A concrete modular gob-side roadway support structure for coal pillar-free mining

A support structure and concrete technology, which is applied in mining equipment, earthwork drilling, shaft equipment, etc., can solve the problems of working efficiency of the wall not connected to the top, long concrete solidification time, and influence of wall stubble, so as to speed up cycle production progress, reduce roadway maintenance costs, and eliminate the effect of setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention, the present invention will be described in further detail in conjunction with examples and drawings. It is to be understood that the specific embodiments described herein are intended to explain the present invention and is not intended to limit the invention. The technical solutions of the present invention will be described in connection with the examples and drawings, but the scope of protection is not limited.

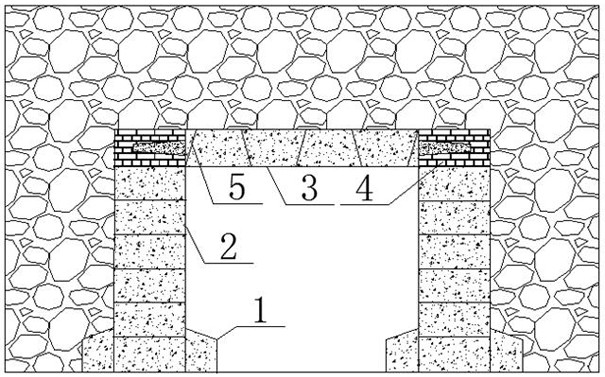

[0037] Coalstone column mining concrete modular coal-column support structure concrete modular wall consisting of three parts:

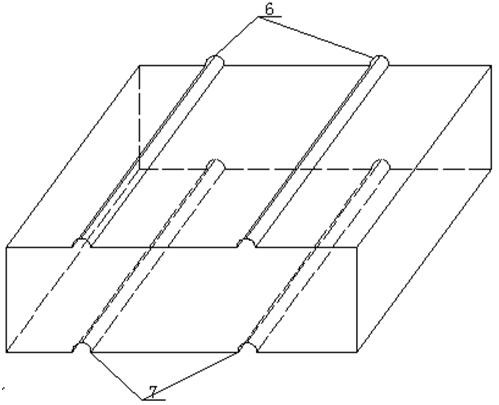

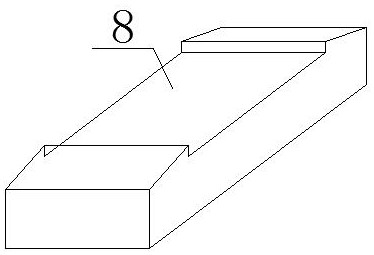

[0038] (1) The upper layer is the top-unloading module, including the top intermediate concrete module 3, the top concrete module 4, the top slot concrete module 5, the top intermediate concrete module 3 design size is 1100mm; the panel design, the intensity of concrete The level is C30, the concrete module is a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com