Patents

Literature

31results about How to "Reduce the rate of penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

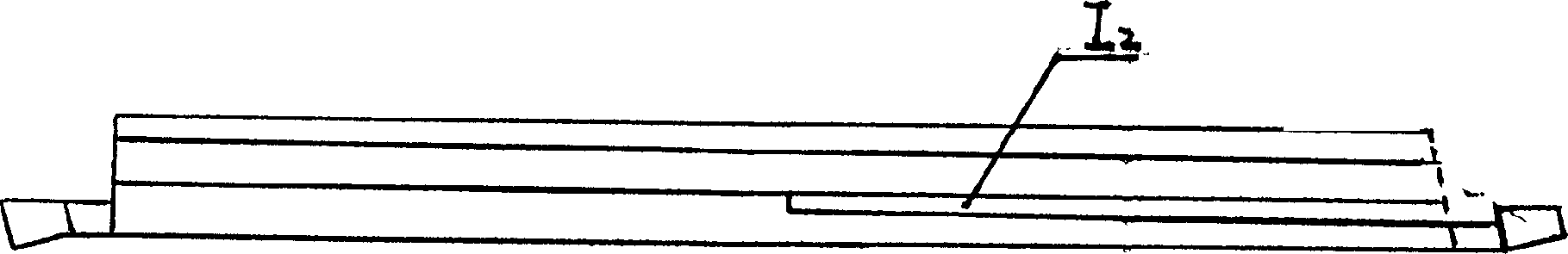

Comprehensive coal-mining process by using long wall mining method

InactiveCN1865657ALow costReduce in quantityUnderground miningSurface miningEngineeringEarth surface

The invention relates to a long-wall coal method, which can be used in stable coal bed, rigid top plate, non-broken incline middle-thickness coal bed, and thick coal bed layered long-wall method. Wherein, it arranges hydraulic support, scrape transporter, and roller coal machine at the long-wall working surface; arranges groove transporter and flexible band transporter at the transport channel; the working surface has ultra long length, which is two times of integrated coal surface; it uses two coal machines on one scrape transporter, to scrape the upper half surface and the lower half surface; and it can arrange middle channel at the middle of integrated surface as the transport channel; and arranges scrape transporters at the upper and lower half working surfaces. The invention has high efficiency, while it can reduce the digging rate and improve the resource recycle rate.

Owner:YANKUANG GRP CO LTD

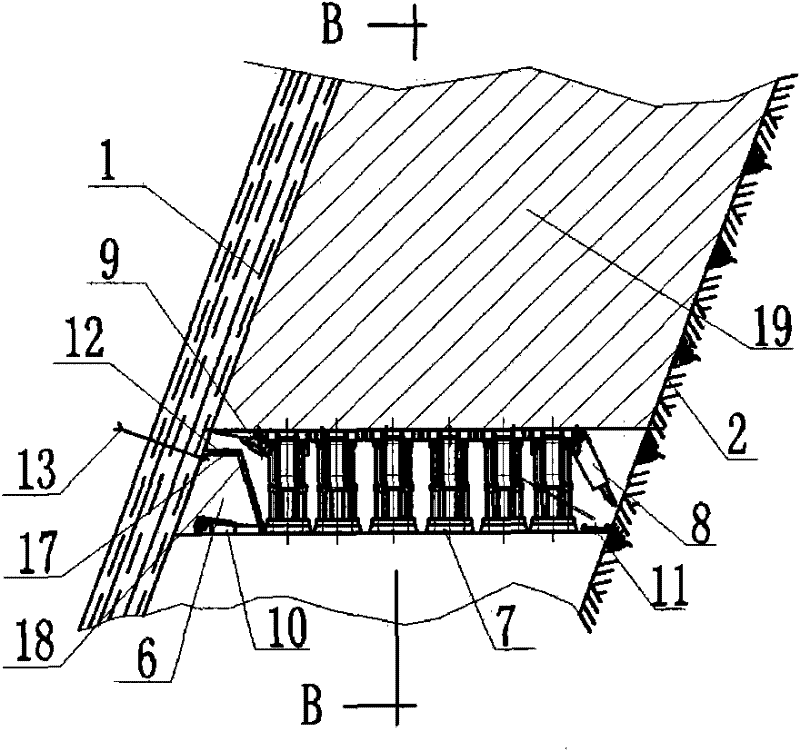

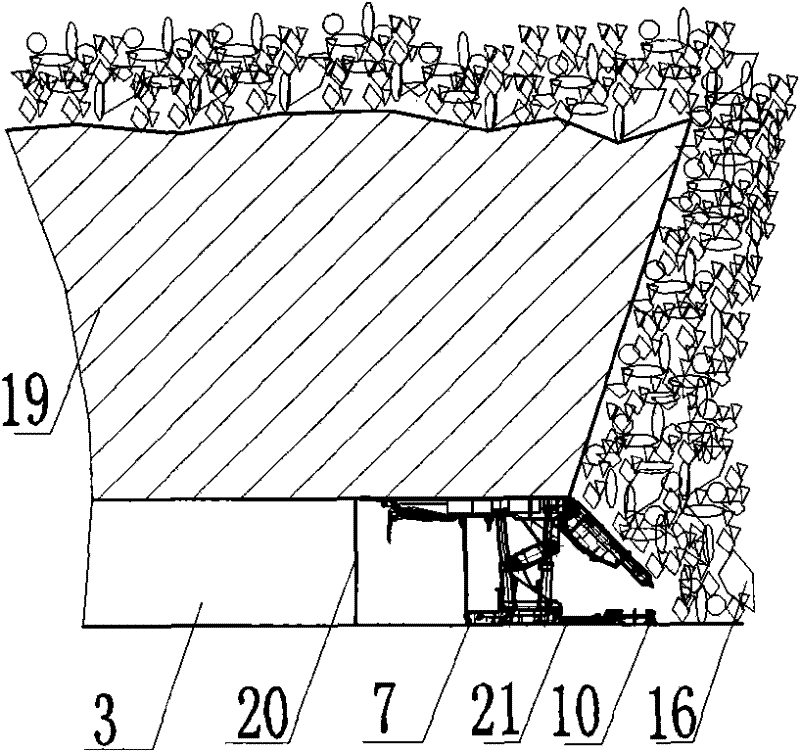

Coal-minin method of high-dipping thick seam

InactiveCN1657745AImprove ventilationReduce air volumeUnderground miningTunnel/mines ventillationEconomic benefitsEngineering

The invention discloses a method for coal mining to the greatly oblique coal layer, comprising two steps: designing the method and back producing technique, placing slit flexible shielding support in the coal layer of 8-10m and deciding return airway and cutting point; the back producing technique includes enlarging airway, installing support, put down support and desinence of working face, etc. The method has simple operational steps as well as remarkable economic benefit.

Owner:KAILUAN GRP

Method of mining coal from heavy pitch thick coal seam

ActiveCN101915101AIncrease productionImprove efficiencyUnderground miningSurface miningEngineeringCoal mining

The invention provides a method for mining coal from a heavy pitch thick coal seam in a horizontal and segmental short wall manner. The method comprises the following steps of: supporting and caving coal by using a top coal caving hydraulic support in a work surface; drilling holes, blasting coal, and conveying the coal with a scraper conveyor; performing gob-side entry retaining by using a prefabricated metal shed or a plastic bucket. The coal-mining method can realize mechanical mining of the heavy pitch thick coal seam, greatly improves yield and efficiency of the working face and ensures safe production.

Owner:TIANDI SCI & TECH CO LTD

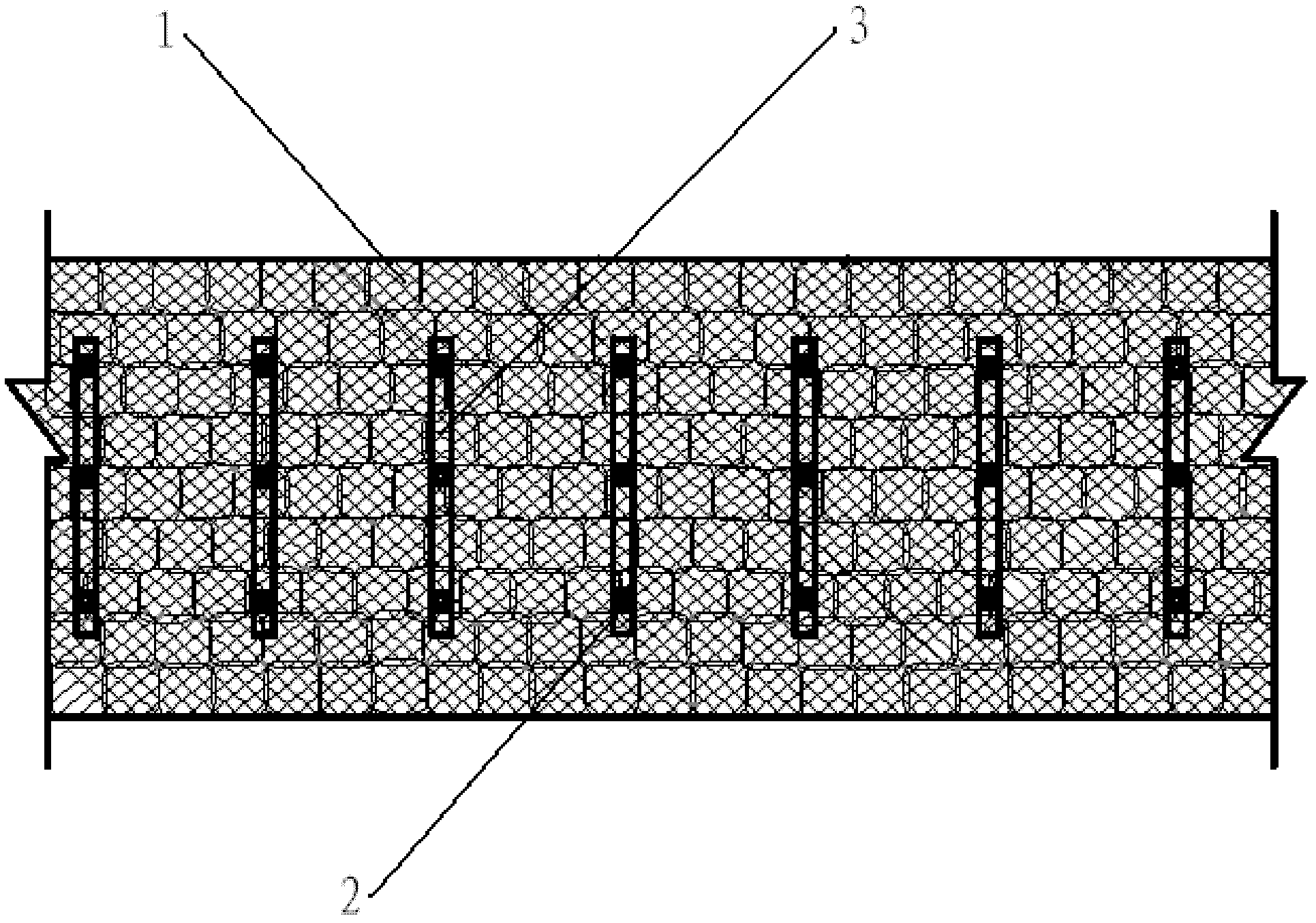

Gob-side entry retaining method for anchor bolt network gangue bag wall body for coal mining without pillars

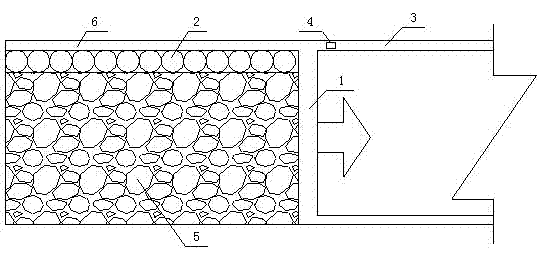

InactiveCN102661169AHigh strengthIncrease stiffnessMaterial fill-upAnchoring boltsGranularityMining engineering

The invention discloses a gob-side entry retaining method for an anchor bolt network gangue bag wall body for coal mining without pillars. The gob-side entry retaining method comprises the following steps of: A, crushing solid wastes obtained by separating tunneling gangue and / or coal gangue until the granularity is small than 0.1m and bagging by adopting plastic woven bags to obtain gangue bags; B, conveying the gangue bags obtained in the step A to the position of a working surface, which is used for building an entry, through an underground conveying system and fixing the gangue bags for building a roadside gangue bag wall body to form a gob-side entry; C, arranging the gangue bag wall body into a plurality of steps with different heights; and D, building the gangue bag wall body to the designed position and height and then mounting anchor bolts and paving a metal net, and simultaneously, paving a vertical protection steel belt, carrying out two-way anchoring or single-side pretightening in a large-pallet lane and keeping a gangue bag filling body in the gangue bag wall body in a three-dimensional stress state to achieve the functions of increasing the side pressure of the gangue bag filling body and improving the strength and the rigidity of the filling body.

Owner:SHANDONG UNIV OF SCI & TECH

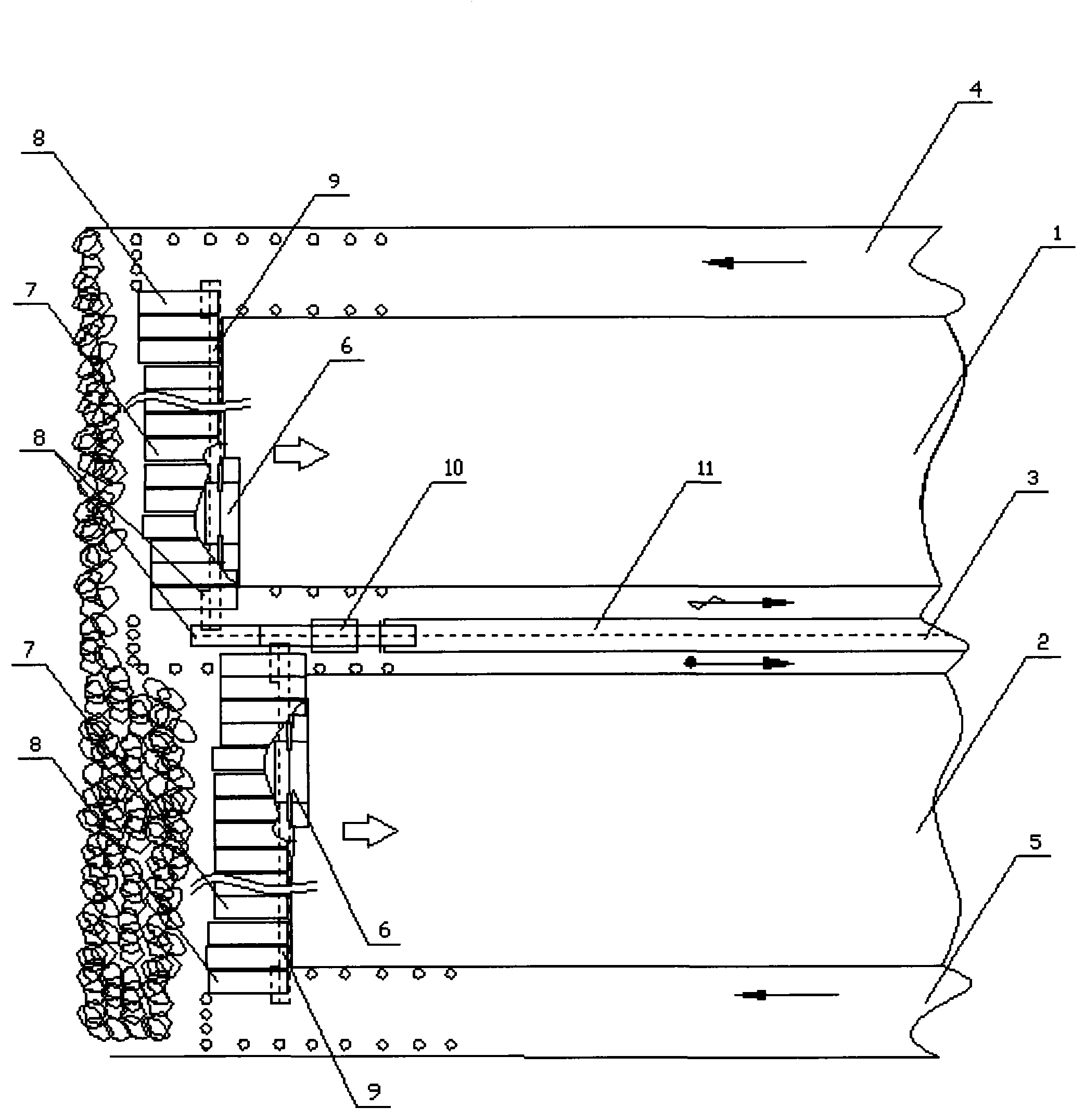

Arrangement method of high gas coal seam extraction working face roadway

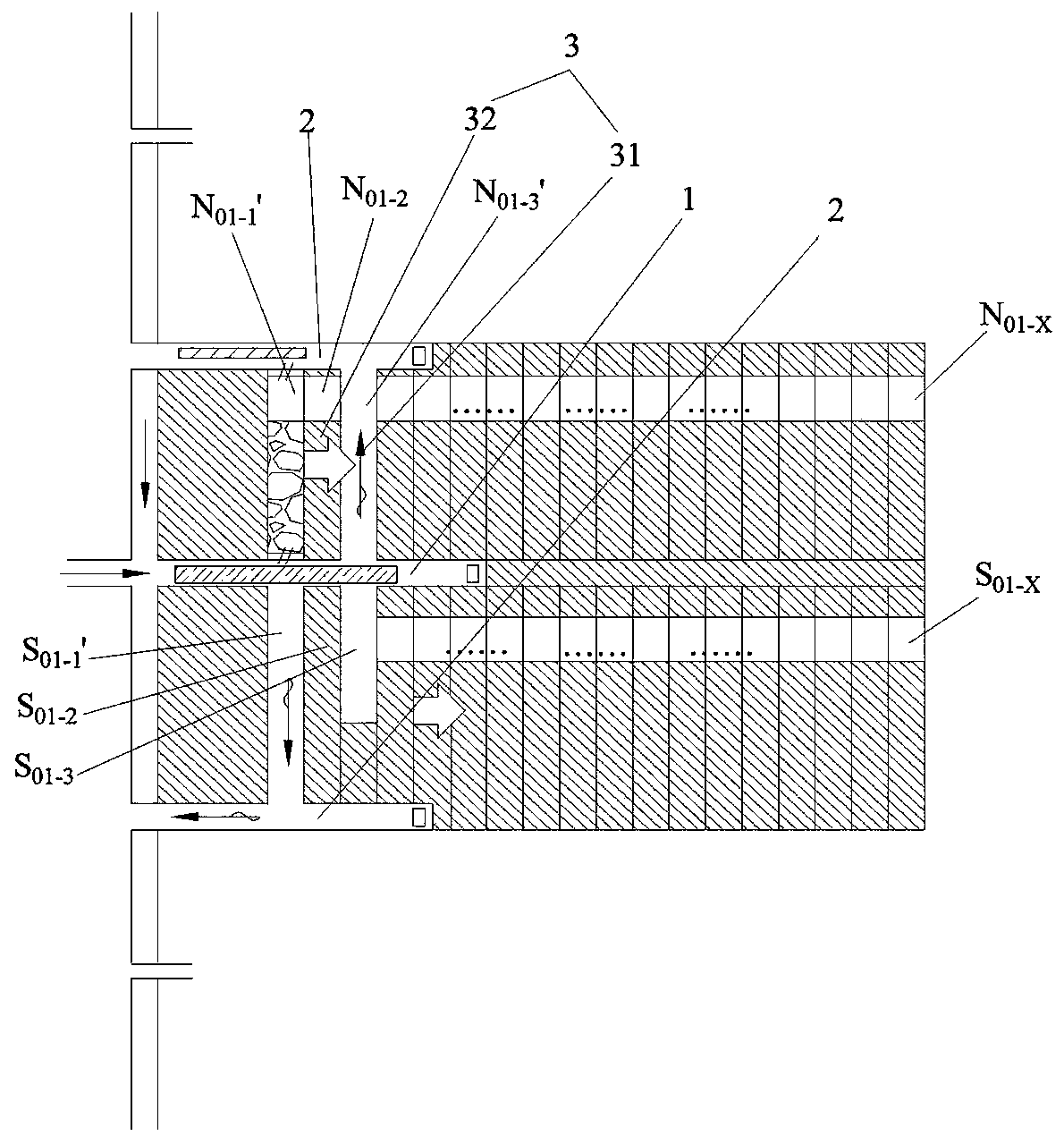

The invention discloses an arrangement method of a high gas coal seam extraction working face roadway, which comprises roadway arrangement of an initial working face and extraction of the working face. After the completion of the extraction of the last working face and the stabilization of an upper overlying rock layer, the next working face gas exhaustion lane is arranged in parallel along a last working face coal column between a last working face extraction region edge and the last working face gas exhaustion lane from a large lane, or the next working face air returning leveling lane is arranged in parallel along the coal seam below the last working face gas exhaustion lane from the large lane, the next working face gas exhaustion lane is in auxiliary hole cut-off communicated with the next working face, or the next working face air returning leveling lane is in hole cut-off communicated with the next working face; and the processes are repeated until the roadway arrangement of the working face of the exploration region and the extraction of the working face is completed. The problems that the loss of the coal columns in the region sections is large and the next working face gas exhaustion lane is difficult to maintain can be solved, so that the next working face gas exhaustion lane of the outer circle can be normally used under the influence of the secondary extraction, thereby improving the extraction ratio of the coal carbon resources and reducing the roadway tunneling ratio.

Owner:CHINA UNIV OF MINING & TECH

Method for supporting retained gob-side entry of blasting-mining working faces of small-area thin seam

ActiveCN105545321AReduce construction difficultyEasy to operateUnderground chambersTunnel liningEngineeringEffective response

The invention discloses a method for supporting a retained gob-side entry of the blasting-mining working faces of a small-area thin seam. The retained gob-side entry of the blasting-mining working faces of the small-area thin seam is supported through an I-shaped steel shed and timber, and single hydraulic props are adopted for reinforcing supporting. The supporting method includes the following steps of 1, advance supporting, wherein anchor rods are additionally anchored on the advance blasting-mining working face in a gate road, and the I-shaped steel shed is erected on the advance blasting-mining working face; 2, lagging supporting, wherein after the I-shaped steel shed is completely erected, single hydraulic props are erected on the lagging blasting-mining working face to reinforce supporting; 3, gob side caving, wherein after materials are fed back to the blasting-mining working faces, if a roof can not automatically fall, explosive-charging caving is carried out. According to the method, entry retaining is achieved through the I-shaped steel shed, the single props and explosive-charging caving; the gob-side entry retaining mode is low in investment, quick in effective response and high in benefit and safety factor, and is one of extremely-beneficial ways for enhancing safe production of a mine.

Owner:SHANDONG UNIV OF SCI & TECH

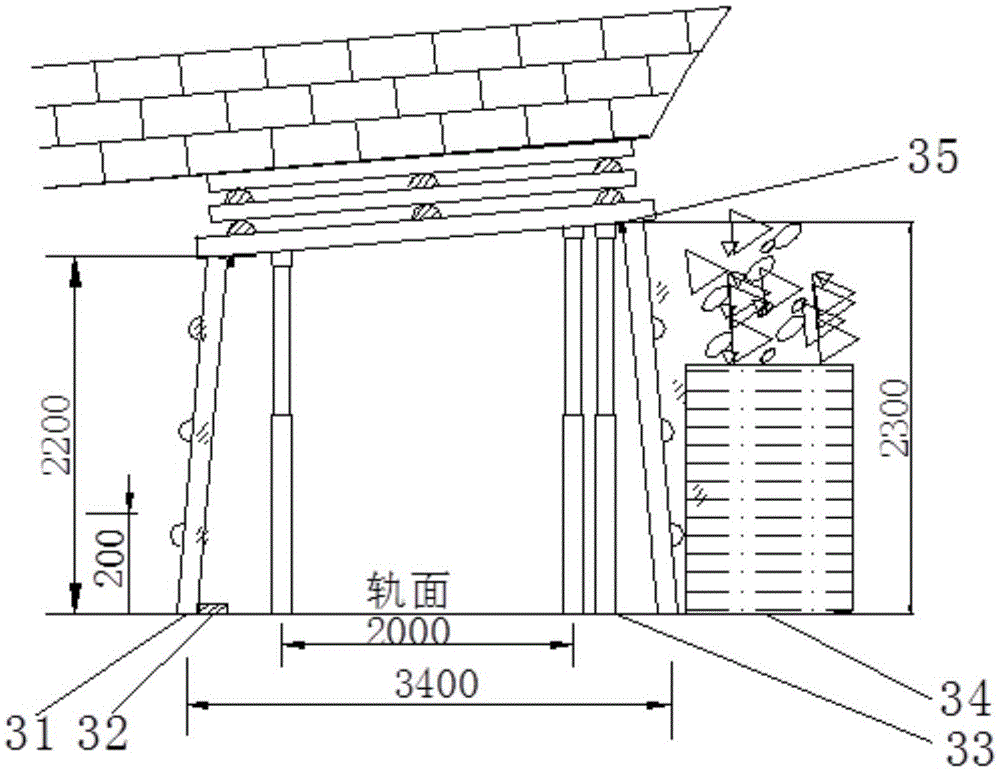

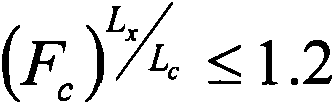

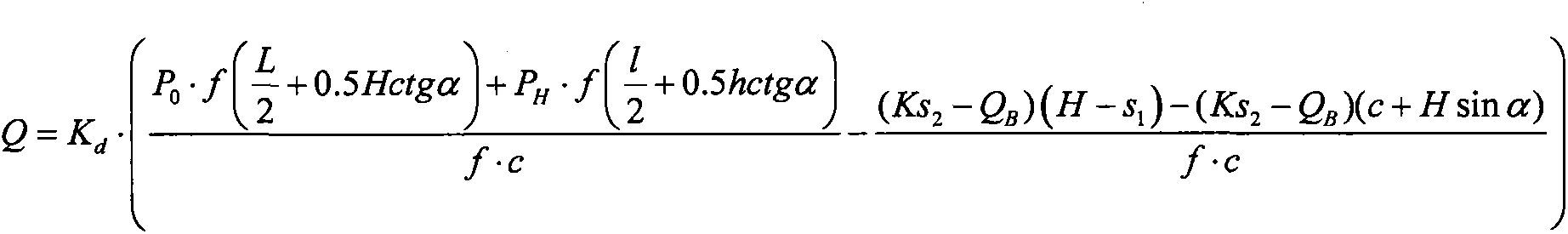

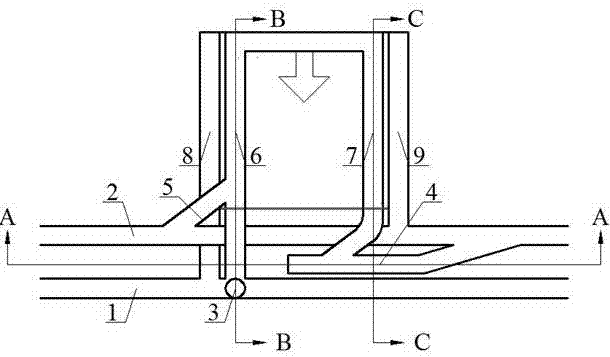

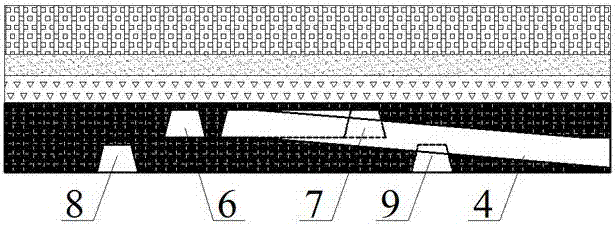

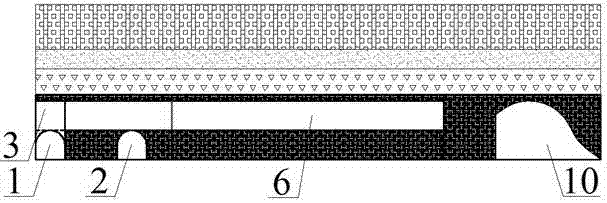

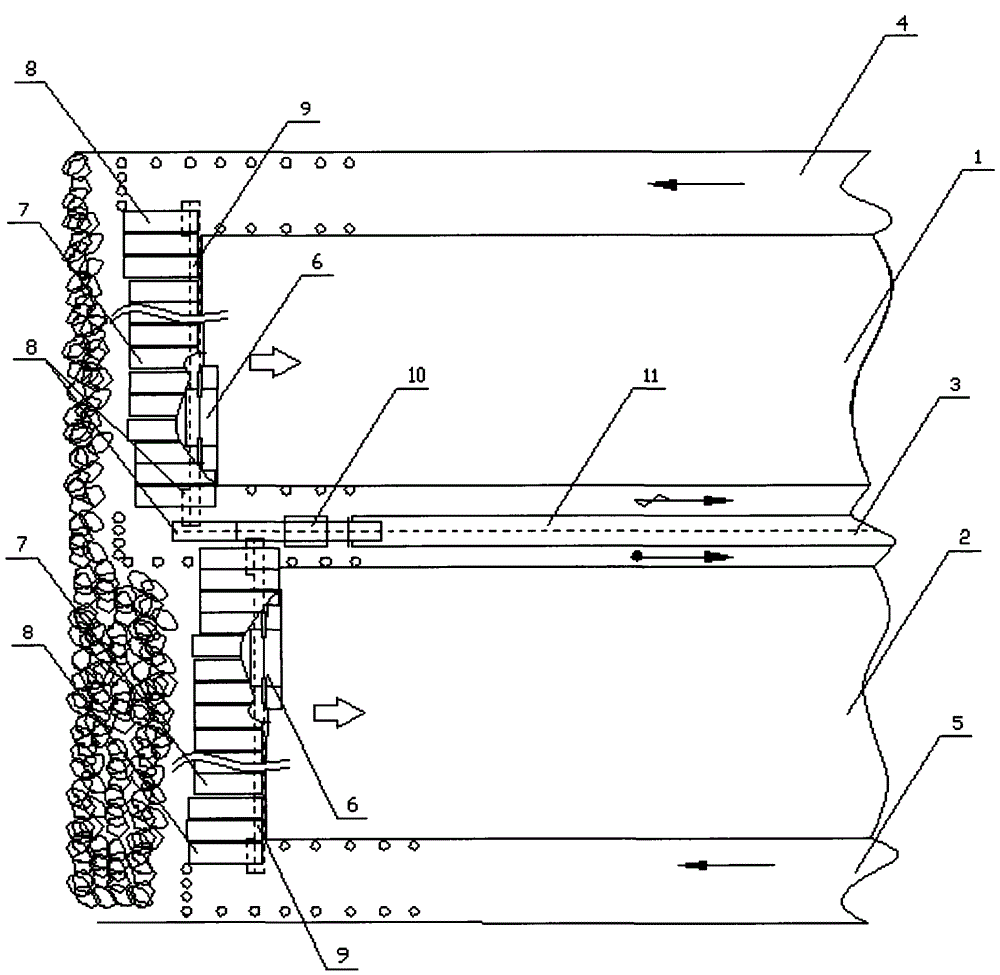

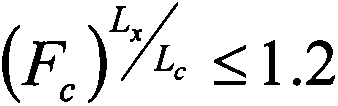

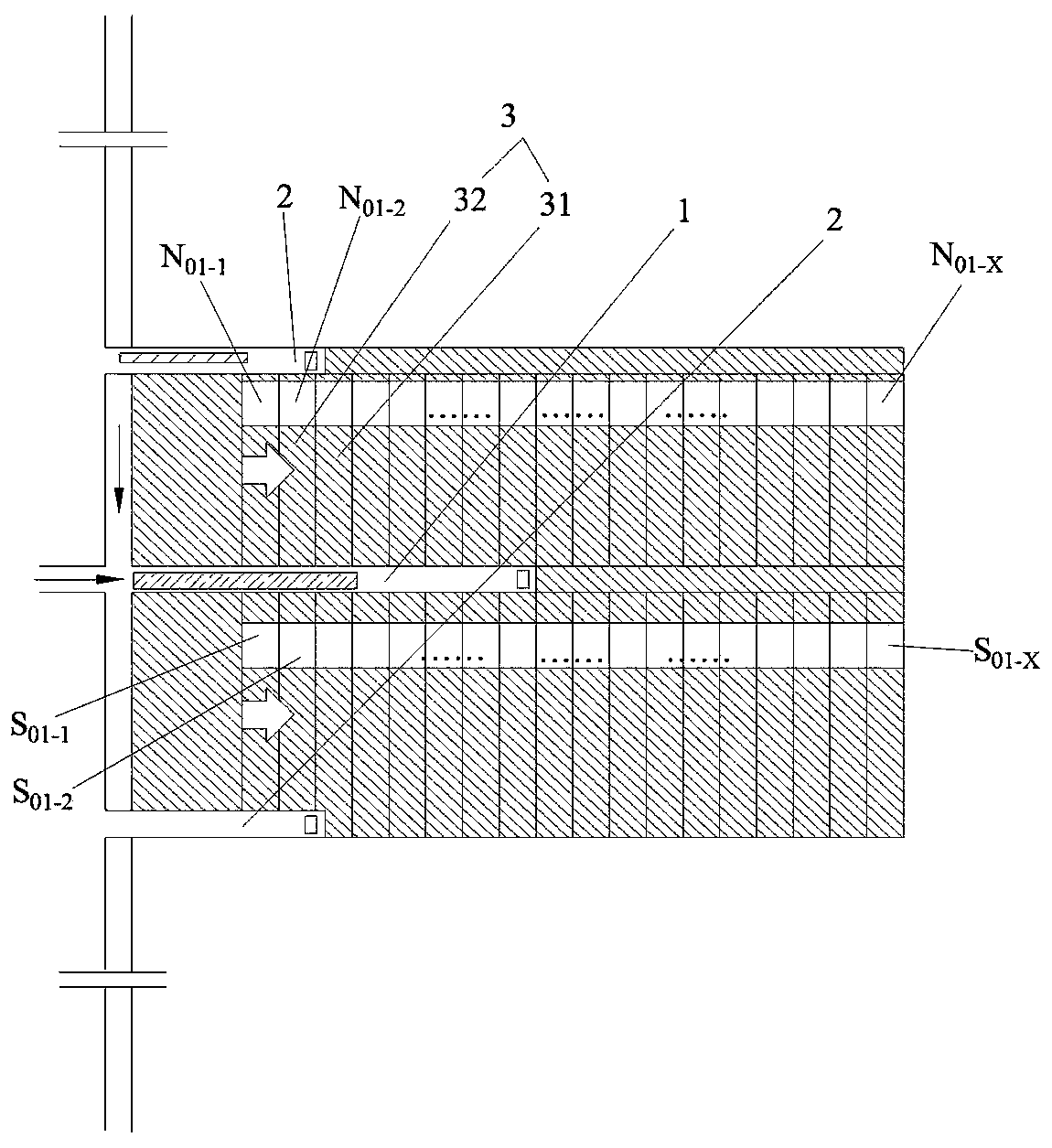

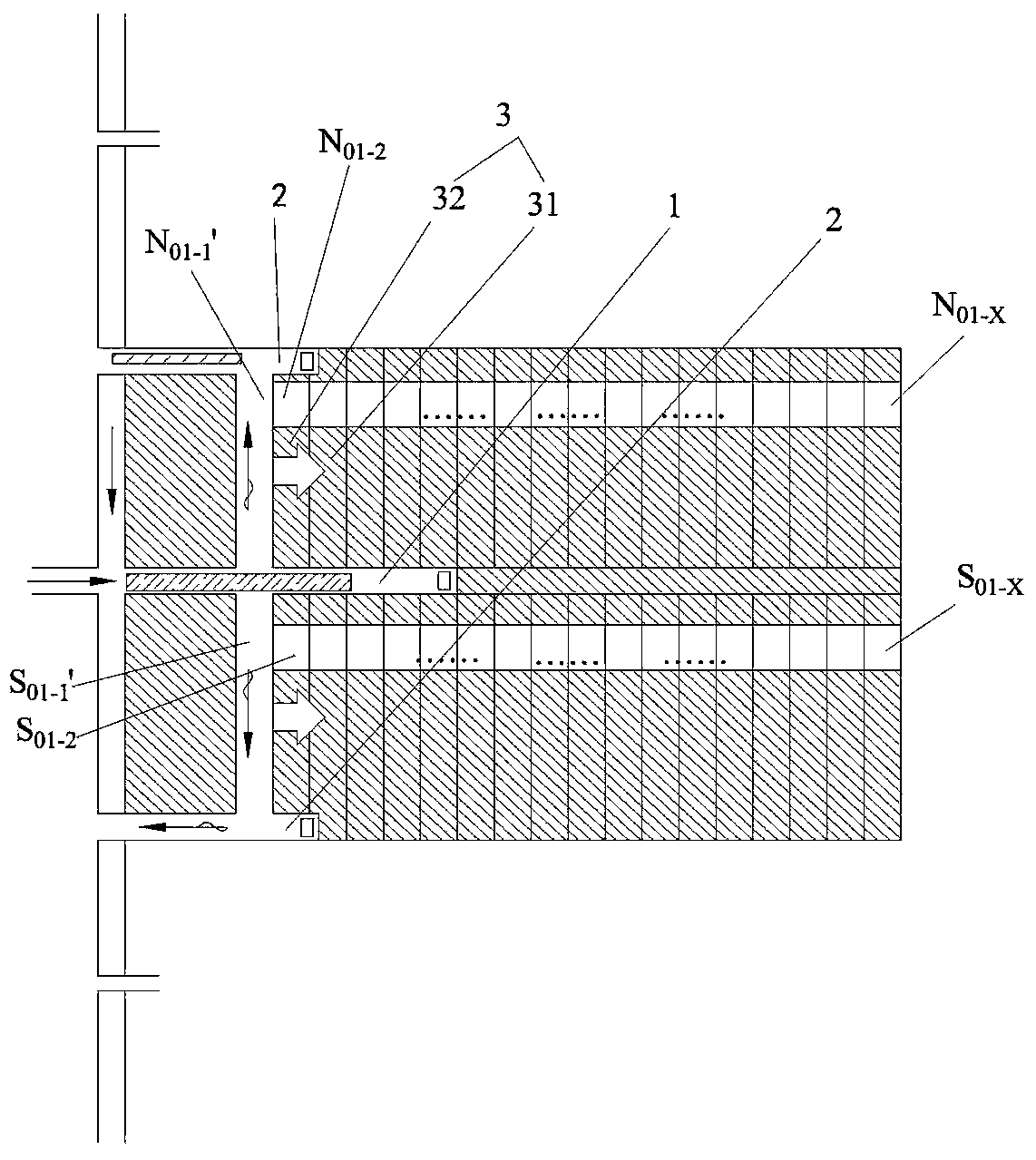

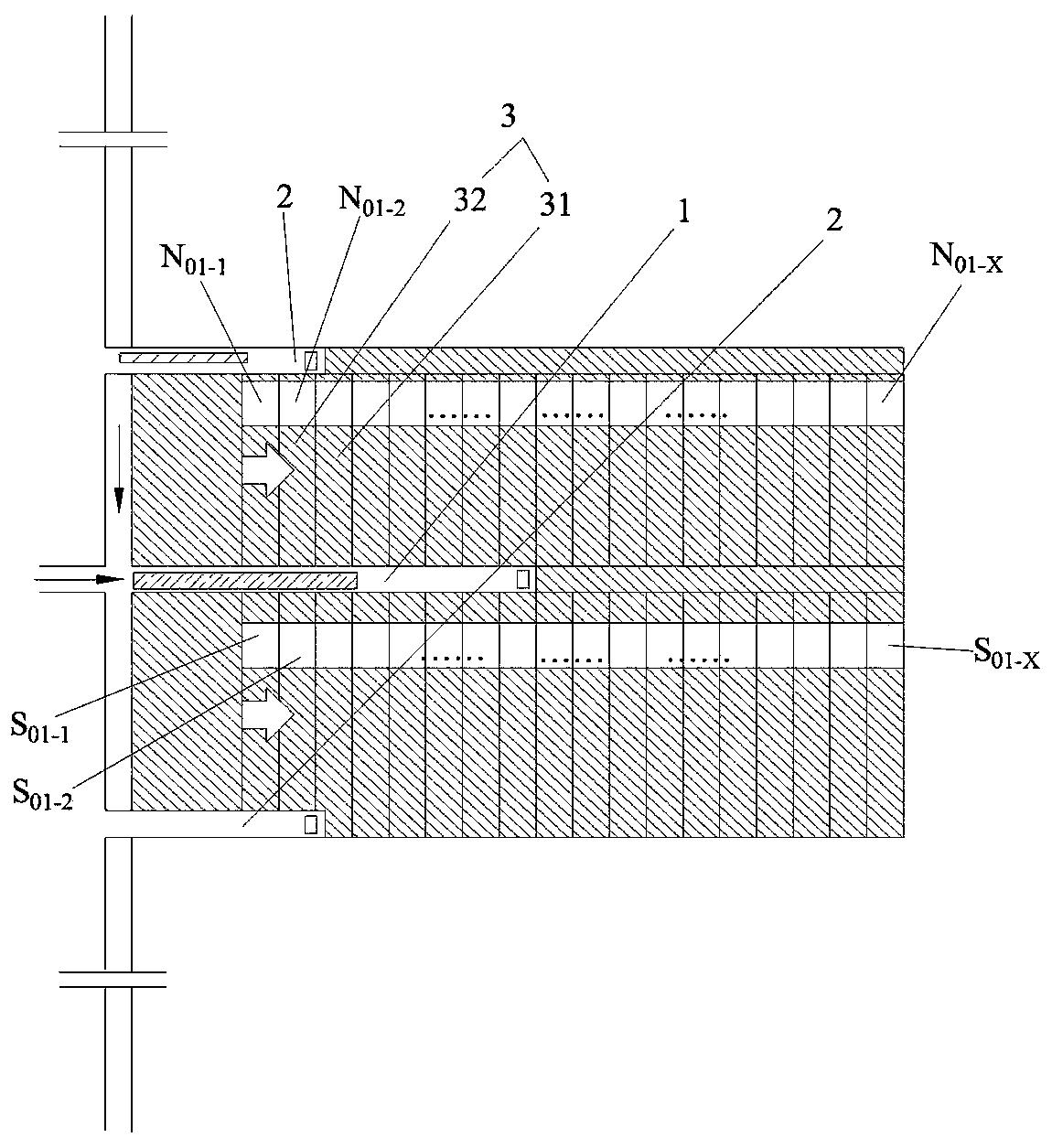

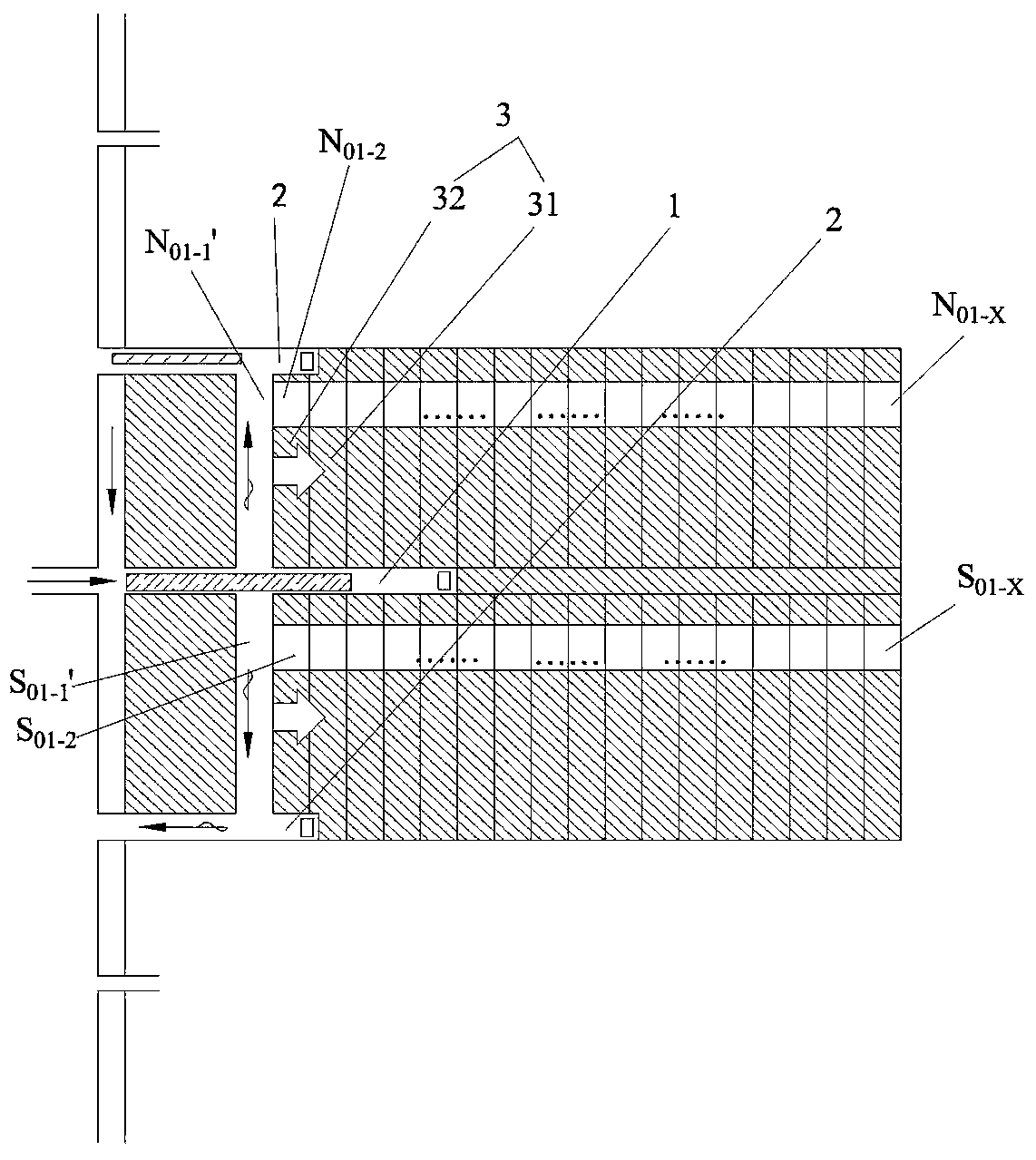

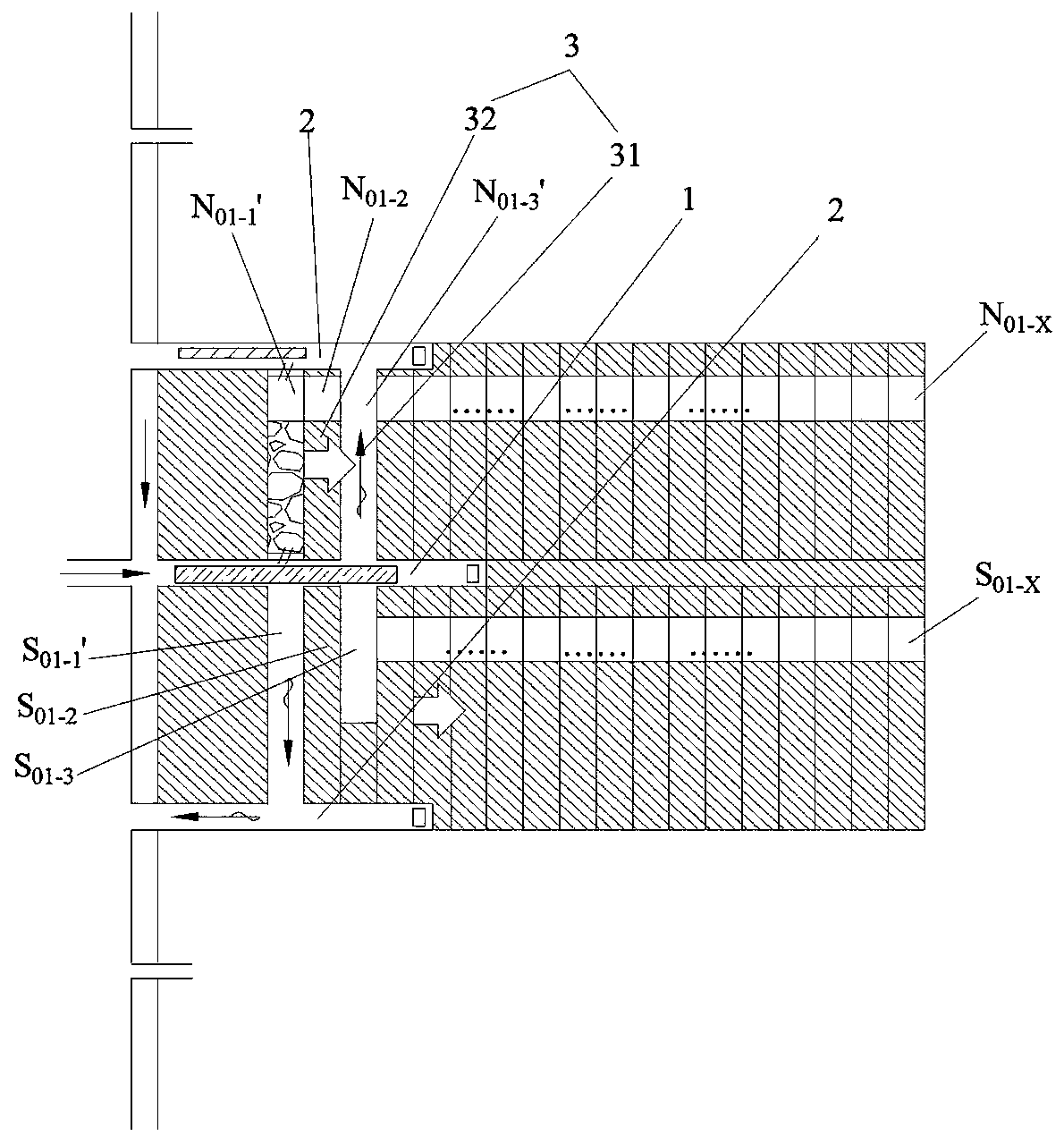

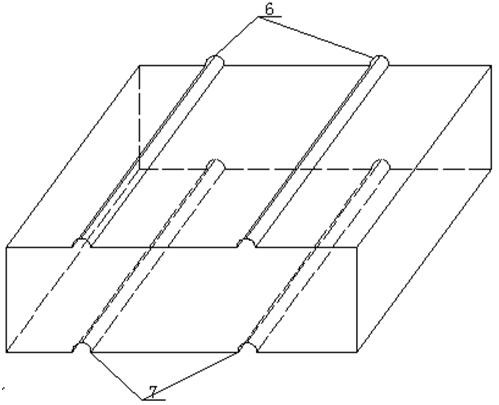

Large-mining-height dual-fully mechanized mining face stoping process

InactiveCN104234715AIncrease productivityEnsure safetyUnderground miningSurface miningMining engineeringGeological structure

The invention provides a large-mining-height dual-fully mechanized mining face stoping process. The stoping process comprises the following steps: (1) determining whether the coal-seam thickness of a mining area of a working face to be mined is within the range of 3.5-7.0m, whether the geological structure is simple and relatively stable in thickness and whether the inclination angle is smaller than 12 degrees; and (2) arranging three parallel stoping tunnels in a main tunnel of a vertical mining area, communicating every two adjacent tunnels by use of an open-off cut to form a large-mining-height fully mechanized mining face, and then forming a left large-mining-height fully mechanized mining face and a right large-mining-height fully mechanized mining face, wherein the dip separation of the two faces is determined according to a formula as described in the specification. The large-mining-height dual-fully mechanized mining face stoping process is used for solving the technical problem that the large-mining-height fully mechanized mining face is incapable of breaking through the yield of 10 million tons / a to a large extent, and meanwhile, provides the enough security guarantee and cost control.

Owner:TIANDI SCI & TECH CO LTD

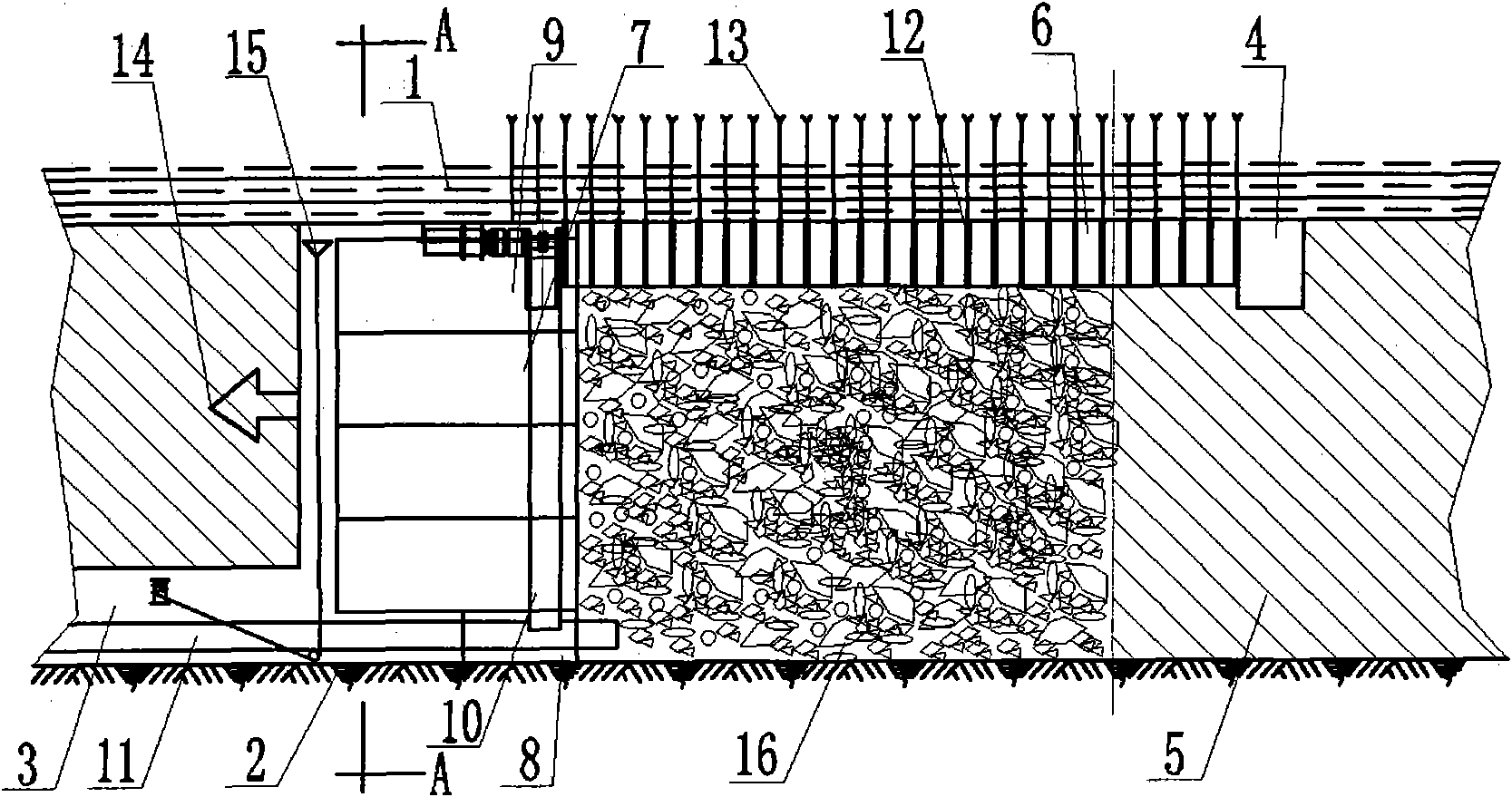

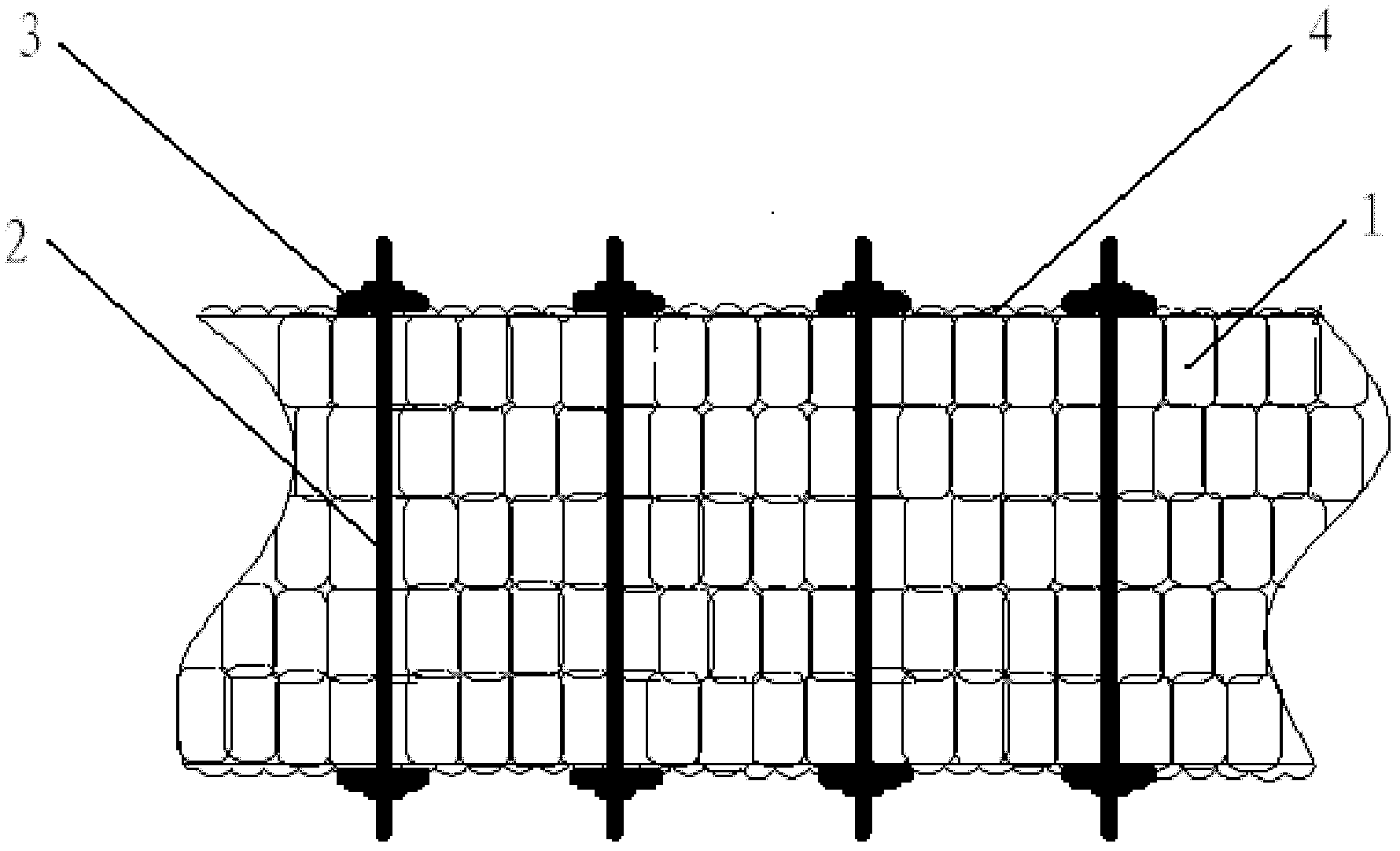

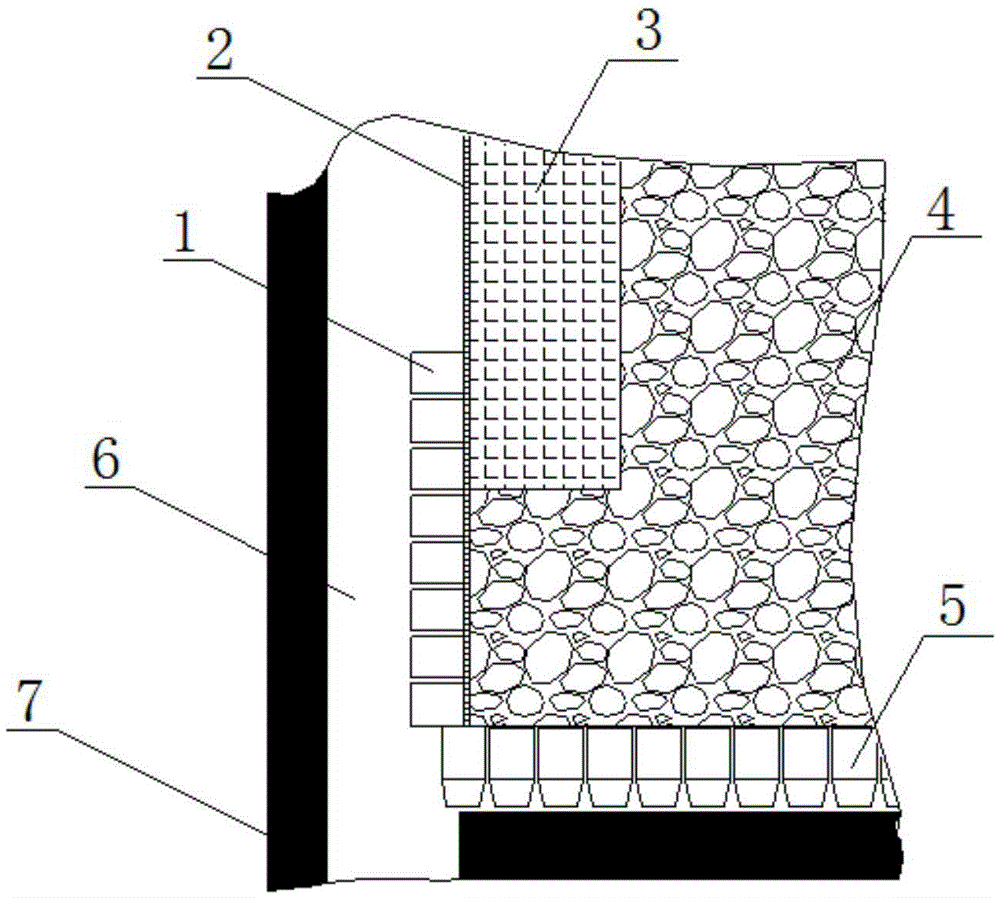

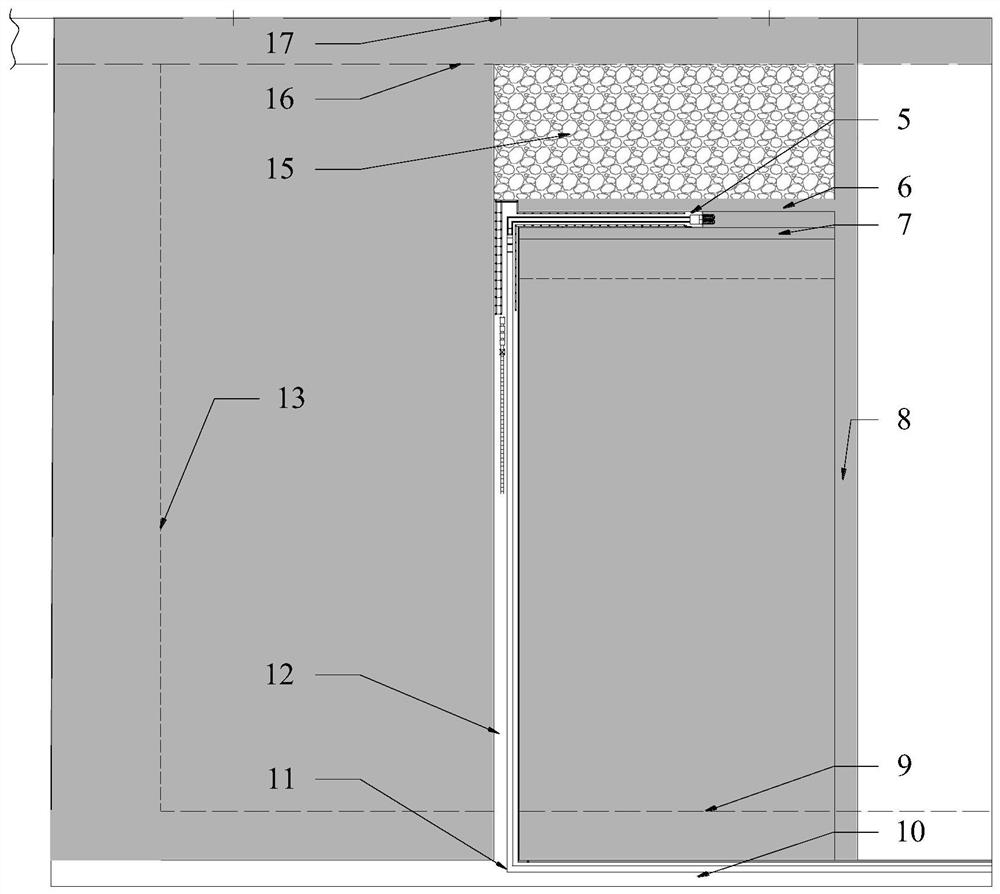

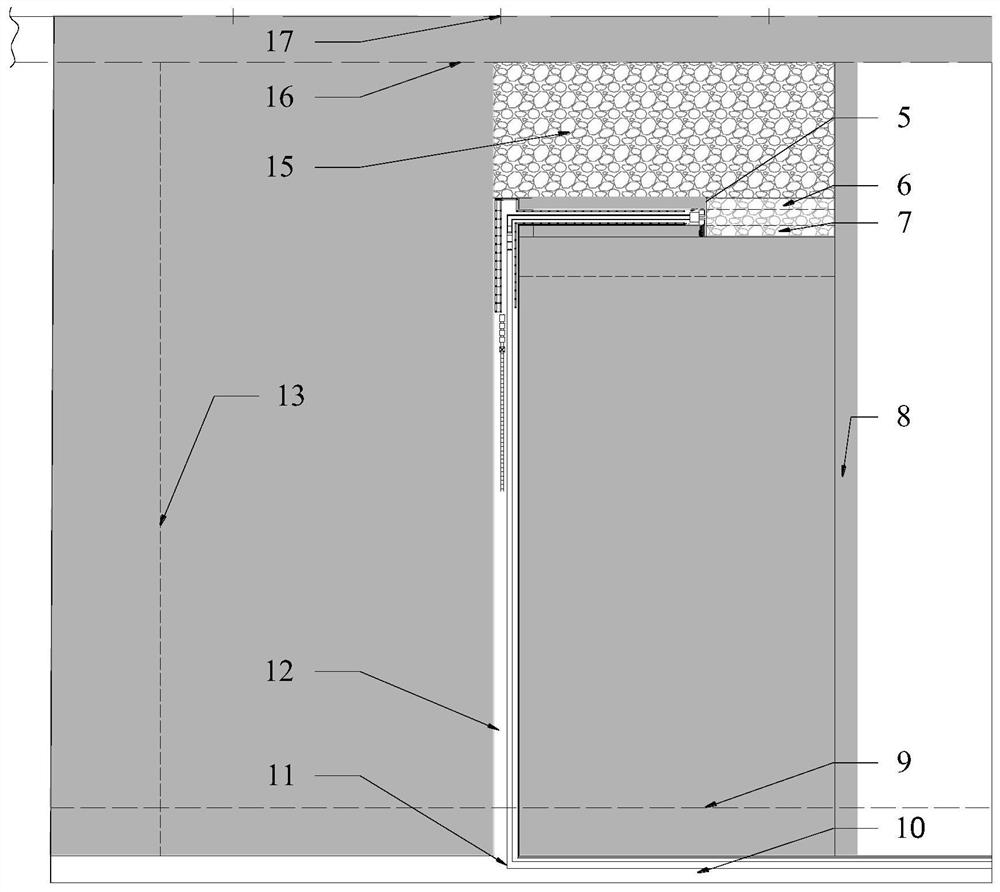

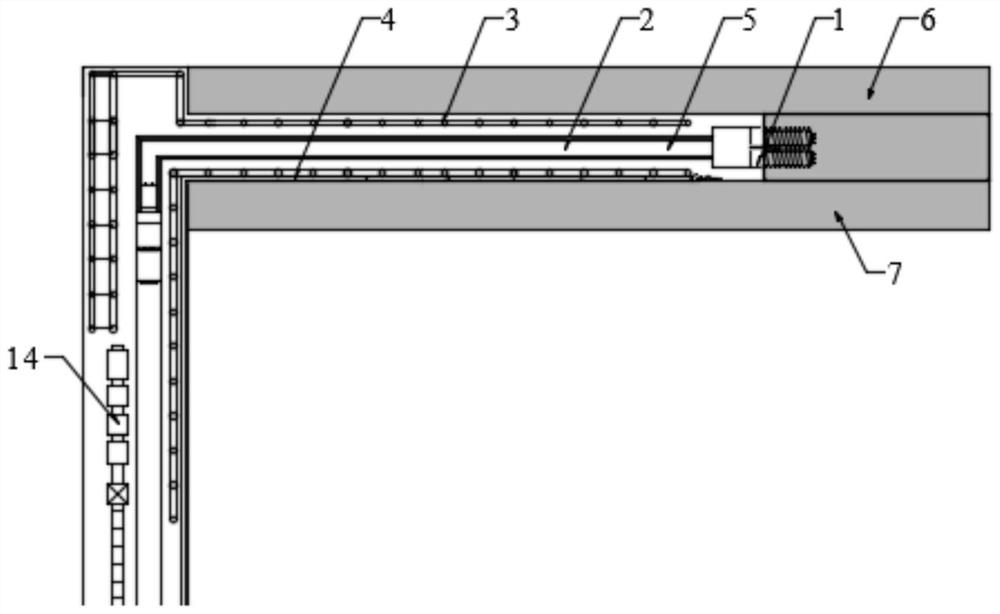

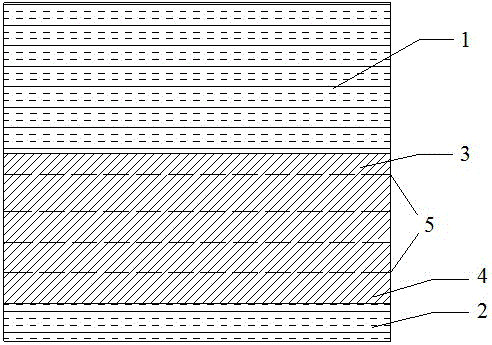

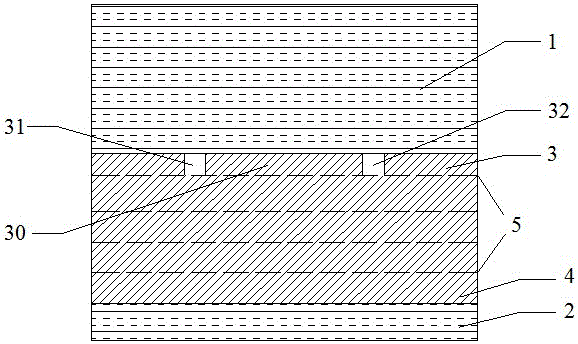

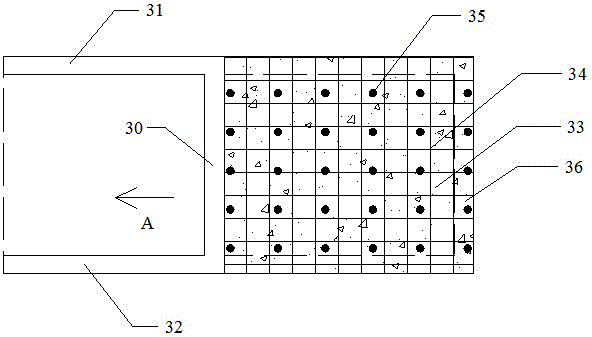

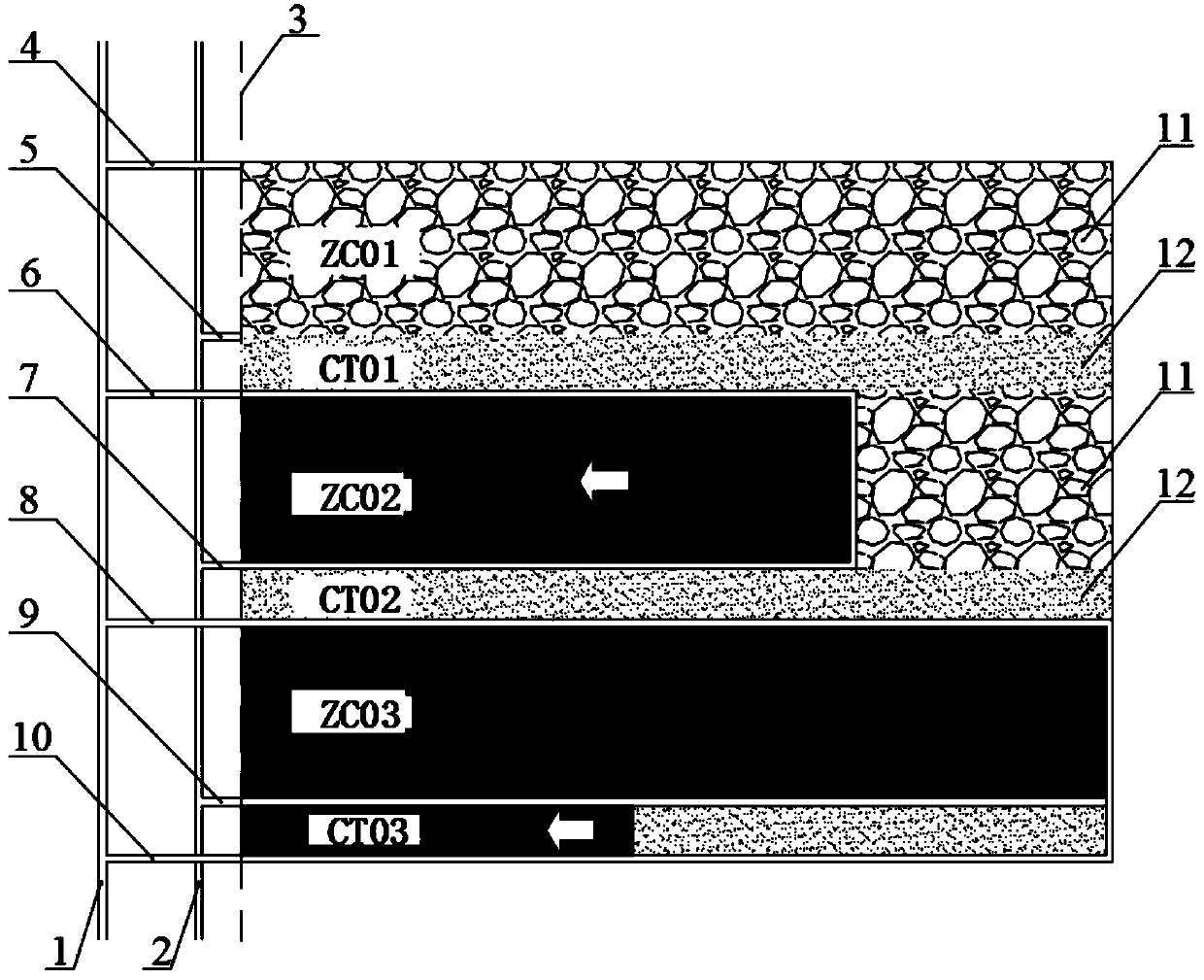

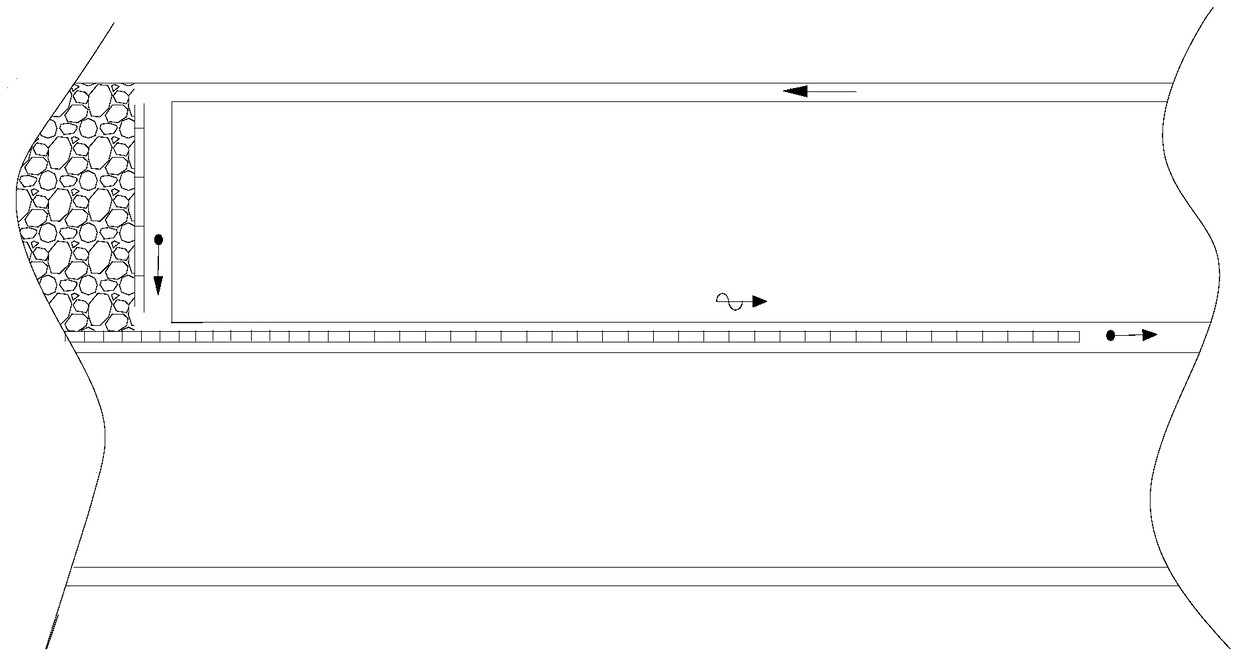

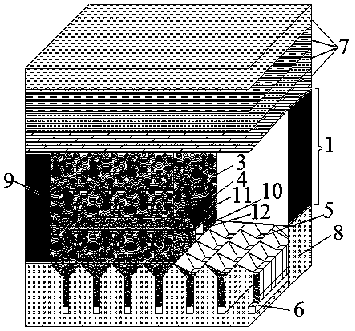

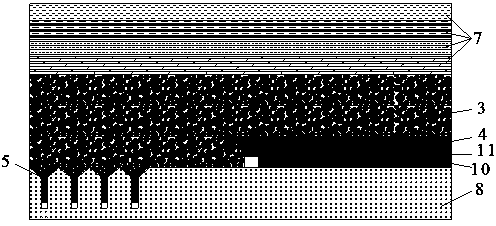

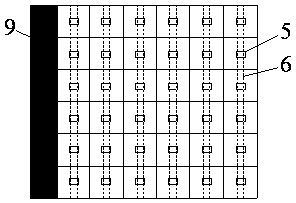

Method for repeated-mining stopping-line coal pillar in extra-thick coal seam residual mining area and filling extra-thick coal seam with layered pasty fluid

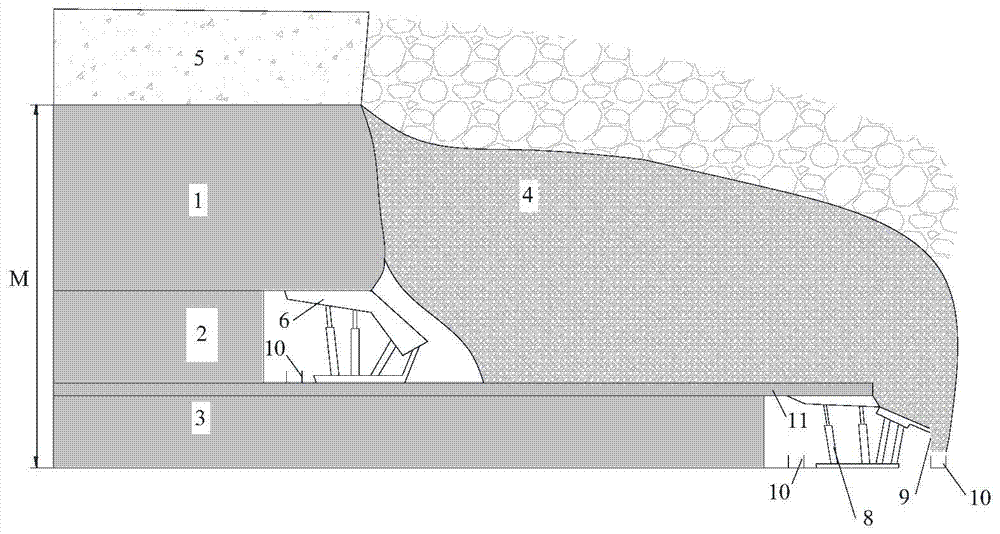

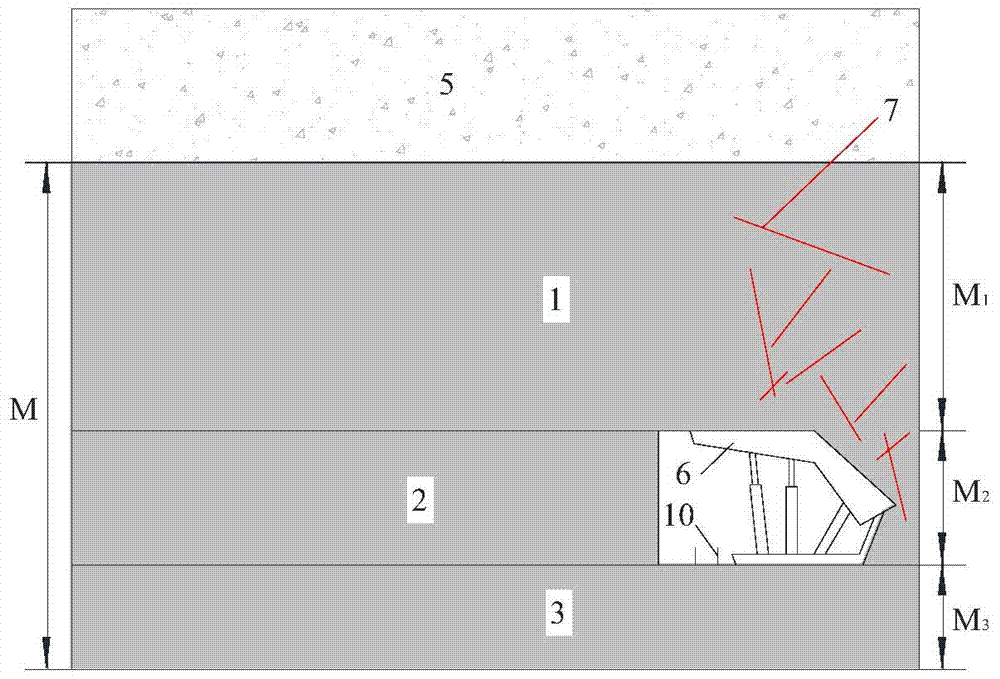

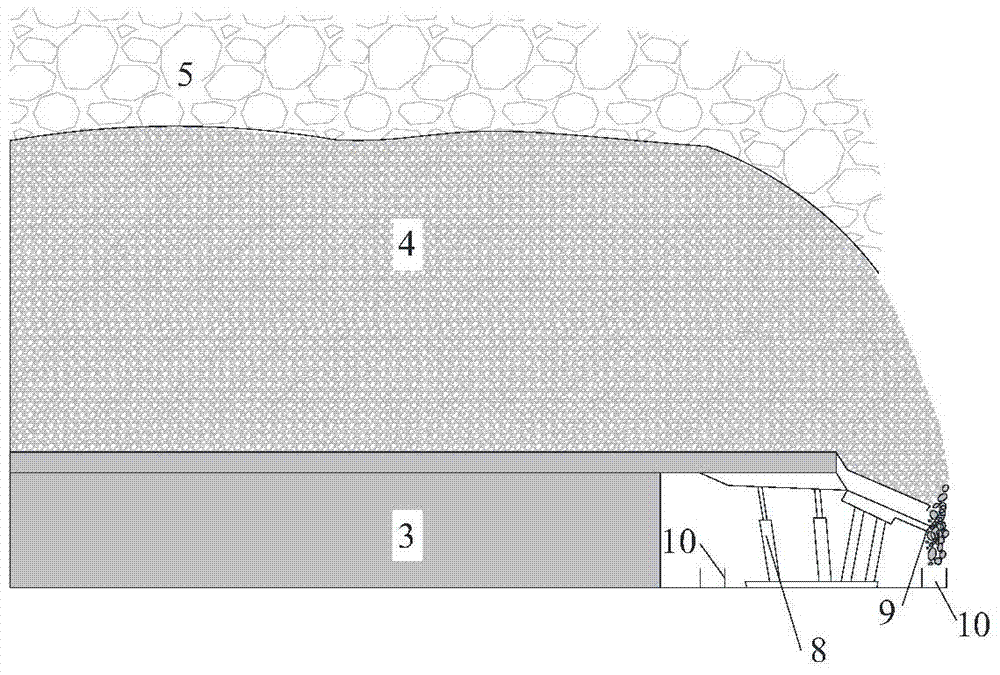

ActiveCN107339105AReduce the rate of penetrationReduce the amount of excavation and excavationUnderground miningSurface miningMining engineeringEconomic benefits

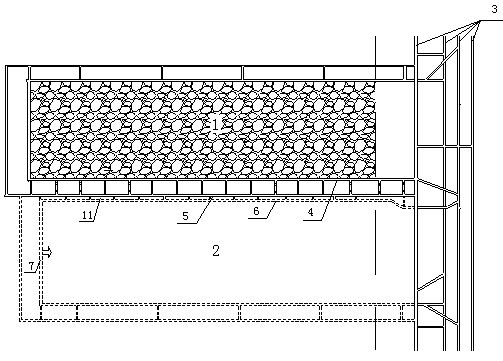

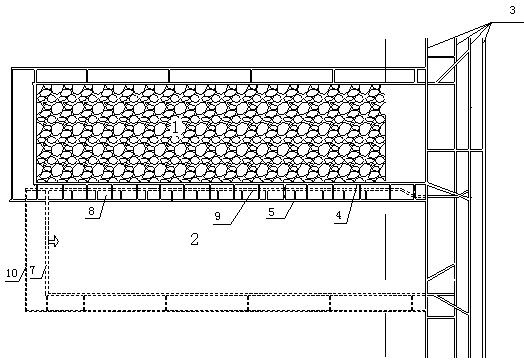

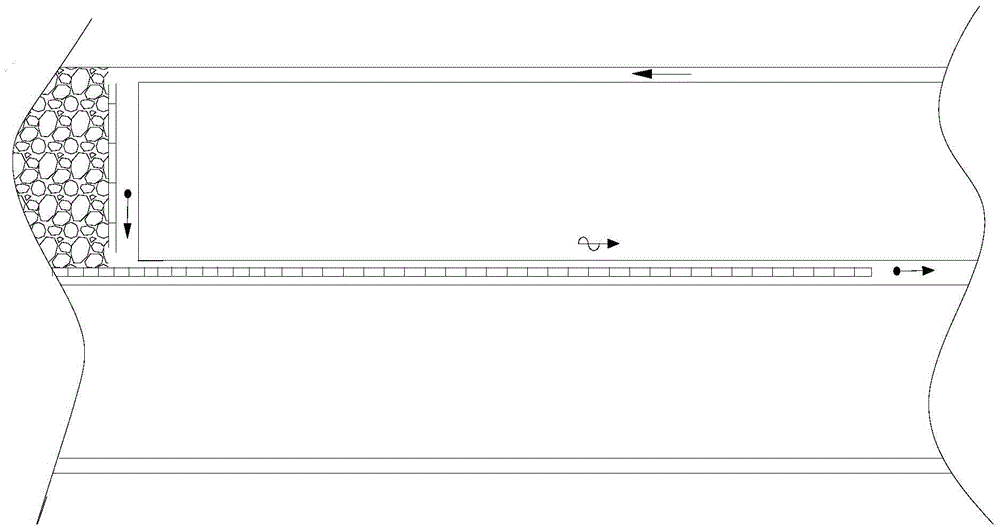

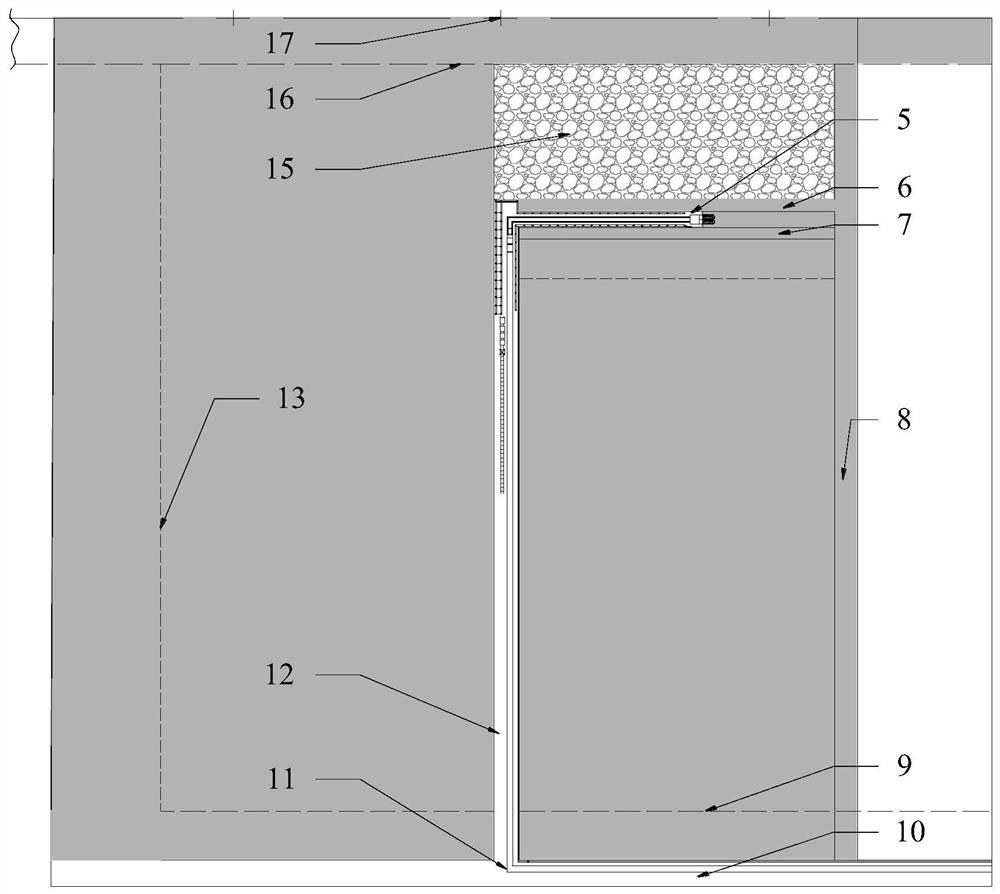

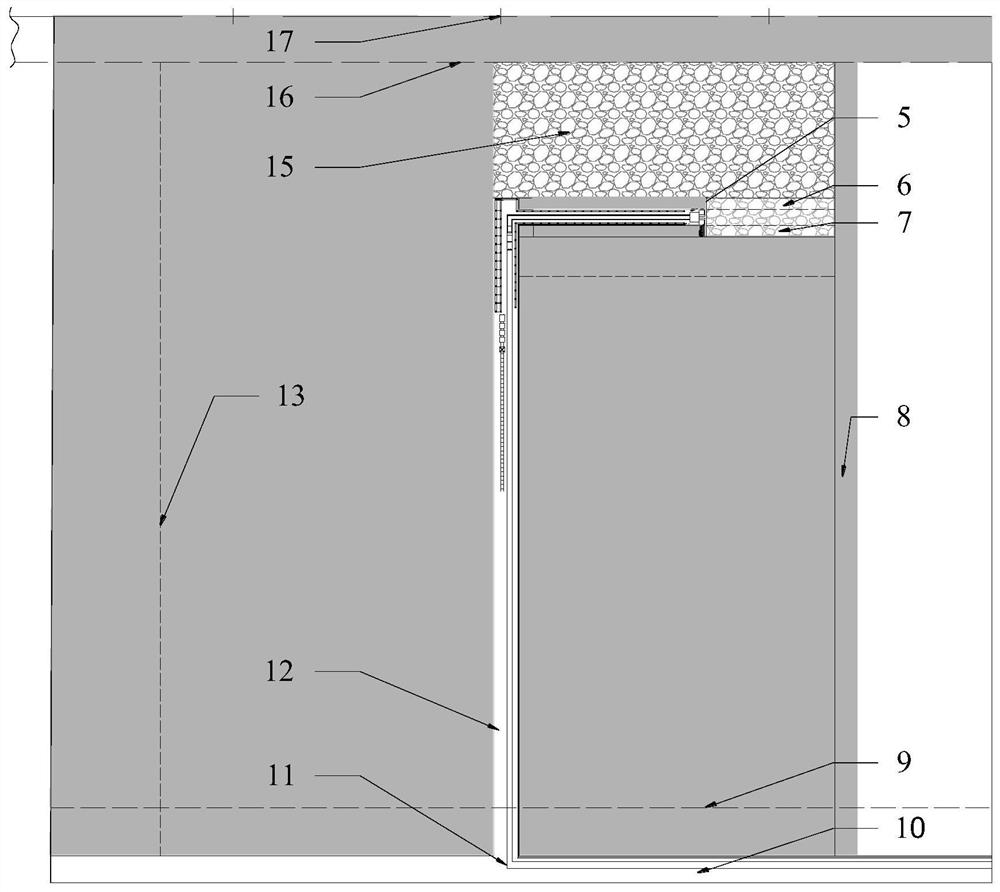

The invention discloses a method for repeated-mining a stopping-line coal pillar in an extra-thick coal seam residual mining area and filling an extra-thick coal seam with layered pasty fluid. The method for repeated-mining the stopping-line coal pillar in the extra-thick coal seam residual mining area and filling the extra-thick coal seam with the layered pasty fluid comprises the steps that 1, the thickness of an extra-thick coal seam is determined according to mine data, and the mining thickness of each separated layer is determined; 2, comprehensive detection is conducted on an original working face gob, and existing potential safety hazards are eliminated; 3, roadway tunneling is conducted on a layered coal seam of the upper portion of the stopping-line coal pillar of the extra-thick coal seam; 4, the end of an original mining roadway of the extra-thick coal seam is blocked off; and 5, mining with filling is conducted on each layered coal seam. According to the method for repeated-mining the stopping-line coal pillar in the extra-thick coal seam residual mining area and filling the extra-thick coal seam with the layered pasty fluid, the amount of pressed coal of the stopping-line coal pillar of the extra-thick coal seam is reduced, waste of coal resources is reduced, and the potential of the coal resources is fully released; and the economic benefits of coal enterprises are improved, the resource pressure of the coal enterprises is relieved, and the lives of a mine and a mine lot are prolonged.

Owner:TAIYUAN UNIV OF TECH

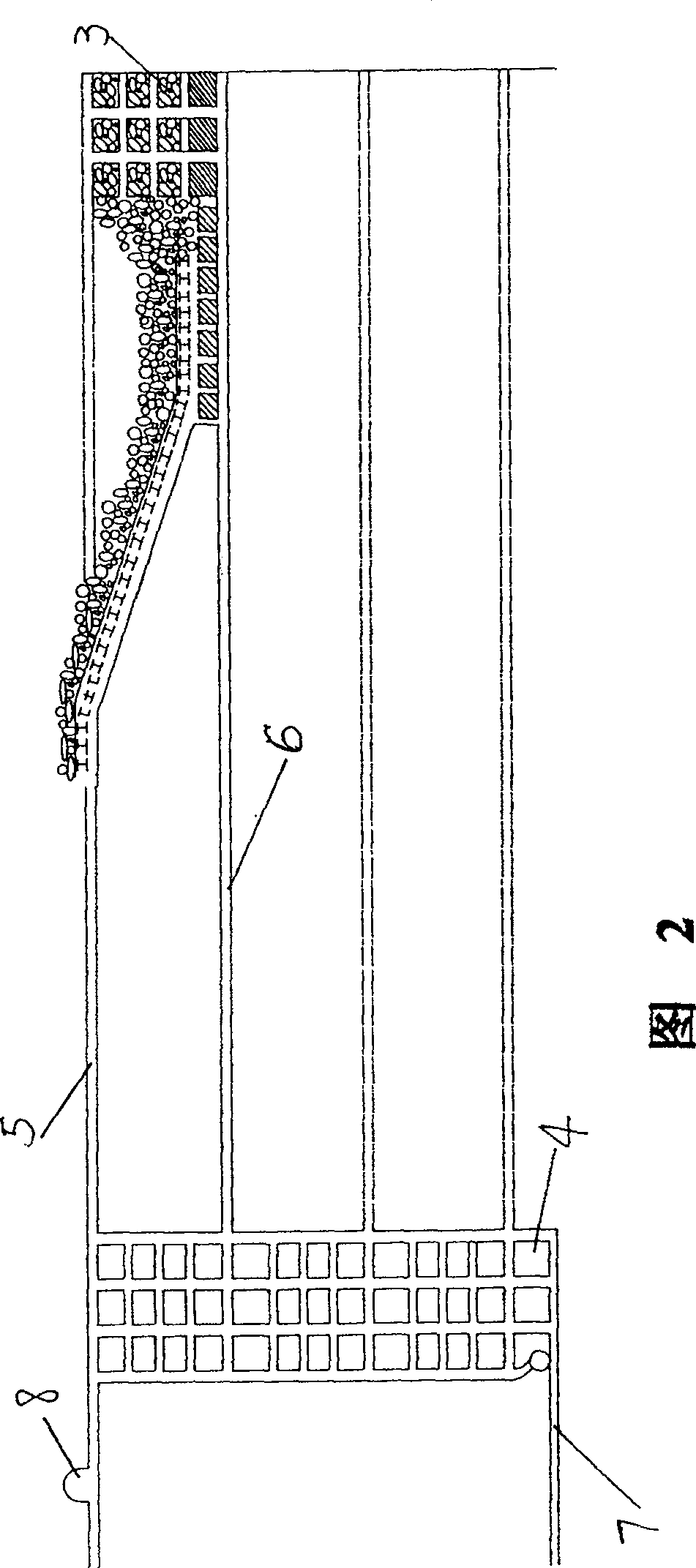

Roadside gangue mixture filling and gob-side entry retaining method for large-dip angle coal seams

InactiveCN105649673ALess maintenance and repairsImprove securityMaterial fill-upMining engineeringSlurry

The invention discloses a roadside gangue mixture filling and gob-side entry retaining method for large-dip angle coal seams. The method is suitable for gob-side retaining of mining roadways through the steep long wall mining method. The method comprises the steps of comprehensively processing and transporting filling coagulation grout, advancing a working surface and supports, erecting the roadway retaining and gangue stopping supporting supports, laying fence nets, laying grouting pipelines and pumping the coagulation grout. The coagulation grout is conveyed to the grouting pipelines for bonding gangue sliding down into a whole on the side, close to a section haulage way, of a gob in the back of a stoping working surface, a complex bearing structure with gangue mixture filling bodies and steel bar meshes as the main part is formed, when the filling bodies formed earliest reach the design strength, the supports are not needed for supporting, and the roadway retaining and gangue stopping supporting supports erected earlier can be advanced and moved forwards along with the working surface and act on the gangue mixture filling bodies newly formed. According to the method, the comprehensive investment is low, movement of gob-side entry retaining top plates can be effectively controlled through the bearing structure, roadway surrounding rock can keep stable and the lateral gangue stopping effect can be realized. In addition, the method is simple, construction is easy and the effect is good.

Owner:CHINA UNIV OF MINING & TECH

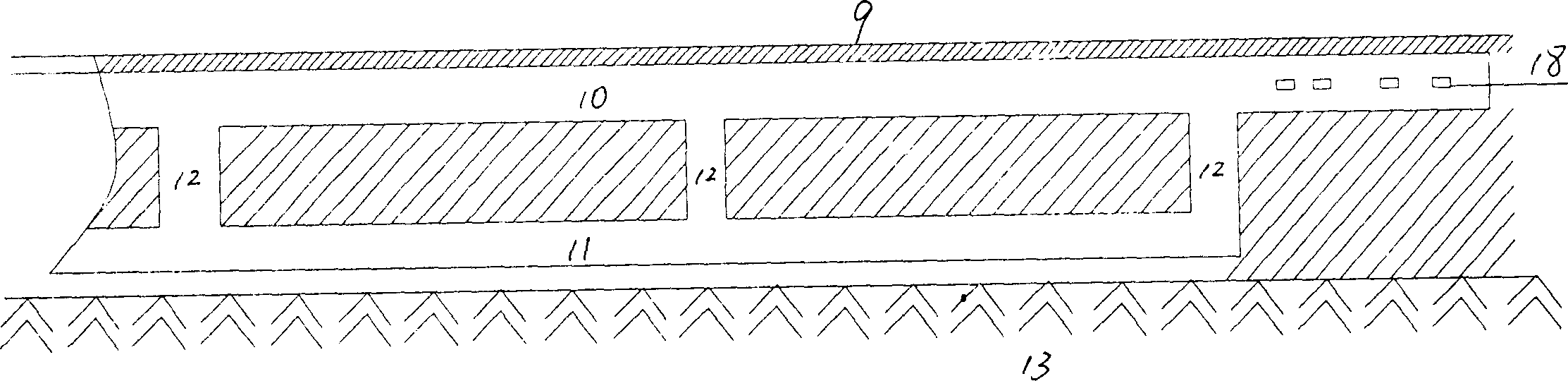

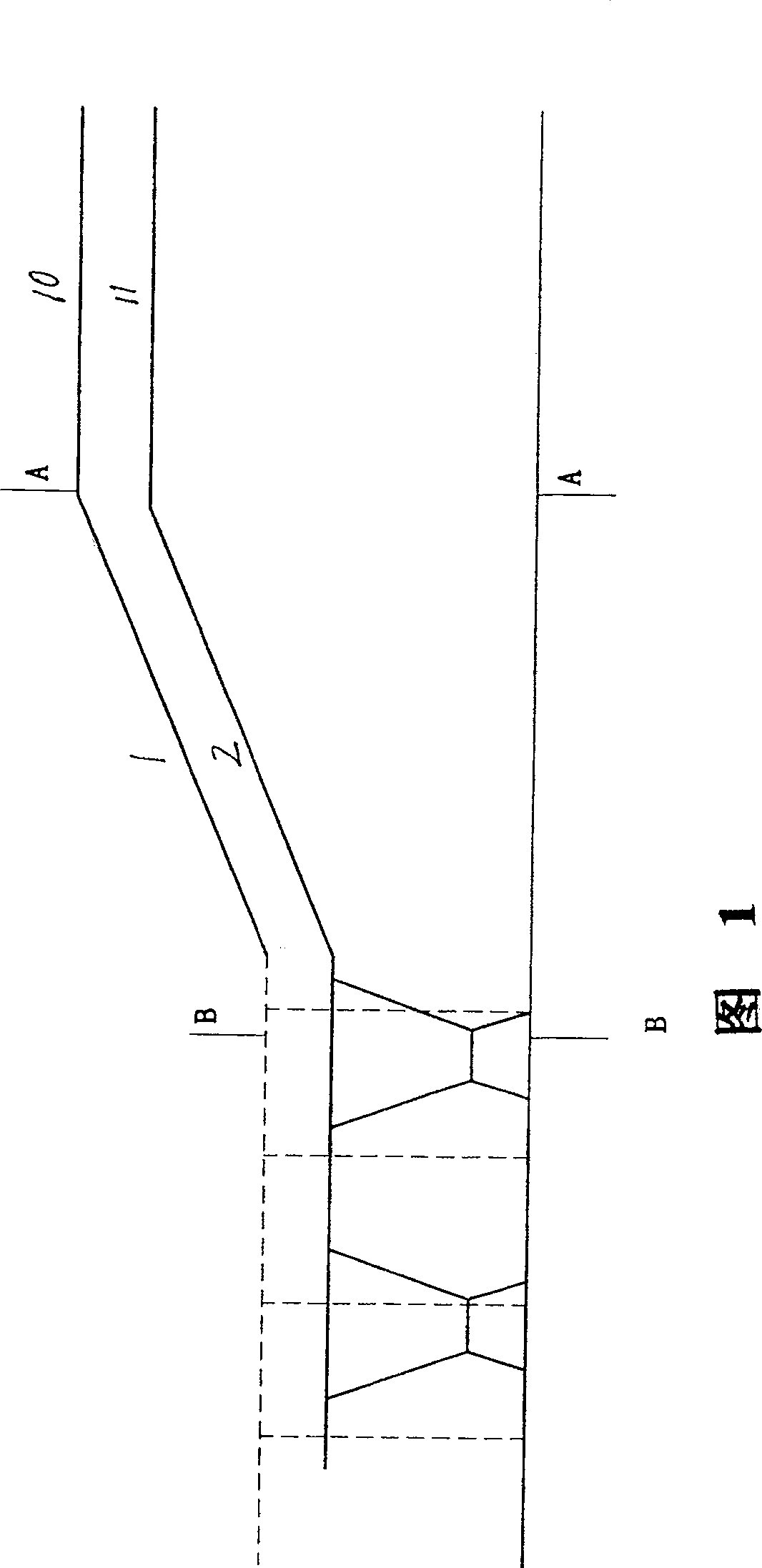

Comprehensive coal-mining process by using long wall mining method

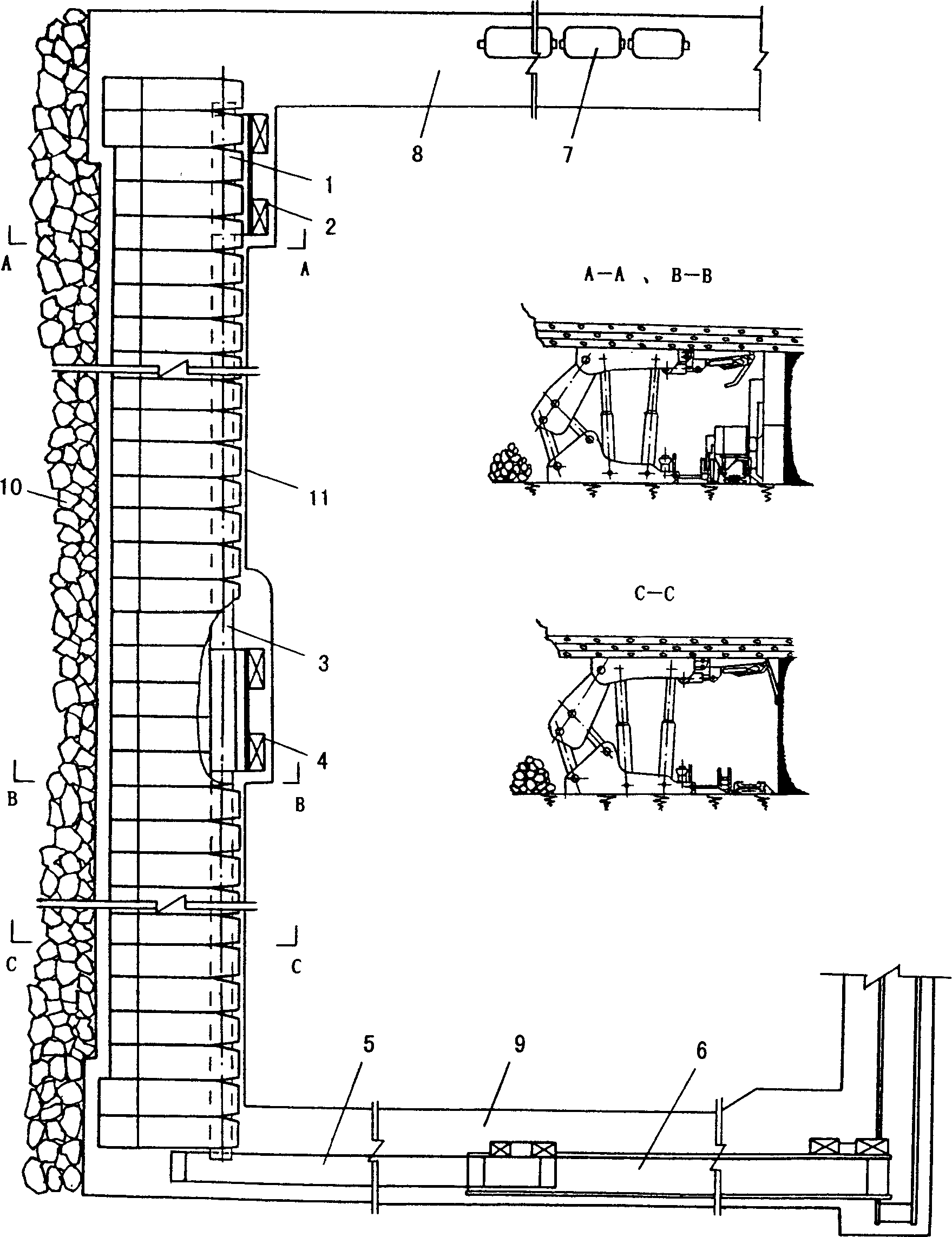

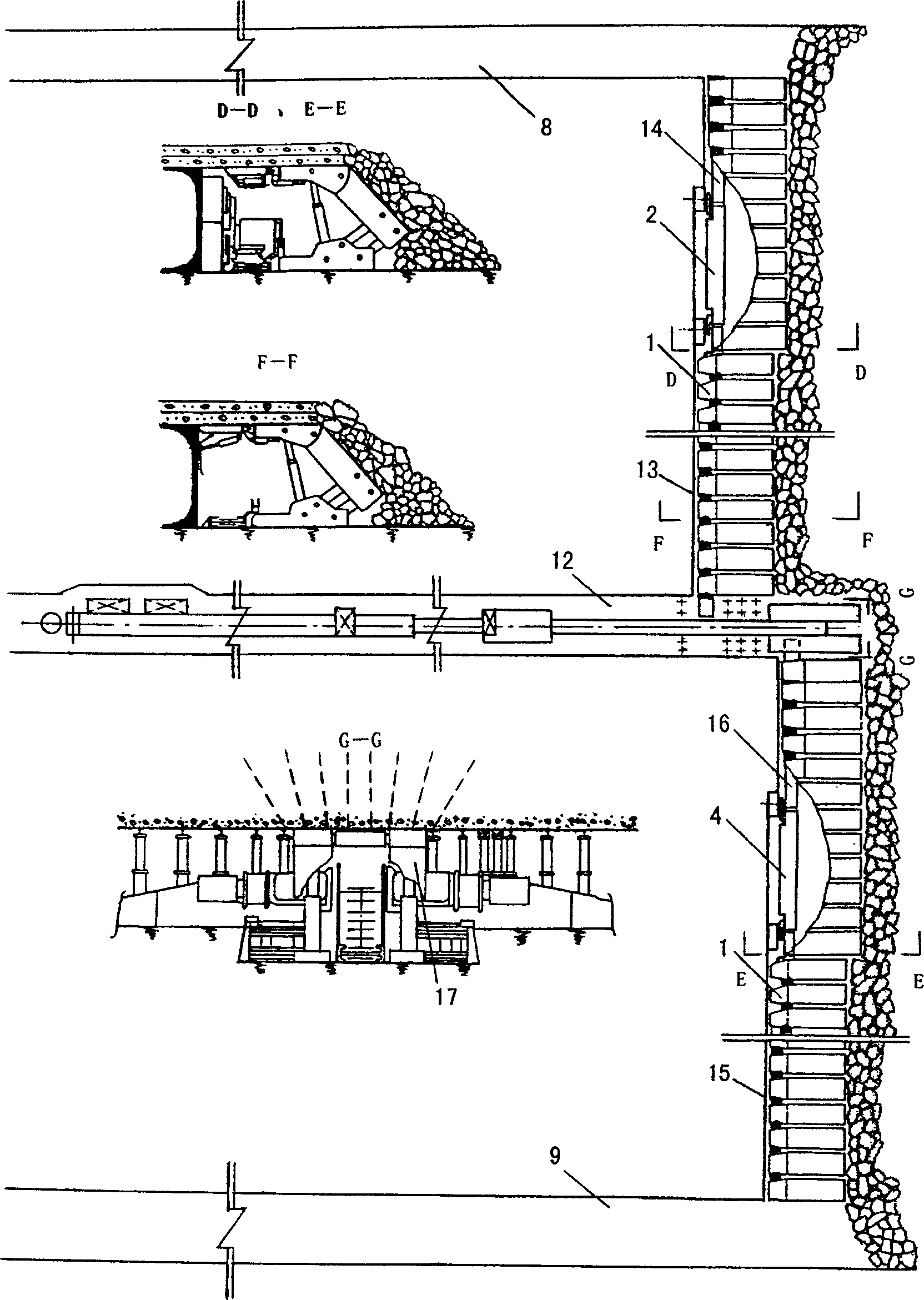

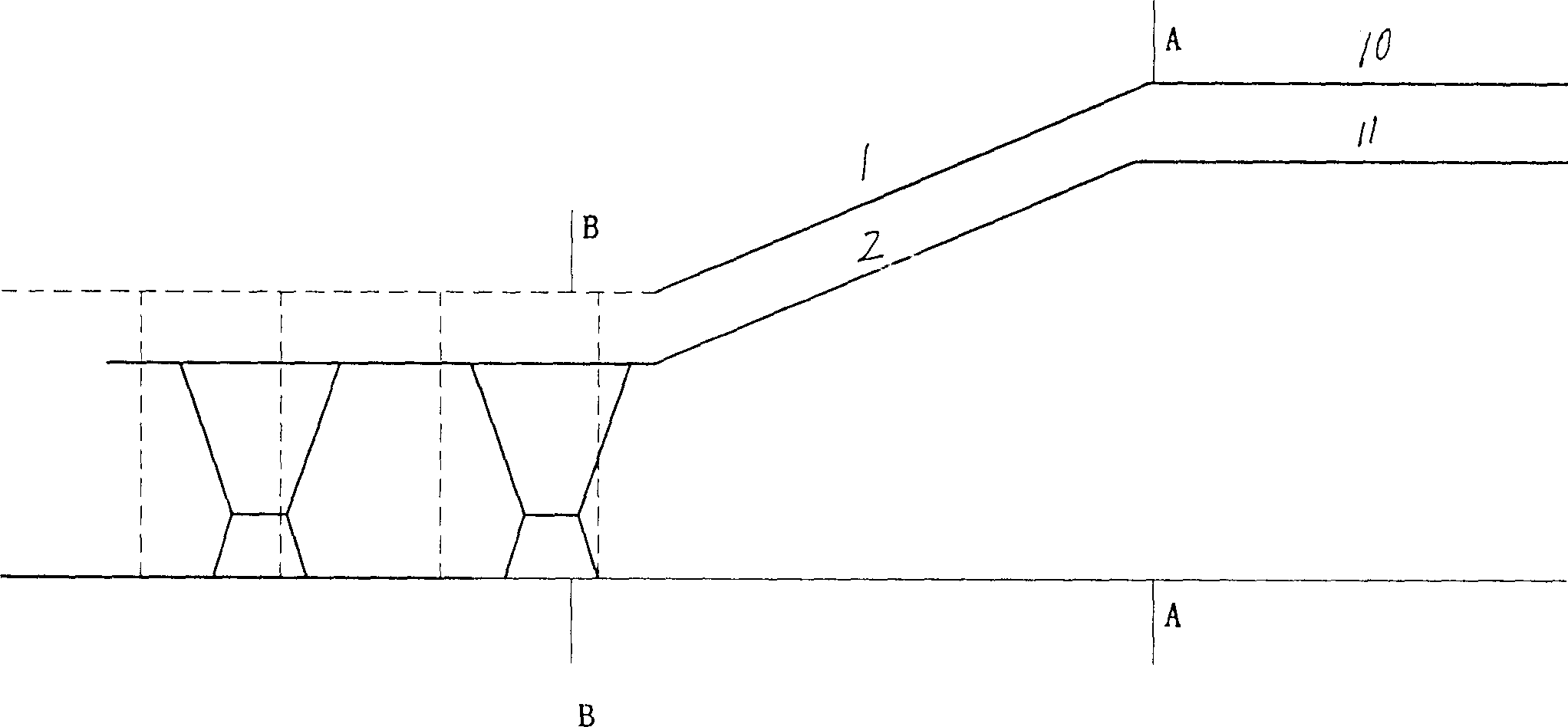

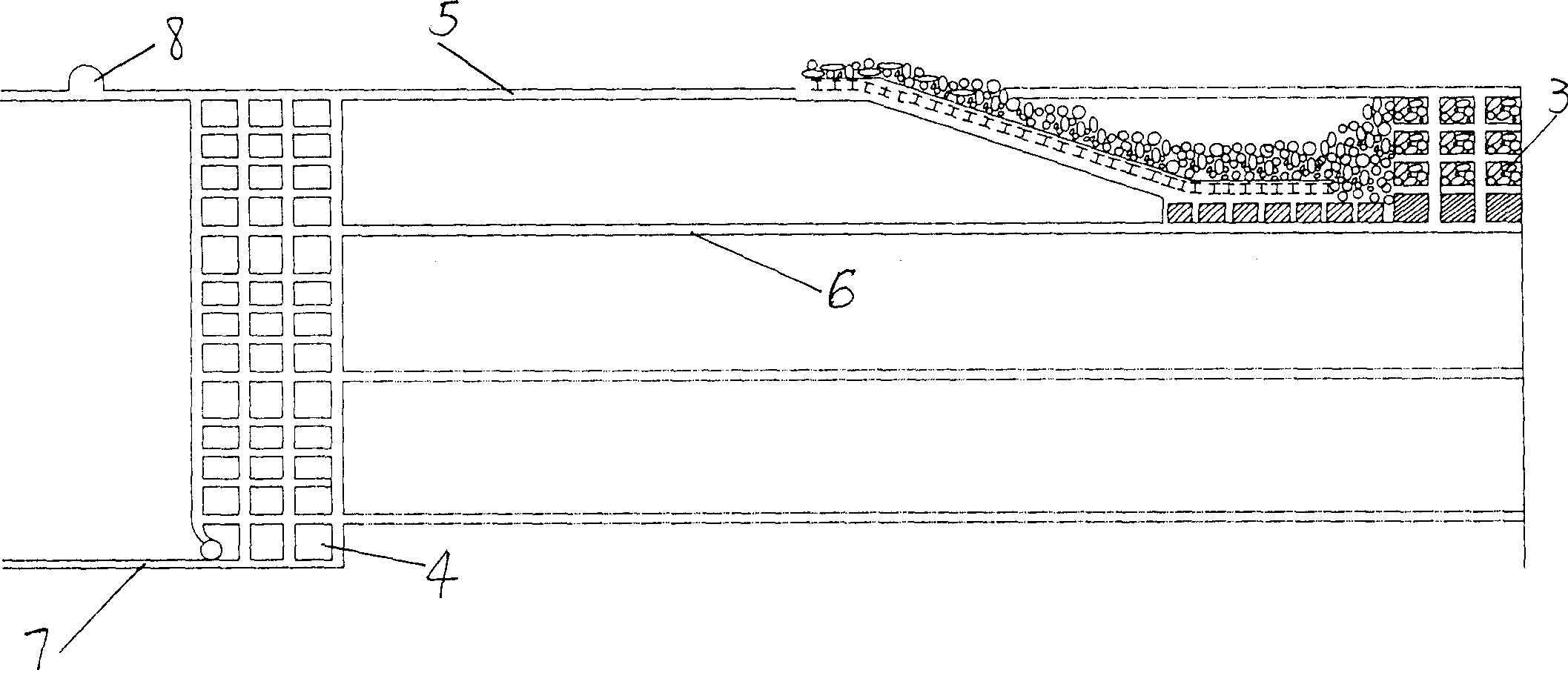

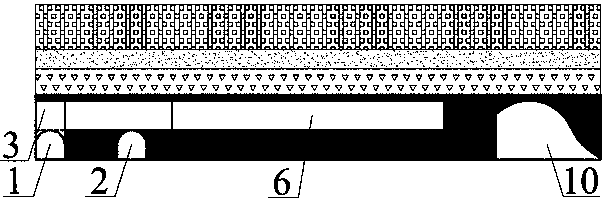

InactiveCN100567703CLow costReduce in quantityUnderground miningSurface miningLongwall miningResource recovery

The utility model relates to a longwall coal mining method fully mechanized mining technology, which involves underground coal mining, and is suitable for longwall mining of stable coal seams, hard roofs, no faults, gently dipping medium-thick coal seams and thick coal seams. Arrange hydraulic supports, scraper conveyors, and roller shearers on the longwall fully mechanized mining face, and arrange trough loaders and retractable belt conveyors on the transport lane. The fully mechanized mining face adopts super-long layout, that is, the face length is arranged according to the length of two fully mechanized mining faces. Two shearers are used, riding on the same scraper conveyor, to cut the coal walls of the upper half and the lower half respectively. The middle roadway can also be arranged in the middle of the super-long fully mechanized mining face as a transportation roadway; a scraper conveyor is arranged on the upper half and lower half of the fully mechanized mining face for opposite transportation to form a fully mechanized mining face. The invention further excavates the production potential of the longwall fully mechanized mining face, improves the output and work efficiency, and makes the production centralized; while realizing high output and high efficiency, it reduces the roadway excavation rate, reduces the loss of coal pillars, and improves the resource recovery rate; full mining is beneficial to the ground surface sink.

Owner:YANKUANG GRP CO LTD

Coal-mining method of high-dipping thick seam

InactiveCN100494627CGood technical and economic effectSuperiorUnderground miningTunnel/mines ventillationEconomic benefitsEngineering

Owner:KAILUAN GRP

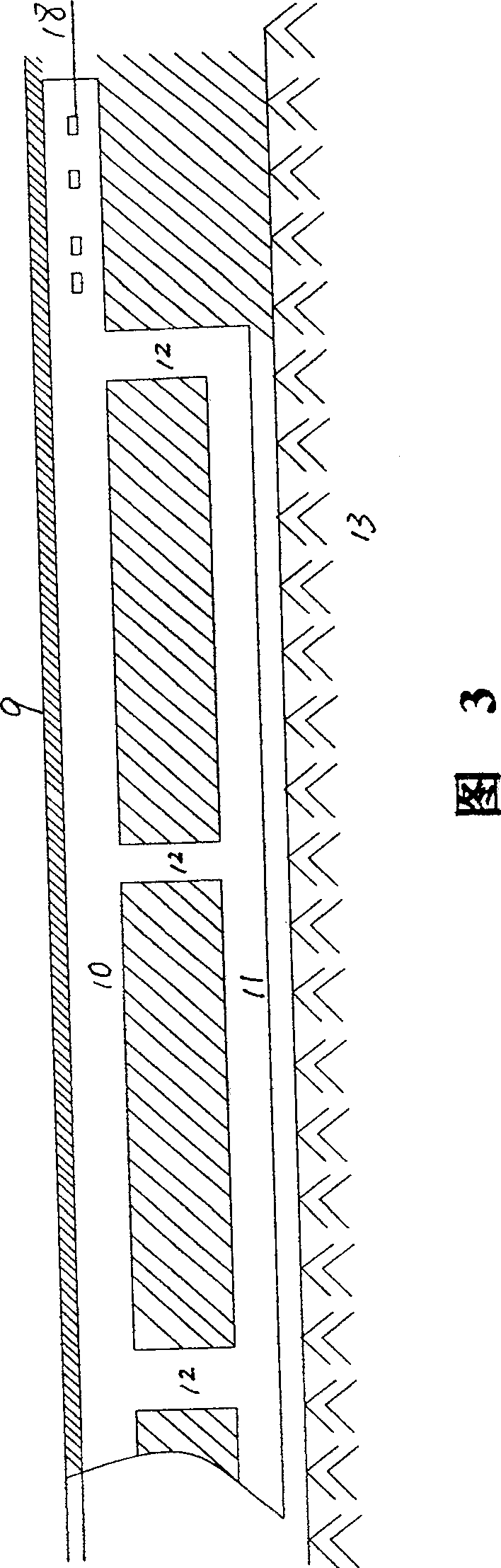

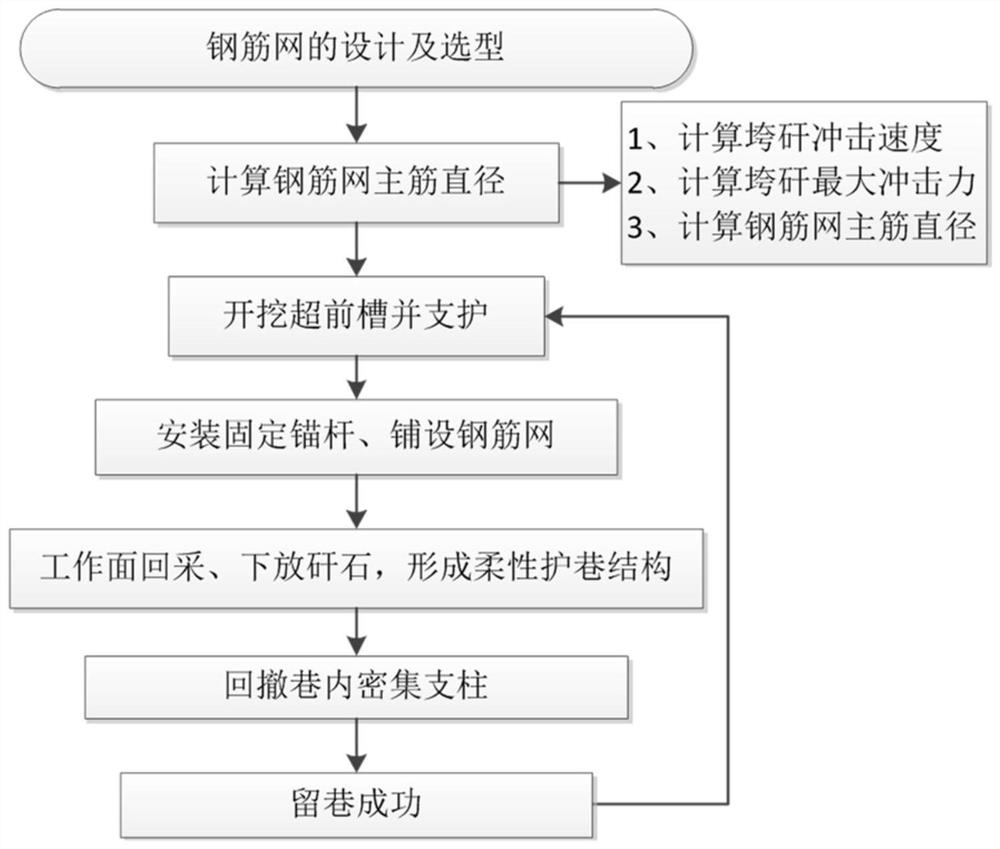

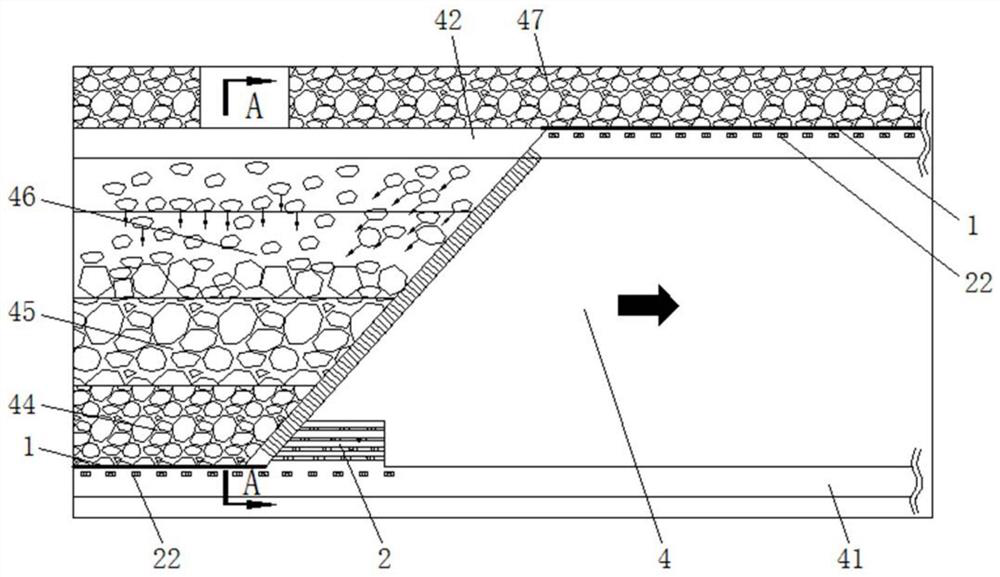

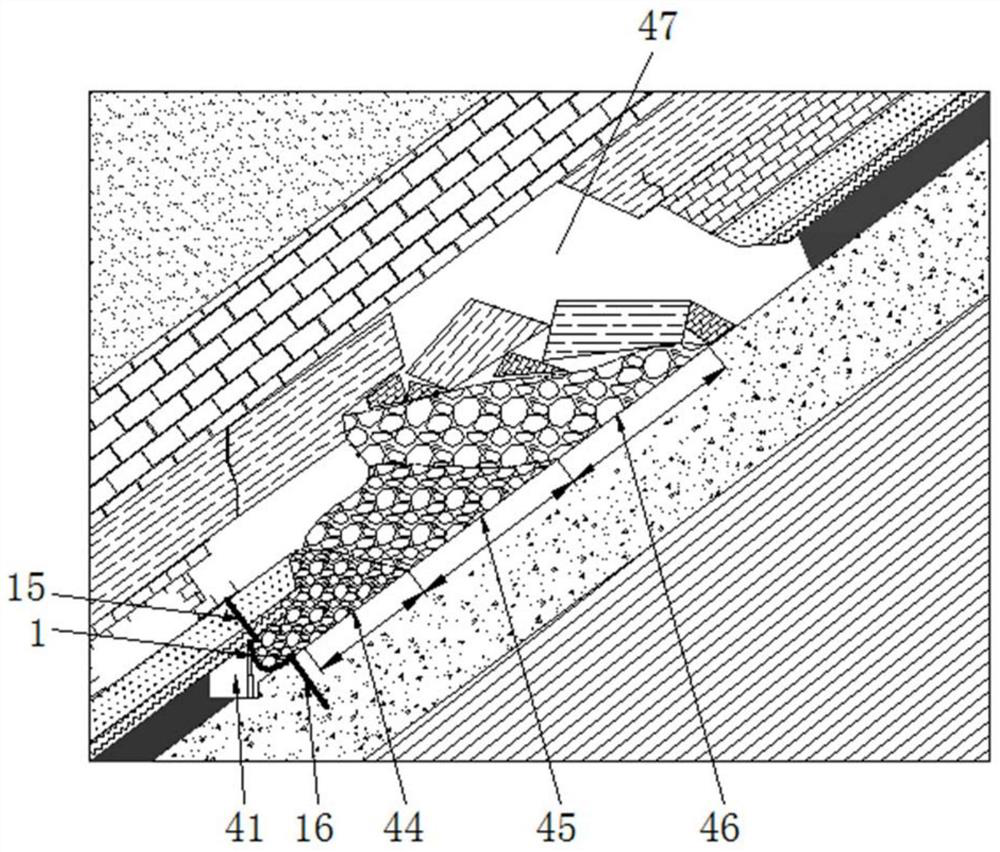

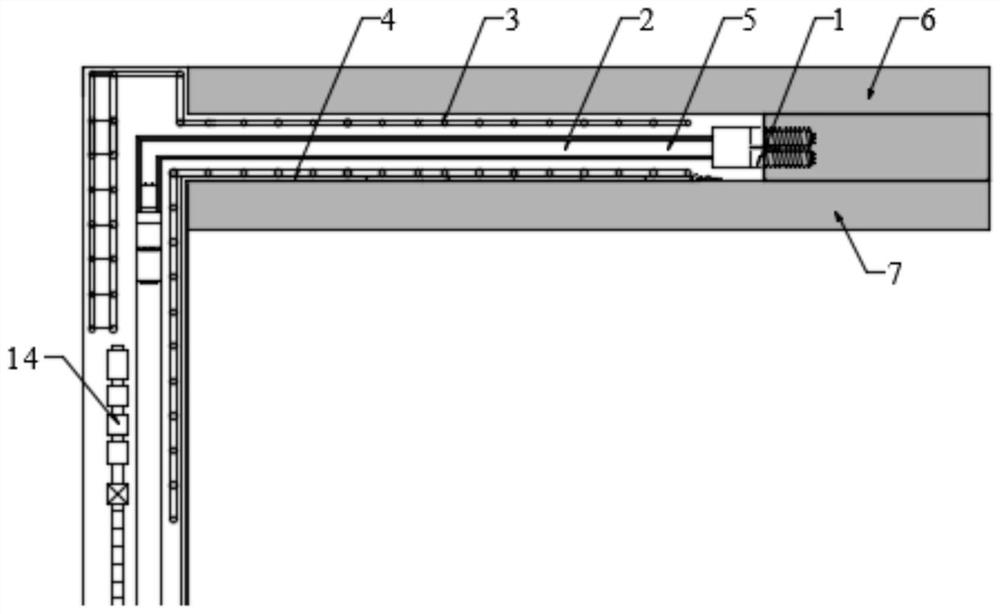

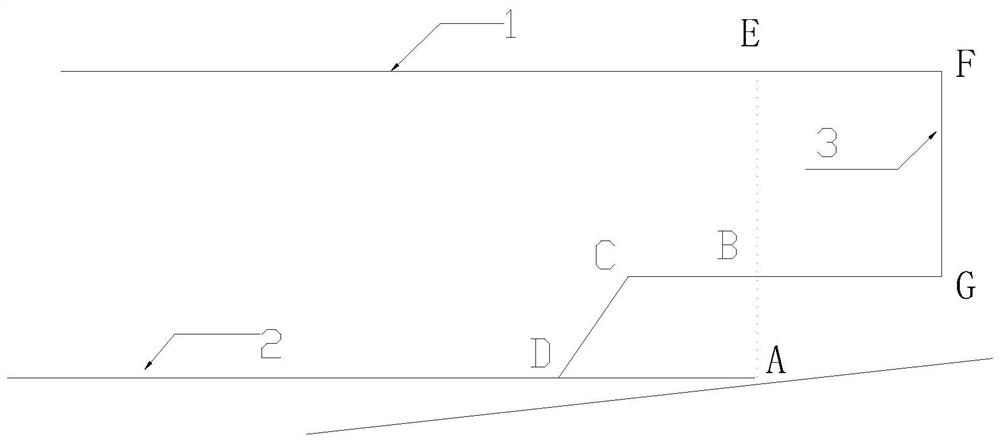

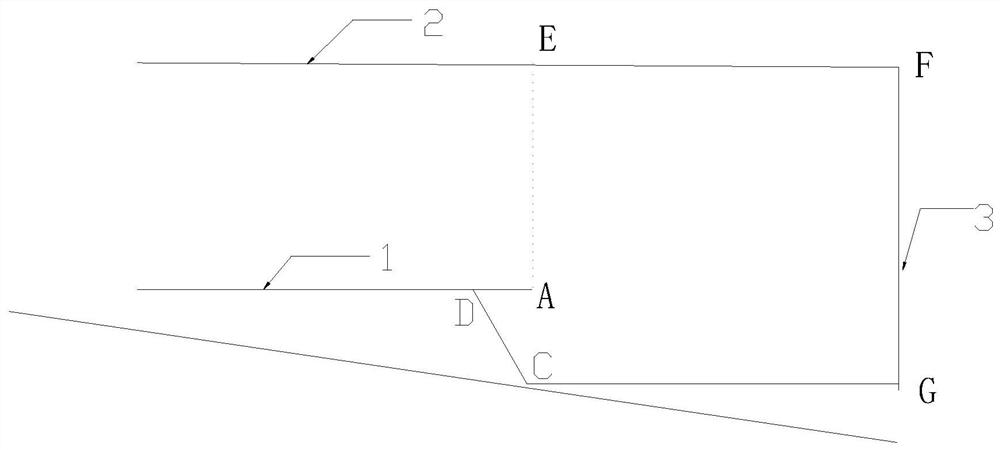

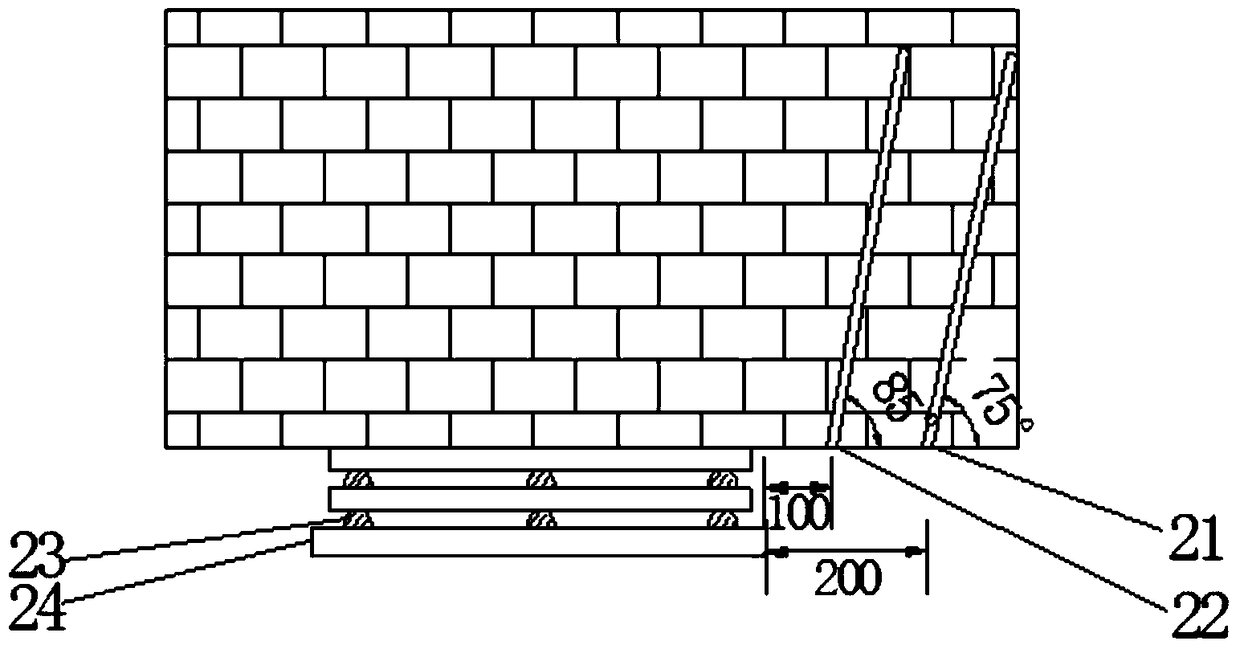

Large inclined angle coal seam gob-side entry retaining flexible roadway protection method

InactiveCN111720165ASmall impact on production at the working faceReduce the cost of retaining lanesGeometric CADWire networkArchitectural engineeringMesh reinforcement

The invention discloses a large inclined angle coal seam gob-side entry retaining flexible roadway protection method which comprises the following specific steps: at the lower end of a working face, adopting a digging and blasting manner to construct an advance groove with the length being 5-10 m and the width being 3-5 m along the working face trend; in the advance groove, fixing an anchor rod through a top plate and a bottom plate, and arranging a specially-made reinforcing mesh to form a flexible structure; intercepting and wrapping gangue collapsing and sliding from a goaf to form a roadway-side supporting body; and enabling the roadway-side supporting body and a cable anchor in the roadway to jointly support and act to maintain the stability of roadway retained surrounding rock. The large inclined angle coal seam gob-side entry retaining flexible roadway protection method has the characteristics of being small to influence to working face production, low in roadway retained cost,simple in technology and high in roadway retained speed.

Owner:CHONGQING UNIV

Mining, digging, transporting, supporting and ventilation integrated intelligent mining technology

ActiveCN111706329AReduce the amount of excavation workSimple work surface layoutUnderground miningSurface miningRock tunnelProcess engineering

The invention discloses a mining, digging, transporting, supporting and ventilation integrated intelligent mining technology. The working surface arrangement manner is simplified, so that the tunneling work amount of a half-coal-rock tunnel is reduced effectively; and unmanned working surface mining with mining, digging, transporting, supporting and ventilation coordinated control is realized through automatic devices such as a double-drum coal cutter, a scraper conveyer capable of realizing right-angle turning, an automatic loading and unloading type support, a telescopic air duct and the like. Compared with traditional mining, the technology has the characteristics of simple working surface arrangement, low roadway tunneling rate, high coal production rate, high device automation degree,safe, capability of realizing efficient and intelligent mining and the like and has the broad popularization and application prospects.

Owner:CHINA UNIV OF MINING & TECH

The mining technology of double-mechanized mining face with large mining height

InactiveCN104234715BIncrease productivityEnsure safetyUnderground miningSurface miningMining engineeringGeological structure

The invention provides a large-mining-height dual-fully mechanized mining face stoping process. The stoping process comprises the following steps: (1) determining whether the coal-seam thickness of a mining area of a working face to be mined is within the range of 3.5-7.0m, whether the geological structure is simple and relatively stable in thickness and whether the inclination angle is smaller than 12 degrees; and (2) arranging three parallel stoping tunnels in a main tunnel of a vertical mining area, communicating every two adjacent tunnels by use of an open-off cut to form a large-mining-height fully mechanized mining face, and then forming a left large-mining-height fully mechanized mining face and a right large-mining-height fully mechanized mining face, wherein the dip separation of the two faces is determined according to a formula as described in the specification. The large-mining-height dual-fully mechanized mining face stoping process is used for solving the technical problem that the large-mining-height fully mechanized mining face is incapable of breaking through the yield of 10 million tons / a to a large extent, and meanwhile, provides the enough security guarantee and cost control.

Owner:TIANDI SCI & TECH CO LTD

A Mining Method of Longwall Working Face in Hugely Thick Coal Seam

ActiveCN105003269BReduce gangue contentReduce manufacturing costUnderground miningSurface miningLongwall miningMonitoring system

Owner:GUIZHOU INST OF TECH

A method of layered paste filling the coal pillar of the stop production line in the residual mining area of the re-mined extra-thick coal seam

ActiveCN107339105BReduce the rate of penetrationReduce the amount of excavation and excavationUnderground miningSurface miningMining engineeringEconomic benefits

The invention discloses a method for repeated-mining a stopping-line coal pillar in an extra-thick coal seam residual mining area and filling an extra-thick coal seam with layered pasty fluid. The method for repeated-mining the stopping-line coal pillar in the extra-thick coal seam residual mining area and filling the extra-thick coal seam with the layered pasty fluid comprises the steps that 1, the thickness of an extra-thick coal seam is determined according to mine data, and the mining thickness of each separated layer is determined; 2, comprehensive detection is conducted on an original working face gob, and existing potential safety hazards are eliminated; 3, roadway tunneling is conducted on a layered coal seam of the upper portion of the stopping-line coal pillar of the extra-thick coal seam; 4, the end of an original mining roadway of the extra-thick coal seam is blocked off; and 5, mining with filling is conducted on each layered coal seam. According to the method for repeated-mining the stopping-line coal pillar in the extra-thick coal seam residual mining area and filling the extra-thick coal seam with the layered pasty fluid, the amount of pressed coal of the stopping-line coal pillar of the extra-thick coal seam is reduced, waste of coal resources is reduced, and the potential of the coal resources is fully released; and the economic benefits of coal enterprises are improved, the resource pressure of the coal enterprises is relieved, and the lives of a mine and a mine lot are prolonged.

Owner:TAIYUAN UNIV OF TECH

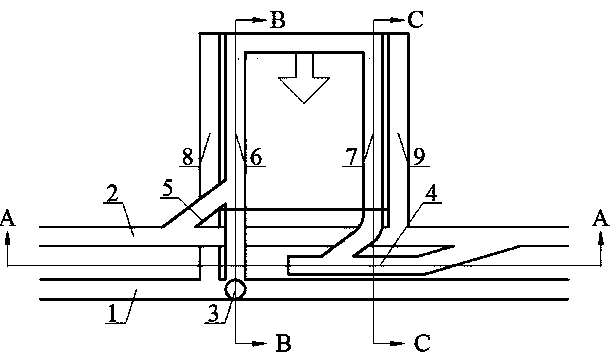

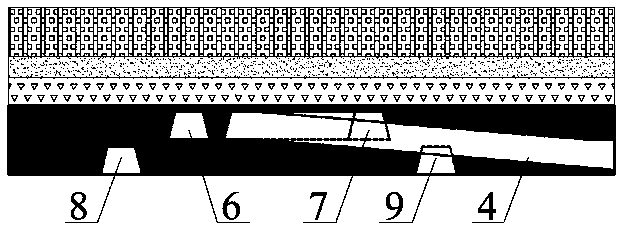

Method for filling gas near roadway of coal mine gob-side entry retaining

The invention discloses a method for filling a gas near a roadway of coal mine gob-side entry retaining, comprising the following steps: firstly, arranging a gas pressurization room on the ground; then, arranging a gas booster pump in an underground mining area haulage roadway 3; arranging a cylinder rubber air sac as high as the mining height on one side close to a goaf along the gob-side entry retaining behind a coal face; aerating the cylinder rubber air sac arranged on one side close to a goaf by the gas booster pump until roof contacting; when the pressure gage of the gas booster pump displays that the pressure reaches the stress of a primary rock, stopping aerating, sealing the cylinder rubber air sac to finish the aeration operation of one cylinder rubber air sac; and when the coalface is continuously advanced, continuously arranging one cylinder rubber air sac behind one aerated cylinder rubber air sac every time the coal face is advanced by one step, and aerating one by one until one exhausting body on one side of the goaf 5 along the gob-side entry retaining 6 is filled and supported. The method is simple, is convenient to operate and has the advantages of small labor intensity of workers and good supporting effect.

Owner:CHINA UNIV OF MINING & TECH

Advance Coal Mining Method without Coal Pillar in Thin Coal Seam

ActiveCN111140233BOptimize layoutIncrease productivityUnderground miningSurface miningMining engineeringCoal pillar

The invention provides a thin coal seam non-pillar-advancing coal mining method, which includes: determining the mining area, arranging roadways, arranging working areas, mining and filling, and complete mining. The advanced coal mining method without coal pillars in the thin coal seam provided by the present invention has the following beneficial effects: the coal mining system is simple in layout, two working faces can be mined at the same time at one time, and the production efficiency is high; the working face adopts the advanced mining process, and three roadways Serving two working faces at the same time, the roadway excavation rate is low, the coal output speed is fast, and it is beneficial to relieve the tension of mining continuity; the solid waste storage space formed by the skip mining method has a regular shape, and both sides are solid structures, which are easy to form regular Filling body; the goaf is used as a solid waste storage space to realize the effective use of underground waste space, reduce the mine pressure, reduce the difficulty of retaining roadways, and prevent surface subsidence; no coal pillars are left in the working face, which improves the recovery rate of coal resources .

Owner:BEIJING ZHONGKUANG INNOVATION ALLIANCE ENERGY & ENVIRONMENTAL SCI RES INST

An integrated intelligent mining process for mining, transportation, branch and communication

ActiveCN111706329BOptimize layoutReduce the rate of penetrationUnderground miningSurface miningProcess engineeringMachine

The invention discloses an intelligent mining technology integrating mining, transportation, support and communication, which effectively reduces the excavation engineering volume of semi-coal and rock roadways by simplifying the layout of the working face, adopts double-drum coal cutters, scraper conveyors that can turn at right angles, and automatic loading and unloading Automatic equipment such as vertical support and telescopic air duct realizes unmanned working face mining with coordinated control of mining, transportation and support; compared with traditional mining, this method has the advantages of simple working face layout, low roadway excavation rate, high coal recovery rate, and equipment automation. High, safe and efficient intelligent mining and other characteristics, has broad prospects for promotion and application.

Owner:CHINA UNIV OF MINING & TECH

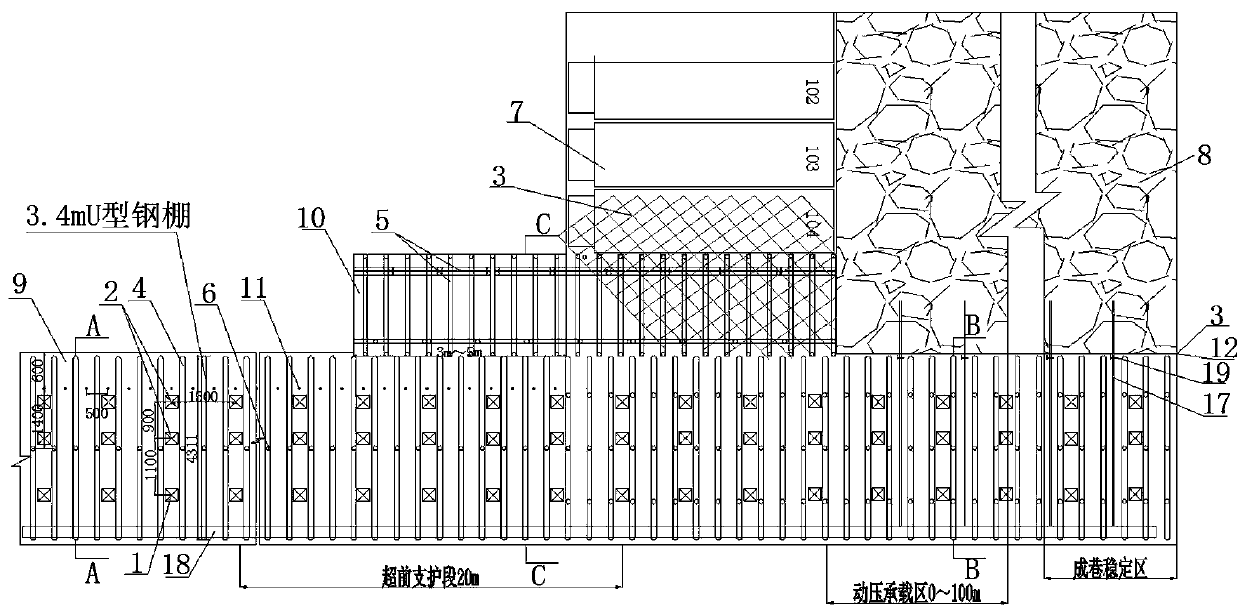

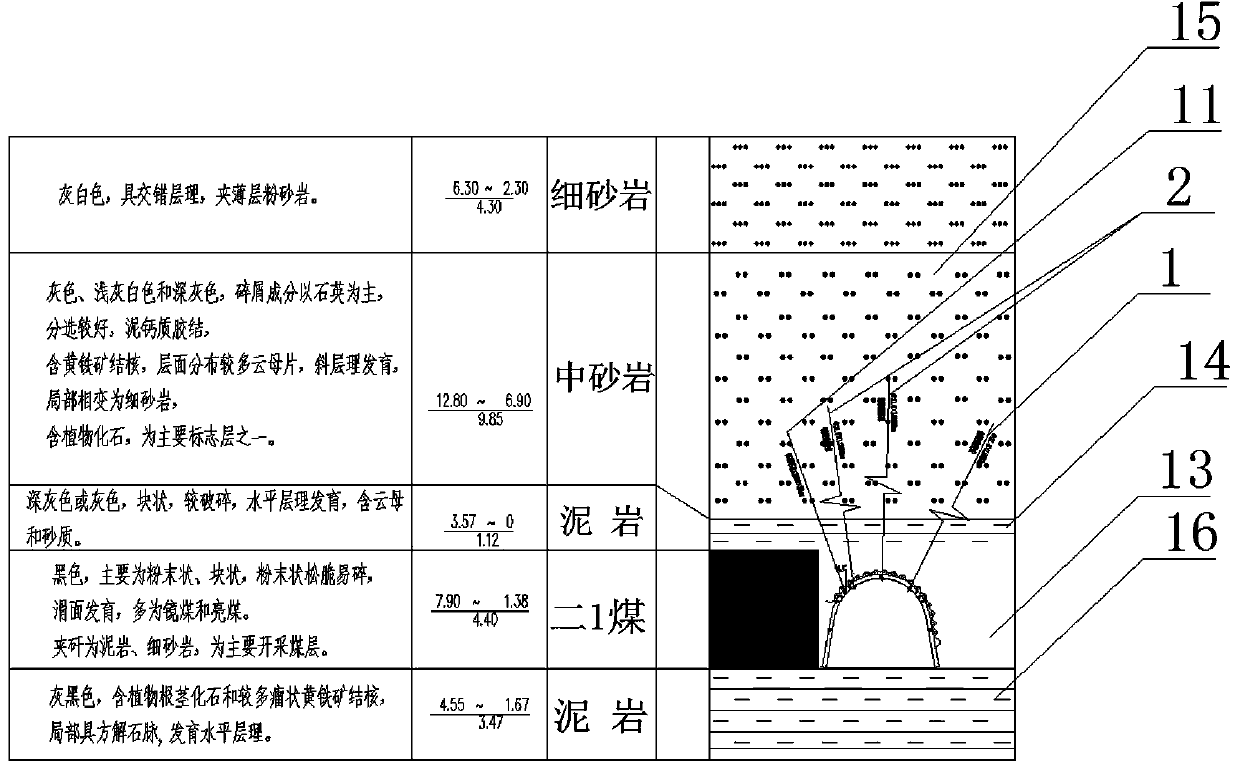

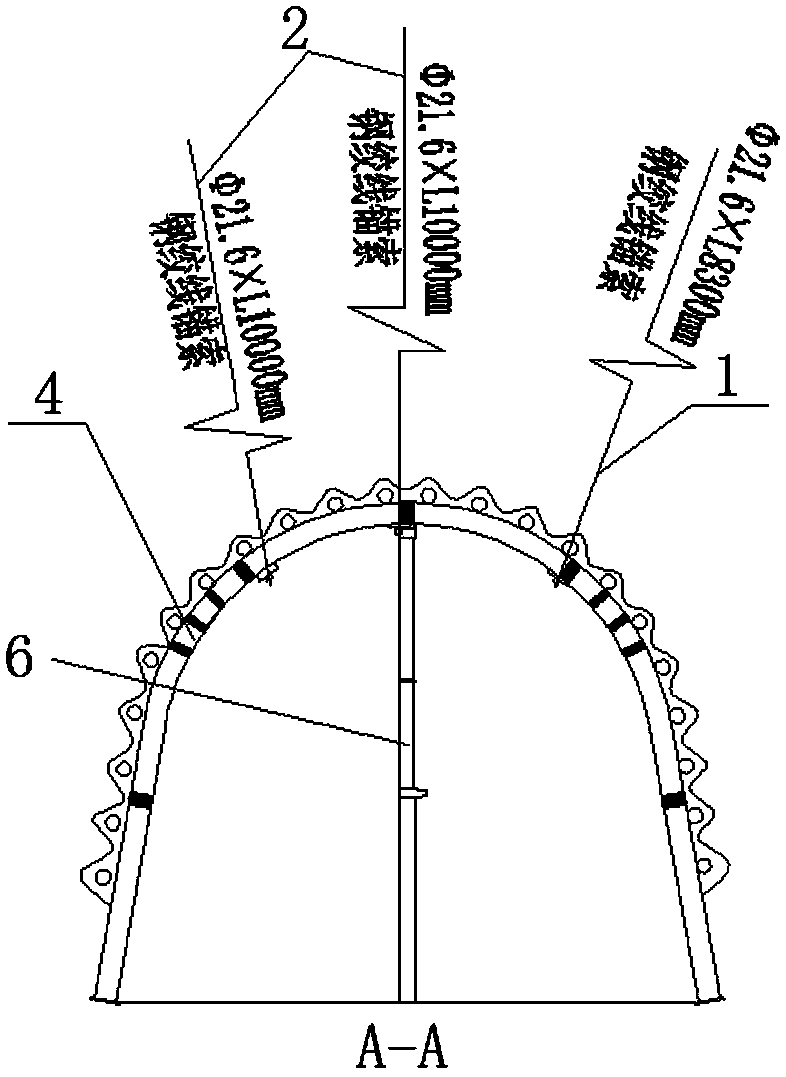

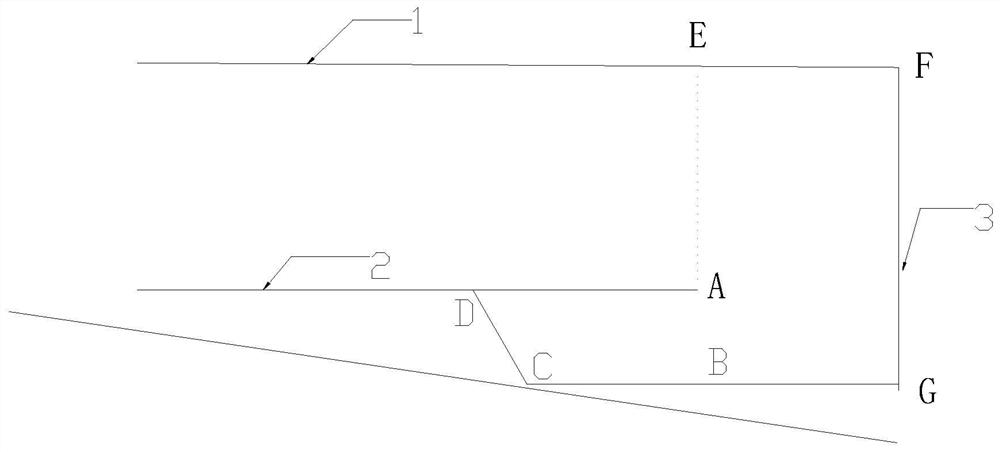

A method for retaining entry along the gob in fully mechanized caving face in high-gas three-soft and extremely unstable coal seam

InactiveCN109098714BHigh recovery rateAlleviate the tense situationUnderground chambersUnderground miningWire gauzeShotcrete

The invention discloses a method for retaining a gateway along a goaf in a fully mechanized caving face of a high gas three-soft unstable coal seam. The method comprises the following steps: 1, usinga constant resistance anchor cable to reinforce and support an original shed supporting soft roof; 2, constructing, cutting a top hole, and implementing presplitting blasting on a top plate of a sidegateway of the goaf 50 meters ahead of a working face; 3, constructing a pedestrian access on the gateway retaining side of the original shed supporting soft roof; 4, supporting a top cover near the gateway retaining side of the working face and laying a wire gauze; 5, laying the wire gauze in the goaf behind a working face frame; 6, enabling a presplit gangue to automatically fall and stack underthe action of the mine pressure until reaching a hard top plate rock at the upper end and forming a gangue wall; 7, using single props to reinforce and support in a dynamic pressure bearing area of the working face; 8, spraying a concrete or not spraying the concrete on the surface of the wire gauze and the gangue wall according to the condition of air leakage of the working face; 9, sequentiallydismounting the single props in a gateway forming stable area, and continuing to circulating the above steps until the whole operation of retaining the gateway along the goaf is finished. The supporting mode is simple, the cost is relatively low, and the gateway is efficiently retained.

Owner:三门峡龙王庄煤业有限责任公司

A Method of Roadway Layout Based on Irregular Mining Area

ActiveCN111963194BReduce lossesPromote recoveryMining devicesUnderground miningMining engineeringArchitectural engineering

The invention relates to a roadway layout method based on irregular mining areas. According to the shape of the mining area of the medium-thick coal seam, the roadways are reasonably arranged. When the roadway is excavated, the third roadway and the joint roadway are excavated by setting the middle point of the roadway excavation. And the fourth roadway, thereby changing the length of the working face, so that the sum of the areas of the multiple rectangular mining areas within the mining area is the largest. The mining area design of the present invention can simplify the roadway system, effectively reduce coal loss, increase the coal recovery rate, make full use of coal resources, ensure and prolong the mining period of the coal mining face and the mining area, reduce the excavation rate, and have good safety conditions and improve the various economic indicators.

Owner:内蒙古维维能源有限公司

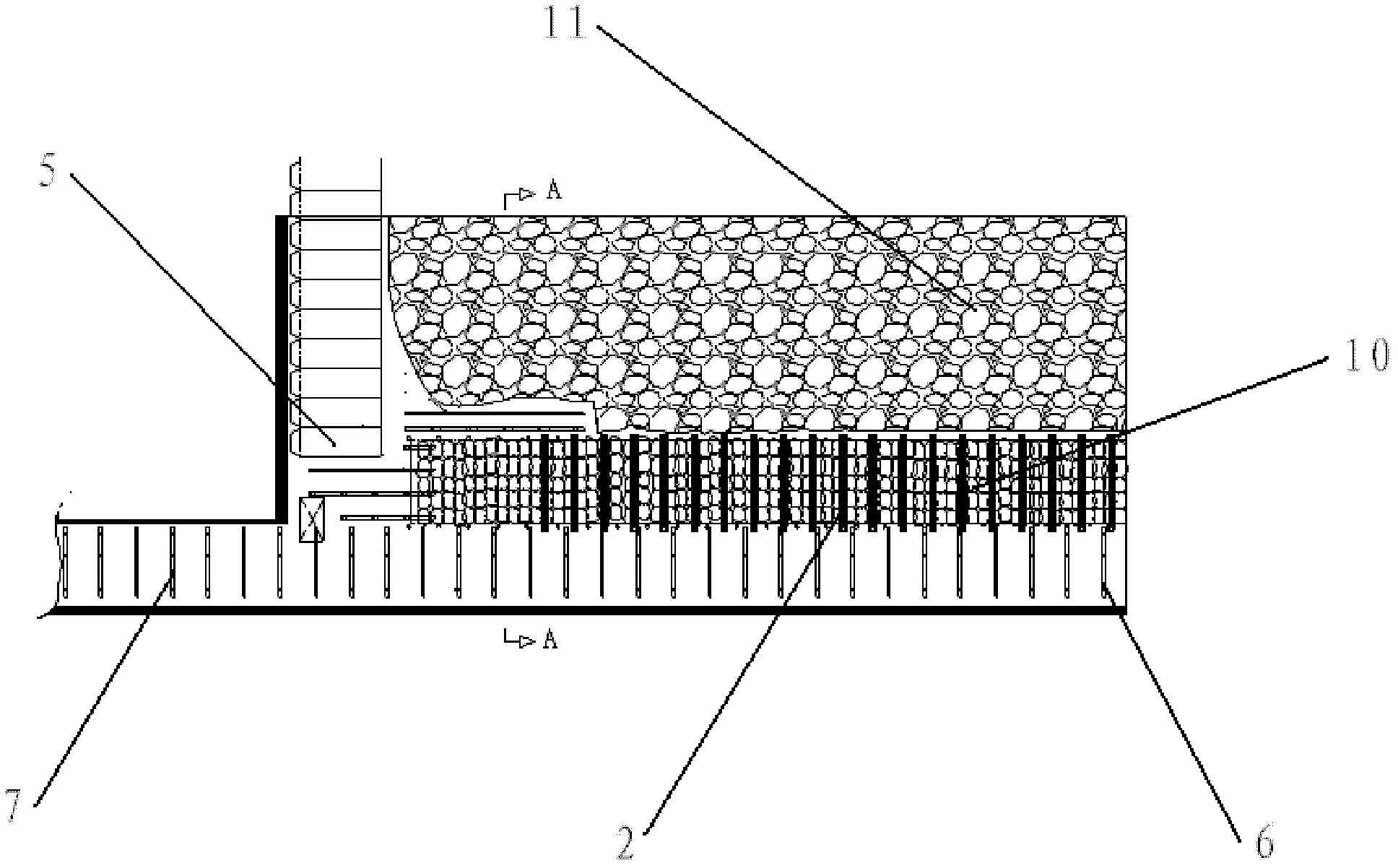

A kind of mine resource segmental full mining local filling mining method

ActiveCN109869150BImprove recovery rateGuaranteed stabilityUnderground miningSurface miningMining engineeringCoal pillar

The invention discloses a mining method of mining resources by subsection and full mining and partial filling. The mining method specifically comprises the steps that a plurality of fully mechanized working faces and filling working faces are alternately arranged at intervals in a mining block section, and stoping of coal resources is carried out by adopting a method of full mining and partial filling; the width of the filling working faces is 30-60m, and transportation roadways and return airways of the filling working faces are reserved by using a gob-side entry retaining technology and usedas transportation roadways or return airways of the adjacent fully mechanized working face; and the width of the fully mechanized working faces is 4-6 times of that of the filling working faces, anda backward-type caving method is adopted for mining. The mining method combines the advantages of fully mechanized mining and filling mining, the problems of strong mine pressure appearance and largedeformation of a gob-side entry in deep high-stress environment are fundamentally solved, the gob-side entry deformation, the segment coal pillar loss and the roadway driving rate are can reduced, solid wastes such as gangue and fly ash are simultaneously processed, and safe, efficient and green mining of coal can be realized.

Owner:CHINA UNIV OF MINING & TECH

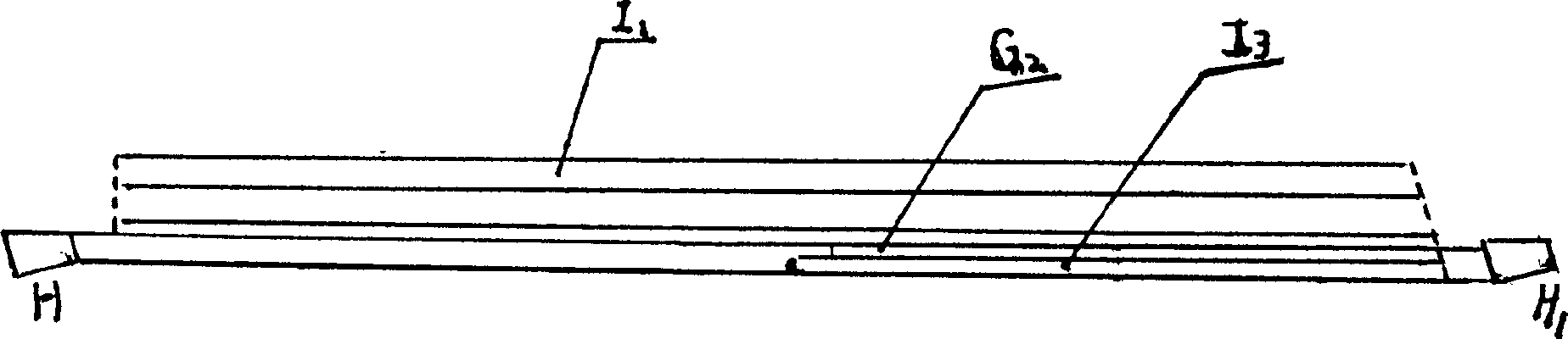

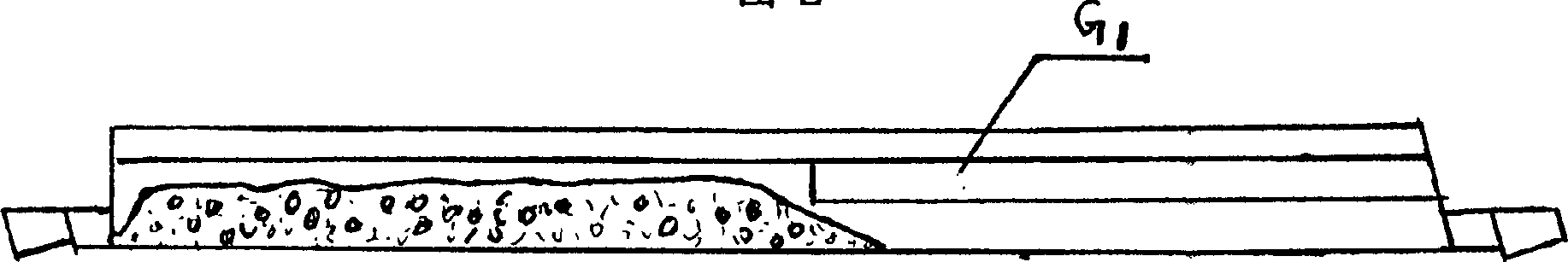

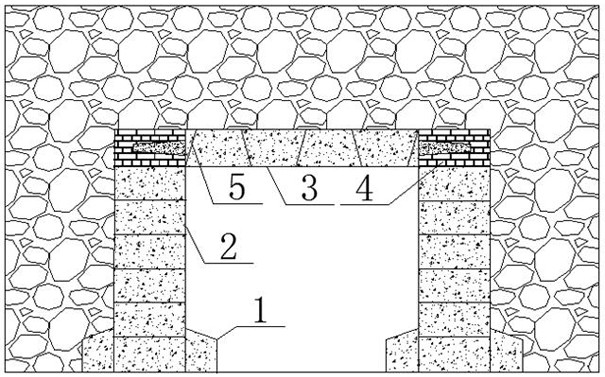

Mining method for once-mining overall height of gypsum ore deposit

InactiveCN1126860COptimize layoutReduce the rate of penetrationUnderground miningSurface miningGypsumMaterials science

The invention is a mining method for mining the whole height of the I gypsum group of the gypsum ore deposit at one time, which has the characteristics of low comprehensive cost and high labor productivity. The method of layer-by-layer mining from bottom to top is adopted in the mining of the mine, first in the gray shale G 2 Drill the shot in the middle, take out the G 2 Separately loaded and transported away, and then in plaster I 3 Drill the hole in the middle and shoot the gun, and the plaster will collapse I 3 , after the mining room is wide enough, the gypsum I 2 Drill the hole in the middle and shoot the gun, and the plaster will collapse I 2 , then in red shale G 1 Drilling holes in the middle and shooting down the red shale G 1 , but not transported away, piled in the mine, and finally in the gypsum I 1 Drill the hole in the middle and shoot the gun, and the plaster will collapse I 1 . The invention has the advantages of simple process, easy realization and popularization.

Owner:LIAOYANG SHENGDA GYPSUM MINE

A support method for gob-side entry retaining in blast mining working face with small area and thin coal seam

ActiveCN105545321BLess investmentQuick resultsUnderground chambersTunnel liningEngineeringMechanical engineering

Owner:SHANDONG UNIV OF SCI & TECH

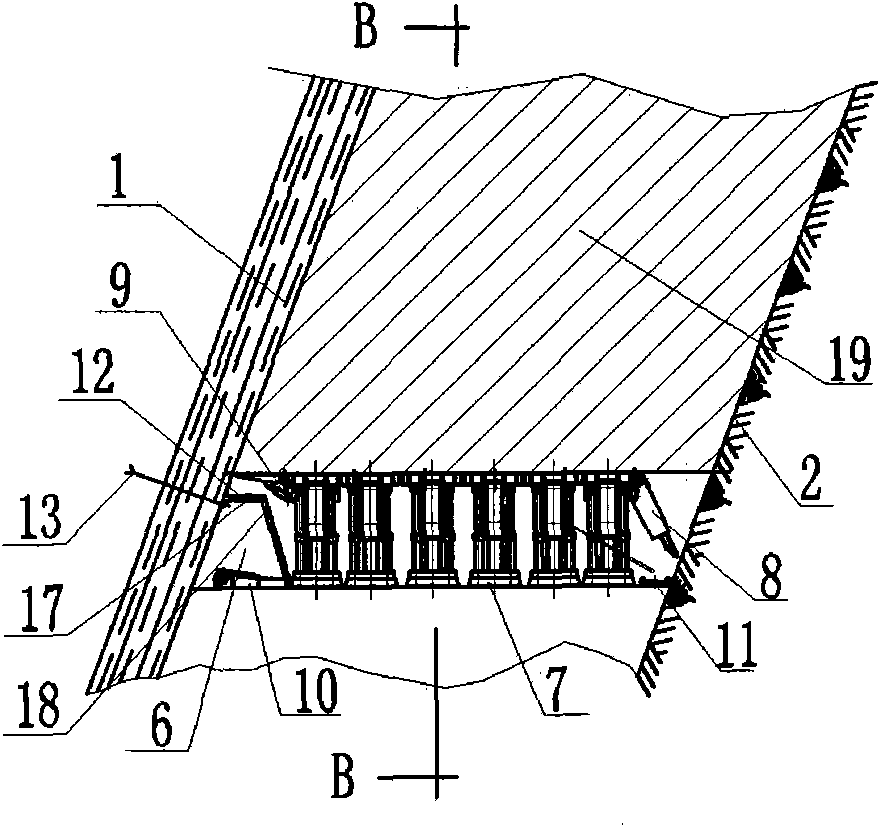

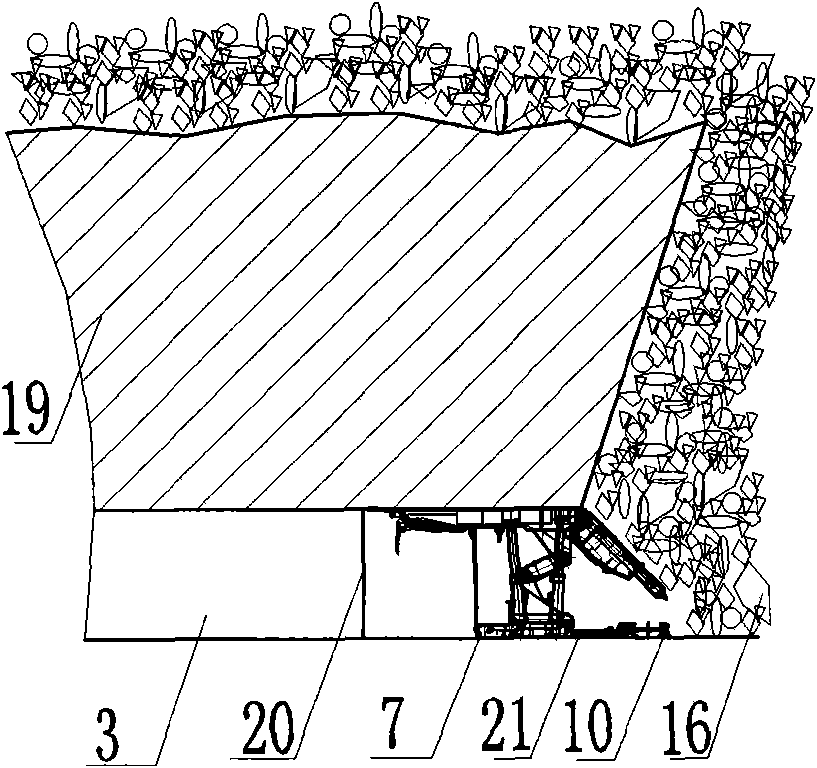

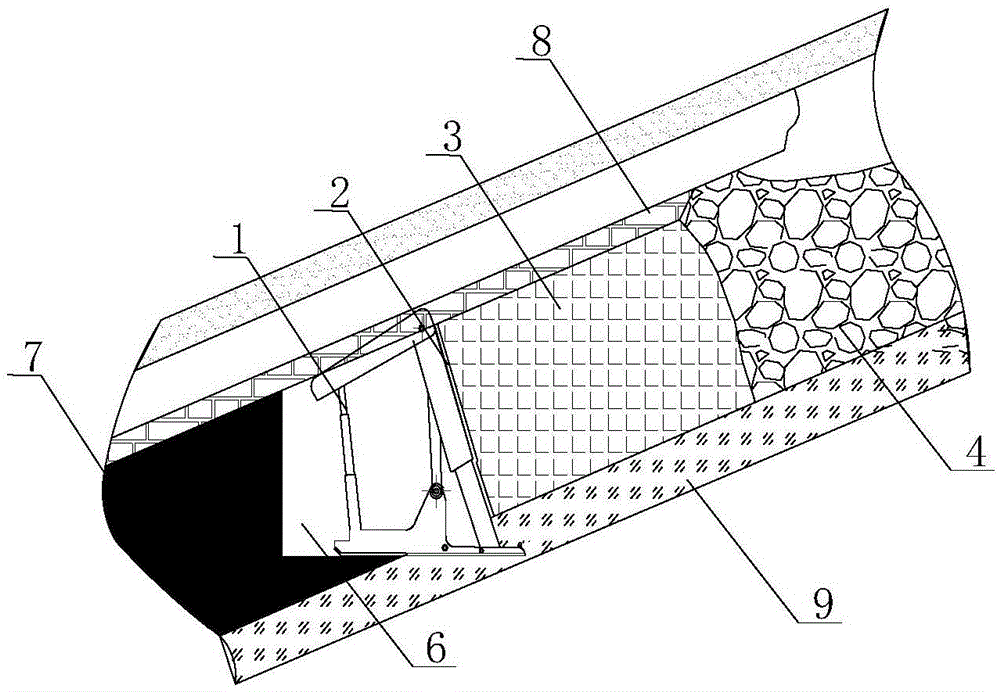

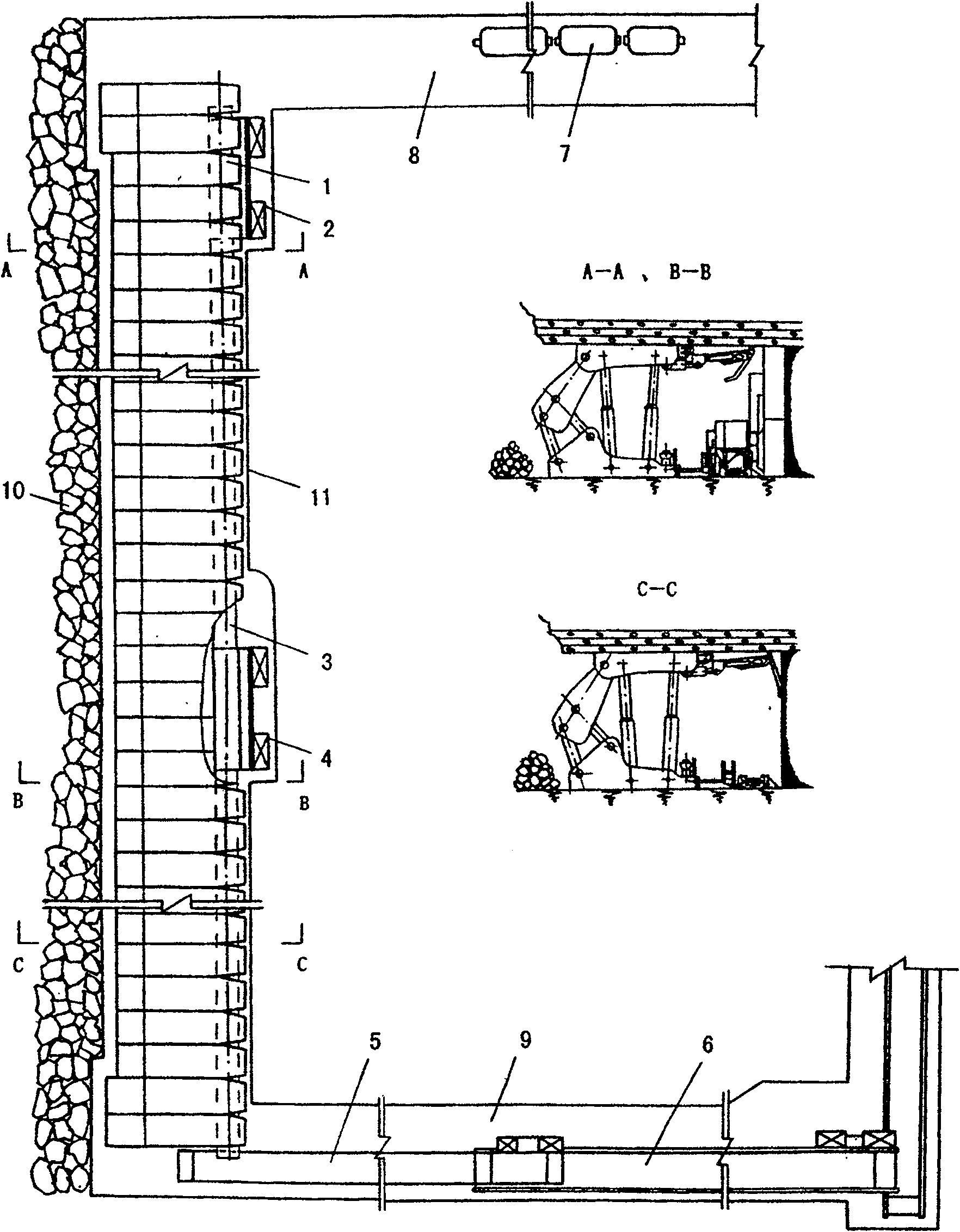

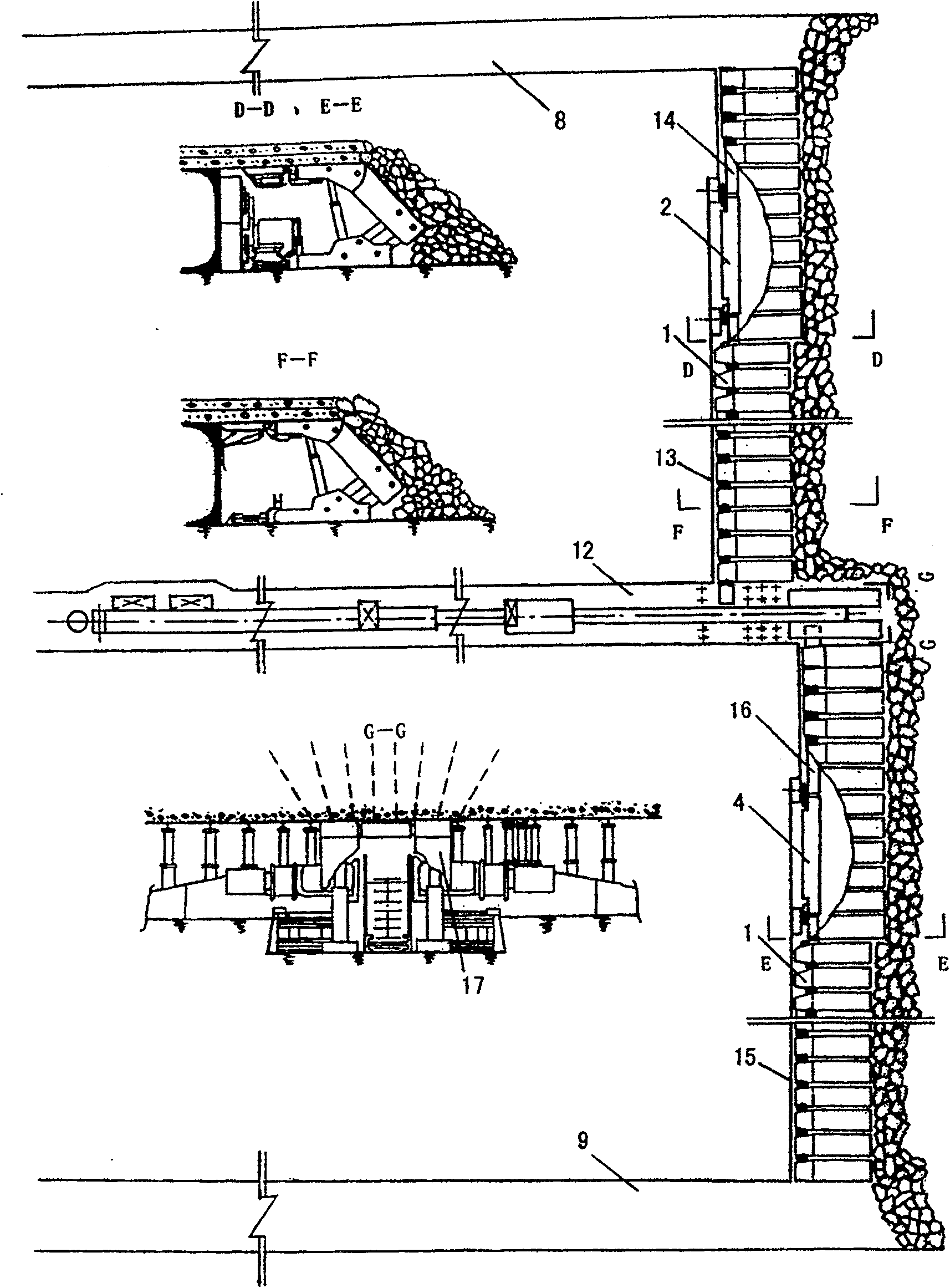

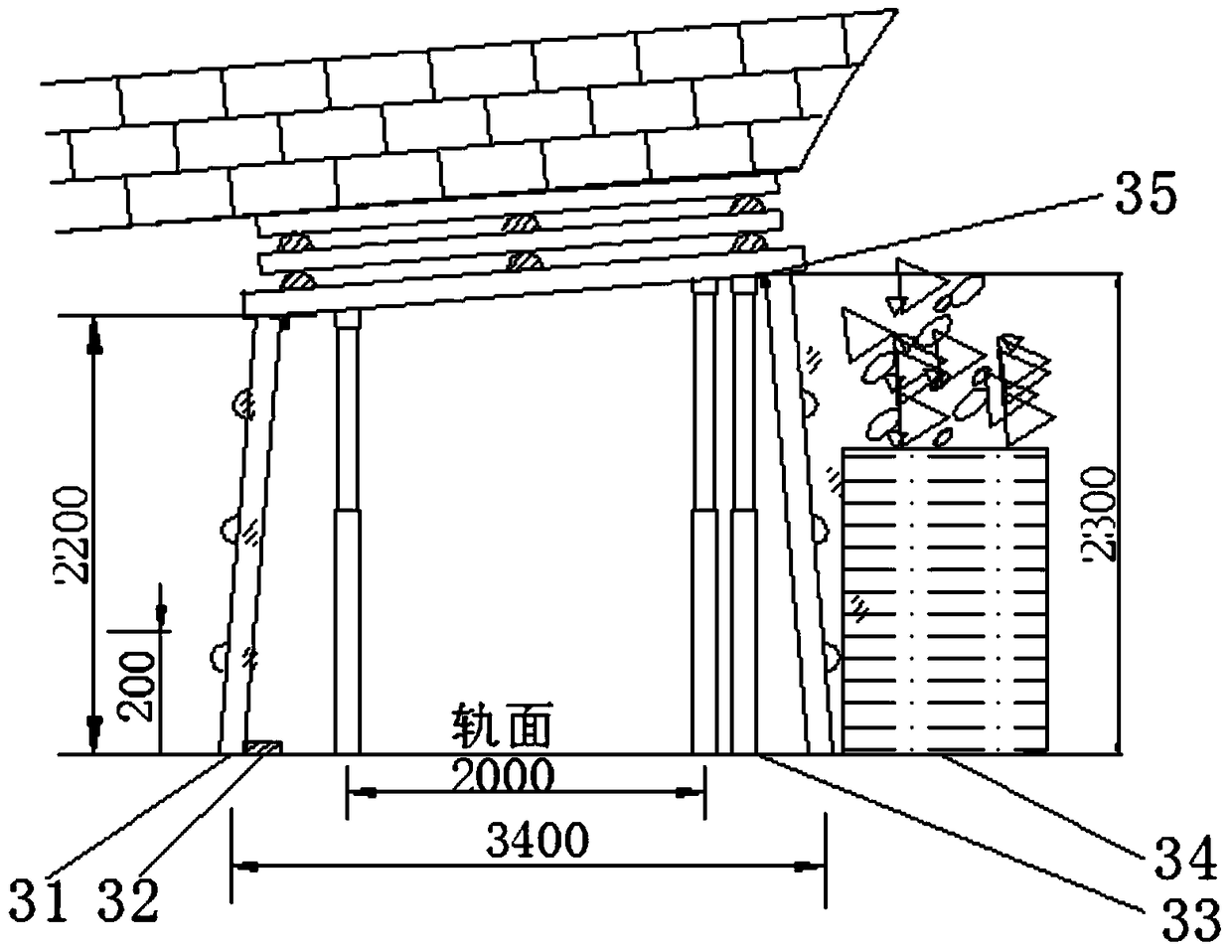

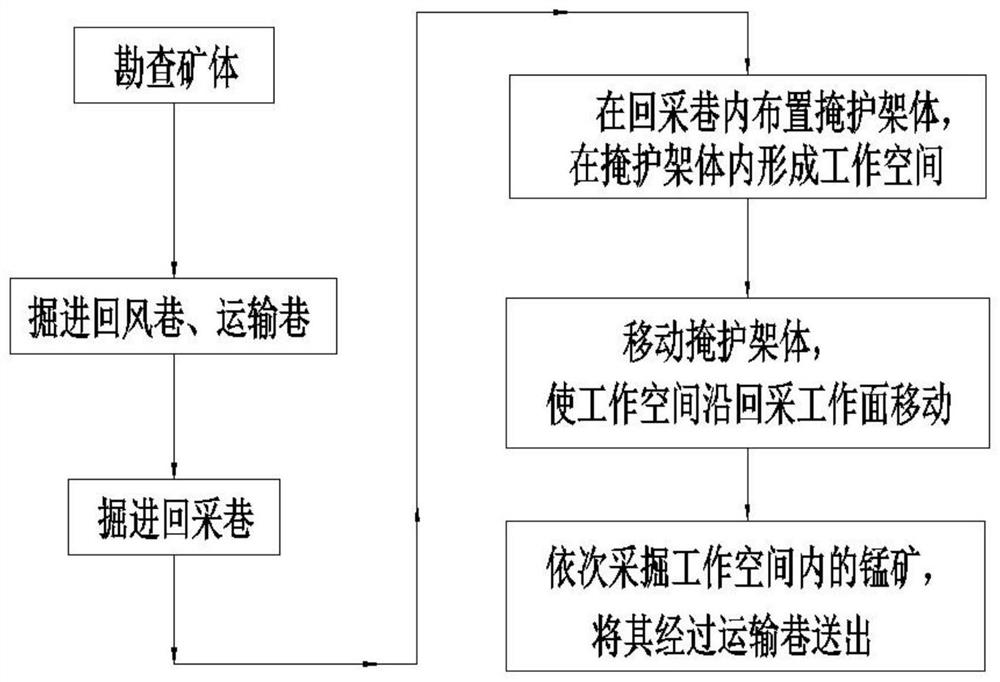

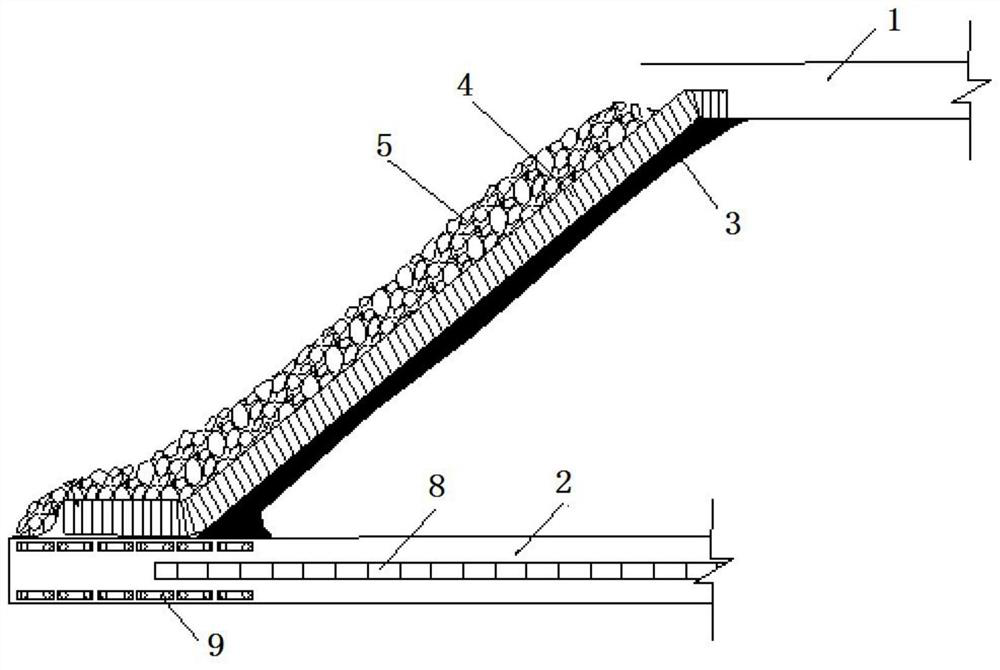

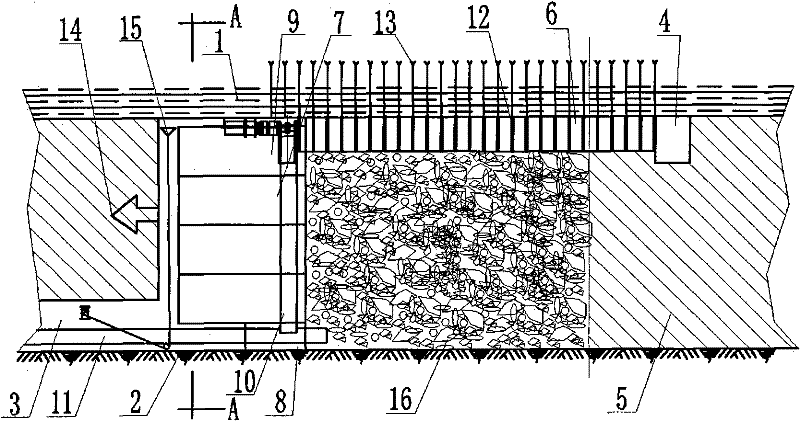

A mining method for mining inclined manganese ore layers in ore bodies with mobile cover supports

ActiveCN108678744BReduce the rate of penetrationSave time on excavation workUnderground miningSurface miningMining engineeringFresh air

Owner:贵州武陵矿业有限公司

Method of mining coal from heavy pitch thick coal seam

ActiveCN101915101BSafe and Efficient MiningSolve coal mining method problemsUnderground miningSurface miningEngineeringCoal mining

Owner:TIANDI SCI & TECH CO LTD

Thin coal seam coal-pillar-free advancing type coal mining method

ActiveCN111140233AOptimize layoutIncrease productivityUnderground miningSurface miningCoal pillarMining engineering

The invention provides a thin coal seam coal pillar-free advancing type coal mining method. The method comprises the following steps: determining a mining area, arranging a roadway, arranging a working interval, mining and filling, and completely mining. The thin coal seam coal-pillar-free advancing type coal mining method has the following beneficial effects that a coal mining system is simple inarrangement, two working faces can be mined at the same time at a time, and the production efficiency is high; the working faces adopt a forward mining process, and three roadways simultaneously serve two working faces, so that the roadway driving rate is low, the coal discharging speed is high, and the mining connection tension is favorably relieved; a jump mining mode is adopted, the formed solid waste storage space is regular in shape, the two sides of the solid waste storage space are of solid structures, and regular filling bodies are easily formed; the goaf is used as a solid waste storage space, so that the underground waste space is effectively utilized, the mine pressure is weakened, the roadway retaining difficulty is reduced, and the surface subsidence is prevented; no coal pillar is left on the working face, and the coal resource recovery rate is increased.

Owner:BEIJING ZHONGKUANG INNOVATION ALLIANCE ENERGY & ENVIRONMENTAL SCI RES INST

A method of layered mining of extremely thick coal seams

ActiveCN108716401BEffective controlReduce the level of disturbanceUnderground miningSurface miningCoalMineralogy

The invention discloses a layered mining method of an ultra-thick coal seam and belongs to the field of safe and efficient mining of the ultra-thick coal seam. The layered mining method includes the steps of layering, layered mining, coal chute digging and reservation layer releasing. In the layering step, the thickness of every layer is required to meet the caving mining thickness in an existingmining technology condition, and the reservation layer above the layers is required to fill a goaf after falling and bulking; in the process of layered mining, the fell reservation layer is not recovered temporarily and is enabled to fill the goaf; coal chutes are dug behind a bottom layer working face by a certain distance and are dug in a coal layer bottom plate, lower portions of the coal chutes are connected with coal conveying roadways, and the quantity of the coal chutes meets the requirement on coal discharging in the later period; the reservation layer releasing is performed after bottom layer working face advance till the ultra-thick coal seam is mined completely. The layered mining method has the advantages that overlying strata is less disturbed, coal conveying roadways are avoided from being damaged and influenced by upper layer mining, safe and efficient mining of the ultra-thick coal seam can be realized, and high practicability and generalization performance are achieved.

Owner:CHINA UNIV OF MINING & TECH

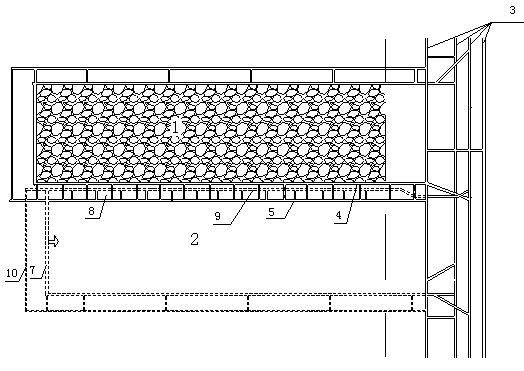

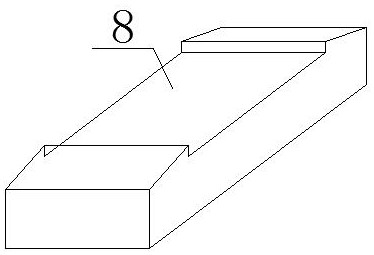

A coal mining method for pre-mining layered and broken top coal in the middle of extra thick coal seam

ActiveCN105317438BReduce the number of relocationReduce the rate of penetrationUnderground miningSurface miningInsertion stentRock pressure

The invention provides a coal mining method for pre-mining layered broken top coal in the middle of an extra-thick coal seam, belonging to the field of coal mining. The method includes firstly arranging a longwall working face in the middle of the coal seam for pre-mining a 3-7m coal seam, then the coal body in the upper part of the coal seam is fully broken under the action of mine pressure and gravity, and the broken coal body falls on the unmined coal body in the lower part of the coal seam; In the future, reserve 2-3m top-coal at the lower part of the coal seam to arrange fully-mechanized caving working face for top-coal caving mining. The height of coal cutting is generally 3-5m, and the reserved 2-3m top-coal and broken caving The coal body in the upper part of the coal seam is released at the coal outlet of the hydraulic support of the fully mechanized caving face at the lower part of the coal seam, and is transported out of the working face by the conveyor behind the support. The thickness of the coal seam can reach 40m at one time. The method of the invention gives full play to the advantages of fully mechanized mining and fully mechanized caving mining, has the advantages of less layering, low roadway excavation rate, high recovery rate, and less times of moving and reversing the working face, and has important guidance for safe and efficient mining of extra-thick coal seams significance.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

A concrete modular gob-side roadway support structure for coal pillar-free mining

ActiveCN111911196BAchieve miningImprove surface recovery rateUnderground chambersTunnel liningMineral SourcesArchitectural engineering

Owner:山西煤炭运销集团晋城有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com