Well drilling method for improving lifting efficiency

A drilling and efficiency technology, applied in the field of drilling to improve lifting efficiency, to achieve the effect of reducing requirements, improving sweep efficiency, and improving working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

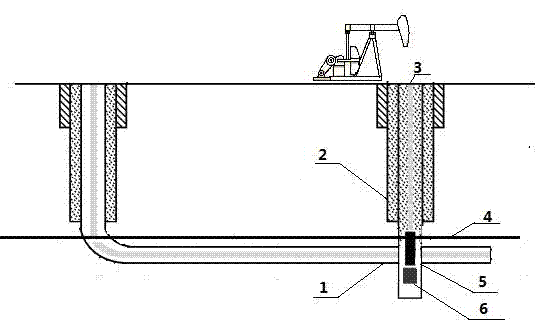

[0009] Attached below figure 1 The present invention will be further described.

[0010] When the liquid level 4 in the original well is lowered to the vicinity of the horizontal section 1, the lifting efficiency is significantly reduced, and the method of the present invention can be used to improve the lifting efficiency. According to the design data and analysis data of the original horizontal well 1, the wellhead position 3 of the vertical well 2 is determined directly above the horizontal section (or inclined section) of the well bottom, and a vertical well is drilled at the determined wellhead position 3 using vertical drilling technology (existing technology) 2. Make it communicate with the original horizontal well 3 and deepen it to a certain depth, complete the well with the sand control technology (existing sand control well technology), and lower the lifting device (existing device) 6 to a certain depth below the original horizontal well section 1, so that Give...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com