Rectification-steam penetration-coupled organic solvent dewatering method and device

An organic solvent and permeation device technology, applied in the field of separation, can solve the problems of unrealized energy coupling, low resource utilization and dehydration efficiency, and achieve clean production and resource recycling, improve energy utilization, and reduce production The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

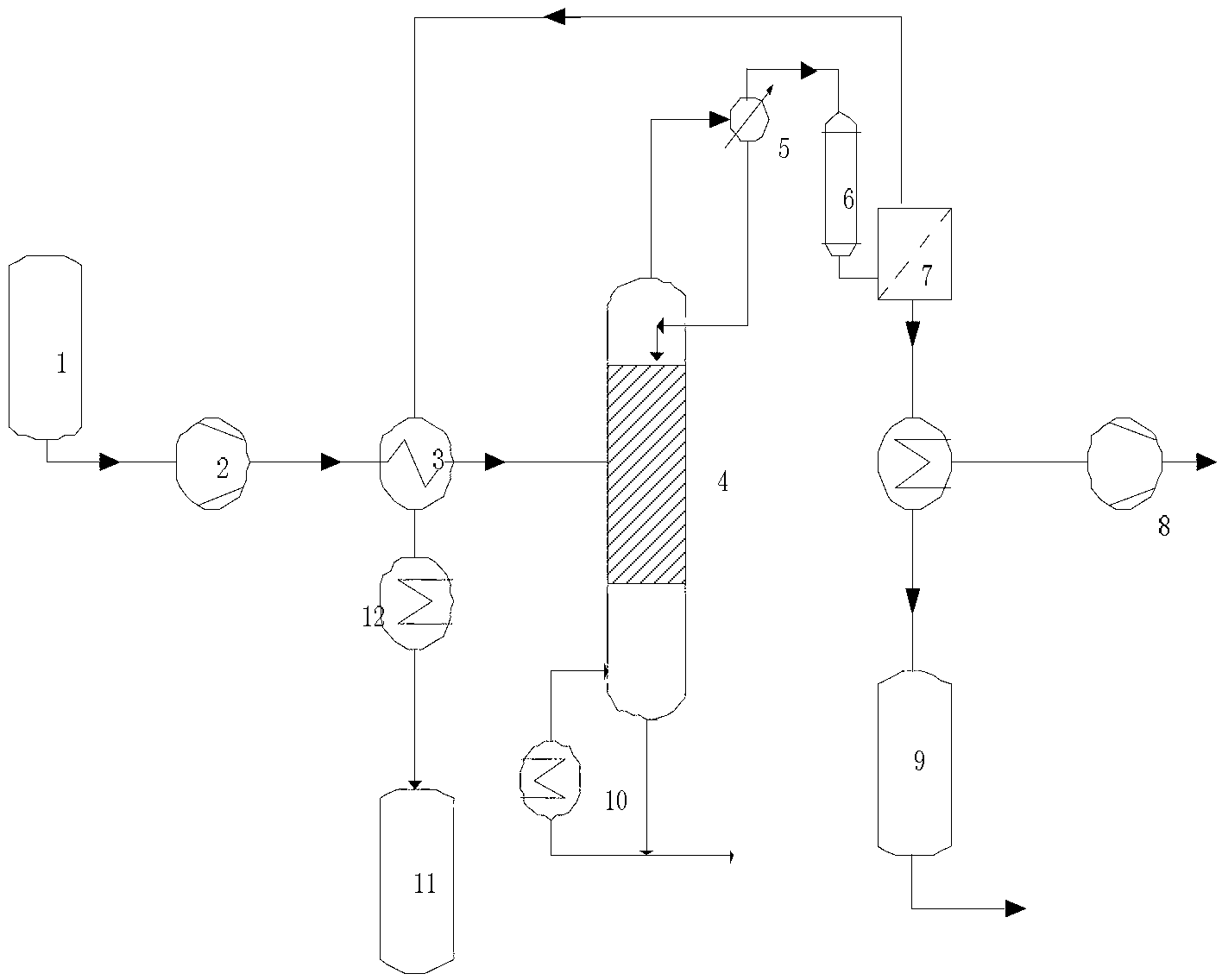

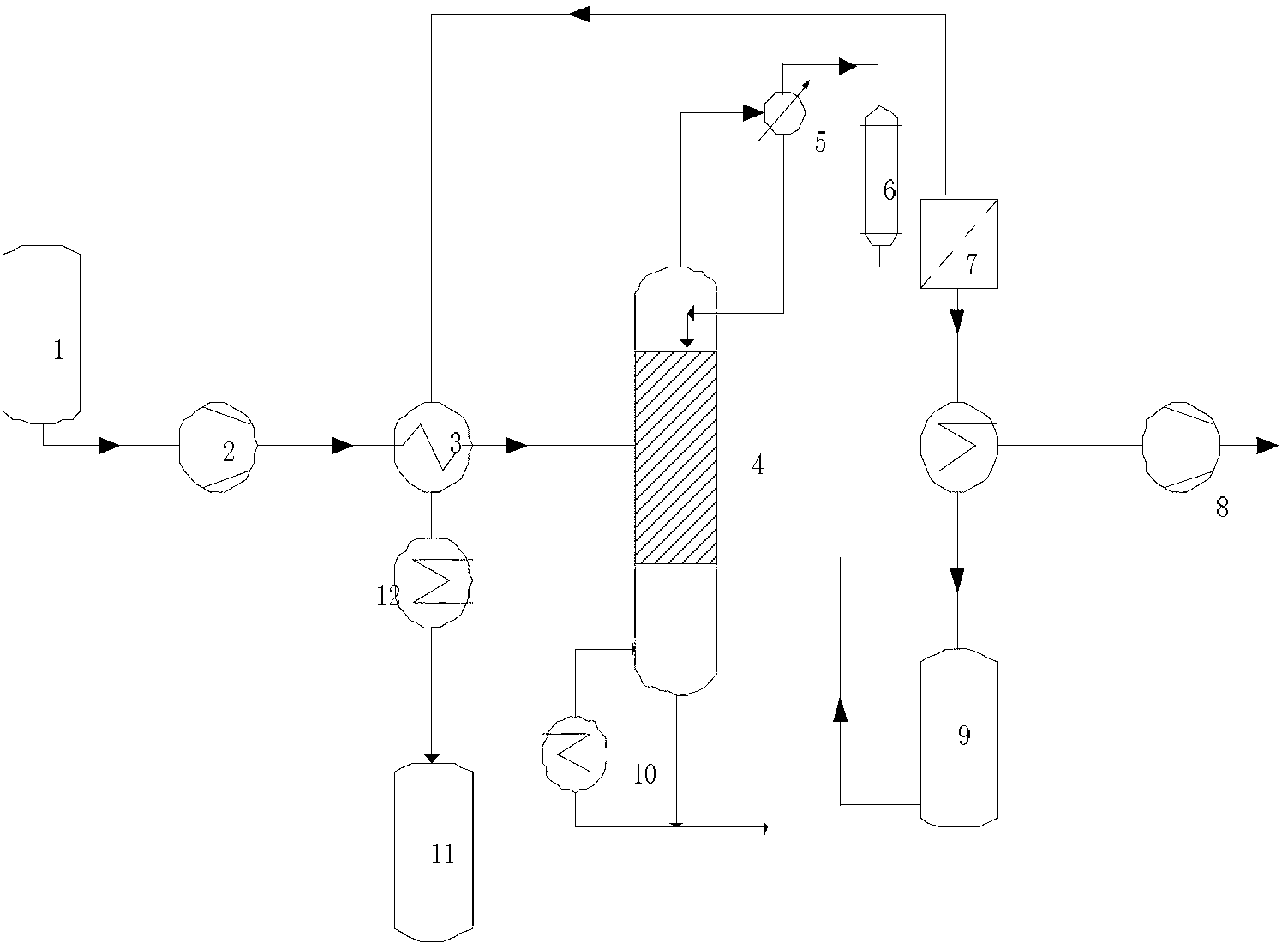

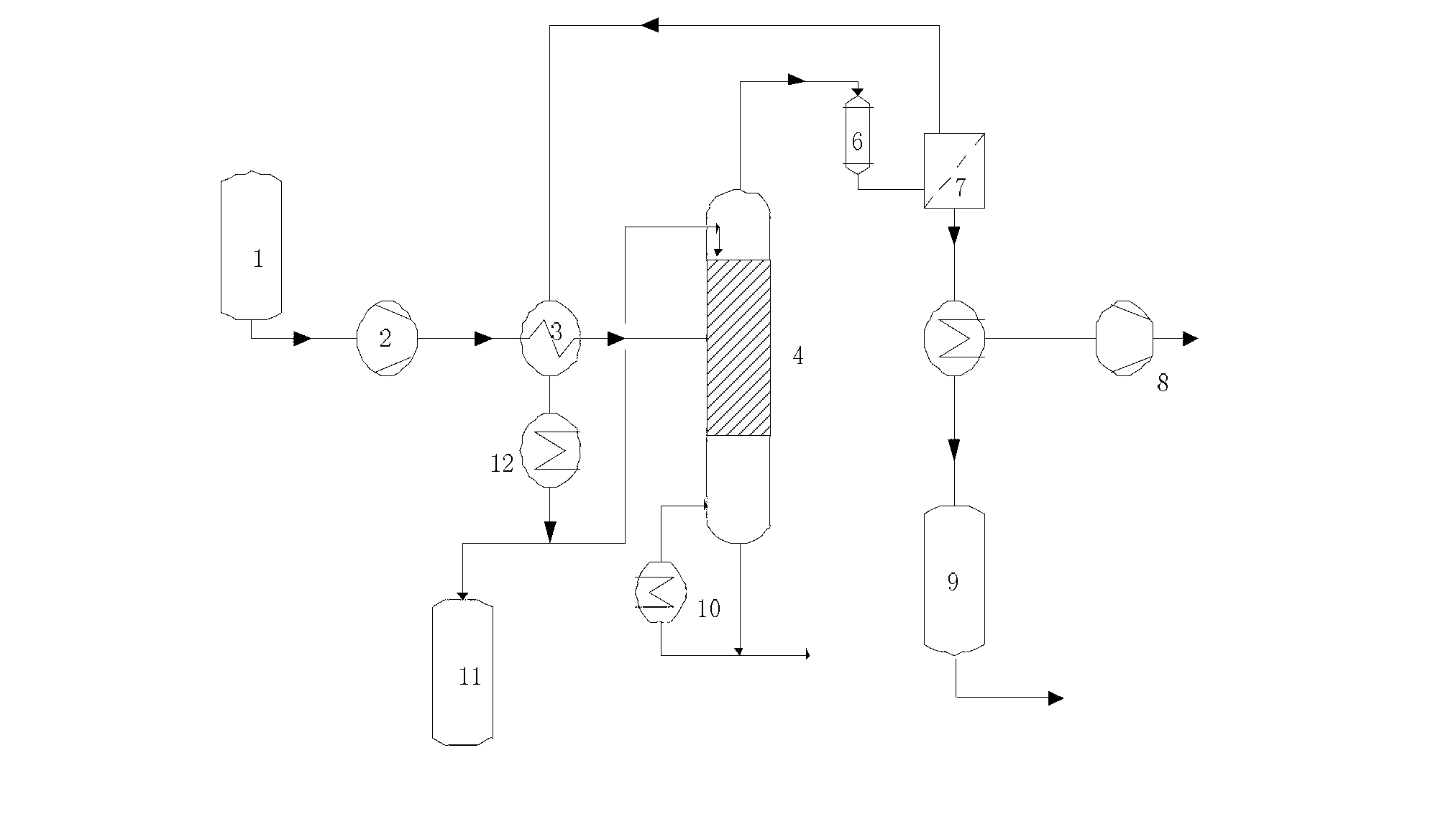

[0034] See figure 1 , the coupling of rectification and steam permeation separation is used in the organic solvent dehydration process, and the steps are as follows:

[0035] The ethanol solution with a water content of 90wt.% and a flow rate of 100kg / h is transported from the raw material tank 1 to the preheater 3 through the raw material pump 2. After being preheated by the product steam, the temperature rises to 90°C and enters the rectification tower 4. The height of the rectification tower is 3.5m, with built-in metal packing, heated by the reboiler 10 in the tower, the reflux ratio at the top of the rectification tower is controlled to be 2.5, the operating pressure is 0.12MPa (gauge pressure), and the steam at the top of the tower passes through the partial condenser 5 After condensation, part of it is refluxed to the rectification tower, and the other part is obtained as ethanol vapor (distillate) with a water content of 20wt.%, 12.38 kg / h, and a temperature of 123°C....

Embodiment 2

[0038] See figure 1 , the coupling of rectification and steam permeation separation is used in the organic solvent dehydration process, and the steps are as follows:

[0039] The methanol solution with a water content of 35wt.% and a flow rate of 80 kg / h is transported from the raw material tank 1 to the preheater 3 through the raw material pump 2. After being preheated by the product steam, the temperature rises to 65°C and enters the rectification tower 4. The height of the rectification tower is 3.5m, with built-in metal packing, heated by the reboiler 10 in the tower, the reflux ratio at the top of the rectification tower is controlled to be 0.5, the operating pressure is 0.12MPa (gauge pressure), and the steam at the top of the tower passes through the partial condenser 5 After condensing, part of it is refluxed to the rectification tower, and the other part is obtained as methanol vapor (distillate) with a water content of 5wt.%, 54.67 kg / h, and a temperature of 87°C. ...

Embodiment 3

[0042] See figure 1 , the coupling of rectification and steam permeation separation is used in the organic solvent dehydration process, and the steps are as follows:

[0043] The acetone solution with a water content of 65wt.% and a flow rate of 100kg / h is transported from the raw material tank 1 to the preheater 3 through the raw material pump 2. After being preheated by the product steam, the temperature rises to 90°C and enters the rectification tower 4. The height of the rectification tower is 3.5m, with built-in metal packing, heated by the tower kettle reboiler 10, the reflux ratio at the top of the rectification tower is controlled to be 1.1, the operating pressure is 0.12MPa (gauge pressure), and the steam at the top of the tower passes through the partial condenser 5 After condensing, part of it was refluxed to the rectification tower, and the other part was obtained as acetone vapor (distillate) with a water content of 7wt.% and 37.5 kg / h at a temperature of 79°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com