Patents

Literature

344results about How to "Improve resource recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thin-base-rock shallow coal-layer water-retaining production suitable-condition classification method

InactiveCN101070759AImprove resource recoveryHigh recovery rateUnderground miningSurface miningBedrockReturn ratio

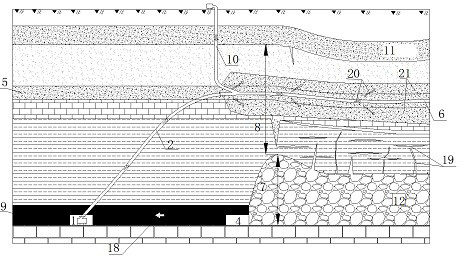

The invention discloses applicable classification method for mining under the shallow bedrock of thin seam keeping water conditions. Apply to thin seam overlying shallow bedrock aquifer water loose the protection of water resources. At first according to the feature of structure or Shallow bedrock, the height of leading water crevasse under different mining height is analyzed and calculated. The estimate formula: HL=9.29M+10.6 can be used to determine the height HL of leading crevasse water under the shallow bedrock of thin seam to the different mining height M. The mining waterproofing security coal rock pillar protector thickness of the thin bedrock shallow submersion coal bed long well working surface is 10 m. According to the classification situation of loose water-bearing stratum water body, the bedrock thickness which is needed is determined under the condition of different mining height. According to classification situation and mining height, mining is separated into reinsurance water mining according to the bedrock thickness. This method has good water resources protection effect, is safe in production, and has high coal resource returns-ratio.

Owner:CHINA UNIV OF MINING & TECH

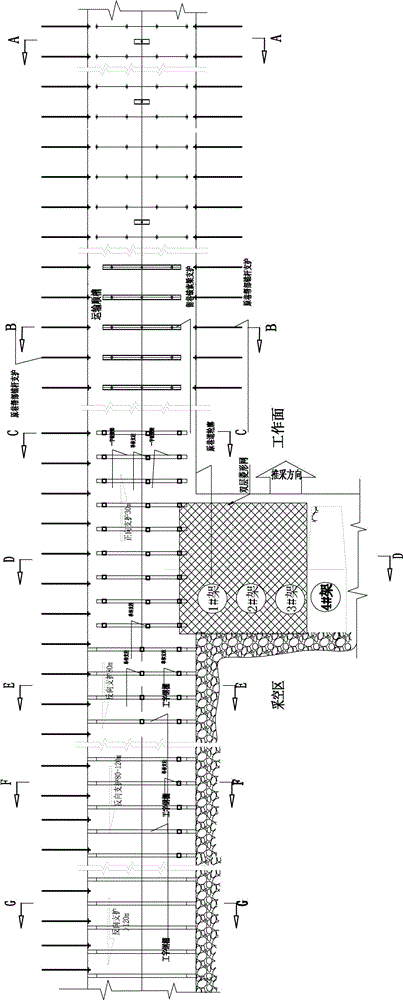

Comprehensive coal-mining process by using long wall mining method

InactiveCN1865657ALow costReduce in quantityUnderground miningSurface miningEngineeringEarth surface

The invention relates to a long-wall coal method, which can be used in stable coal bed, rigid top plate, non-broken incline middle-thickness coal bed, and thick coal bed layered long-wall method. Wherein, it arranges hydraulic support, scrape transporter, and roller coal machine at the long-wall working surface; arranges groove transporter and flexible band transporter at the transport channel; the working surface has ultra long length, which is two times of integrated coal surface; it uses two coal machines on one scrape transporter, to scrape the upper half surface and the lower half surface; and it can arrange middle channel at the middle of integrated surface as the transport channel; and arranges scrape transporters at the upper and lower half working surfaces. The invention has high efficiency, while it can reduce the digging rate and improve the resource recycle rate.

Owner:YANKUANG GRP CO LTD

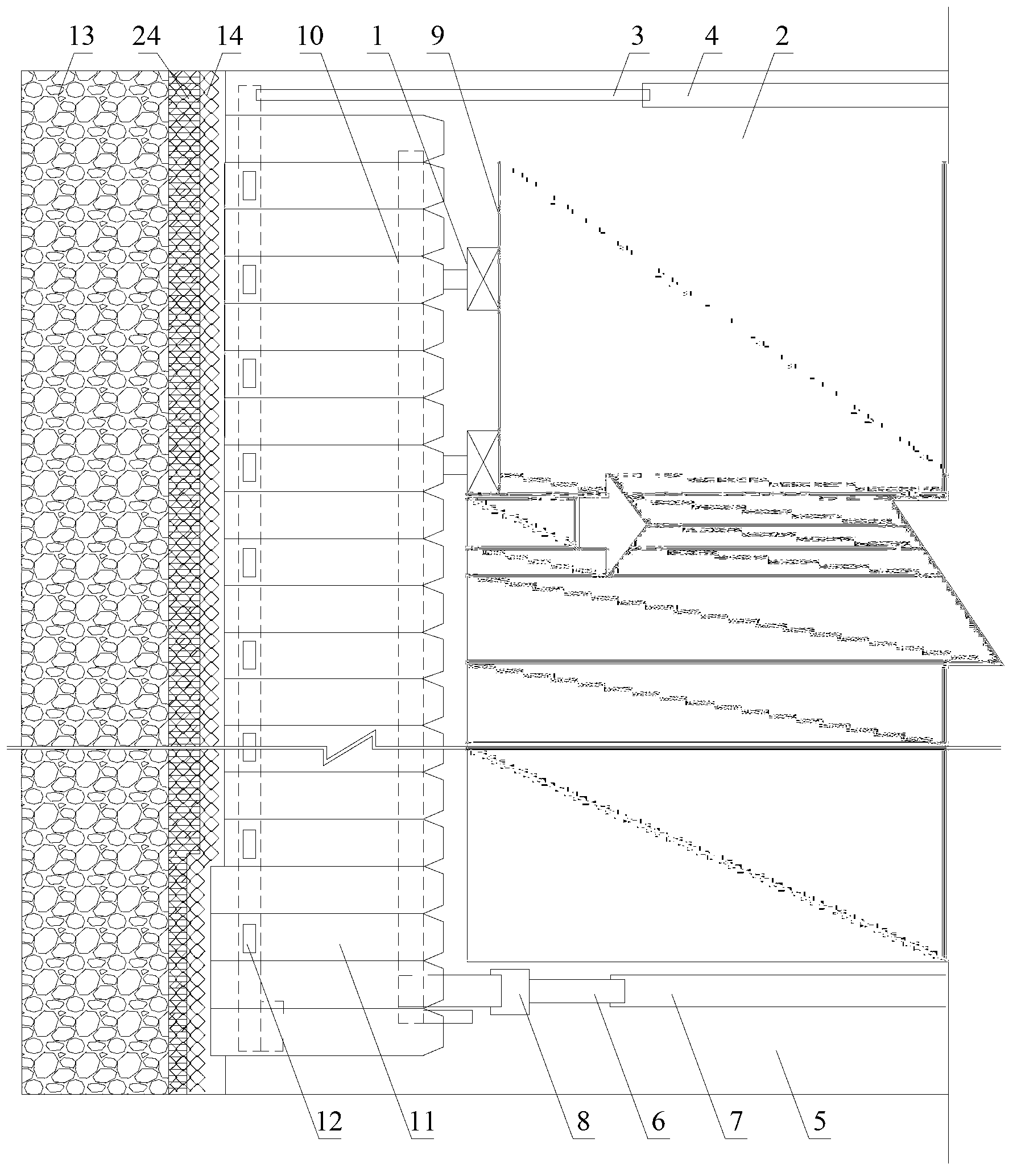

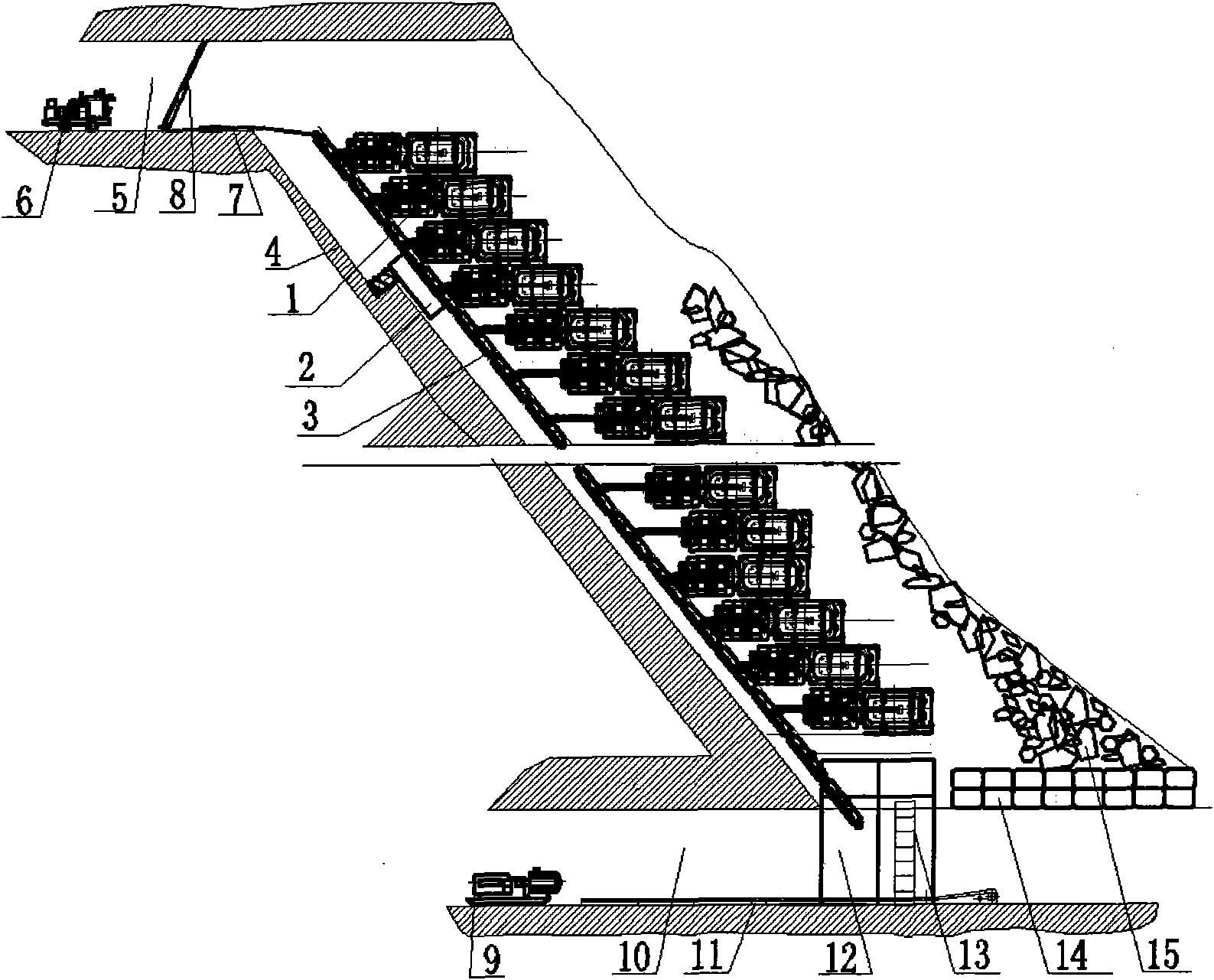

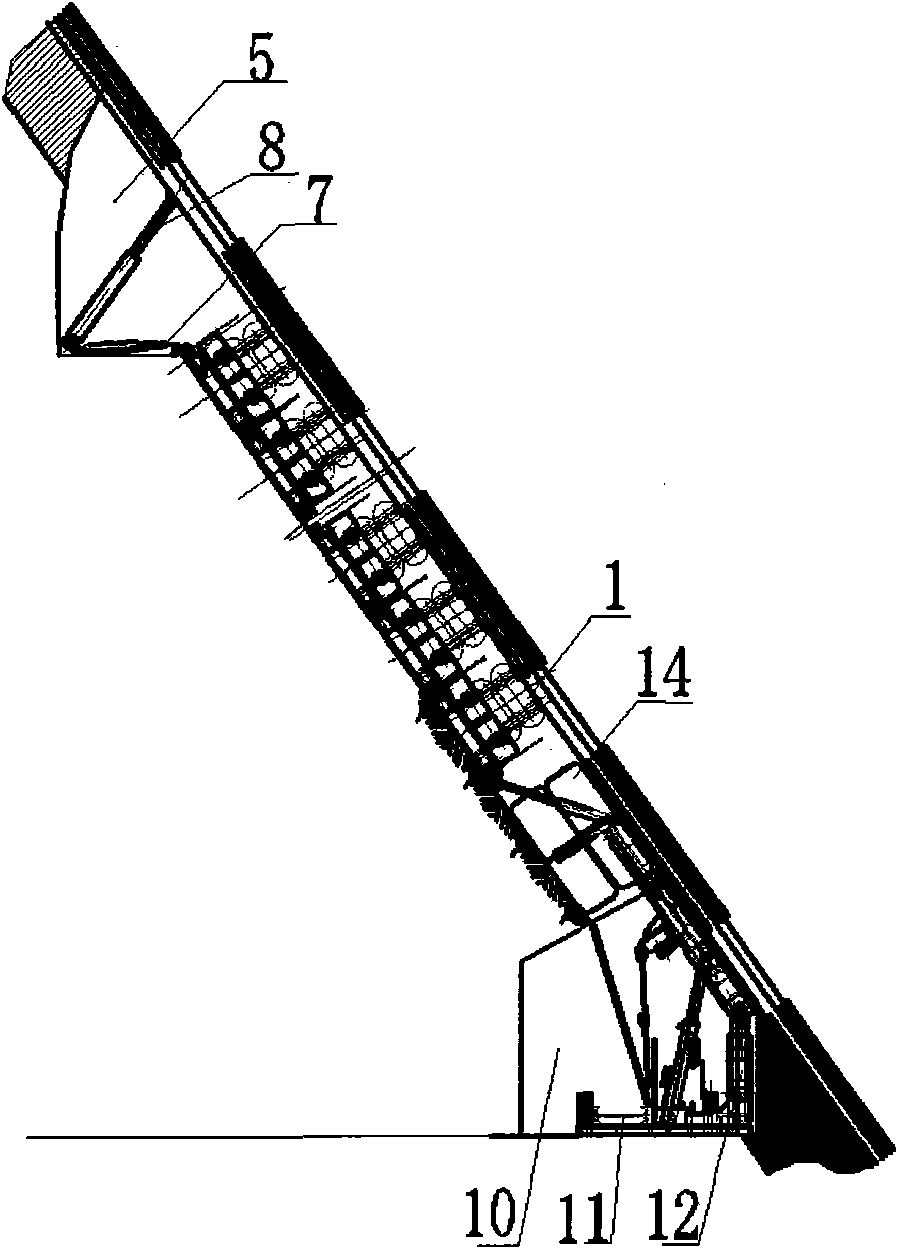

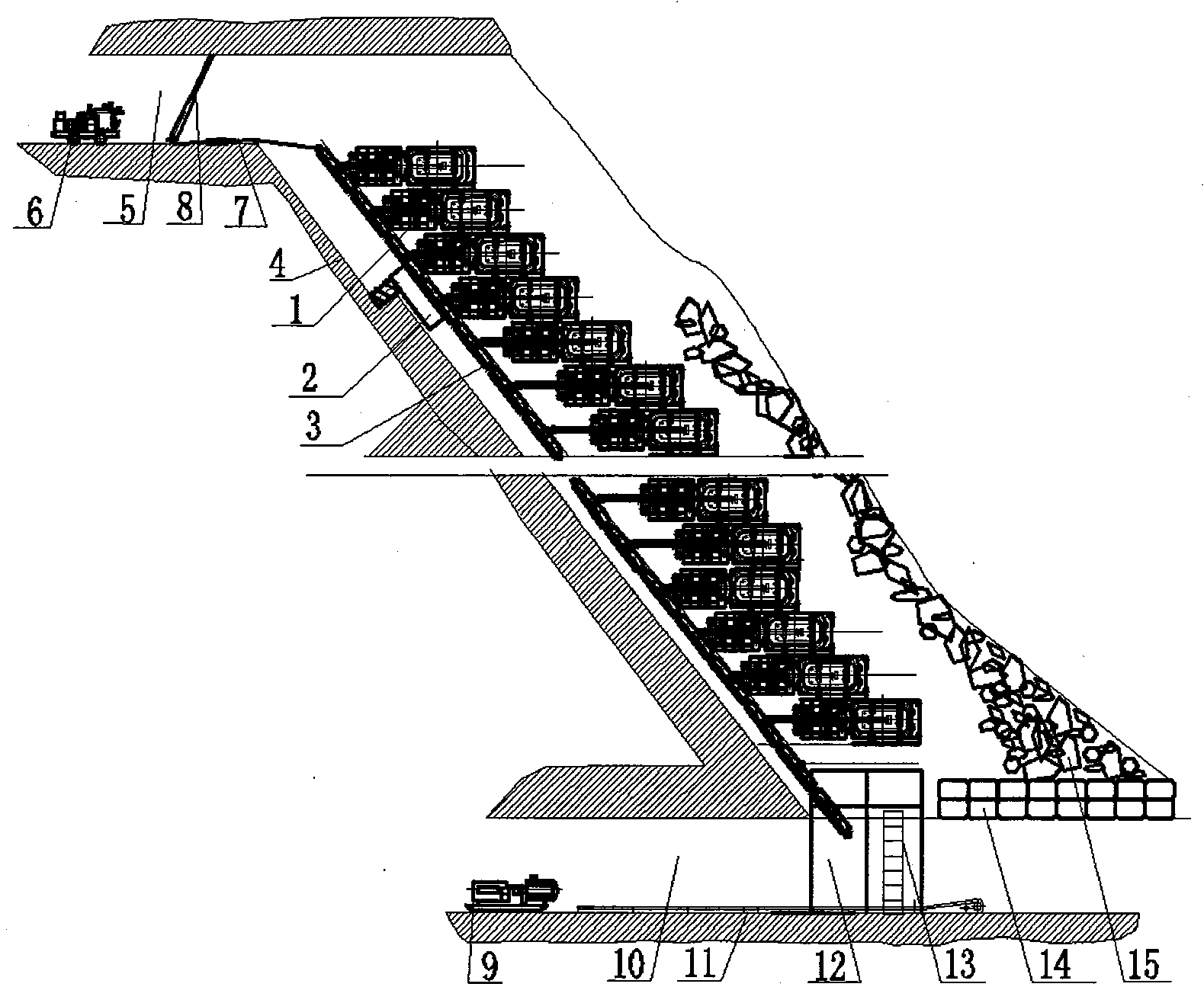

Inclined separated layer solid filling coal mining method for super thick coal seam

ActiveCN103306720ASolve sinkingFree resourcesUnderground miningSurface miningSolid massEarth surface

The invention discloses an inclined separated layer solid filling coal mining method for a super thick coal seam, which is suitable for the exploitation of an 'under three' super thick coal seam. The method comprises the following steps: determining the number of inclined separated layers according to the principle that thickness of each separated layer is 2.5-4.5 m; adopting a exploitation sequence that mining layer by layer, and filling at a next row; arranging tunnels and equipment according to the conventional solid filling coal mining method; carrying out a circulating sequence that coal mining firstly, metal nets and bamboo fences paving secondly, and filling finally to complete the filling exploitation of a first mining surface and a first separated layer; meanwhile, mining according to the same filling coal mining method under the shield of a manual false roof formed by the first separated layer at the corresponding position of a second separated layer 4 months after a working face of the first separated layer finishes mining; circulating in the way that the exploitation of one separated layer is performed under the shield of a manual false roof manufactured by an upper separated layer continuously until the whole super thick coal seam is mined out. Through the adoption of the method, resources of the 'under three' super thick coal seam can be utilized, the rock formation movement and earth surface sinking can be effectively controlled; and the recovery ratio is high, the production efficiency is high, the cost is low, and the method has wide practicability in the field of thick coal seam filling exploitation.

Owner:CHINA UNIV OF MINING & TECH

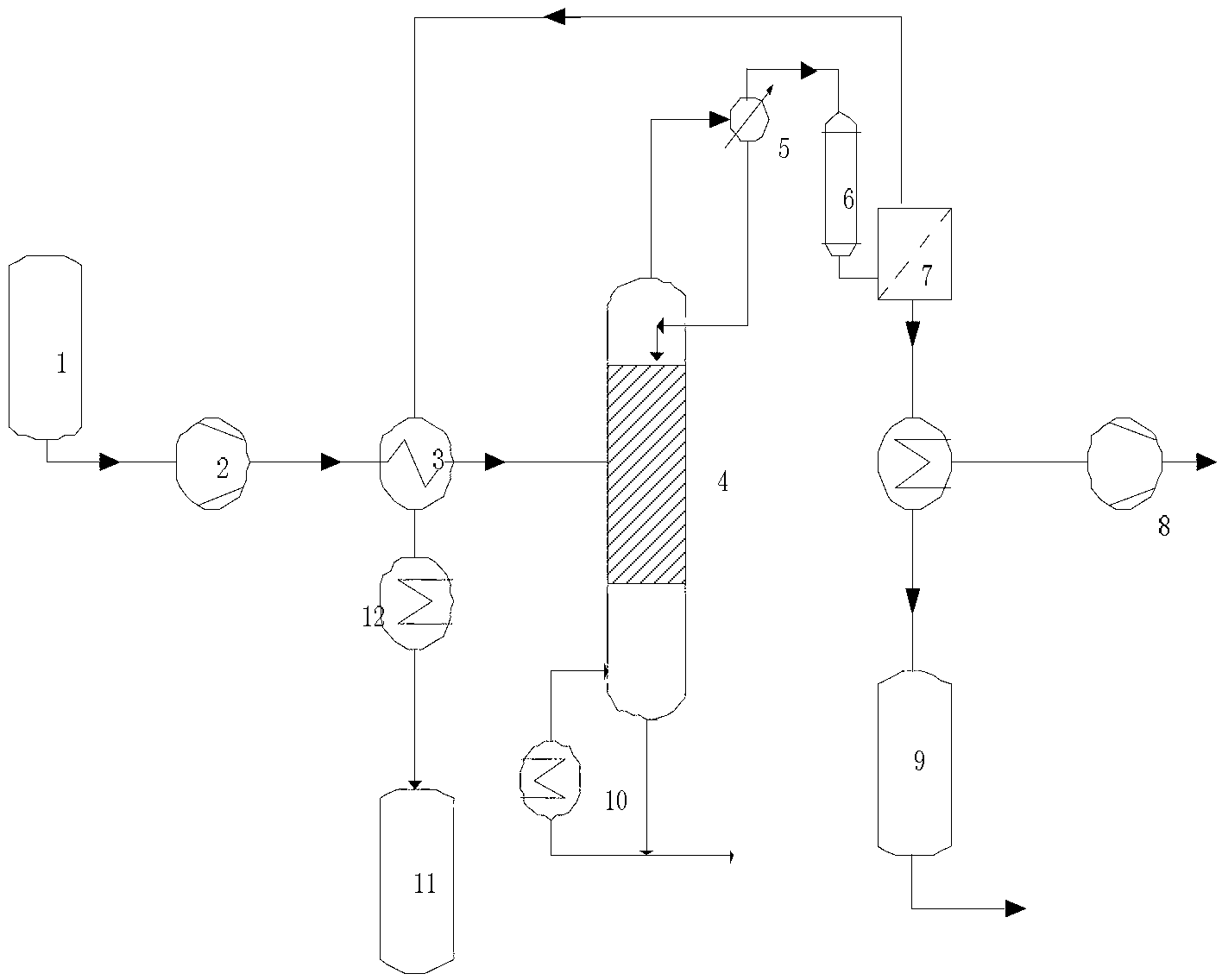

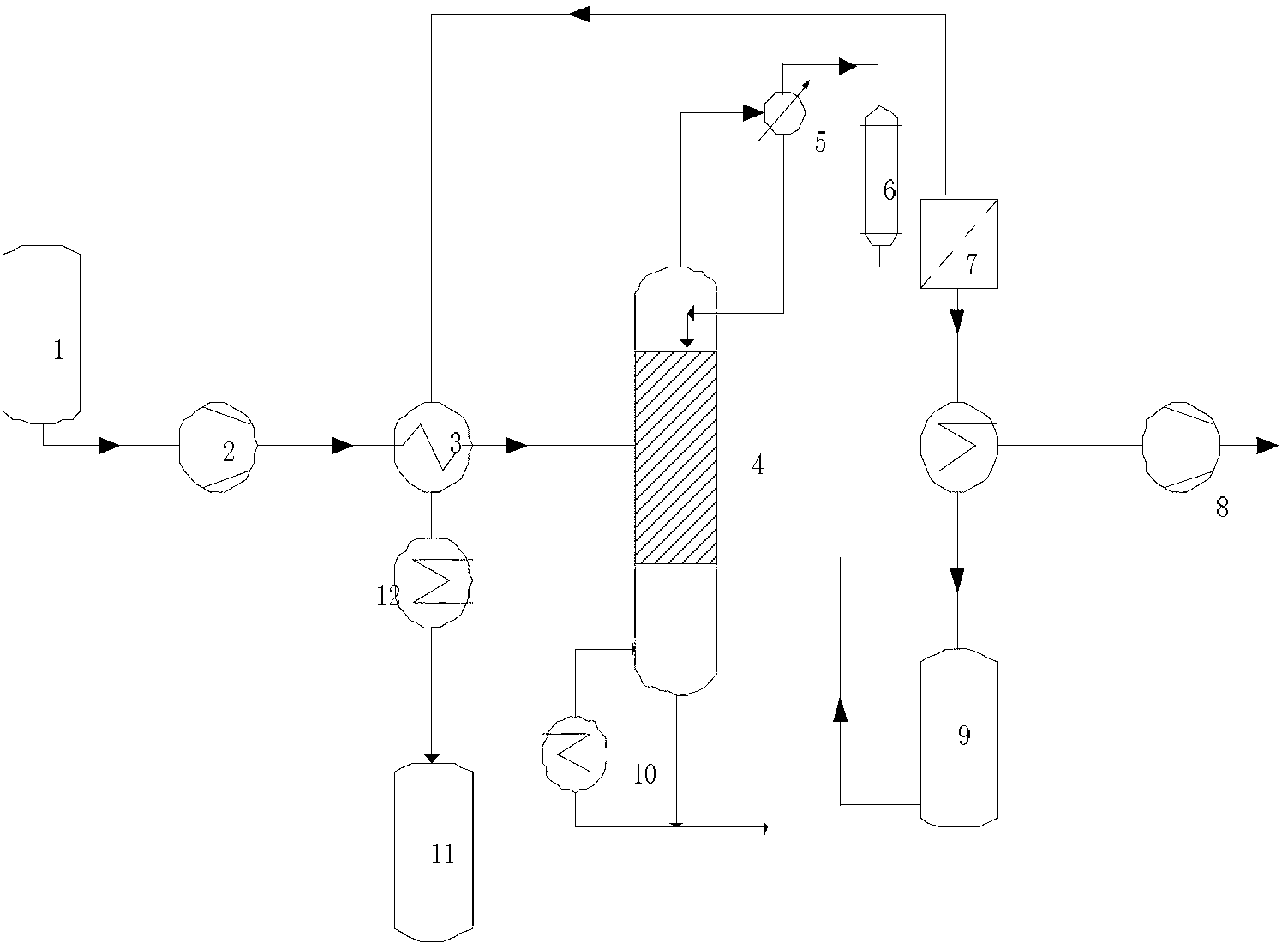

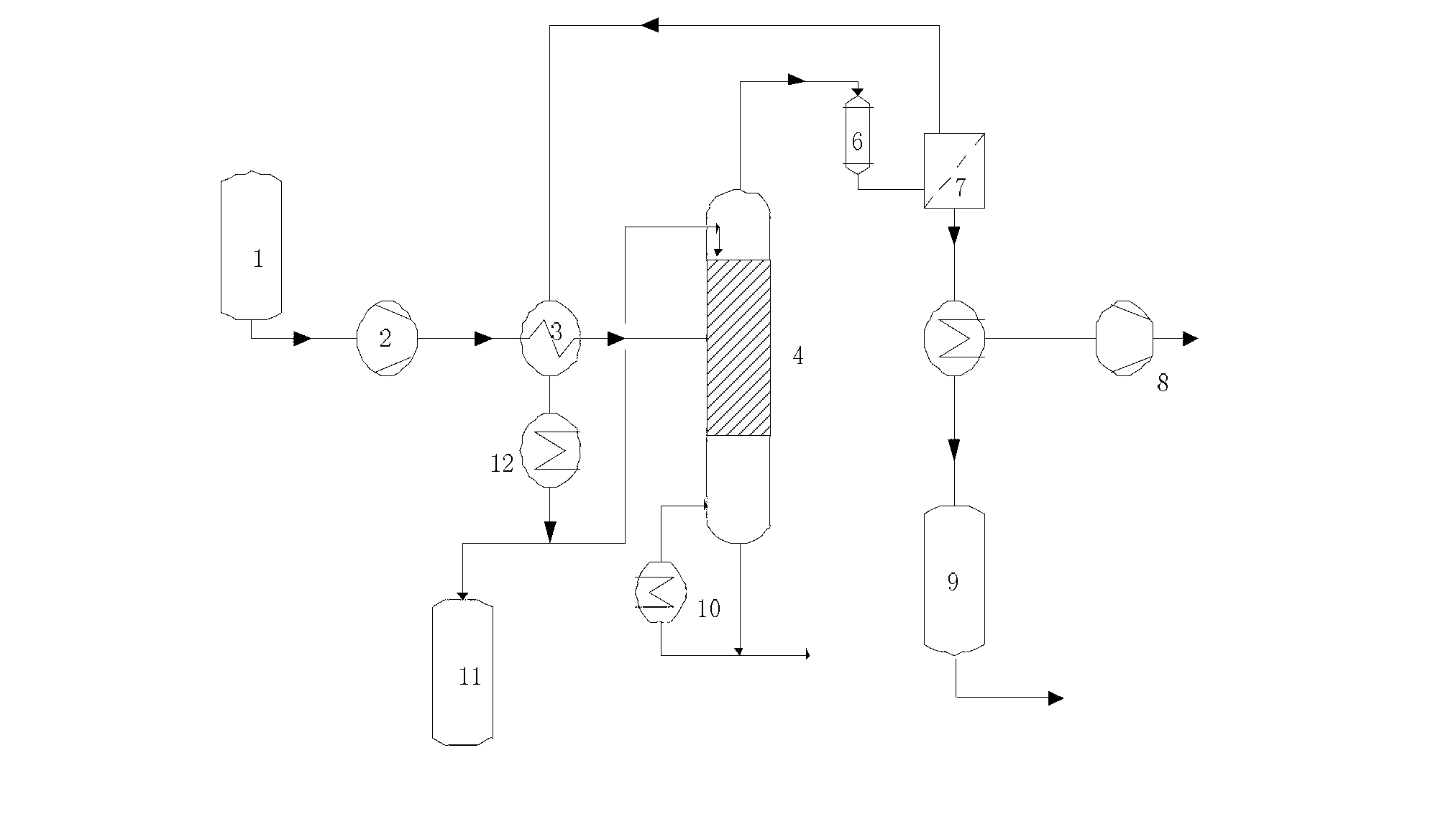

Rectification-steam penetration-coupled organic solvent dewatering method and device

ActiveCN103071307AReduce pollutionEliminate reprocessing costsDistillationFractional distillationOrganic solventProcess engineering

The invention relates to a rectification-steam penetration-coupled organic solvent dewatering method and a rectification-steam penetration-coupled organic solvent dewatering device, belonging to the technical field of separation. The rectification-steam penetration-coupled organic solvent dewatering method comprises the step of sending an aqueous organic solvent into a rectifying tower, wherein at least one part of steam at the top of the rectifying tower is not condensed and is directly separated by a steam penetrating device, a penetrated side is water and an intercepted side is organic solvent. The rectification-steam penetration-coupled organic solvent dewatering device comprises a raw material tank, a raw material pump, a preheater, the rectifying tower and the steam penetrating device which are sequentially connected, wherein the top of the rectifying tower is directly connected with the steam penetrating device. Compared with the prior art, in the organic solvent dewatering process, a third component is not added, so that environmental pollution caused by the third component and the retreatment cost of the third component are eliminated, an azeotropic rectification process and an extractive rectification process are omitted, condensation of a product at the top of the rectifying tower and re-evaporation in the steam penetrating device are omitted, energy consumption is lowered and the product quality is improved.

Owner:JIANGSU NINE HEAVEN HIGH TECH

Coal mining method for high-dipping low seam

InactiveCN101942999AAchieve mechanical propertiesIncrease productionUnderground miningSurface miningLongwall miningMining engineering

The invention relates to a coal mining method for a high-dipping low coal seam by long-wall mining. The method comprises the following steps of: supporting a roof by a self-advancing air bag support; arranging a working surface in a mode of advancing to the dip; mining coal by drilling and blasting or using an off-pan shearer; transporting the coal in a mode of gravity haulage; filling a goaf with gangue or sand; and filling a lower end with gangue bags, precast concrete blocks or solidified macromolecular foaming slurry. The coal mining method has the advantages of realizing mechanical coal mining for the high-dipping low coal seam, improving the yield per unit and efficiency of the working surface, effectively protecting the exploited ground, improving the recovery rate of mines, and guaranteeing the coal seam mining safety.

Owner:TIANDI SCI & TECH CO LTD

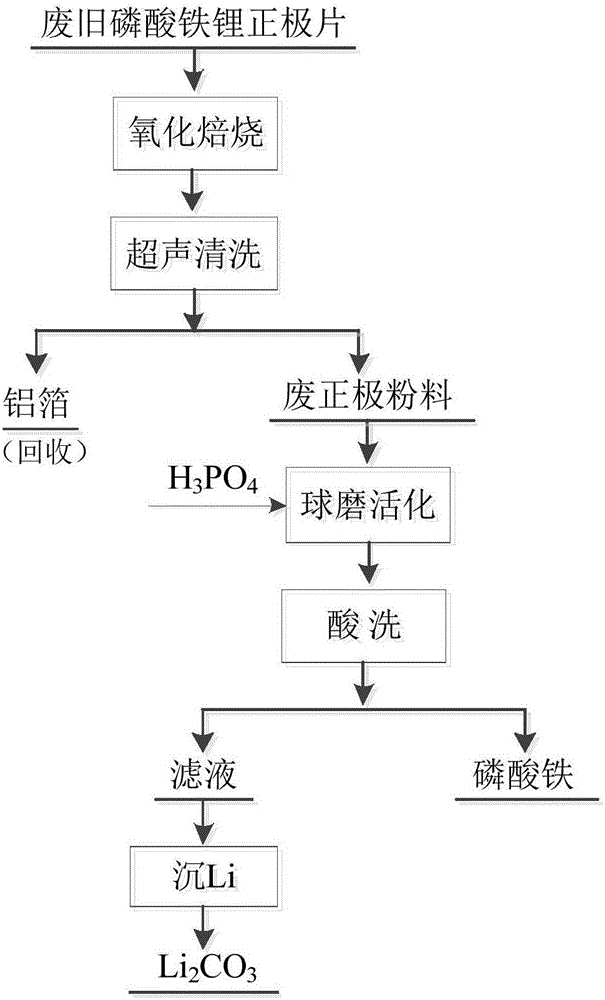

Method for recycling iron phosphate and lithium carbonate from lithium iron phosphate waste

ActiveCN106450547AAdaptableNothing producedWaste accumulators reclaimingBattery recyclingPhosphoric acidIndustrial scale

The invention discloses a method for recycling iron phosphate and lithium carbonate from lithium iron phosphate waste. The method comprises the following specific steps: (I) oxidizing roasting; (II) carrying out pole piece cleaning; (III) adding phosphoric acid and performing ball-milling activation; (IV) performing acid pickling to separate FePO4; and (V) precipitating lithium of the filtrate to obtain a target object Li2CO3. The method disclosed by the invention has the following advantages: the P, Fe and Li resources in the lithium iron phosphate waste can be fully utilized to prepare iron phosphate and lithium carbonate products with high added value, no waste of Fe is generated, the resource recycling rate is high, the technological process is short, the reaction system is simple, a few raw materials are consumed, the cost is low, the product value is high, and the method is very suitable for industrial scale production.

Owner:JINGMEN GEM NEW MATERIAL

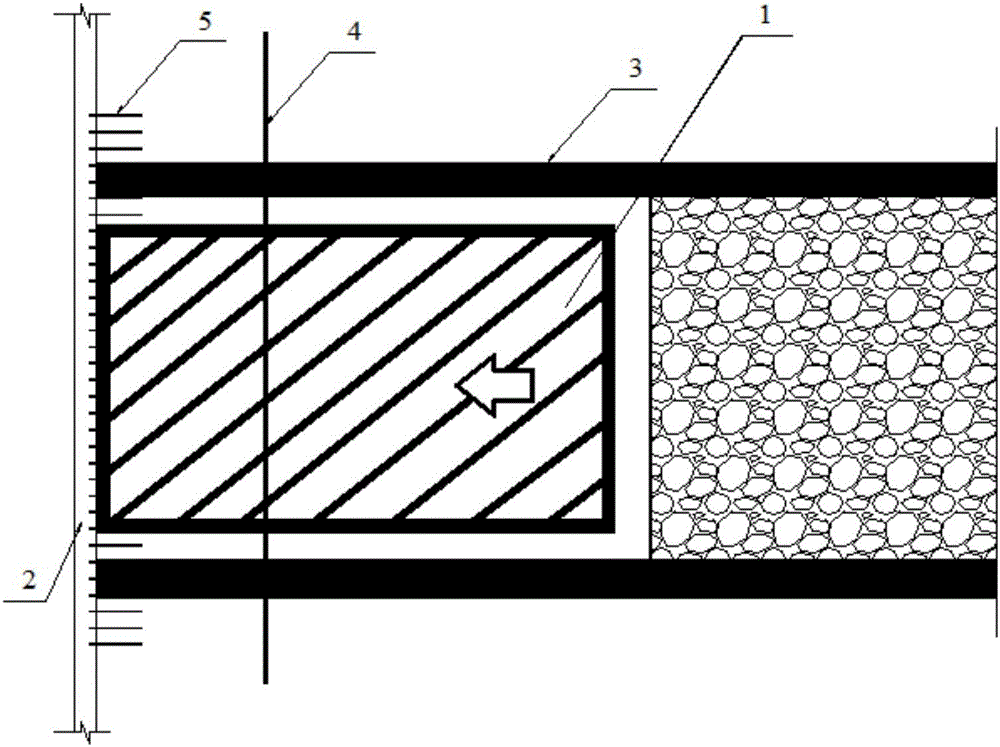

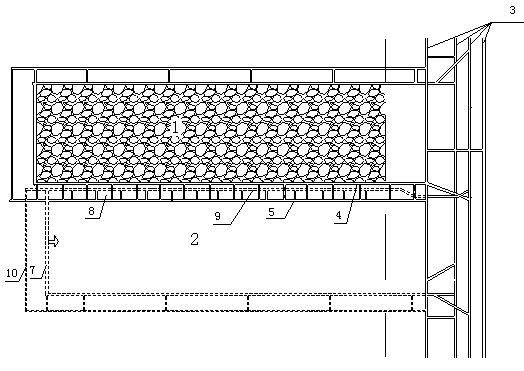

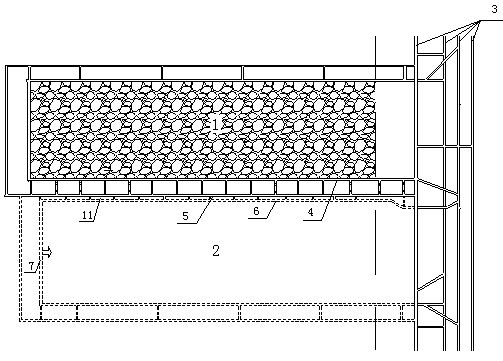

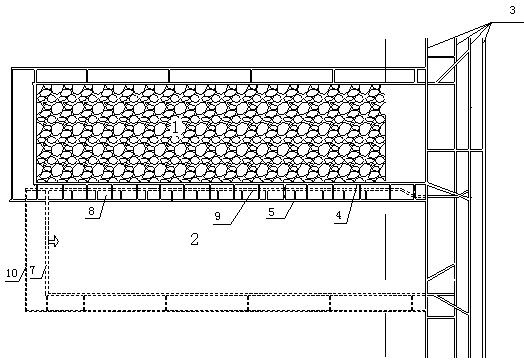

Mining method employing solid filling and fully-mechanized coal mining hybrid working face

ActiveCN104405437AAvoid pollutionSolve the tunnelingUnderground miningSurface miningSolid massFilling materials

The invention discloses a mining method employing a solid filling and fully-mechanized coal mining hybrid working face, namely a method for carrying out coordinated and combined mining by combining solid filling with fully-mechanized coal mining on the same coal face. Coal mining is carried out by adopting a strike retreating-longwall mode; coal cutting, coal charging and coal handling procedures are the same as those of a fully-mechanized coal mining process; a solid filling section of the hybrid working face is used for supporting a roof by virtue of a filling and mining hydraulic support; solid filling materials are backfilled to a goaf management roof by virtue of a porous hopper conveyor which is suspended behind and below of the filling and mining hydraulic support; a fully-mechanized coal mining section is used for supporting the roof by virtue of a fully-mechanized coal mining hydraulic support; the goaf is managed by adopting a caving method. The mining method is beneficial for giving play to dual advantages of solid filling and fully-mechanized coal mining; the problem of environmental pollution caused by accumulation of solid wastes such as gangue, coal ashes and construction wastes on the ground is reduced by solid filling; the working face is lengthened by combining with fully-mechanized coal mining; tunneling of a mining roadway is reduced; the single yield and single effect of the working face are improved; the requirements of a modern mine on production capacity are met.

Owner:CHINA UNIV OF MINING & TECH +1

Fully-mechanized caving mining process technology with large mining height in super-high seam (14-20m)

ActiveCN101967975AIncrease coal breaking effectIncrease coal discharge spaceUnderground miningSurface miningControl measureCoal mining

The invention provides a coal mining method of fully-mechanized caving mining with large mining height in a super-high seam, a coal caving process, reasonable type of a support, production capacity of equipment, comprehensive control measures of coal wall spalling of working face, a technical route for improving the recovery rate of the fully-mechanized caving face with the large mining height, and feasibility evaluation indexes (thickness of the seam, top coal cavability, coal wall stability and roof pressure strength) of the fully-mechanized caving mining with the large mining height, and further forms a whole set of fully-mechanized caving mining process technology with the large mining height. The coal mining method is that the coal cutting height is 4.2-4.8m; the length of the working face is 200-280m; and the web of a coal mining machine is 0.8-1m. The process technology can increase the coal cutting quantity by 43%, shorten the coal caving time by 9%, relatively reduce the coal caving quantity by 9%, improve the resource recovery rate by 5% and reduce the mining-caving ratio to below 1:3 by increasing the coal cutting height, and can further realize the relatively balanced production of mining and caving of the working face.

Owner:DATONG COAL MINE GRP

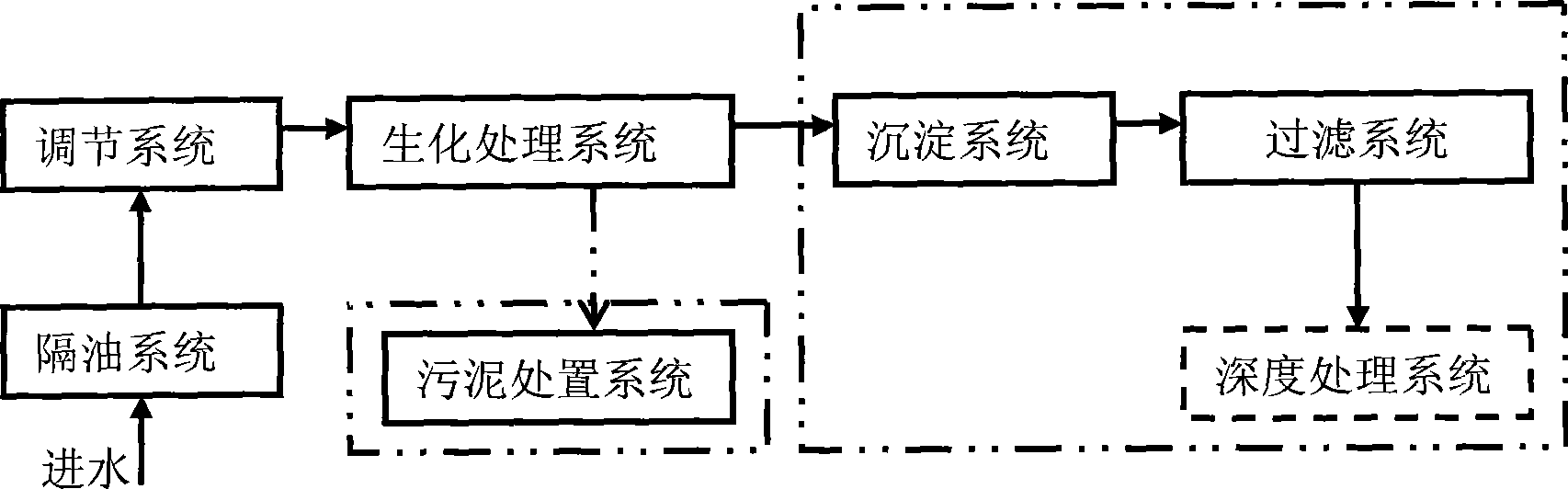

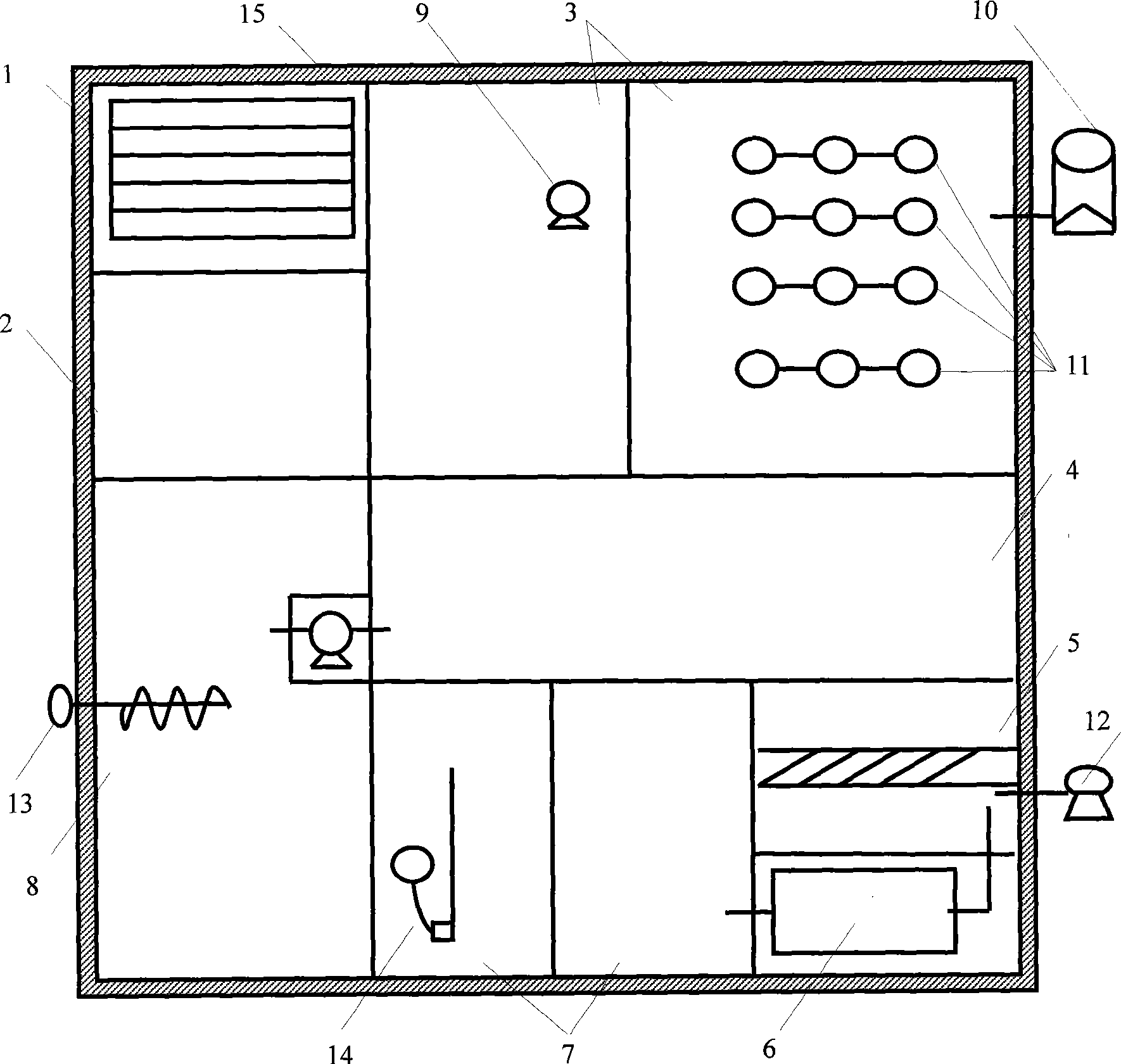

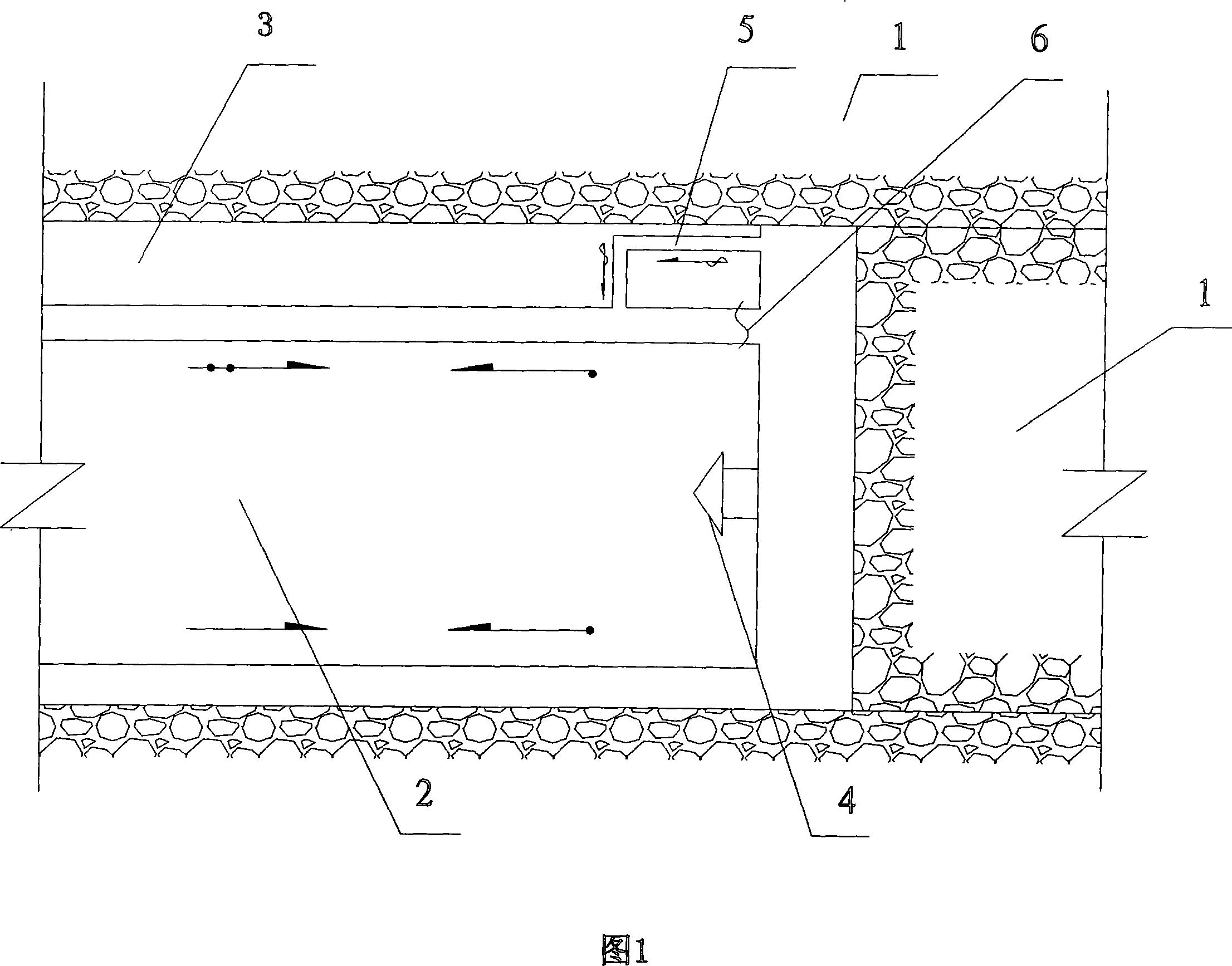

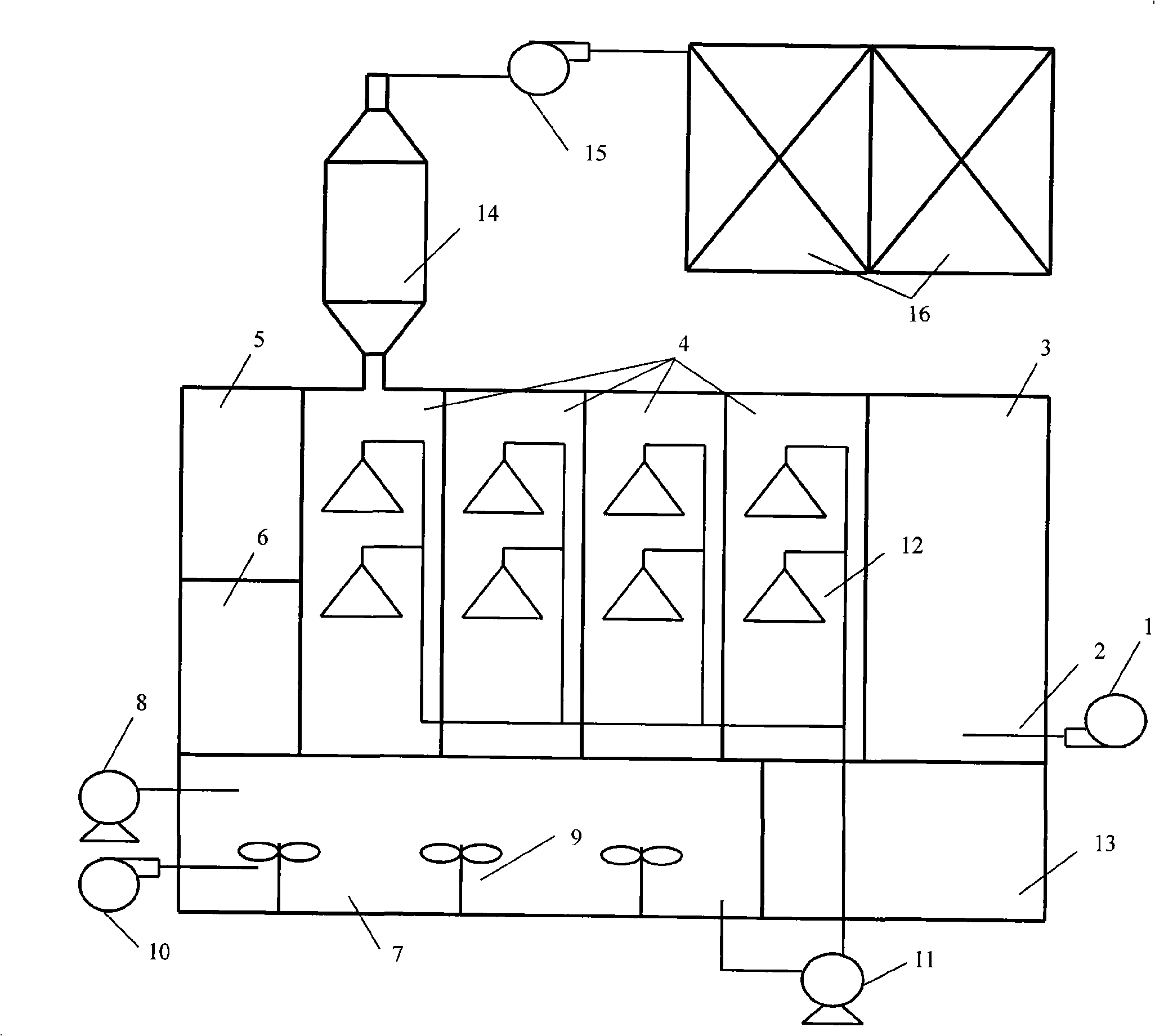

Apparatus for integrated treatment and comprehensive utilization of wastewater and use thereof

InactiveCN101462816AImpact treatmentAvoid cloggingBio-organic fraction processingFatty/oily/floating substances removal devicesSludgeSandwich board

The invention relates to a wastewater integrated treatment and comprehensive utilization device and application thereof. A method for the wastewater integrated treatment and comprehensive utilization comprises the following steps: firstly leading the wastewater into an oil interceptor tank and then into an equalizing tank; leading the wastewater after neutralization regulation into a biochemical treatment tank where a sump pump and an aeration device are arranged; leading the wastewater after the biochemical treatment into a sedimentation tank; leading the sedimentated wastewater into a filter tank with built-in filler for the filtration treatment of the wastewater; arranging a back flushing device or filtering material regeneration device beside the filter tank; leading the water outputted from the filter device into an advanced treatment tank to obtain the reclaimed water up to the standards; leading the reclaimed water into a reclaimed water tank where a liquid level controller is arranged for controlling the liquid level; and lifting the rest sludge in the sedimentation tank to a sludge drying compost tank, and carrying out the moderate temperature and high temperature composting of the rest sludge through a temperature controlled heating device. The integrated device is enveloped by an insulating layer formed by polyurethane sandwich boards. The invention provides an integrated device which has the advantages of modularized unit structure, high treatment efficiency, strong self control, wide adaptability, less investment and convenient motion and transportation.

Owner:ZHEJIANG UNIV

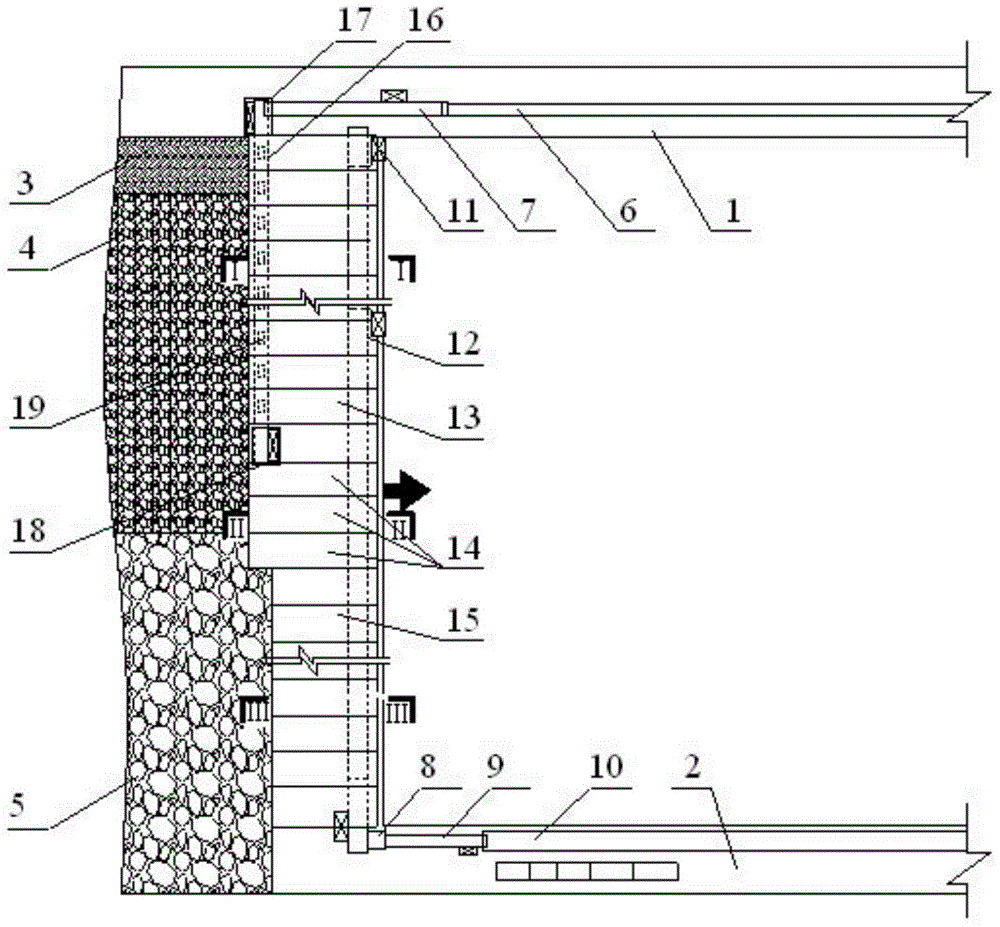

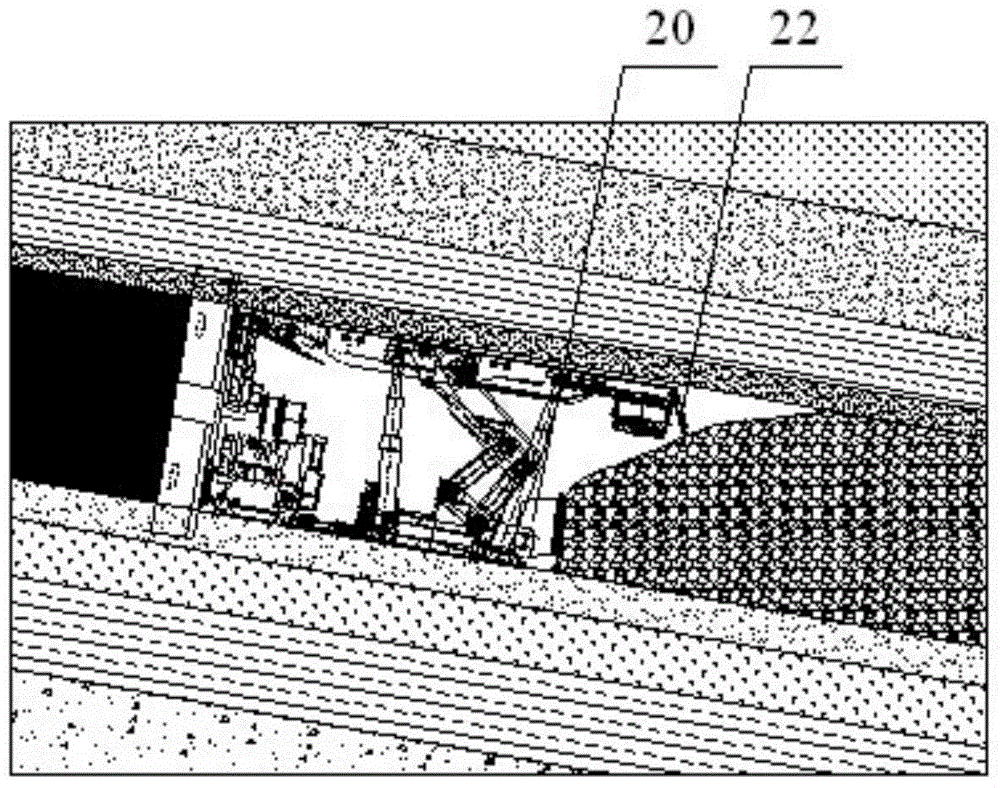

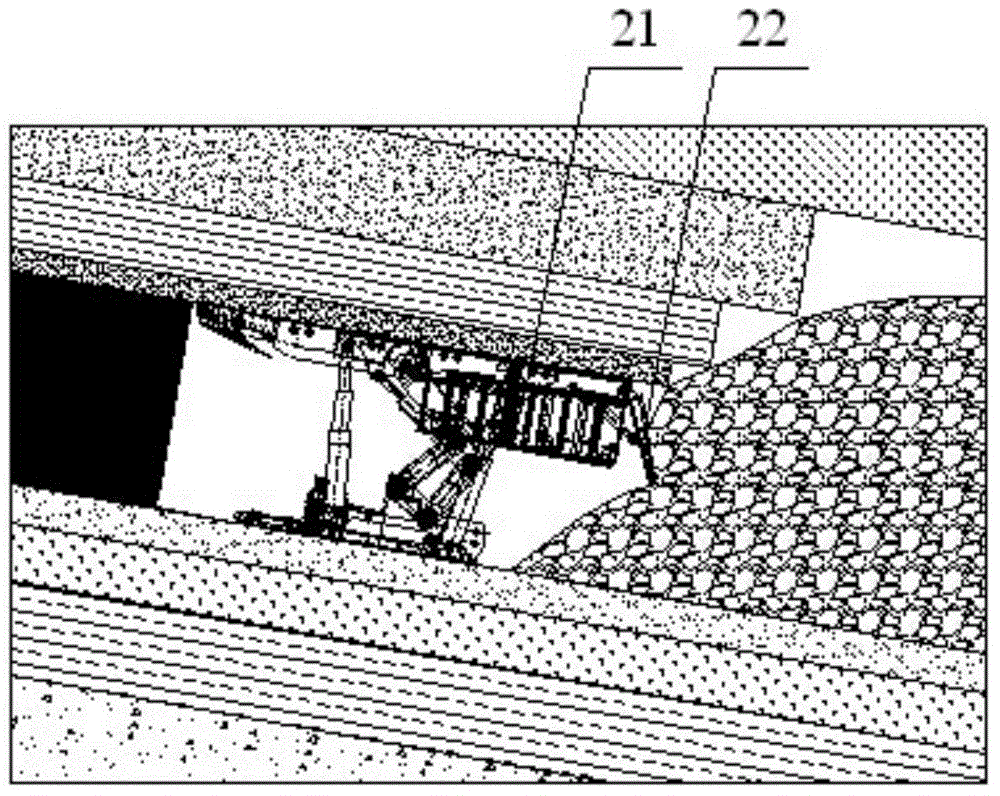

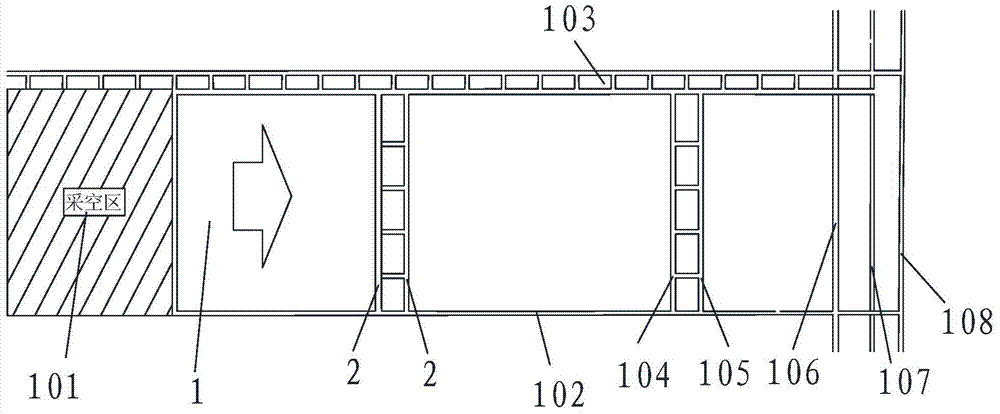

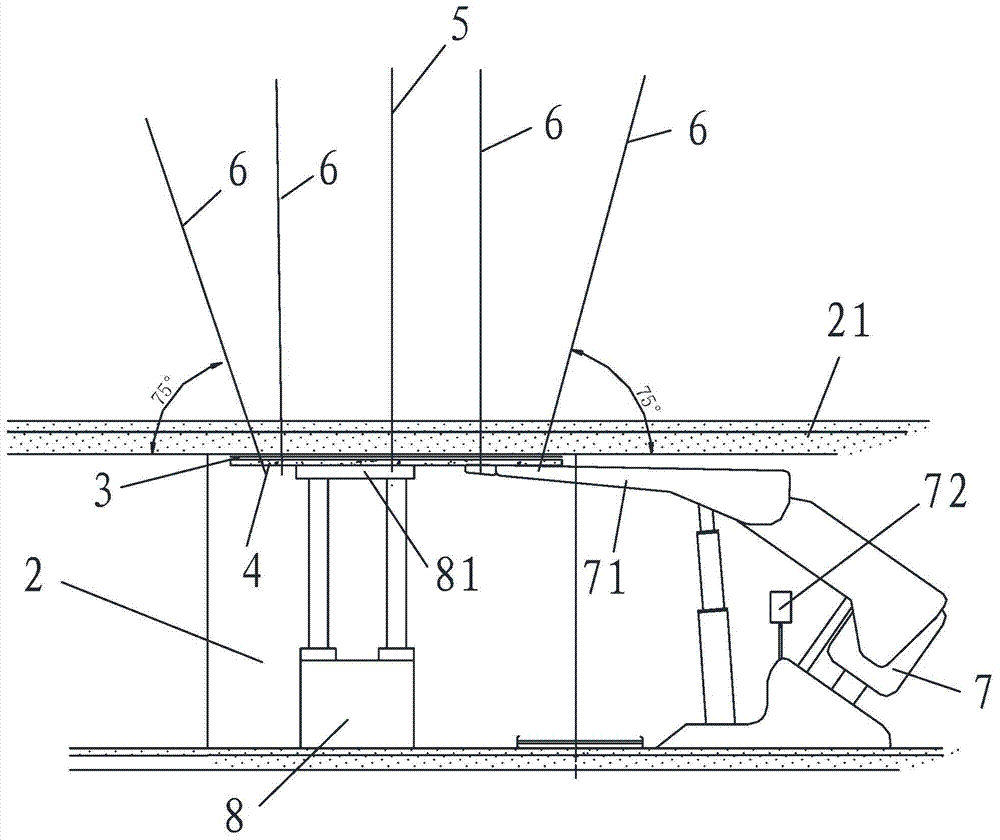

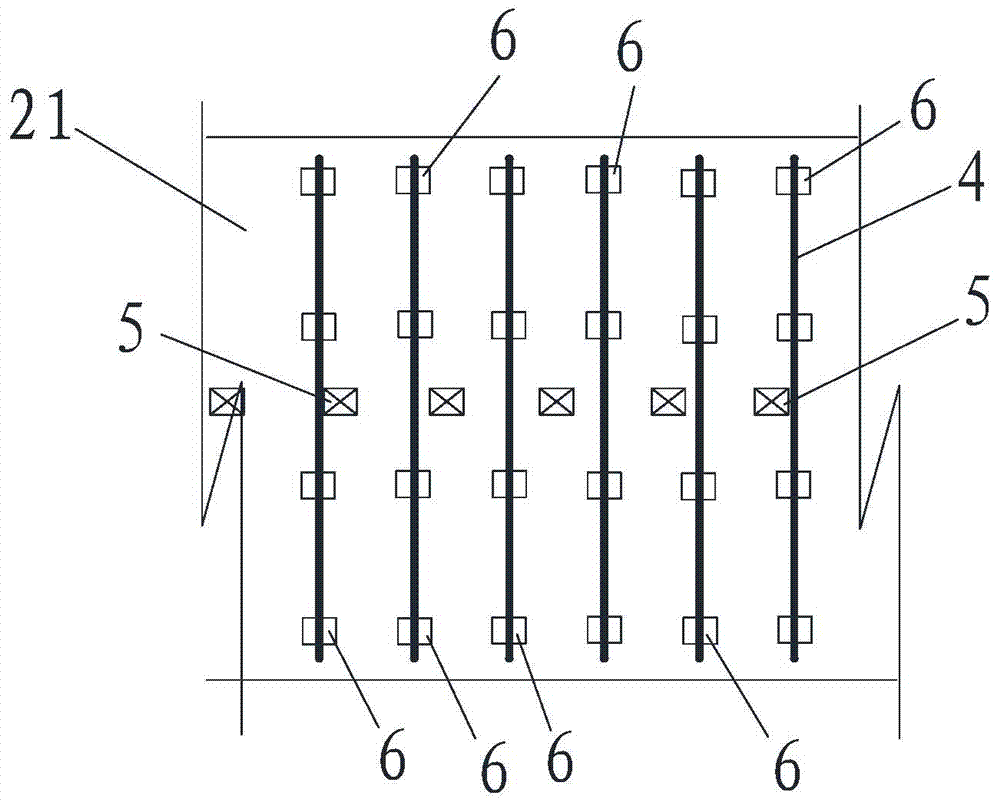

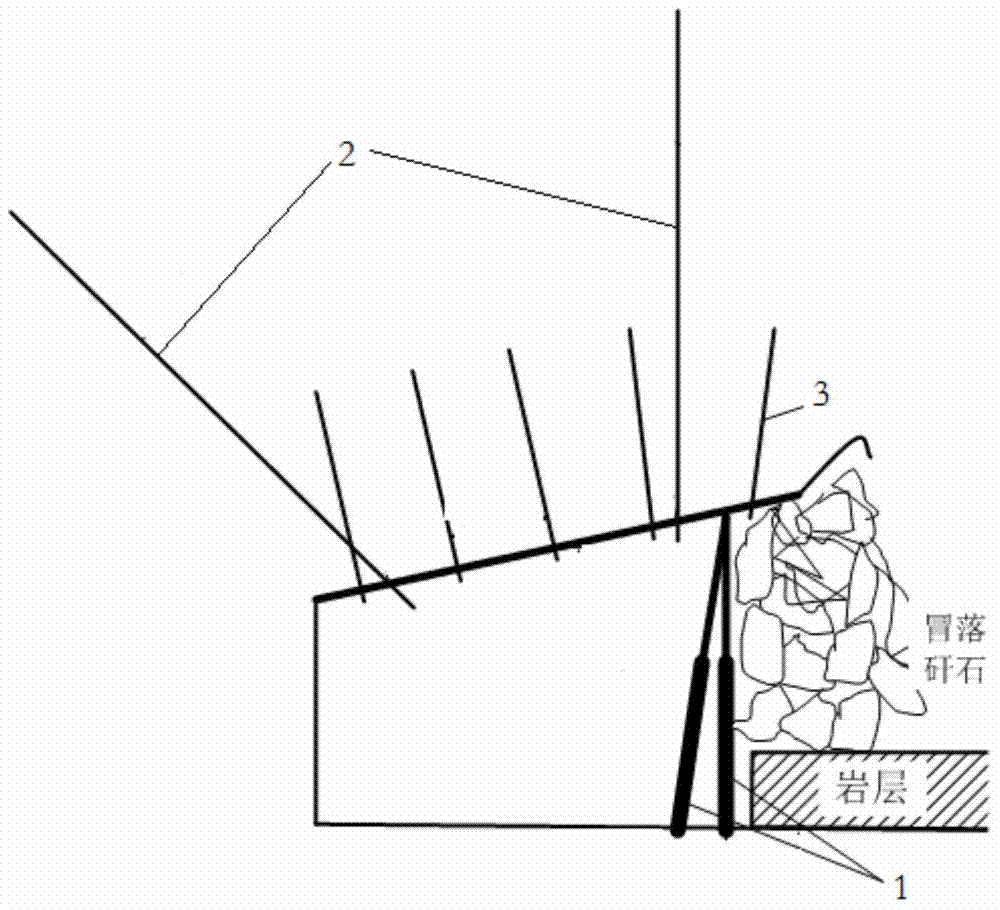

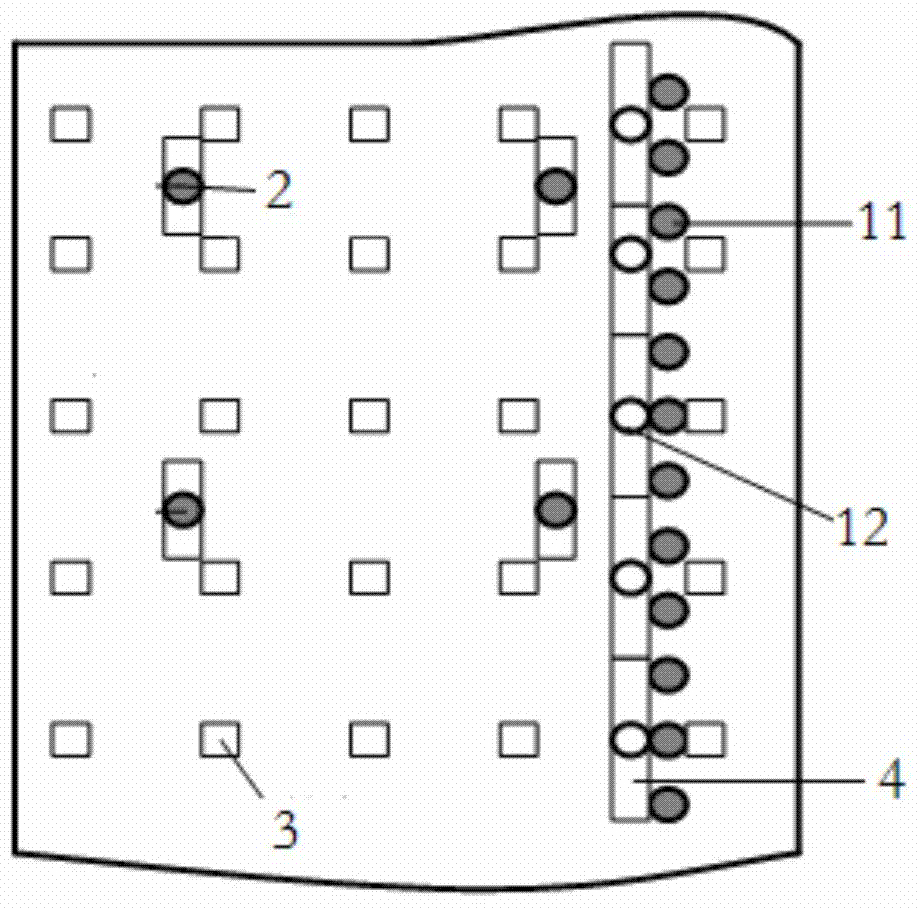

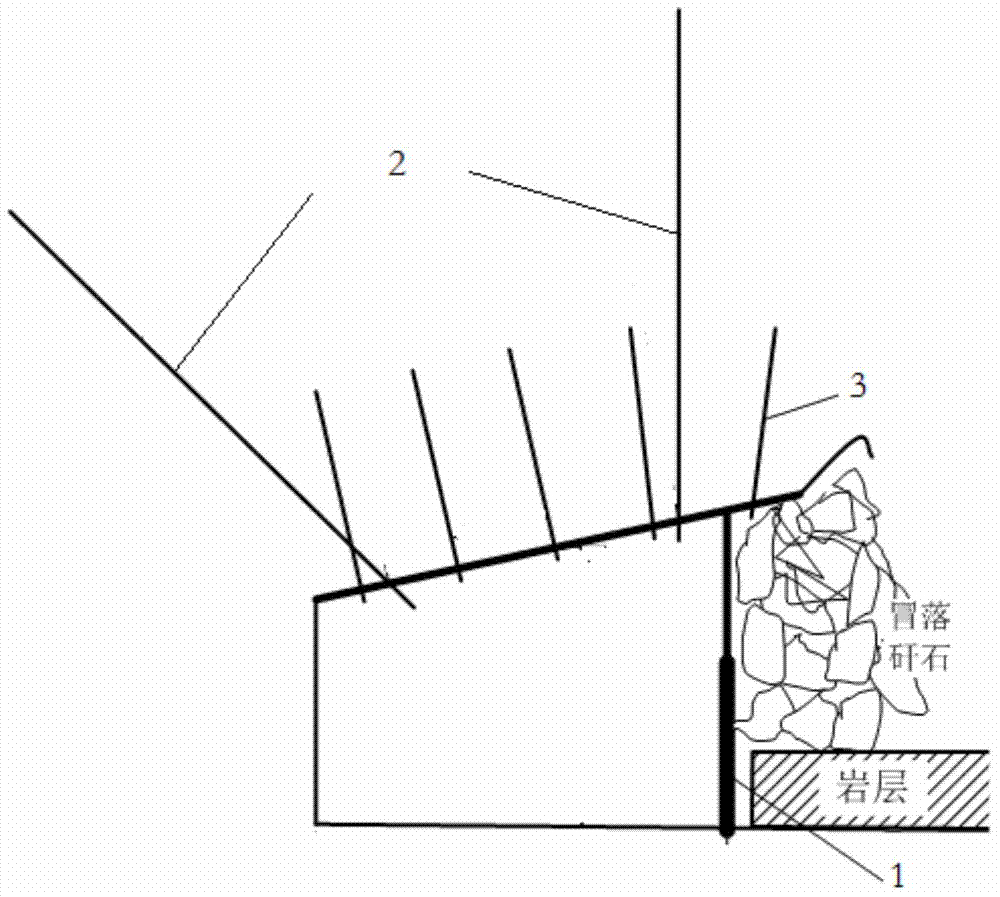

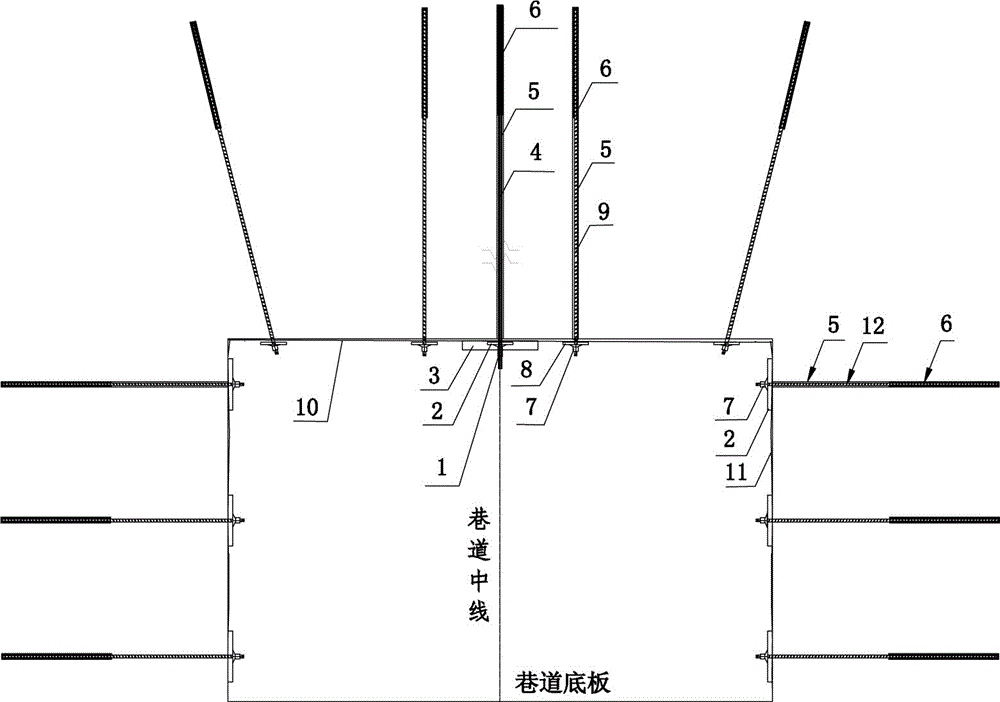

Abandoned roadway timbering device and construction method of fully mechanized coal mining face passed through abandoned roadway

ActiveCN103696788AReduce roof fall accidentsImprove support strengthUnderground miningSurface miningStructural engineeringCoal mining

The invention discloses an abandoned roadway timbering device which comprises a metal net, a steel belt, a protective net, timbering anchor ropes, hanging timbering anchor ropes, anchor rods and a hydraulic support. The steel belt is installed on a top plate of an abandoned roadway through multiple hanging timbering anchor ropes, the hanging timbering anchor ropes located at two ends of the steel belt and the top plate form an included angle alpha, the metal net is fixed under the top plate through the hanging timbering anchor ropes and the timbering anchor ropes, the steel belt is located under the metal net, multiple timbering anchor ropes are installed on the top plate located on a central line of the abandoned roadway, a hydraulic chock is located in the abandoned roadway, a top beam of the hydraulic chock abuts against the top plate, and the protective net is installed on the roadway side of the abandoned roadway through the anchor rods. The invention further discloses a construction method of a fully mechanized coal mining face passed through the abandoned roadway.

Owner:CHINA SHENHUA ENERGY CO LTD +1

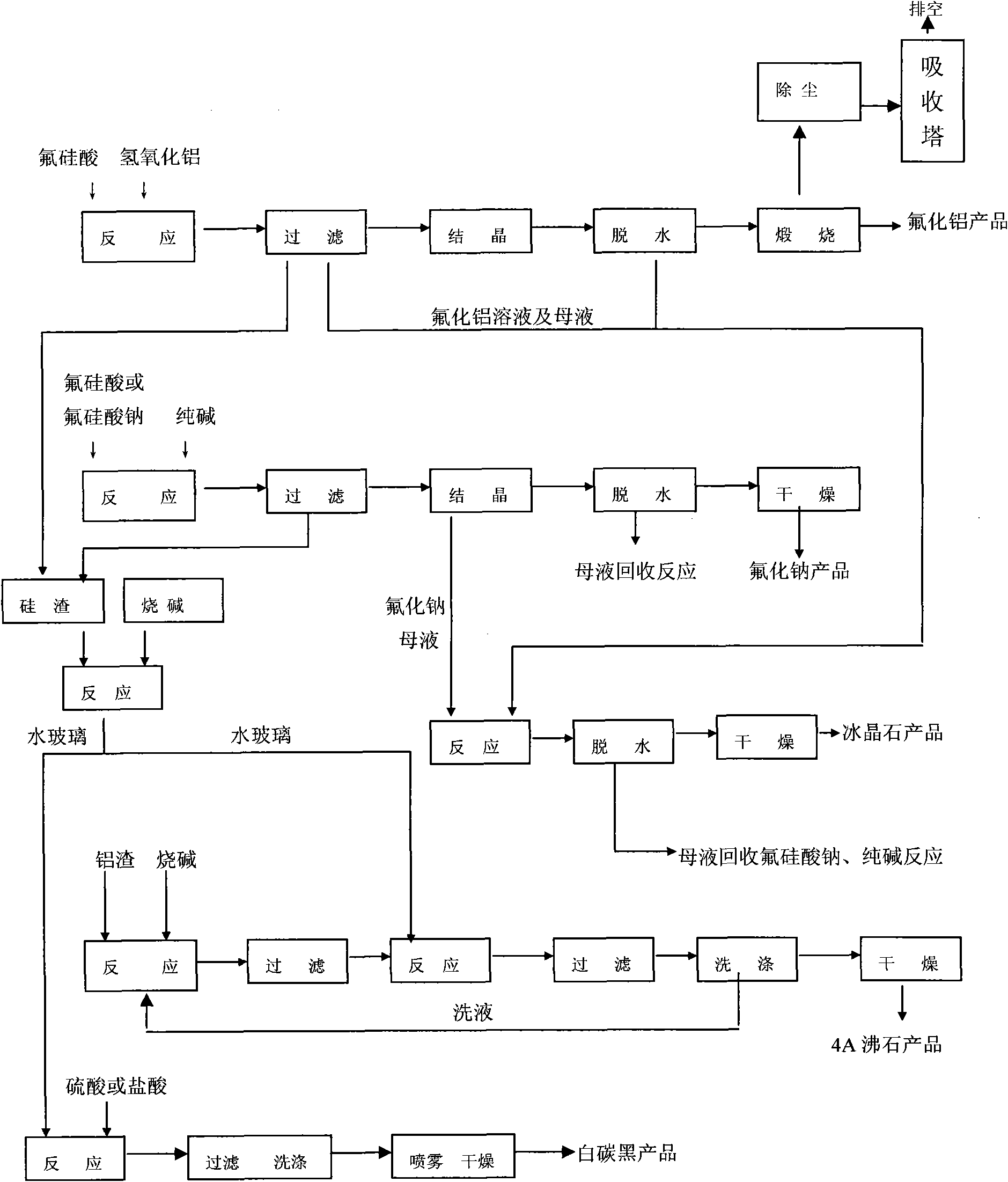

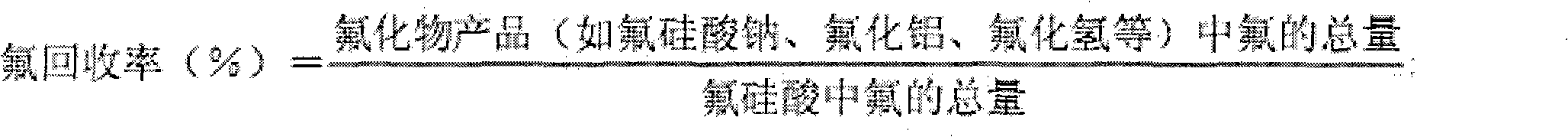

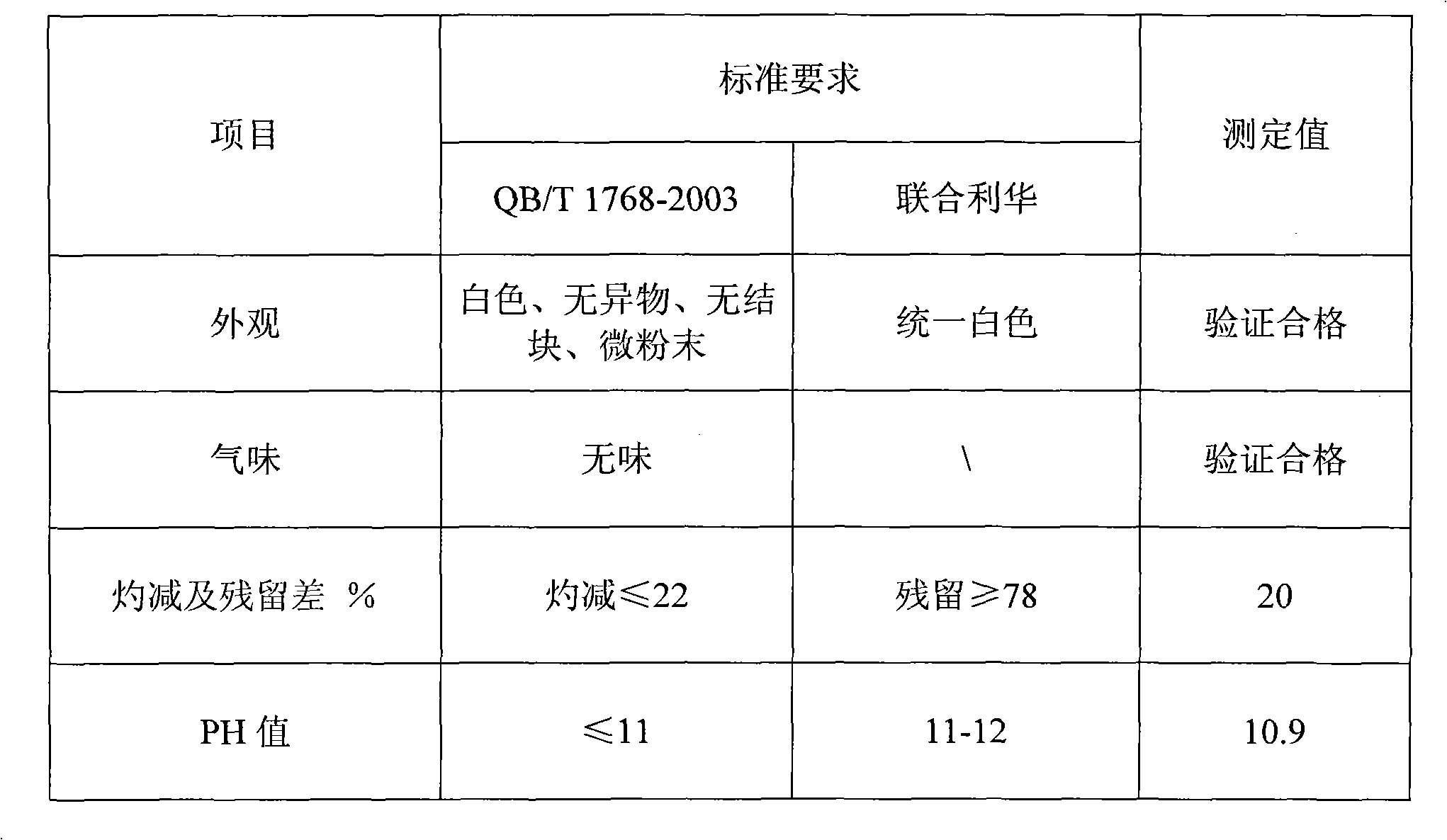

Process method for producing fluorine compounds and silicon compounds by cleanly utilizing fluosilicic acid

ActiveCN101913637AHigh recovery rateTake advantage ofSilicaAlkali metal silicatesChemical industrySlag

The invention discloses a process method for producing fluorine compounds and silicon compounds by cleanly utilizing fluosilicic acid. The process method comprises the following steps of: preparing fluosilicic acid as a phosphorus chemical by-product into an anhydrous aluminum fluoride product, a sodium fluoride product and a cryolite product, and combining with other industrial waste silicon slags and aluminum slags to prepare a 4A zeolite product. The process method comprehensively utilizes the fluosilicic acid and has high resource recovery rate, wherein the recovery rate of the fluorine element reaches higher than 90 percent. Waste silicon dioxide slags generated in the process can be recycled to produce white carbon black and the 4A zeolite, and a mother liquor, a cleaning solution and waste gas which are generated in the production process are all recycled, thereby the environmental pollution is reduced, and the purposes of zero emission and no pollution are truly achieved, thus the method completely meets the requirement for clean production. The invention has the advantages of advanced production process, good product quality and high value, wherein the fluorine content of the aluminum fluoride is high and between 63-65 percent; the quality index of the obtained white carbon black meets the requirement on the standard of the chemical industry; and the quality of the 4A zeolite product meets the requirements on the national standard and the standard of European and American developed countries.

Owner:四川励志环保科技有限公司

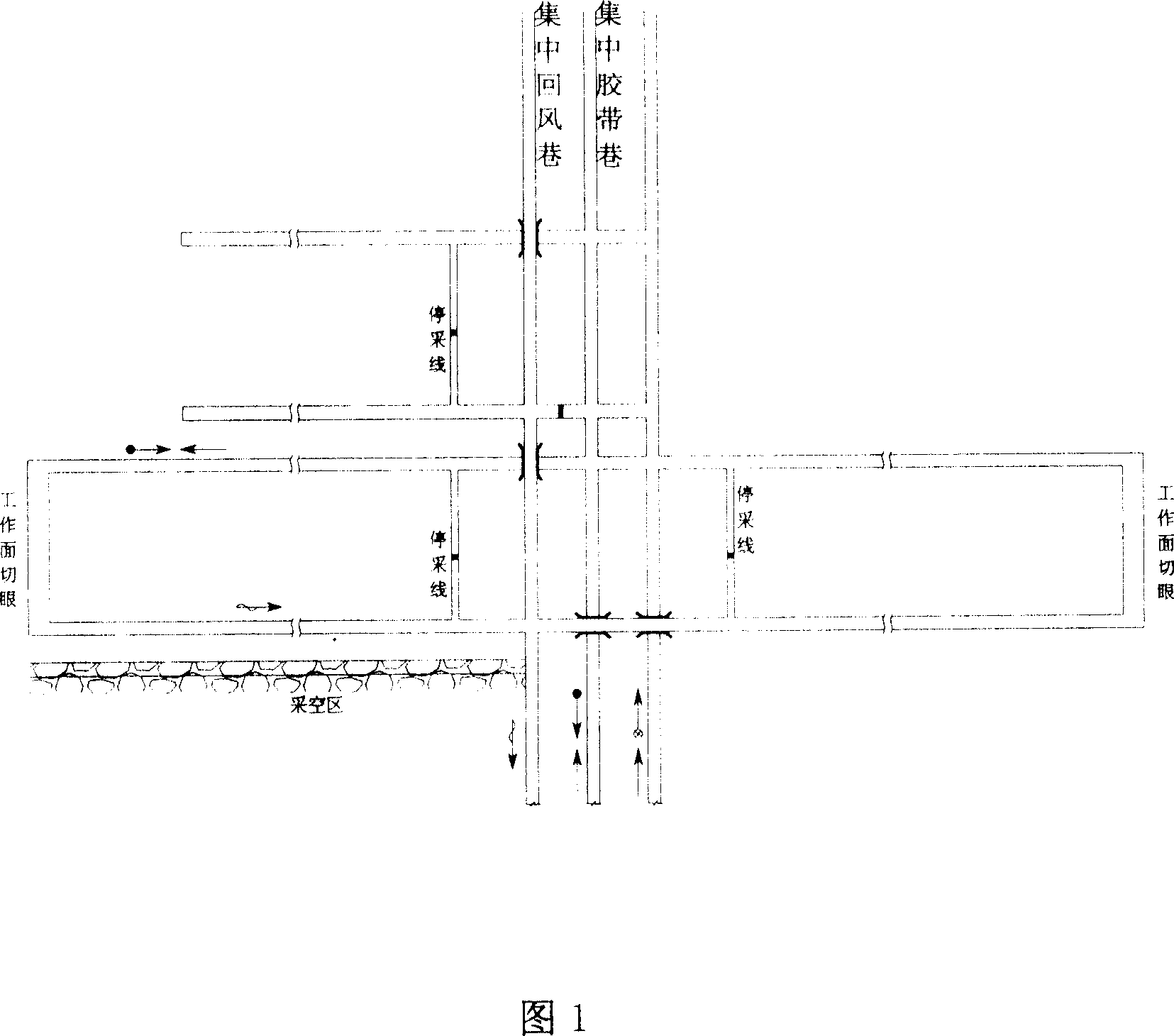

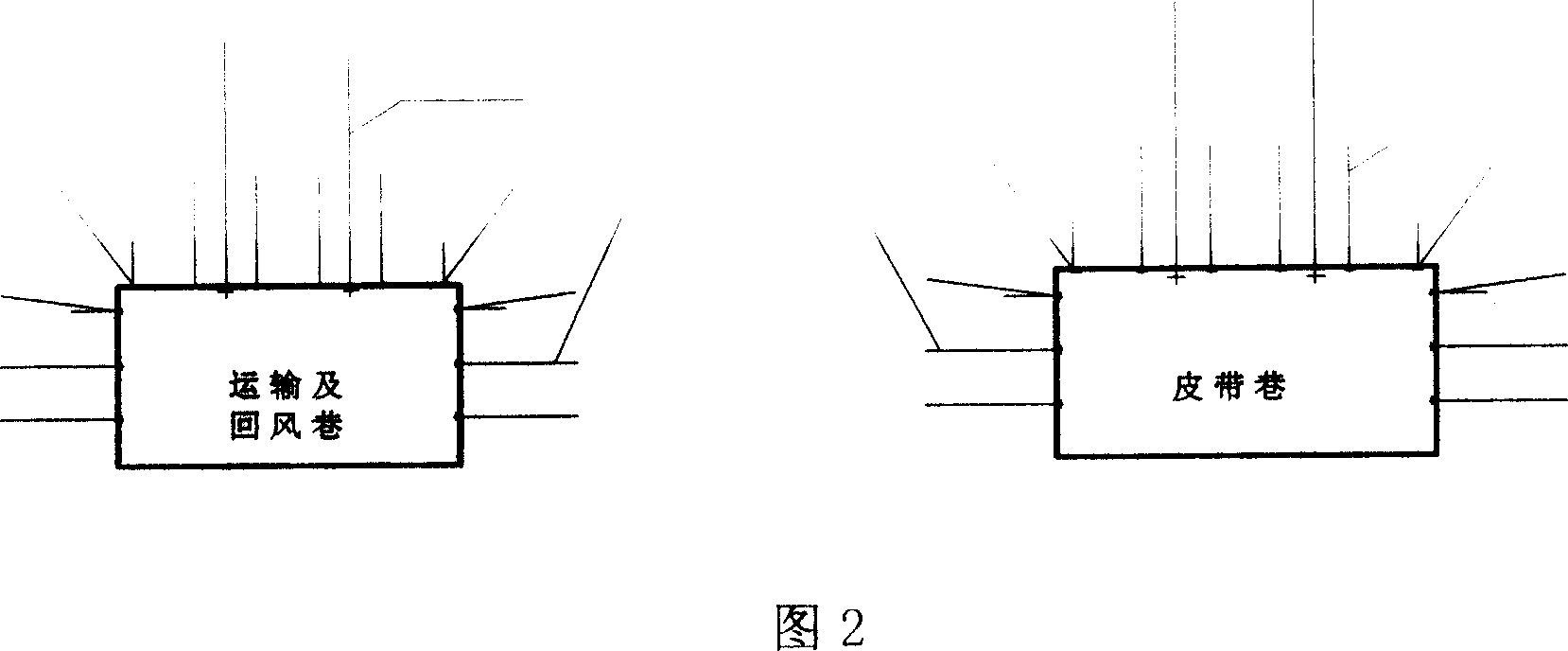

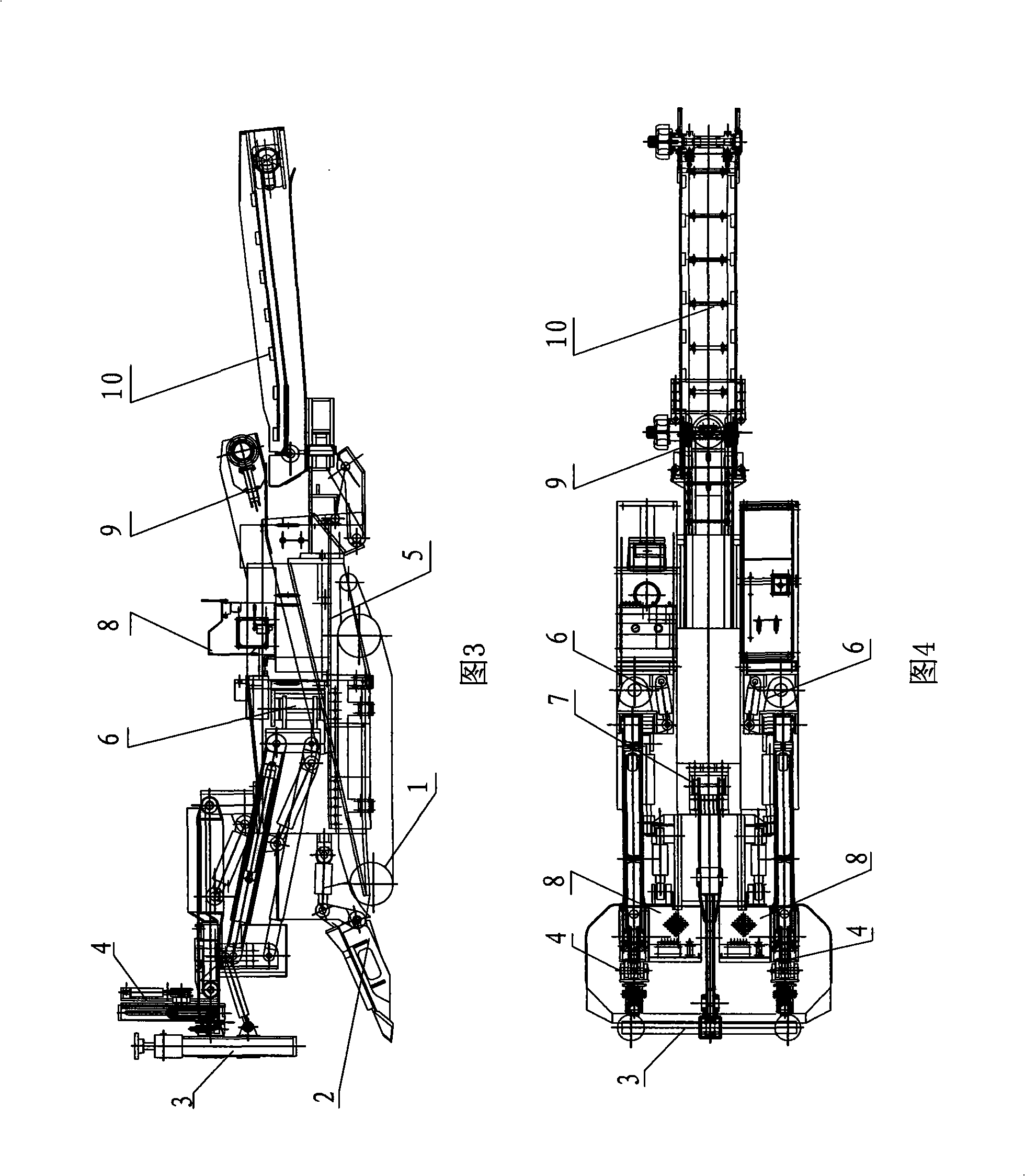

Full-seam cutting, retreating, separate moving and full-caving comprehensive mechanized coal mining method and equipment

ActiveCN1932240ALarge air volumeImprove support strengthUnderground miningSurface miningIt equipmentTransport system

The present invention provides a full-seam mining retreating separately-moving full-span comprehensive mechanized coal-cutting method and its equipment. It is mainly characterized by that it adopts full-seam mining support form, utilizes crawler-type single-drum shearer to cut coal and utilizes the separate movement of coal-cutting equipment coal-conveying equipment and supporting equipment and transporting system to implement coal-cutting operation. Besides, said invention also provides the concrete steps of said mechanized coal-cutting method.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

Method for extracting rim angle coal and re-extracting after warehouse coal extracting

InactiveCN101302931ASave resourcesImprove resource recoveryUnderground miningBlastingResource depletionCoal pillar

The invention relates to a method for re-mining after the coal mining in a barn and the stoping of irregular coal. The method of the invention includes the arrangement of roadways and the technologies of mining, coal blasting, coal loading, coal transporting, supporting and dual-wing recovery and is characterized in that as for the arrangement of the roadways, a plurality of sections are divided in a panel and two preparation roadways are arranged in the sections, with one preparation roadway serving as an air intake way and the other one as an air return way; after the coal mining is finished in the previous section, the air intake way of the previous section can be taken as the air return way of the next section; only one air return way needs excavating in the next section; a long strip-shaped room pillar is arranged between the two preparation roadways, which ensures that the stopping of the next room pillar can be carried out under the less pressure of a top plate; as for the technology of mining, room mining is first carried out in the strip-shaped room pillar by adopting anchor net support; the coal at two wings are recovered by bidirectional retreating after the air return way is communicated, which causes small and medium-sized coal mines with 'resource depletion' to realize the re-mining and large and medium-sized coal mines to achieve the stopping of coal pillars and the irregular coal, thus improving recovery ratio and conserving resources.

Owner:闫振东

Pyrolysis based resource reclaiming process of waste circuit board

InactiveCN101767104AImprove resource recoveryMeet the requirements of circular economy developmentSolid waste disposalElectronic waste recyclingPartial oxidationPrinted circuit board

The invention discloses a pyrolysis based resource reclaiming process of a waste circuit board, belonging to the technical field of waste resource reclamation and recycle. The method comprises the following steps: placing a waste circuit board with an electric element detached in a pyrolyzing furnace for thermal cracking; collecting pyrolyzed oil, pyrolyzed gas and pyrolyzed residues generated in the pyrolyzing process; directly introducing the purified pyrolyzed gas serving as gas into a pyrolysis system to provide energy for the pyrolyzing process; polymerizing the pyrolyzed oil and formaldehyde to synthesize pyrolyzed oil-phenolic aldehyde resin; selectively synthesizing carbon functional materials with different shapes and structures by using the prepared pyrolyzed oil-phenolic aldehyde resin as precursor; peeling glass fiber in the collected pyrolyzed waste circuit board residues from a metal layer, and reclaiming glass fiber cloth and metal; and removing carbon on the surface of the separated glass fiber by adopting a partial oxidization method, and preparing a veneer sheet together by the carbon and the synthesized pyrolyzed oil-phenolic aldehyde resin. The process ensures that material reclamation in the waste circuit board forms a closed circulation system, and has high resource reclamation rate.

Owner:DALIAN UNIV OF TECH

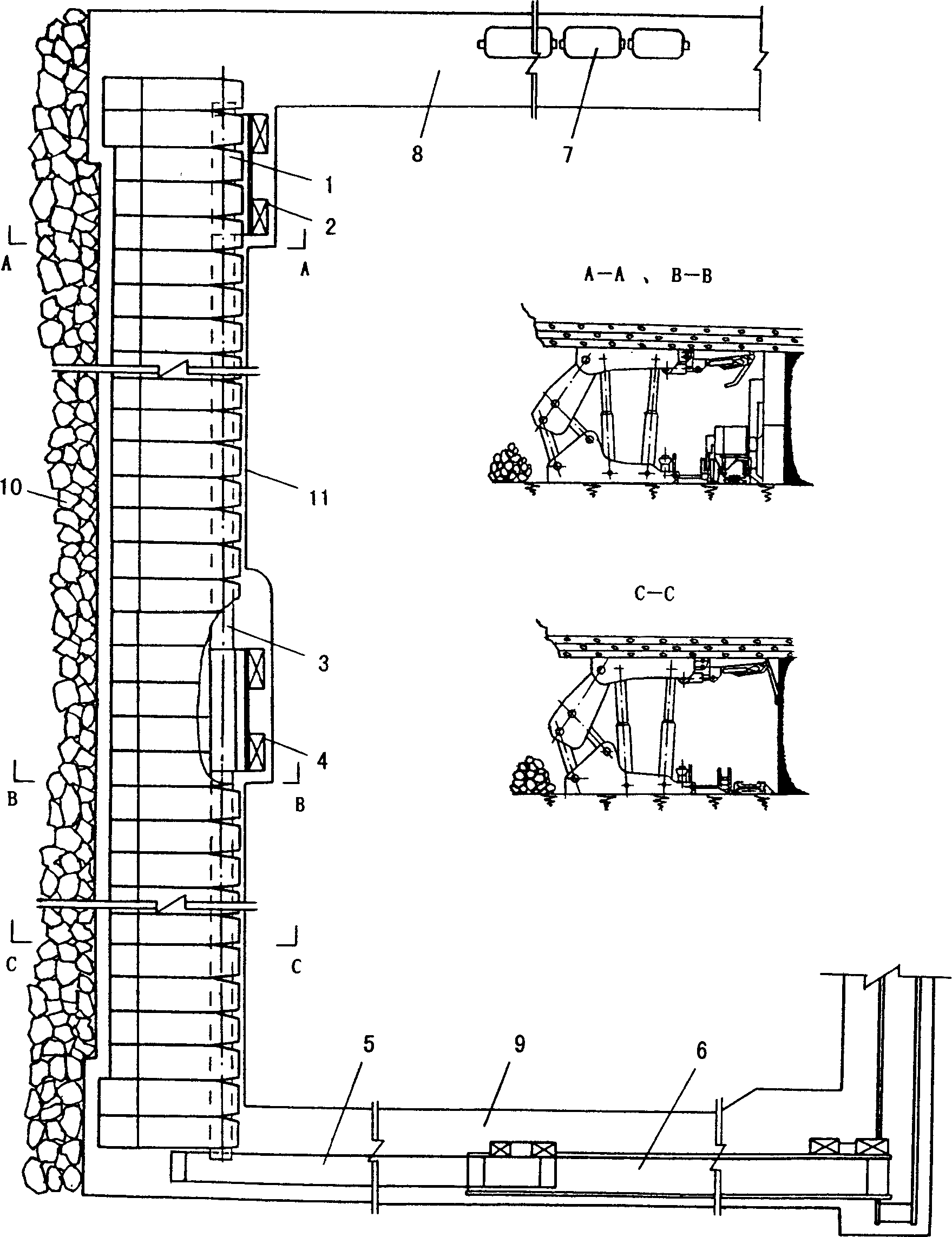

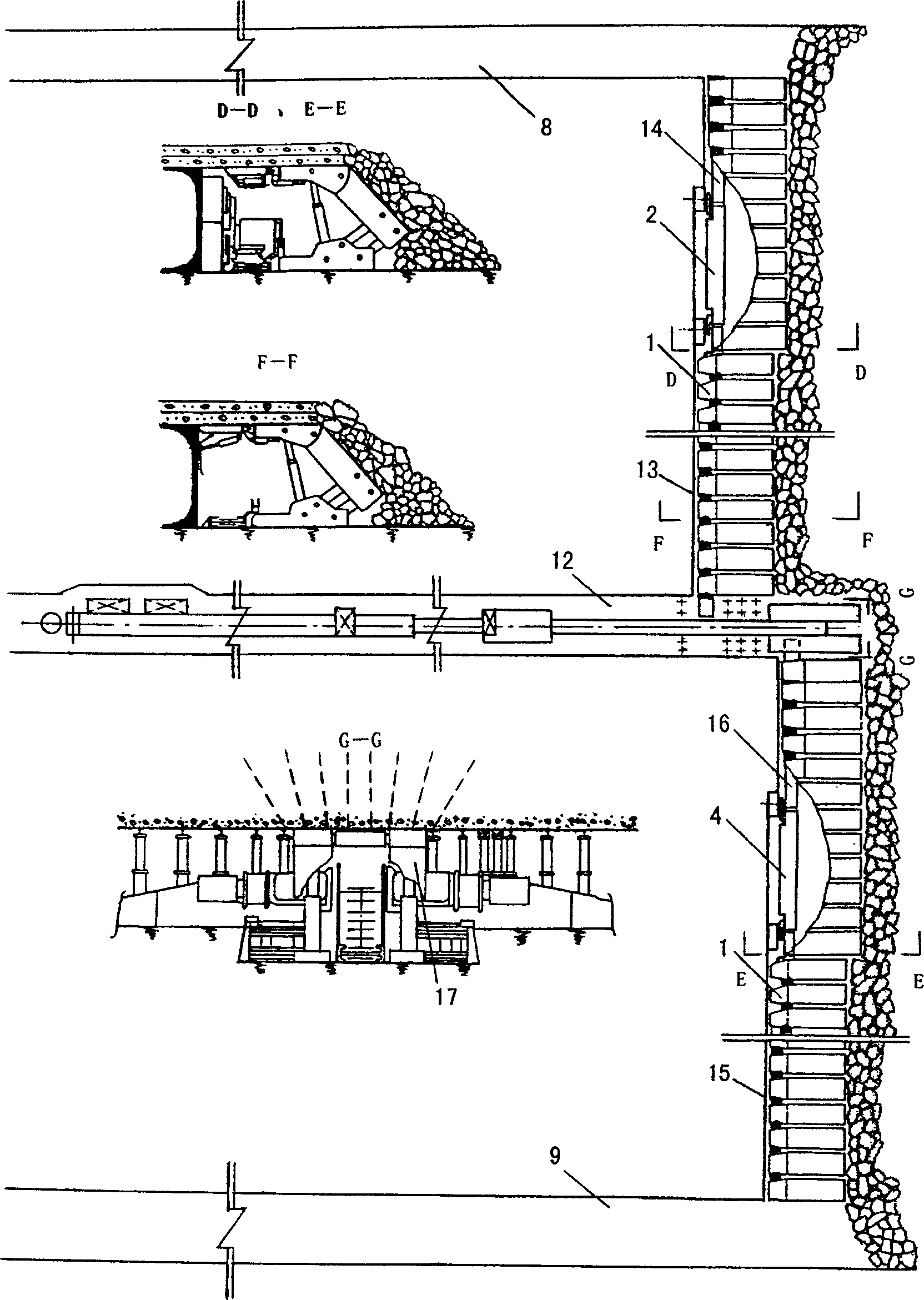

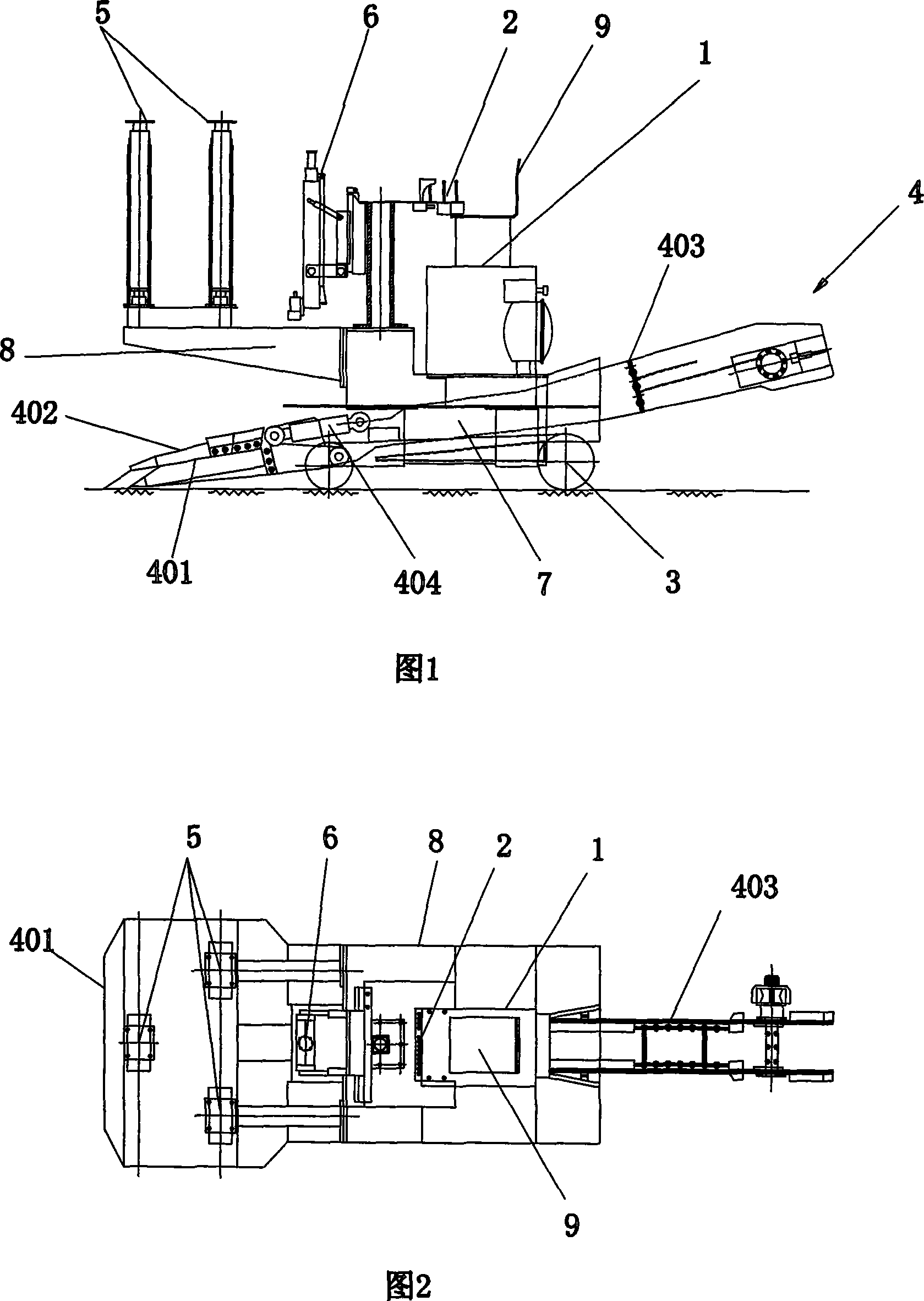

Explosion coal-falling, coal-loading, coal-conveying and anchor-rod supporting mechanism integration operation method and apparatus

InactiveCN101025086AIncrease the speed of excavationExcavation section is largeUnderground miningSurface miningResource recoveryEngineering

The invention provides a blast-winning, coal loading, coal conveying and anchor rod-timbering mechanical integrated operating method and device. And the device mainly comprises: hydraulic system, hydraulic control table, track walking part, coal loading and conveying part, timbering part, and hydraulic anchor rod machine, and the method uses integrated device, scraper conveyor and gate coal conveyor; and its drivage circulating speed is 1m to 1.5 m, blast-winning and after the fumes have settled, making the integrated device enter into the operating site, and after completing coal loading and conveying, making anchor rod timbering; after completing the anchor rod timbering operation, making the integrated device exit the operating site and over 20 meters distant from the operating site, and then making drilling and blasting operation. And it improves explosion level of blast winning and resources recovery, and reduces operators.

Owner:闫振东

Underground no pillar recovery method of coal mine

InactiveCN101033689AImprove the recovery rate of coal resourcesReduce roadway excavation work and maintenanceUnderground miningTunnel/mines ventillationDrill holeCoal pillar

The invention provides a pack recovery method without coal wedge. It contains the following technologies: set up coal wedge, drilling along and vertical space, stoping coal wedge, ventilation system, engaging measure, safe and transport measure. Construct and drill round hole along the gob brim of picked working face on afterbody of working face and drill holes along the roof by drilling along space. 1-3 round holes are taken as circulating holes of stoping working face. Drilling vertical space drills holes connecting with drilling along space in track tunnel. The number of holes is same as that of drilling along space. The invention arranges ventilating holes along the gob brim, which can avoid and weaken the influence of fixed stay pressure, replace remaining and digging tunnels along space and improve the recovery rate of coal resource. It reduces quantities and maintenance of tunnel driving. The drilling along space is safe, highly active and has low-loss.

Owner:LANG FANG JING LONG GRAND IND MACHINERY CO LTD

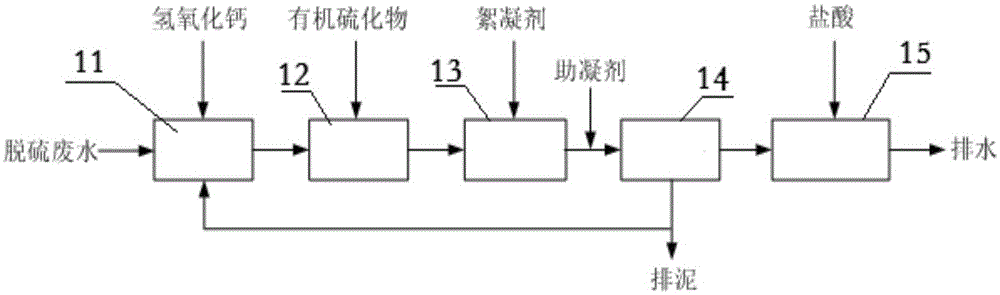

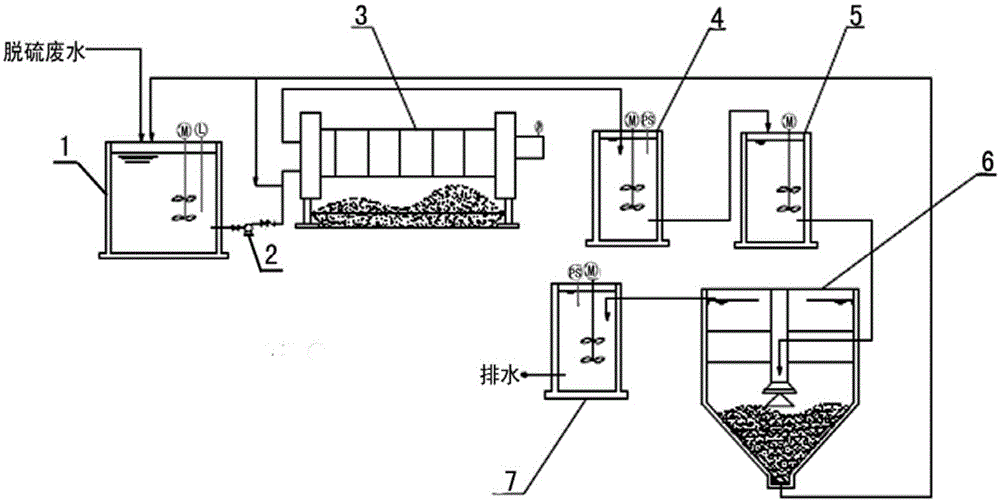

Desulfurization wastewater treatment system and desulfurization wastewater treatment method

ActiveCN105000713AReduce solid contentSolid load and failure rate reductionMultistage water/sewage treatmentFertilizerGypsum

The present invention discloses a desulfurization wastewater treatment system and a desulfurization wastewater treatment method. The desulfurization wastewater treatment system comprises: a wastewater buffer pool, wherein the water inlet is connected with the outlet of an apparatus for producing desulfurization wastewater; a sludge pressing device, wherein the input end and the water outlet of the wastewater buffer pool are connected; a multi-stage treatment pool, wherein the water inlet is connected with the water outlet of the sludge pressing device; a clarification pool, wherein the water inlet is connected with the water outlet of the multi-stage treatment pool; and a pH value re-adjusting box, wherein the water inlet is connected with the clear water outlet on the upper portion of the clarification pool. The invention further provides a wastewater treatment method adopting the system. According to the present invention, the wastewater treatment method is particularly suitable for pellet flue gas wet desulphurization wastewater, the process is simple, the solid content in the system is low, the operating cost is reduced while the desulfurization by-product gypsum and the slow-release fertilizer can be recycled, and the final effluent meets the national discharge standard.

Owner:BEIJING ZHTD ENVIRONMENTAL PROTECTION TECH CO LTD

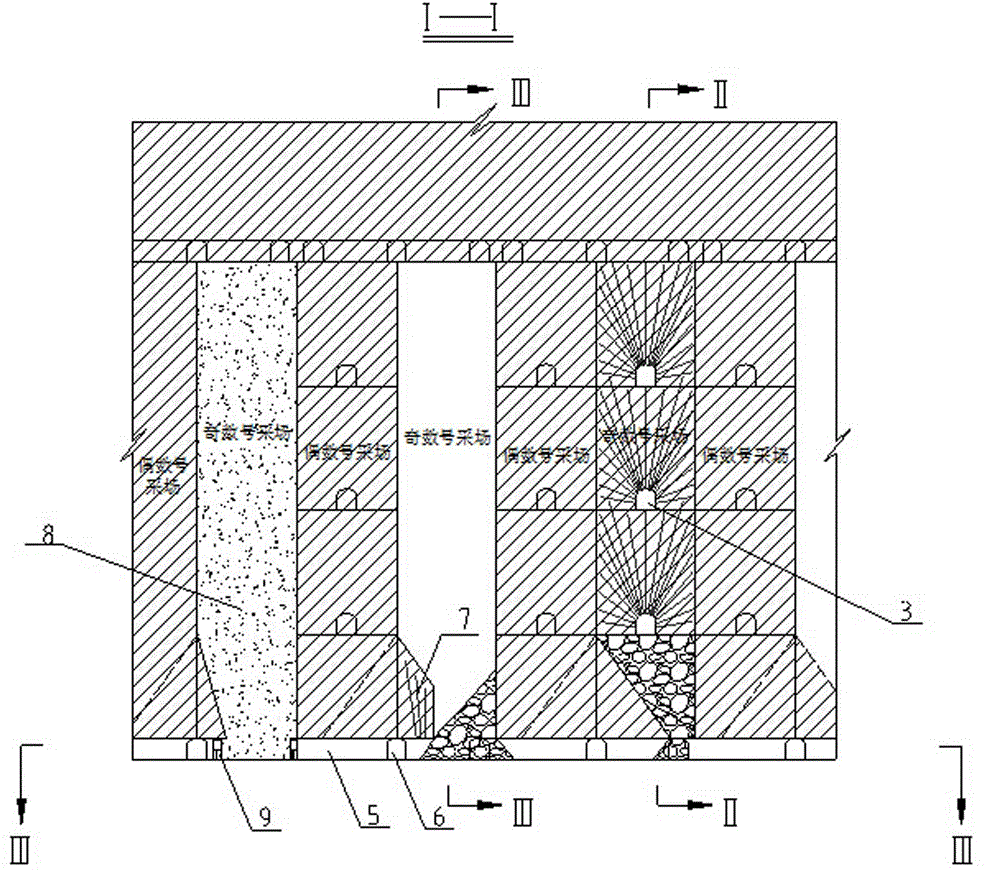

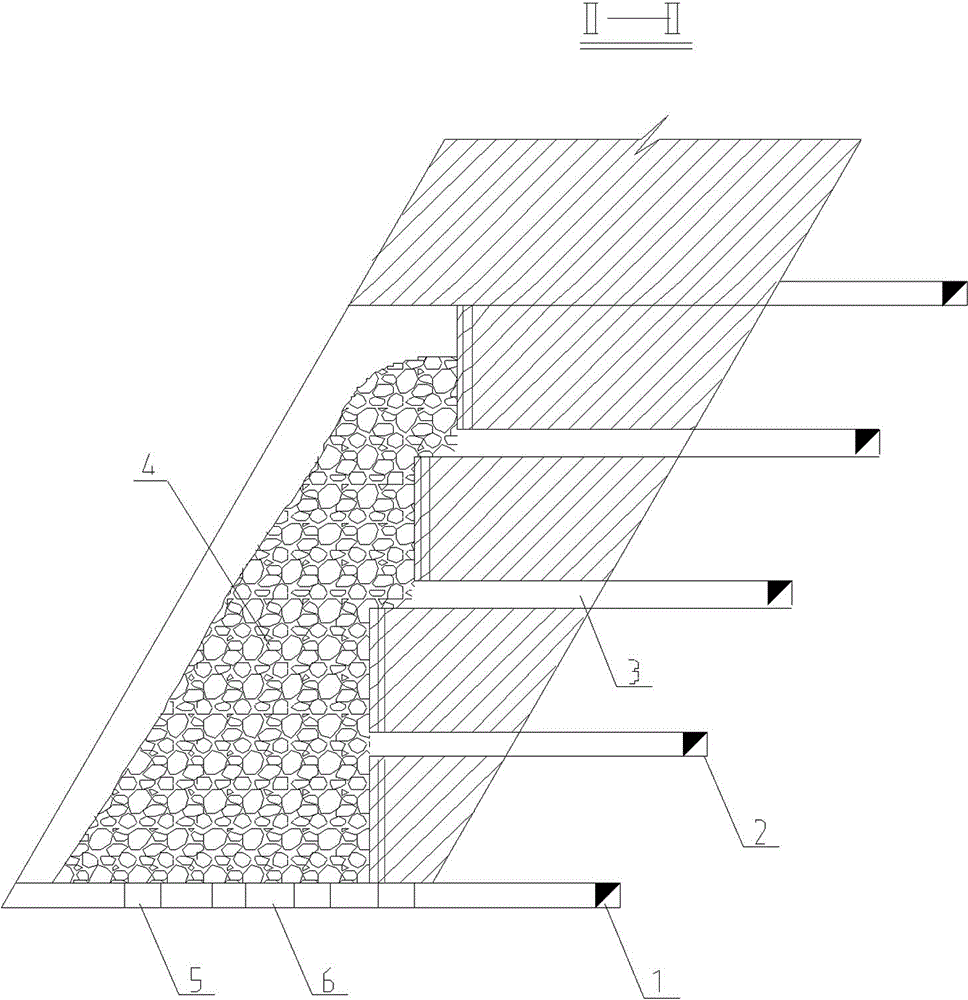

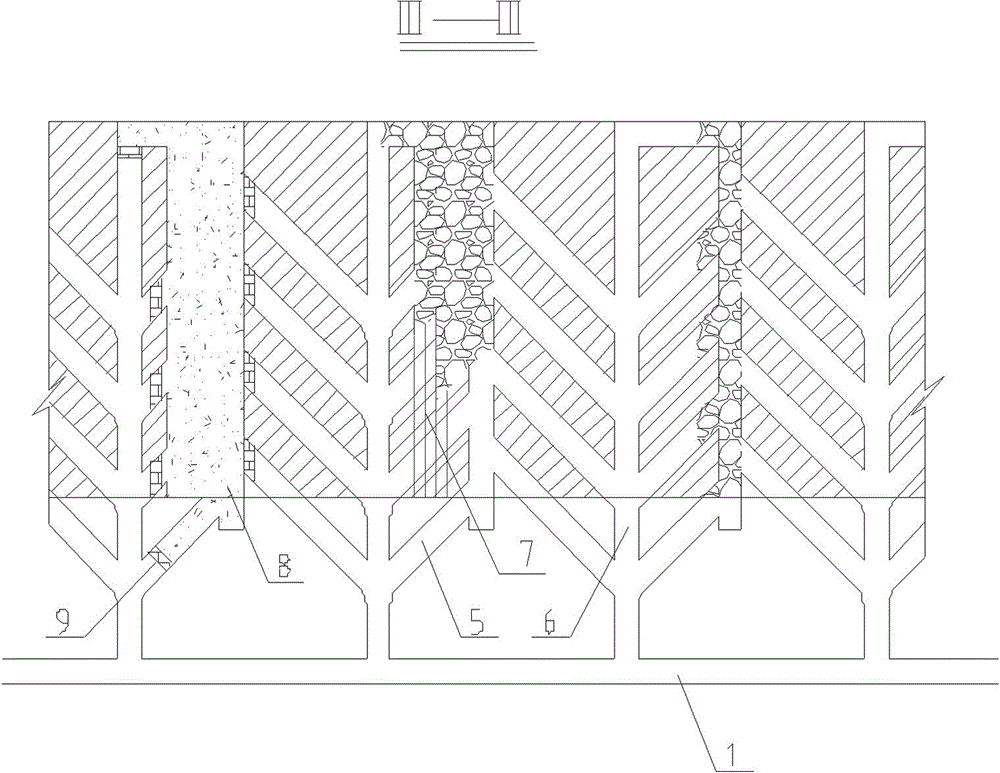

Large-structure sublevel drilling stage ore removal mining method with delayed filling

ActiveCN104863592AReduce labor intensityImprove stope production capacityUnderground miningSurface miningResource recoveryStructure of the Earth

The invention relates to a large-structure sublevel drilling stage ore removal mining method with delayed filling. The mining method comprises stoping in stopes and bottom structure recovery which are carried out synchronously in a crossed manner, and comprises the following steps: step 1, stoping in odd-numbered stopes, wherein the stoping manner is sublevel drilling stage ore removal, and mined out space I is not filled immediately; step 2, stoping in 1 / 2 bottom structures I corresponding to the odd-numbered stopes, and filling ore rooms and the mined out space I, corresponding to the 1 / 2 bottom structures I, of the ore rooms after stoping is finished; step 3, stoping in even-numbered stopes, wherein mined out space II is not filled immediately; step 4, stoping in 1 / 2 bottom structures II corresponding to ore pillars, and filling the ore pillars and the mined out space II, corresponding to the 1 / 2 bottom structures II, of the ore pillars after stoping is finished. The mining method has the advantages that the mining-cutting work amount is reduced greatly; the production capacity of a single stope is high; the efficiency is high; workers' labor intensity is low; production, dispatching and management are simple. Moreover, stoping of the main ore in a stope and recovery of ore in the bottom structure of the stope are realized synchronously in a crossed manner, and the stoping operation is safe, so that the resource recovery rate is high.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST +1

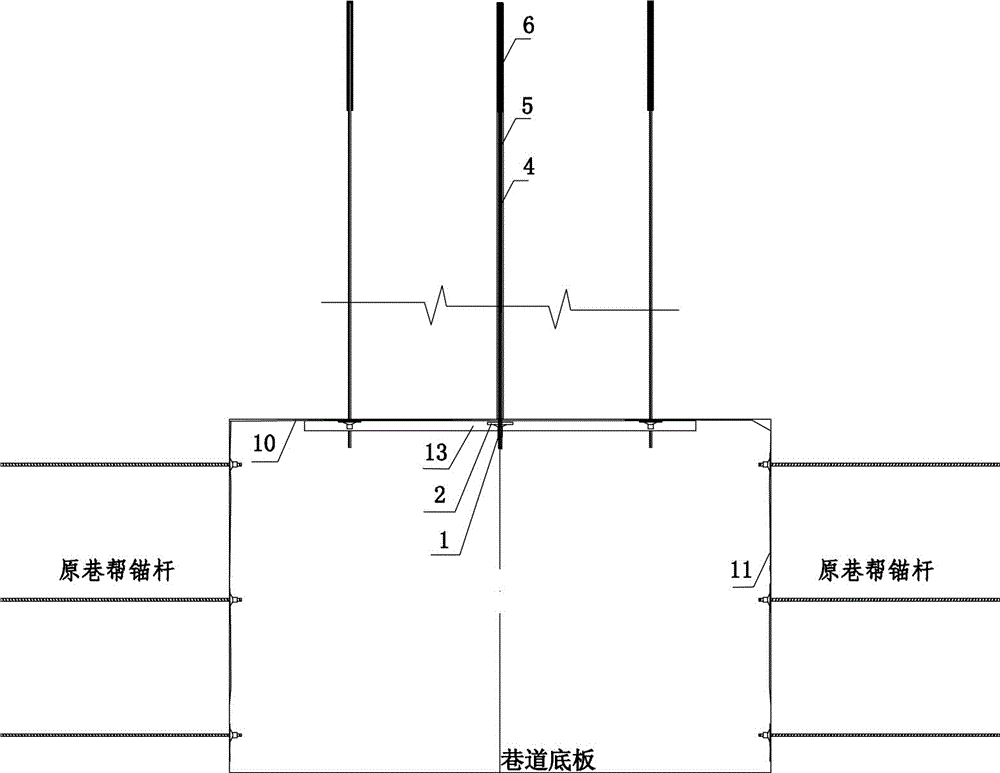

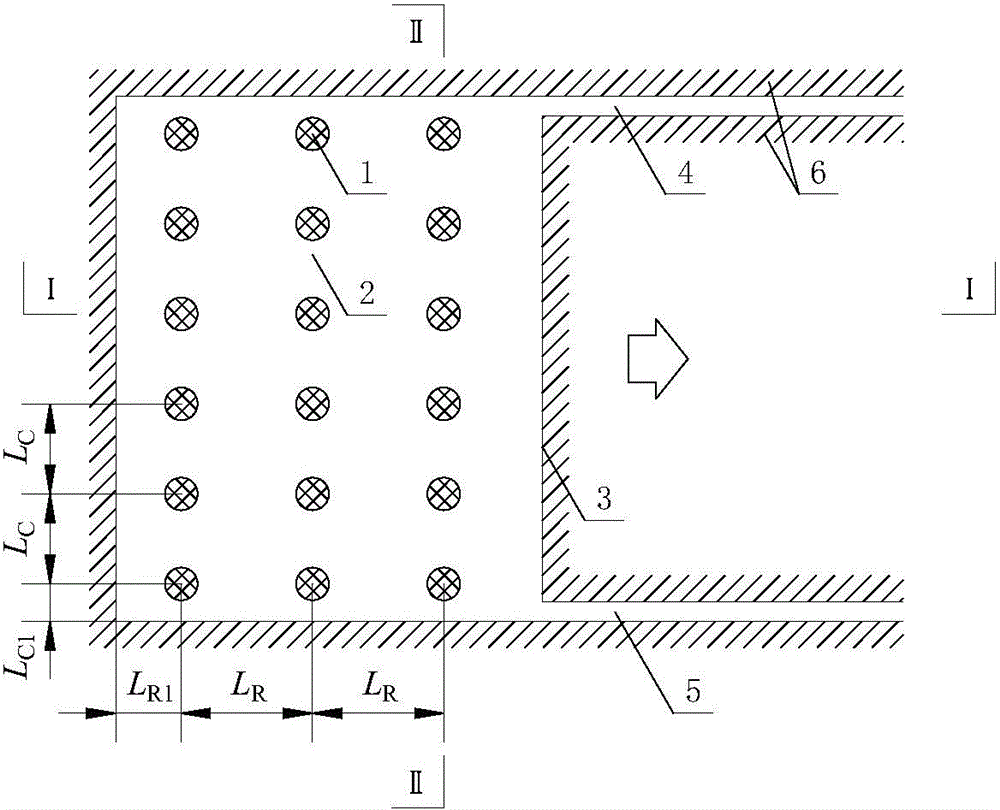

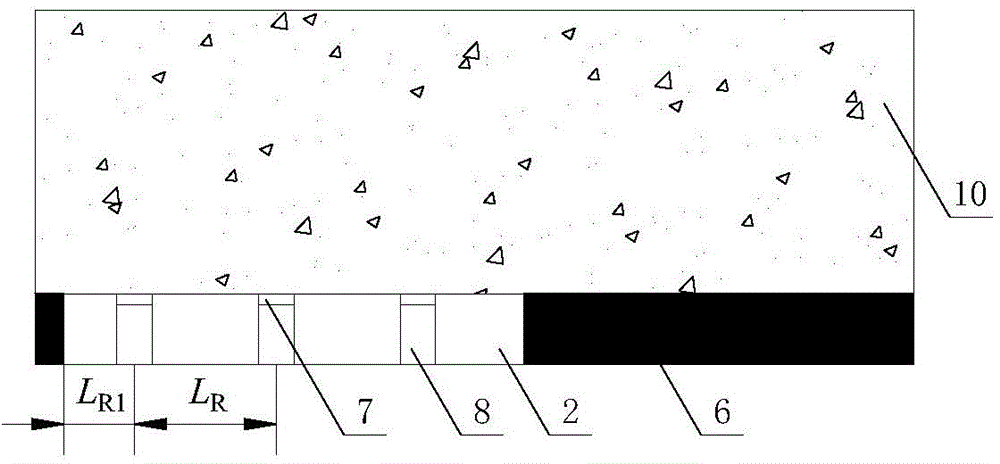

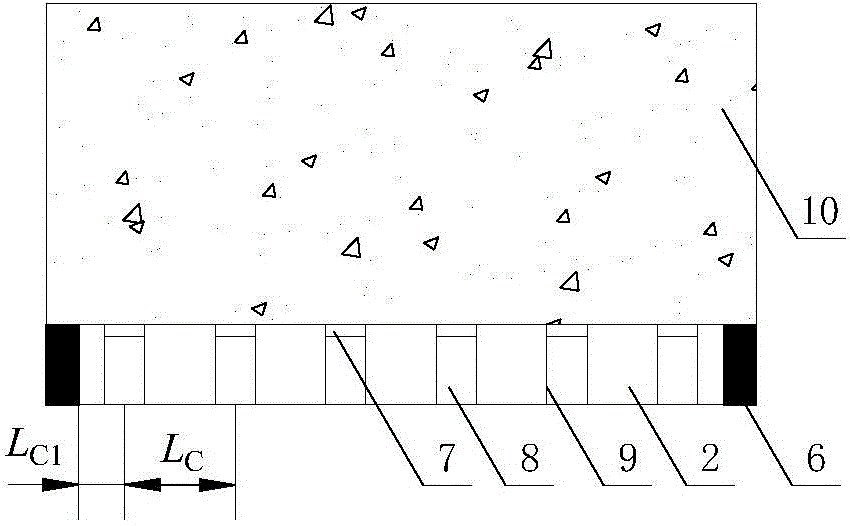

Coal mine gob-side entry retaining side supporting method

InactiveCN103758529AImprove resource recoveryImprove damageUnderground chambersTunnel liningSupporting systemCoal

The invention discloses a coal mine gob-side entry retaining side supporting method. The coal mine gob-side entry retaining side supporting method comprises the following steps of supporting the coal mine gob-side entry retaining side through intensive individual hydraulic supporting columns; constructing anchor cable supports for the gob-side entry retaining top plates based on the original rocker bolt supports, enabling the gob-side entry retaining to adopt double-line rocker bolt supports, enabling the distance between the rocker bolts to be 2 m and the row distance to be 2.2 m and enabling the anchor bolts which are close to one side of the coal wall to be installed along a certain inclination angle and the anchor bolts which are close to one side of a gob to be installed perpendicular to the top plates; constructing a row of single hydraulic supporting columns on the inner side of the intensive single hydraulic supporting columns after the designed pretress of the anchor bolts is achieved and enabling the column distance to be 1.2 to 1.5 m; enabling the insensitive single hydraulic supporting columns to be out successively from back to front and enabling supplement single hydraulic supporting columns and the installed anchor bolts to be formed into a gob-side entry retaining side auxiliary supporting system. The coal mine gob-side entry retaining side supporting method solves the problem that the gob-side entry retaining side supporting is difficult.

Owner:BEIJING HAOHUA ENERGY RESOURCE

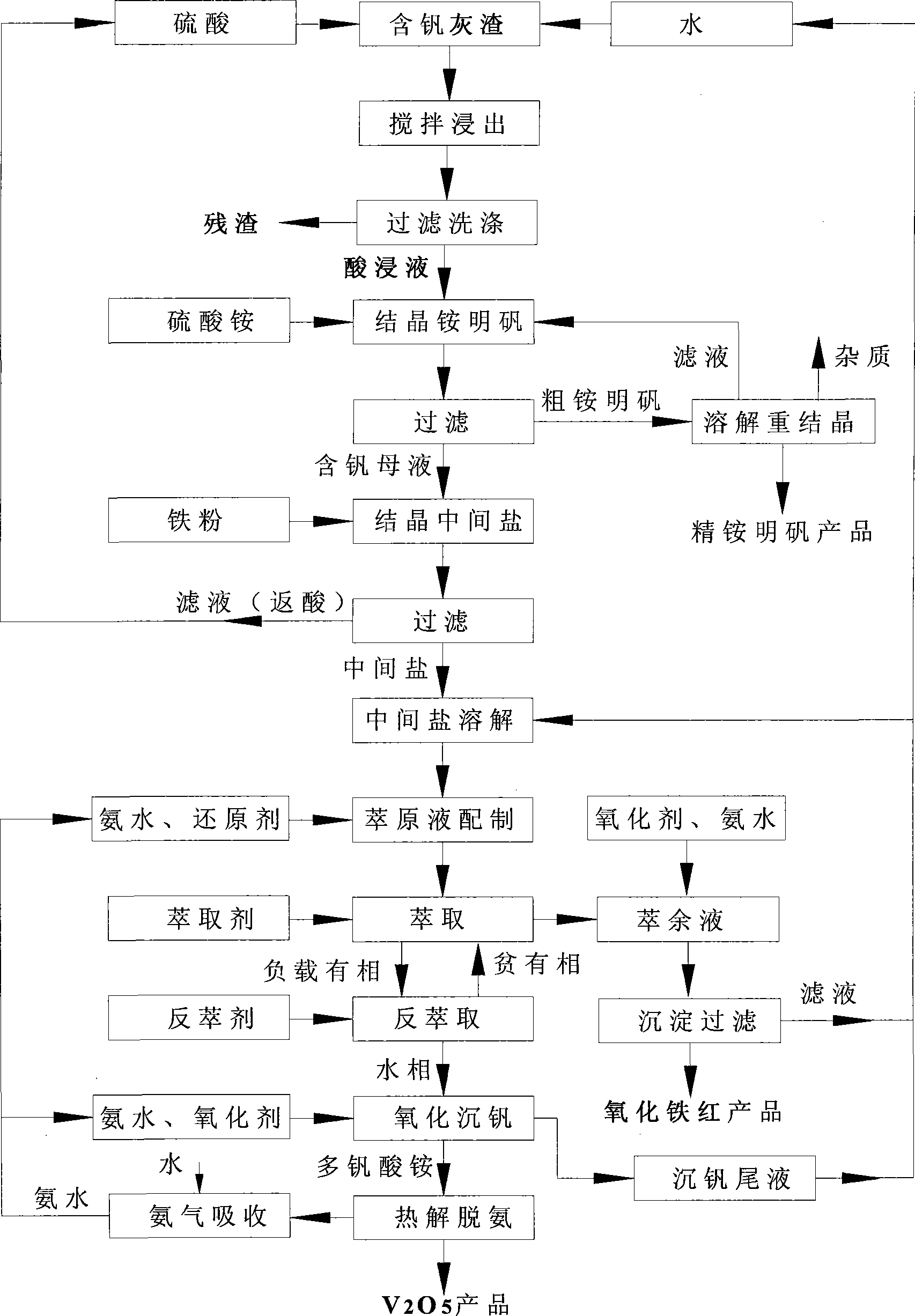

Vanadium pentoxide extraction method by direct acid dipping of stone coal ash containing vanadium

InactiveCN101381103ASimple processImprove the operating environmentVanadium oxidesSlagResource utilization

The invention provides a method for extracting vanadic oxide from vanadiferous stone coal ash slag through direct acid leaching. The method comprises the following steps: an acid leaching solution obtained by the vanadiferous stone coal ash slag through direct acid leaching is added with ammonium sulphate to prepare tschermigite as a byproduct; a vanadiferous mother solution is added with an iron simple substance and is heated, evaporated, condensed and crystallized to form an intermediate salt crystal in order that vanadium is fully enriched in intermediate salt; the intermediate salt is dissolved to prepare an extractive stock solution; the extractive stock solution is subjected to extraction, back extraction, oxidation and vanadium precipitation to prepare ammonium ployvanadate; and the ammonium ployvanadate is subjected to pyrolysis and deamination to prepare a V2O5 product with purity of over 98 percent. The process is wholly operated in a liquid phase and has no pollution by exhaust gas; waste liquid is basically returned to a system for reclaiming and utilization; the discharged waste liquid is little and is easy to treat; the total reclaiming rate of vanadium can reach over 75 percent; simultaneously, aluminum resource in the ash slag can be reclaimed to form the tschermigite as the byproduct; and the yield of the byproduct can reach dozens to hundreds of times of the yield of the V2O5 product. The process has the advantages of good operating condition, high mechanization and automation degree, high resource utilization rate, low comprehensive cost, good benefit and light pollution.

Owner:ZHEJIANG UNIV +1

Method and device for optimizing mining stopping line position with hydrofracture pressure relieving

ActiveCN106321049AAchieve transferTo achieve surrounding rock weakeningFluid removalCoal miningEnvironmental geology

The invention relates to the technical field of coal mining, in particular to a method and device for optimizing a mining stopping line position with hydrofracture pressure relieving. The method for optimizing the mining stopping line position with hydrofracture pressure relieving comprises the following steps that the geological state of a working face is obtained, and structural data of a roof rock layer is determined; according to the structural data, holes are obliquely drilled towards a roof from a mining roadway and are drilled at a preset distance in the length direction of the mining roadway, and thus a plurality of hydrofracture pressure relieving holes arranged in sequence are obtained; hydrofracture pressure relieving treatment is carried out on multiple preset positions of each hydrofracture pressure relieving hole to form multiple cutting cracks; the roof rock layer is cut off along the cutting cracks of all the hydrofracture pressure relieving holes. By means of the method and the device, the influence of the advanced supporting pressure of the working face to the mining roadway can be effectively reduced, transferring of the prestress of the roof and weakening of surrounding rock can be achieved, the purpose of reducing and optimizing the mining stopping line position of the working face can be achieved, and the recycling rate of coal resources can be increased.

Owner:CCTEG COAL MINING RES INST

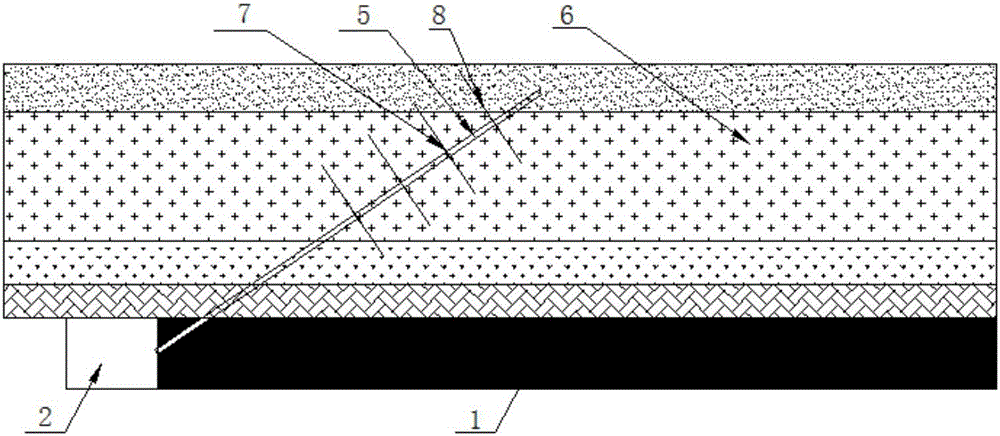

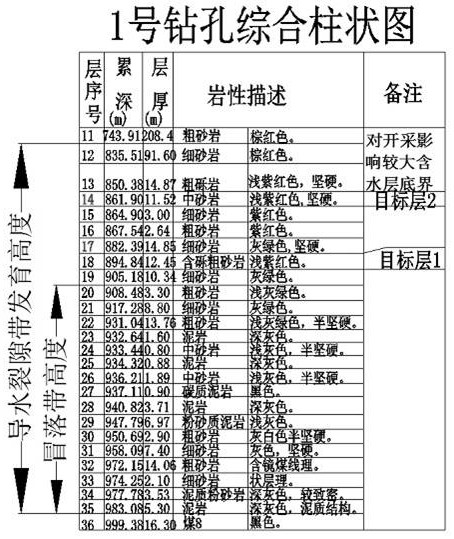

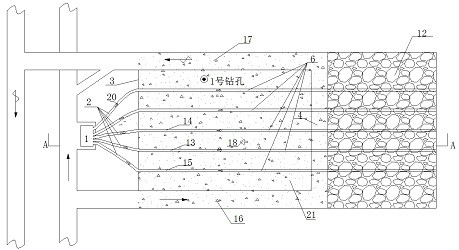

Technology for preventing and treating coal seam roof water damage through dynamic pressure maintaining grouting blocking fissures of horizontal long drill holes in mining fractured zone

InactiveCN112392431AReduce water lossMitigate the threat of water damageSealing/packingSlurryStoping

The invention discloses a technology for preventing and treating coal seam roof water damage through dynamic pressure maintaining grouting blocking fissures of horizontal long drill holes in a miningfractured zone, and relates to the technical field of stope face safety of coal mines with roof water damage. At present, domestic roof water damage prevention and control technologies mainly comprisegoaf filling, strip mining, thickness-limited mining, drainage, static grouting and the like, and great limitations exist in deep water-rich extra-thick coal seam mining, such as waste of a large number of resources, high cost and unsatisfactory water control effect. According to hydrogeology of a mining area and development characteristics of the height of a mining overlying strata water diversion fractured zone under specific mining conditions, a reasonable target layer is selected, the horizontal long drill holes are formed, slurry meeting the requirements of the technology is selected, and along with mining of a working face, the horizontal long drill holes in the mining fractured zone dynamically block fissures in a pressure maintaining mode to prevent and treat coal seam roof waterdamage.

Owner:陈存强 +1

Process and device for recovering electrolytic copper from copper-containing wastewater

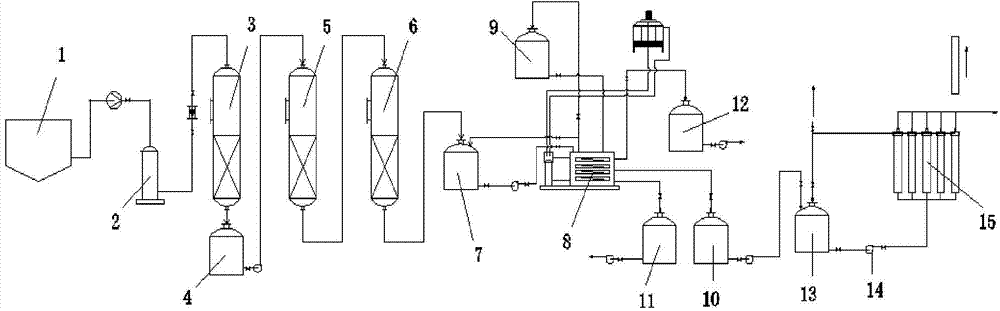

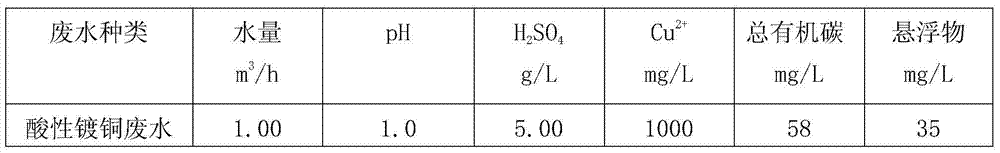

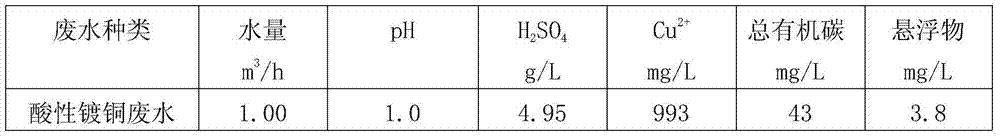

ActiveCN104773887AEnable direct recyclingReduce processing costsWater contaminantsWaste water treatment from metallurgical processElectrolysisAutomatic control

The invention relates to a process and device for recovering electrolytic copper from copper-containing wastewater. The electrolytic copper is produced by adopting the technological processes of removing suspended matters and part of organic matters through pretreatment, carrying out ultrafiltration treatment, retaining concentrated copper sulfate with a nanofiltration membrane, recovering wastewater and acids with a reverse osmosis membrane and carrying out cyclone electrolysis. The process and the device have the beneficial effects that the recovery rate of the electrolytic copper is 90% and the copper purity is more than 99.95%; meanwhile, the wastewater recovery rate is more than 90%; the recovery rate of free sulfuric acid in the wastewater is more than 90%; the resource recovery rate is high and the economic benefits are good; adopting the technological processes of combined adsorption resin, ultrafiltration membrane, acid stabilizing nanofiltration membrane and high desalting rate reverse osmosis membrane, compared with other membrane recovery systems, the process has the advantage that the properties and service lives of the membranes can be maintained for a long term; the process has the effects of achieving automatic control and ensuring stable operation of a wastewater treatment system and the quality of recovered matters; the process is suitable for recovering copper in the copper-containing wastewater in the electroplating industry, the electronic industry and the metallurgical industry and other copper-containing industrial wastewater and for wastewater treatment.

Owner:NANJING LINEHOME ENVIRONMENTAL TECH CO LTD

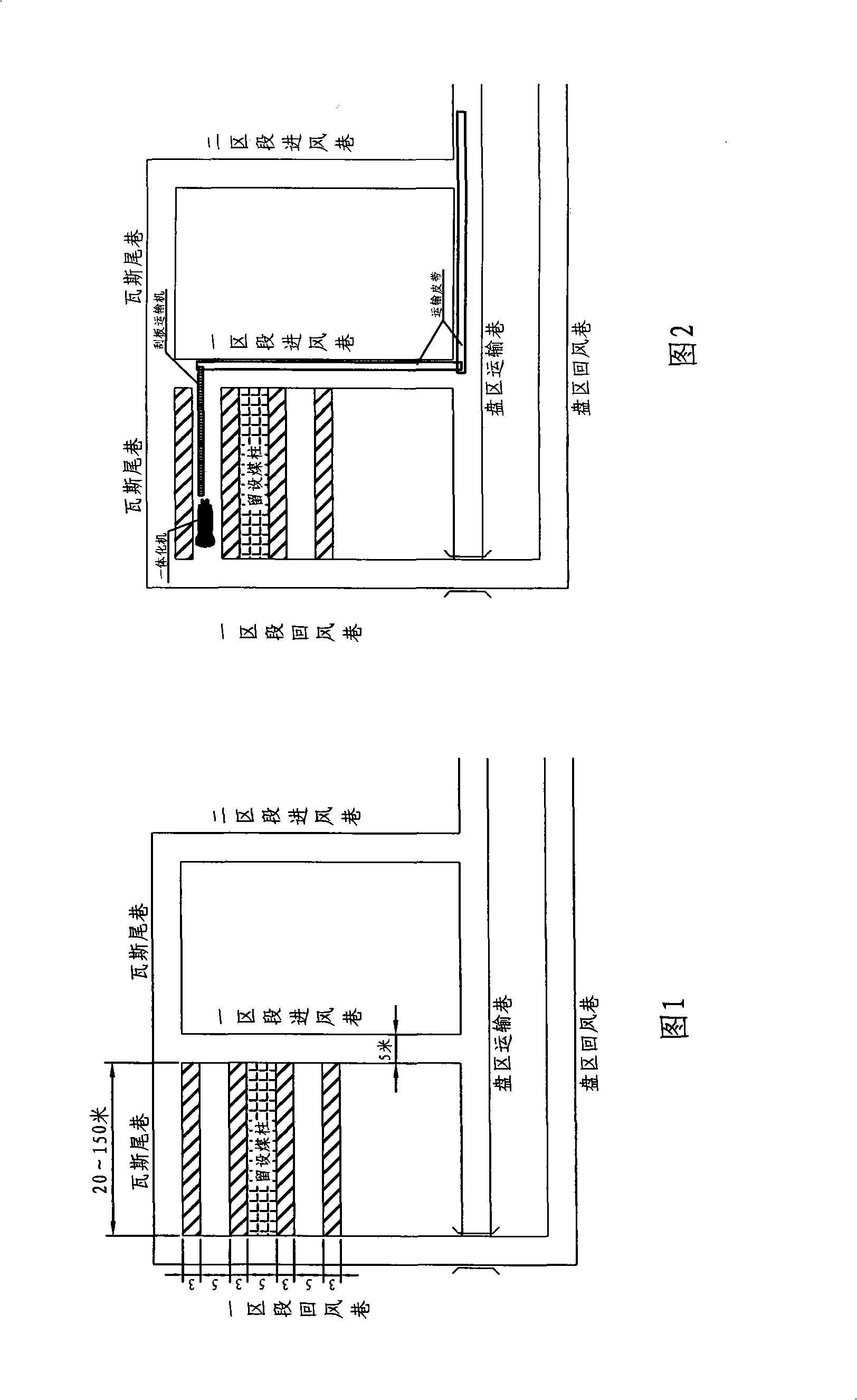

Arrangement method of high gas coal seam extraction working face roadway

The invention discloses an arrangement method of a high gas coal seam extraction working face roadway, which comprises roadway arrangement of an initial working face and extraction of the working face. After the completion of the extraction of the last working face and the stabilization of an upper overlying rock layer, the next working face gas exhaustion lane is arranged in parallel along a last working face coal column between a last working face extraction region edge and the last working face gas exhaustion lane from a large lane, or the next working face air returning leveling lane is arranged in parallel along the coal seam below the last working face gas exhaustion lane from the large lane, the next working face gas exhaustion lane is in auxiliary hole cut-off communicated with the next working face, or the next working face air returning leveling lane is in hole cut-off communicated with the next working face; and the processes are repeated until the roadway arrangement of the working face of the exploration region and the extraction of the working face is completed. The problems that the loss of the coal columns in the region sections is large and the next working face gas exhaustion lane is difficult to maintain can be solved, so that the next working face gas exhaustion lane of the outer circle can be normally used under the influence of the secondary extraction, thereby improving the extraction ratio of the coal carbon resources and reducing the roadway tunneling ratio.

Owner:CHINA UNIV OF MINING & TECH

Cutting head type shortwall coal-winning machine and comprehensive mechanized coal mining technology

ActiveCN101798925AReduce cutting powerReduce electricity costsUnderground miningSlitting machinesControl systemElectrical control

The invention discloses a cutting head type shortwall coal-winning machine and comprehensive mechanized coal mining technology. A tunneller type cutting device is used, and the coal-winning machine is a hydromechatronics coal-winning machine which is in electric traction, electrically drags a cutting head, carries out hydraulic drive to change a cutting arm pitch angle and swings inside and outside the working face. The coal-winning machine mainly comprises a machine body, a cutting device, a travelling mechanism, a coal shovelling device, an auxiliary device, an auxiliary hydraulic system and an electrical control system. The coal-winning technology uses technical equipment, such as a coal-winning machine, a hydraulic support, a scraper conveyor, an elevating conveyor, a breaker, a crossheading belt, an advance support hydraulic support and the like. The technical flow is as follows: the coal-winning machine retracts to the working surface tail, a scraper-trough conveyer is pushed tocoal wall, coal is cut to the machine head, the machine is retracted, coal is cleaned, and the support is pulled. The coal-winning machine has compact structure, small volume and weight, strong adaptability and convenient installation and transportation, can solve a series of problems of four low, three high, two long and one poor in small and medium coal mining technology and provides matching coal mining technology.

Owner:闫振东

Gob-side entry retaining mining support process method

ActiveCN104061001AImproving the safety environment of lane keeping operationImprove resource recoveryUnderground chambersTunnel liningStopped workEngineering

The invention discloses a gob-side entry retaining mining support process method. The method comprises the following steps: I, performing mining entry retaining reinforcement or roadway driving entry retaining reinforcement primary support; II, performing advance support on the end of the entry retaining side of a stoping work face, and adopting beeline-shaped beams and single hydraulic pillars in advance segment support like an advance support method adopted in ordinary stoping, wherein the differences lie in that 1, the advance support length in entry retaining is 5 meters greater than a length required in a specification, namely, the normal mining length is 25 meters while the entry retaining mining length is 30 meters; 2, longitudinal beeline-shaped beams are changed into transverse beeline-shaped beams, namely, the beeline-shaped beams are arranged along the work face instead of a roadway; III, performing double-net support on No. 1 to No. 3 frames on the stoping work face; IV, preserving roadway support; V, forming a natural false edge on the side of an entry retaining stoping side, wherein along with the continuous forward movement of the work face, the direct top in a stoping region collapses, dropping gangues naturally roll onto a diamond mesh behind the No. 1 to No. 3 frames at the end, and rocks covering the mesh drop naturally under the action of deadweights.

Owner:BINHU COAL MINE ZAOZHUANG MINING GRP

Handling method and device for double-medium stacked supporting and hard top plate type mined-out area

InactiveCN104564137AImprove effectivenessImprove recoveryUnderground miningSurface miningCoalEngineering

The invention discloses handling method and device for a double-medium stacked supporting and hard top plate type mined-out area, and aims at solving the construction problem that the hard top plate of a thick coal mine seam is difficultly fallen. The method is that a base stack body fills in the mined-out area after the mining at the working face; the base stack body and the top plate are subjected to flexible roof contact by filling chemical materials; the spacing and arrangement distance of the filled stacks are influenced by the mining depth, height and lithology of the top plate and other factors, wherein the arrangement distance is 15 to 30m, and the spacing is 8 to 15m; the section of the filled stack can be circular, rectangular or quadrate; the effective section area is 0.8 to 1m<2>; the flexible roof contact medium is 1 / 10 to 1 / 8 of the mining height; the base stack can be filled by grouting concrete or gravels and other materials. The method and device are particularly suitable for continuous mining of shallow buried thin coal seam layers; the design that the working surface is frequently moved while supporting the mined-out area through tool posts is replaced, or the complex processes of softening the top plate by filling water and blasting and pre-cracking are decreased.

Owner:CHINA UNIV OF MINING & TECH

Exhuast gas desulfurization, recycle and treatment method and apparatus

InactiveCN101342459AReduce manual operationStable processing capacityCalcium/strontium/barium sulfatesDispersed particle separationGypsumExhaust gas

The invention relates to a smoke gas desulfurization and recycling method; the smoke gas is processed in an smoke desulfurization and recycling integrated device; the smoke gas desulfurization and recycling technology has three stages: a first stage is an exhaust gas dedusting technology, by which particulate matter in the smoke gas is removed; a second stage is an exhaust gas desulfuration technology, by which SO<2> / SO<3> is removed; a third stage is a post-processing technology, by which the exhaust gas is dried and purified and manufactured into a product; and waste seriflux is made into gypsum after being oxidized; the smoke gas desulfurization and recycling method and the device of the invention are suitable for processing the smoke gas containing the SO<2> / SO<3> produced in various industrial production processes and recycling a material, thereby taking full advantage of a resource, decreasing pollutant emission and having the advantages of high processing efficiency, high coefficient of recovery, wide adaptability and smaller investment.

Owner:ZHEJIANG UNIV

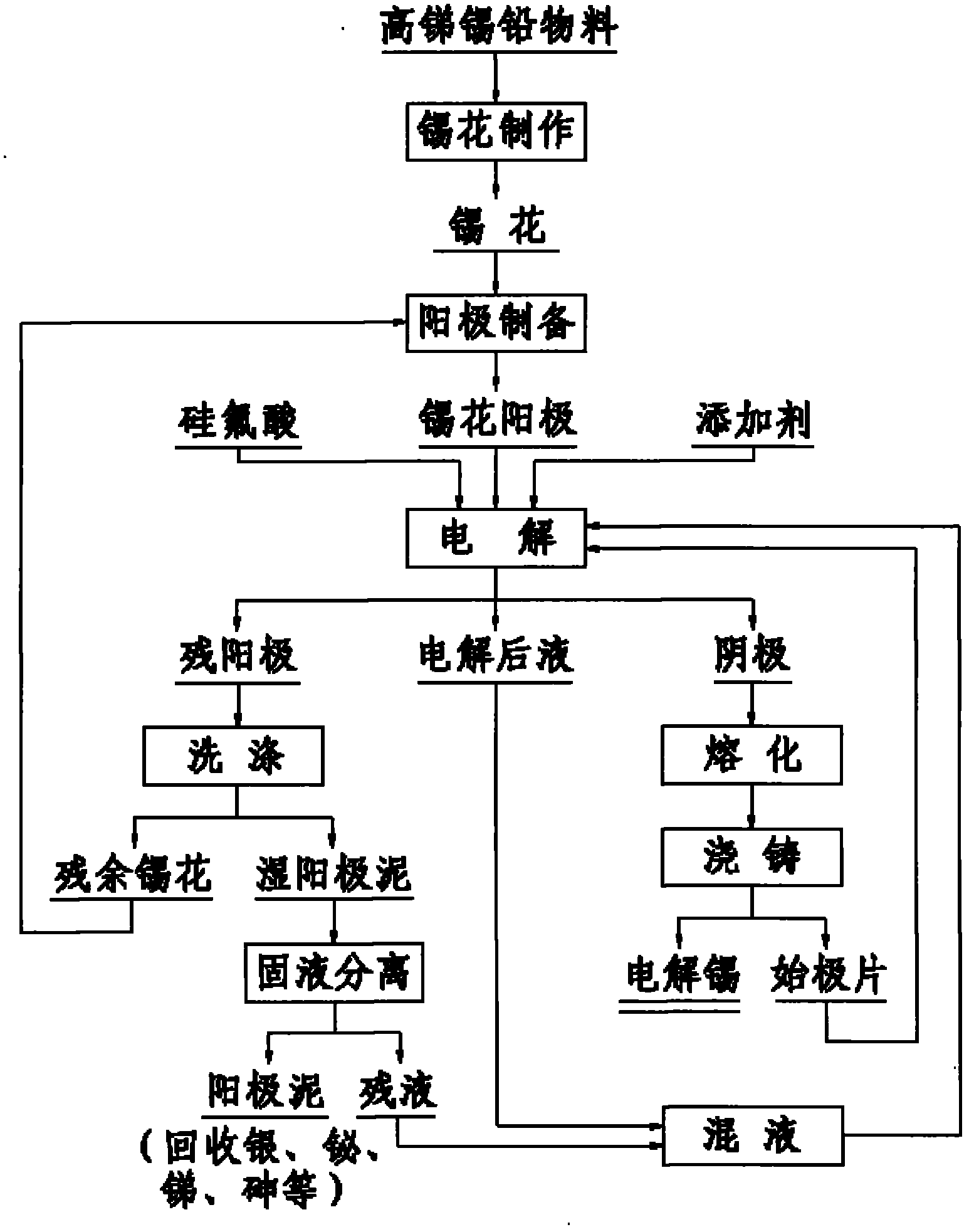

Comprehensive method for separating stibium from materials containing stibium, tin and lead

InactiveCN101974765AEasy to separateEffective open circuitPhotography auxillary processesProcess efficiency improvementFiberHydrometallurgy

The invention provides a comprehensive method for separating stibium from materials containing the stibium, tin and lead, which is suitable for removing the stibium and recovering other valuable metals from tin lead materials containing stibium with high content. The invention puts an emphasis on that the comprehensive method comprises the following steps of: granulating the materials containing the stibium to manufacture irregular tin grains with the thicknesses of 2-5 mm and the grain diameters of 2-30 mm; then placing tin grain sheets into an anode frame lined with acid-resisting fibers to manufacture a tin grain anode; placing the fine tin lead materials as starting sheets into an electrolytic cell filled with silicofluoric acids to carry out electrolysis by electrifying DC, wherein tin and lead metals are electrolyzed and deposited on a cathode to obtain a cathode product with total tin and lead content more than 99.8 percent and stibium content less than 0.2 percent, and the valuable metals, i.e. the stibium, gold, silver, and the like, are gathered in anode mud; and finally recovering the valuable metals, i.e. the stibium, the gold and the silver, from the anode mud. A wet-process metallurgical process has advanced and reasonable process and can greatly enlarge the contact area of electrolyte and the anode, reduce the current density during the electrolysis and eliminate the anode passivation phenomena.

Owner:YUNNAN TIN GROUP HLDG

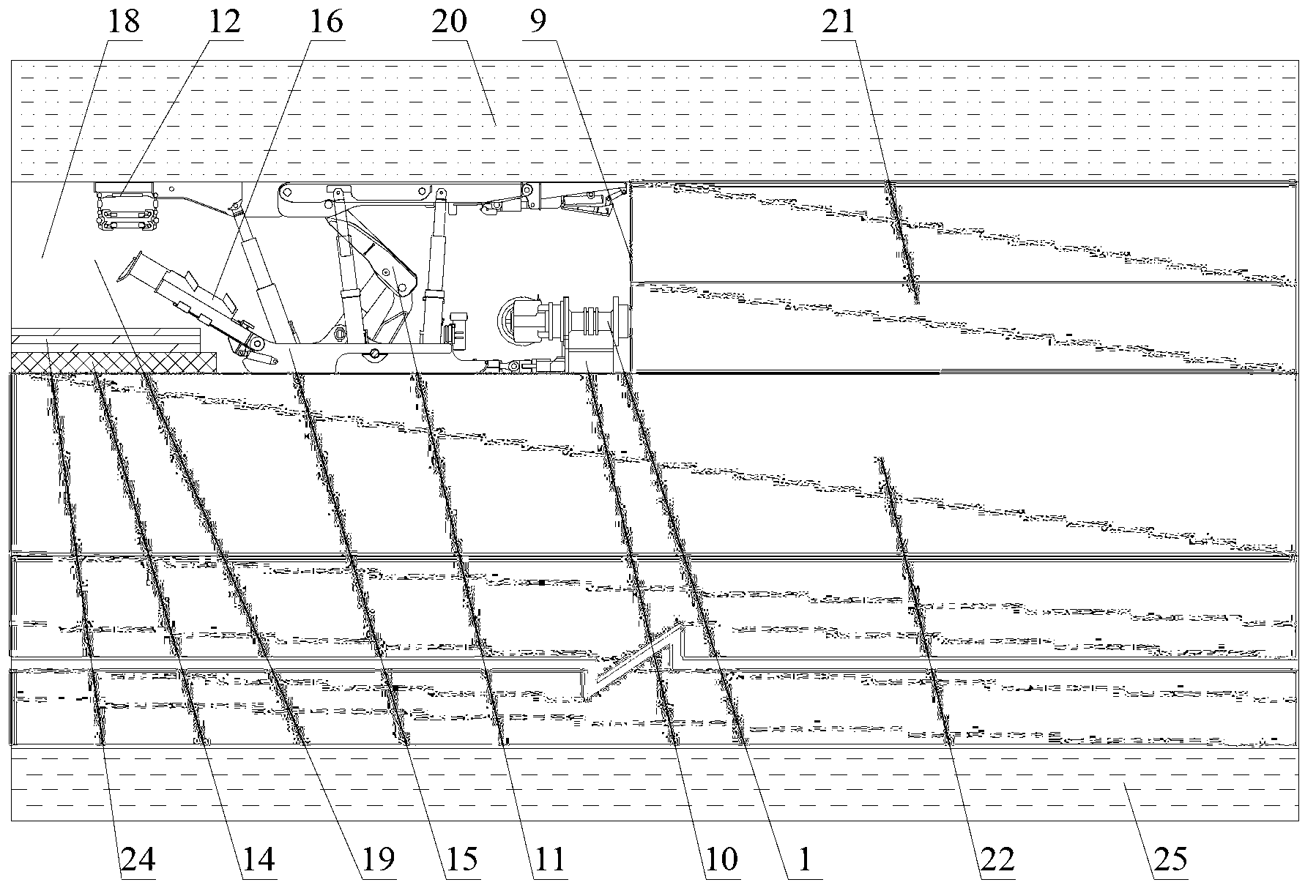

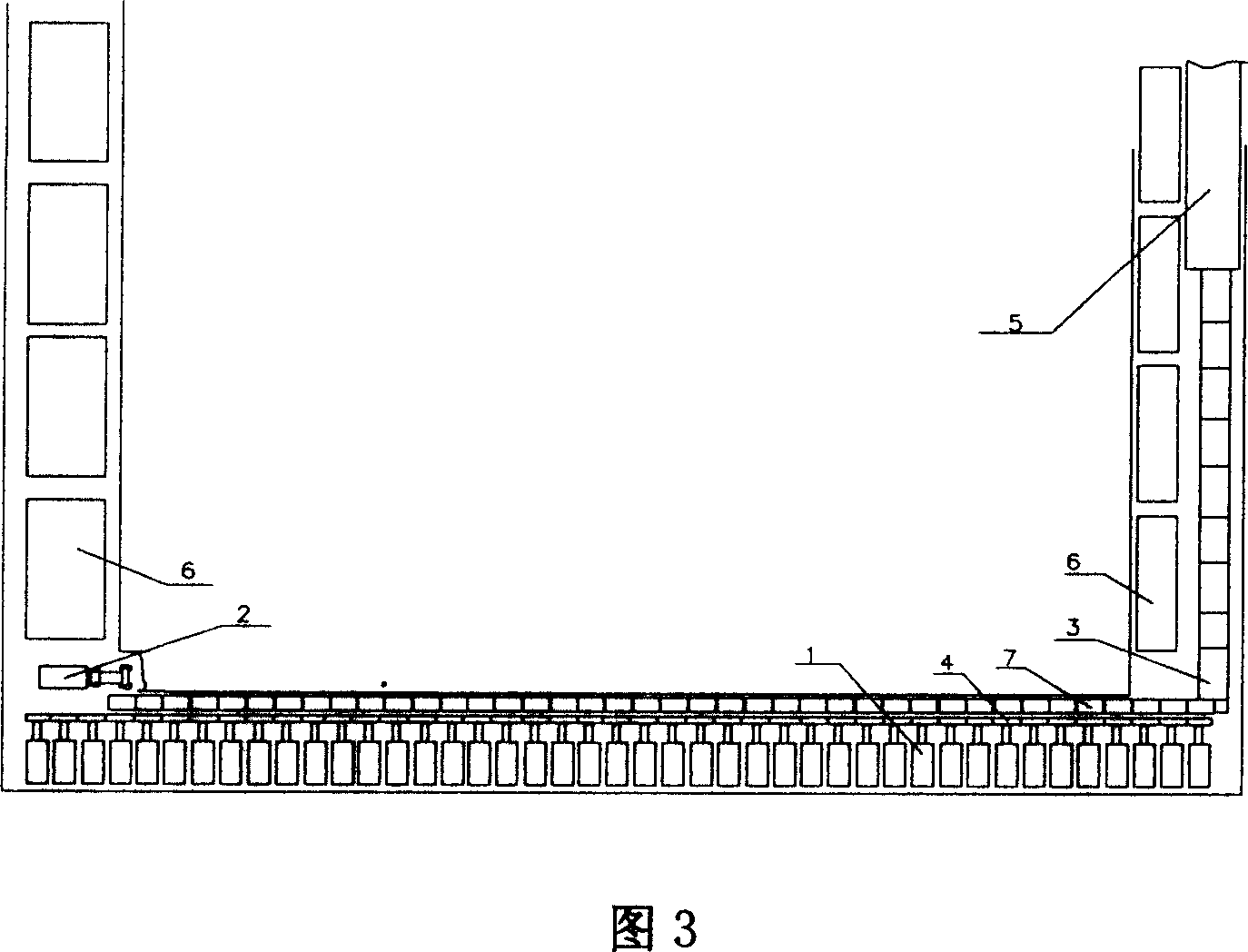

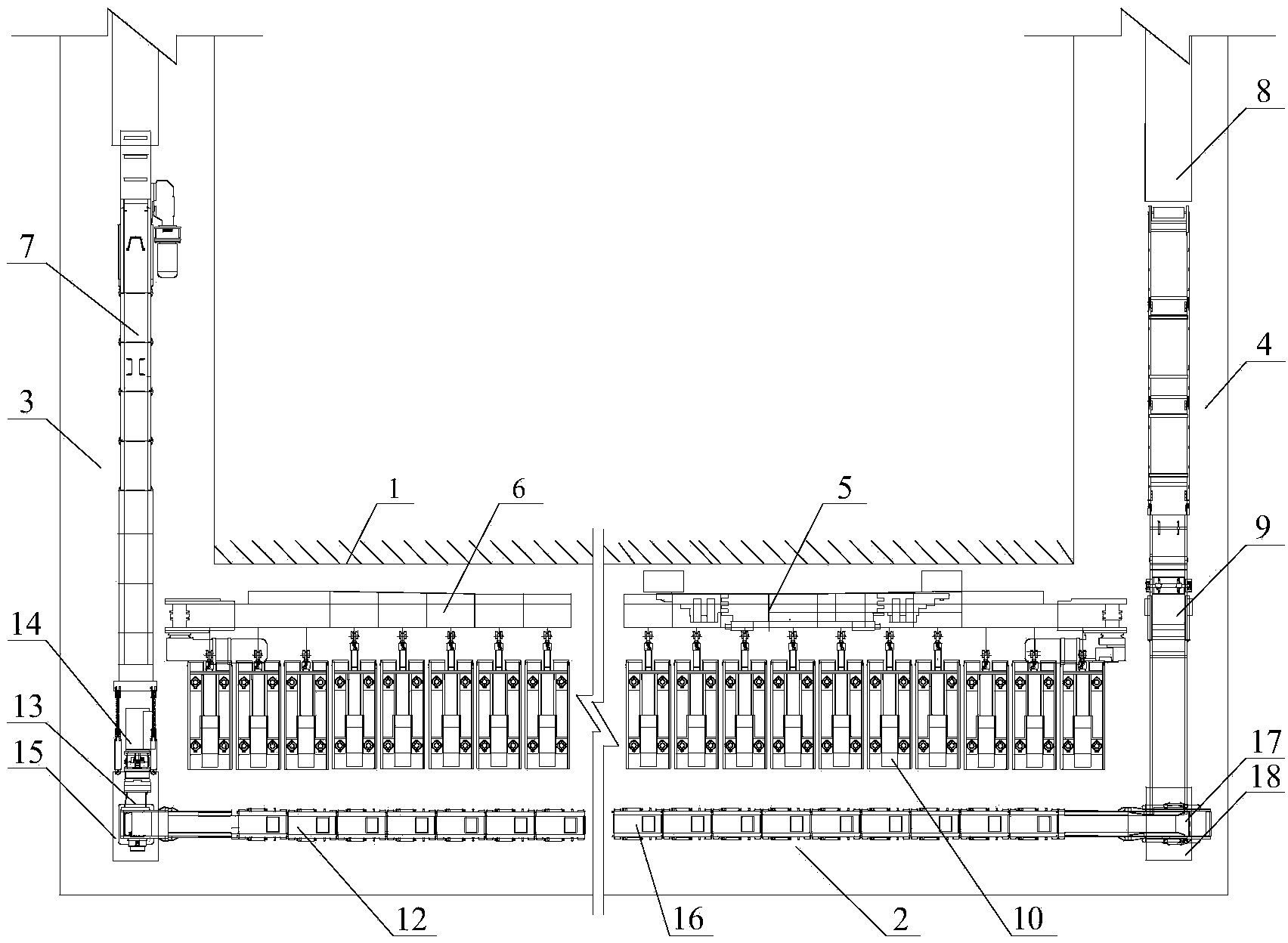

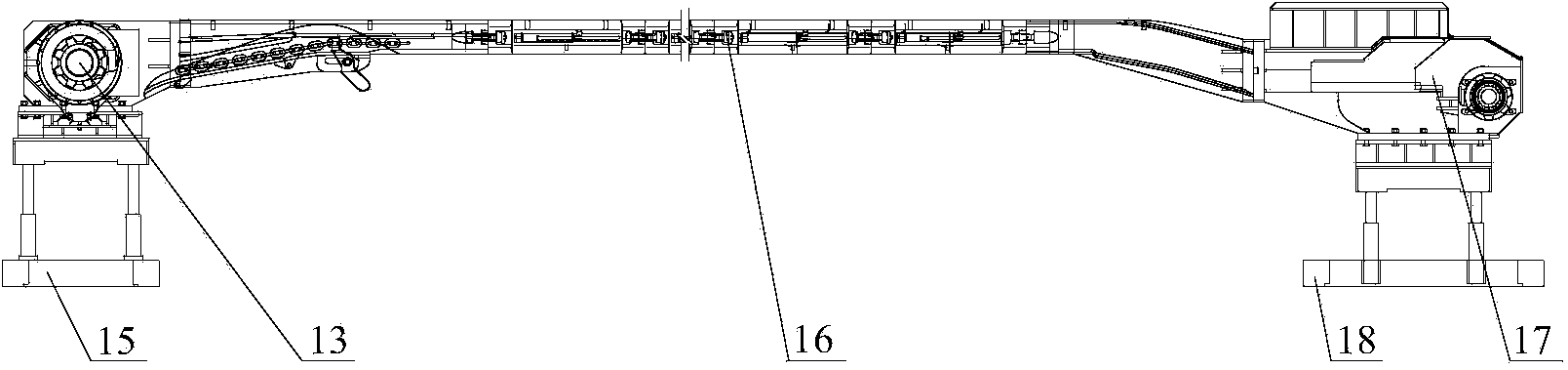

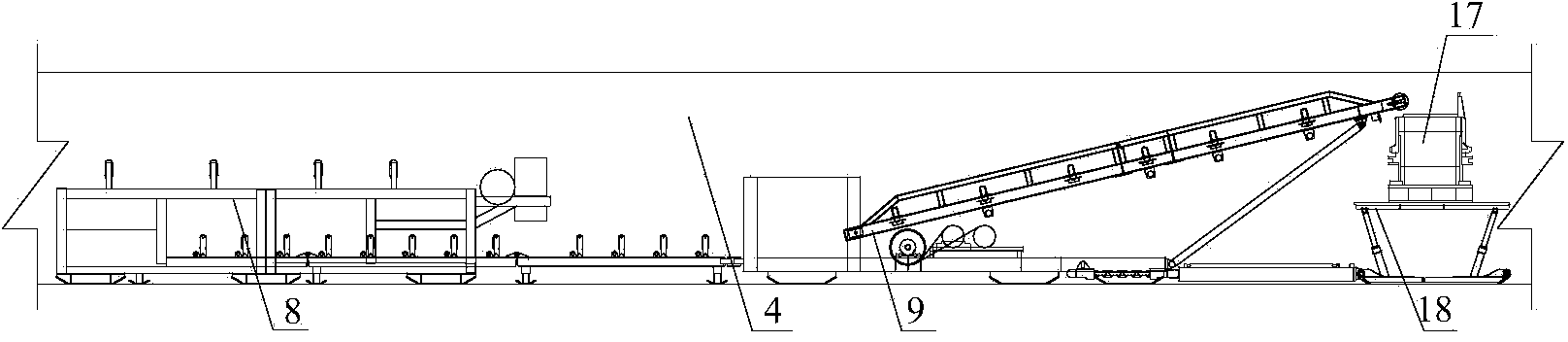

Equipment matching method for solid-filling coal face of coal mine

ActiveCN103939139AEfficient miningImprove resource recoveryMaterial fill-upUnderground transportIntegrated operationsEngineering

The invention provides an equipment matching method for a solid-filling coal face of a coal mine and belongs to coal mining with filling methods. According to the equipment matching method, equipment is composed of a coal cutter, a scraper conveyer, a milling with filling hydraulic support, a coal conveying device, a machine head, a drive motor, a machine head lifting platform, a gangue belt conveyer, a self-moving transfer conveyer, a machine tail, a machine tail lifting platform, a punning mechanism and a conveyer middle section, wherein the coal cutter, the scraper conveyer and the milling with filling hydraulic support are arranged on the coal face; the coal conveying device, the machine head, the drive motor and the machine head lifting platform are arranged in a coal conveying roadway; the gangue belt conveyer, the self-moving transfer conveyer, the machine tail and the machine tail lifting platform are arranged in a gangue conveying roadway; the punning mechanism and the conveyer middle section are arranged in the milling with filling coal face. The conveyer middle section and the punning mechanism are arranged on the rear portion and the bottom of the mining with filling hydraulic support respectively. The self-moving transfer conveyer is in lap joint with the gangue belt conveyer and the machine tail. The machine tail is arranged on the machine tail lifting platform. The machine head and the drive motor are arranged on the machine head lifting platform. A delayed shoring method is used for achieving management of a coal face transition section. By the adoption of the equipment matching method, integrated operation of filling and mining of a comprehensively mechanical solid filling work face is achieved, and the recovery rate of a resource exhaustion type mine is greatly increased.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com