A loop heat pipe geothermal mining system with adjustable working fluid circulation flow

A working fluid circulation and heat pipe type technology, applied in the field of loop heat pipe type geothermal mining system, can solve the problems of low heat transfer efficiency and achieve the effects of avoiding too deep liquid pool, maximizing heat transfer efficiency, and avoiding carryover effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

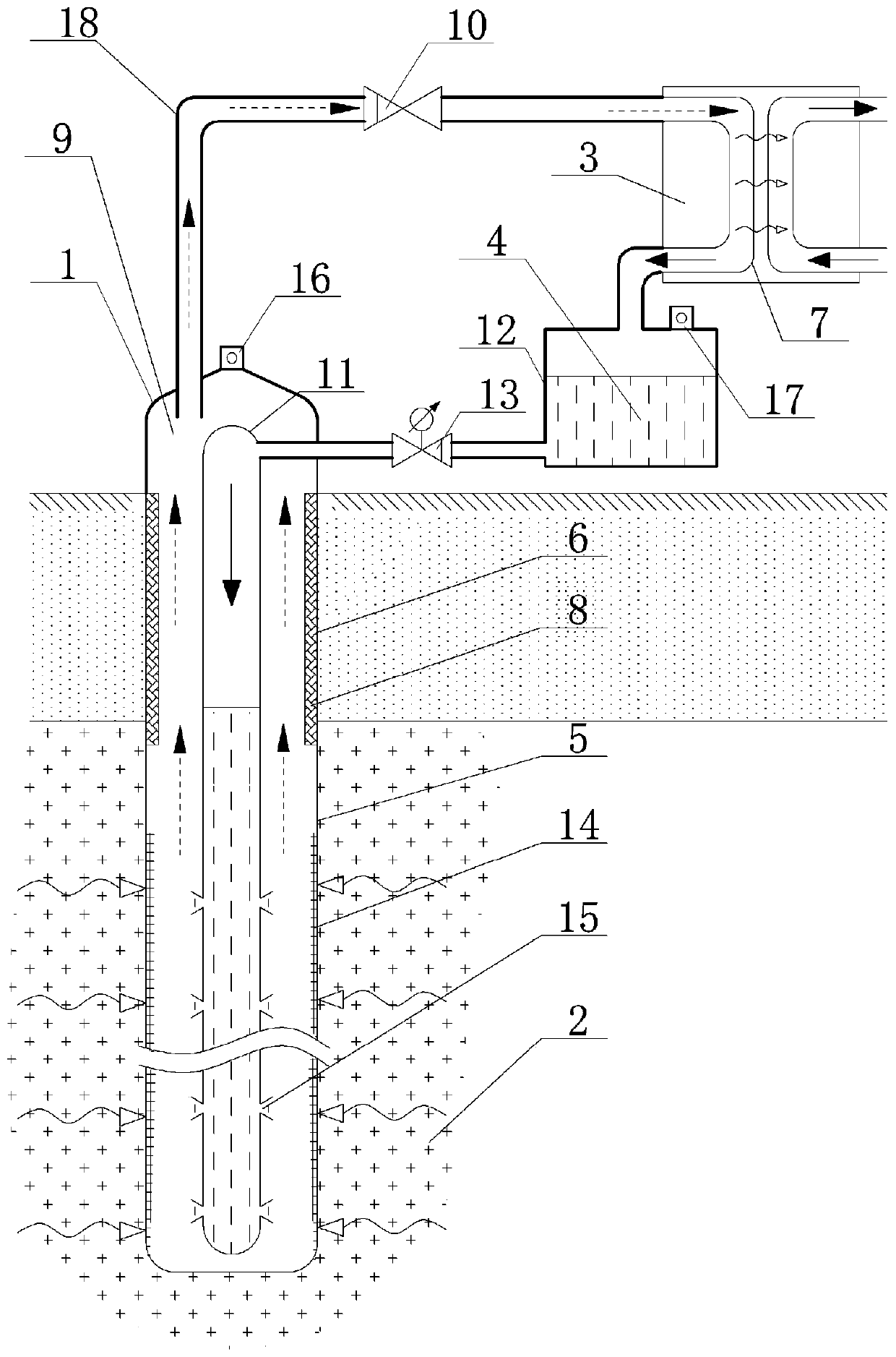

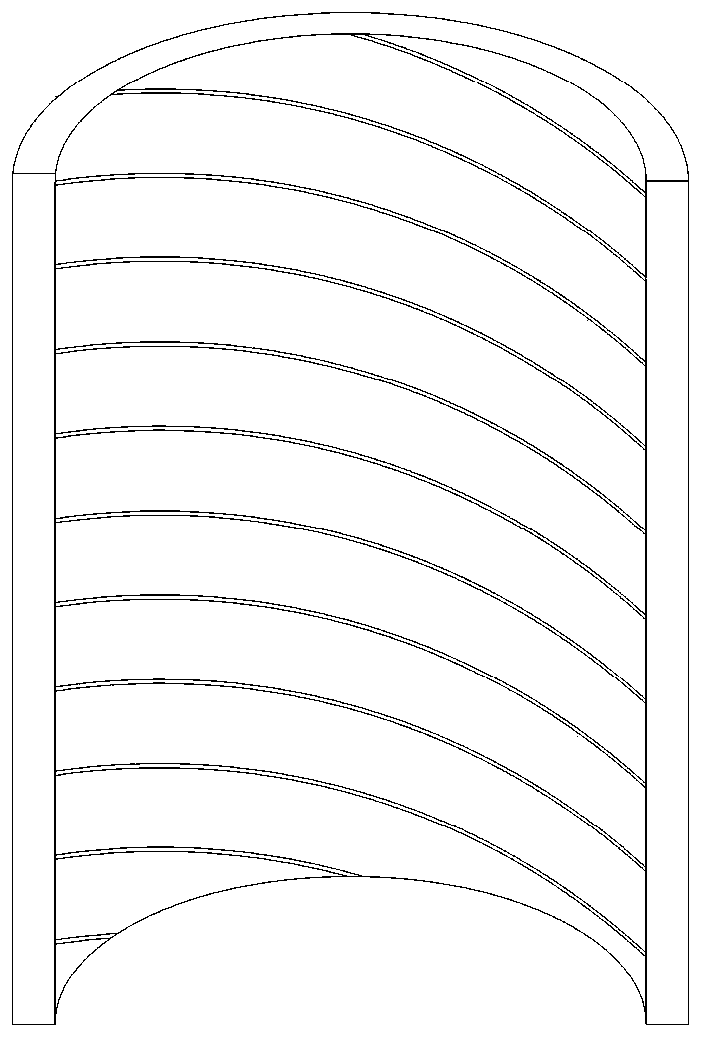

[0028] Such as figure 1 with figure 2As shown, the sleeve-type loop heat pipe 1 includes an outer sleeve 9, an inner sleeve 11 and a connecting pipe. The one-way valve 10 or the steam pump, the connecting pipe and the outer casing 9 are connected, the inner casing 11 is located in the outer casing 9, and the part of the outer casing 9 located in the high-temperature heat storage 2 of the formation is provided with an evaporation section 5, and the outer casing 9 Micro-grooves 14 are provided on the inner wall corresponding to the region of the evaporation section 5, and the outer sleeve 9 is provided with an insulating section 6 at the part outside the high-temperature heat storage 2, and the connecting pipe is provided with an insulating section 6, and the inner sleeve 11 tube Perforations 15 are arranged on the wall corresponding to the area of evaporation section 5. The aperture and distribution density of the perforations 15 are determined according to the circulation ...

Embodiment 2

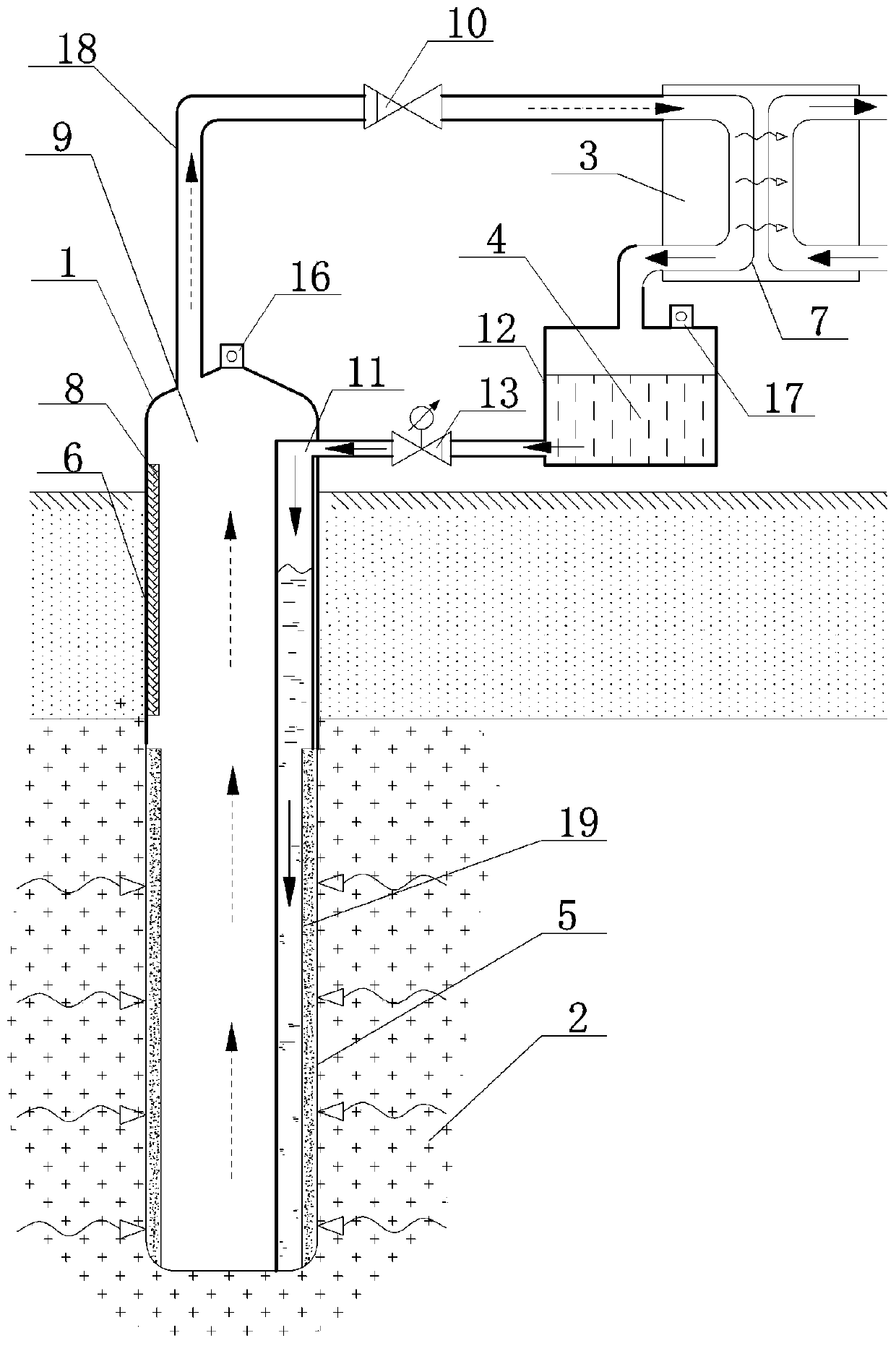

[0044] The casing type loop heat pipe 1 includes an outer casing 9, an inner casing 11 and a connecting pipe, and the top of the inner casing 11 is sequentially connected with the one-way throttle valve 13, the liquid storage tank 12, the surface heat exchanger 3, and the one-way valve. 10 or a steam pump, connecting pipe and outer casing 9, the inner casing 11 is located in the outer casing 9, and the part of the outer casing 9 located in the high-temperature heat storage 2 of the formation is provided with an evaporation section 5, and the outer casing 9 corresponds to the evaporation section The inner wall of the area 5 is provided with micro-grooves 14 and porous metal layer 19 in turn, and the part of the outer casing 9 located outside the high-temperature heat storage 2 is provided with an insulating section 6, and the connecting pipe is provided with an insulating section 6, and the porous metal The layer 19 is provided with a porous metal layer slit 20 parallel to the a...

Embodiment 3

[0050] Such as Figure 5 As shown, the sleeve type loop heat pipe 1 includes an outer sleeve 9, an inner sleeve 11 and a connecting pipe, and the top of the outer sleeve 9 is connected with a one-way throttle valve 13, a liquid storage tank 12, a ground heat exchanger 3, a one-way The valve 10 or the steam pump and the connecting pipe are connected end to end in sequence, the bottom and top of the inner sleeve 11 are open and located at the upper part of the outer sleeve 9, and the gap between the outer sleeve 9 and the inner sleeve 11 is provided with a return section The part of the outer casing 9 located in the high-temperature heat storage 2 of the formation is provided with an evaporation section 5, and the part of the outer casing 9 located outside the high-temperature heat storage 2 is provided with an adiabatic section 6, and the inner casing 11 and the outer casing 9 An annular gate 22 is provided in the area where the gap is located at the junction of the evaporation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com