Arrangement method of high gas coal seam extraction working face roadway

A technology for mining face and roadway layout, which is applied in the direction of gas discharge, tunnels, safety devices, etc., which can solve the problems of difficult maintenance of gas discharge roadway, waste of resources, and large loss of coal pillars in sections, so as to improve the recovery rate of coal resources , increase the mining ratio, and reduce the loss of coal pillars in the section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

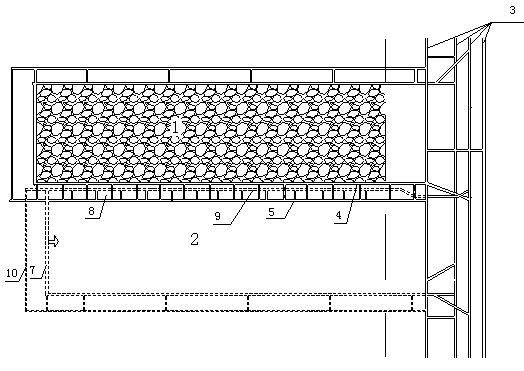

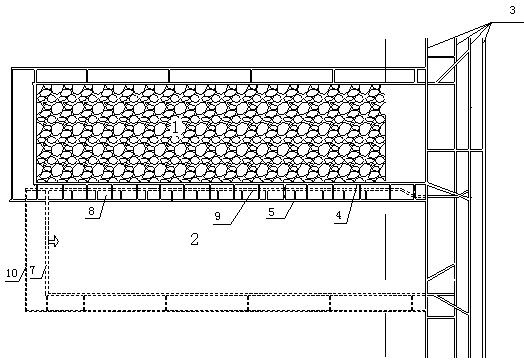

[0011] Embodiment 1, as figure 1 As shown, the first layout method of the roadway in the mining face of high gas coal seam:

[0012] 1. Arrange the initial working face, adopt double roadway layout and excavation, that is, excavate the return air level roadway 4 of the previous working face and the gas discharge roadway 5 of the previous working face at the same time, and the distance between the double roadways is 25~35m;

[0013] 2. Carry out the mining of the initial working face, and maintain the gas discharge lane 5 of the previous working face during the mining process;

[0014] 3. After the mining of the previous working face is completed and the overlying stratum is stable, the coal pillar 8 of the previous working face between the main road 3 along the goaf 1 edge of the previous working face and the gas discharge roadway 5 of the previous working face is parallel Open a gas discharge lane 9 in the next working face, the distance between the gas discharge lane 9 in t...

Embodiment 2

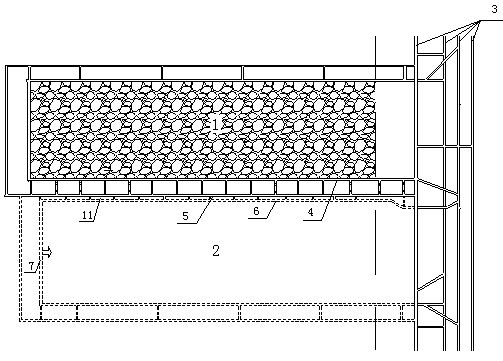

[0016] Embodiment 2, as figure 2 As shown, the layout method of the roadway in the mining face of high-gas coal seam II:

[0017] 1. Arrange the initial working face, adopt double roadway layout and excavation, that is, excavate the return air level roadway 4 of the previous working face and the gas discharge roadway 5 of the previous working face at the same time, and the distance between the two roadways is 25~35m;

[0018] 2. Carry out the mining of the initial working face, and maintain the gas discharge lane 5 of the previous working face during the mining process;

[0019] 3. After the mining of the previous working face is completed and the overlying rock stratum is stable, a return air roadway 6 of the next working face is parallelly opened in the coal seam below the gas discharge roadway 5 of the previous working face from the roadway 3, and the next working face is returned to The width of the coal pillar 11 of the next working face between the air level roadway 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com