks (1a, 1b or 2a, 2b) on one device (7 or 8) are similar in design and are offset in relation to each other, so that associated sensors (4) output a digital signal. The rotational angle is calculated based on the lag between the two digital signals. In a further embodiment it is provided that a torsion element (5) having a known torsional stiffness is situated between the two devices (7, 8). Torque transferred by the rotatable body (3) can also be calculated therefore from the angular difference of the two devices 7, 8. The device is used preferably in the steering axle of a motor vehicle.

Owner:ROBERT BOSCH GMBH

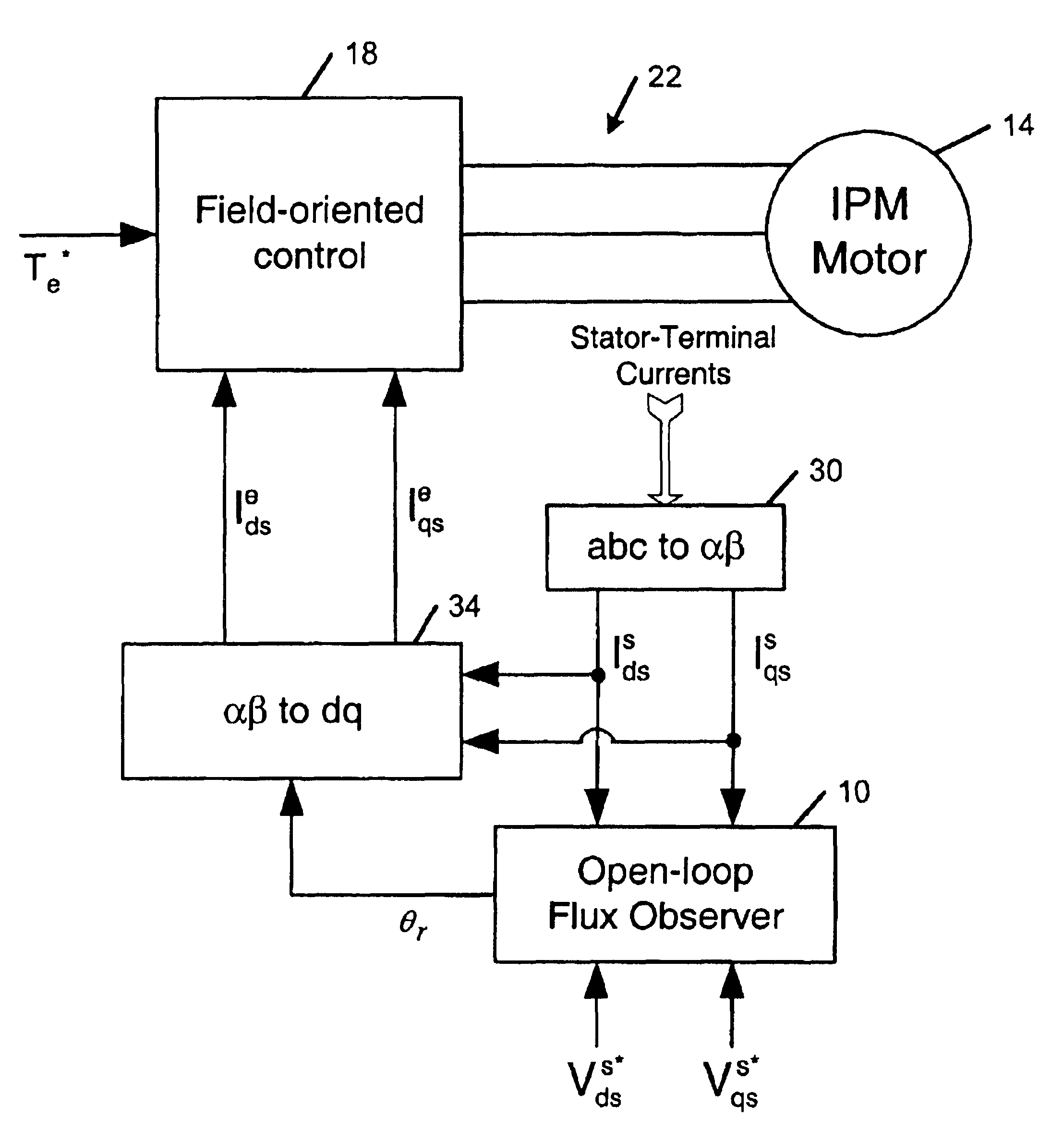

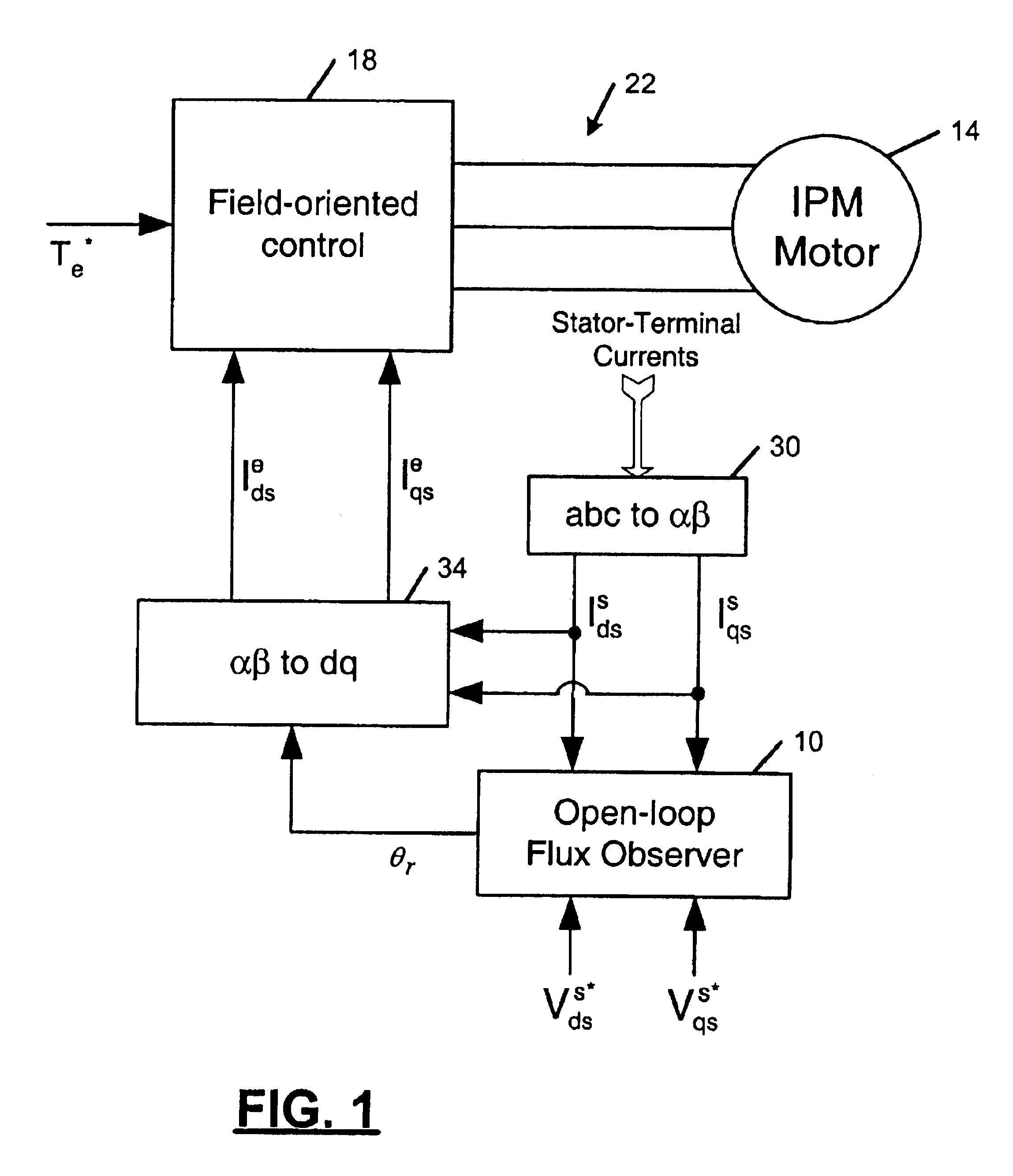

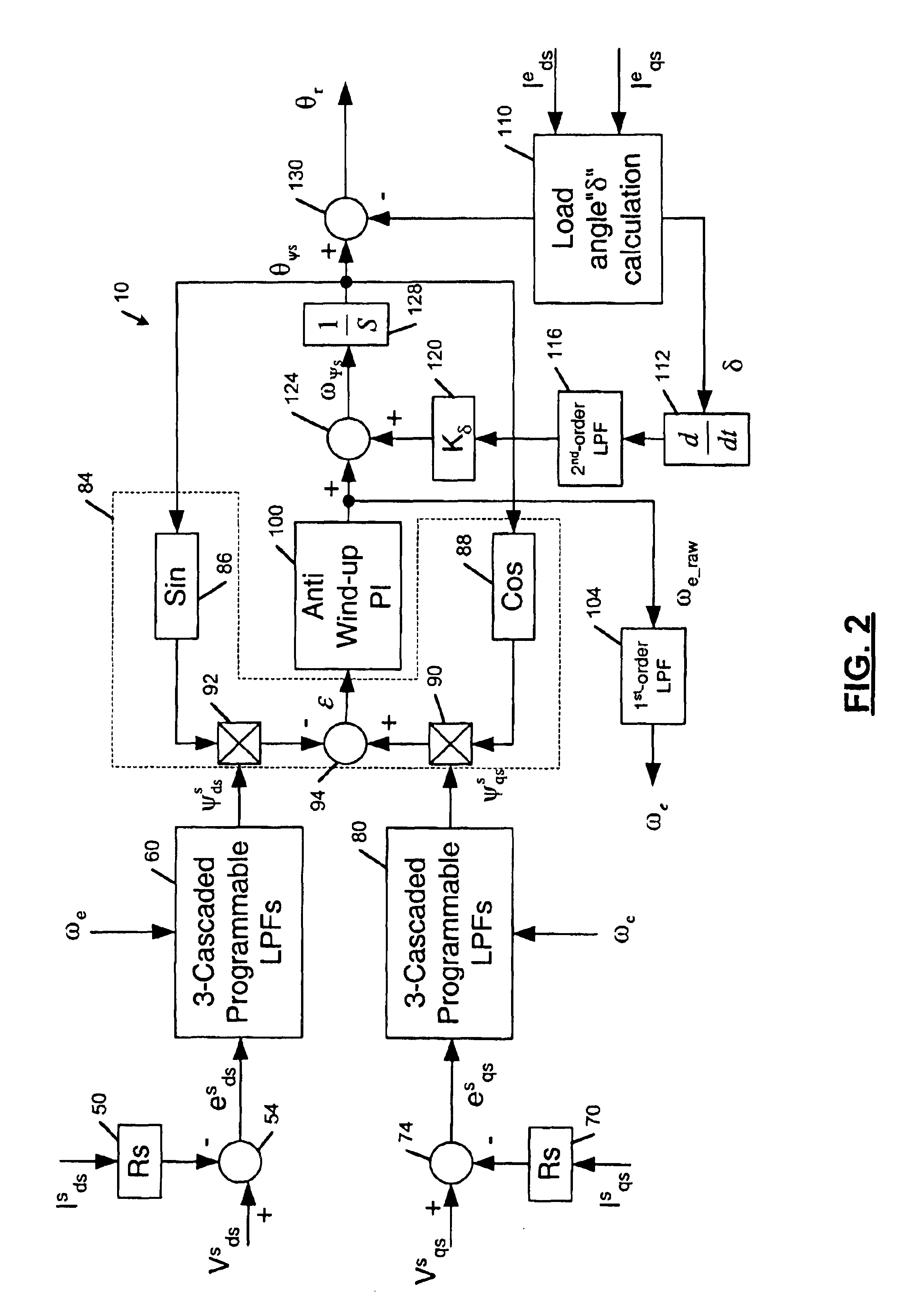

Flux observer in a sensorless controller for permanent magnet motors

A control system includes a field oriented controller that receives a torque command and that generates phase voltages for an electric machine. A first transformation module receives stator terminal currents and generates d-axis and q-axis stationary frame currents. An open loop flux observer receives d-axis and q-axis stationary frame voltage commands and the d and q-axis stationary frame currents. The open loop flux observer includes a vector cross product calculator that generates an error signal that is proportional to an angular difference between an estimated stator flux and a computed stator flux and a proportional integral controller that generates an estimated rotor angular position based on the error signal. A second transformation module receives the d-axis and q-axis stationary frame currents and the estimated rotor angular position and generates d-axis and q-axis synchronous reference frame feedback currents that are output to the field oriented controller.

Owner:GM GLOBAL TECH OPERATIONS LLC

Survey system

ActiveUS7321420B2Easy to operateReduce the burden onAngle measurementSurveying instrumentsSurvey instrumentMeasurement point

Owner:KK TOPCON

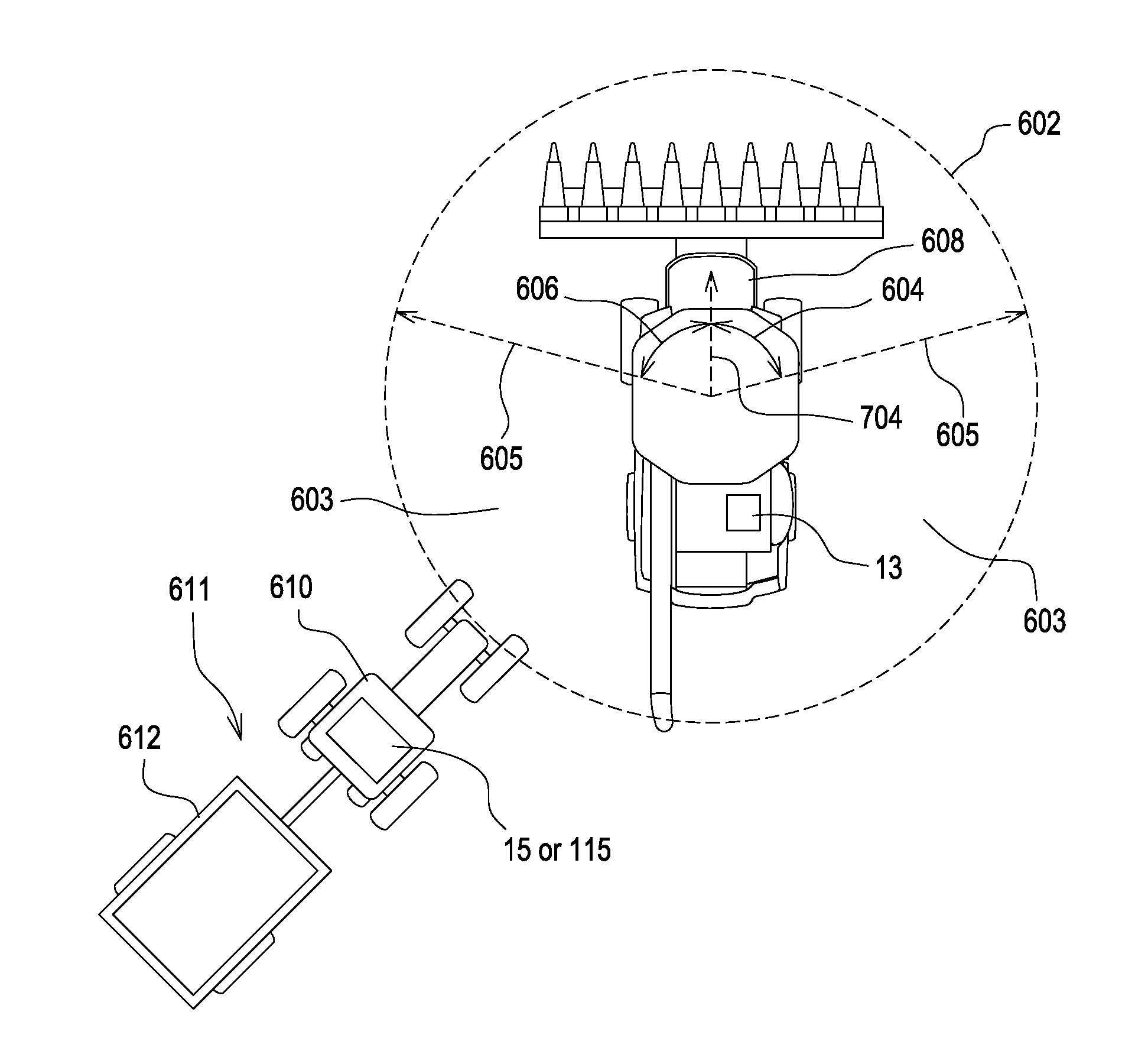

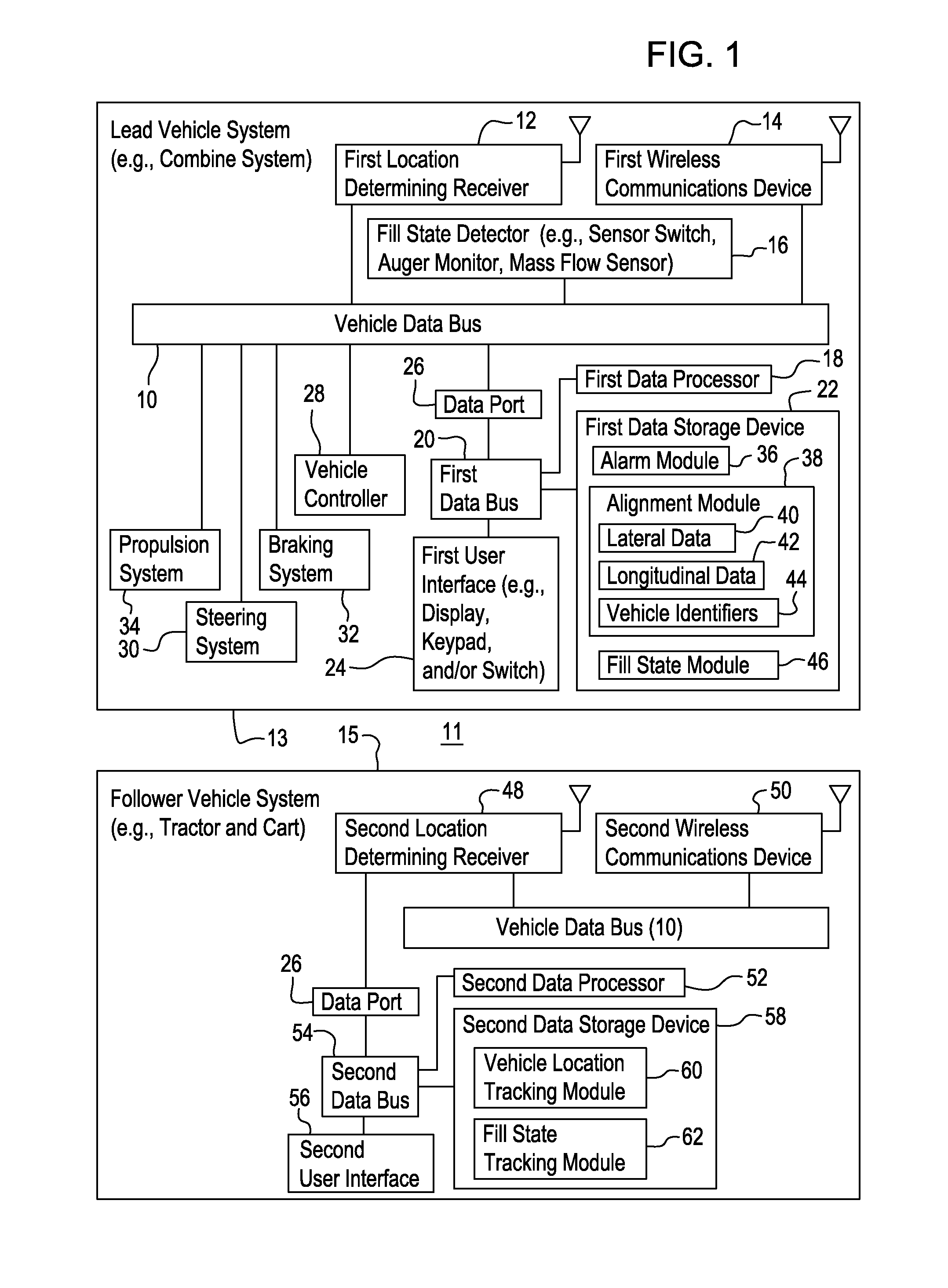

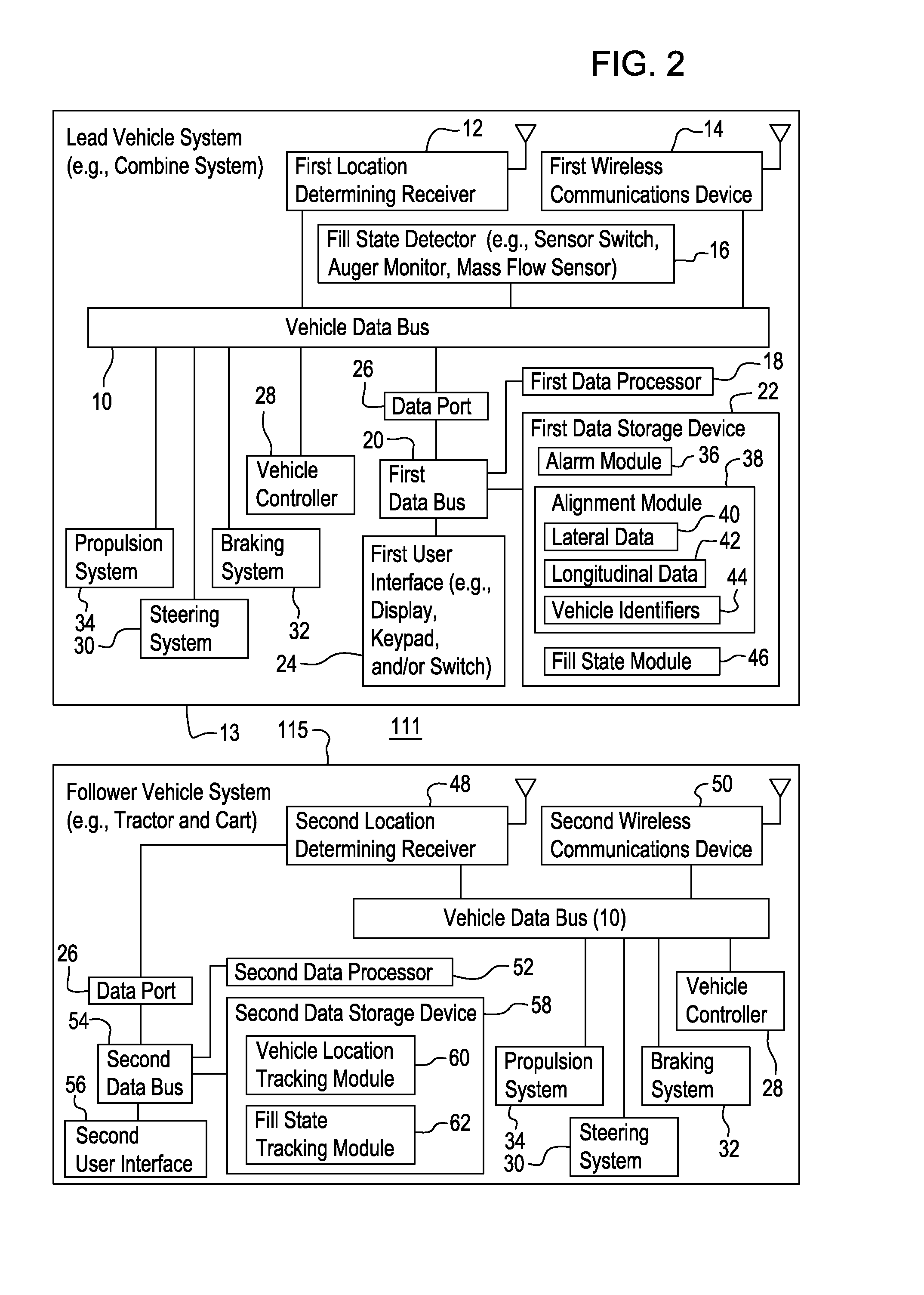

Method and system for transferring material between vehicles

A user interface alerts an operator of the lead vehicle if the follower vehicle location is within a predefined radius of the lead vehicle location and a predetermined angular difference with respect to a heading of the lead vehicle. A user interface response mechanism is configured such that the operator can accept or reject jointly coordinated movement of the lead vehicle and follower vehicle for unloading the lead vehicle during an unloading period. The first wireless communications device is adapted to transmit an alignment data message to the follower vehicle to maintain a target offset between the lead vehicle and the follower vehicle, where the target offset is based on a first vehicle identifier of the follower vehicle, a second vehicle identifier of the lead vehicle, and preset target offset stored in at data storage device associated with the lead vehicle.

Owner:DEERE & CO

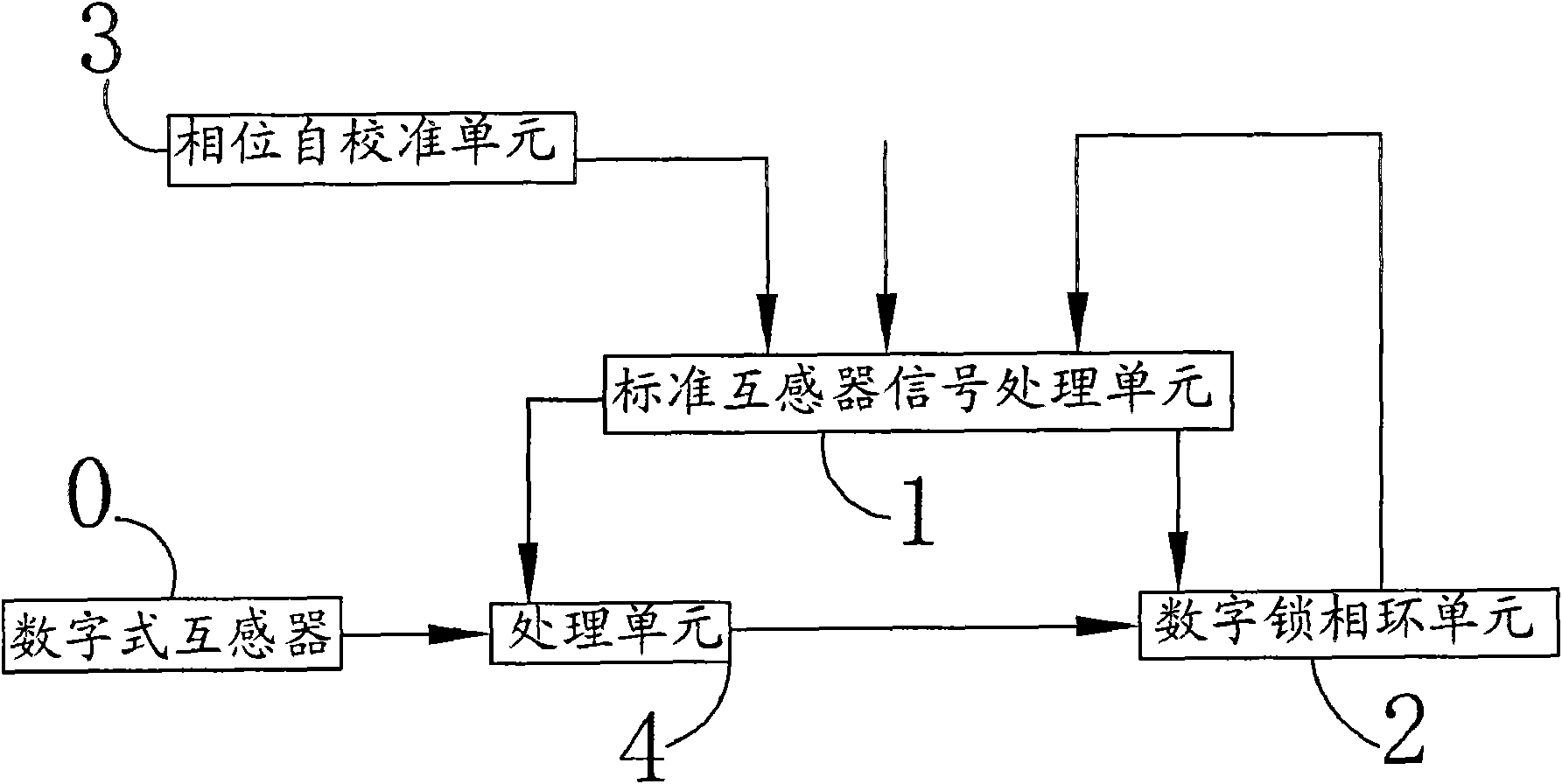

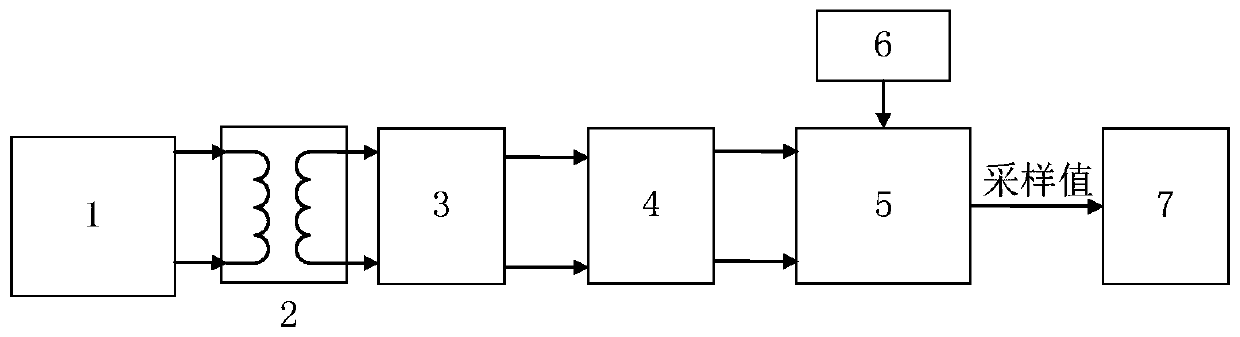

Device for measuring and checking errors of digital mutual inductor

The invention discloses a device for measuring and checking errors of a digital mutual inductor, which comprises a phase self-calibration unit, a standard mutual inductor signal processing unit, a processing unit and a digital phase-locked loop unit, wherein the phase self-calibration unit is used for generating a calibration signal; the standard mutual inductor signal processing unit is used forreceiving an input signal of a standard mutual inductor or the calibration signal, and outputting a first analog signal and a first digital signal which corresponds to the analog signal and is subjected to analog / digital conversion after the processing; the processing unit receives the first digital signal and a second digital signal which is from a digital mutual inductor to be tested and synchronous with the first digital signal, and analyzes and calculates fundamental components of various signals and harmonic components in each time to obtain an angular difference, a phase difference and aphase error of the digital mutual inductor to be tested; and the digital phase-locked loop unit receives and locks the first analog signal, and receives a frequency dividing ratio data signal which is emitted by the processing unit and is based on the sampling data of the digital mutual inductor to be tested to generate a sampling frequency signal to the standard mutual inductor signal processingunit.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST

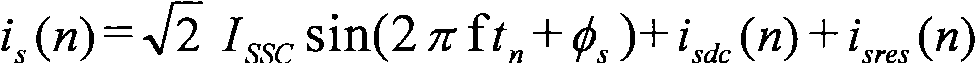

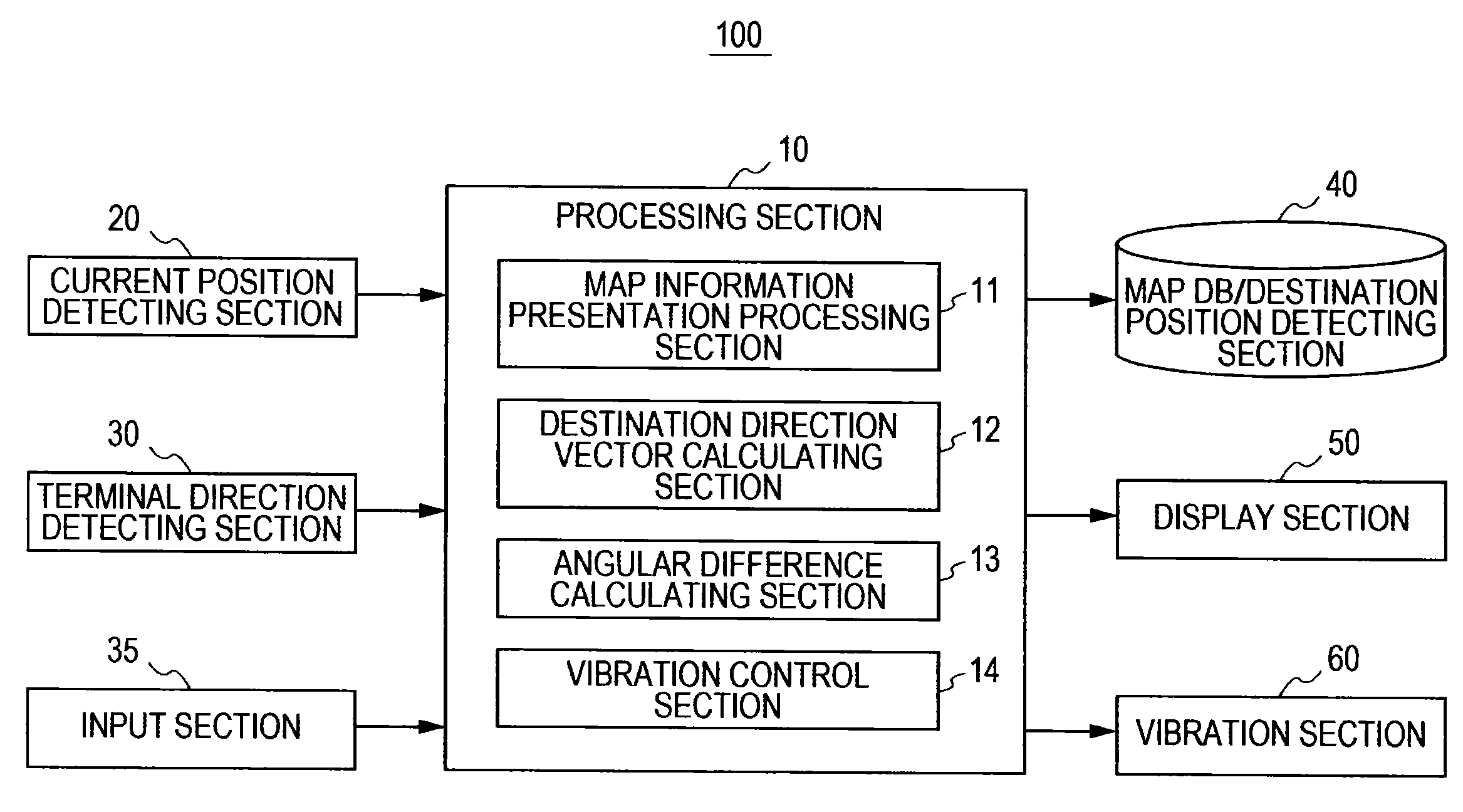

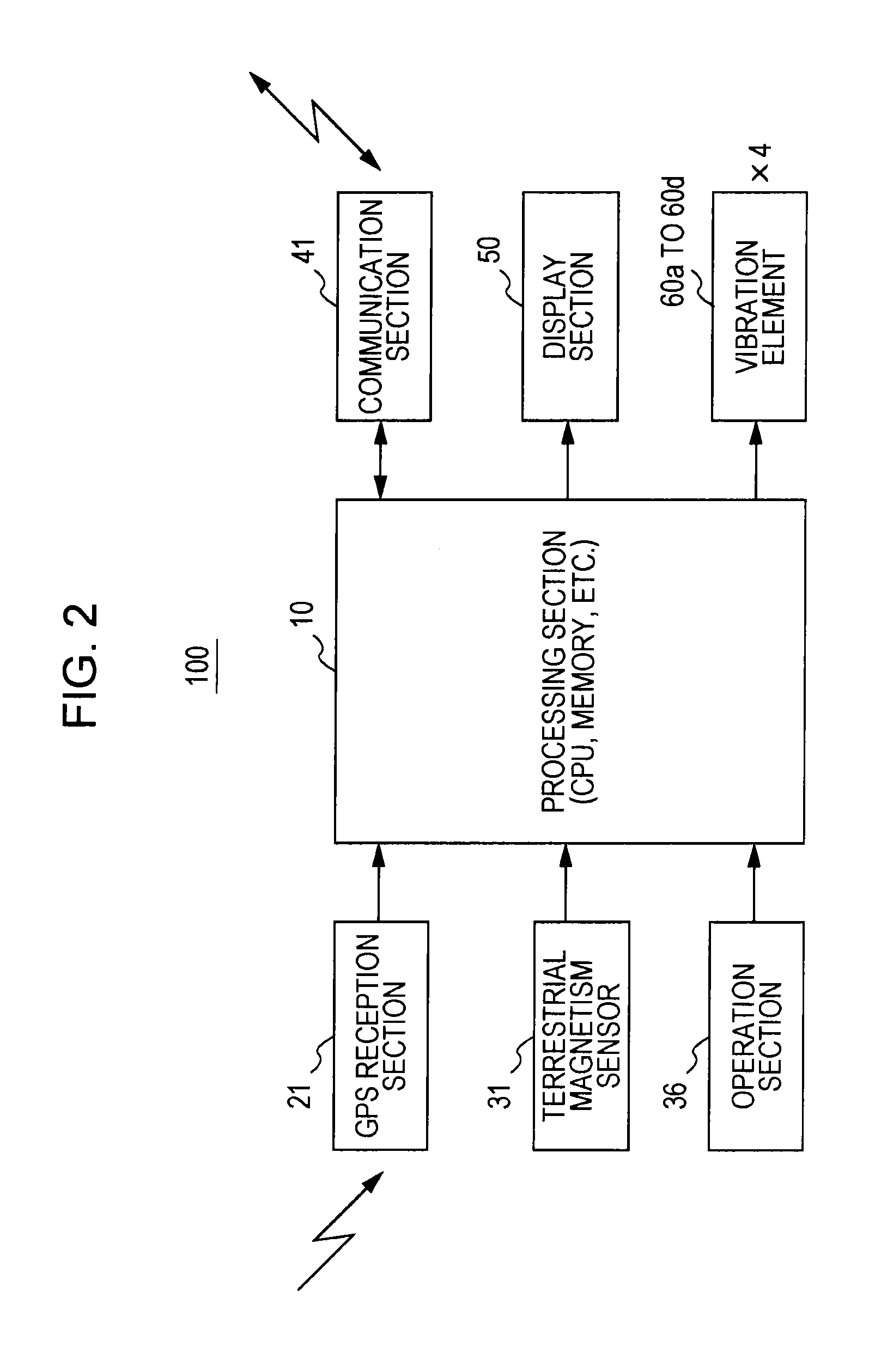

Portable navigation device and method with active elements

InactiveUS20120150431A1Smooth and safe navigationSmooth navigationInstruments for road network navigationNavigational calculation instrumentsEngineeringVisual perception

A portable navigation device and method are capable of presenting a destination direction to a user without resorting to visual sensation with a relatively simple configuration. Vibration elements are disposed on or in different positions of a housing. The respective vibration intensities of the vibration elements are determined on the basis of an angular difference θ between a destination direction Vn and a terminal direction Vd. The vibration elements are respectively controlled in accordance with the determined vibration intensities. The position of a vibration, which is obtained as a result of blending vibrations of the vibration elements is sensed by a user.

Owner:SONY MOBILE COMM INC

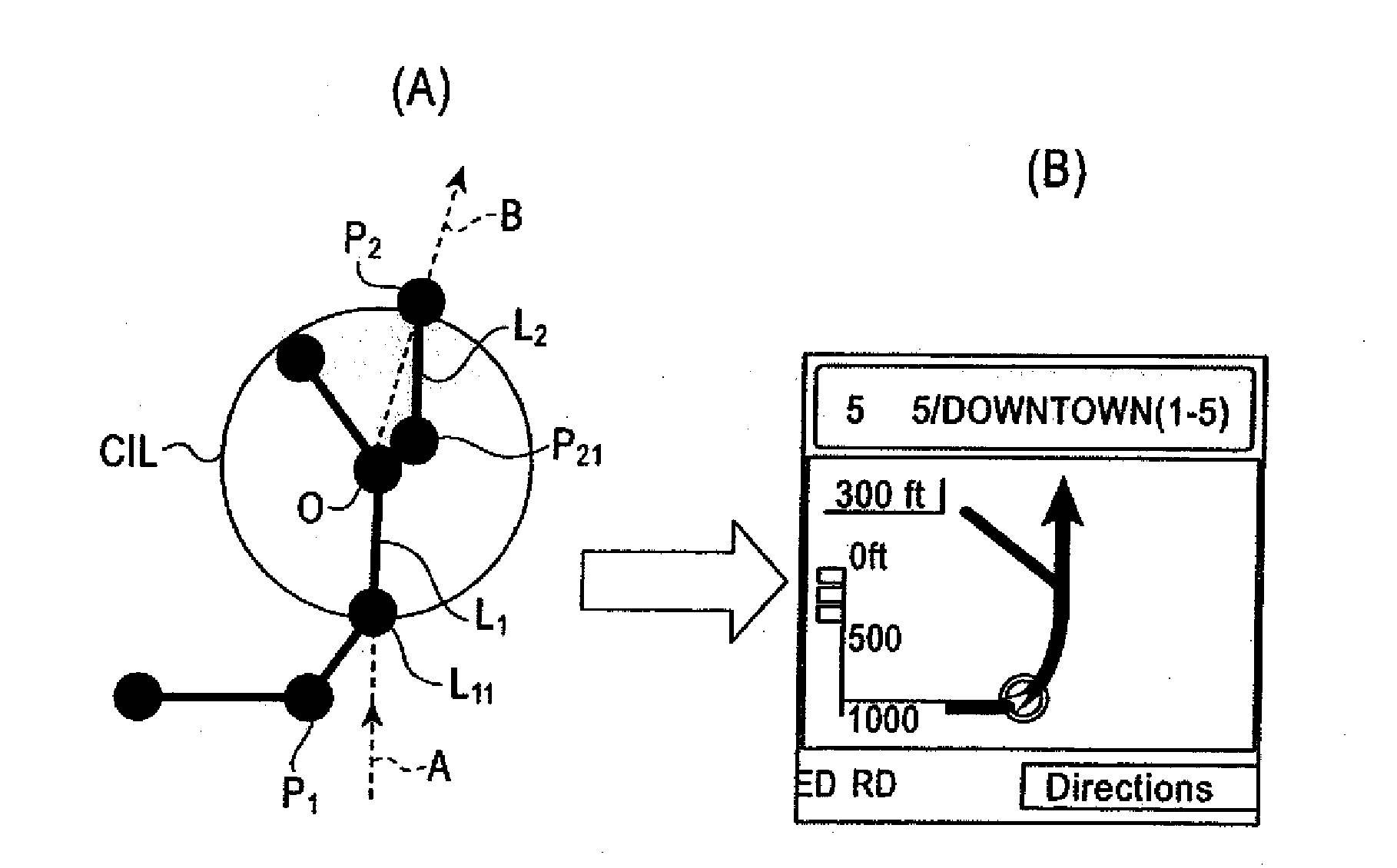

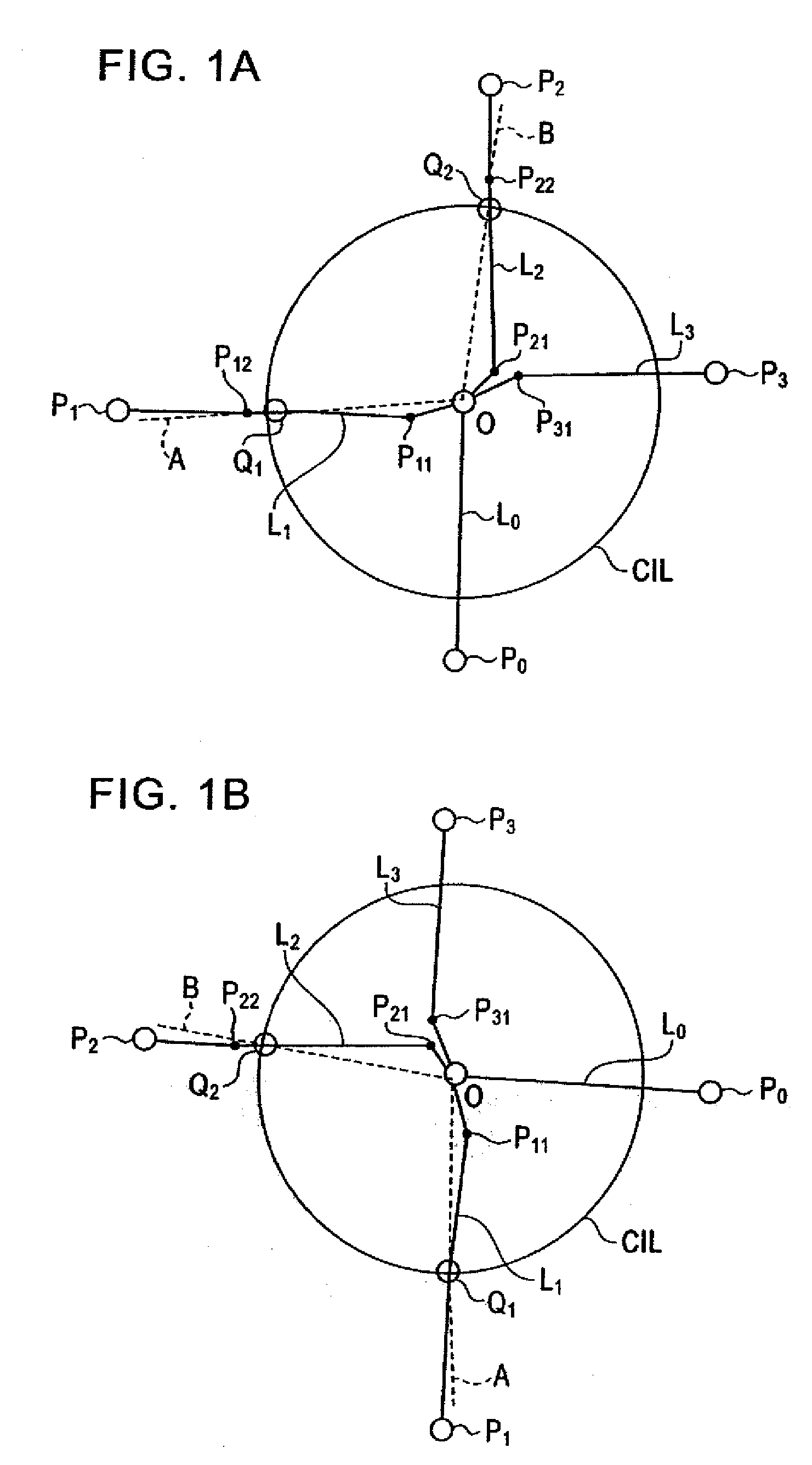

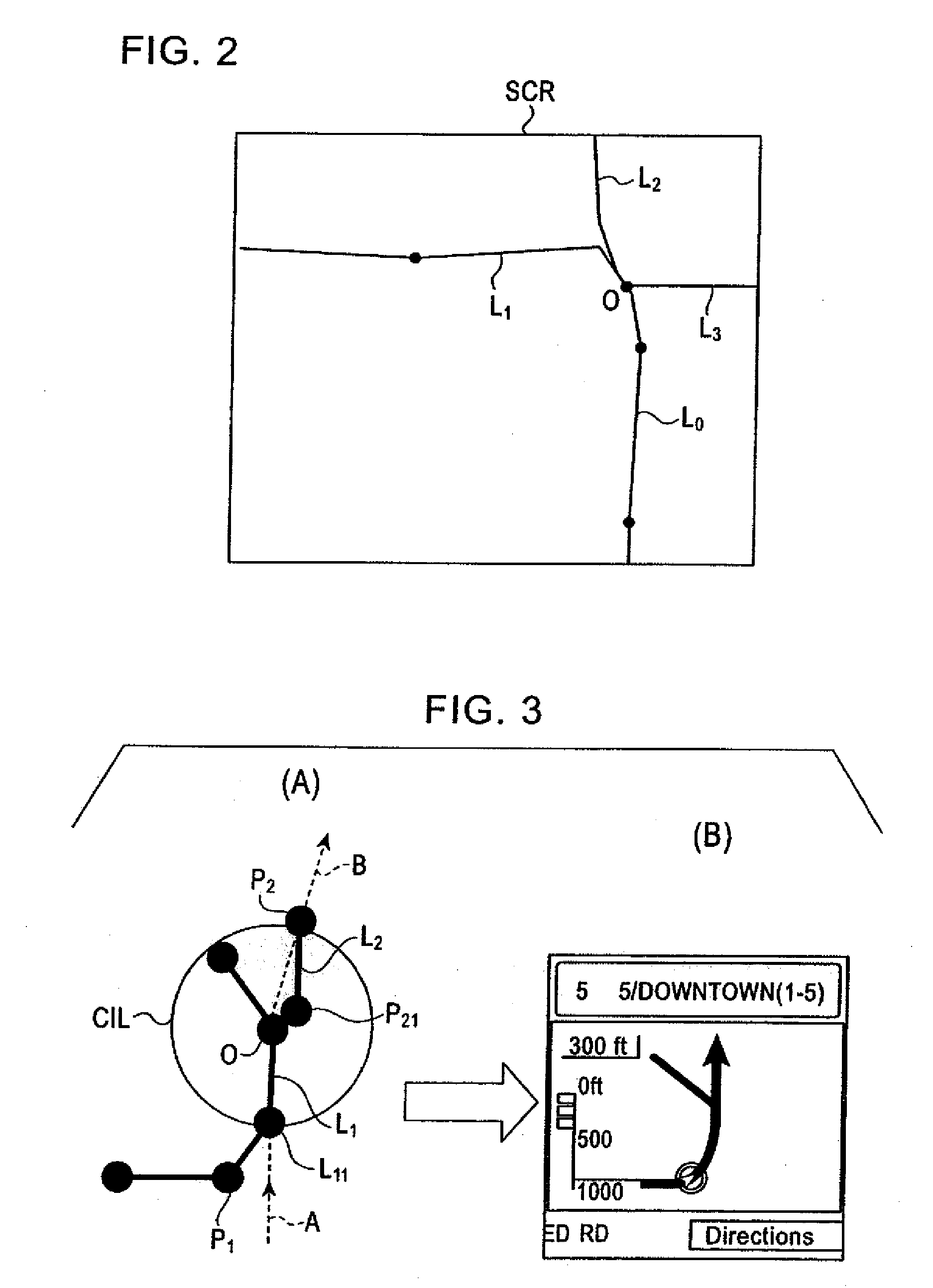

Navigation system, enlarged intersection image displaying method used in the system, and map information generating method

ActiveUS20080208466A1Accurately announcedAccurate estimateInstruments for road network navigationRoad vehicles traffic controlNavigation systemAngular difference

When a vehicle travels along a guidance path and approaches an intersection, a vehicle navigation system determines crossing points between a circle having its center set to the intersection and a predetermined radius, and an approach link and an exit link for the intersection. The system also sets a direction connecting the crossing point for the approach link and the intersection as an approach direction, and sets a direction connecting the intersection and the crossing point for the exit link as an exit direction. The system determines a traveling direction at the intersection based on an angular difference between the approach direction and the exit direction, and determines a display position of the intersection on a screen. Further, an enlarged intersection image is drawn such that the approach direction is aligned with a 12 o'clock direction on the screen.

Owner:ALPINE ELECTRONICS INC

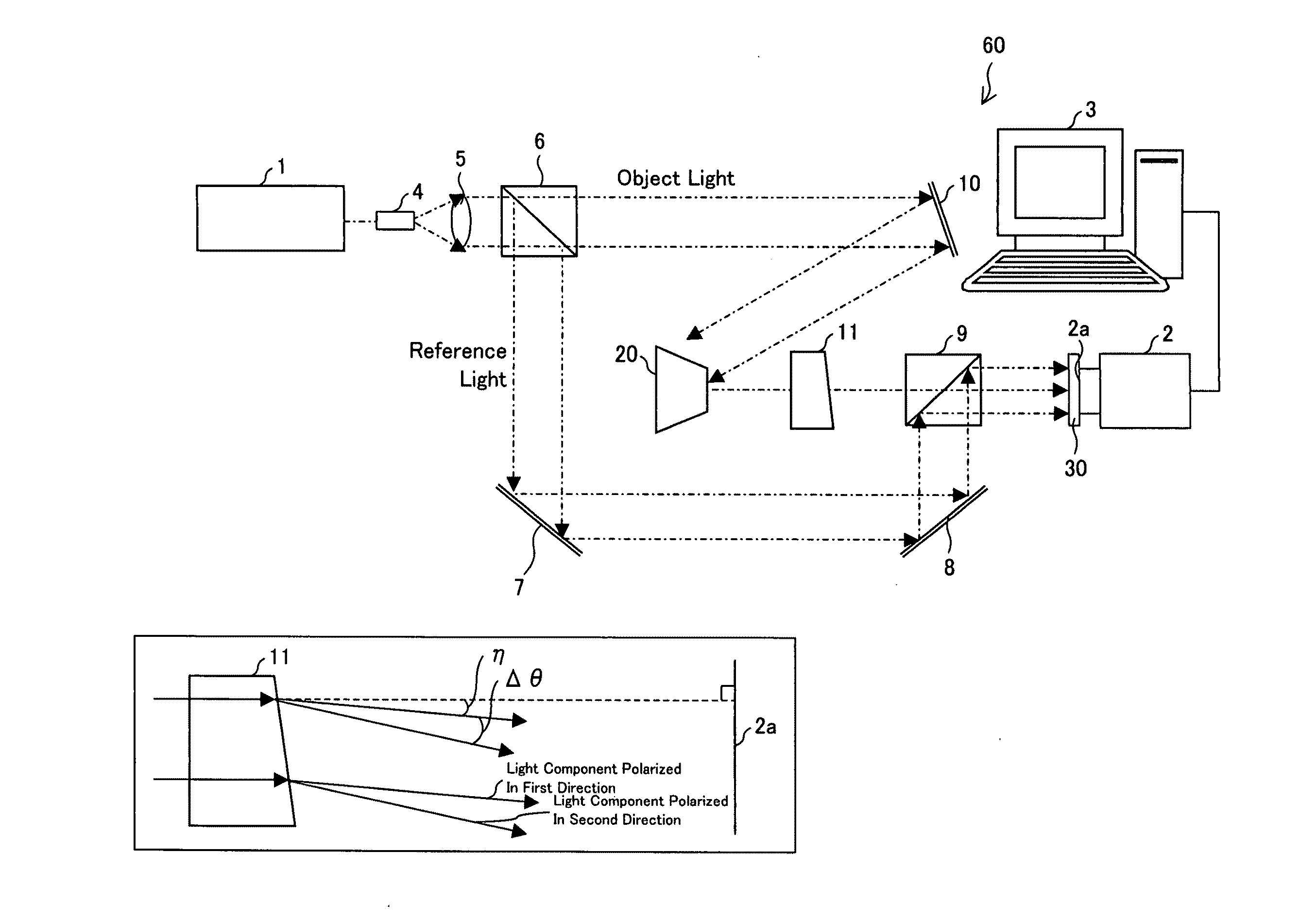

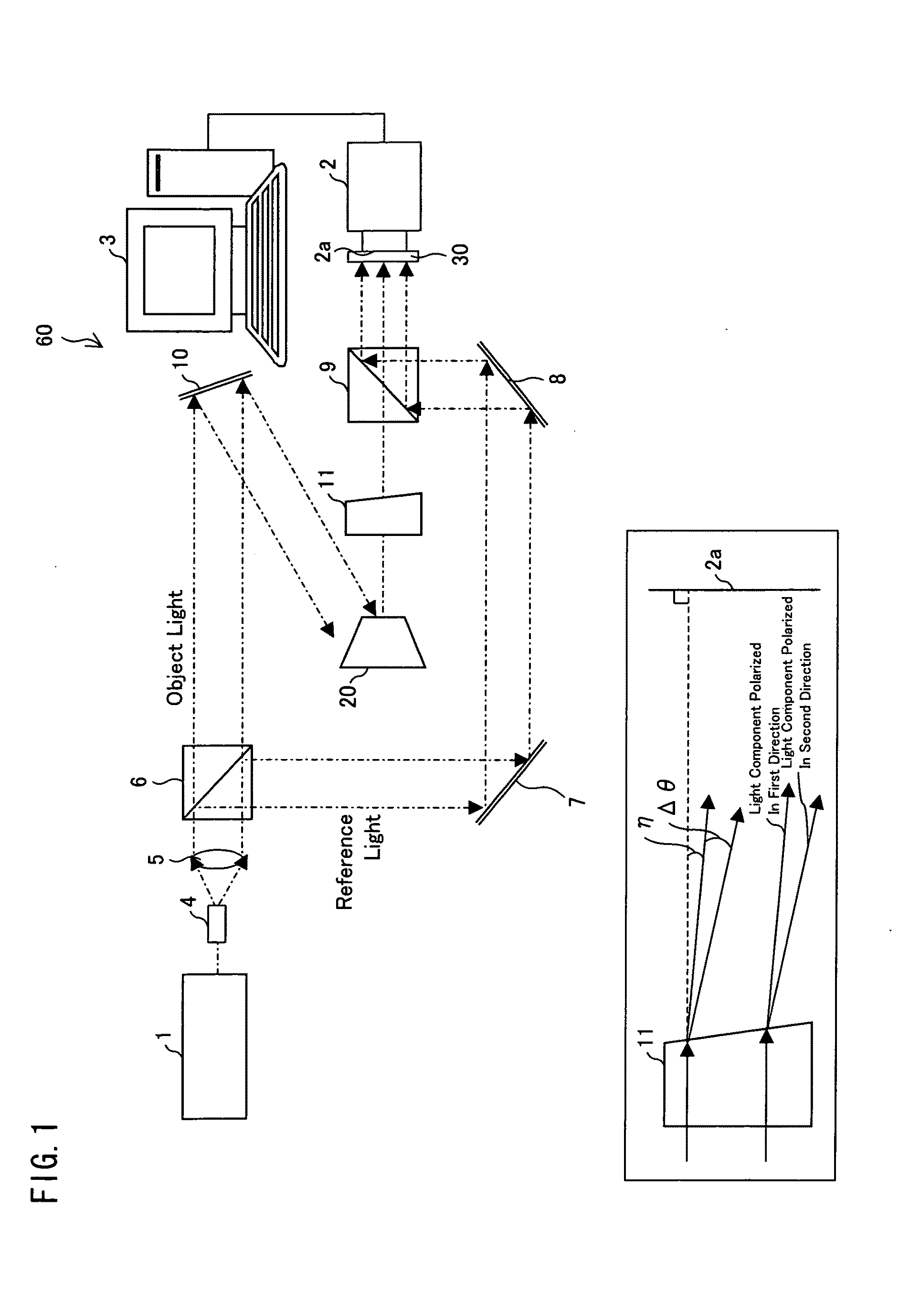

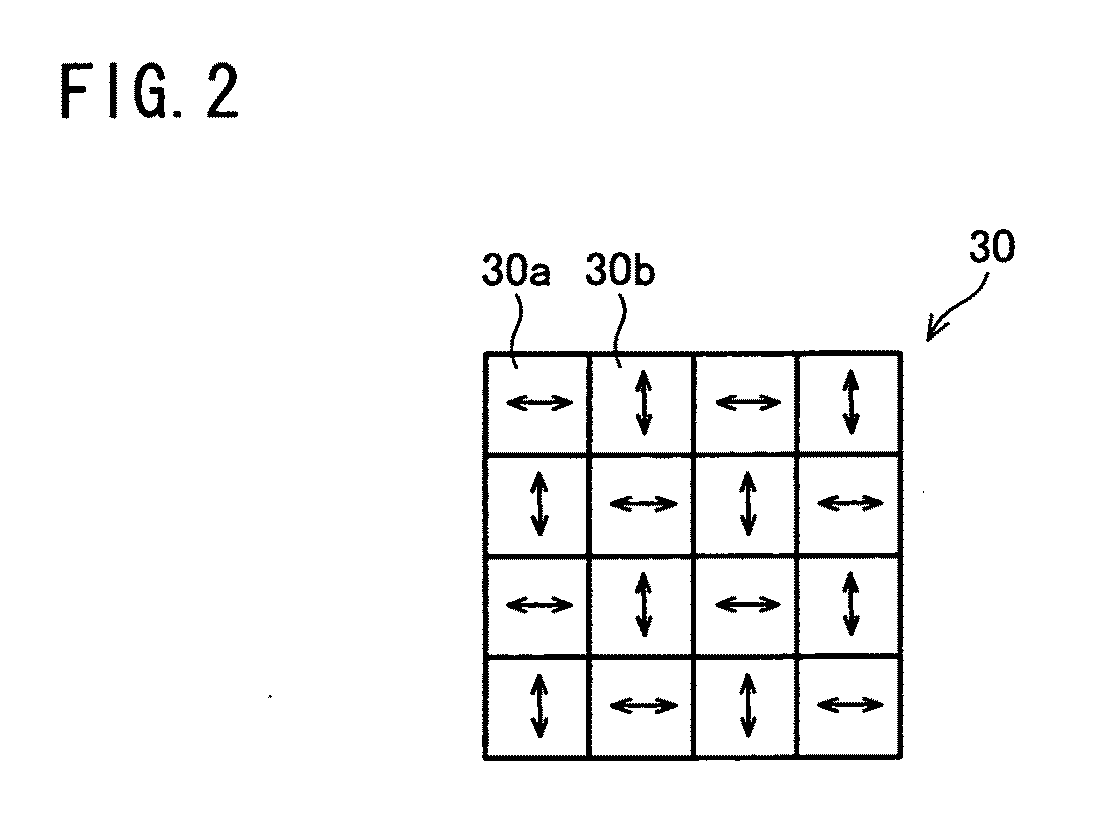

Interference measurement apparatus and method for measuring interference

InactiveUS20110292402A1Holographic light sources/light beam propertiesUsing optical meansMeasurement deviceBeam splitter

An embodiment of the present invention realizes an interference measurement apparatus which can obtain an interference image to be used for obtaining three-dimensional information of a subject which dynamically changes. An interference measurement apparatus of the present invention, which captures an interference image formed by the reference light beam and the object light beam which has reached the image-capturing element via a subject, the interference measurement apparatus includes: a laser light source; a beam splitter which splits a laser beam into a reference light beam and an object light beam; and an image-capturing element; a polarization splitting section which splits the object light beam into two types of object light beams which are different in polarization direction so that an angular difference is caused between respective propagation directions of the two types of object light beams; and a polarizer array device which allows (i) the reference light beam and (ii) the two types of object light beams which have reached the polarizer array device via the subject to pass through the polarizer array device (30), the polarizer array device in which a plurality of first polarizer regions and a plurality of second polarizer regions are arranged, and each of the plurality of first polarizer regions and each of the plurality of second polarizer regions respectively allowing light components which are different in polarization direction. This makes it possible to obtain, by one-time image capturing, a plurality of interference patterns required for phase unwrapping.

Owner:NAT UNIV KYOTO INST OF TECH

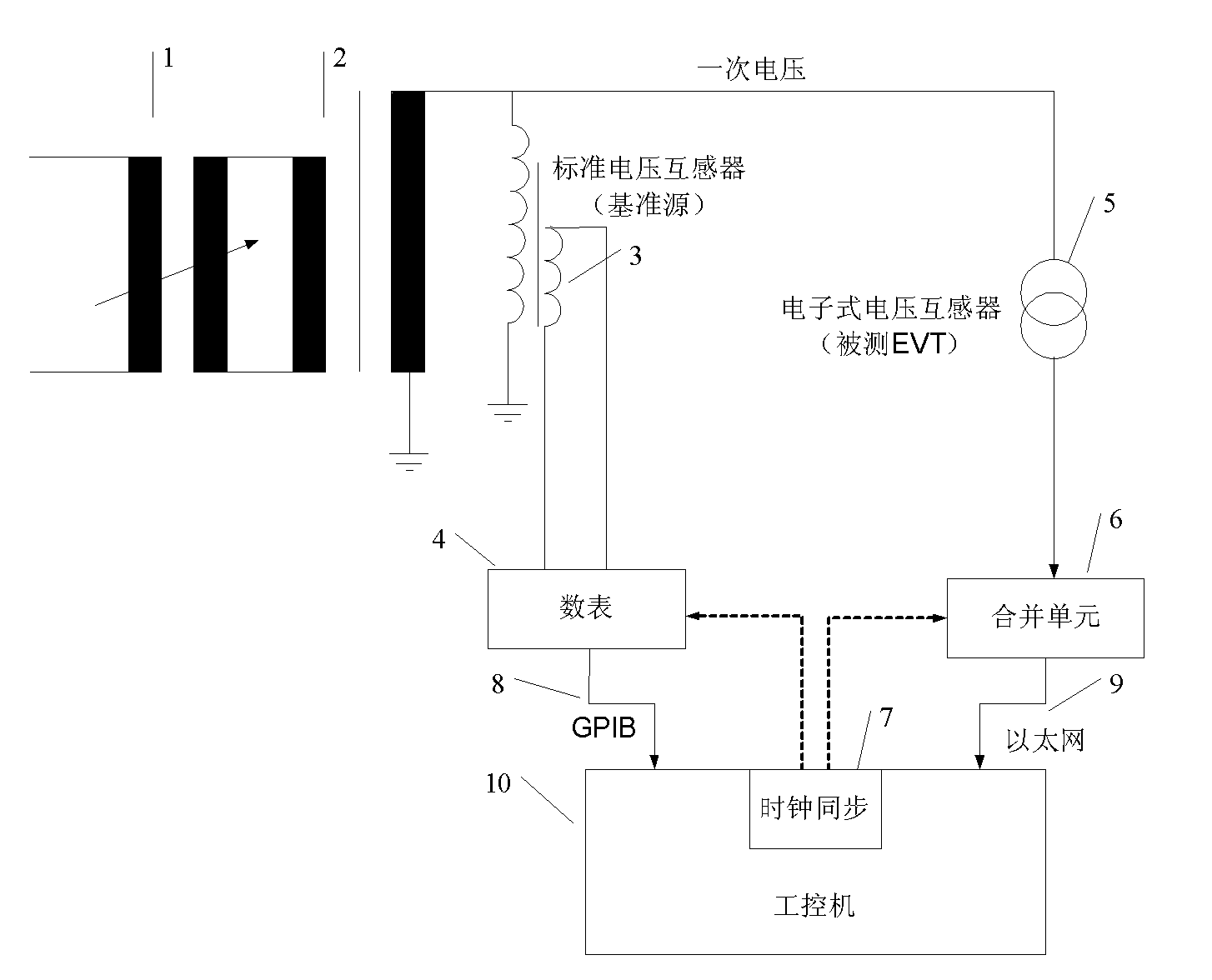

Electronic type transformer checking system

InactiveCN101806876AHigh measurement accuracyImprove stabilityElectrical measurementsPersonal computerEngineering

The invention provides an electronic type transformer checking system, comprising a voltage regulator, a current booster (or a pressure booster), a standard CT (Current Transformer) or a standard PT (Pressure Transformer), a numerical table, an electronic type current transformer (or an electronic type voltage transformer), a merge unit, a synchronous clock circuit and an industrial personal computer. The numerical table acquires a current measurement value of a standard CT or a voltage measurement value of the standard PT), and the merge unit acquires a current measurement value of the electronic type current transformer (or a voltage measurement value of the electronic type voltage transformer). The measurement results acquired by the numerical table and the measurement results acquired by the merge unit are sent to the computer synchronously, and the computer calculates ratio difference and angular difference. The invention has the advantages of high precision, good stability and tracing basis, and can be applied to checking electronic type transformers with high precision.

Owner:HUAZHONG UNIV OF SCI & TECH

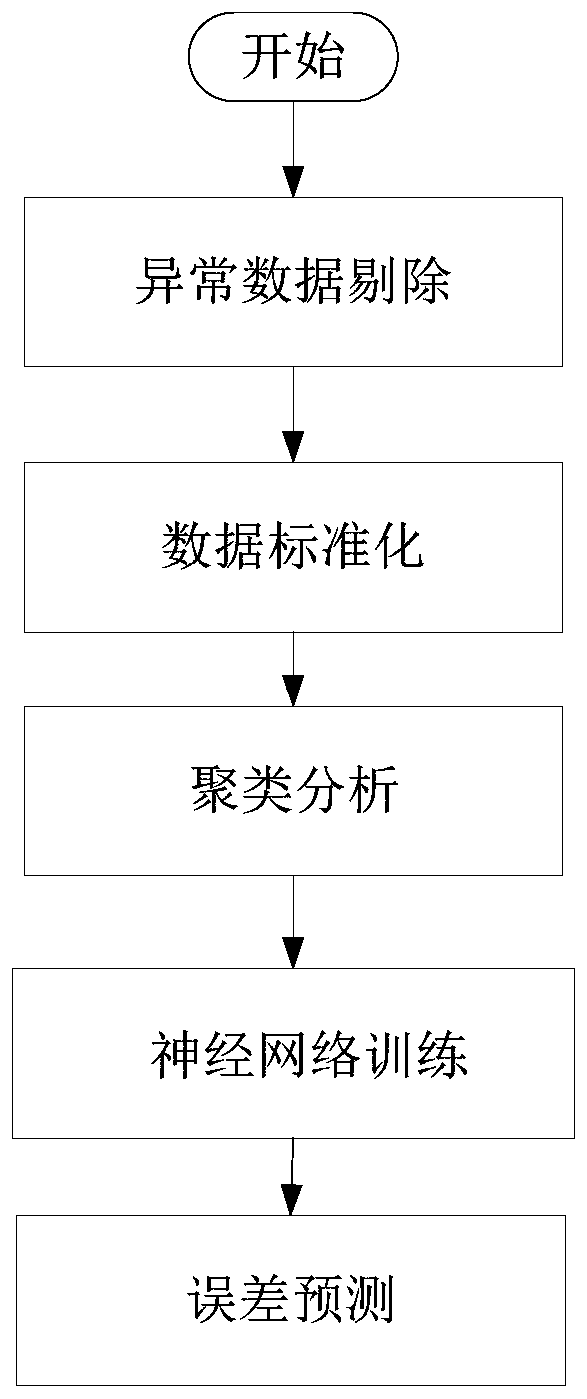

Electronic transformer error prediction method

ActiveCN110095744ASolve the problem that there is no definite functional relationshipRealize online estimationElectrical measurementsTransformerDeterministic function

The invention discloses an electronic transformer error prediction method. The method comprises: collecting error data and environmental parameter data of an electronic transformer to generate sampledata and rejecting abnormal data among the collected data; on the basis of a Z-score standardization method, carrying out standardization processing on the sample data; carrying out clustering processing on historical data of environmental parameters and establishing an electronic transformer error prediction model by training and learning; and according to the environmental parameter values, predicting a ratio error and an angular difference of the electronic transformer based on a prediction model. The method has the following advantages: no physical model needs to be established; on the basis of the multi-dimensional data driving method, the online estimation of the electronic transformer error can be realized according to the error data and environmental parameter data of the electronic transformer, so that a problem that no deterministic function relation exists between the error and the environmental parameter of the electronic transformer is solved and the accuracy of electronictransformer error prediction is improved.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +5

Digital image stabilization device and method

ActiveUS20120162450A1Improve efficiencyEfficient processingImage enhancementTelevision system detailsSorting algorithmMotion vector

A method of Digital Image Stabilization (DIS) including a feature point sorting algorithm for selecting optimal feature points, and a computationally efficient tile-vector based Hierarchical Block-Matching search algorithm for deriving motion vectors of the selected feature points, and a feature point motion vector grouping / comparison process for grouping pairs of the selected feature points based on their vector magnitude ratio and their angular difference.

Owner:SAMSUNG ELECTRONICS CO LTD

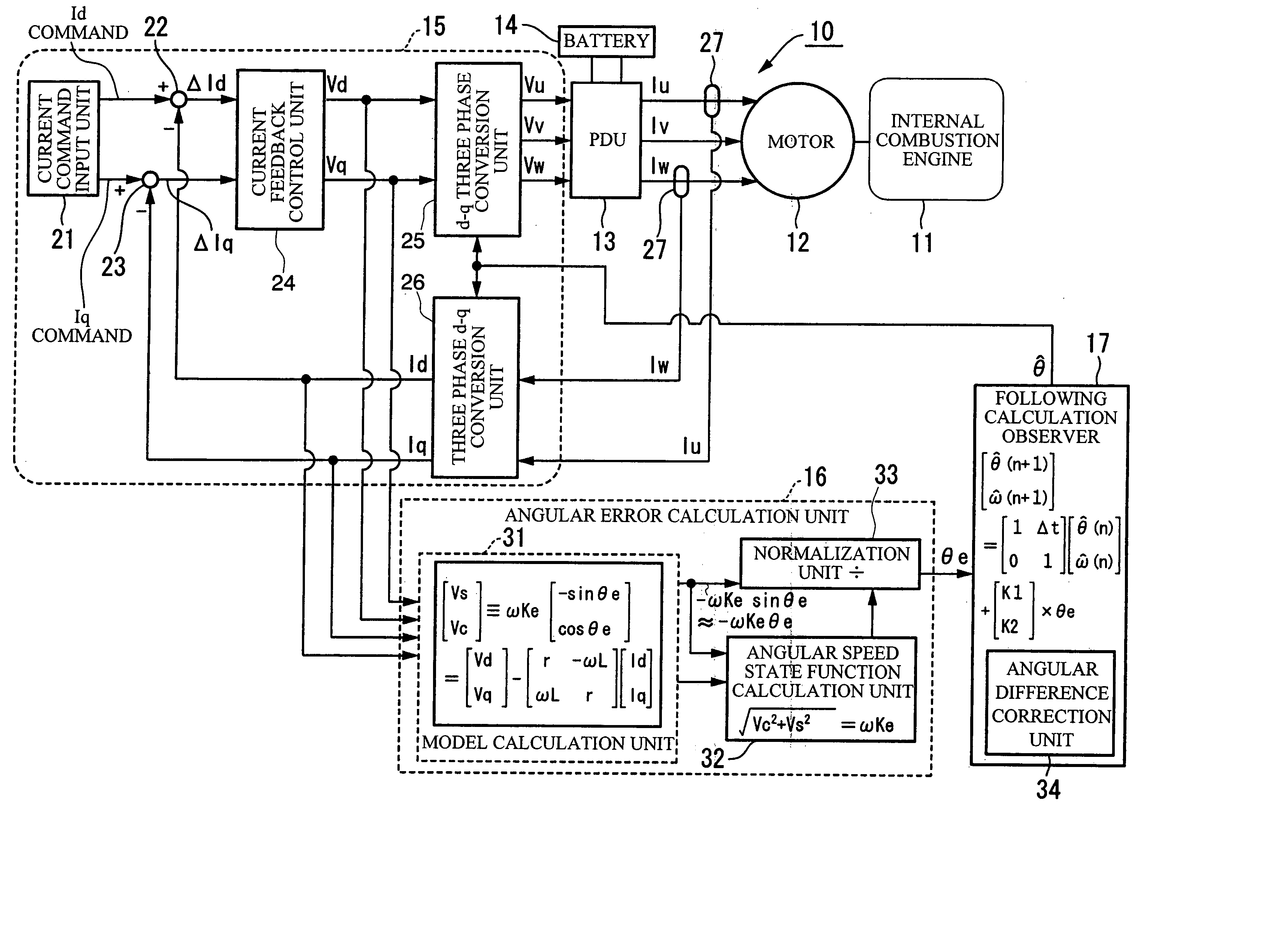

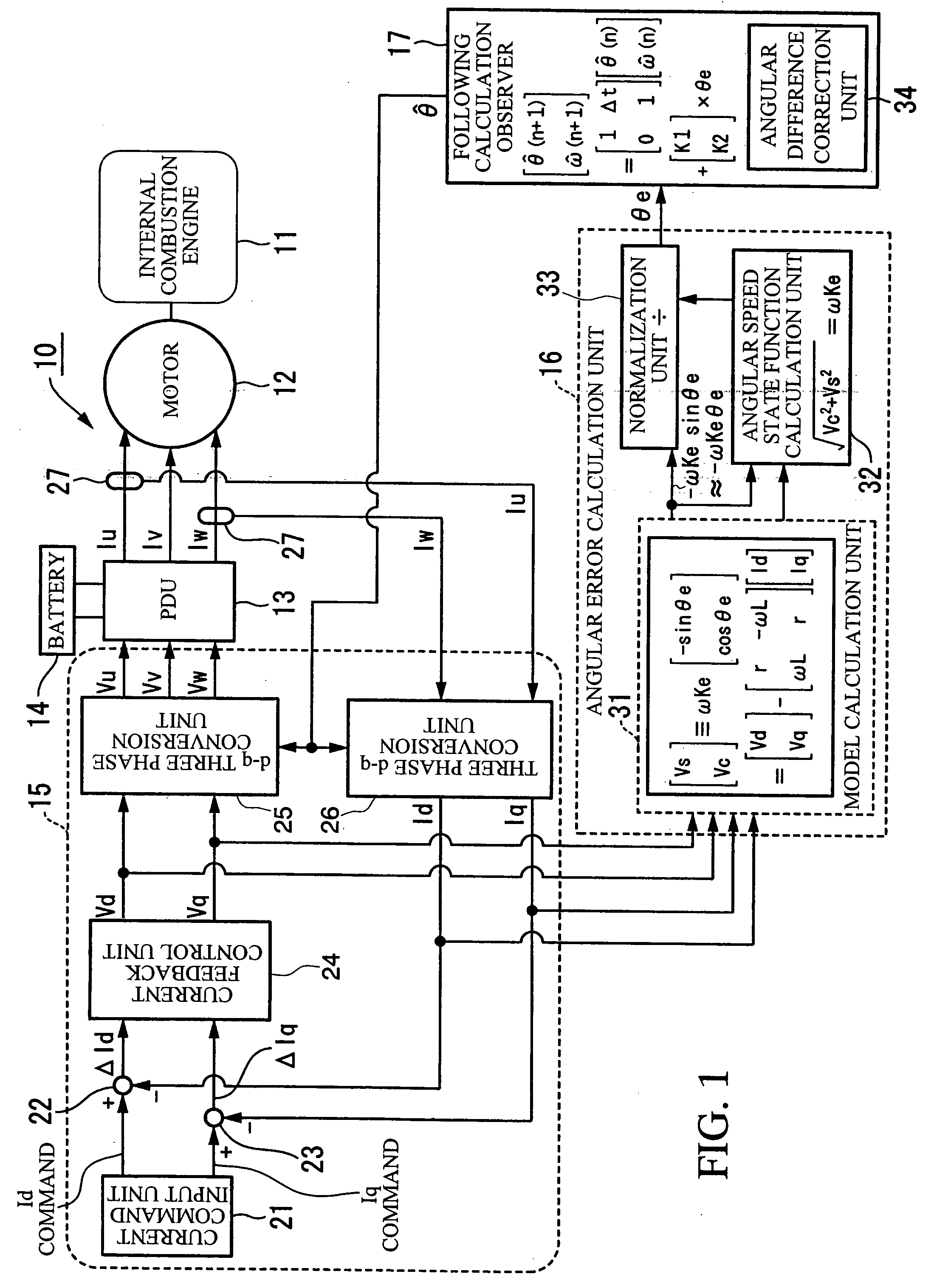

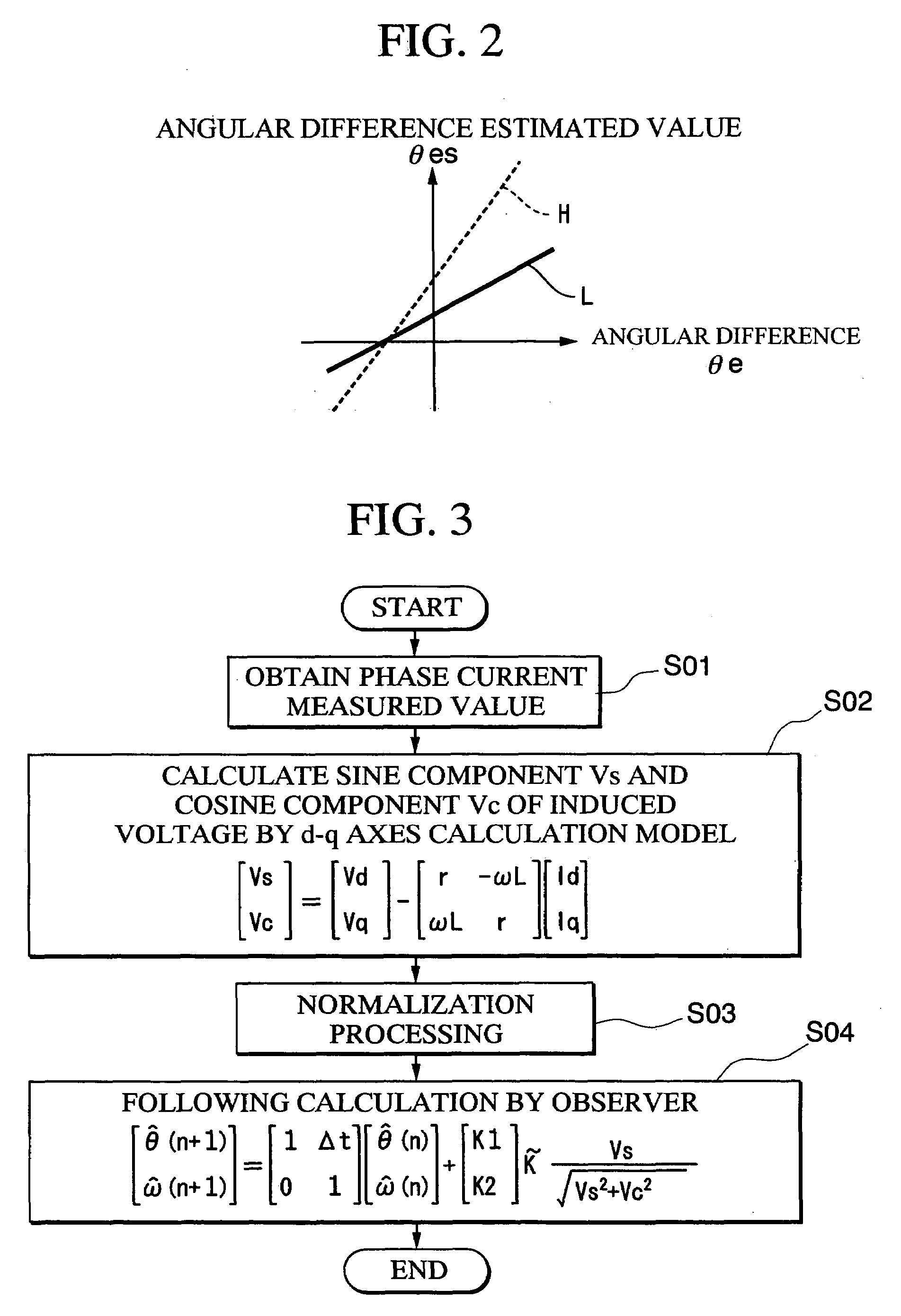

Control apparatus for brushless DC motor

ActiveUS7064504B2Improve estimation accuracySynchronous motors startersVector control systemsPhase currentsConductor Coil

A control apparatus for a brushless DC motor that rotatably drives the brushless DC motor including a rotor having a permanent magnet, and a stator having stator windings of a plurality of phases that generate a rotating magnetic field for rotating the rotor, by a current passage switching device constituted by a plurality of switching elements and performing successive commutation of current to the stator windings. The control apparatus includes: an angular error calculation device for calculating a sine value and a cosine value of an angular difference between an estimated rotation angle with respect to the rotation angle of the rotor and an actual rotation angle, based on a line voltage that is a difference between phase voltages of the plurality of phases on an input side of the stator winding and phase currents of the plurality of phases; and an observer for calculating the rotation angle of the rotor based on the sine value and the cosine value of the angular difference.

Owner:HONDA MOTOR CO LTD

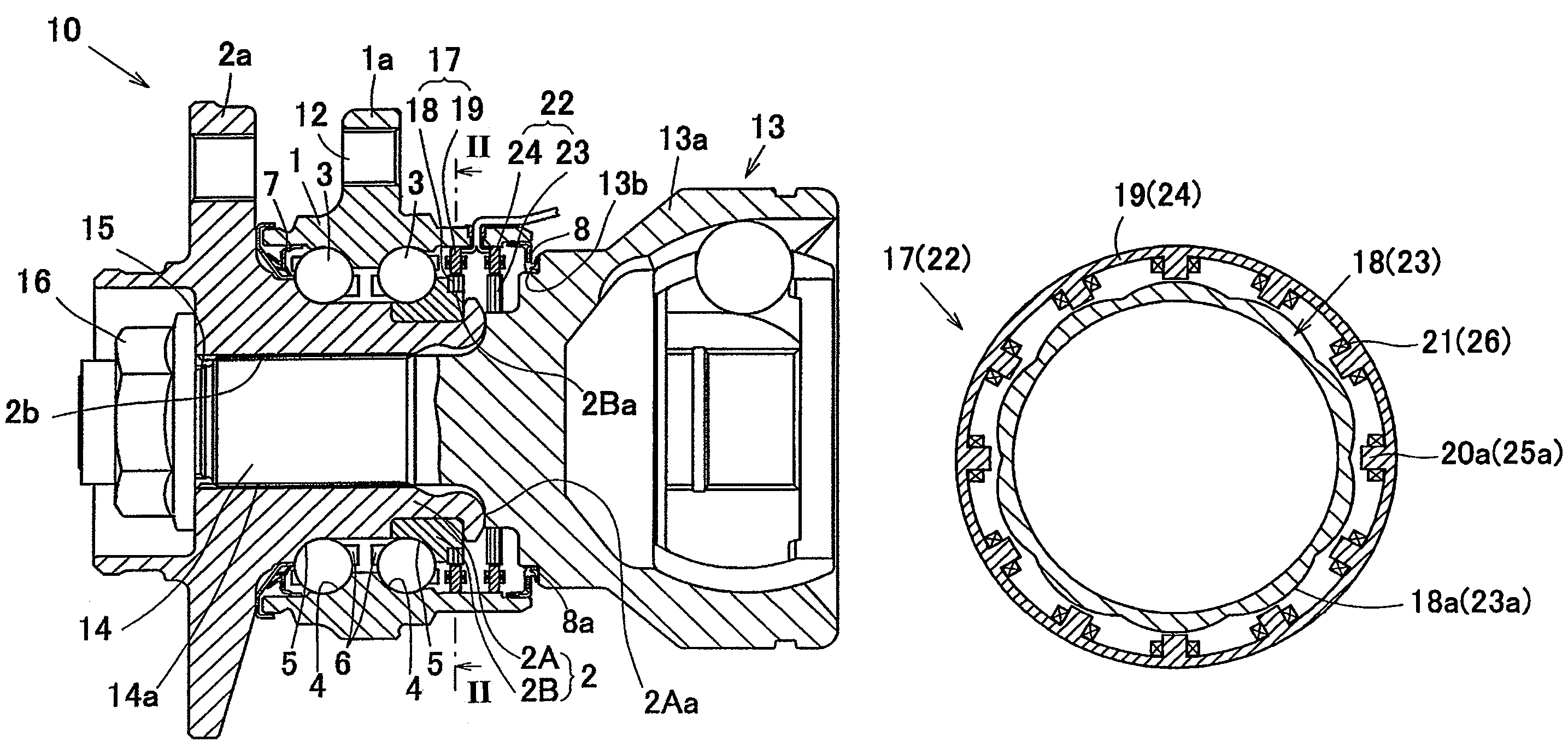

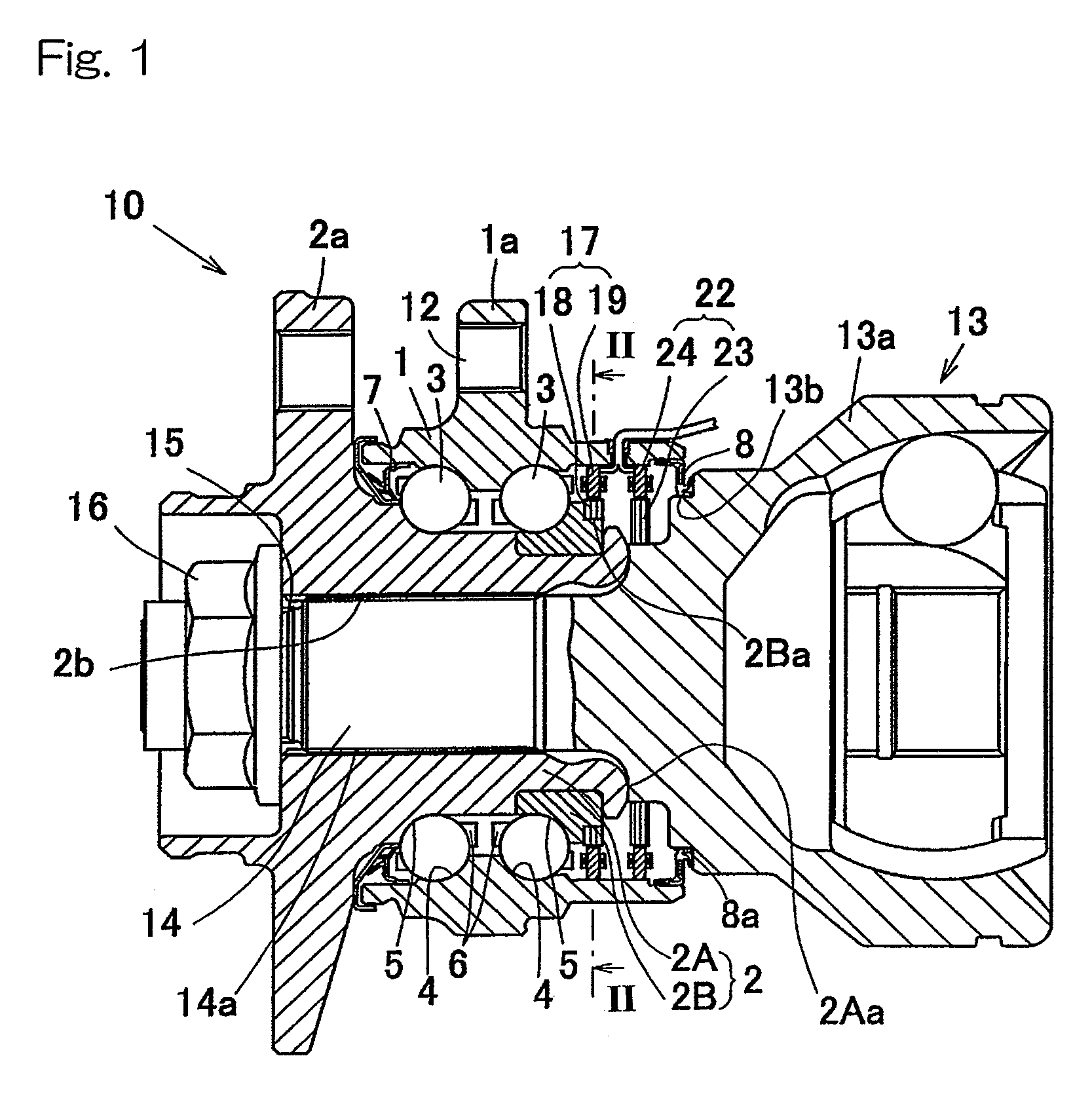

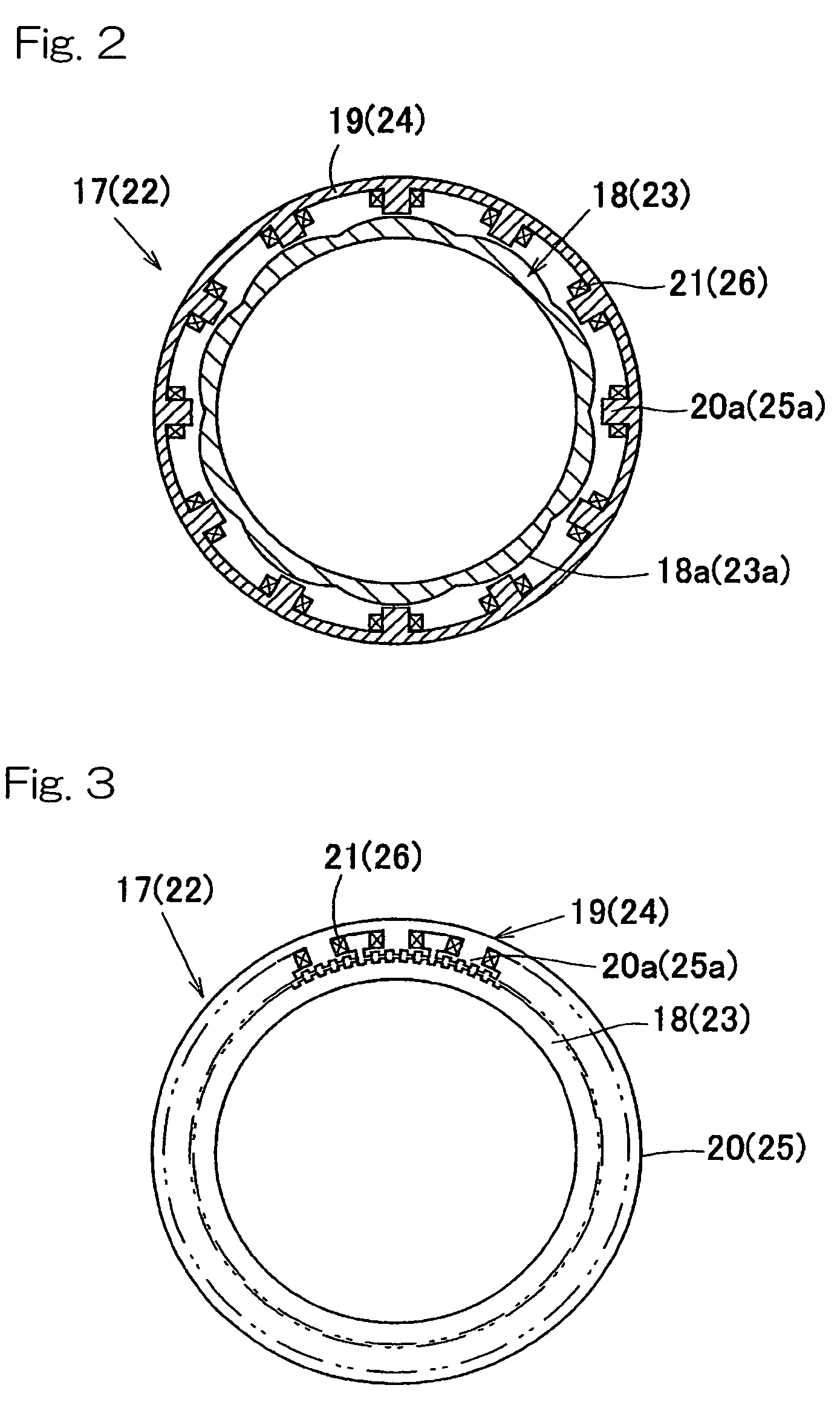

Wheel support bearing assembly with built-in load sensor

ActiveUS7604413B2Accurate detectionCompact installationRoller bearingsBearing assemblyUniversal jointEngineering

A wheel support bearing assembly comprises a stationary outer member and a rotatable inner member. The to-be-detected parts of angle detection sensors are fixed to the inner member and an outer race of a constant velocity joint connected to the inner member, respectively. Detecting parts of the angle detection sensors are fixed to the outer member in face-to-face relation with the to-be-detected parts. The bearing assembly also includes a load conversion unit detecting a relative angular difference between the inner member and the constant velocity universal joint by comparing the detection signals from the detecting parts to detect the load acting on the bearing assembly.

Owner:NTN CORP

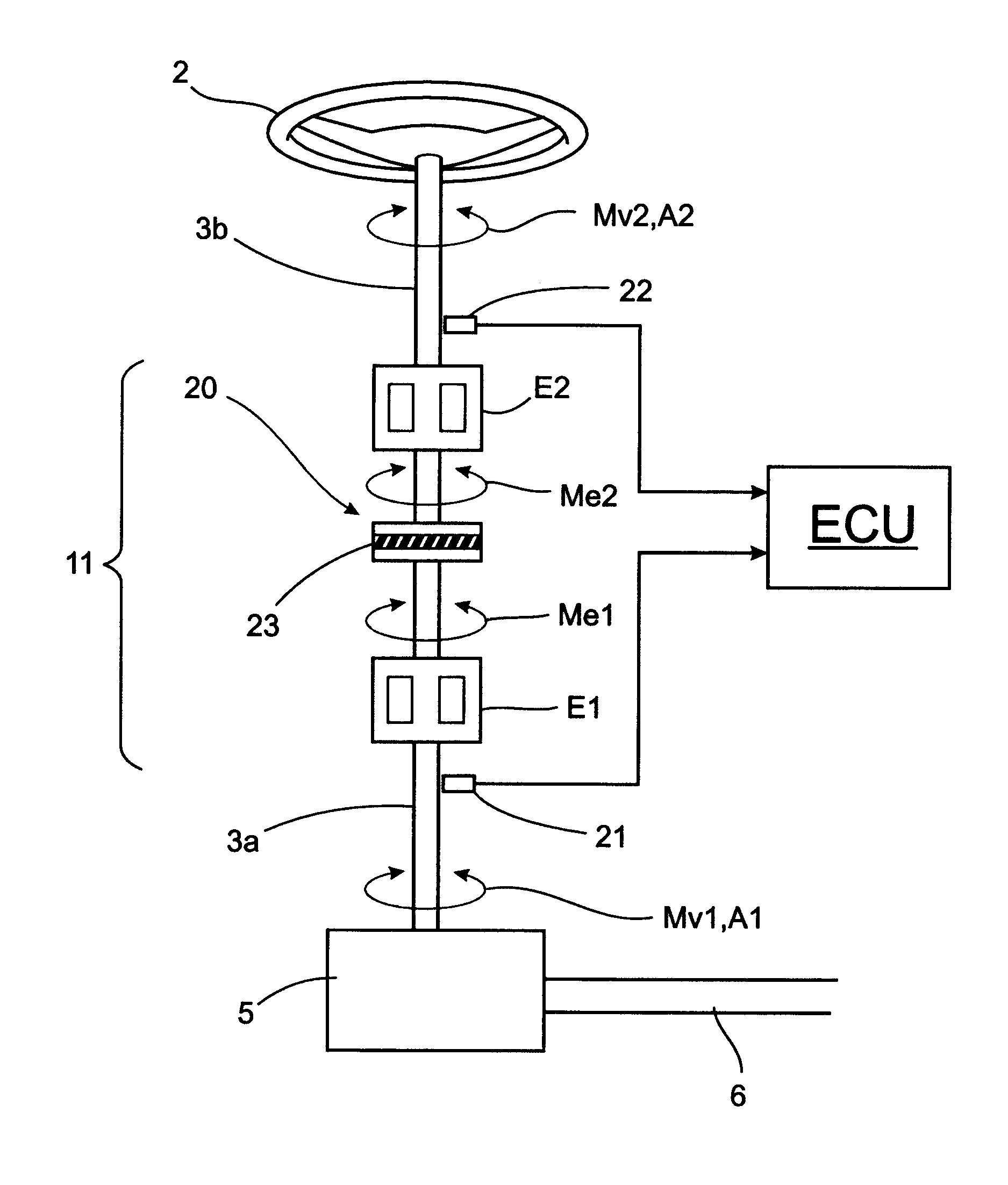

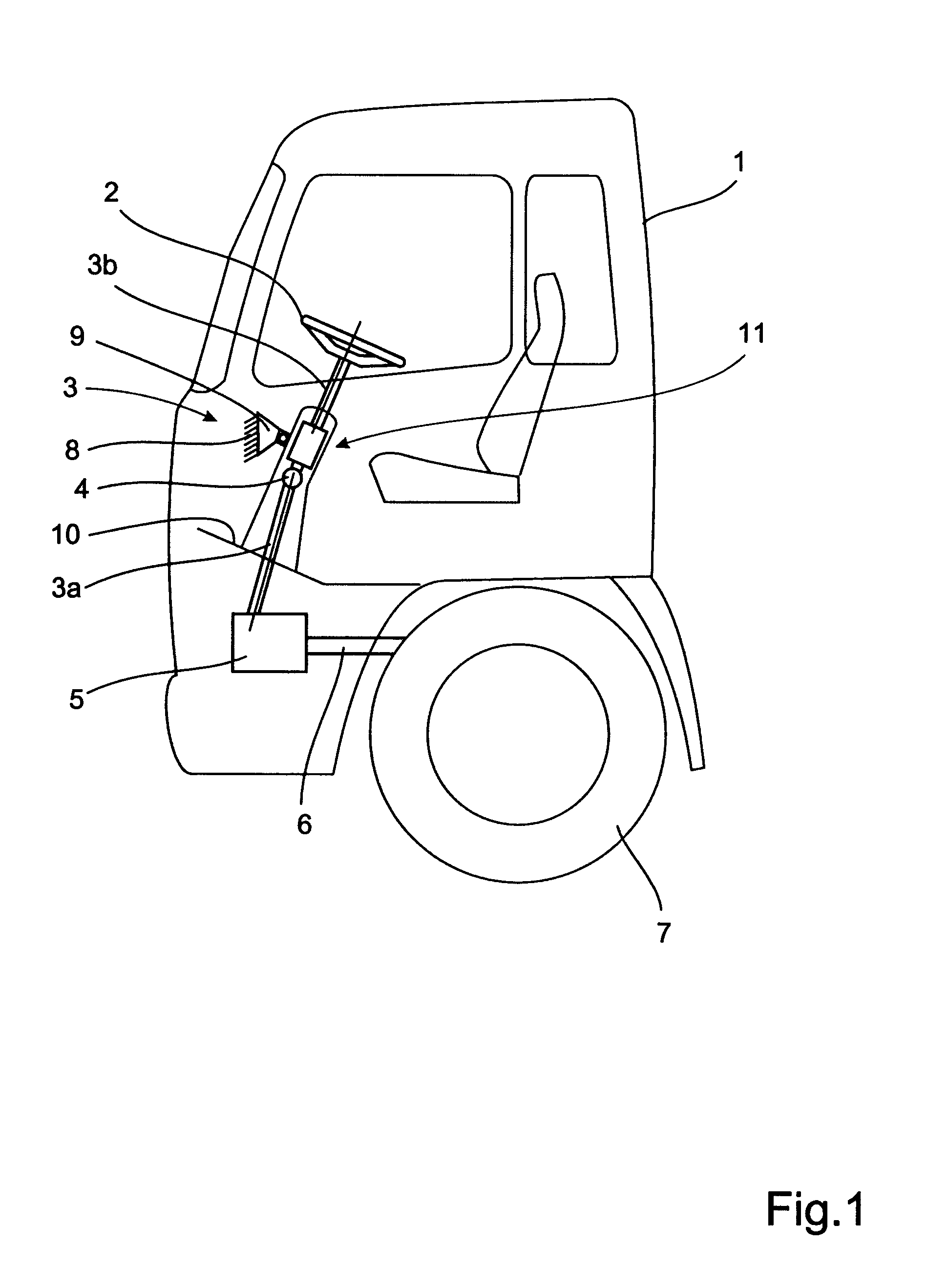

Method and arrangement for an electrical steering system

ActiveUS20150329141A1Much effortShorten speedSteering initiationsDigital data processing detailsSteering angleDriver/operator

A method and an arrangement for assisting a driver of a vehicle during operation by providing the driver with a desired steering feel, wherein the vehicle includes a steering arrangement including an input shaft connected to a manually operated steering device, an output shaft connected to at least one pair of ground engaging members and a mechanical interconnection connecting the output shaft and the input shaft. The method involves detecting a first steering angle for the output shaft, which first steering angle indicates the position of the ground engaging members; detecting a second steering angle for the input shaft, which second steering angle indicates the position of the steering device; comparing the first and second steering angles and determining a current state of the steering arrangement; and controlling a first actuator connected to the output shaft and a second actuator connected to the input shaft in response to the detected first and second steering angles, in order to achieve a desired state of the steering arrangement; and applying a torque to the steering device proportional to the angular difference between the output shaft and the input shaft using a resilient portion in the mechanical interconnection, in order to provide the driver with a desired steering feel.

Owner:VOLVO LASTVAGNAR AB

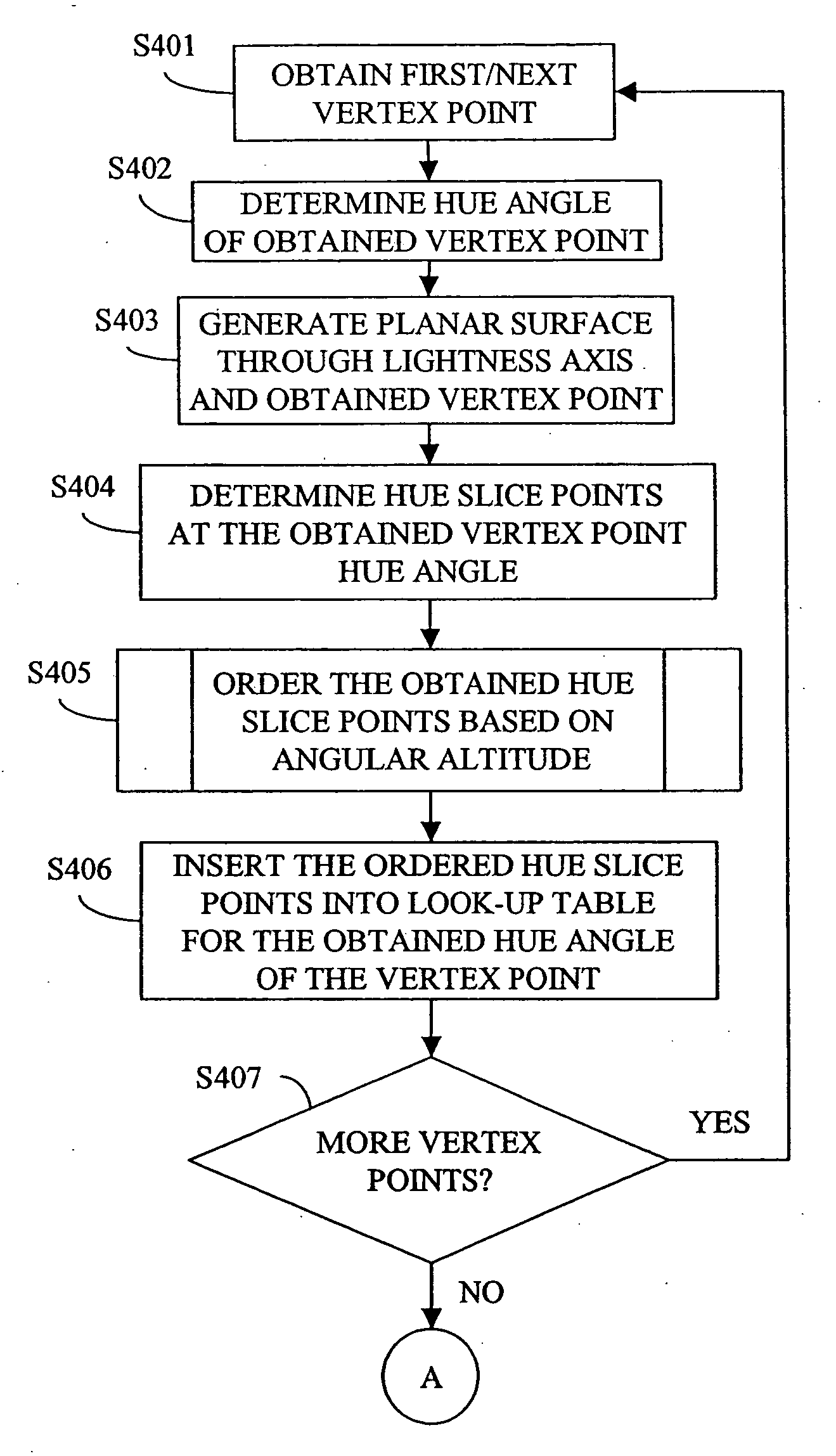

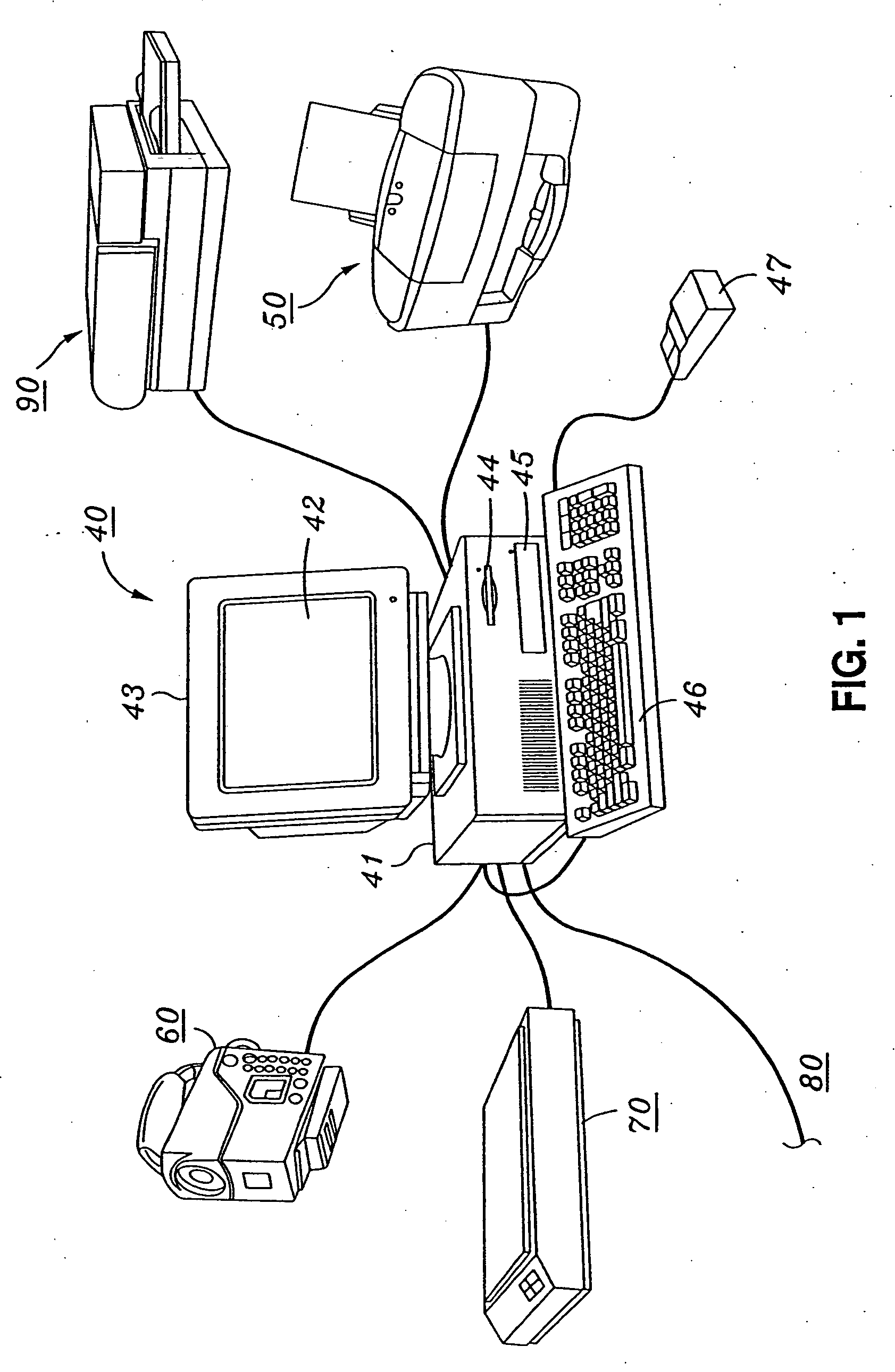

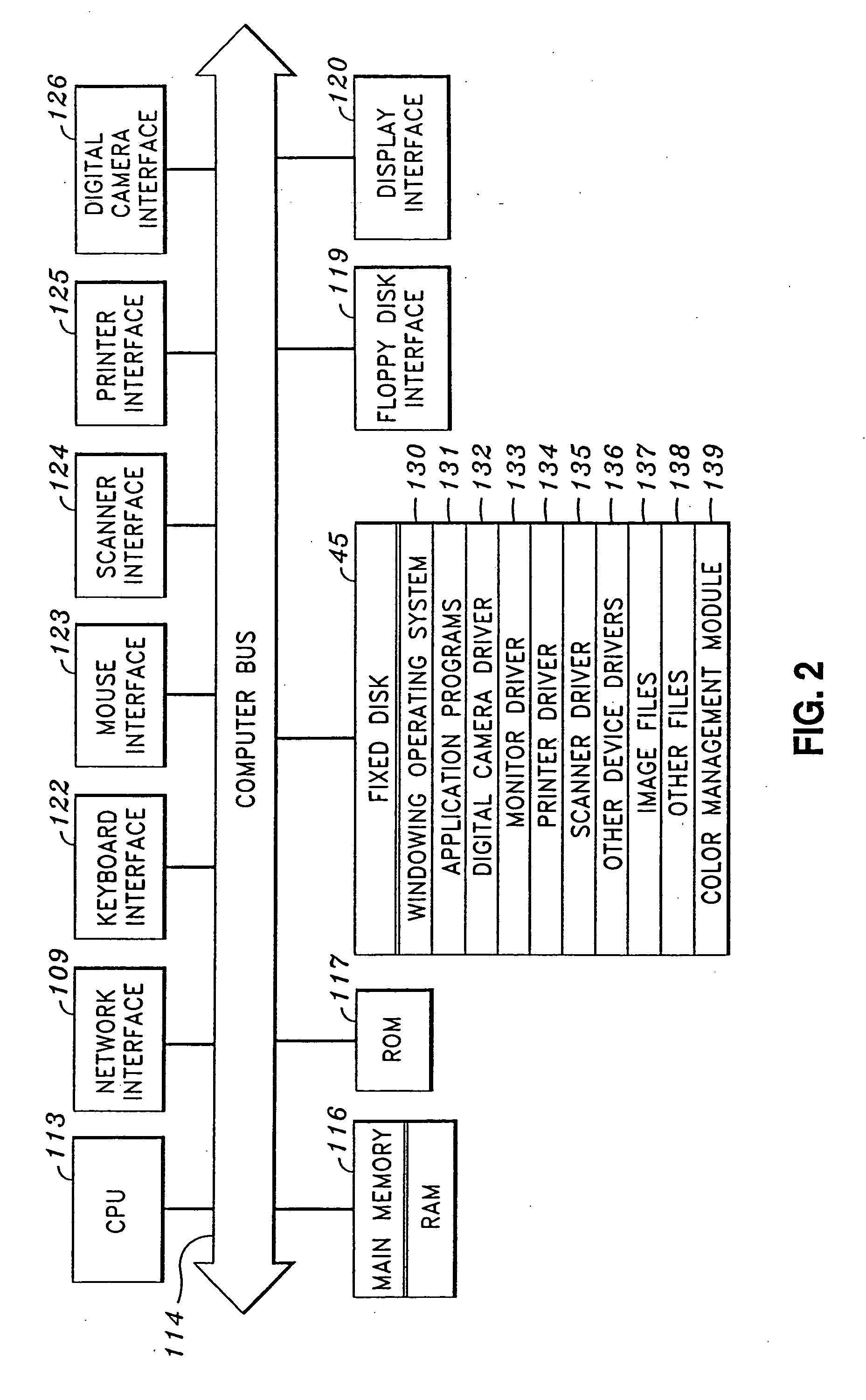

Generation of hue slice table for gamut mapping

InactiveUS20060170999A1Accurate representationDigitally marking record carriersColor signal processing circuitsGamutVertex point

A table representing a color gamut for a device for use in a color management system where colors are represented in a color appearance space comprises data representing a collection of hue slices through a boundary surface of the color gamut. The collection of hue slices comprises entries for vertex point hue slices obtained at each vertex point on the boundary surface of the color gamut, and entries obtained for additional hue slices between adjoining vertex point hue slices, where a number of the additional hue slices is determined such that there is no more than a specified angular difference between each hue slice. Each hue slice is represented by a hue value and a collection of hue slice points each containing a lightness value and a chroma value. The hue slice points of each hue slice are ordered in the table based on an angular altitude of each point, the angular altitude of each point being determined between a lightness axis of the color gamut and a vector projected from a midpoint of the lightness axis to the hue slice point.

Owner:CANON KK

On-site calibrating method and device of capacitor voltage transformer

ActiveCN101556320AReduce labor intensityShorten test timeElectrical measurementsInstrument transformerSecondary side

The invention relates to an on-site calibrating method and an on-site calibrating device of a capacitor voltage transformer. The invention directly measures voltage and current signals at the primary side and the secondary side of the measured capacitor voltage transformer and calculates the ratio and angular differences of the measured capacitor voltage transformer by utilizing the measured result, so that the invention can realize separately measuring the error of the measured capacitor voltage transformer only by the on-site calibrating device of the capacitor voltage transformer and does not need equipment such as a standard transformer, a voltage regulator, a voltage booster, a reactor and the like, thus saving calibrating time, lowering labor intensity of workers and resolving the difficulty of difficult implementation for error test of the on-site capacitor voltage transformer.

Owner:RED PHASE INC

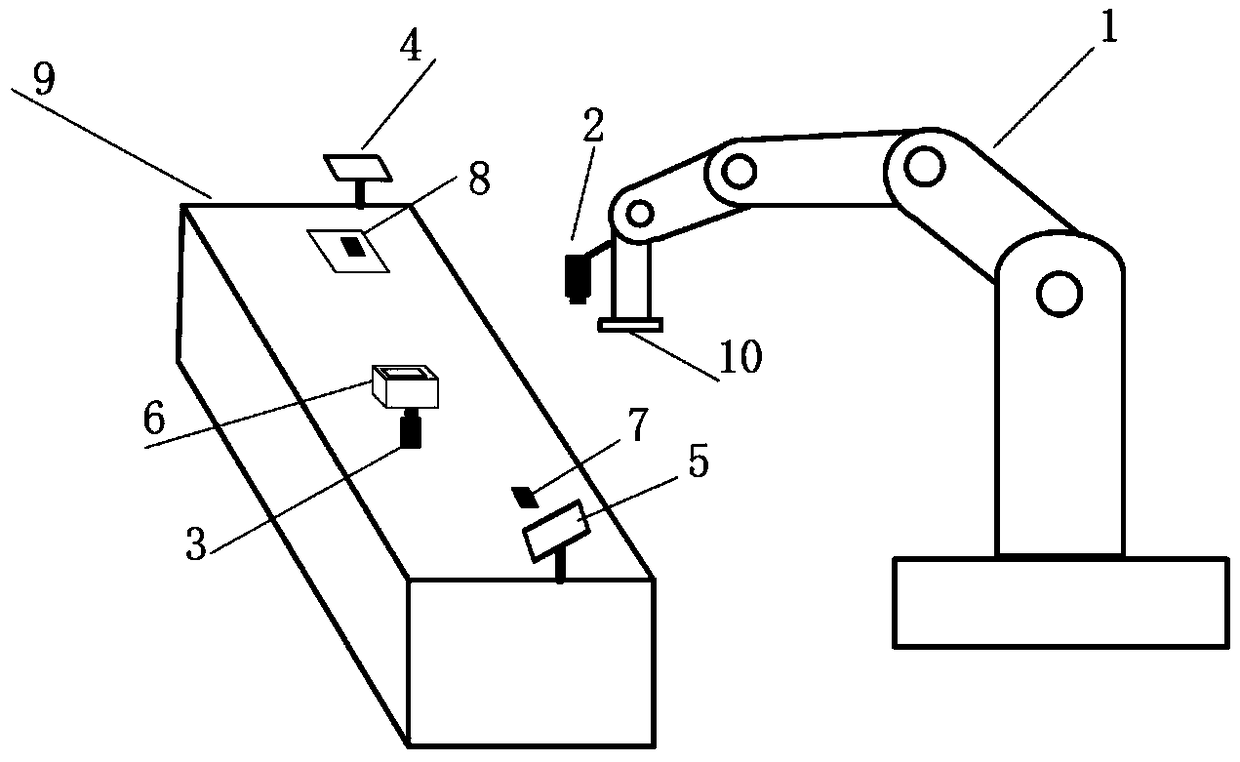

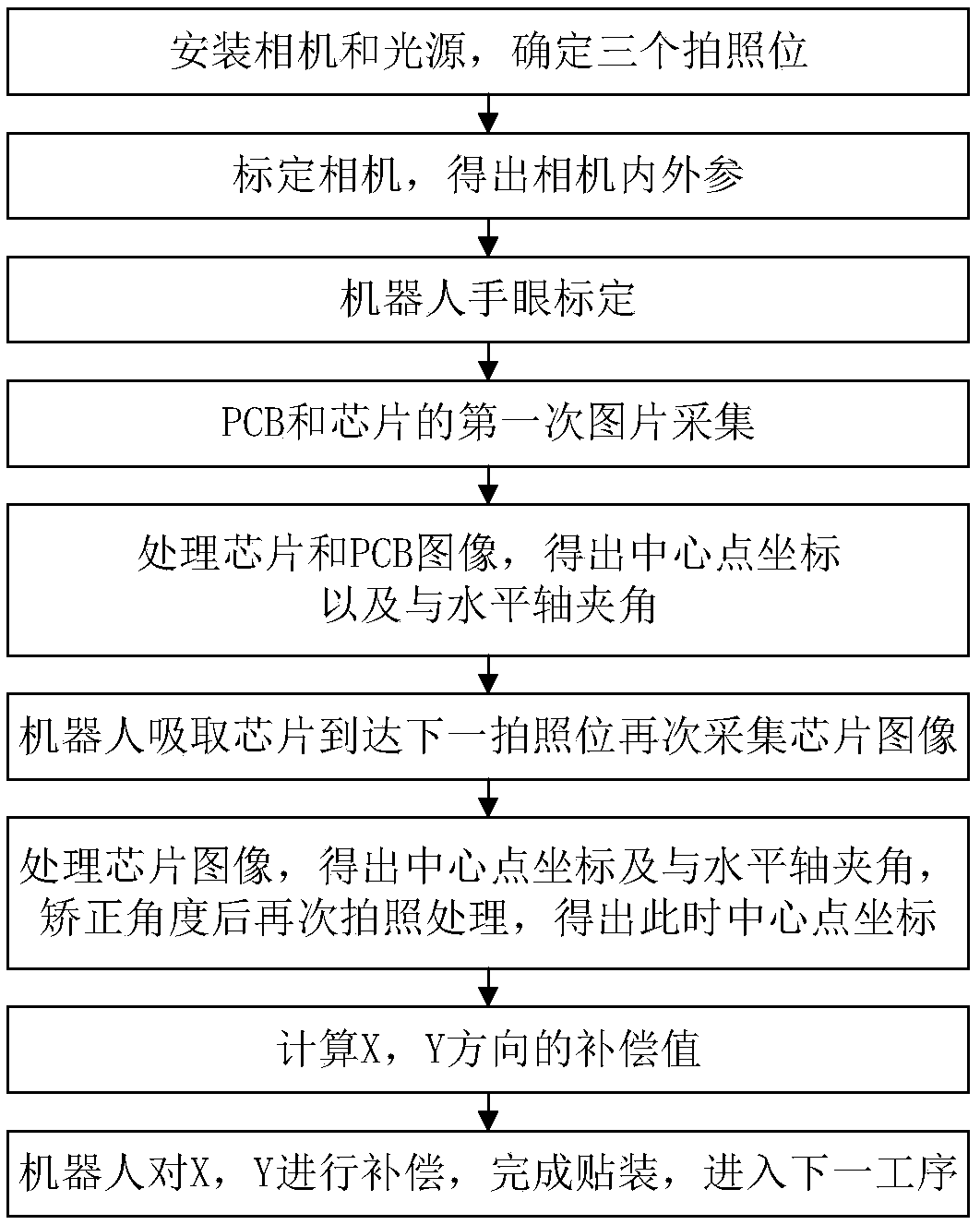

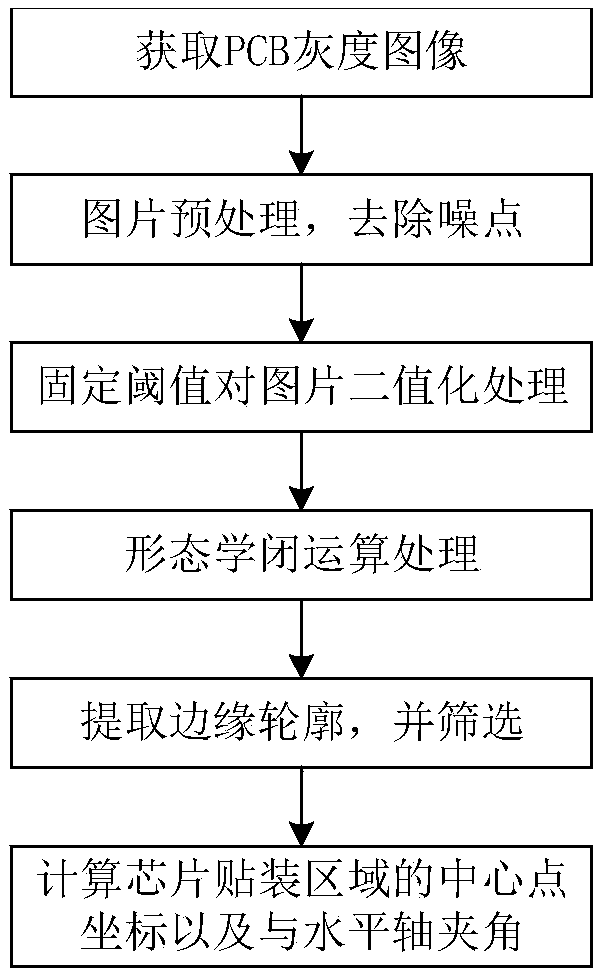

Chip mounting method and system for guiding robot vision

ActiveCN108766894AIncrease freedomIncrease flexibilitySemiconductor/solid-state device manufacturingAngular degreesHorizontal axis

The invention discloses a chip mounting method and system for guiding robot vision. A second industrial camera is additionally arranged in each of a PCB placing area and a chip placing area; a robot is used for absorbing chips to be moved to the positions of the second industrial cameras, the images of the absorbed chips are shot, and angular difference between the included angle of the chip mounting area and a horizontal axis and the included angle of the chips after the chips are absorbed and the horizontal axis is compared so that an end actuator rotates at the position of P3 in the angulardifference, angular compensation is carried out, compensation is carried out on X axis and Y axis, the sliding error generated when the chips are absorbed or in the moving process after the chips areabsorbed is improved, and the mounting precision is improved; moreover, a six-axis robot is adopted, due to the fact that the six-axis robot has higher degree of freedom and flexibility, the chip mounting inside workpieces such as cavities is realized, and flexible production is achieved; and then, first industrial cameras are arranged on the hands of the robot, and the robot is easier to move, so that the visual control method based on position is higher in flexibility and wider in range of application.

Owner:HUNAN UNIV

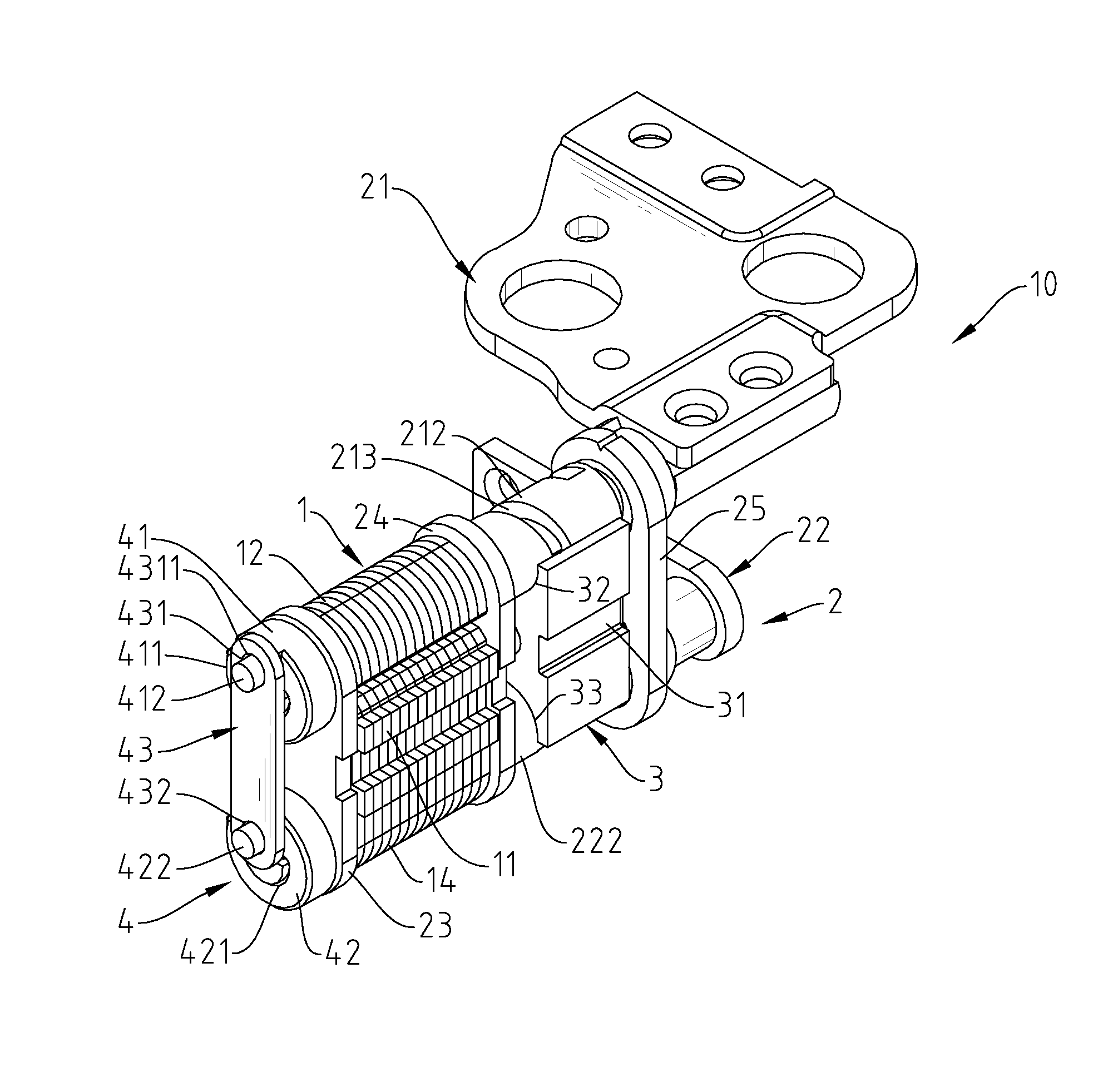

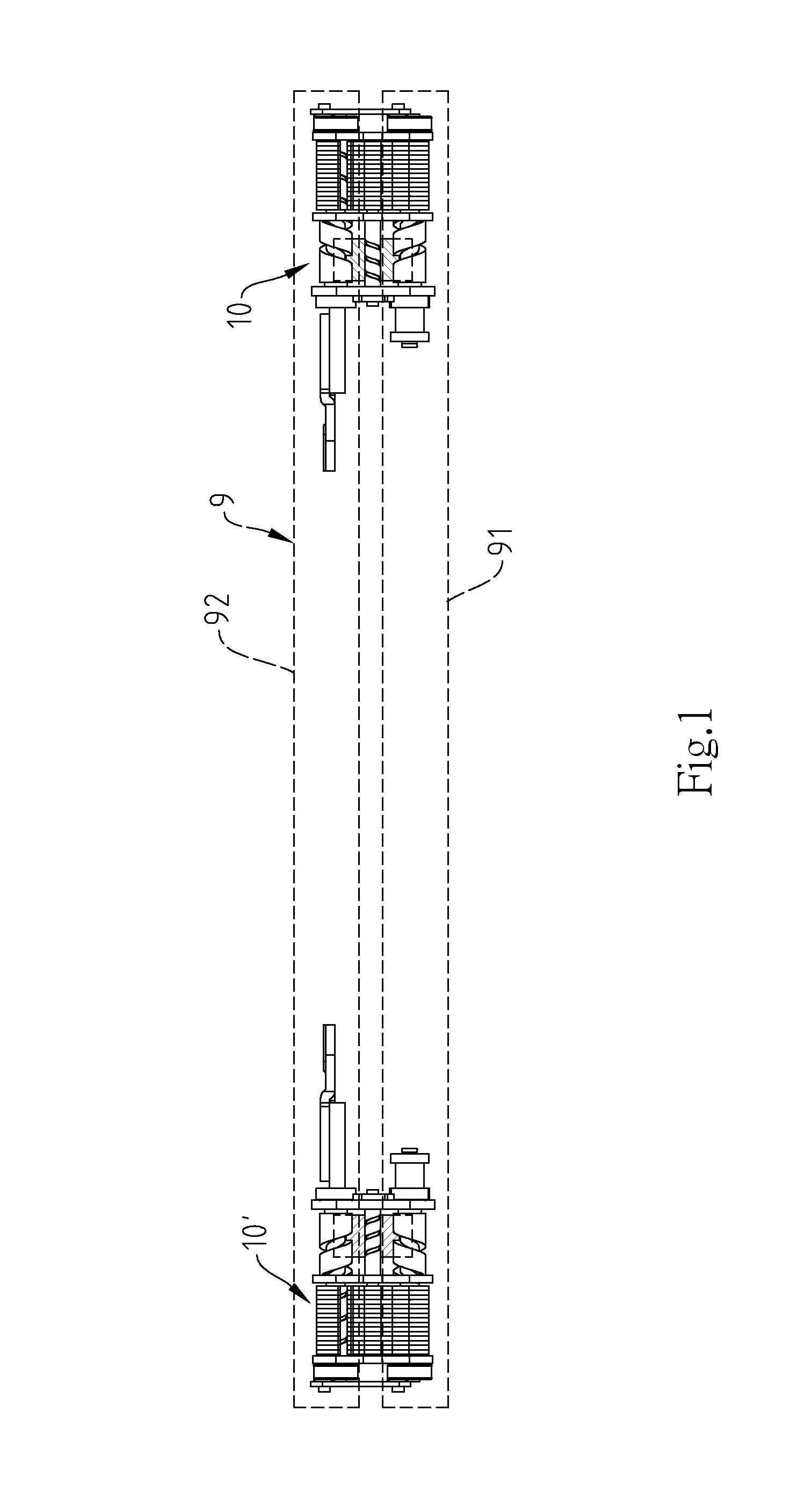

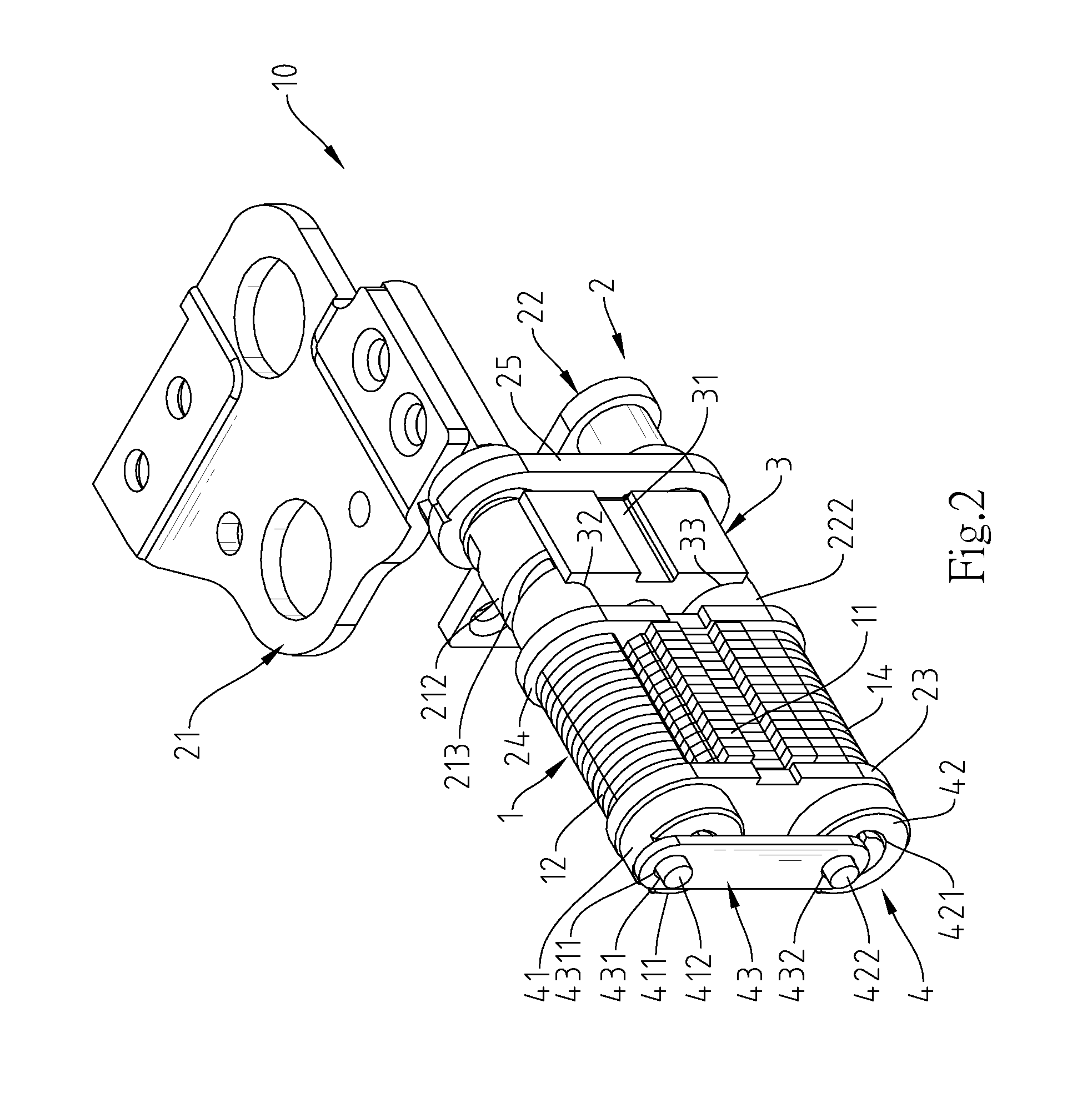

Dual-shaft hinge for flip-up electronic product

ActiveUS9274566B1Preventing excessive hinge wearShortens hinge lifespanDigital data processing detailsPin hingesTurn angleControl theory

A dual-shaft hinge connected between a cover member and a base member of a flip-up electronic product is disclosed to include a hinge shaft set including a first hinge shaft having a spirally extended propelling groove, a second hinge shaft having a spirally extended position-limit groove, a female hinge member coupled to the first hinge shaft and the second hinge shaft, a sliding block set having a first protrusion and a second protrusion respectively located at two opposite sides thereof and respectively coupled to the propelling groove and the position-limit groove, and a linkage adapted to limit the rotating angle of the first hinge shaft and the turning angle of the female hinge member about the second hinge shaft, preventing errors in angular difference between the two opposite lateral sides of the cover member and the two opposite lateral sides of the base member.

Owner:HUNG YIU LIN

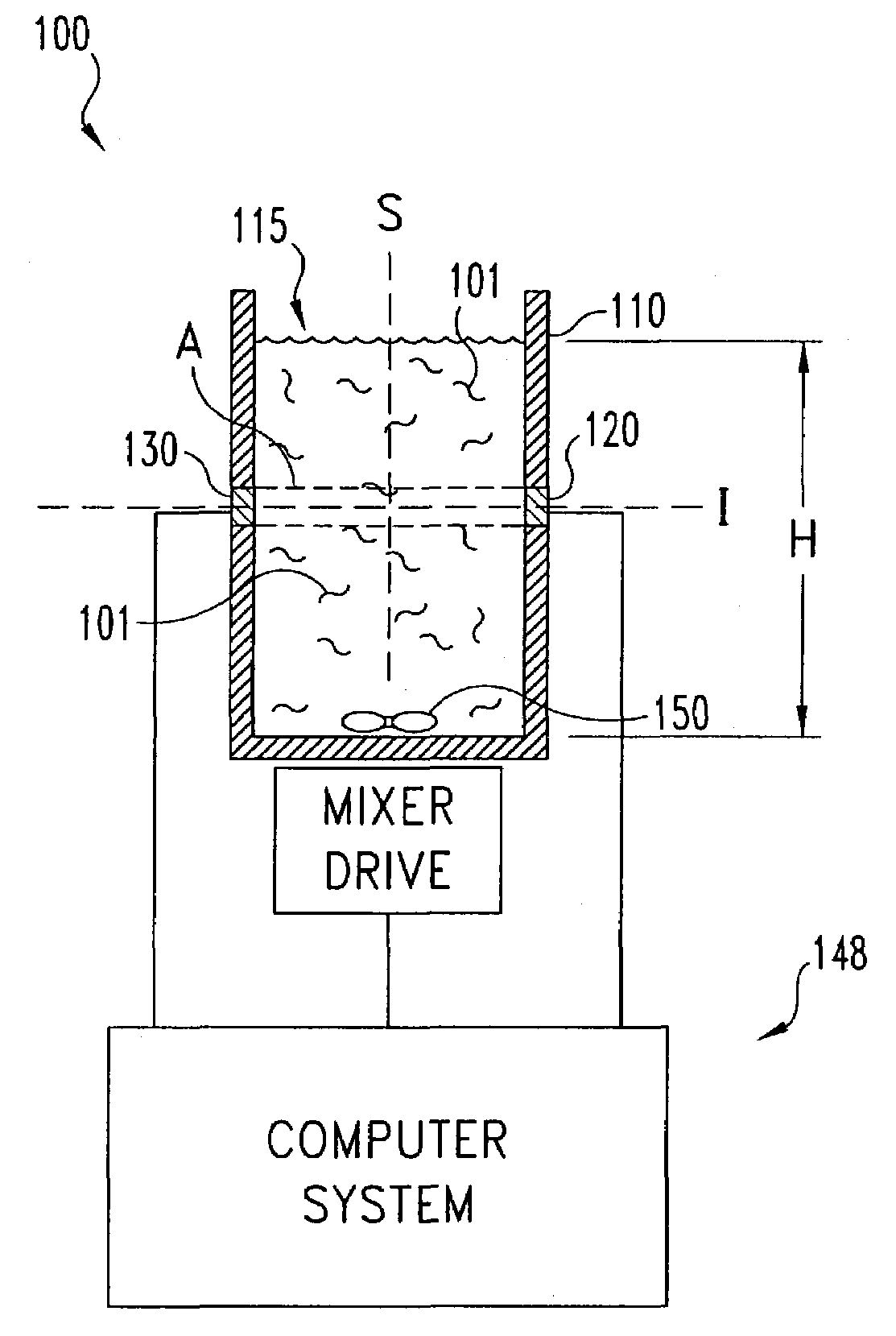

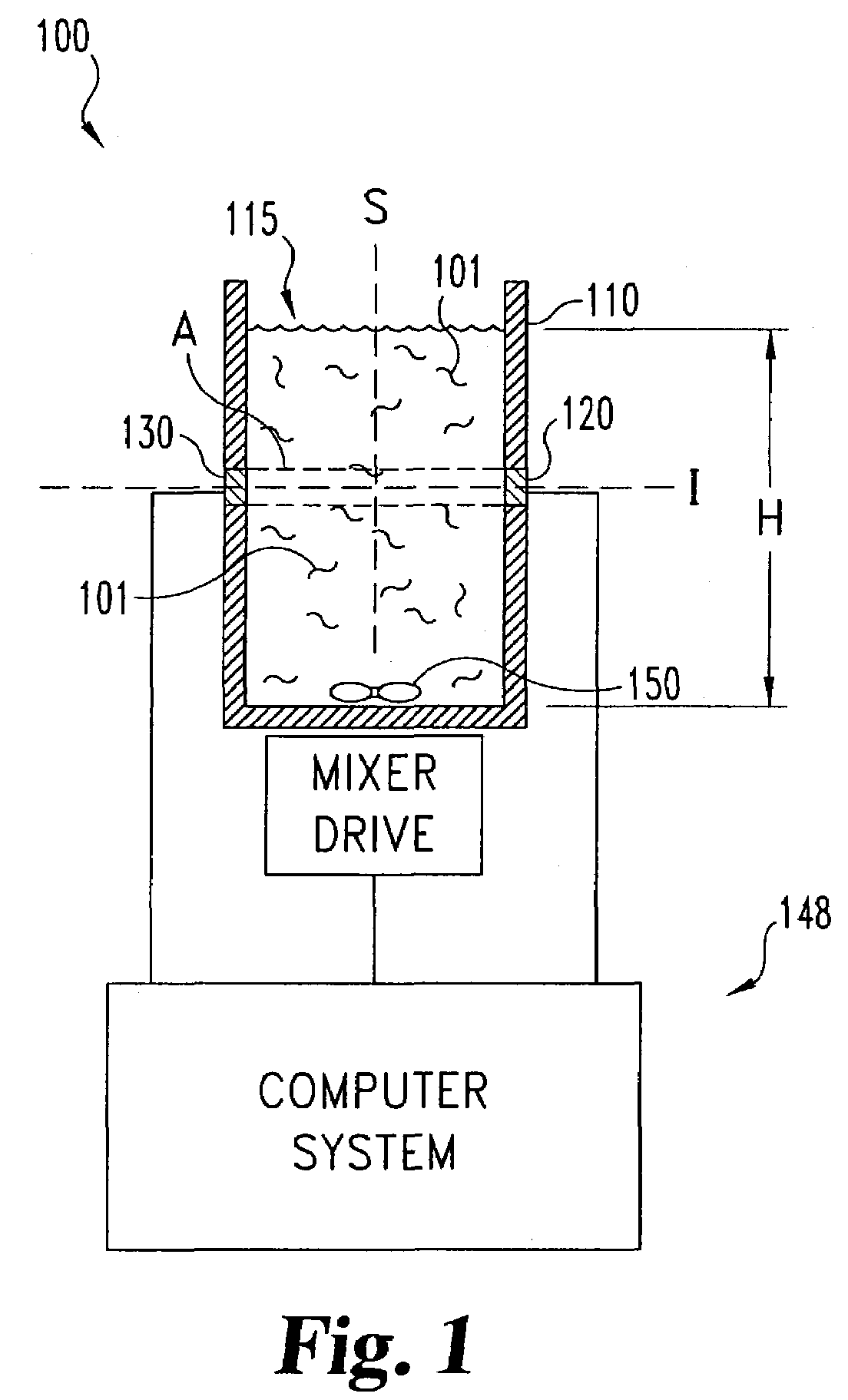

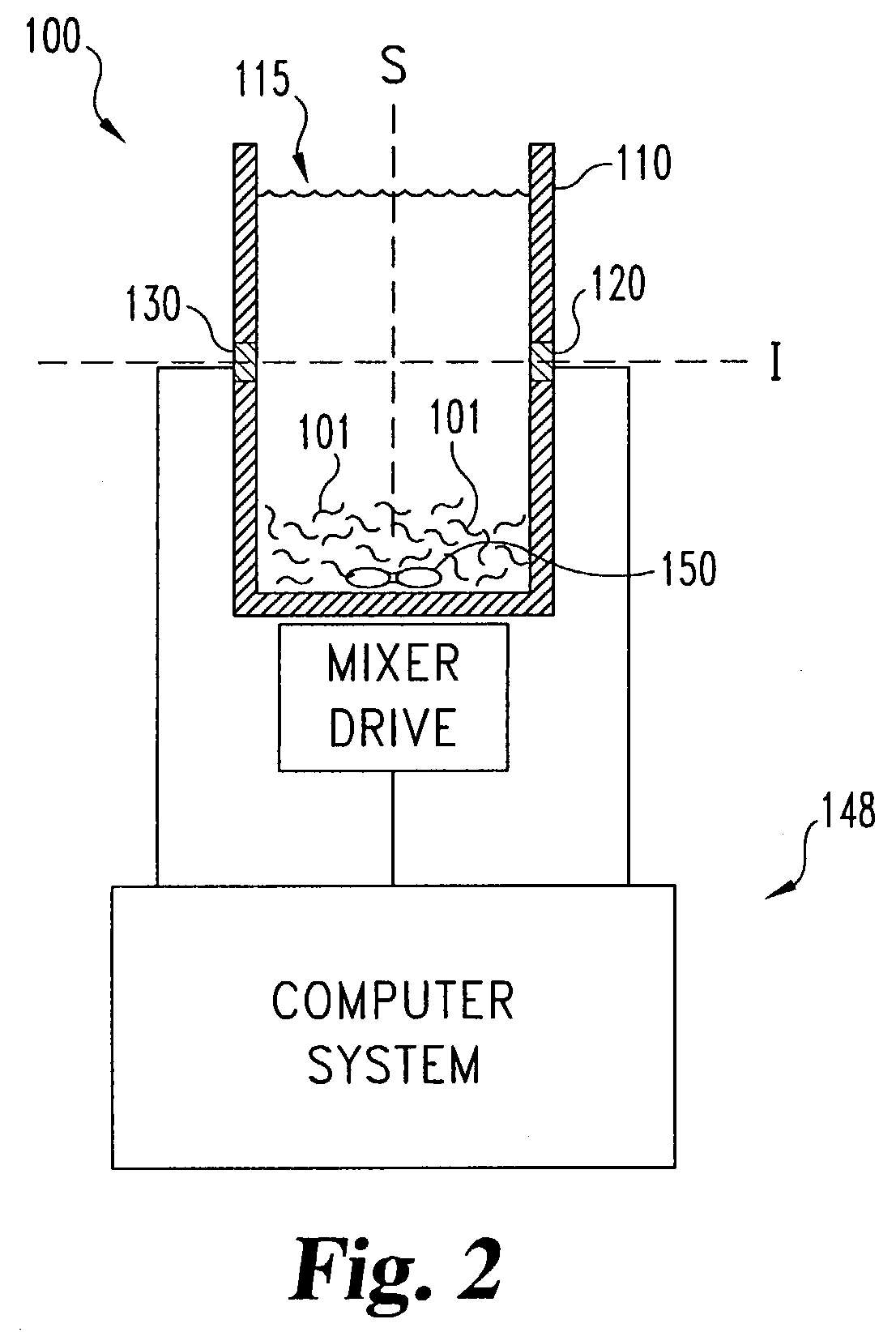

System and technique for ultrasonic characterization of settling suspensions

InactiveUS7140239B2Non-invasively characterizedEfficient and effectiveResponse signal detectionPaper testingUltrasound attenuationSonification

A system for determining properties of settling suspensions includes a settling container, a mixer, and devices for ultrasonic interrogation transverse to the settling direction. A computer system controls operation of the mixer and the interrogation devices and records the response to the interrogating as a function of settling time, which is then used to determine suspension properties. Attenuation versus settling time for dilute suspensions, such as dilute wood pulp suspension, exhibits a peak at different settling times for suspensions having different properties, and the location of this peak is used as one mechanism for characterizing suspensions. Alternatively or in addition, a plurality of ultrasound receivers are arranged at different angles to a common transmitter to receive scattering responses at a variety of angles during particle settling. Angular differences in scattering as a function of settling time are also used to characterize the suspension.

Owner:BATTELLE MEMORIAL INST

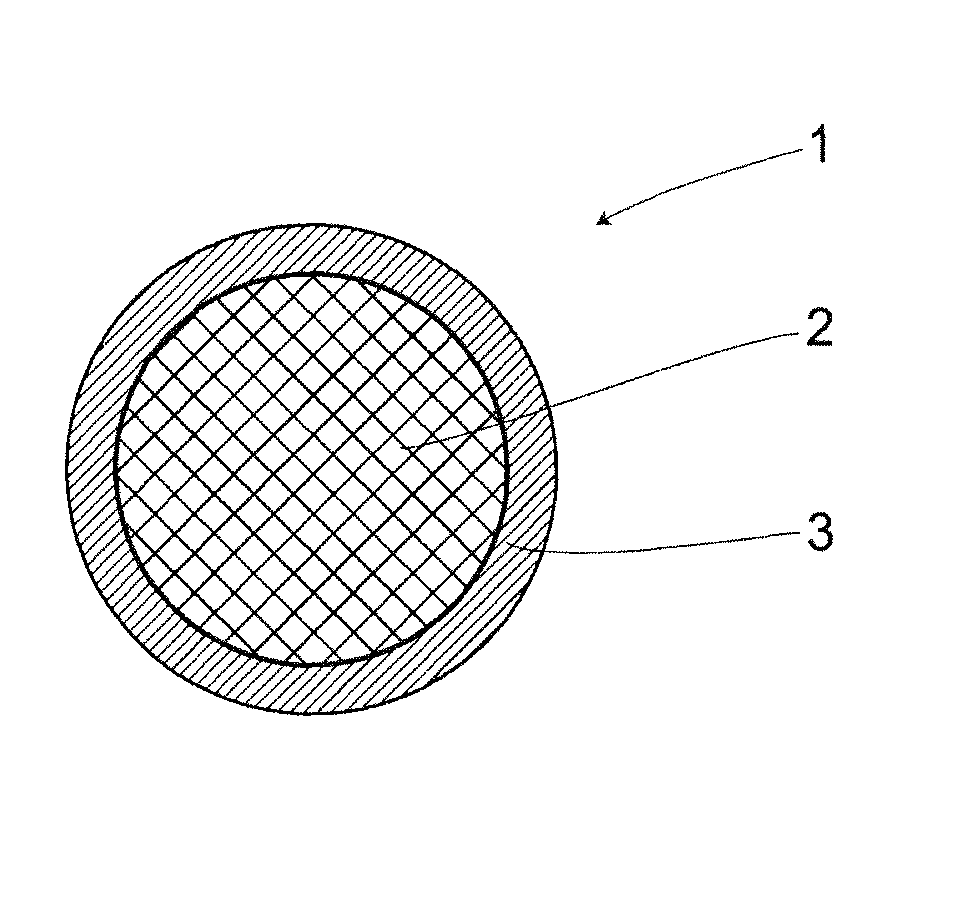

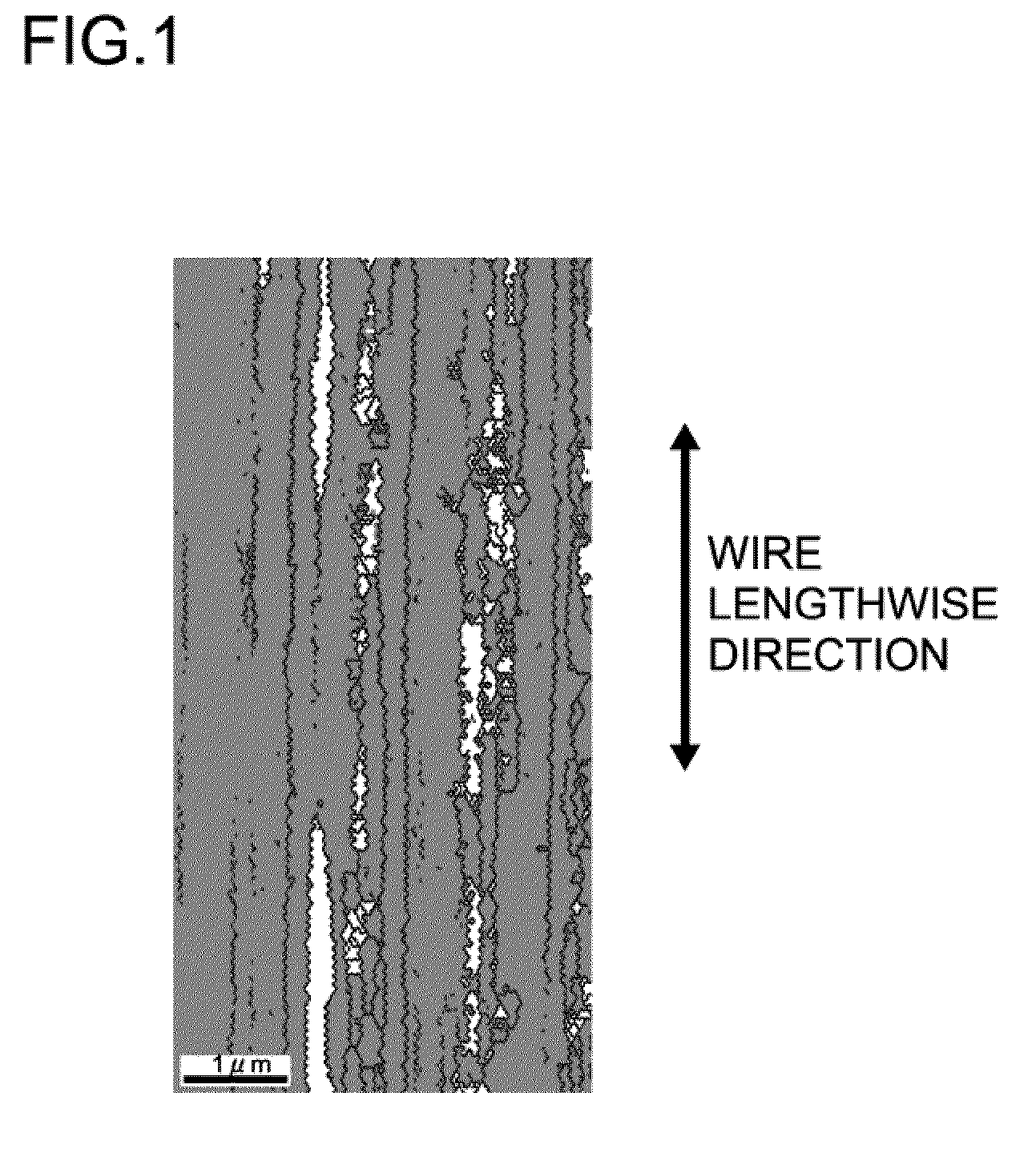

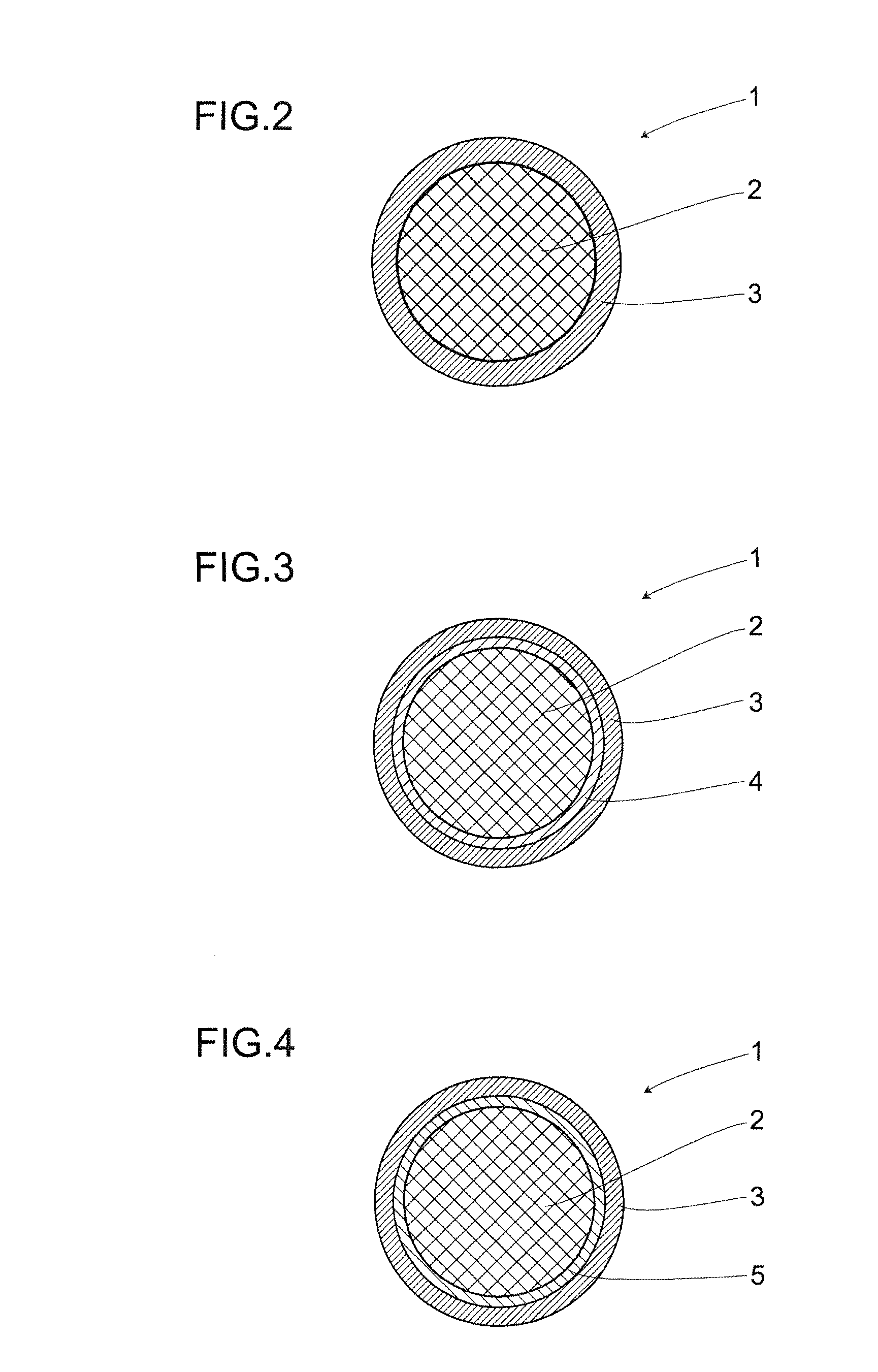

Bonding wire for semiconductor devices

ActiveUS8389860B2Reduce harmImprove stabilityNon-insulated conductorsSolid-state devicesPower semiconductor deviceAngular degrees

Owner:NIPPON MICROMETAL CO LTD +1

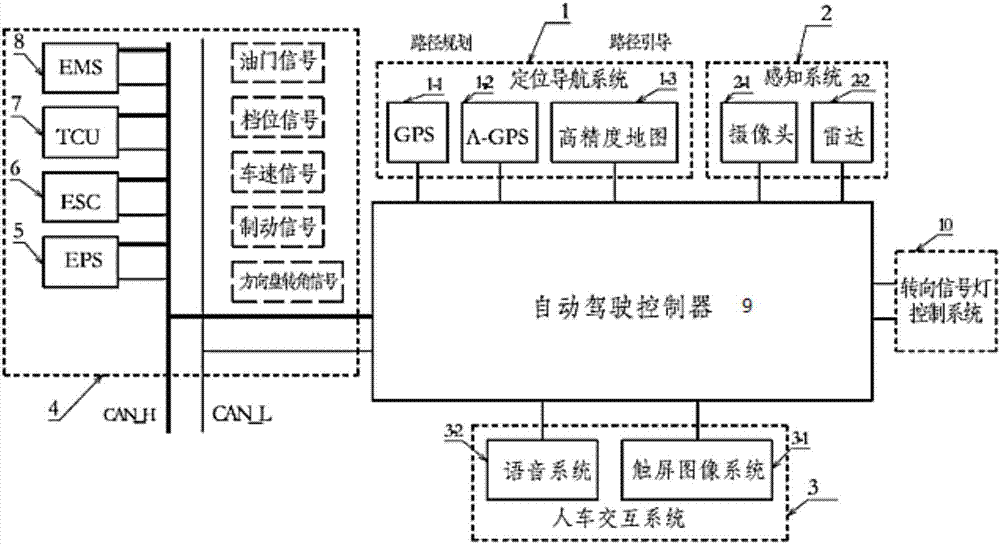

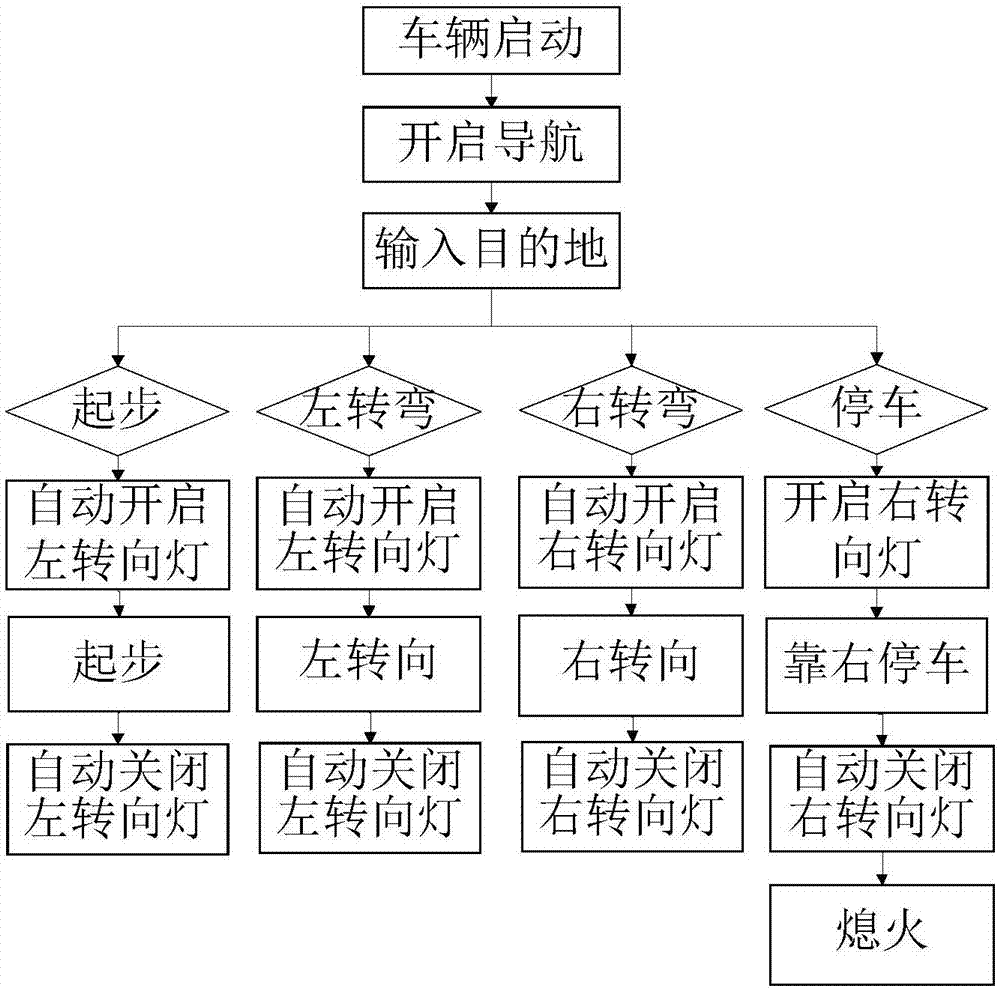

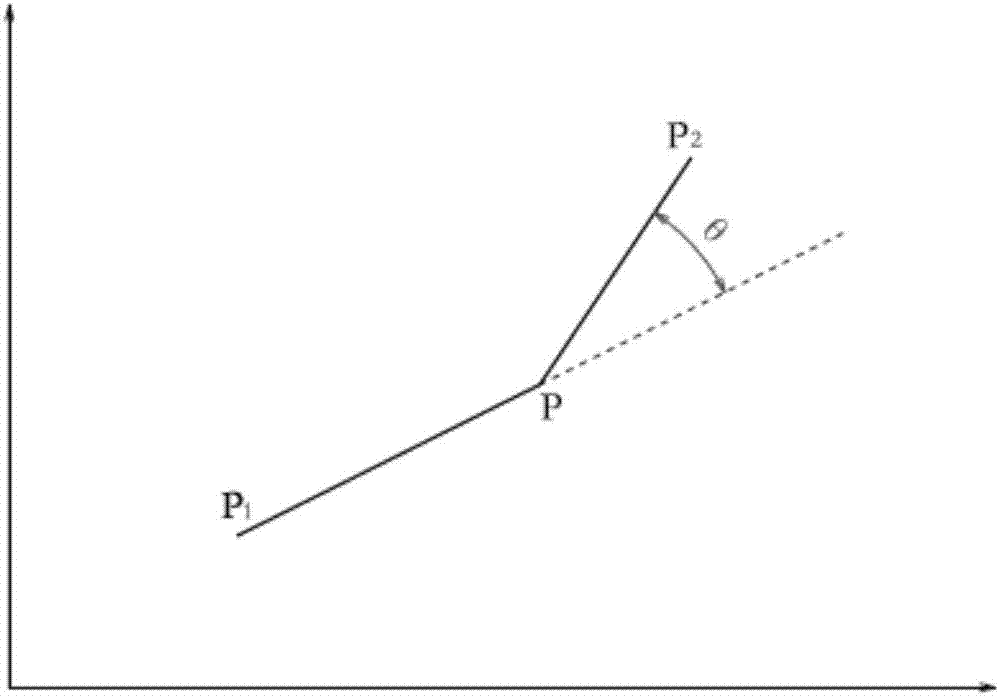

Steering signal lamp automatic control method and system based on automatic driving

ActiveCN107161075AImprove traffic safetyRemind attention to safetyOptical signallingCar drivingAutomatic control

The invention relates to the technical field of car electronics, in particular to a steering signal lamp automatic control method and system based on automatic driving. When the difference value K of the planned route curvature Kj and the curvature Kr of a road lane line in front of a car driving route exceeds the preset calibration value k0, meanwhile, the angular difference absolute value |theta| of a displacement point P1P of previous time and a displacement point PP2 of later time of a planned route meets the condition that the difference of |theta| and theta0 is larger than zero, and a point P2 is located on the right side of a P1P extension line, a right steering lamp is started; when the difference value K of the planned route curvature Kj and the curvature Kr of the road lane line in front of the car driving route exceeds the preset calibration value k0, meanwhile, the angular difference absolute value |theta| of the displacement point P1P of the previous time and the displacement PP2 of the later time of the planned route meets the condition that the difference of |theta| and theta0 is larger than zero, the point P2 is located on the left side of the P1P extension line, or the real-time distance L of a barrier T in front of the same lane is smaller than the safe distance L0, a left steering lamp is started; and advance control over the steering signal lamps in an automatic driving mode is achieved by judging whether the steering lamps of a car are started or not in advance and turning off the steering lamps at appropriate time.

Owner:DONGFENG MOTOR CORP HUBEI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com