Oil displacement agent composition and preparation method and application thereof

A technology of oil-displacing agent and composition, applied in the field of oil-displacing agent composition and its preparation, to achieve the effects of improving development effect, improving oil washing efficiency, and ultra-low interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] According to the present invention, the preparation method of the oil displacement agent composition includes providing the first solution and gas respectively, and the preparation method of the first solution includes: cationic surfactant, amphoteric surfactant, alcohol, polymer mixed with water,

[0050] The cationic surfactant is tetraalkylammonium chloride and / or tetraalkylammonium bromide, preferably, at least one alkyl group is a long-chain alkyl group containing 12-18 carbon atoms, and other alkyl groups are independently selected from One of methyl, ethyl, propyl and butyl, more preferably, one or two alkyl groups are long-chain alkyl groups containing 12-18 carbon atoms, and other alkyl groups are independently selected from methyl groups or ethyl;

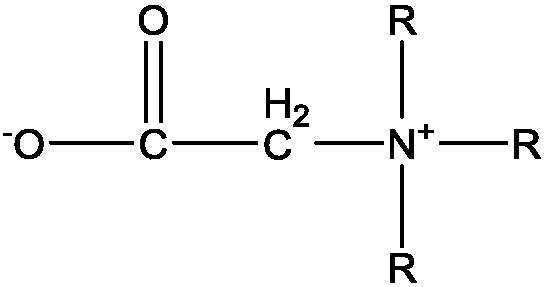

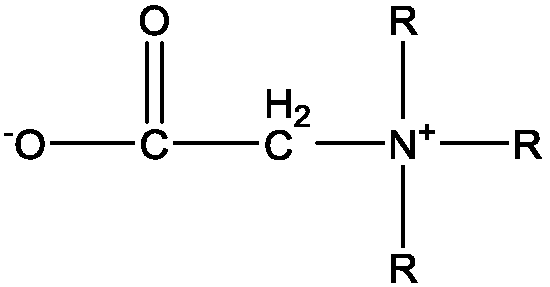

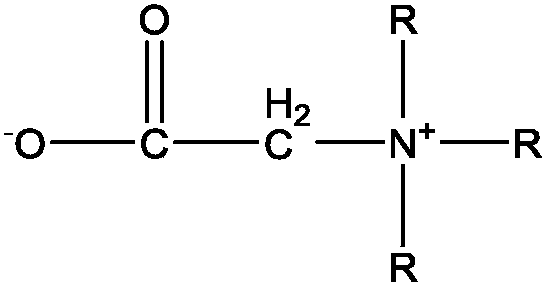

[0051] The amphoteric surfactant is a trialkyl betaine represented by the following formula, wherein at least one R is a long-chain alkyl group containing 10-18 carbon atoms, and other Rs are each independently se...

Embodiment 1

[0071] This example is used to illustrate the preparation and performance of the oil displacement agent composition provided by the present invention.

[0072] (1) Weigh 800g of clear water (salinity is 0mg / L), add polyacrylamide ammonium (viscosity average molecular weight 3000×10 4 , degree of hydrolysis 20 mol%) 3g, stirred and dissolved for 4h. Add 3 g of cationic surfactant dimethyl dioctadecyl ammonium chloride, add 3 g of octadecyl dimethyl betaine, then add 0.5 g of ethanol, add water to 1000 g, stir for 20-30 min until completely dissolved, and obtain An aqueous solution of the non-gaseous components of an oil displacing composition.

[0073] The gas in the oil displacing composition is CO 2 , under the same pressure conditions, CO 2 The volume content is 1 time of the total volume of the non-gas phase component mixture.

[0074] (2) Take the above aqueous solution and heavy oil (viscosity 9600mPa.s at 50°C), and use Model TX500C interfacial tension to measure the...

Embodiment 2

[0076] This example is used to illustrate the effect of using the oil-displacing agent composition of the present invention for oil-displacement on enhanced recovery of heavy oil.

[0077] A rock core with a size of 4.5mm×4.5mm×300mm and a permeability of 3000md was used to conduct the enhanced oil recovery experiment (the oil displacement agent is the same as in Example 1). The core was dried, vacuumed and saturated with water, saturated with heavy oil at 70°C (same as in Example 1), and aged for 48 hours. (1) Water flooding at an injection rate of 1.5mL / min to a water content of 95% by volume. (2) Inject 0.05 PV of the non-gas phase component aqueous solution in the oil displacement agent composition of Example 1 at an injection rate of 1.5 mL / min, and inject CO at an injection rate of 1.0 mL / min. 2 0.05PV, repeated alternate injection for 3 cycles. (3) Continue water flooding at an injection rate of 1.5mL / min to a water content of 95% by volume.

[0078] Experimental re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com