Handling method and device for double-medium stacked supporting and hard top plate type mined-out area

A goaf treatment and hard roof technology, applied in safety devices, ground mining, mining equipment, etc., can solve the problems of reducing mining efficiency, increasing construction procedures, and increasing mining costs, so as to improve production efficiency and increase The effect of improving recovery rate and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

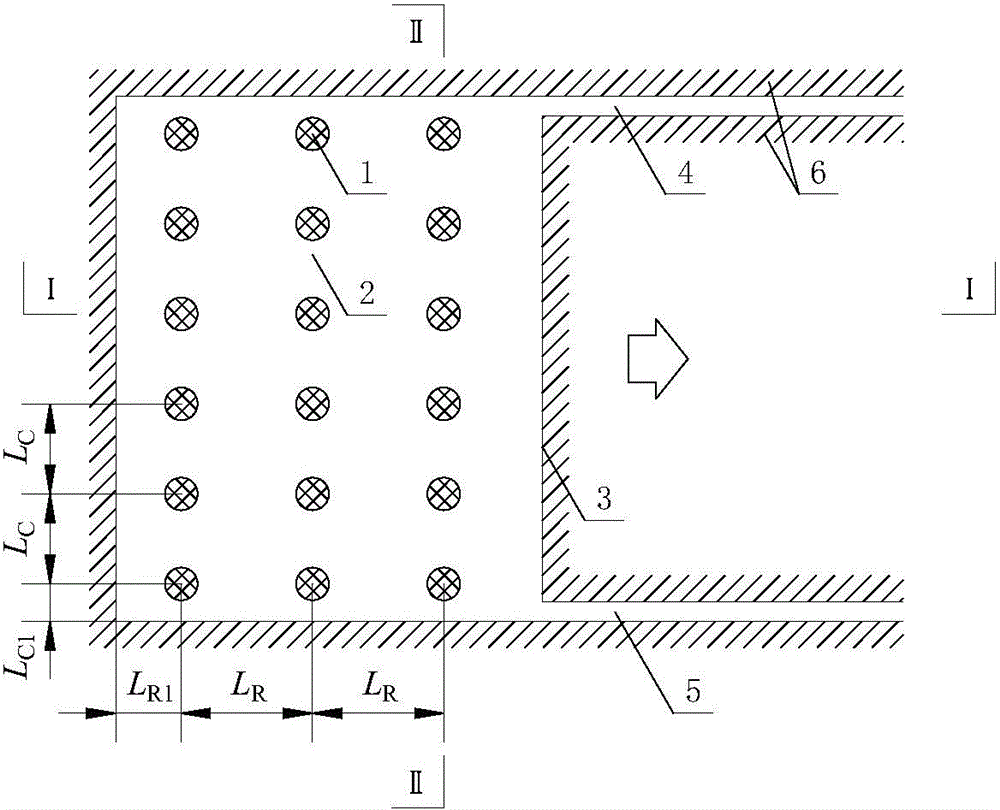

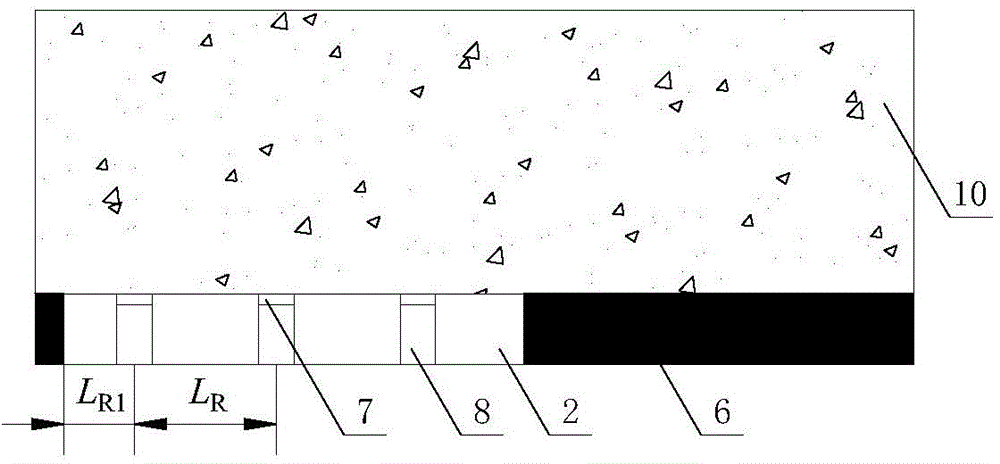

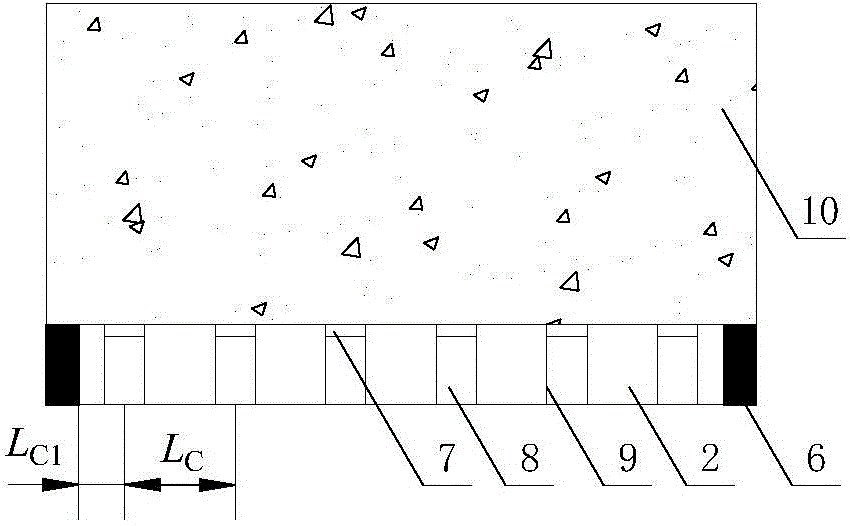

[0023] The coal mine goaf treatment device with double-medium stack supporting hard roof of the present invention is mainly composed of filling stacks 1 and molds 9 arranged at intervals and supported in the goaf 2 of the hard roof, and the filling stack 1 is double-medium filling The stack is composed of the base stack 8 and the top stack 7 located on the top of the base stack 8. The section of the filling stack 1 is circular, rectangular or square, and the effective cross-sectional area is 0.8-1m 2 , the row distance L of filling stack 1 R 15~30m, spacing L C 8-15m; the base stack 8 is filled with concrete or gravel material through a mold 9, and the top stack 7 is filled with injected chemical materials.

[0024] The method for treating gobs in coal mines with double-medium stacked supporting hard roof of the present invention, the specific steps are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com