Comprehensive method for separating stibium from materials containing stibium, tin and lead

A comprehensive method and material technology, applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of high anode residue rate, low production efficiency, and small processing capacity of high antimony tin materials, so as to improve the comprehensive recovery of resources High efficiency, improved production efficiency, and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

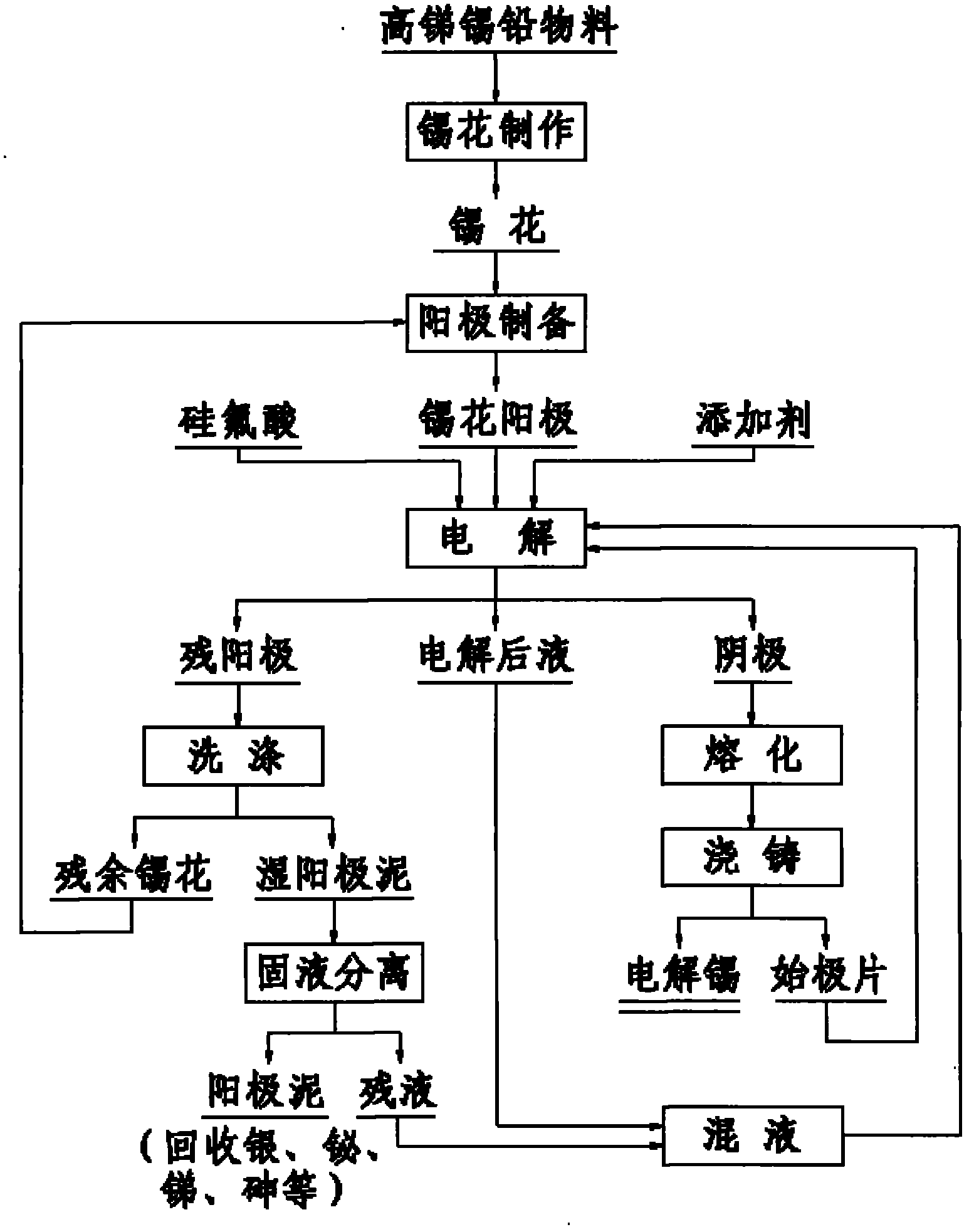

Image

Examples

Embodiment 1

[0020] Adopt the present invention to process the composition of antimony-tin-containing material in electric furnace as shown in table 1. The composition of the electrolyte is: Sn 2+ 133.13g / L, Pb 2+ is 65.99g / L, the total fluorosilicic acid is 332.03g / L, and the free fluorosilicic acid is 73.97g / L. The controlled cathode current density is 100A / m 2 , the cell voltage is (0.6-1.2) V, and other conditions are the same as those described in the above-mentioned technical solution.

[0021] Table 1 Antimony-containing tin material composition table

[0022] element

[0023] Table 2 Composition of cathode tin products

[0024] element

[0025] Table 3 Composition of anode slime

[0026] element

[0027] Ingredient / %

[0028] A total of 219.823 tons of materials containing antimony and tin were put into the trial production, 175.130 tons of cathode tin products (the composition of which are shown in Table 2) and 49.112 tons of anode slim...

Embodiment 2

[0030] The composition of antimony-tin-lead-containing materials treated by the present invention in electric furnace and blast furnace is shown in Table 4. The composition of the electrolyte is: Sn 2+ 44.98g / L, Pb 2+ 41.25g / L, total fluorosilicic acid 243.05g / L, and free fluorosilicic acid 155.43g / L. The controlled cathode current density is 80A / m 2 , the cell voltage is (0.7-1.0) V, and other conditions are the same as those described in the above-mentioned technical solution.

[0031] Table 4 Composition table of materials containing antimony and tin

[0032] element

[0033] Table 5 Composition list of cathode solder products

[0034] element

[0035] Table 6 Composition of anode slime

[0036] element

[0037] A total of 243.616t of materials containing antimony, tin and lead were put into the trial production, 239.472t of cathode solder products (the composition of which are shown in Table 5) were produced, and 41.921t of anode slime (t...

Embodiment 3

[0039] The compositions of materials containing antimony, lead and bismuth in the reverberatory furnace treated by the present invention are shown in Table 7. The composition of the electrolyte is: Sn 2+ 21.53g / L, Pb 2+ It is 59.32g / L, the total fluorosilicic acid is 275.28g / L, and the free fluorosilicic acid is 207.49g / L. The controlled cathode current density is 95A / m 2 , the cell voltage is (0.8-1.4) V, and other conditions are the same as those described in the above-mentioned technical solution.

[0040] Table 7 Composition table of materials containing antimony and tin

[0041] element

[0042] Table 8 Composition of cathode lead products

[0043] element

[0044] Table 9 Anode slime composition list

[0045] element

[0046] A total of 168.525t of materials containing antimony, lead and bismuth were put into the trial production, 139.714t of cathode lead products (the composition of which is shown in Table 8) and 75.113t of anode slime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com