Patents

Literature

84results about How to "Achieve mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

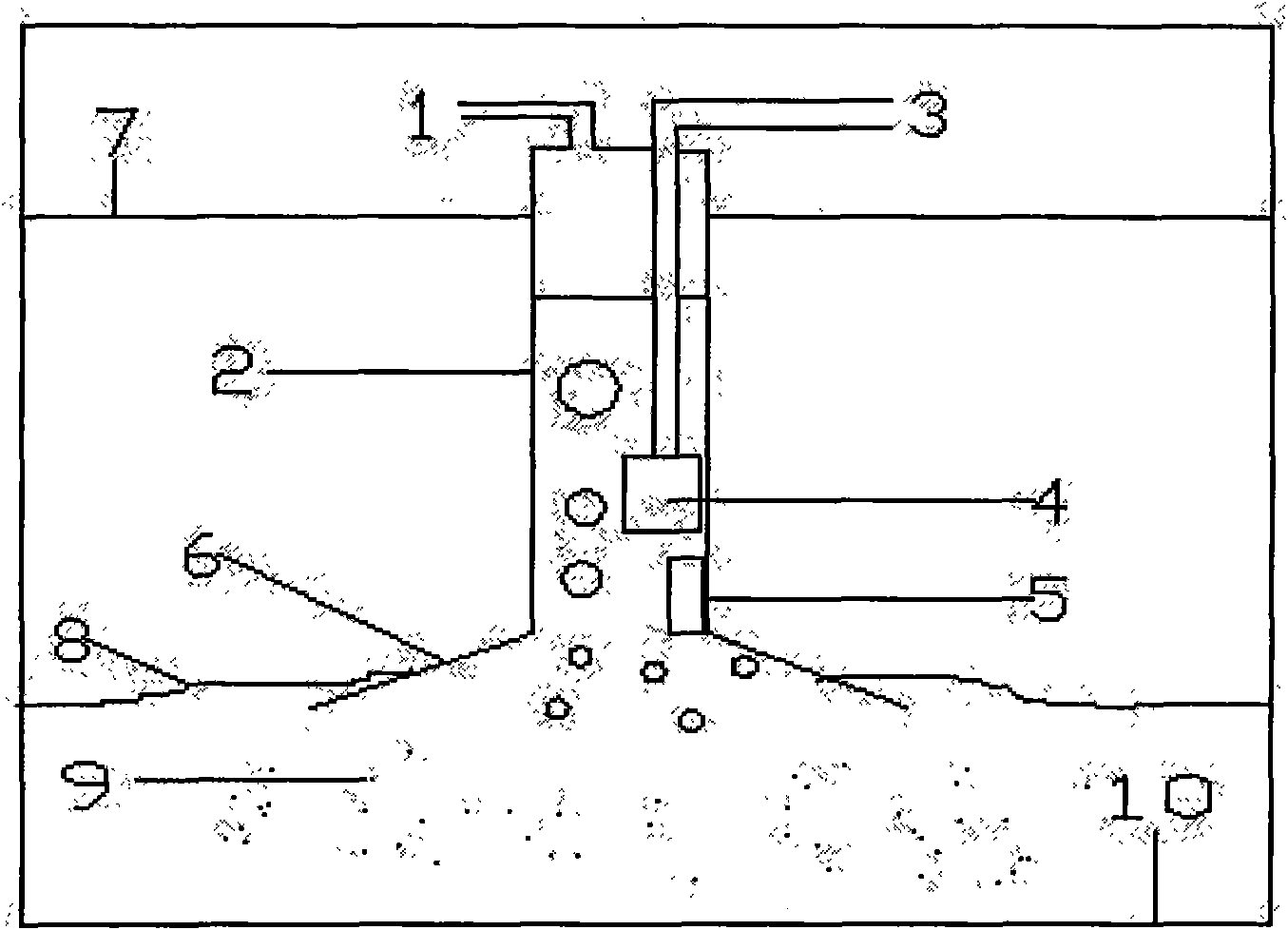

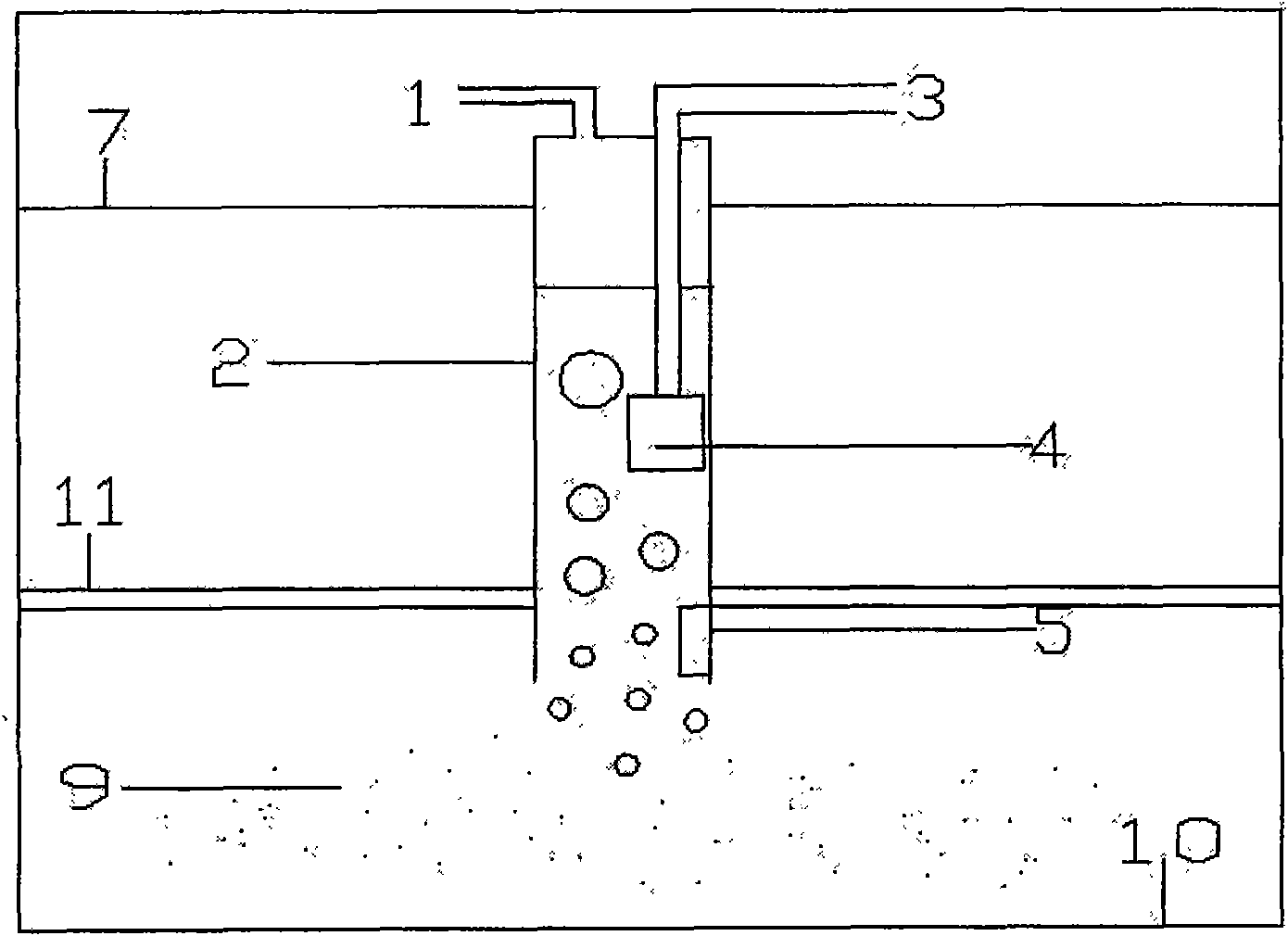

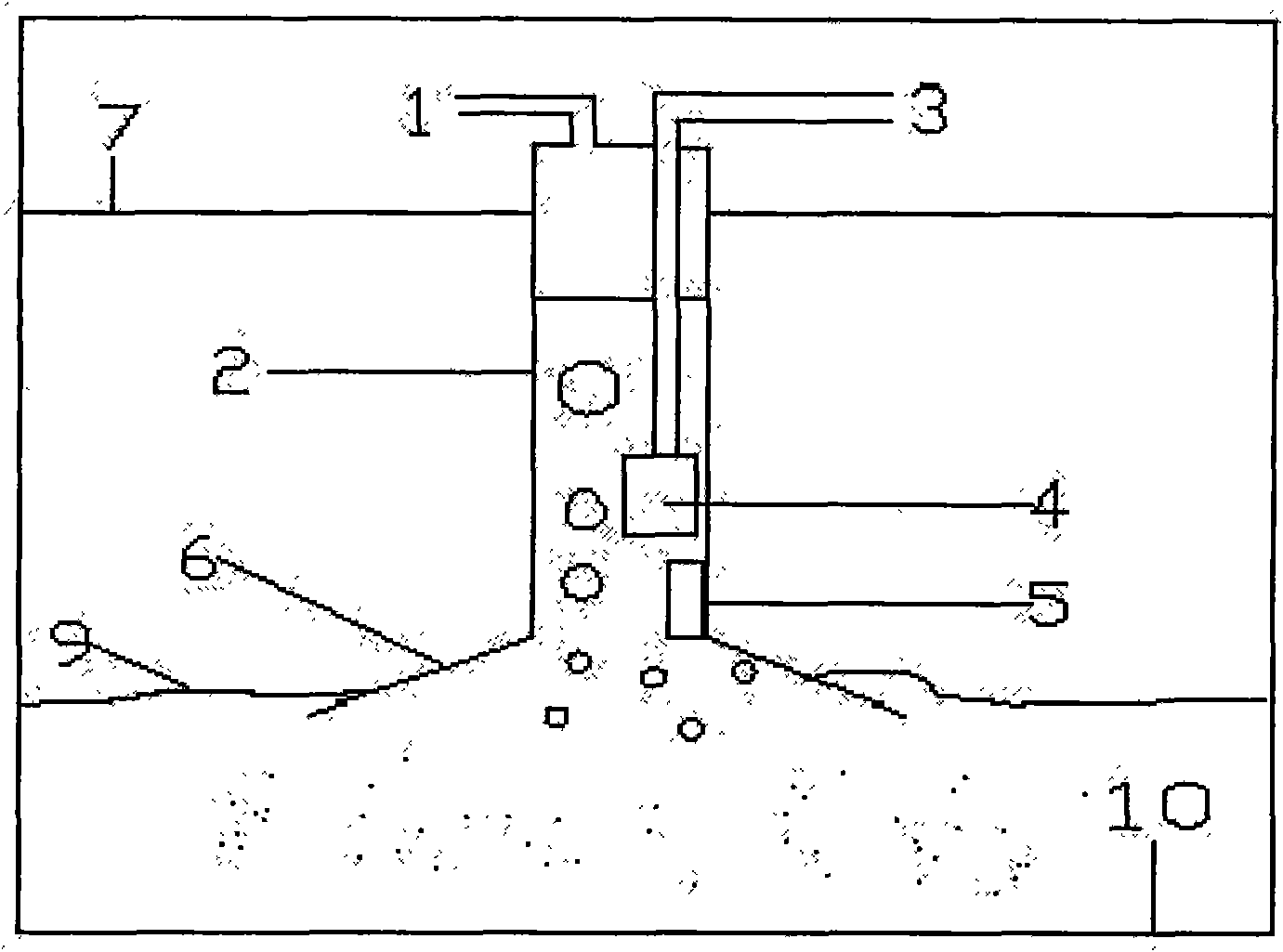

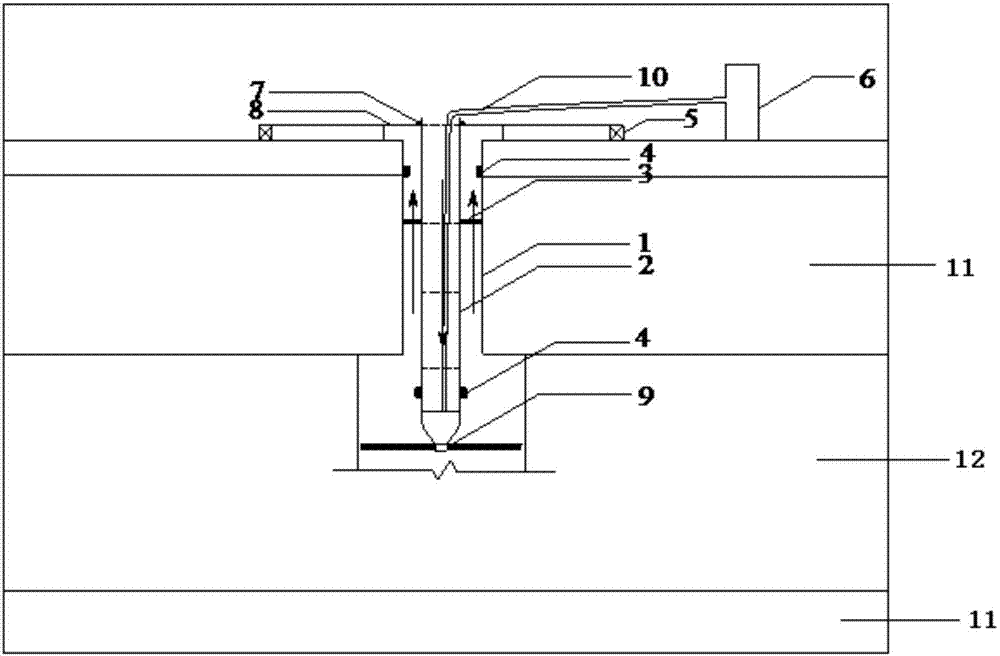

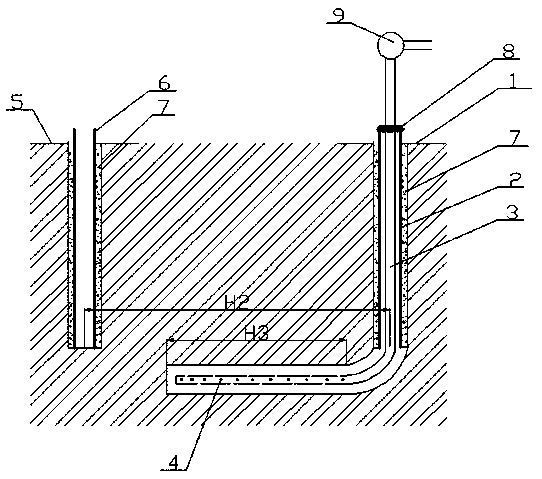

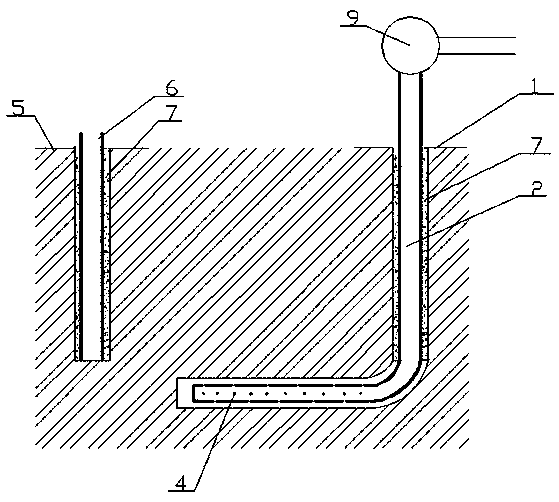

Extraction device for undersea gas hydrate and extraction method thereof

ActiveCN101555797AAchieve miningMining technology is simpleConstructionsMineral miningGas collecting tubeEngineering

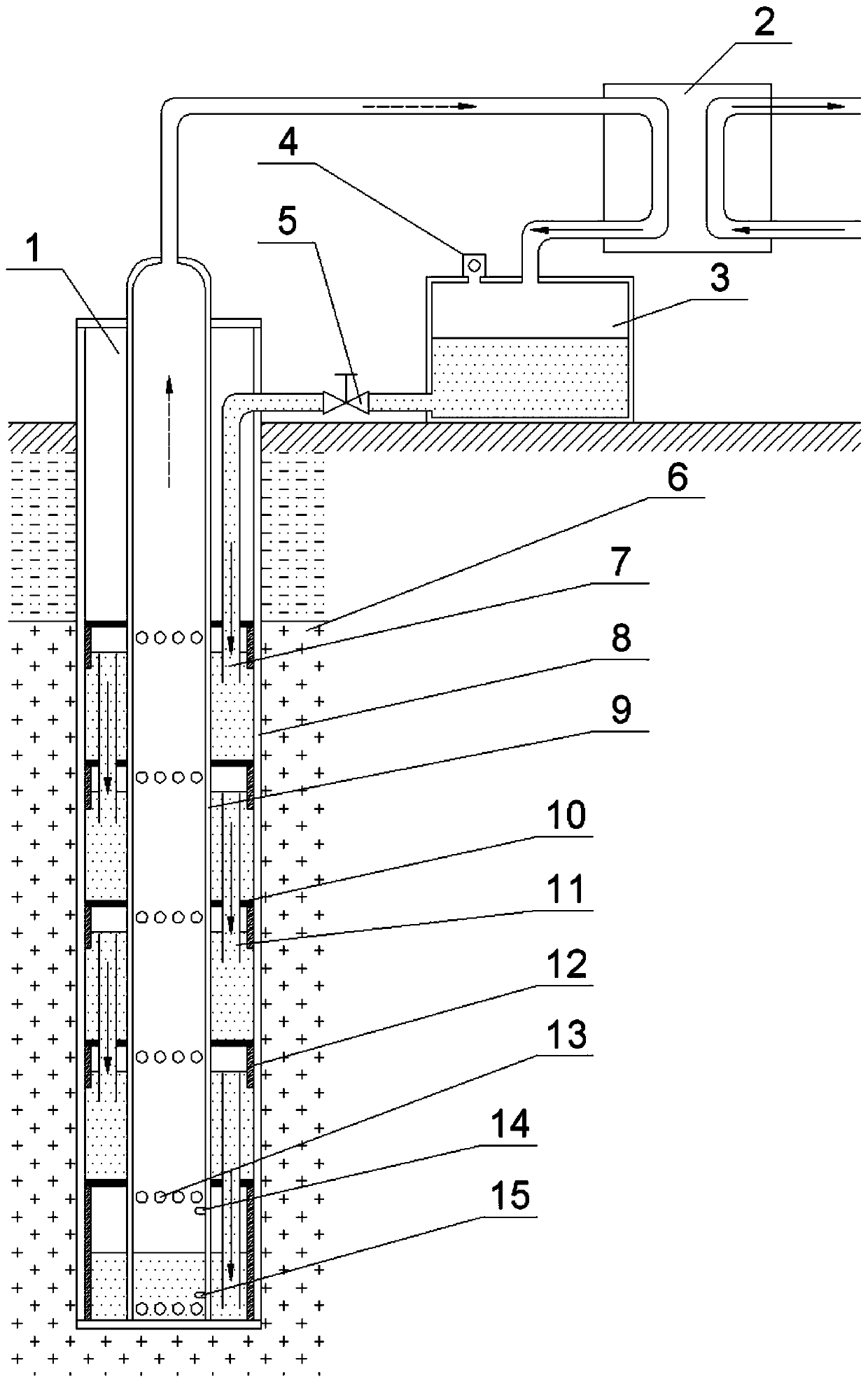

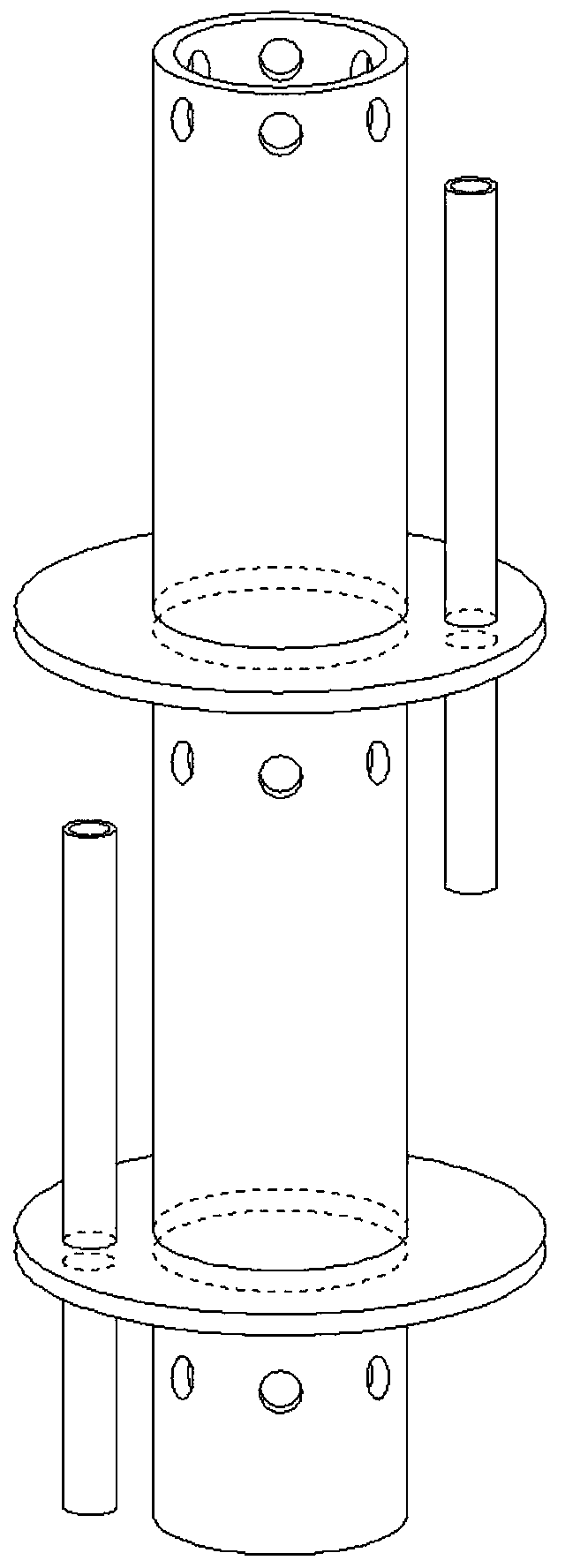

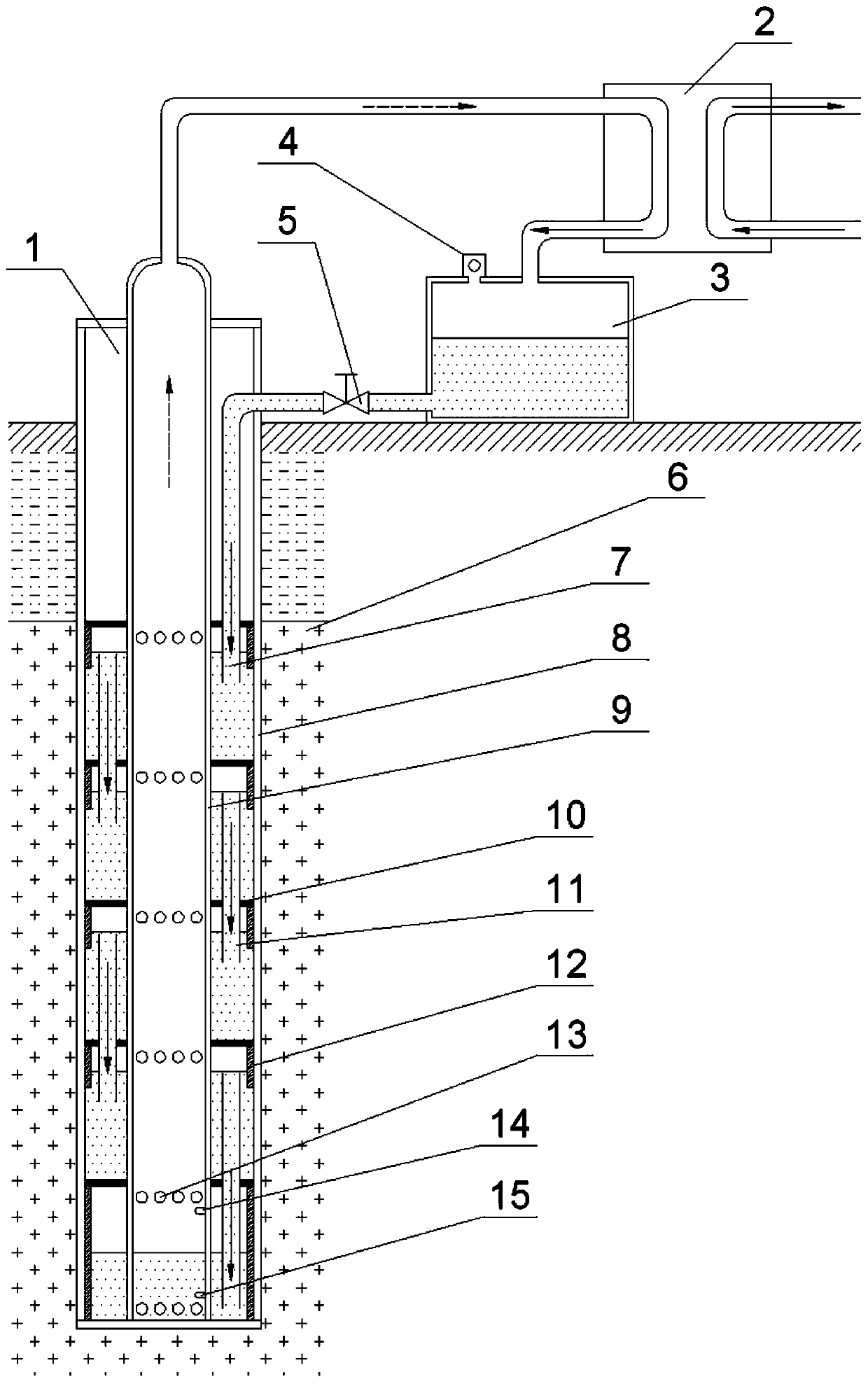

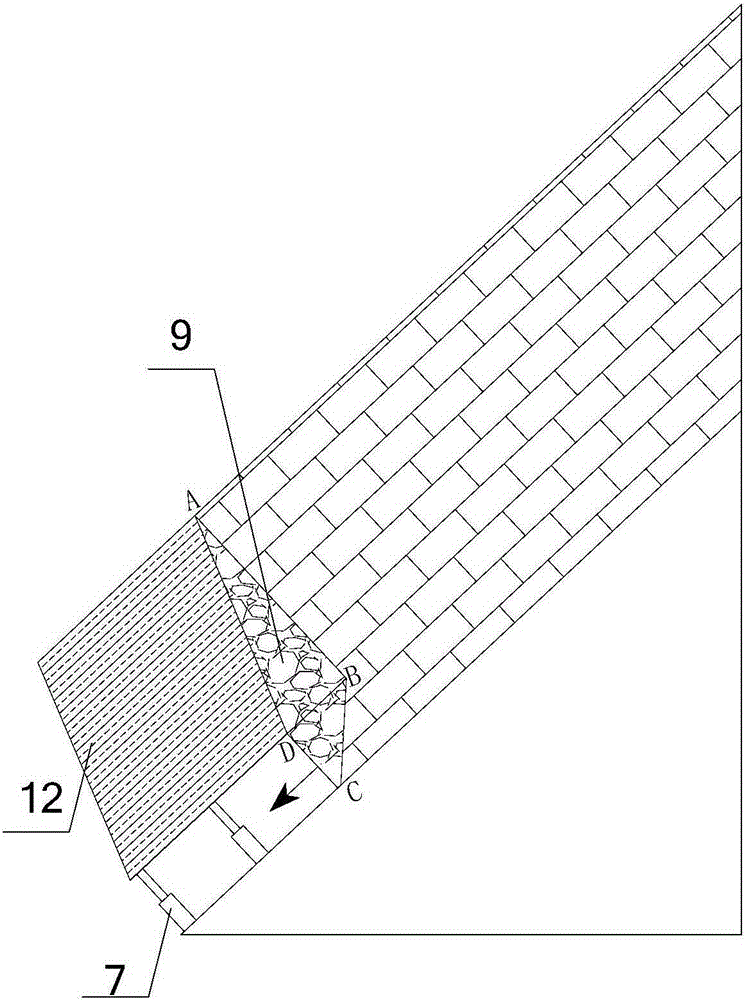

The invention discloses an extraction device for undersea gas hydrate and an extraction method thereof, which is characterized in that the device is directly communicated with undersea (10) gas hydrate layer (9) through a hollow rigid body (2); or the hollow rigid body is communicated with undersea (10) gas hydrate layer (9) through layers of sand and clay (8) or impermeable bed (11); a water pump (4) and a test and supervisory equipment (5) are provided on one side of the hollow rigid body, the water pump is connected with a drain pipe (3) which is above the sea level (7) through a pipe, the test and supervisory system is connected with an image pickup system and a pressure testing system, and a gas collecting pipe (1) is arranged on the top of the inside of the hollow rigid body. The extraction method comprises the following steps: 1) a hollow rigid body is built on the sea separated with water, and the hollow rigid body is communicated with undersea gas hydrate layer; 2) water in the hollow rigid body is drained out via a water pump to lower the water height in the hollow rigid body and reduce the pressure acting on the gas hydrate layer and the gas hydrate is decomposed into gas and water when the pressure acting on the gas hydrate layer is less than the balance pressure; 3) the decomposed gas escapes upward, is discharged through the gas collecting pipe and is collected.

Owner:SICHUAN UNIV

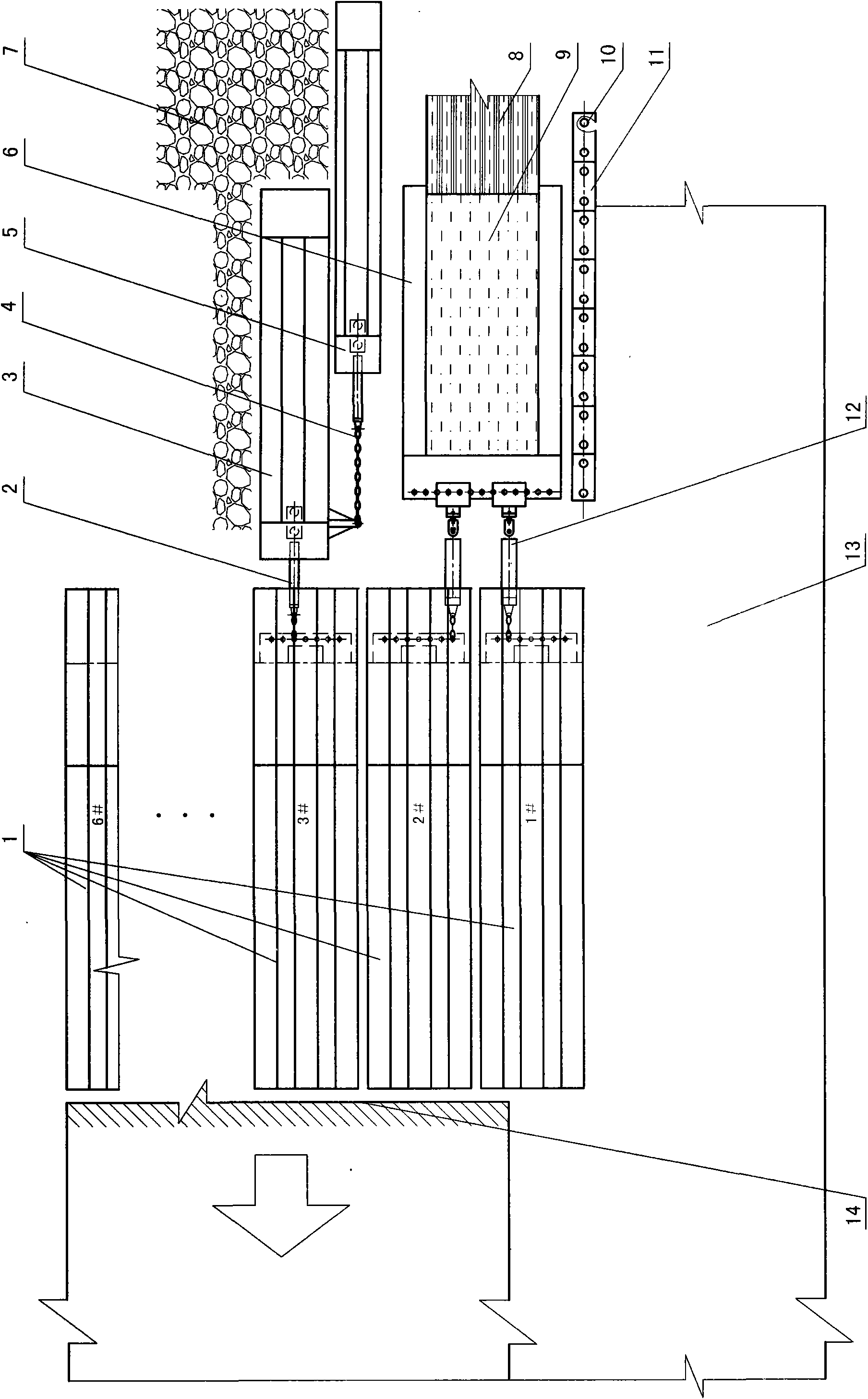

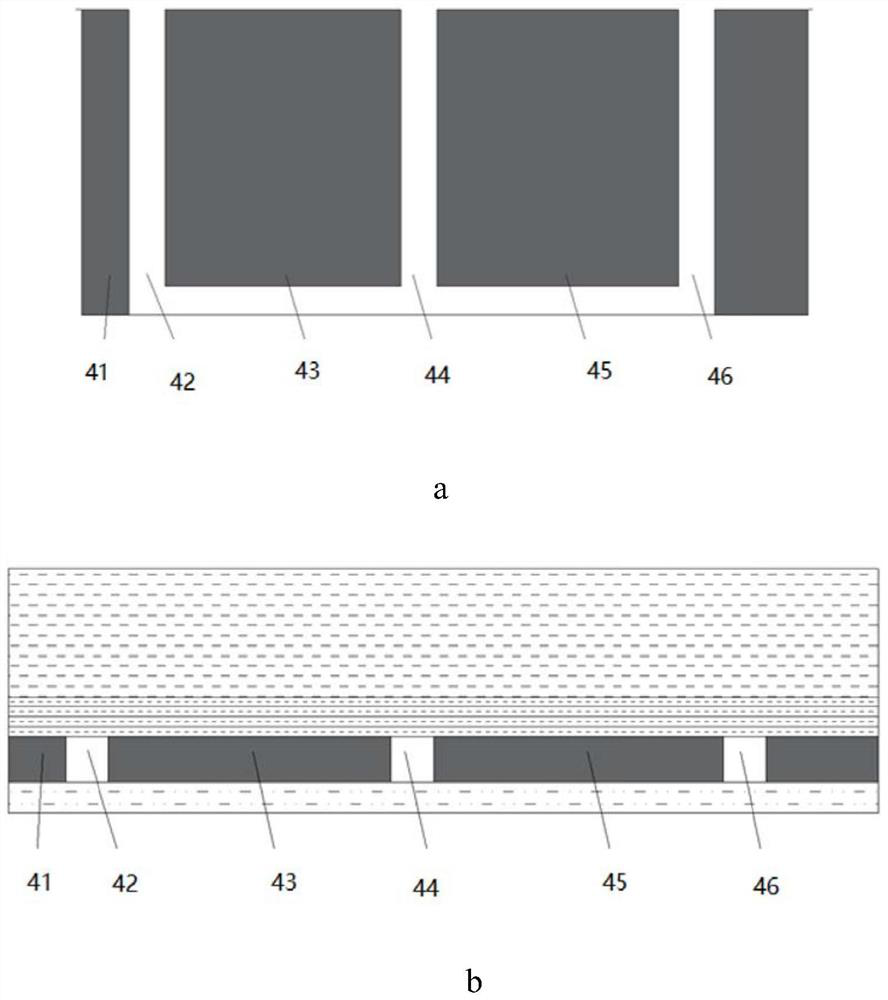

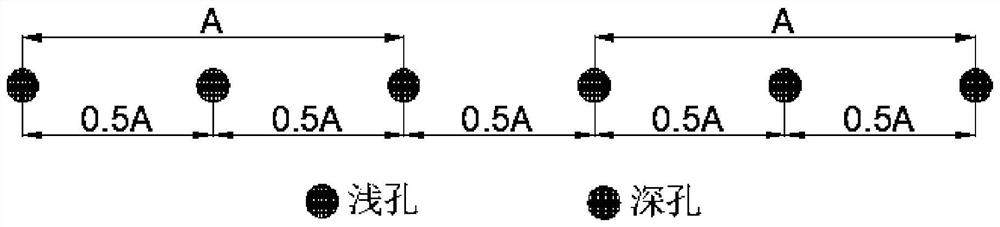

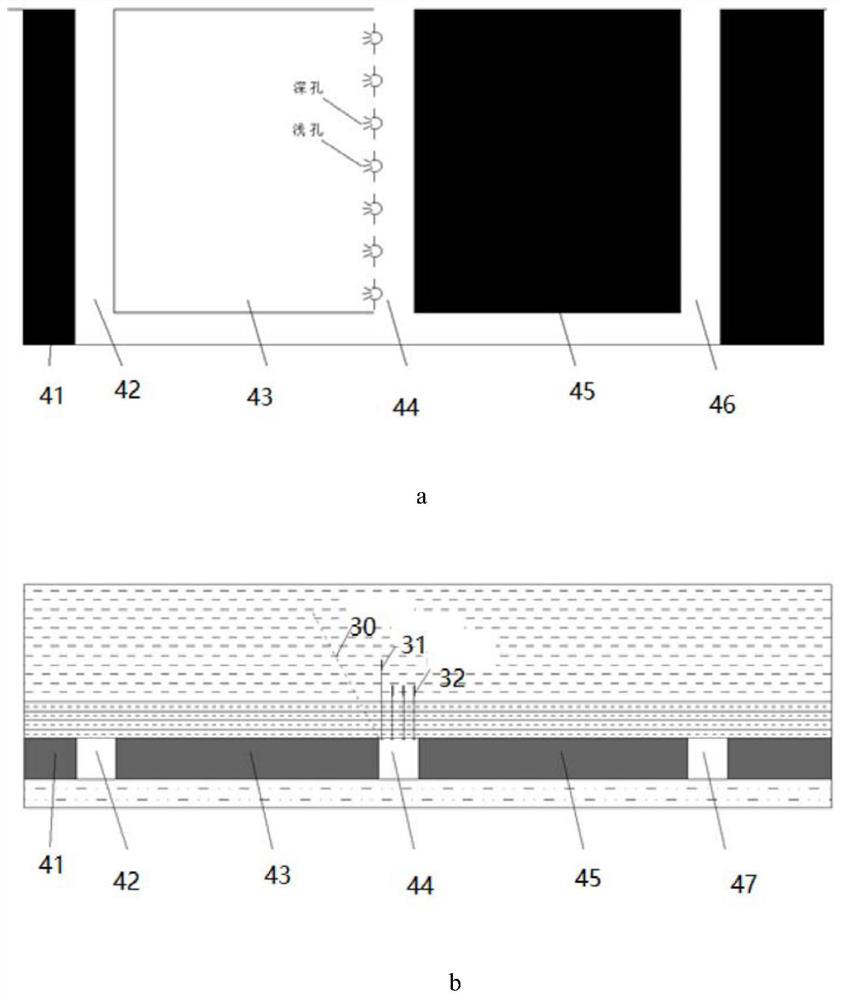

Gob-side entry retaining and sectional coal seam gas pre-extracting method for single low-permeability outburst coal seam

InactiveCN103670496AEmission reductionAchieve miningUnderground miningSurface miningMining engineeringCoal pillar

The invention relates to the field of mine support and gas extraction, in particular to a gob-side entry retaining and sectional coal seam gas pre-extracting method for a single low-permeability outburst coal seam. A plurality of bedding drill holes are drilled in an air inlet crossheading and an air return crossheading of a working surface towards the working surface in the inclined direction of the coal seal in a parallel mode, and a pneumatic gas extraction device is used for carrying out gas extraction; gas of an adjacent working surface is extracted along the inclined bedding drill holes of the coal seam in the downstream direction of a transportation crossheading of the working surface, and an extraction pipeline is communicated for extracting gas of the coal seam of the adjacent working surface; after extraction, robbing is carried out on the coal seal of the working surface; extraction is not stopped until finish, and the steps are repeated until extraction of the coal seam is finished. According to the method, coal mining without pillars is achieved, the recovery rate of coal is improved, the total gas extraction time is saved, the gas extraction effect is improved, and coal mining and gas extracting are achieved at the same time.

Owner:CHINA UNIV OF MINING & TECH

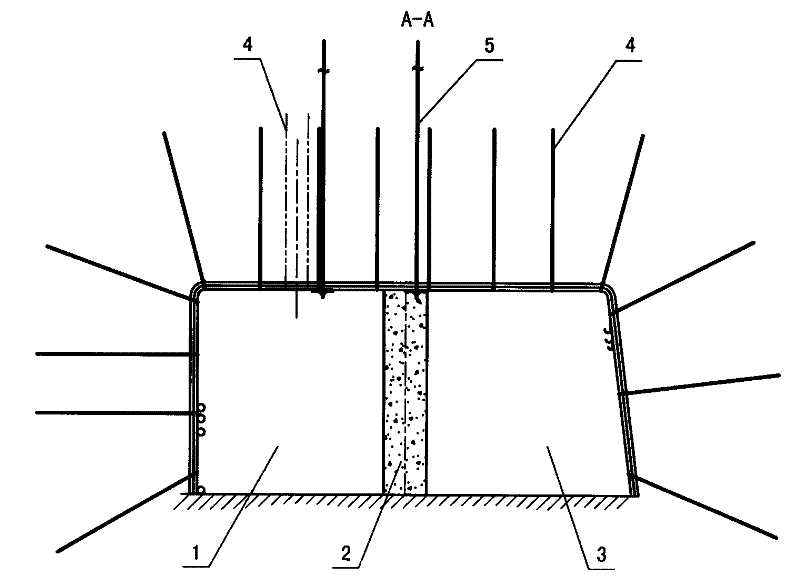

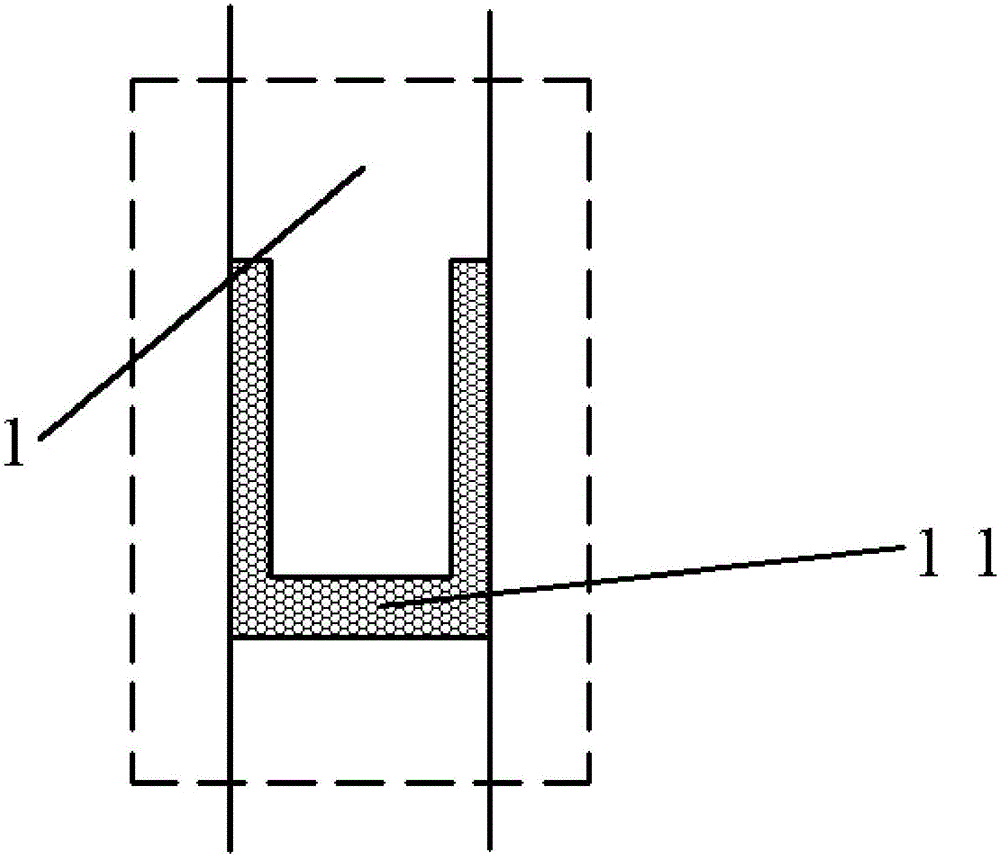

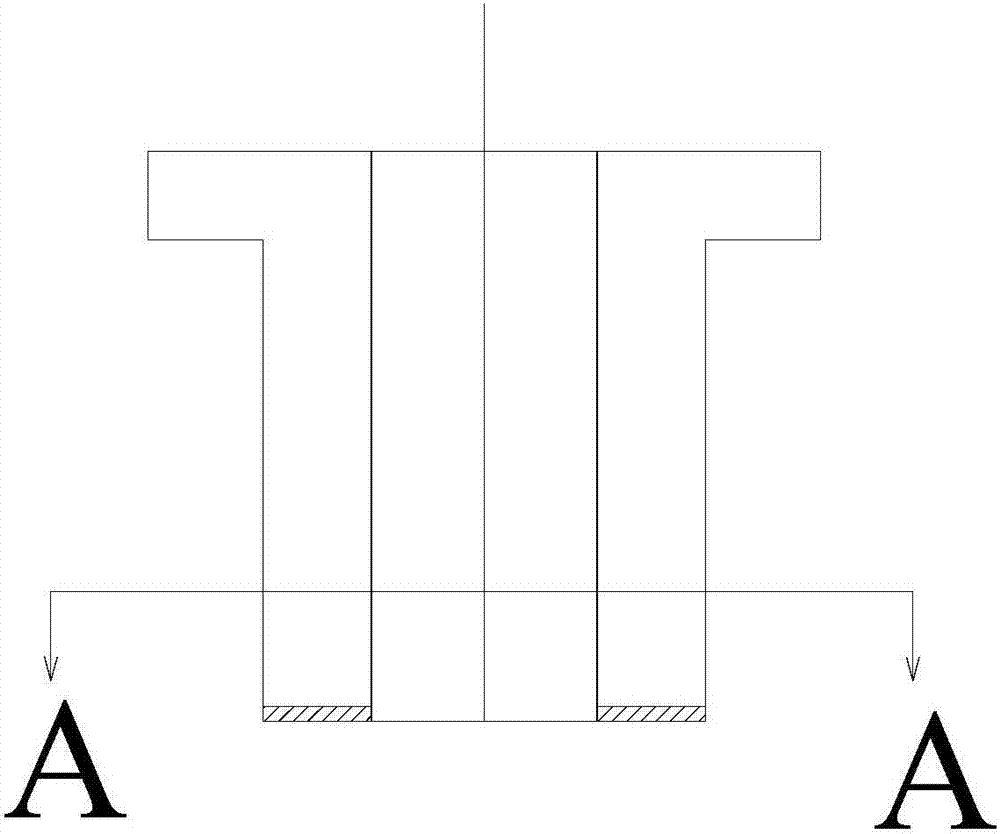

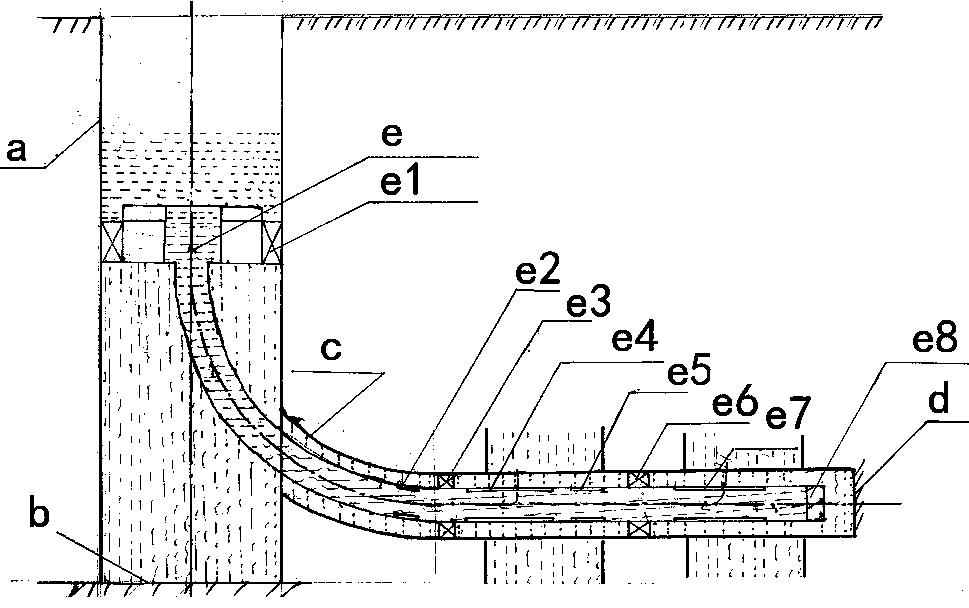

Method for retaining gob-side tunnel

InactiveCN102337904AAchieve miningTake advantage ofMining devicesUnderground chambersEngineeringStructural engineering

The invention discloses a method for retaining a gob-side tunnel, which overall arranges the retaining of the gob-side tunnel in a stope working face gateway tunneling period, and comprises the steps of: combining the stope working face gateway with the gob-side retained tunnel, namely the next section gateway, together to be served as one tunnel for tunneling; and constructing tunnel concrete pier columns between the stope working face gateway and the gob-side retained tunnel, wherein the tunnel concrete pier columns are served as support in the tunnel and also served as one part of the side support for the gob-side retained tunnel; namely comprising the steps of: widening the section of the tunnel by tunneling, reserving the tunnel section according to the shrinkage factor of the god-side retained tunnel suffering from two times of support pressure, and pouring the reinforcing steel bar concrete pier columns in middle of the transverse direction of the tunnel to match with a cable anchor for supporting. The tunnel concrete pier columns are arranged along the whole length of the tunnel at intervals, and used for dividing the tunnel into two parts. Insulating walls are constructed between two adjacent columns after the columns are constructed. When the stope is starting, the support is needed to be temporarily reinforced at two sides of the columns according to requirements along with the advancing of the stope working face. According to the method for retaining a gob-side tunnel, the retaining of the gob-side tunnel and the tunneling of the stope working face gateway are overall arranged, and the tunnel concrete pier column support is arranged; therefore, the side support intensity and support resistance of the retained tunnel are greatly enhanced, the influence of support pressure in two times of mining is effectively controlled. The method for retaining gob-side tunnel is particularly suitable for using in flexible mining faces of bottom plate and / or top plate.

Owner:贾民

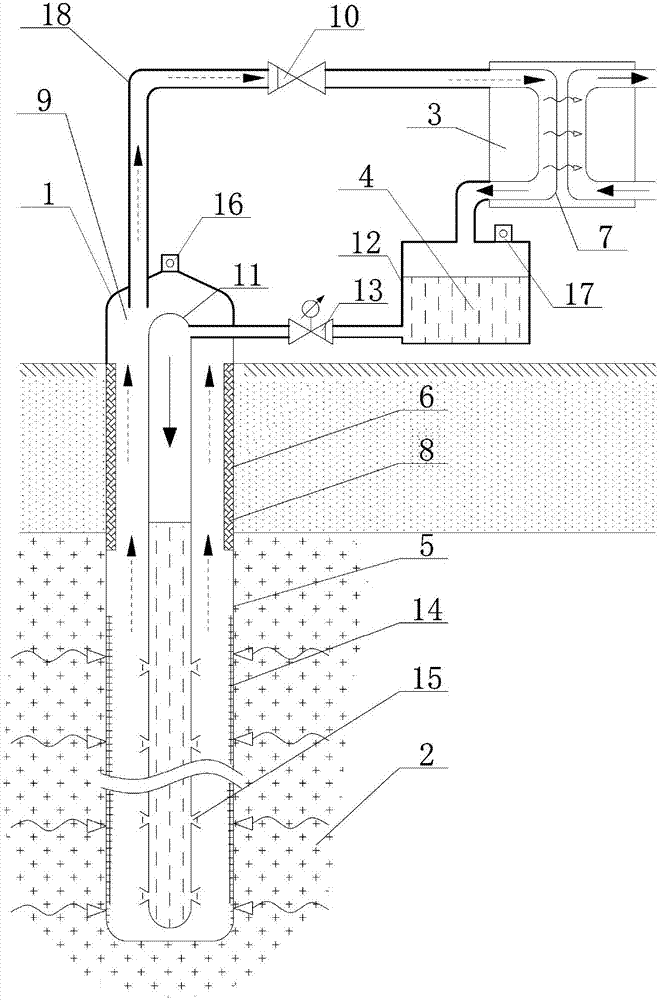

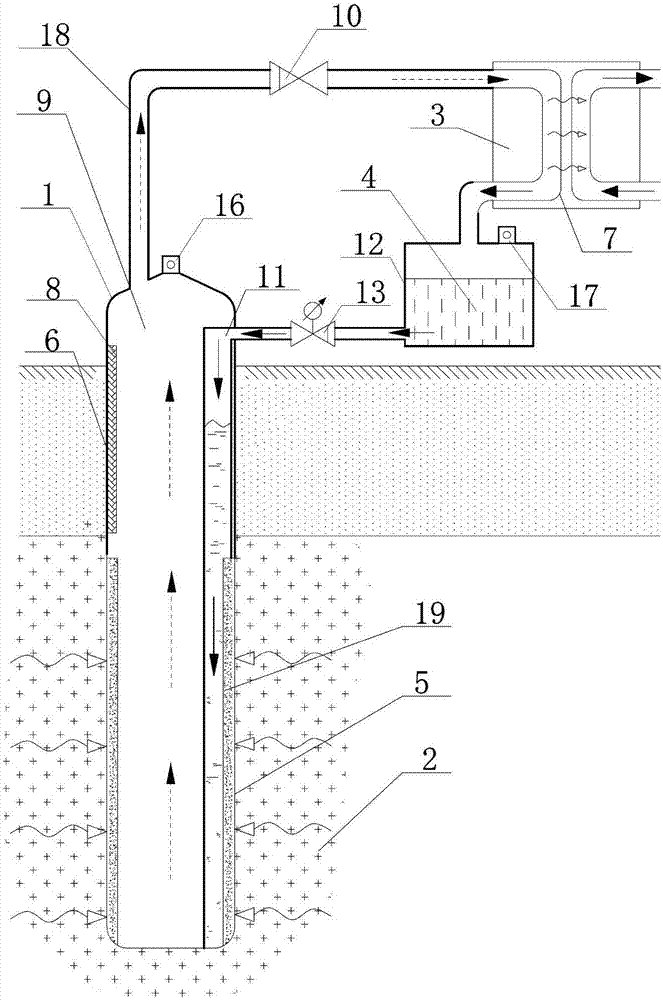

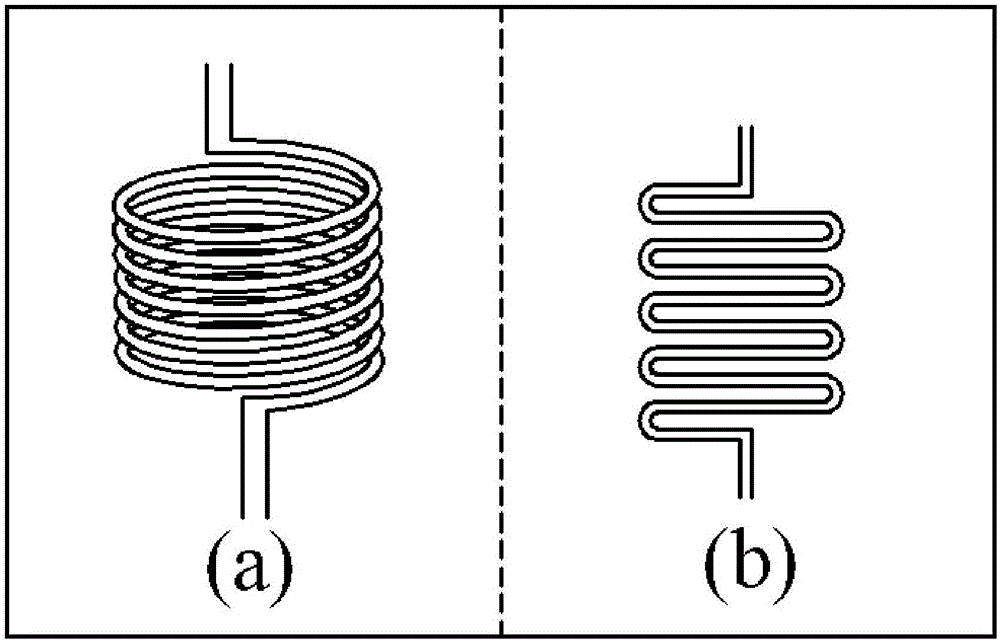

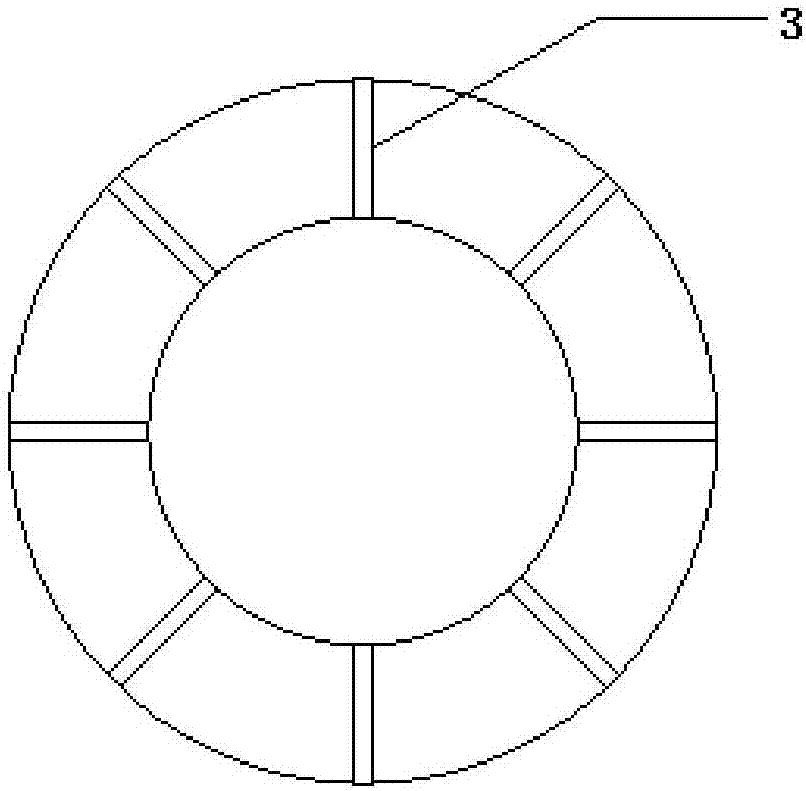

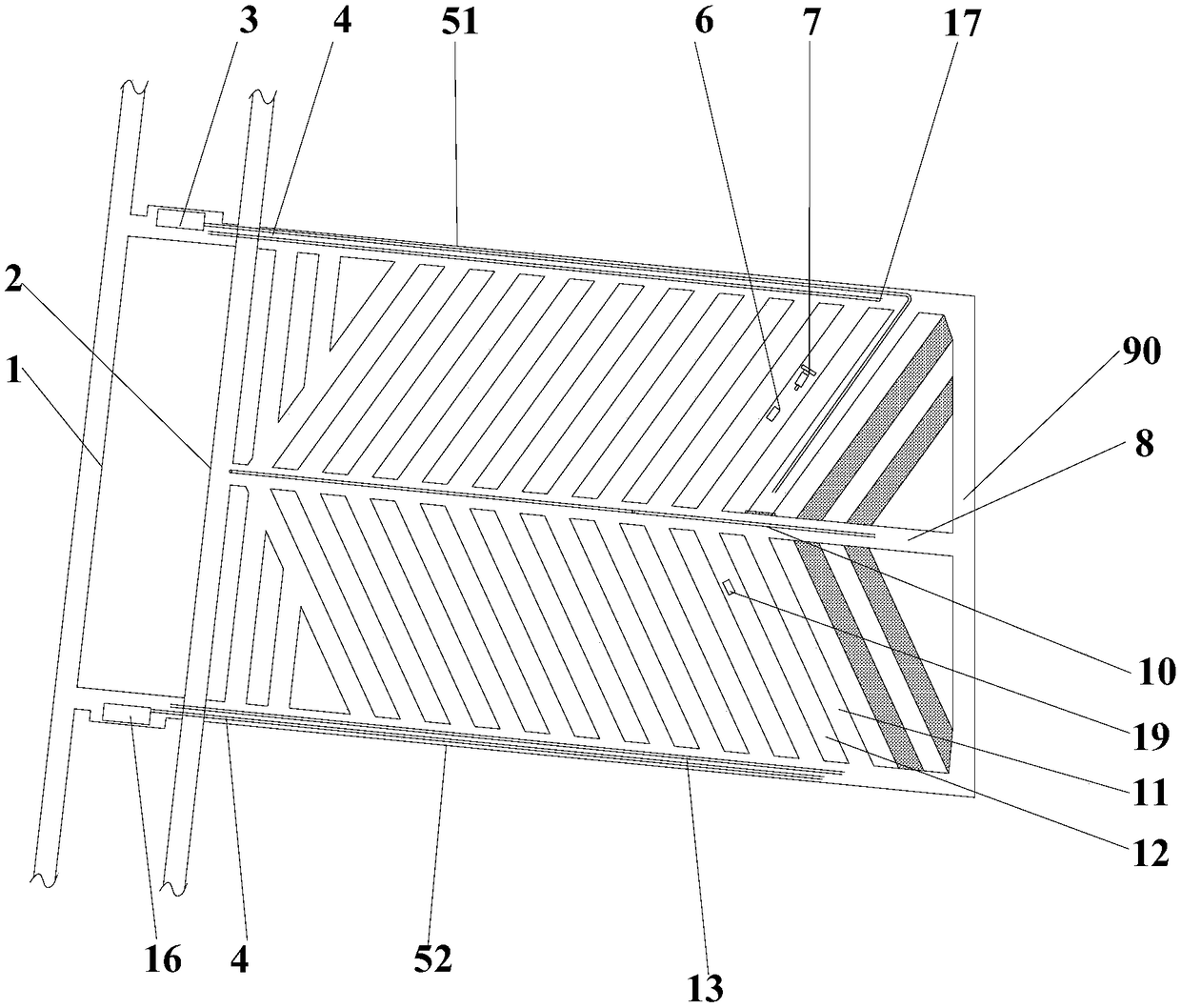

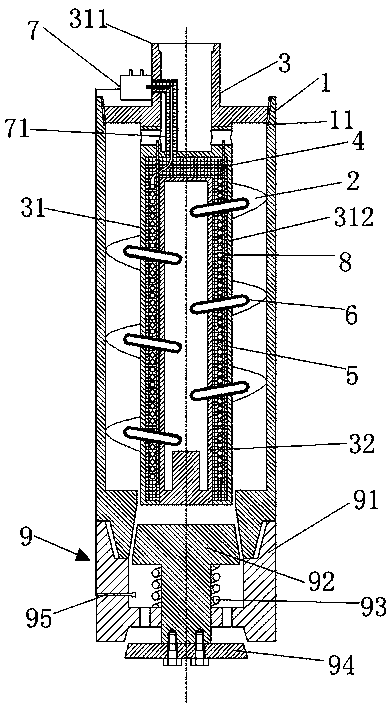

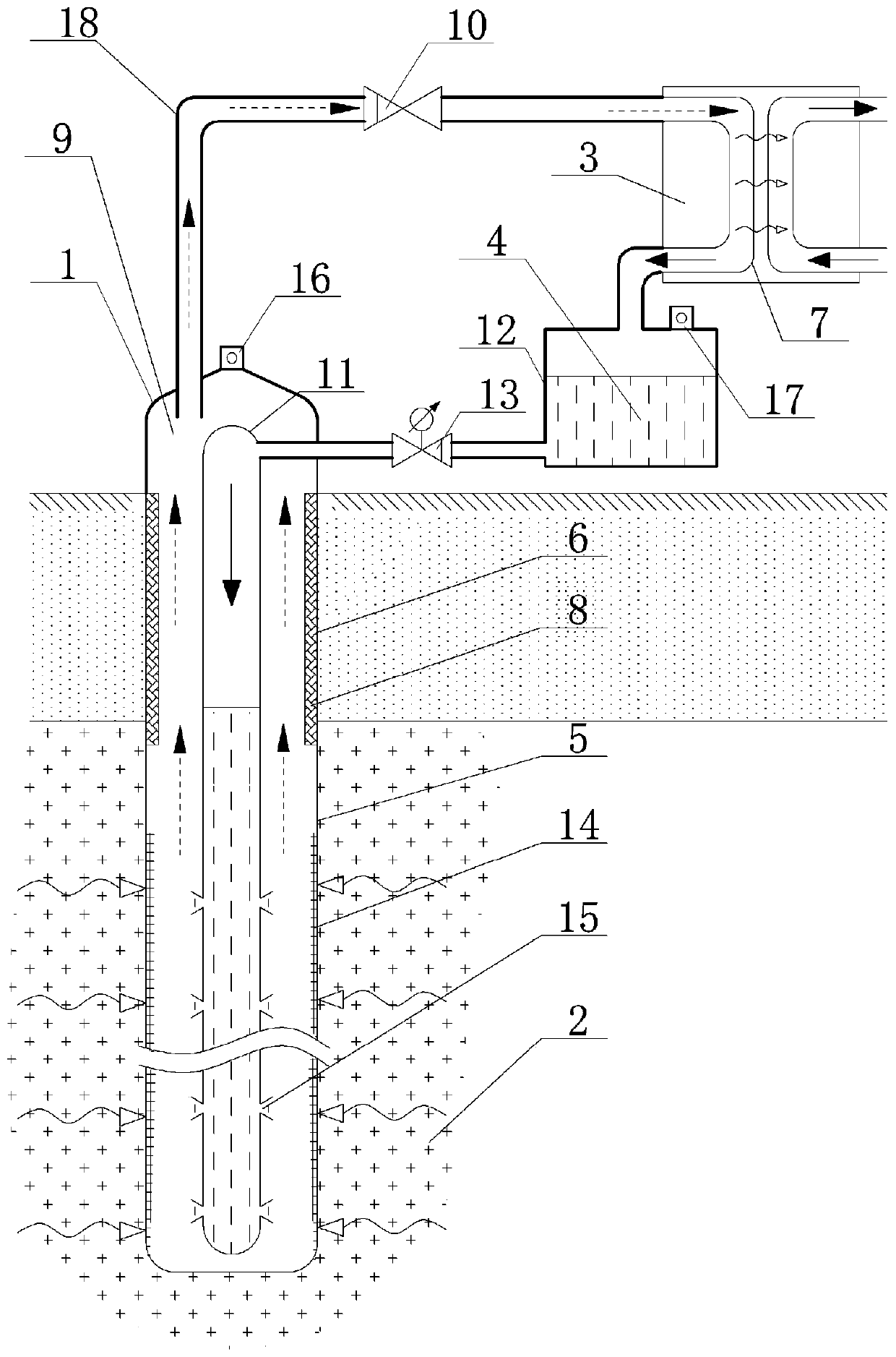

Loop heat pipe type terrestrial heat exploitation system with adjustable and controllable working medium circular flow

ActiveCN107144035AAchieve miningAvoid lostOther heat production devicesGeothermal energy generationEvaporationEngineering

The invention discloses a loop heat pipe type terrestrial heat exploitation system with adjustable and controllable working medium circular flow. The loop heat pipe type terrestrial heat exploitation system comprises a casing pipe type loop heat pipe, an earth surface heat exchanger and a liquid storage box. The earth surface heat exchanger and the liquid storage box are both located on the ground. The casing pipe type loop heat pipe comprises an evaporation section, a heat insulation section and a backflow section. The evaporation section is located in a high temperature heat reservoir. The earth surface heat exchanger is provided with a condensation section, and the condensation section and the outside carry out heat exchange. A one-way valve or a steam pump is arranged between the heat insulation section and the condensation section. A one-way throttle valve is arranged between the liquid storage box and the backflow section. The evaporation section, the heat insulation section, the condensation section, the liquid storage box and the backflow section are communicated in sequence end to end. Working medium fluid of the liquid storage box enters the evaporation section through the backflow section, and the liquid working medium fluid entering the evaporation section generates film boiling after absorbing heat. According to the loop heat pipe type terrestrial heat exploitation system, the working medium fluid of the liquid storage box passes through the backflow section, the liquid phase backflow mode and the boiling mode of the evaporation section are controlled, the effective filling factor of the terrestrial heat pipe can be adjusted in real time, and therefore terrestrial heat energy is stably and efficiently extracted.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

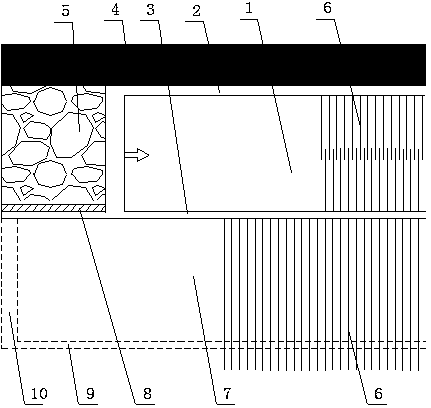

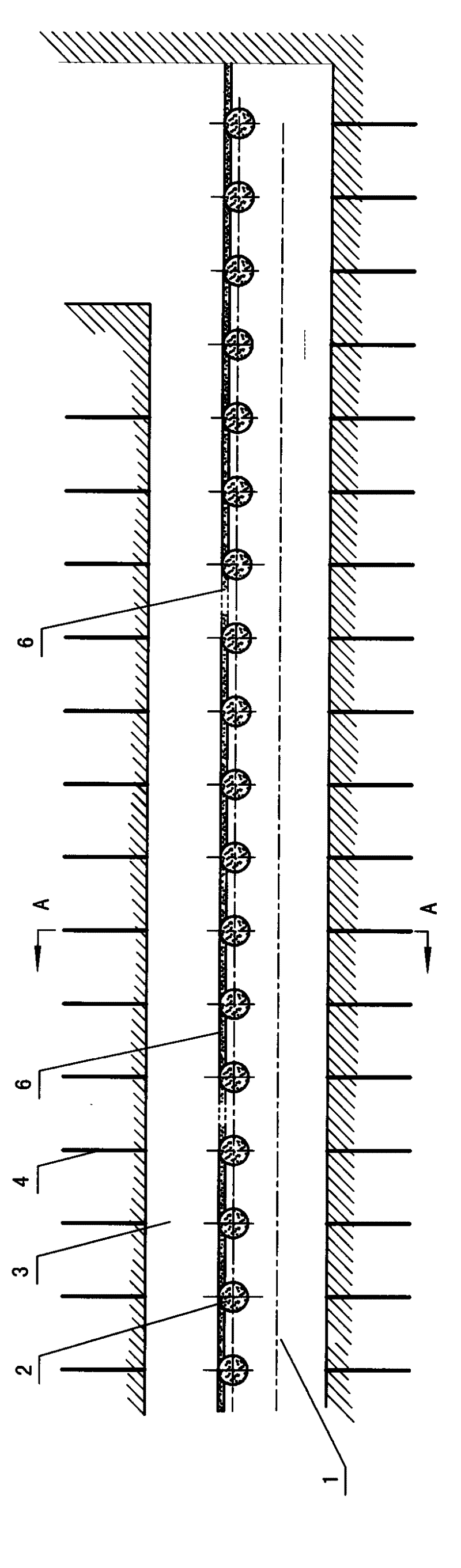

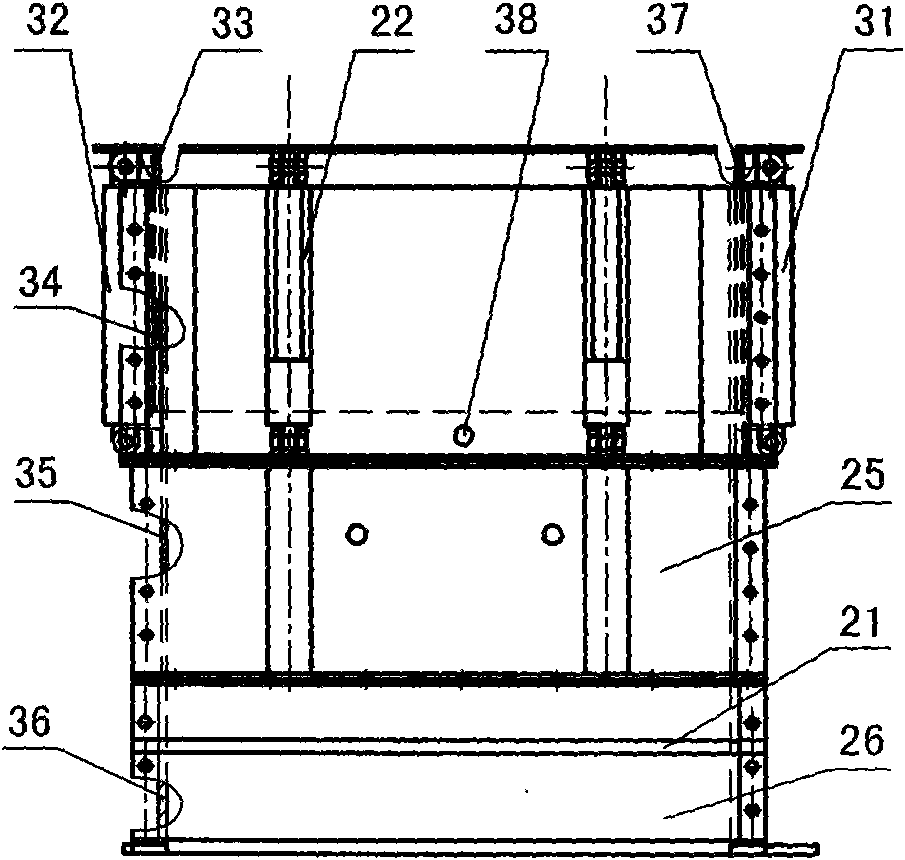

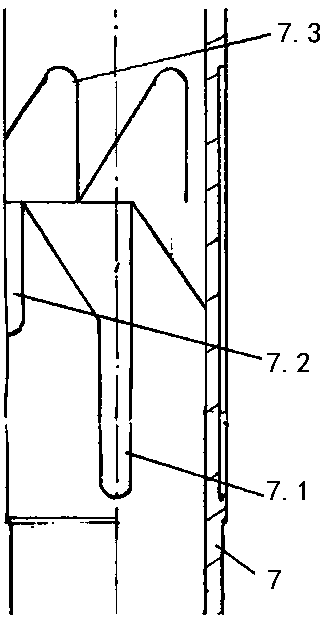

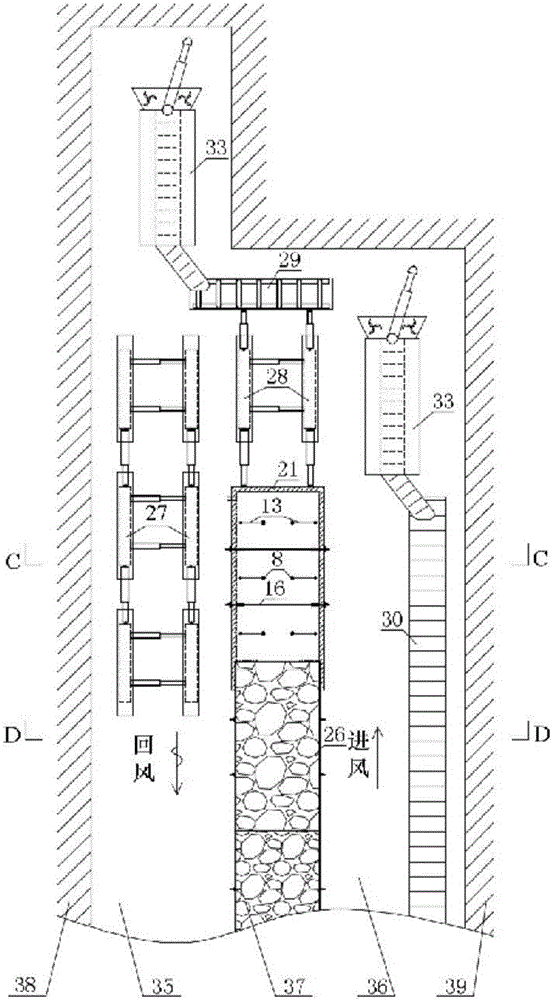

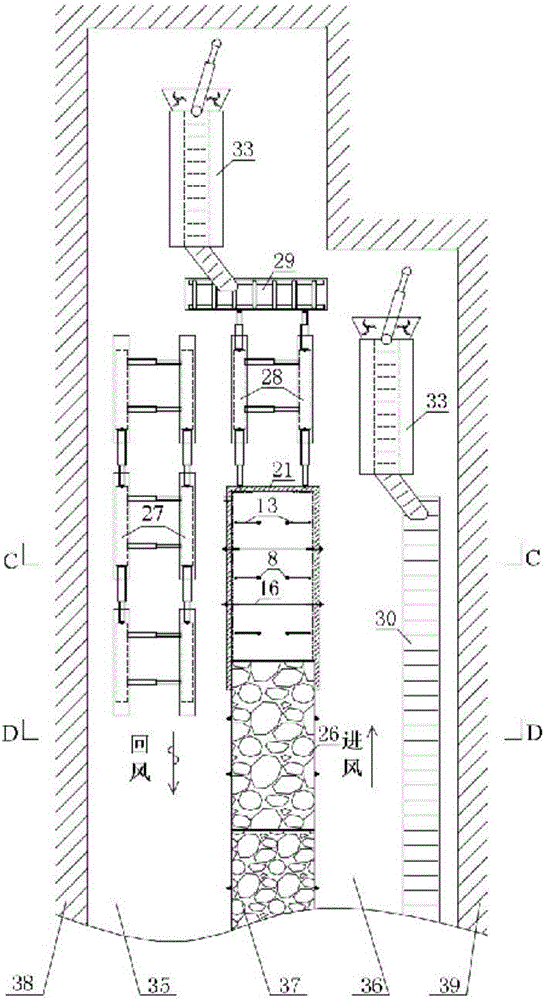

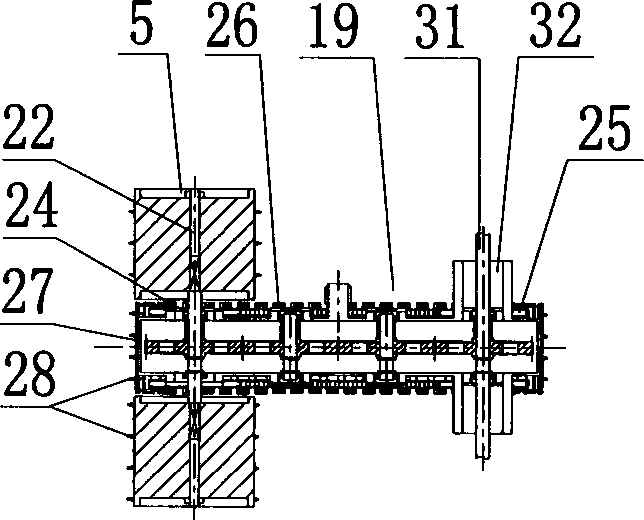

Gob-side road retaining supporting method and road-injecting slip mould

The invention relates to a gob-side road retaining supporting method of mining roadways of coal mines, comprising the following steps of: feeding a concrete to a filling mould by using a pump to pour along the lapse of a working surface on a gob side of the gob-side road retaining, and constructing a roadside backfilling wall 8; supporting top plates arranged above the backfilling wall 8 and outside the backfilling wall 8 by using an anchor cable and constructing in the front side of a leading support 1; adopting a height-adjustable integral pull-shift type road-injecting slip mould 6 by the backfilling mould; using blindage supports 3 and 5 on one side of the gob of the road-injecting slip mould to temporarily support; connecting the road-injecting slip mould and the blindage supports with the leading support 1 through a pull-shift jack to shift; and enabling the blindage supports, the roadside backfilling wall and the top surfaces of each leading support supported by the external anchor cable to be provided with grooves for protecting anchor cables of anchor rods. Besides the advantages of digging less roads, realizing pillarless exploration, releasing the tension of mining drifting and the like, the invention also has the advantages that the height of the road-injecting slip mould is integrally regulated by means of integral pull-shift hydraulic, the road-injecting slip mould is convenient to use and the work efficiency is improved; the supporting of the anchor cable is matched with the supporting of the backfilling wall to effectively control a separation layer of an immediate roof, and the blindage supports and the leading support can protect the anchor cables and the anchor rods from being jacked broken so as to lose efficacy.

Owner:兖矿能源集团股份有限公司

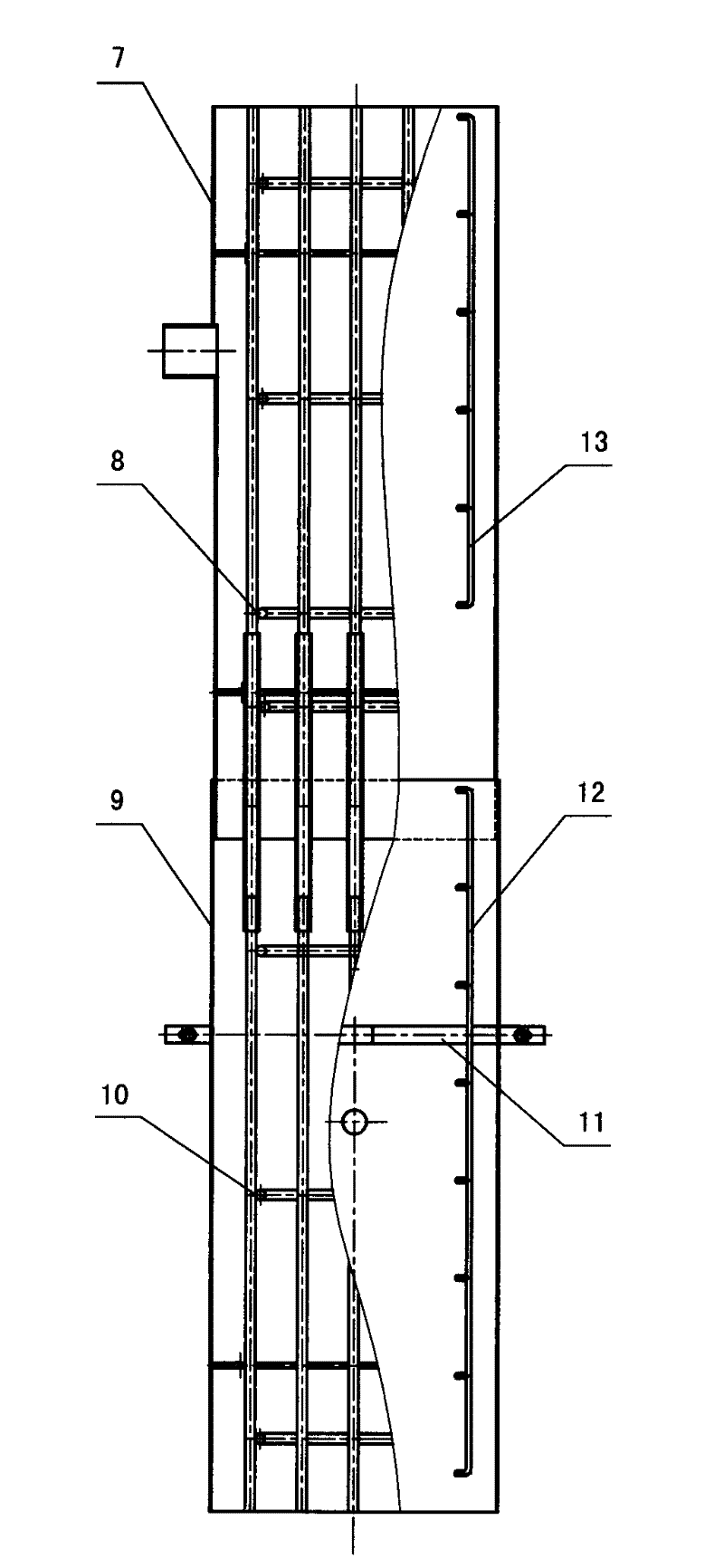

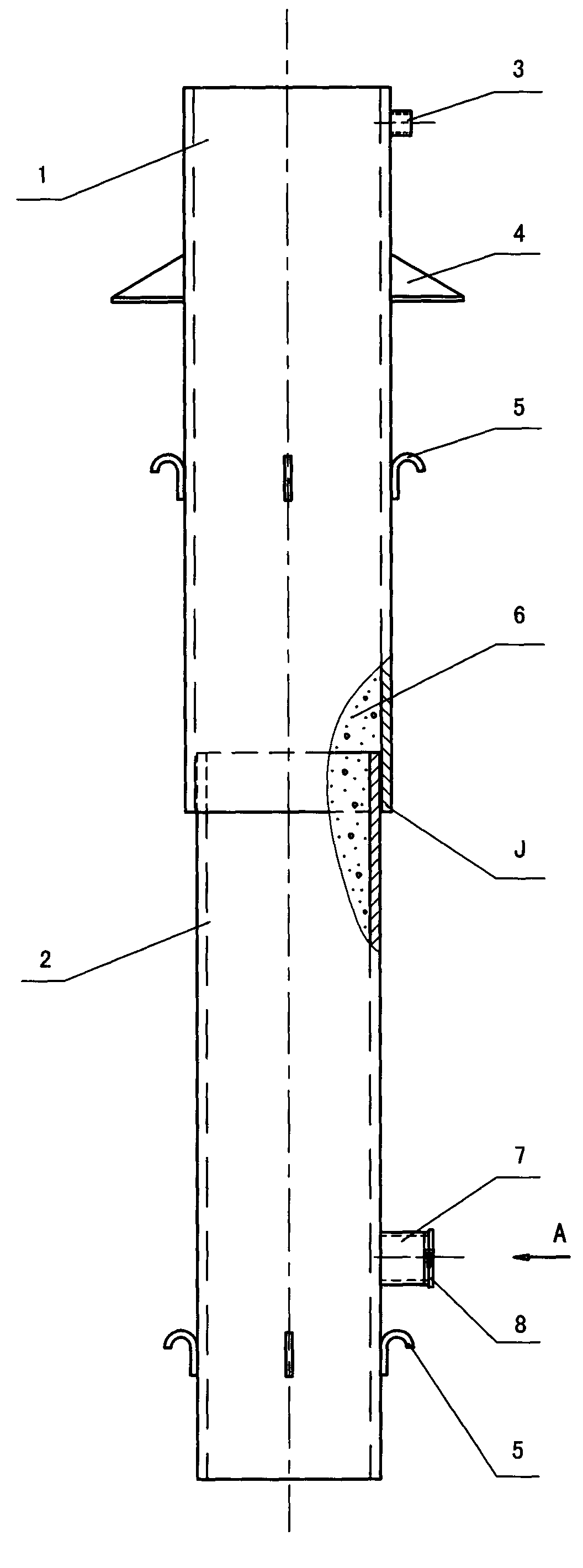

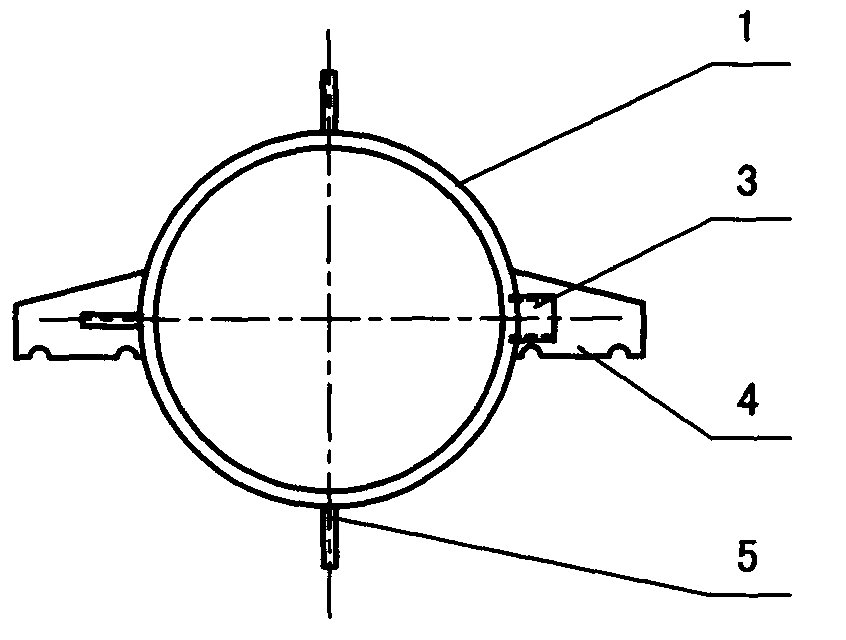

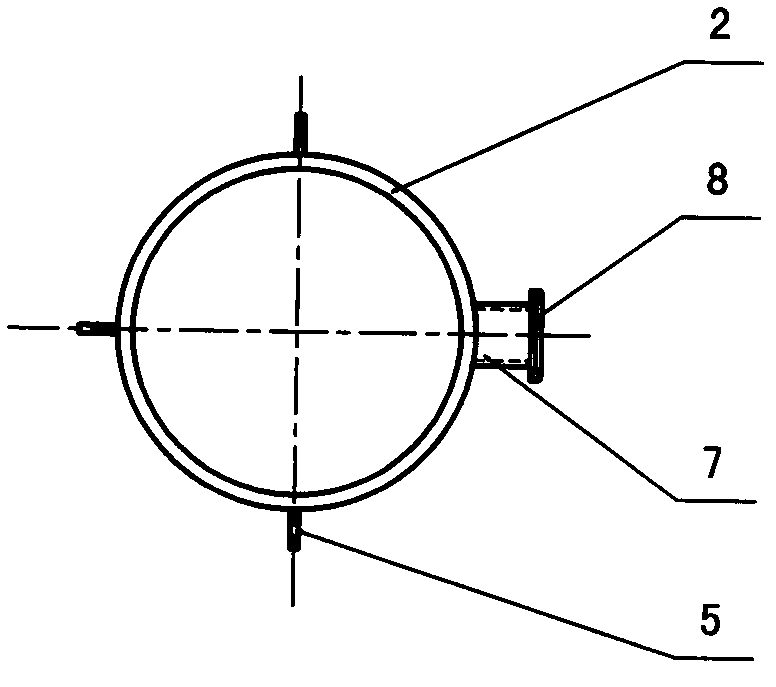

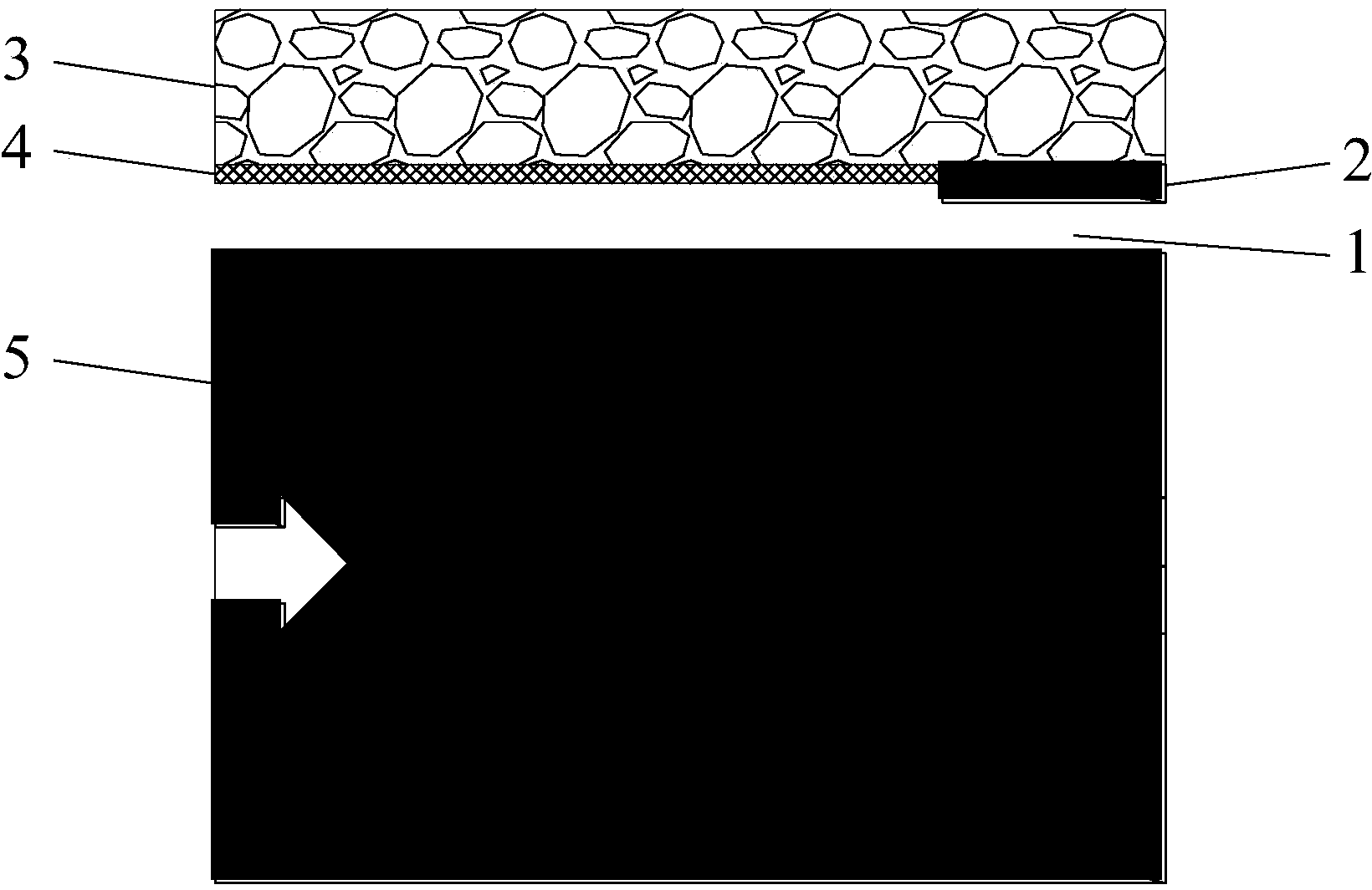

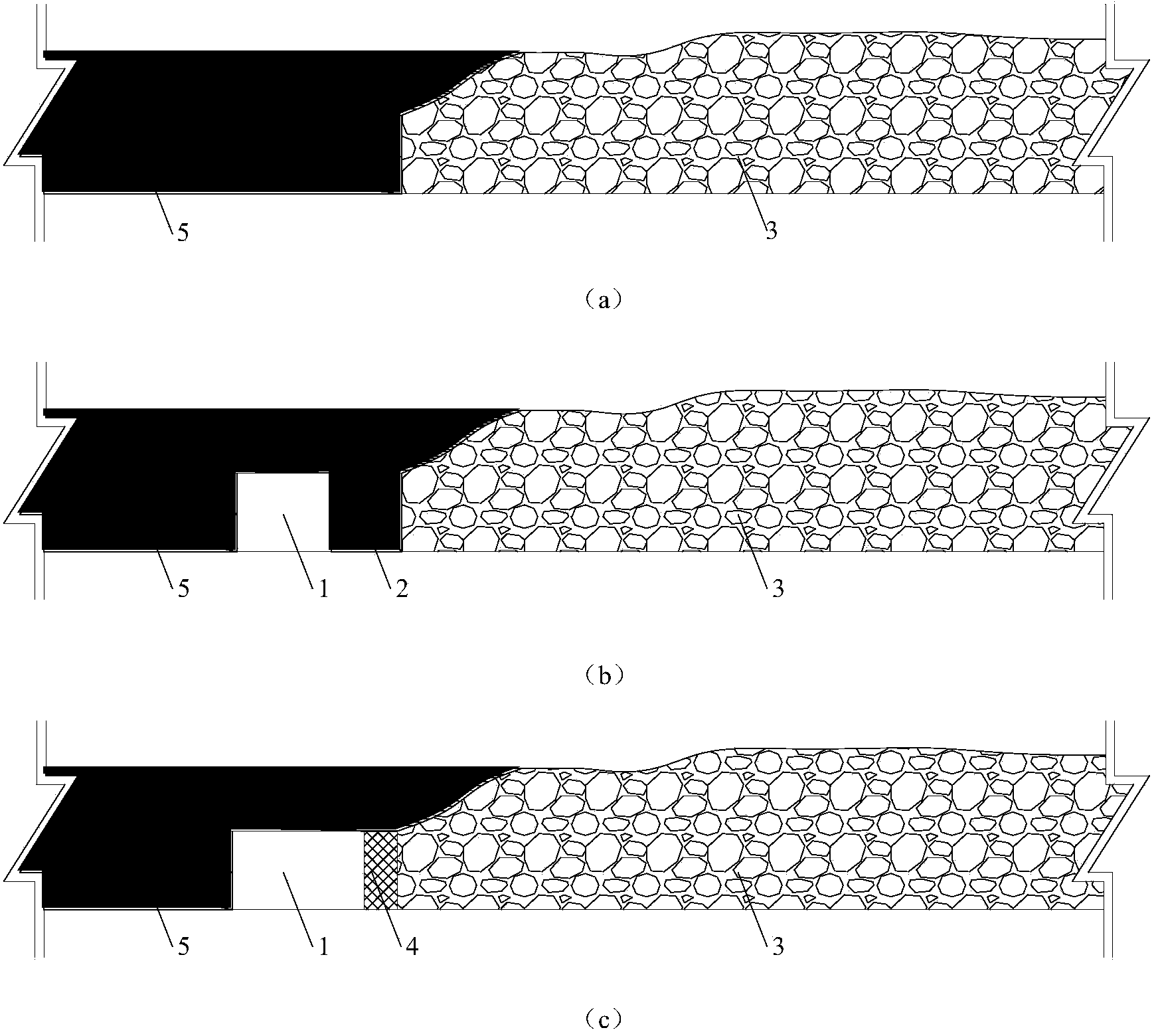

Mine recyclable steel cylinder packing pier column and construction method thereof and method for gob-side entry retaining

ActiveCN102493823AEasy constructionSimple structureProps/chocksProtective coversMaterials scienceSteel cylinder

The invention relates to a mine recyclable steel cylinder packing pier column and a construction method thereof and a method for gob-side entry retaining, which belong to the field of mine laneway support. The steel cylinder packing pier column is a steel cylinder sand and stone packing pier column and consists of a height-adjustable steel cylinder mould and sand and stone packing which is filled in the steel cylinder mould, wherein the sand and stone packing is bulk sand or / and stones which are filled compactly, and also can contain other particulate matters; a filling opening is formed on the top of the steel cylinder mould; a discharging outlet is formed and an openable end cover of the discharging outlet is arranged on the lower part of the steel cylinder mould; two sides of the upper part of the steel cylinder mould are provided with support bases; the pier column is added with water and filled and constructed by a concrete injector; and the steel cylinder mould is taken as an outer wall of the pier column after being filled. The invention also provides a method for recycling the steel cylinder mould of the pier column and a self-advancing pneumatic vibration device. The pier column has a novel and practical structure, is readily available in materials, high in construction efficiency and low in support cost, and is easy to construct; the steel cylinder mould can be recycled for saving steel; and the yielding property of the support of the pier column is greatly improved to ensure that the pier column can meet the requirement that the influence of two-time mining is tolerated by the gob-side entry retaining well and is particularly suitable for the gob-side entry retaining.

Owner:兖矿能源集团股份有限公司

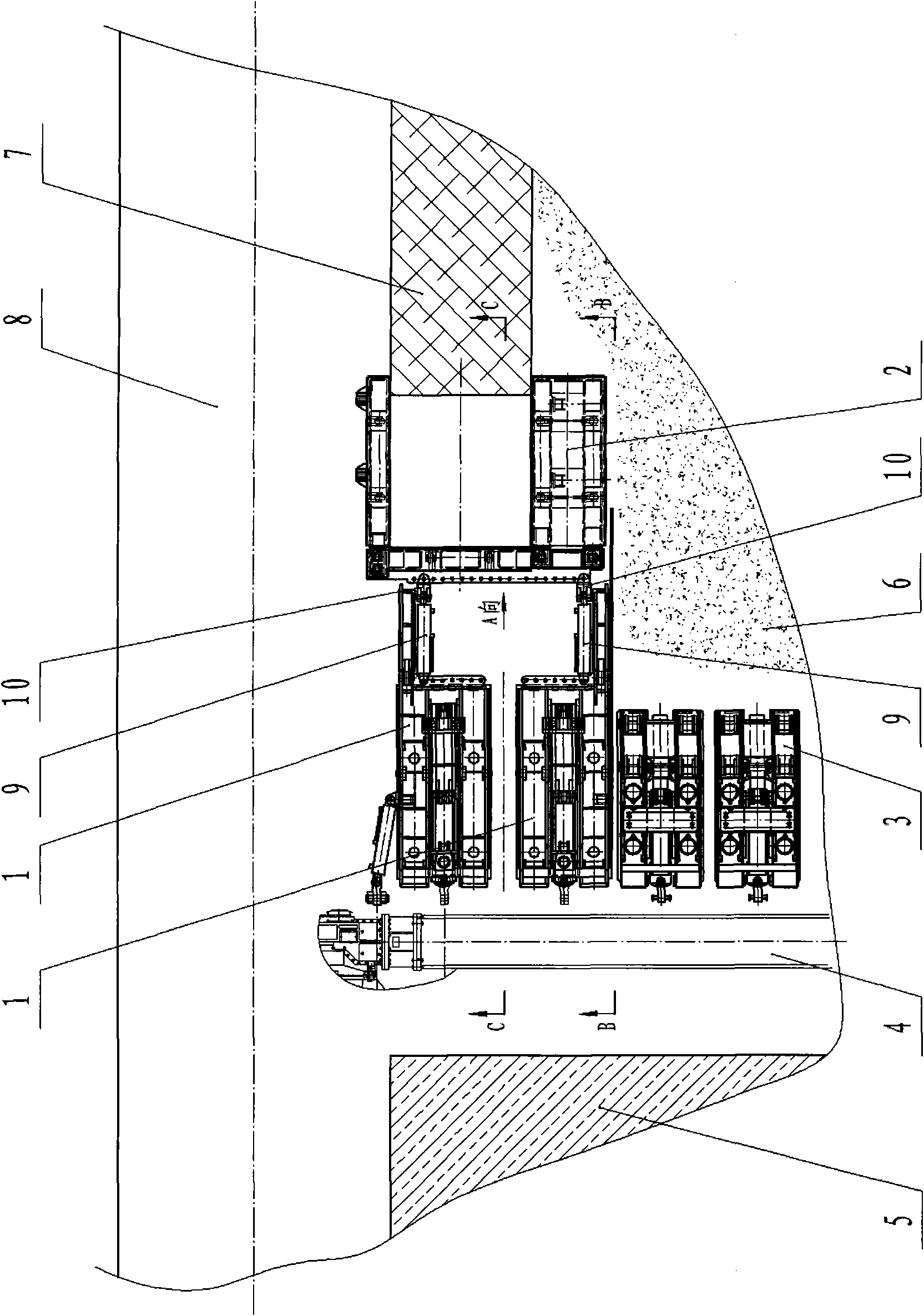

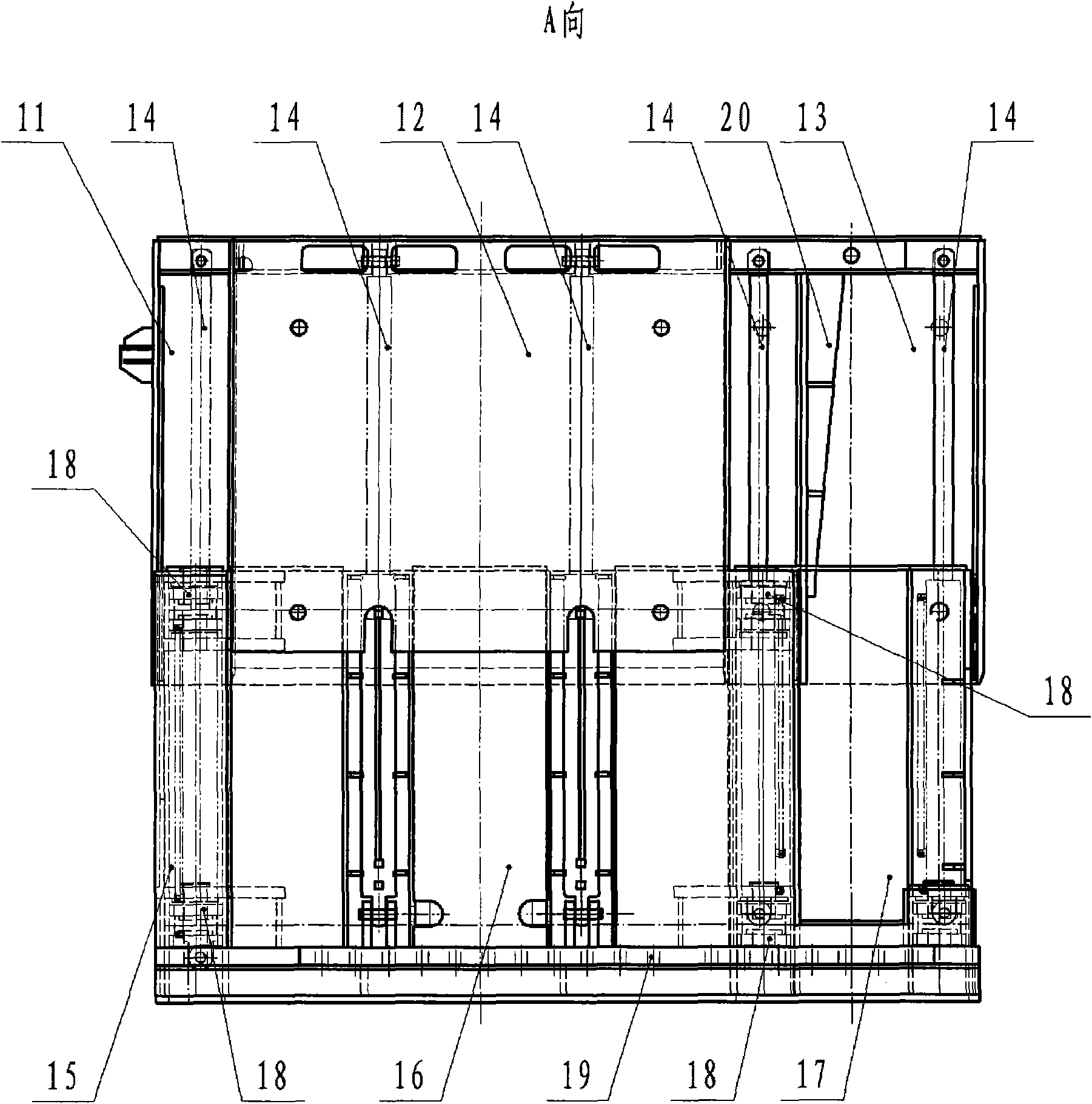

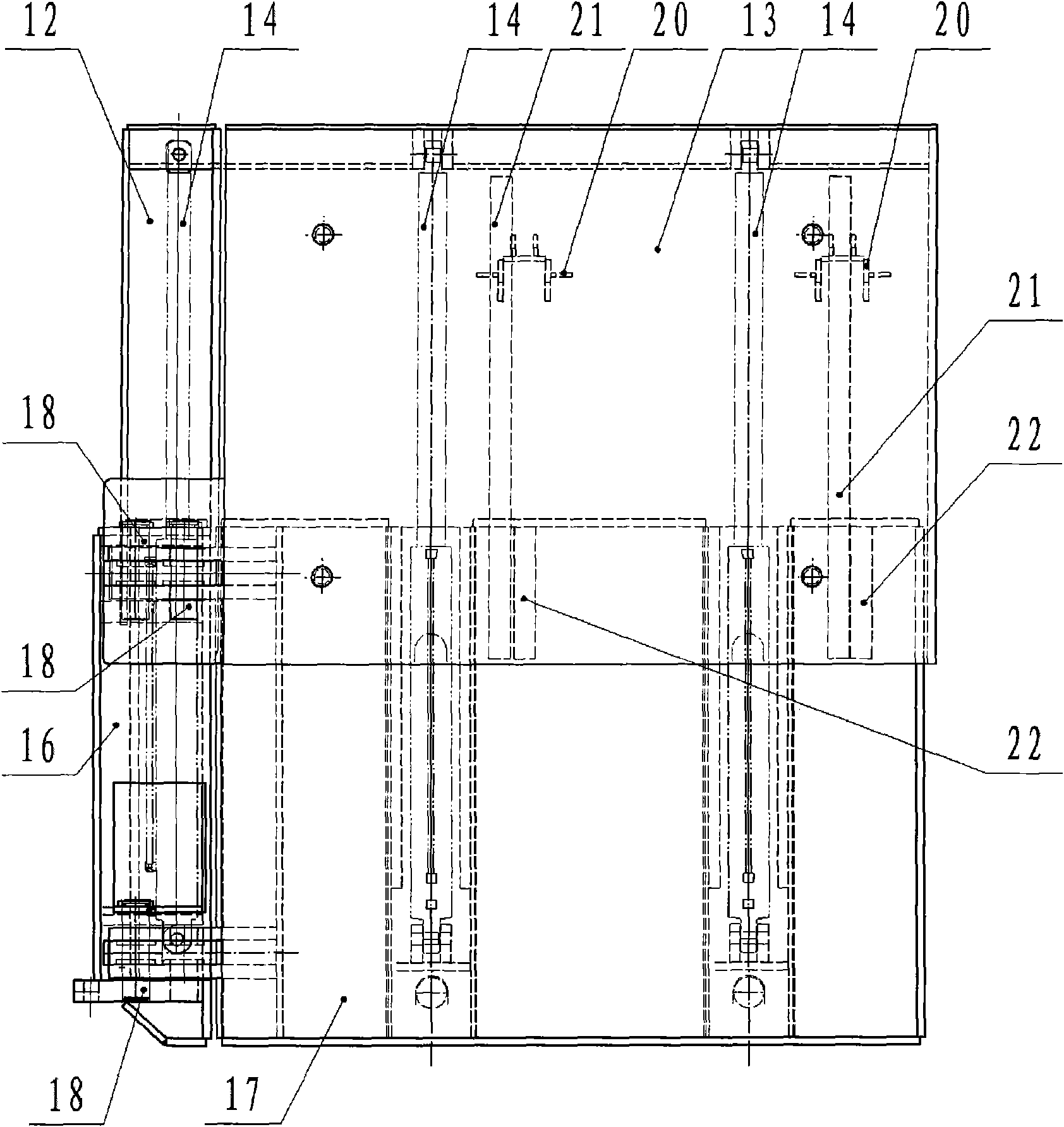

Gob-side entry retaining work mould base

ActiveCN101560883AAchieve miningReasonable structural designMaterial fill-upMine roof supportsHydraulic cylinderBand shape

The invention discloses a gob-side entry retaining work mould base, which effectively conquers the defect that template integrity is low in prior suspension equipment. The mould base comprises coal mining equipment, a baffle support frame and a filling mould box, wherein, the coal mining equipment is paved along work surface; the baffle support frame consists of a top beam and a bottom base, is connected with a four bar linkage mechanism and is supported by a hydraulic vertical column; and the filling mould box is arranged right ahead along a gob entry retaining filling wall body. The technical point is as follows: the bottom base of the baffle support frame is connected with the filling mould box by a hydraulic cylinder and a connecting head; the baffle support frame is provided with an upper baffle and a lower baffle by the rear part of one side of the gob; the tail end of the top beam is joggled with the end part of the rear top beam; and the bottom part of the top beam is joggled with the rear part of the bottom base by the hydraulic vertical column. The invention has reasonable design, safe and convenient operation, leads a mould setting device and a mould moving device not only to be internally independent but also to match with the coal mining equipment so as to carry out normal coal mining and roof support parallel job, obviously improves integrity and the degree of mechanization, and can form a strip-shaped regular wall body at the isolated gob near the entry.

Owner:SHENYANG TIAN AN TECH CO LTD

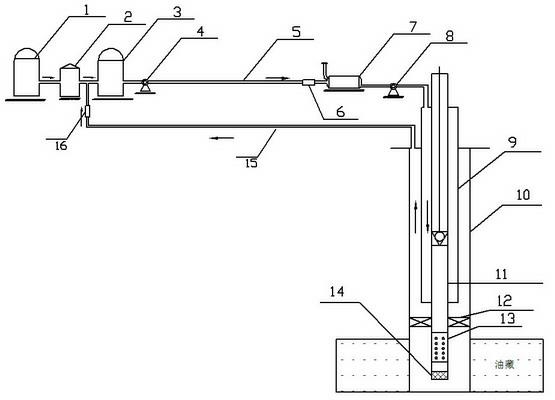

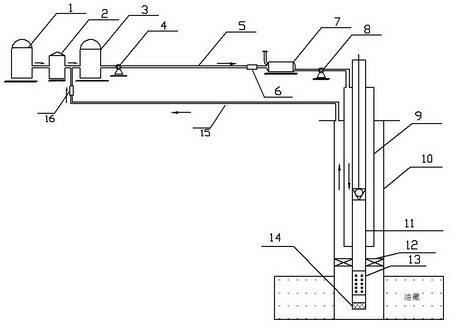

Hot water injection circulation viscosity reduction system for producing ultra-deep ultra-heavy oil and application method thereof

The invention relates to a hot water injection circulation viscosity reduction system for producing ultra-deep ultra-heavy oil and an application method thereof, belonging to the field of viscosity reduction production of heavy oil in an oilfield. The hot water injection circulation viscosity reduction system comprises a ground circulation system and an underground circulation viscosity reduction system, wherein the ground circulation system is formed by sequentially connecting a clear water tank, a water softening device, a softened water tank, a water supply pump, a magnetization device, a water jacket furnace and a water injection pump, which are arranged on a circulating injection pipeline, as well as a pressure relief valve on a circulating outflow pipeline; and the underground circulation system adopts a liquid injection and outflow pipeline constituted by a heat insulation oil pipe annulus, a sleeve annulus and a packer, as well as an inner-layer oil pipe, the packer, a sieve pipe and a screw plug to constitute an oil production pipeline. The hot water injection circulation viscosity reduction system according to the invention can reduce the viscosity of heavy oil, be conductive to production of the ultra-deep ultra-heavy oil and solve the problems of low effective pump efficiency, short pump inspection period of high energy consumption in a viscosity reduction process by light oil blending, and further has the advantages of low oil production cost, easiness in popularization and application and the like.

Owner:SOUTHWEST PETROLEUM UNIV

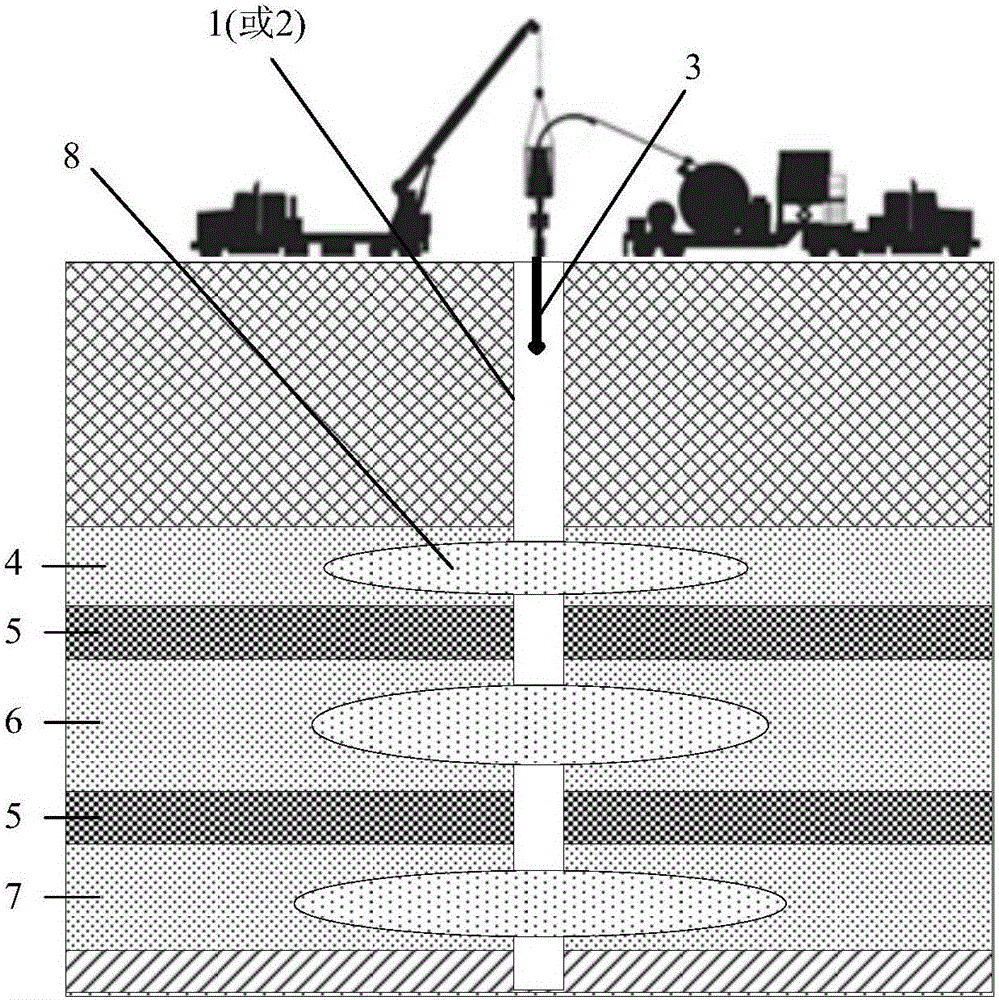

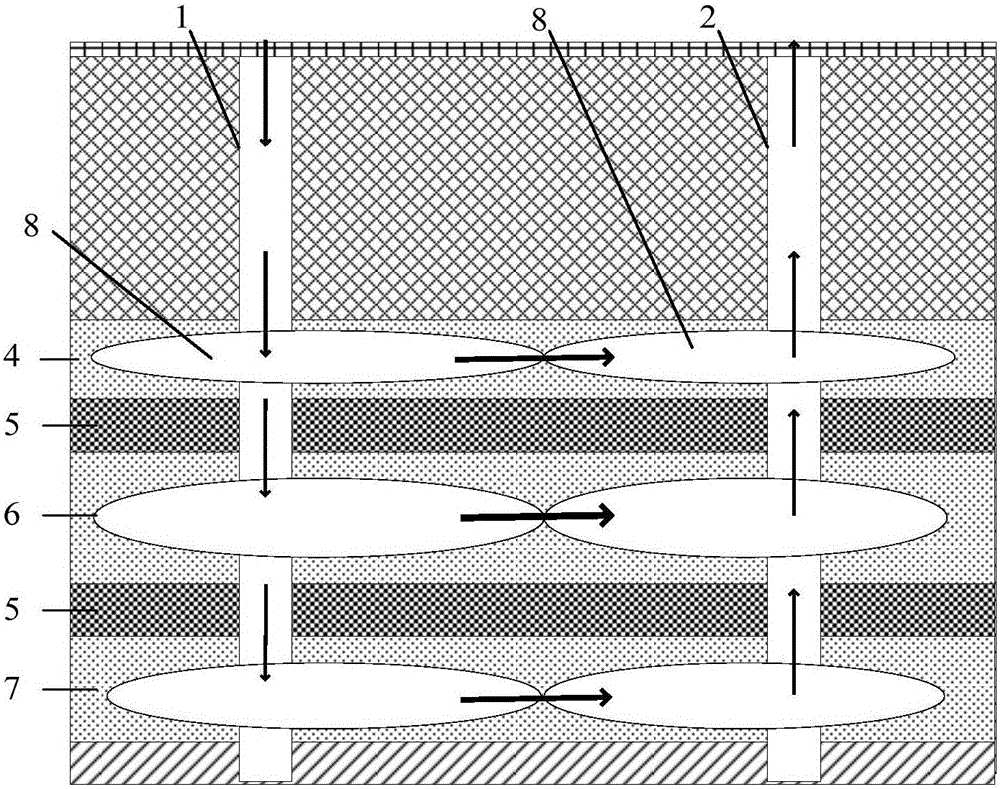

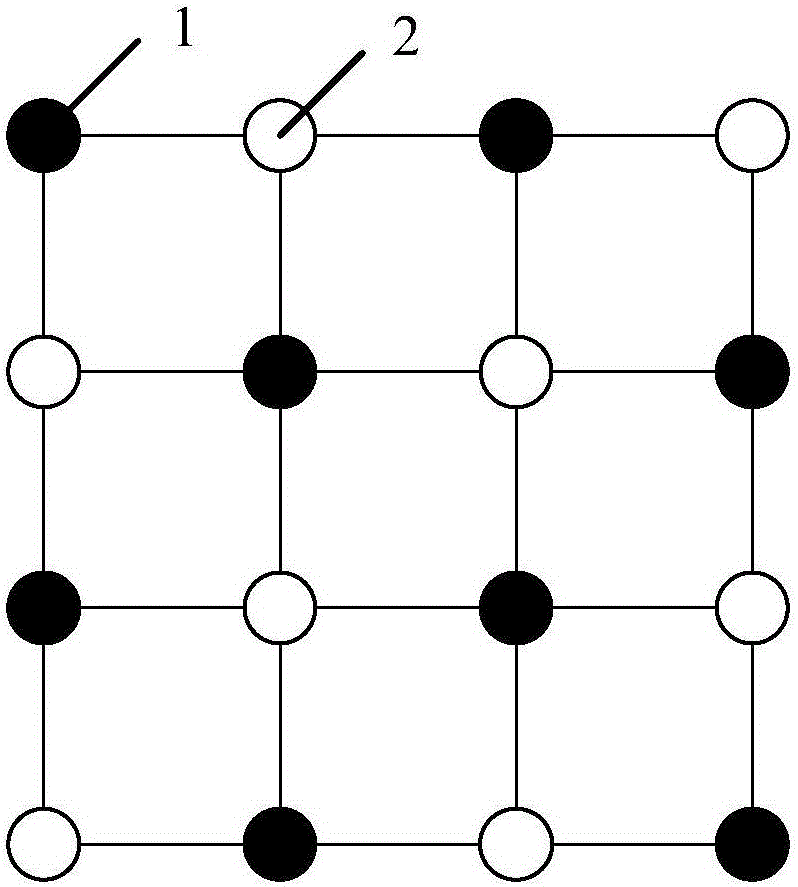

Method for mining thin inter bed oil shale

The invention relates to a method for mining thin inter bed oil shale. The method comprises the steps that first, a first well completion shaft and a second well completion shaft are arranged downwards from the ground surface of the distribution area of the oil shale, and the first well completion shaft and the second well completion shaft both penetrate through a same oil shale layer; second, an artificial fracturing method is adopted, a crack communicating the first well completion shaft and the second well completion shaft is formed in the oil shale layer; and third, water vapor is injected into the first well completion shaft, and oil gas is collected from the second well completion shaft. The water vapor is injected into the first well completion shaft, and enters the crack. The water vapor brings heat into the oil shale layer. When the oil shale layer is heated, and the temperature of the oil shale layer reaches the pyrolysis temperature of kerogen, the kerogen in the oil shale layer is pyrolyzed. The oil gas enters the second well completion shaft and is mined from the second well completion shaft. The heat content of the water vapor is large, stratums are quickly heated when being heated by the water vapor, and the method is environmentally friendlier.

Owner:CHINA PETROLEUM & CHEM CORP +1

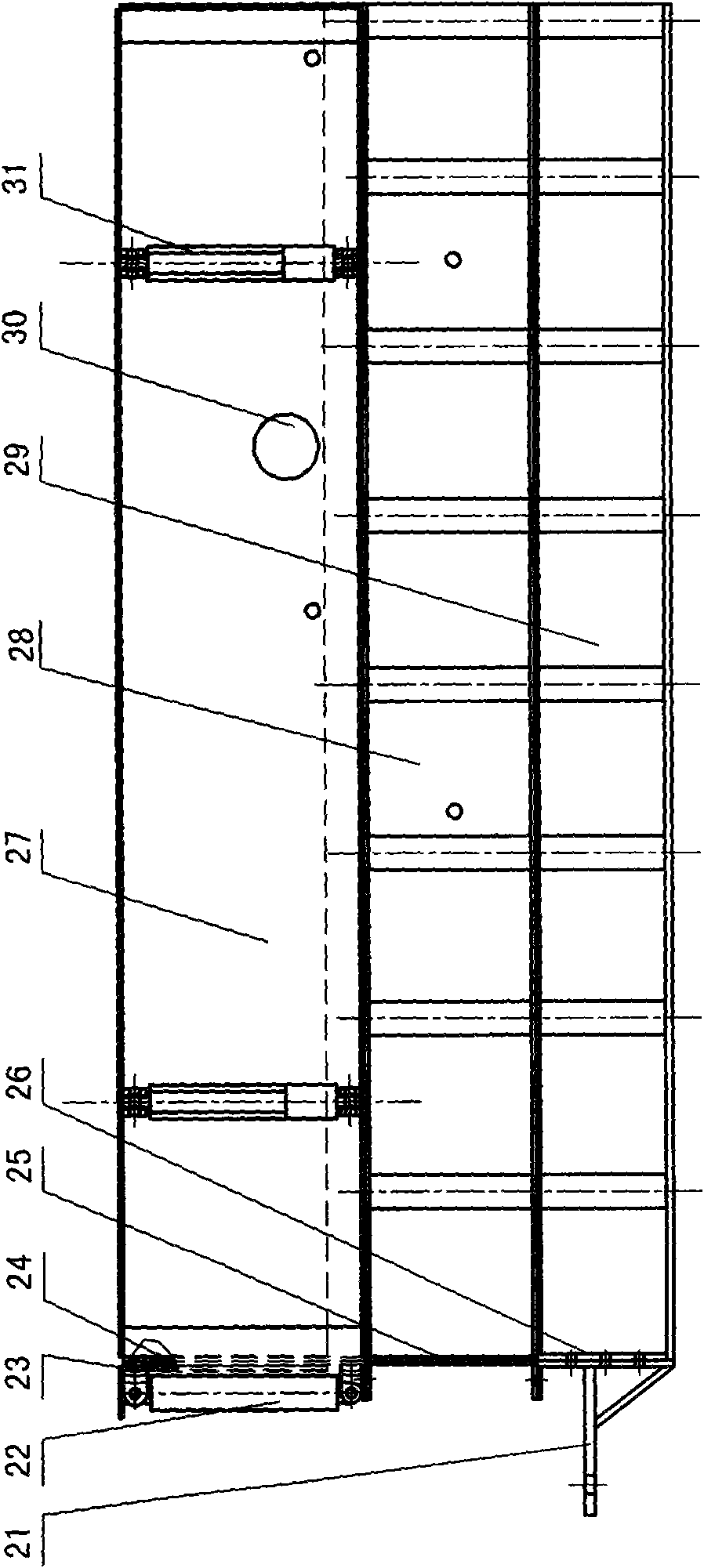

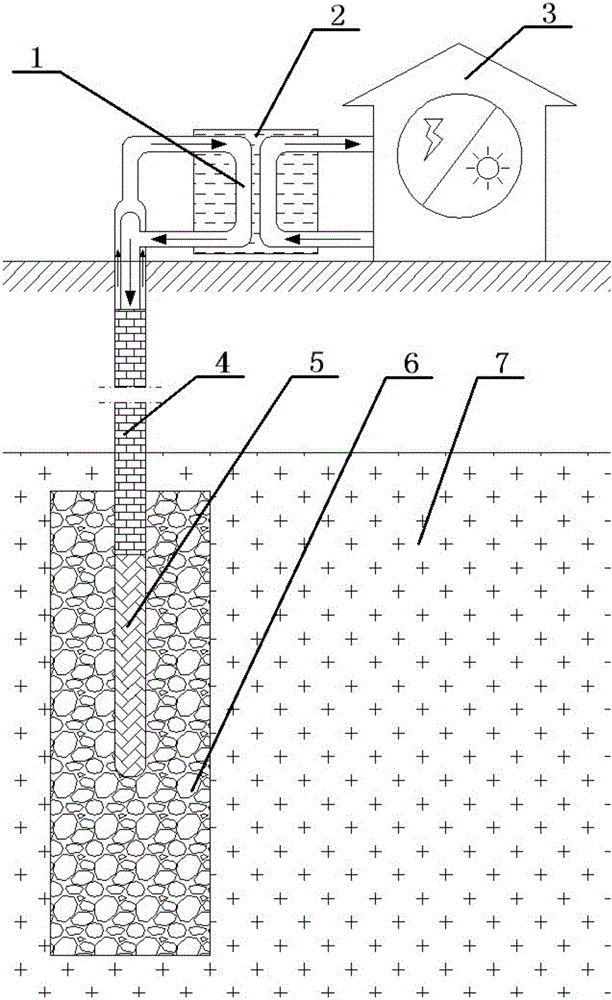

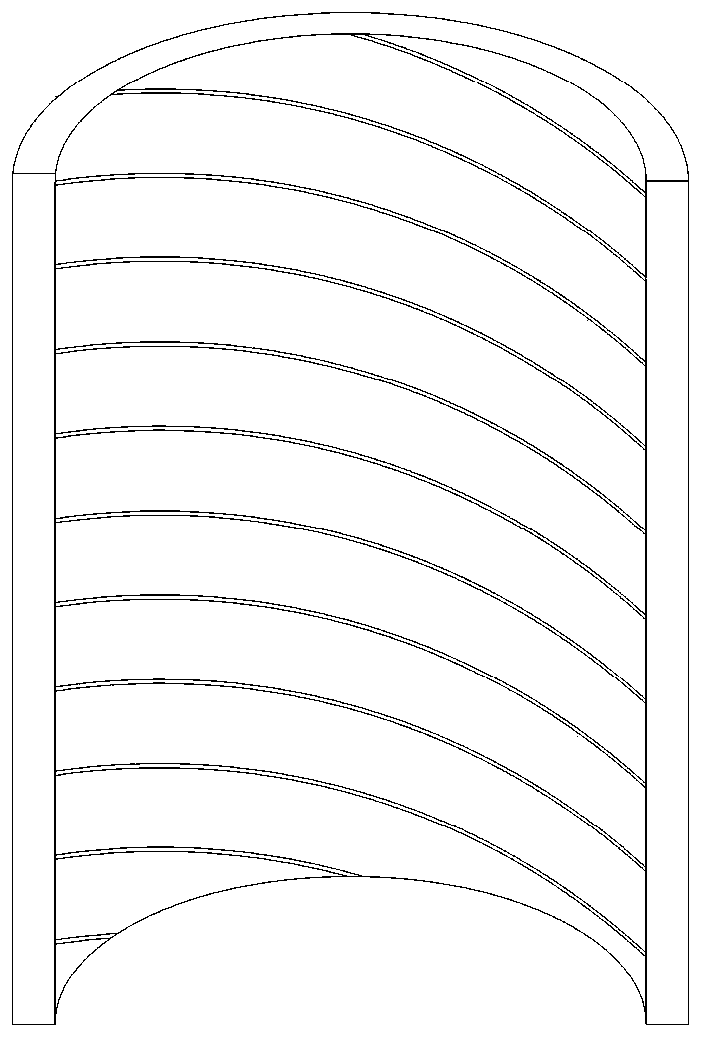

Stepped gravity heat pipe geothermal exploitation system without liquid accumulation effect

ActiveCN110030746AAchieve miningFully moistenedCollector components/accessoriesGeothermal energy generationLiquid storage tankHeat transfer efficiency

The invention provides a stepped gravity heat pipe geothermal exploitation system without a liquid accumulation effect. The system comprises a gravity heat pipe, a condenser and a liquid storage tank,wherein the gravity heat pipe comprises a liquid return pipe, an outer pipe and an inner pipe, the liquid return pipe is located in a gap between the outer pipe and the inner pipe and is connected with the liquid storage tank, the gap between the outer pipe and the inner pipe adopts a stepped separation structure, a liquid working medium sequentially flows into the separation sections of all stages from the liquid storage tank through the liquid return pipe, and passes through the pipe wall of the outer pipe to absorb heat from high-temperature rock and then is gasified, and after the liquidworking medium becomes a gaseous working medium, then the gaseous working medium enters the inner pipe again and flows into the condenser, and then flows into the liquid storage tank again for circulation after being subjected to heat release condensation. Compared with the prior art, the heat pipe heat absorption section is designed to be of the stepped separation structure, and the liquid levelof each separation section is limited to a certain height through corresponding liquid level control pipe; and the design can solve the problem that the working medium is difficult to evaporate due toexcessively high liquid level while the heat absorption section is fully wetted, so that the heat transfer efficiency when a super-long heat pipe is used for exploiting the geothermal energy is greatly improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

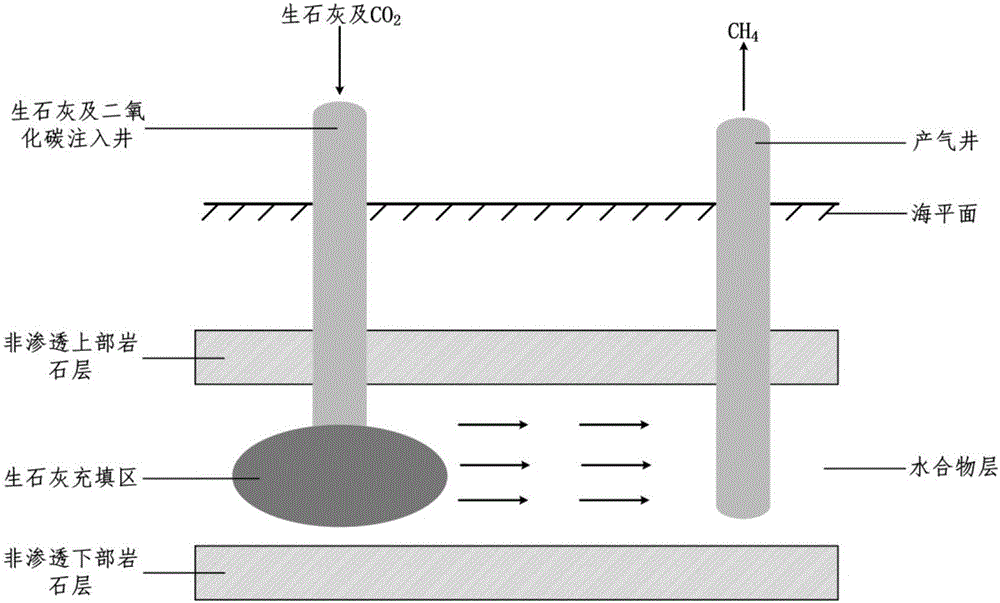

Method for jointly exploiting hydrates and hermetically storing carbon dioxide by aid of quicklime and carbon dioxide injection processes

ActiveCN106437653AIncrease temperatureBreak phase balanceGas treatmentMethane captureGreenhouseInstability

The invention provides a method for jointly exploiting hydrates and hermetically storing carbon dioxide by the aid of quicklime and carbon dioxide injection processes. The method includes selecting hydrate occurrence regions as target regions and drilling quicklime and carbon dioxide injection wells and gas production wells; injecting quicklime into hydrate layers from the quicklime and carbon dioxide injection wells to form quicklime filling regions; completely carrying out reaction on the quicklime and water in the hydrate layers and then injecting the carbon dioxide from the quicklime and carbon dioxide injection wells; controlling outlet pressures of the gas production wells to allow gas production pressures to be higher than carbon dioxide and hydrate phase-balance pressures corresponding to the temperatures of the hydrate layers and lower than methane and hydrate phase-balance pressures corresponding to the temperatures of the hydrate layers; collecting methane gas at well mouths of the gas production wells. The method has the advantages that the hydrates can be safely and efficiently exploited, environmental problems such as decrease of the strength of existing hydrate layers and instability of strata in natural gas hydrate exploitation procedures can be effectively solved, and the purposes of hermetically storing the carbon dioxide and abating greenhouse effects can be achieved.

Owner:DALIAN UNIV OF TECH

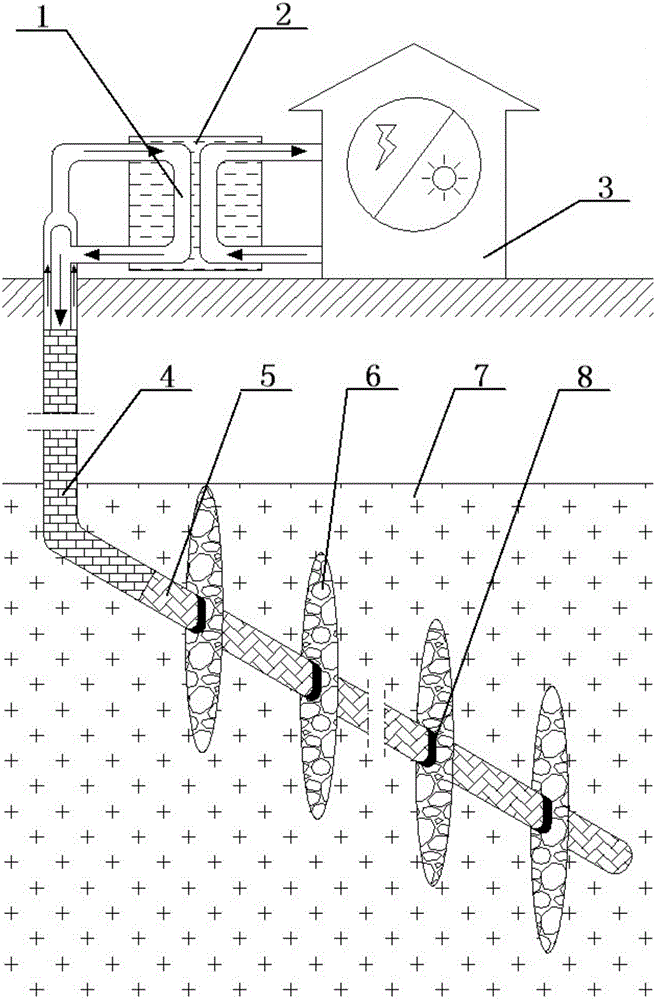

System for efficiently exploiting geothermal energy in dry-hot rock by means of heat pipe

The invention discloses a system for efficiently exploiting geothermal energy in dry-hot rock by means of a heat pipe. The system comprises the geothermal heat pipe, hypertonicity geothermal reservoirs formed in a high-temperature dry-hot rock target area and filled with fluid working mediums, and a heat exchanger and a heat utilization device which are located on the ground. The geothermal heat pipe is provided with heat pipe condensation sections, a heat pipe heat insulation section and a heat pipe evaporation section, wherein the heat pipe condensation sections, the heat pipe heat insulation section and the heat pipe evaporation section communicate sequentially. The heat pipe evaporation section penetrates through the hypertonicity geothermal reservoirs, the heat pipe condensation sections and the heat utilization device conduct heat exchanging through the heat exchanger. According to the system for efficiently exploiting the geothermal energy in the dry-hot rock by means of the heat pipe, the problem that the heat recovery rate of a conventional geothermal heat pipe heat recovery technology is too low is solved. The geothermal energy in the dry-hot rock is exploited through the geothermal heat pipe, and the heat evaporation section of the geothermal heat pipe is arranged in the geothermal reservoirs, by means of the thermal convection effect of the fluid working mediums in the geothermal reservoirs, the heat recovery quantity of the heat pipe is greatly increased, and the economy of the heat pipe mining dry-hot rock geothermal technology is improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

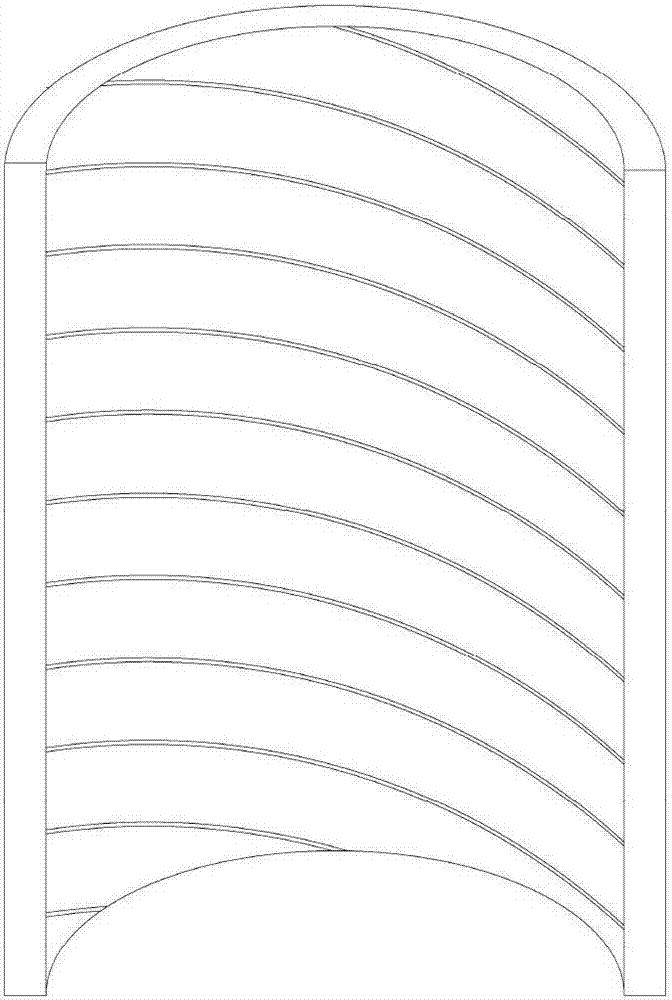

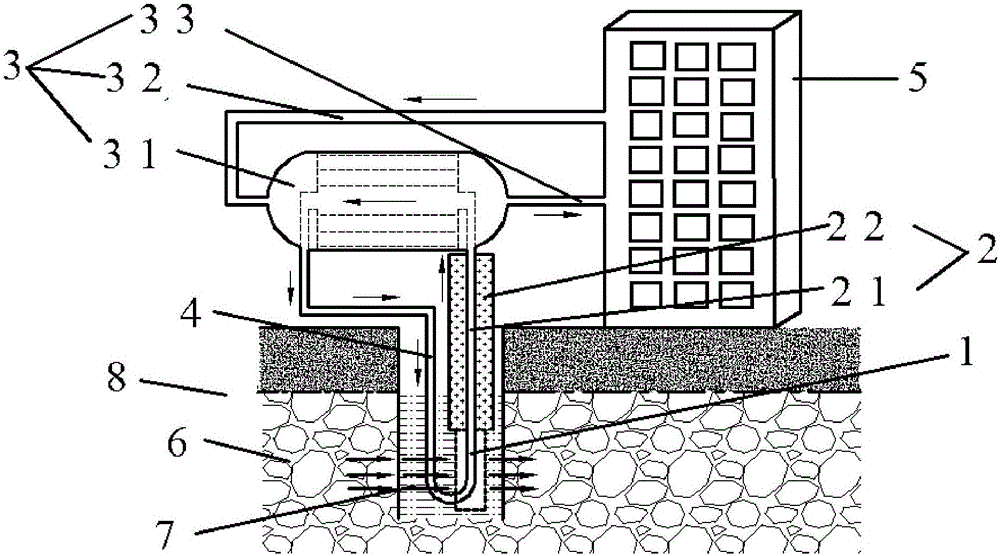

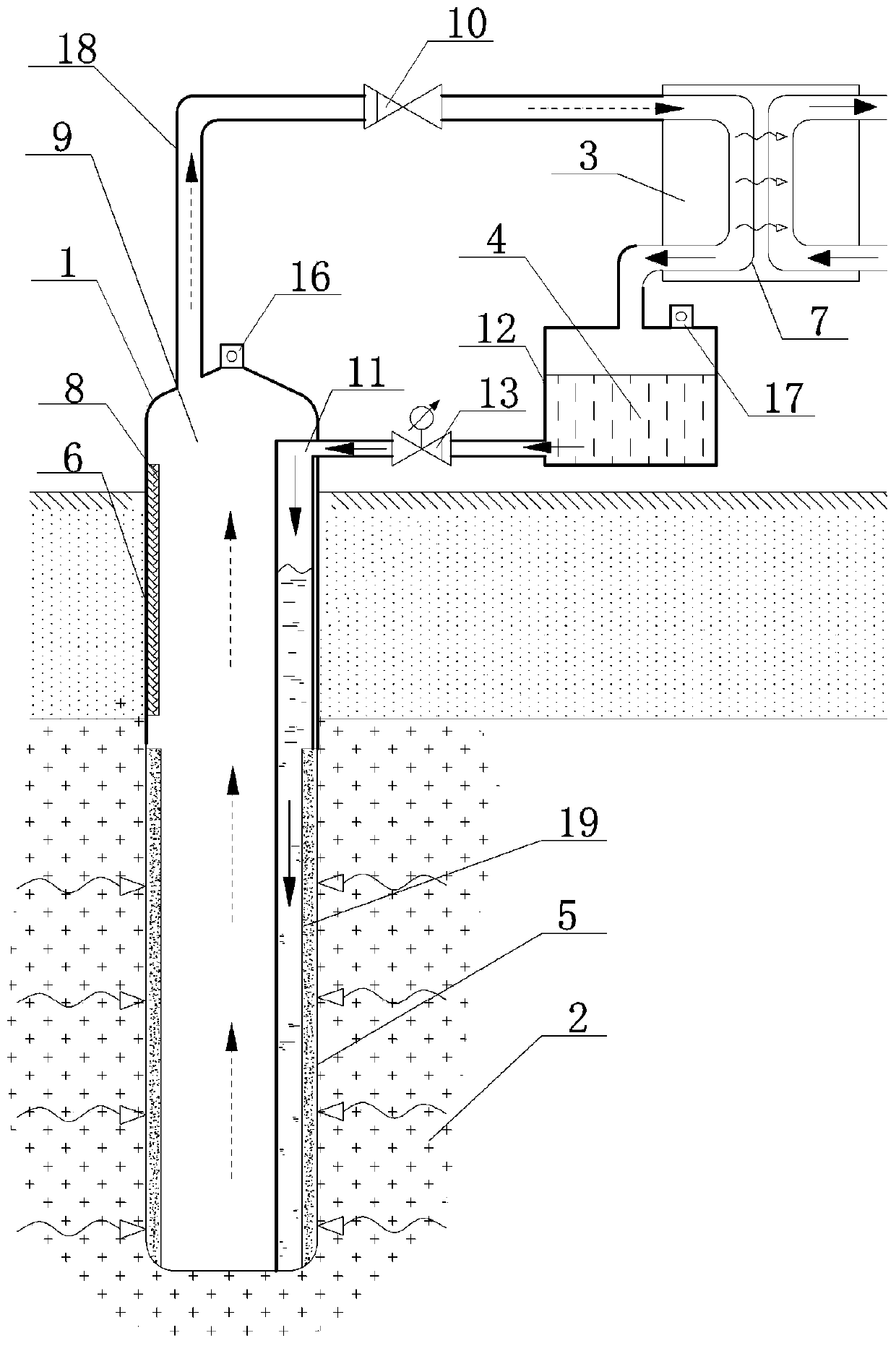

Loop type heat pipe exploitation middle-shallow layer hydrothermal type geothermal system

InactiveCN106705720AAchieve miningAvoid conflictOther heat production devicesGeothermal energy generationEvaporationHeat transfer efficiency

The invention discloses a loop type heat pipe exploitation middle-shallow layer hydrothermal type geothermal system which comprises a loop type heat pipe, a heat utilization device and a middle-shallow layer groundwater hypertonicity geothermal reservoir. The loop type heat pipe is provided with a loop type heat pipe evaporation section, a loop type heat pipe heat insulation section, a loop type heat pipe condenser and a loop type heat pipe fluid pipeline section which are located in the hypertonicity geothermal reservoir; the loop type heat pipe heat insulation section comprises a steam pipeline section and a heat insulation material layer for tightly wrapping the outer wall of the steam pipeline section; and one end of the loop type heat pipe evaporation section is communicated with one end of the loop type heat pipe fluid pipeline section, the other end of the loop type heat pipe fluid pipeline section is communicated with one end of the steam pipeline section through the heat release side of a heat exchanger, and the other end of the steam pipeline section is communicated with the other end of the loop type heat pipe evaporation section. By means of the loop type heat pipe exploitation middle-shallow layer hydrothermal type geothermal system, the problem about self starting of the overall geothermy exploitation system can be solved; and meanwhile, the heat long-distance transportation can be achieved, the problem of conflicts of steam flow and liquid flow of a tradition heat pipe is solved, and the heat transferring efficiency is greatly improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Non-chain-pillar exploitation method

InactiveCN103953346AReduce the difficulty of supportAchieve miningUnderground miningSurface miningLower zoneEnvironmental geology

The invention discloses a non-chain-pillar exploitation method. The method comprises the following steps: tunneling a lower zone track lane along a reserved narrow chain pillar in a goaf after recovery of an upper zone working surface is ended; replacing the reserved narrow chain pillar with a filling body constructed along the edge of the goaf ahead a lower zone working surface after tunneling of a lower zone mining roadway is ended; gradually constructing the filling body in sections along with extending of the working surface until recovery of the lower zone working surface is finished; and sequentially circulating until coal mining of an overall area is finished. The support difficulty of gob-side entry driving is lowered, deformation of gob-side entry driving is effectively controlled, the goaf is isolated, and the recovery rate of coal resources is improved. The method is simple, safe, reliable and environmentally friendly, and has a useful effect.

Owner:CHINA UNIV OF MINING & TECH

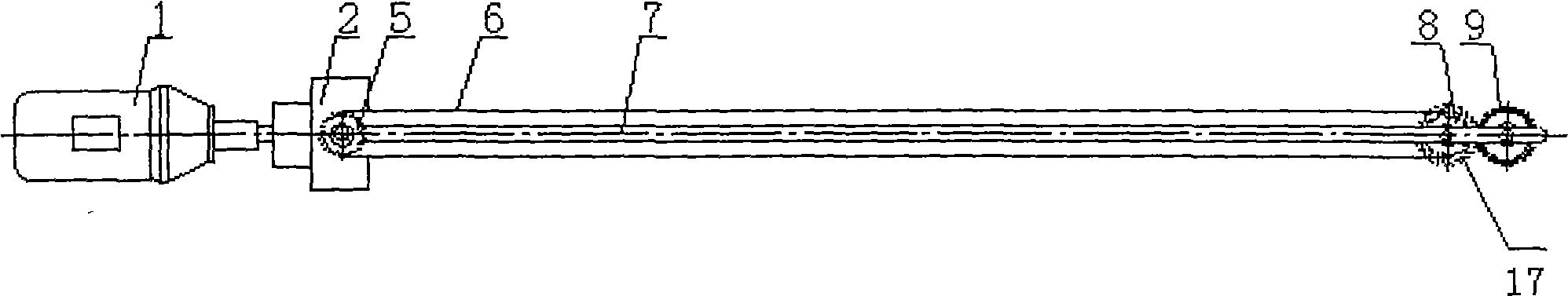

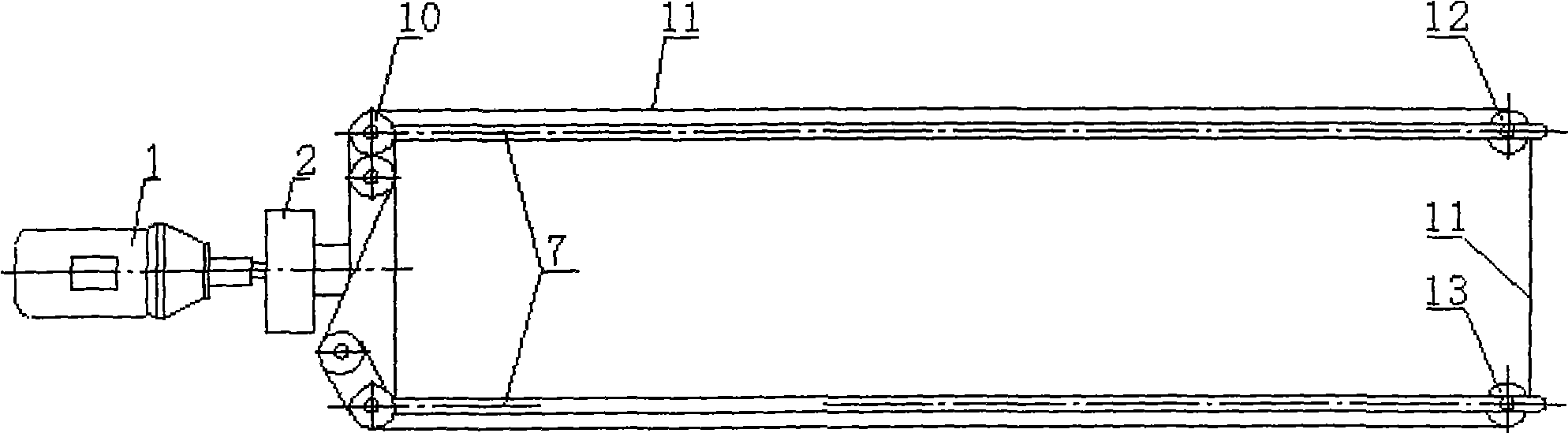

Toothed chain type method and apparatus for cutting stone

InactiveCN101502981AAchieve miningRealize cutting and excavationStone-like material working toolsOcean bottomGranolithic

The invention discloses a toothed chain stone cutting machine, which consists of a drill, a toothed chain saw and an in-depth saw. The drill is a machine for vertically feeding into rocks through rotation; the toothed chain saw is a machine for expanding based on holes made by the drill; the in-depth saw is a machine for expanding and cutting five rock edges of upper, down, left, right and inside according to the cruciform slot made by the toothed chain saw, which is applicable to both the excavation of mining marble, granite and other stones and the cutting and excavation of road, railway and rock tunnels under river and sea without damaging the working surface and producing any vibration to the mountain or tunnel of the working surface, thus ensuring the construction safety.

Owner:莫文龙

Fluidized mining method of combustible ice through rotary jet grouting and pressure relieving

Owner:CHINA UNIV OF MINING & TECH

Full negative pressure short wall filling coal mining method

PendingCN108301833AUndamagedEffective isolationUnderground miningSurface miningEngineeringStructural engineering

The invention provides a full negative pressure short wall filling coal mining method. The full negative pressure short wall filling coal mining method comprises the following steps that 10, positionsof a centralized return air lane and a centralized transportation lane are determined, and a transportation roadway, a first return air roadway and a second return air roadway are arranged; 20, tunneling is carried out on a branch lane in a first mining area, and after the branch lane is penetrated, tunneling is carried out on a branch lane in a second mining area, at the same time, supporting iscarried out on a penetrated branch lane, and a communication port between the penetrated branch lane and the transportation roadway is blocked; 30, the penetrated branch lane is filled after pluggingis finished; 40, tunneling is carried out on another branch lane in the first mining area, at the same time, supporting is carried out on a penetrated branch lane in the second mining area and a communication port between the penetrated branch lane and the transportation roadway is blocked; 50, the penetrated branch lane in the second mining area is filled after plugging is finished; 60, steps 10to 50 are cycled until the branch lane is completely filled; and 70, after filling is completed, reserved coal pillar lanes are successively mined according to the direction from the far end to the near end.

Owner:路彬

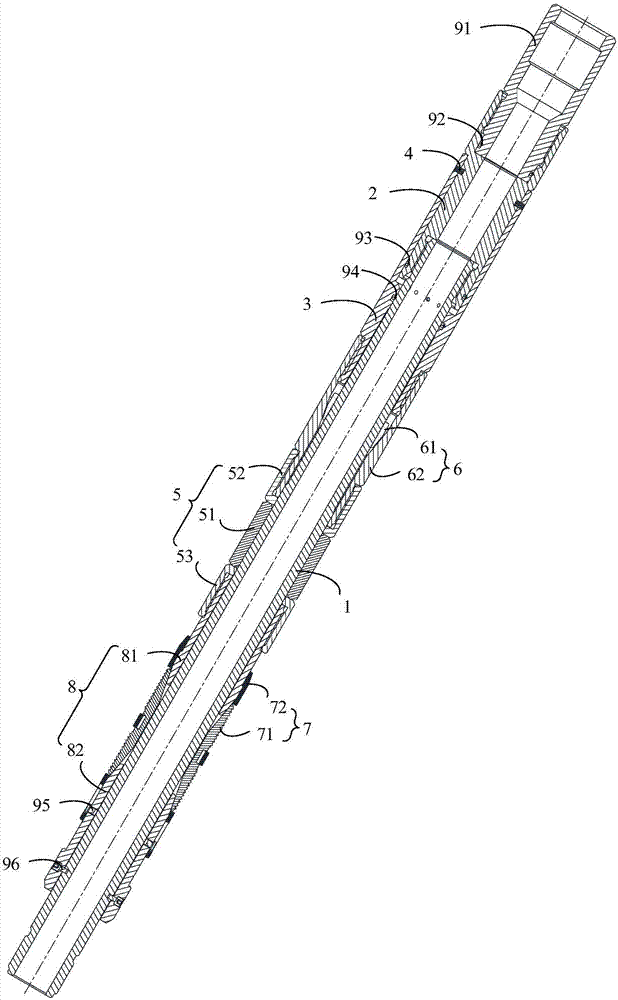

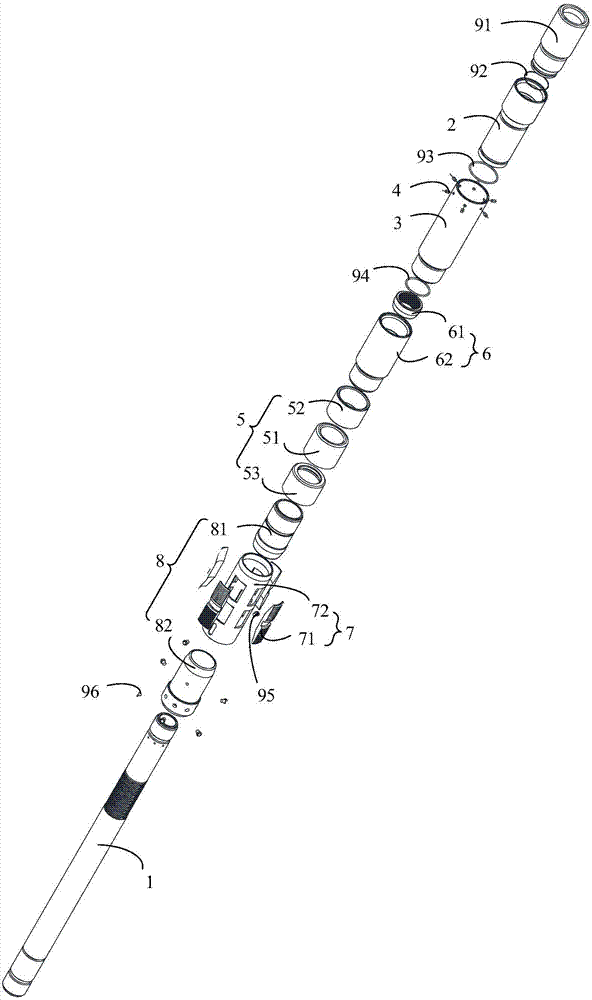

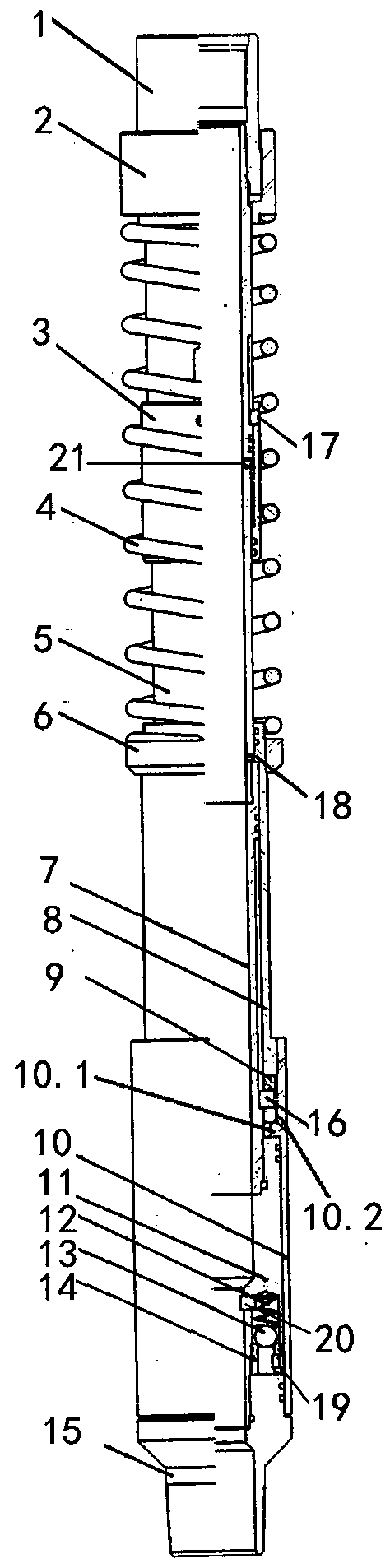

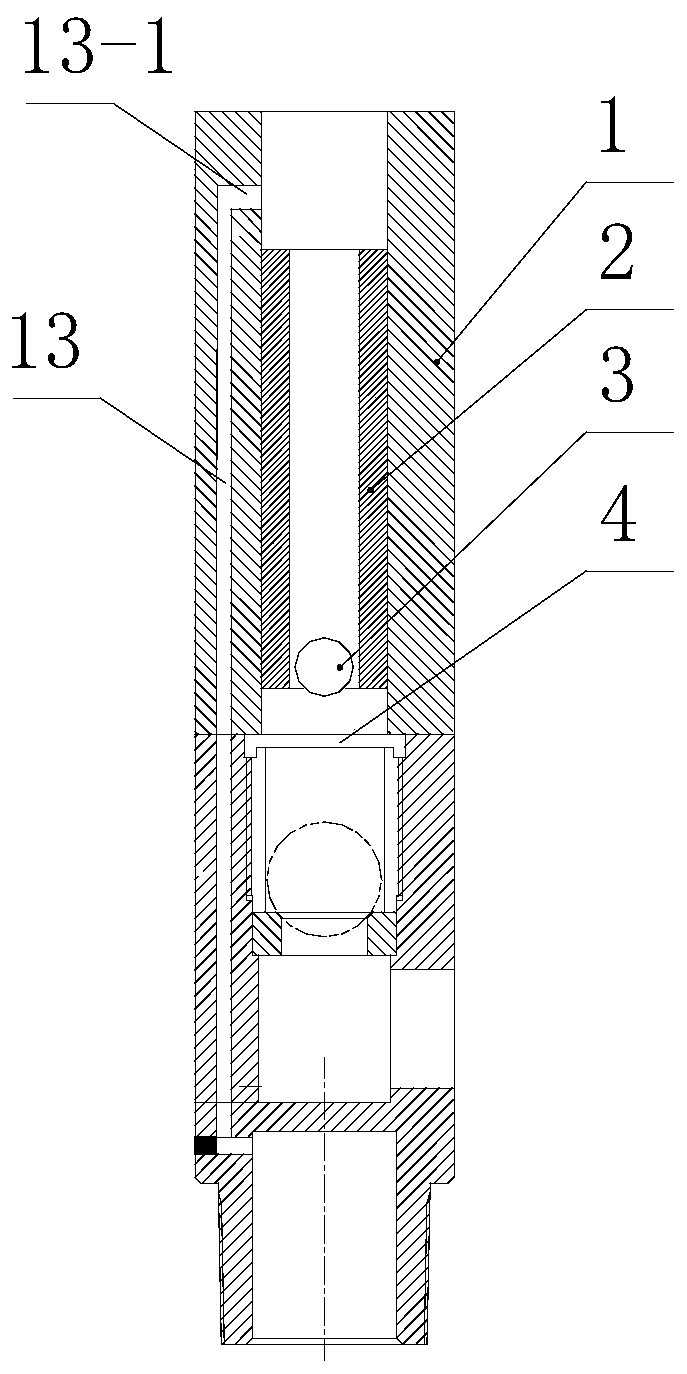

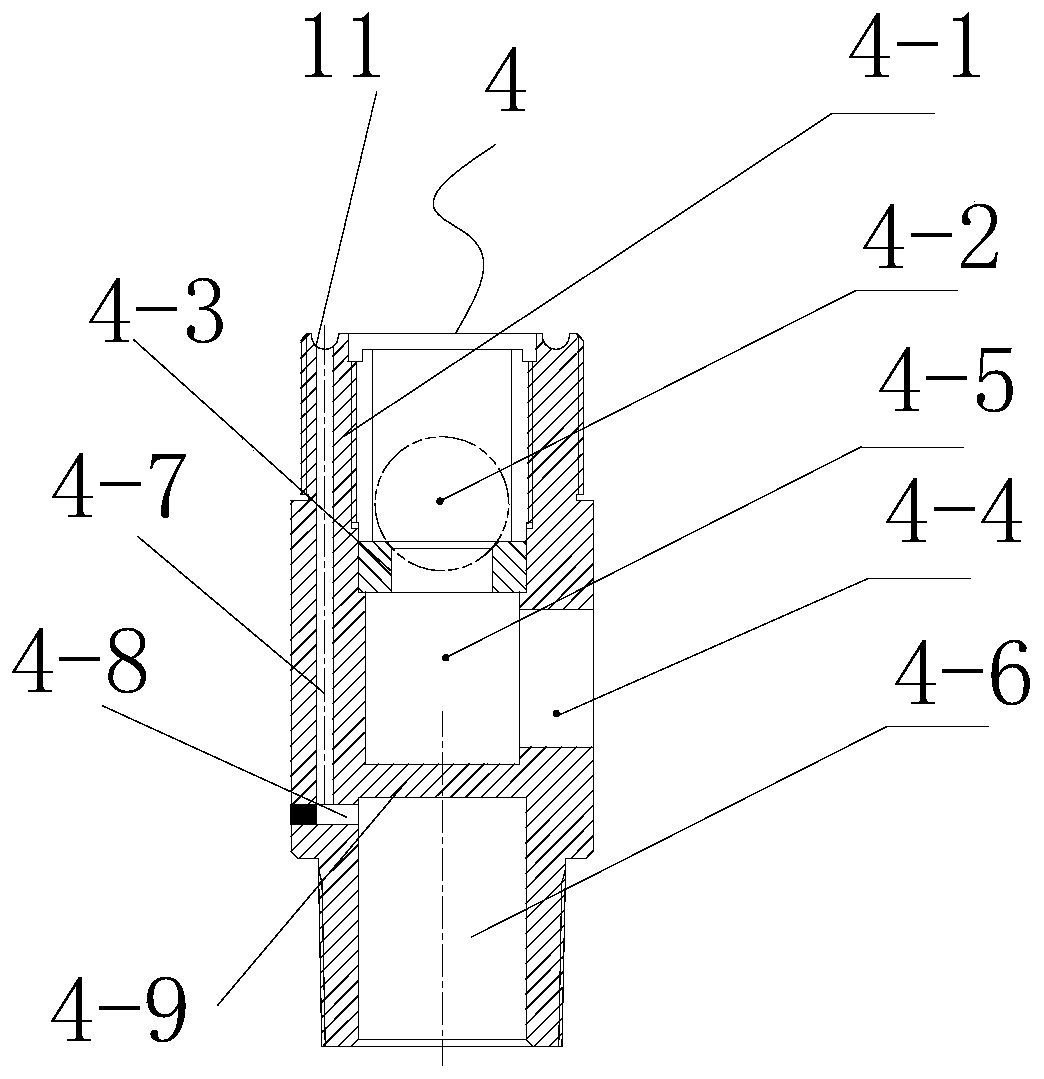

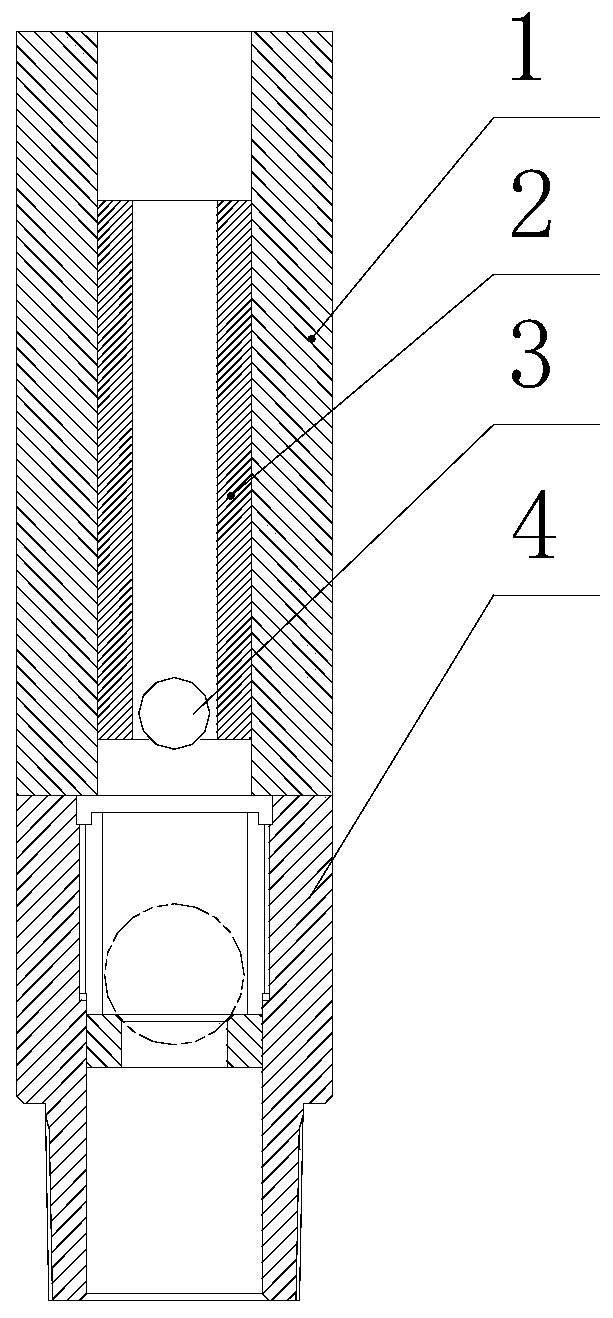

Coiled tubing hanger

The invention discloses a coiled tubing hanger comprising a core shaft, an upper connector, a piston, a rubber cylinder assembly, a locking assembly, a tubing clamping assembly and a slip expansion guiding assembly. A pressure conveying hole is formed in the core shaft; the outer wall of the core shaft is sleeved with the upper connector connected with the core shaft; the core shaft is sleeved with the piston, and the piston is connected with the upper connector through first shearing nails; the outer wall of the core shaft is sleeved with the rubber cylinder assembly; the core shaft is sleeved with the locking assembly, and the locking assembly is connected with the core shaft in a matched mode; the tubing clamping assembly comprises slips which can be extruded to clamp a tubing and a slip seat for fixing the slips; and the slip expansion guiding assembly comprises an upper cone body and a lower cone body, and the outer wall of the core shaft is sleeved with the upper cone body and the lower cone body. According to the coiled tubing hanger provided by the invention, influence of an inlet gas extraction device on a downhole safety valve can be effectively avoided, the purpose of safe control is realized, oil gas extraction can be realized, and safety of extraction is guaranteed.

Owner:SHENZHEN HIGHLEAD OILFIELD TECH DEVCO LTD

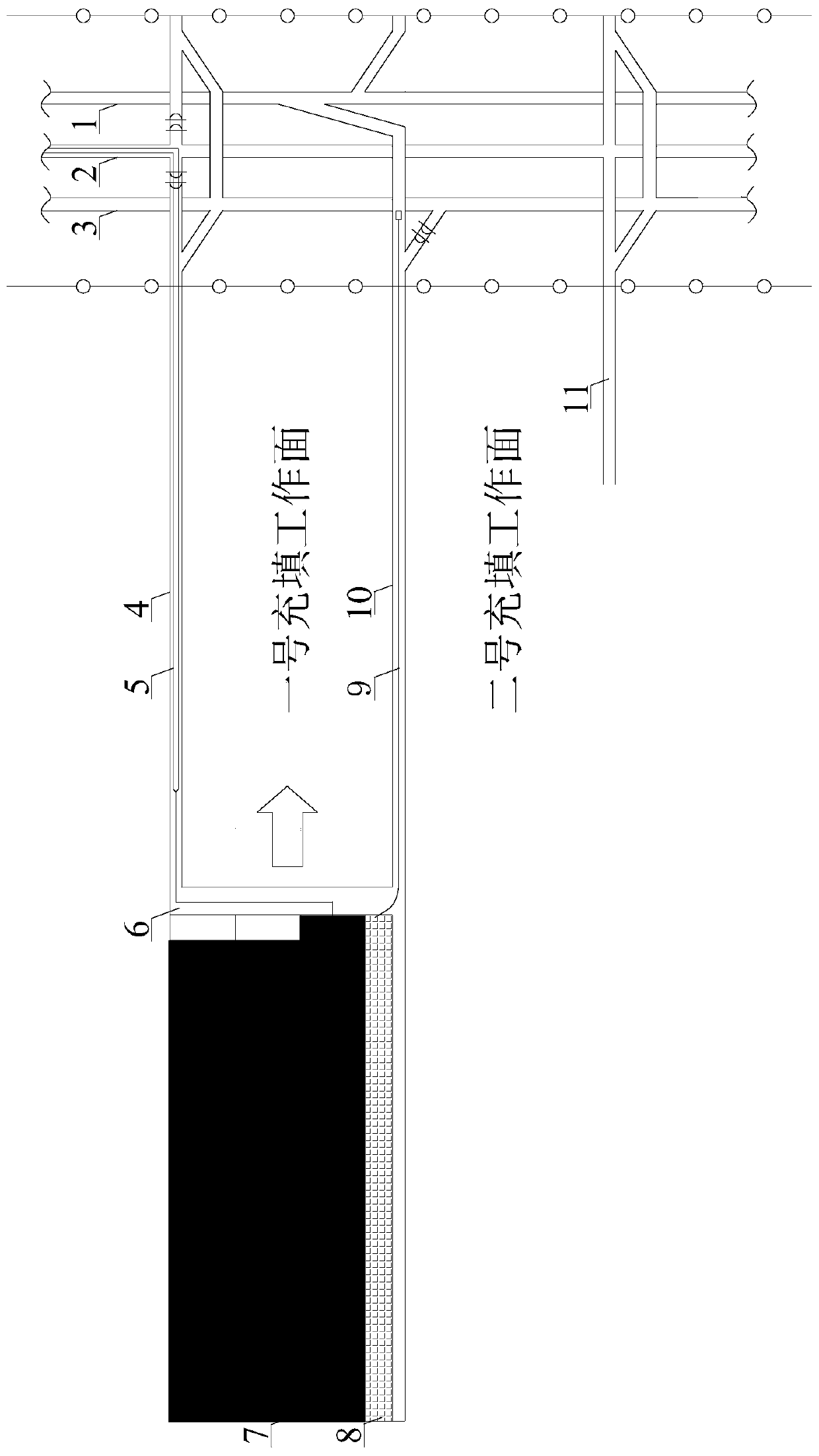

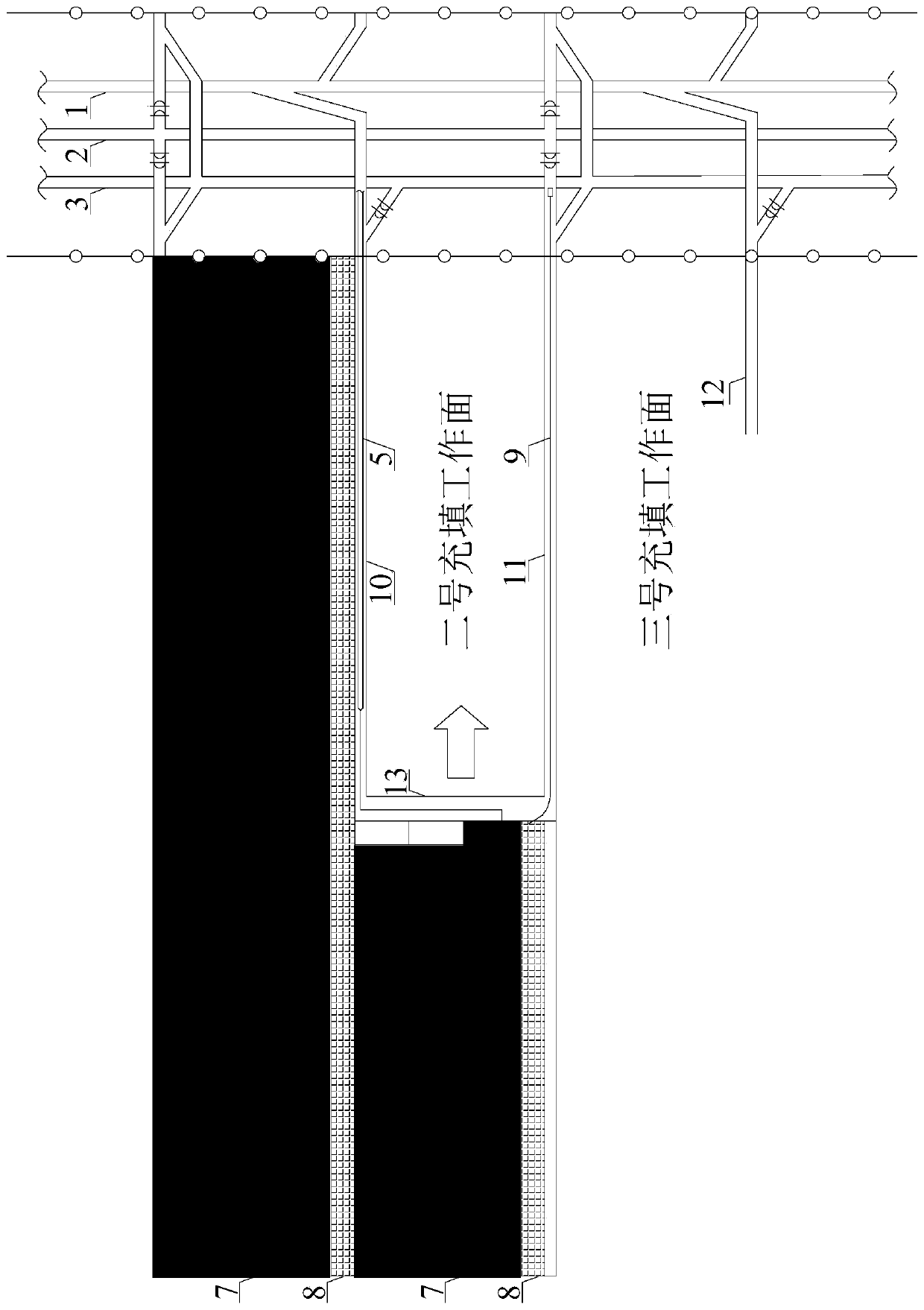

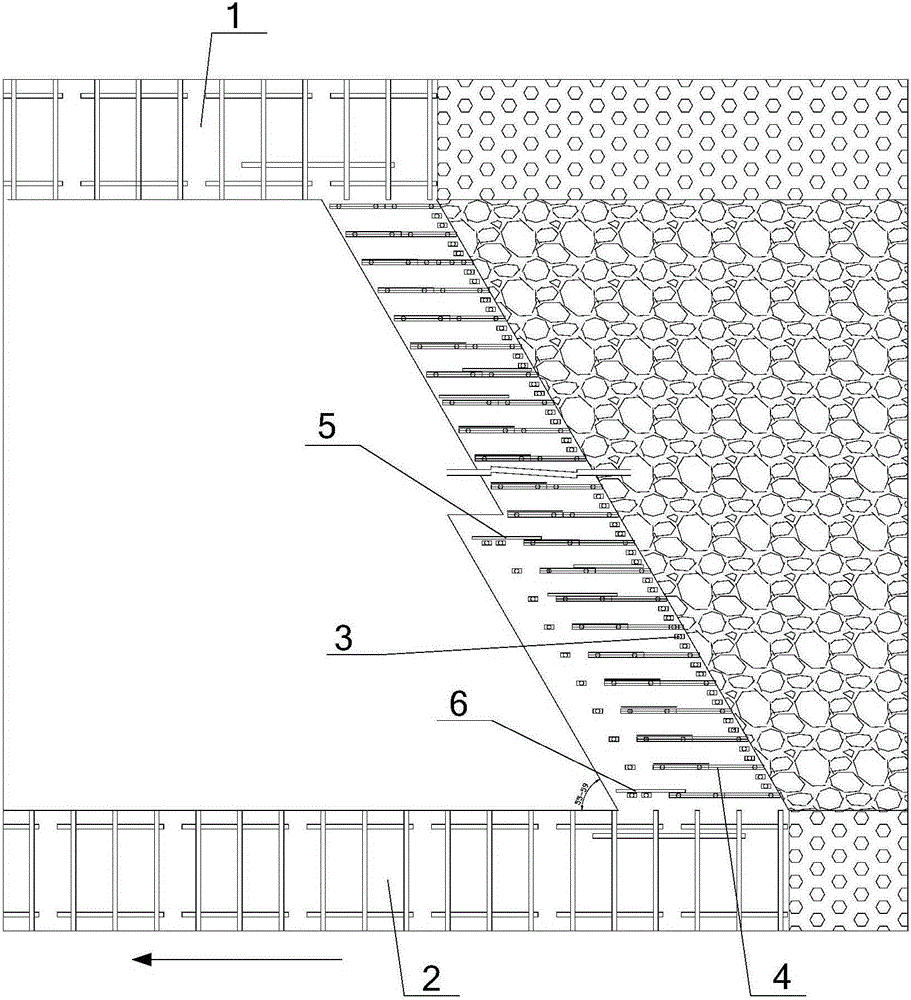

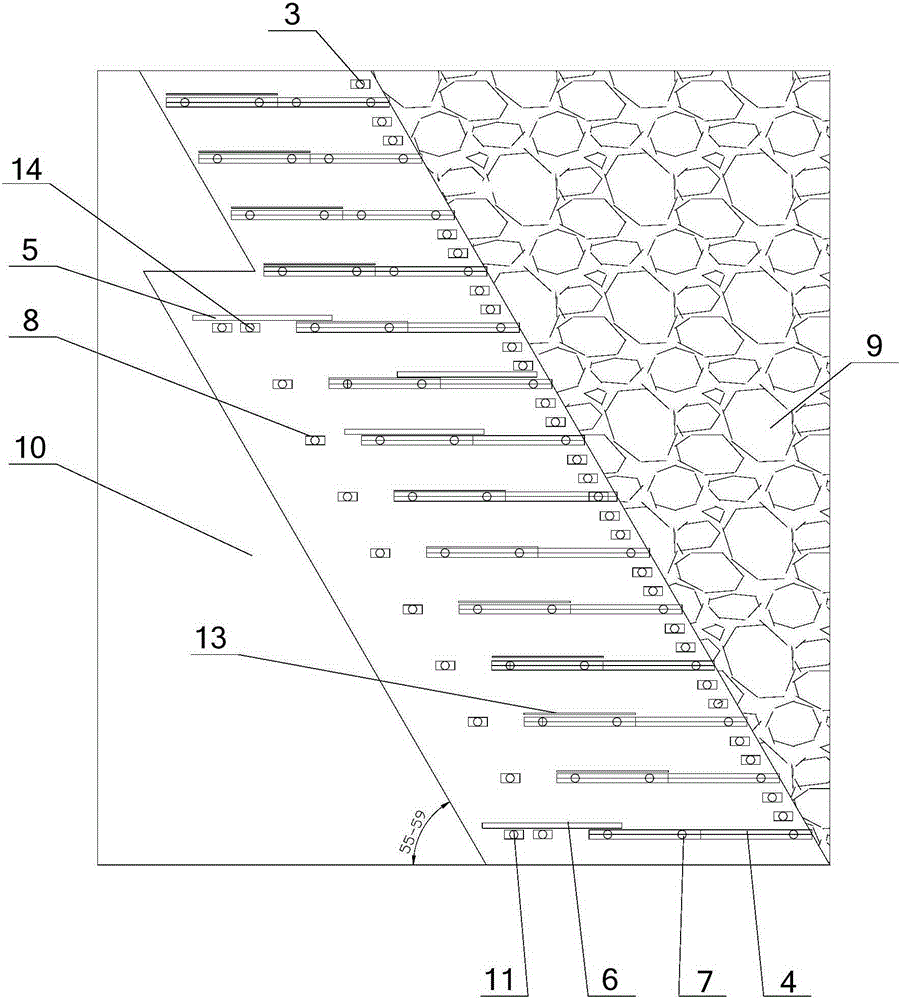

Superhigh-water material filled working face gangue pumping gob-side entry non-pillar mining method

ActiveCN110424966ASlow down subsidenceHigh strengthUnderground miningSurface miningPlacer miningCoal pillar

The invention provides a superhigh-water material filled working face gangue pumping gob-side entry non-pillar mining method. The method specifically comprises the steps of establishing a superhigh-water material filling system and a mine gangue pumping and filling system respectively; excavating a haulage roadway and a track roadway and forming a cutting hole in a mining area to form a complete first mining working face; conducting mining on the mining working face according to the normal working procedures; conducting backfilling on a mined goaf through a superhigh-water material; conductingfilling on the portion, where the roadway needs to be reserved close to the working face, of the goaf by pumping gangue filling bodies; after completion of filling, reserving the track roadway as thetrack roadway of a next working face, and excavating a new haulage roadway and forming a cutting hole to form a second mining working face; after completion of filling, reserving the haulage roadwayas the haulage roadway of the next working face, and excavating a new track roadway and forming a cutting hole to form a third mining working face, and repeating the steps. Through the superhigh-watermaterial filled working face gangue pumping gob-side entry non-pillar mining method, the strata pressure intensity of the working face is weakened, non-pillar mining is realized, and the mining rateof the mining area is remarkably increased.

Owner:CHINA UNIV OF MINING & TECH

Steeply-inclined coal seam working face and coal mining method

InactiveCN106523010AReduce occupancyRelieve pressureUnderground miningSurface miningIndustrial engineeringCoal mining

The invention discloses a working face of a steeply-inclined coal seam. Inclining direction of the working face is in falsely-inclined straight line arrangement while advancing direction of the same is strike of the coal seam, and concentration is linear concentration in straight line arrangement from an air way to a machine way along the inclining direction of the working face; a support comprises multiple rows of basic point columns arranged parallel to the inclining direction of the working face and multiple groups of metal hinging top beams supported by a plurality of the basic point columns, length direction of each metal hinging top beam is strike of the working face, and the metal hinging top beams are arranged parallelly. The concentration is linear, so that distance in the strike direction of the working face is shortened, and unsupported roof span is shortened. In addition, the support comprises the metal hinging top beams and the basic point columns which replace capped point columns, so that supporting area is increased, a roof is effectively controlled, probability of roof collapse accidents is reduced, and mining cost is lowered. The invention further discloses a steeply-inclined coal seam mining method applied to the working face.

Owner:四川达竹煤电(集团)有限责任公司金刚煤矿

Thick coal seam confined concrete pillar roof cutting roadway forming coal pillar-free mining method

ActiveCN113073978AScientific and reasonable mining arrangementAchieve miningMining devicesUnderground miningMining engineeringStructural engineering

The invention discloses a thick coal seam confined concrete pillar roof cutting roadway forming coal pillar-free mining method. The main principle of the method is that coal pillar arrangement is canceled, methods of advanced seam-blasting roof breaking, constant-resistance anchor cable steel belt supporting, strong dynamic pressure area strong supporting and seam-blasting crack combined roof cutting, strong dynamic pressure area contractible gangue blocking supporting, slow-release deformation-resistant area contractible confined concrete pillar supporting roof plate adopting, stable area microcapsule inhibitor slow-release foam material sealing roadside gangue side adopting and the like are adopted in a lower gate road of a previous working face, the purposes of pre-fracture roof breaking pressure relief of a gob-side roadway roof before mining, combined roof cutting filling roadside after mining, contractible strong pillar supporting roof cutting short-arm roof plate, roadside strong flexible material sealing air leakage prevention and the like are achieved, coal pillar-free mining is achieved, and the method is a more scientific and reasonable coal mining arrangement mode.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Hydraulic starting and closing device for layered oil production of sidetracked well

ActiveCN109458162AOil recovery achievedRealize layered oil recoveryFluid removalWell/borehole valve arrangementsWell drillingOil production

The invention relates to a hydraulic starting and closing device for layered oil production of a sidetracked well. According to the technical scheme, a liquid inlet ring is connected to the upper sideof a lower connector, a one-way valve is arranged in a containing cavity of the lower side of the liquid inlet ring, and the liquid inlet ring is connected with a reversing track; a starting and closing execution valve bush is connected to the outer wall of the liquid inlet ring, a rotation ring sleeves the outer side of the reversing track, and a track pin is placed in a track groove of the reversing track through a track nail hole of the rotation ring; a sealing reversing sleeve is connected to the upper end of the starting and closing execution valve bush, an upper connector is connected to a pressure adjustment check ring, then a return spring sleeves a sealing short segment, one end of the return spring is in contact with a pressure check ring, the other end of the return ring is incontact with the pressure adjustment check ring, and the pressure adjustment check ring drives the sealing reversing sleeve to conduct sliding cooperation along the outer wall of the sealing short segment; a liquid outlet is formed in the lower end of the sealing short segment. The hydraulic starting and closing device has the advantages that an original three-layer structure is converted into a two-layer structure through a structural conversion part, the inner diameter of a layered oil production tool is further increased, layered oil production on multiple oil layers is achieved, and the applicative range is wider.

Owner:王皓

Down-hole fluid heater for non-conventional energy

ActiveCN108301817AIncrease heating rateImprove sealingInsulationFluid removalInsulation layerPower flow

The invention discloses a down-hole fluid heater for non-conventional energy. The heater comprises a shell, a continuous spiral baffle plate, a center pipe, an insulation layer, an eddy current coil,a heat dissipation rod, a high temperature hot pipe, a wiring box and a one-way valve. According to the down-hole fluid heater for non-conventional energy, fluid is indirectly heated by using an eddycurrent effect, and through combination of boiling heat transfer of liquid-state sodium in the center pipe, the high temperature hot pipe and the continuous spiral baffle plate, the speed of heating the down-hole fluid is increased. In the down-hole operation process of a heater, by changing input current, secondary sealing of a heater outlet is achieved, and the down-hole fluid can be effectivelyprevented from flowing back into the heater.

Owner:JILIN UNIV

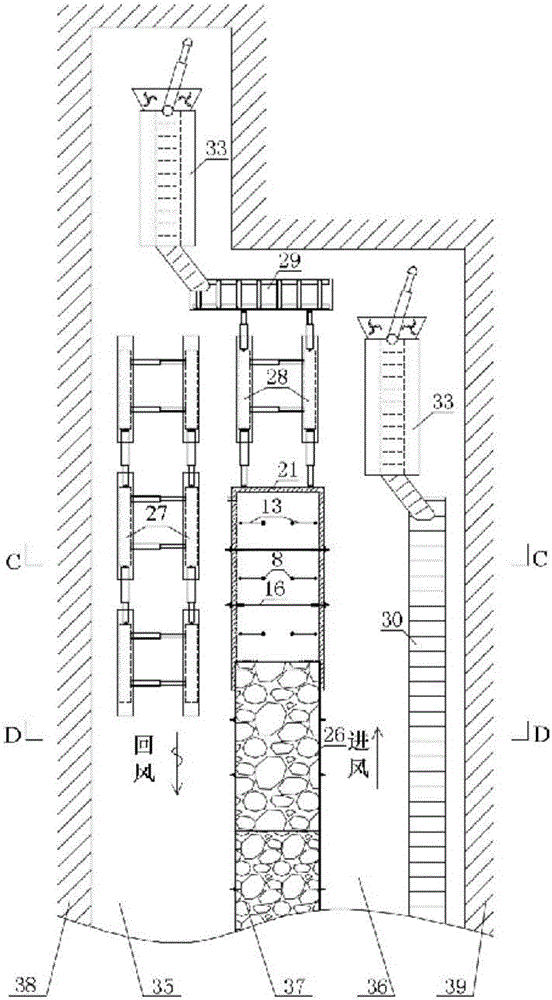

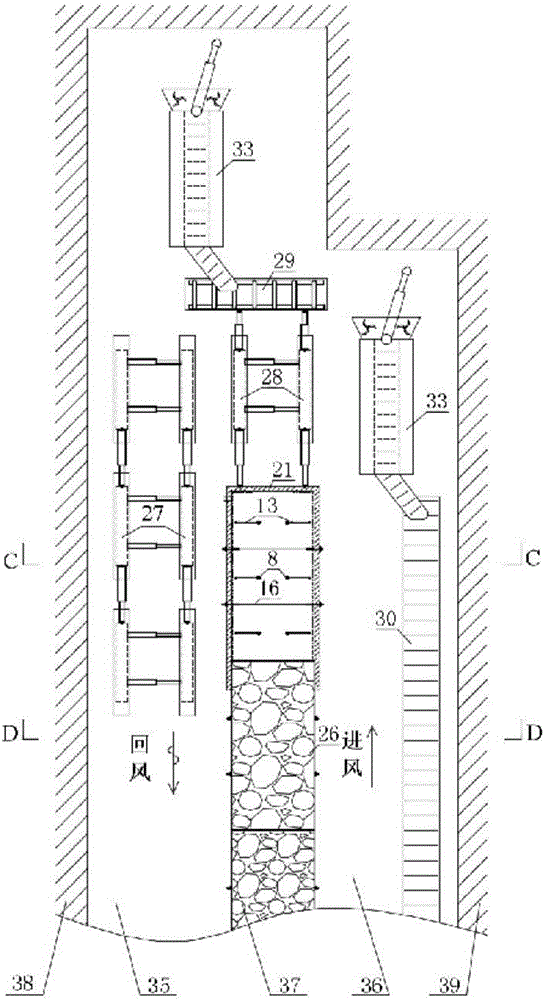

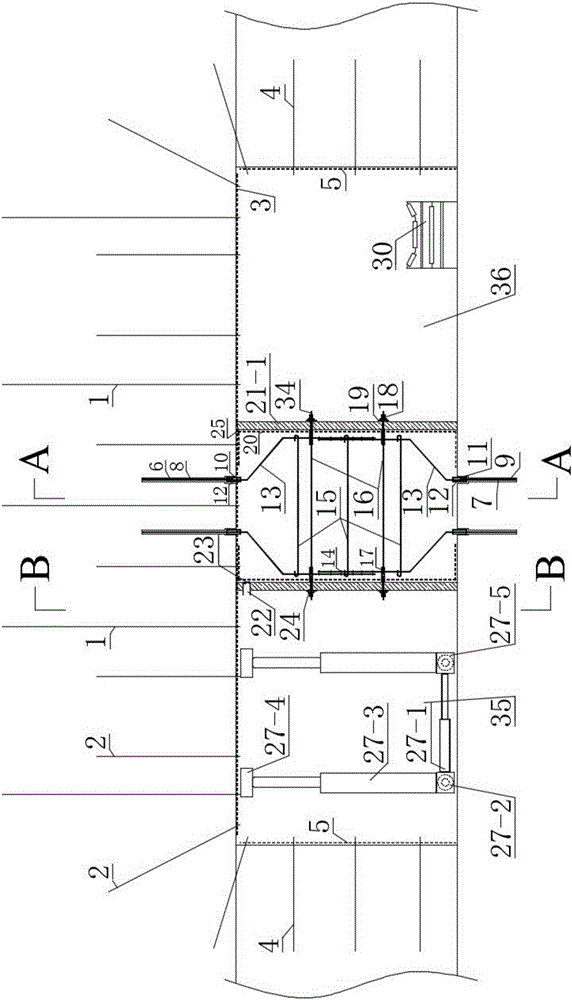

Support method for U-type ventilation primary tunneling setting-up double roadways

ActiveCN105937401ASave human resourcesReduce preparation timeUnderground chambersTunnel/mines ventillationCoalCoal pillar

The invention discloses a support method for U-type ventilation primary tunneling setting-up double roadways. The method includes the steps of tunneling a tunnel face; moving an n-shaped filling and pouring movable formwork (21) forward; installing a sliding device for resisting wall displacement and transformation and a pre-tensioning method prestress anchoring device in the horizontal direction; pouring concrete to form artificial coal pillars; carrying out stepping movement; moving a support; propelling a tunneling machine (33) by following the tunneling tunnel face. The support method for the U-type ventilation primary tunneling setting-up double roadways is easy to implement, safe and reliable and saves cost, after one roadway is excavated, the one-to-two roadway setting-up mode is adopted, which is beneficial for improving ventilation during tunneling, the work of excavating one mining roadway is omitted, a great number of manpower resources are saved, the setup time of the coal face is reduced, continuing tension of excavating work is relieved, section coal pillars are omitted, an artificial built concrete wall structure is adopted to achieve coal-pillar-free mining, the recovery ratio is increased, coal resources are fully explored, and requirements of multiple mining movement influence for fore supporting pressure and post-mining peak pressure are met.

Owner:XIAN UNIV OF SCI & TECH

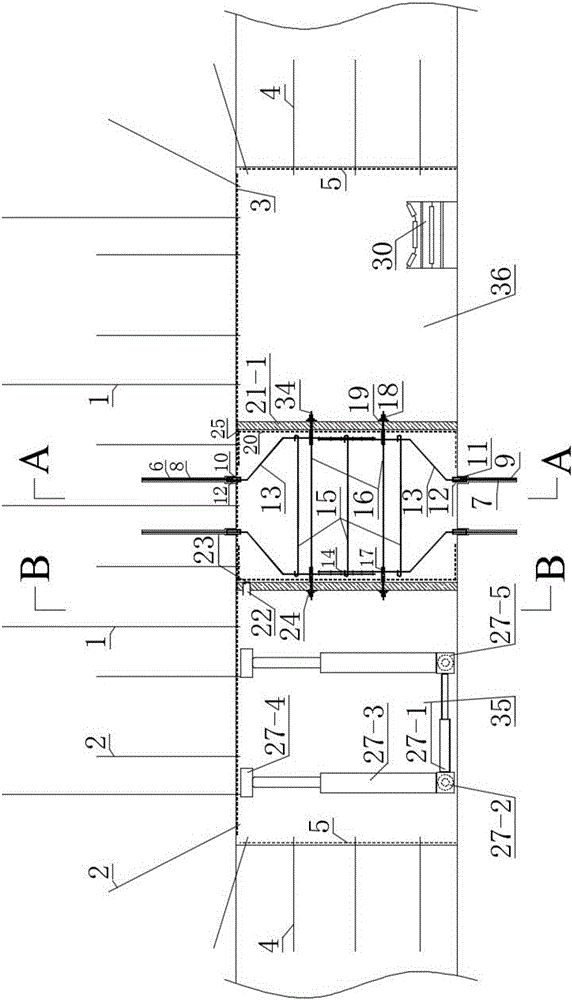

One-time tunneling two-roadway-retained excavating operation production line

ActiveCN105937400AImprove recovery rateFully developedUnderground chambersTunnel/mines ventillationProduction lineEngineering

The invention discloses a one-time tunneling two-roadway-retained excavating operation production line. A single roadway is divided into two roadways including a gate roadway on one side and a remained gob-side roadway on the other side along a mid-partition wall located behind an excavating face and timbered by concrete grouting workers after single roadway tunneling during stope face roadway tunneling, and heading machines and adhesive-tape rock discharging conveyers are arranged in the two roadways. A communicating roadway communicated with the gate roadway and the remained gob-side roadway is arranged behind the excavating face, the gate roadway, the remained gob-side roadway and the communicating roadway jointly form a U-shaped ventilation structure, an advanced-timbering self-moving formwork hydraulic pull frame timbering device is arranged in the communicating roadway, and the rear end of the advanced-timbering self-moving formwork hydraulic pull frame timbering device is in abut joint with the mid-partition wall. The one-time tunneling two-roadway-retained excavating operation production line is easy to construct, safe and reliable, the costs are saved, one-time excavating and timbering construction along the remained gob-side roadway and the stoping gate roadway is not only completed, roadway ventilation can be also achieved, and the requirement for multiple influences induced by mining about advanced bearing pressure and peak pressure after excavation can be met.

Owner:XIAN UNIV OF SCI & TECH

Combined oil well pump for preventing well flushing from polluting oil layer

ActiveCN109779563APrevent leakageReduce production efficiencyCleaning apparatusFluid removalEngineeringPumpjack

The invention relates to a combined oil well pump capable of preventing well flushing from polluting an oil layer. The combined oil well pump an oil pump cylinder, a plunger assembly, a fixed valve, adiaphragm packer and a plug. The combined oil well pump is characterized in that a pump cylinder flow guide channel is arranged on the pump cylinder wall of the oil well pump; the upper end of the pump cylinder flow guide channel is connected with a small radial hole communicating with the inner cavity of the pump cylinder; the arrangement position of a radial small hole connected with the upperend of the flow guide channel is that the radial small hole communicates with the inner cavity of the pump cylinder when the plunger is positioned at the bottom dead center; an axial flow guide hole communicating with the flow guide channel is formed in the side wall of the fixed valve and communicating with a center hole in the lower portion of a partition plate of the fixed valve through a smallradial hole in the side wall of the fixed valve; and a channel for transmitting pressure to the diaphragm packer through well flushing fluid in the pump cylinder is formed. The combined oil well pumphas the beneficial effects that well flushing fluid can be prevented from entering the oil layer to cause leakage of the well flushing fluid, the oil layer is prevented from being polluted, and the oil well production efficiency is improved.

Owner:天津五一泰科机电科技有限公司

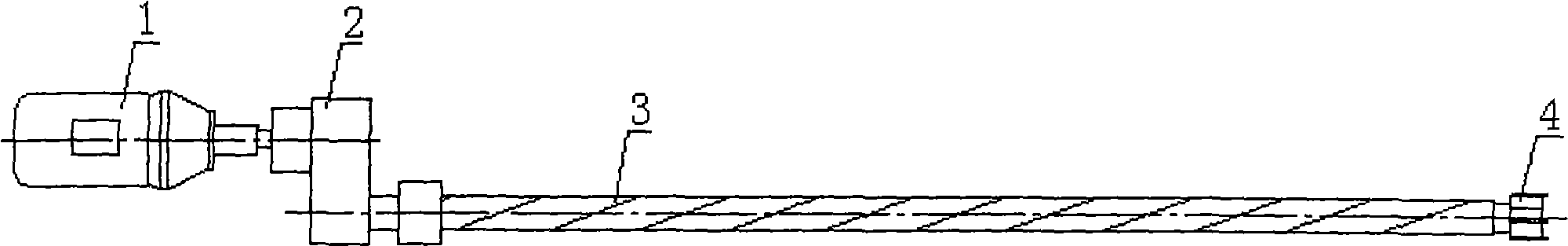

Well drilling method for improving lifting efficiency

InactiveCN103089149AImprove sweeping efficiencyAchieve miningDrilling rodsDirectional drillingWorking fluidWell drilling

The invention discloses a well drilling method for improving the lifting efficiency. The technical scheme includes that the well drilling method comprises firstly, analyzing a combination of an actual drilling track of an original horizontal well bore and a completion string and a tripping-in position in detail, and determining communication positions of a vertical well and a horizontal well and the position of the vertical well in order to change the flowing direction of formation fluid to avoid an original fingering channel and improve the flow profile of the formation fluid; then communicating a straight-hole drilling section with the original horizontal well bore by the aid of a vertical well drilling technology, and deepening the straight-hole drilling section to a certain degree to guarantee that a lifting device is always positioned below a working fluid level; cooperating with a sand control process to realize well completion; and finally tripping the lifting device to a position below an original well section and starting production. The well drilling method has the advantages that merits of the horizontal well and merits of the vertical well are combined, shortcomings of the horizontal well and shortcomings of the vertical well are overcome, horizontal well drilling and vertical well exploiting are realized, the flow profile is adjusted, the performance of the lifting device is sufficiently played, the service life of the lifting device is prolonged, and the lifting efficiency of the lifting device is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

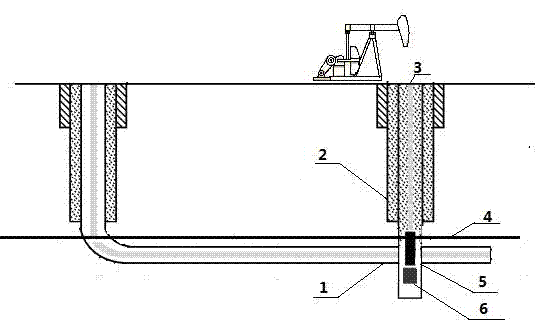

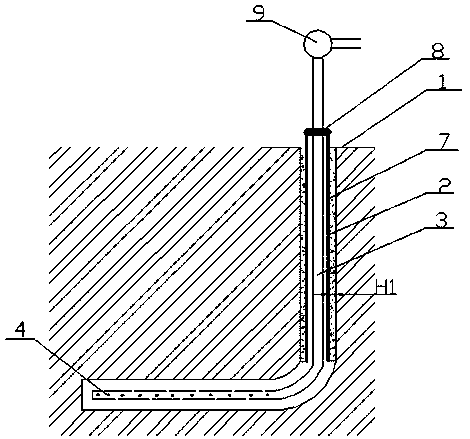

Sieve tube process brine extraction device

The invention relates to the technical field of mining and discloses a sieve tube process brine extraction device which comprises an inclined shaft (1), an inclined shaft casing pipe (2) and a centralpipe (3), wherein the tail end of the central pipe (3) is sealed; the inclined shaft casing pipe (2) is positioned in the vertical section of the inclined shaft (1); the central pipe (3) is positioned in the inclined shaft casing pipe (2); a preset distance H1 is formed between the inner wall of the inclined shaft casing pipe (2) and the outer wall of the central pipe (3); the lower part of the central pipe (3) extends to be overlapped with the horizontal section of the inclined shaft (1); and a plurality of water orifices (4) are formed in the side wall of the section, overlapped with the horizontal section of the inclined shaft (1), of the central pipe (3) in the length direction of the central pipe (3). Compared with the prior art, through adding the simple central pipe, the sieve tubeprocess brine extraction device can greatly increase the mining coefficient, is simple in structure, convenient to implement and saves energy and reduces emission.

Owner:南风集团淮安元明粉有限公司

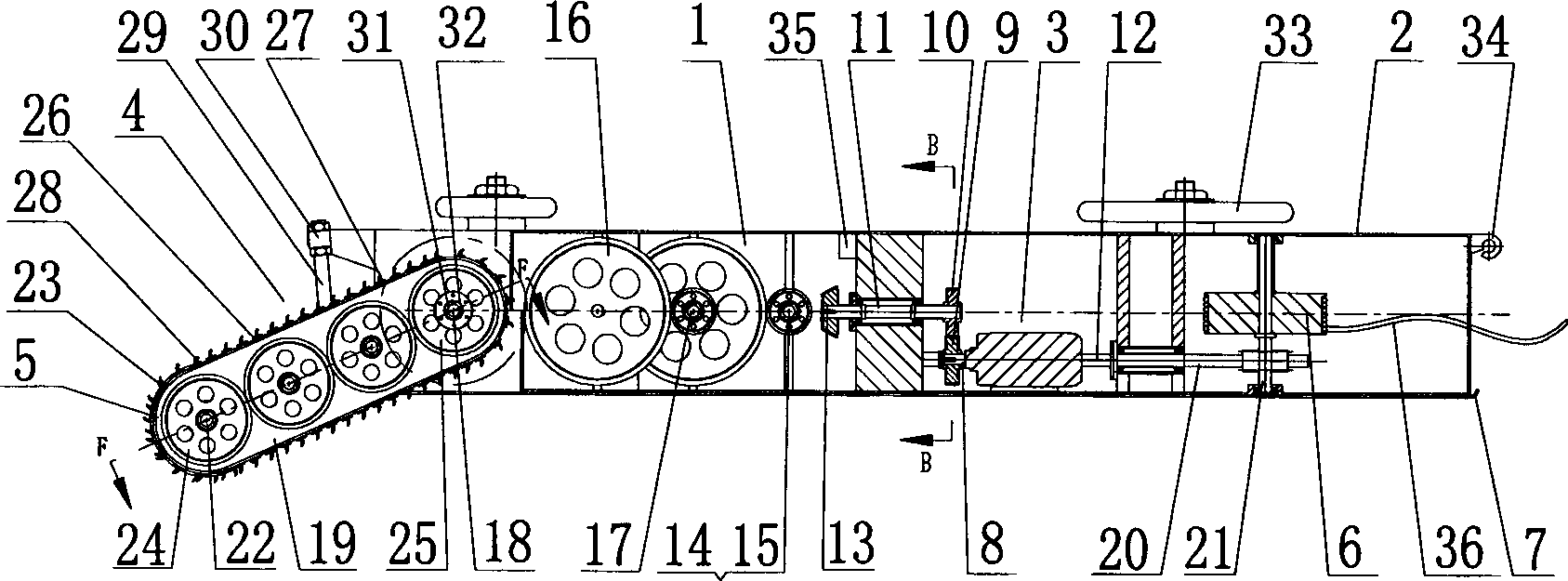

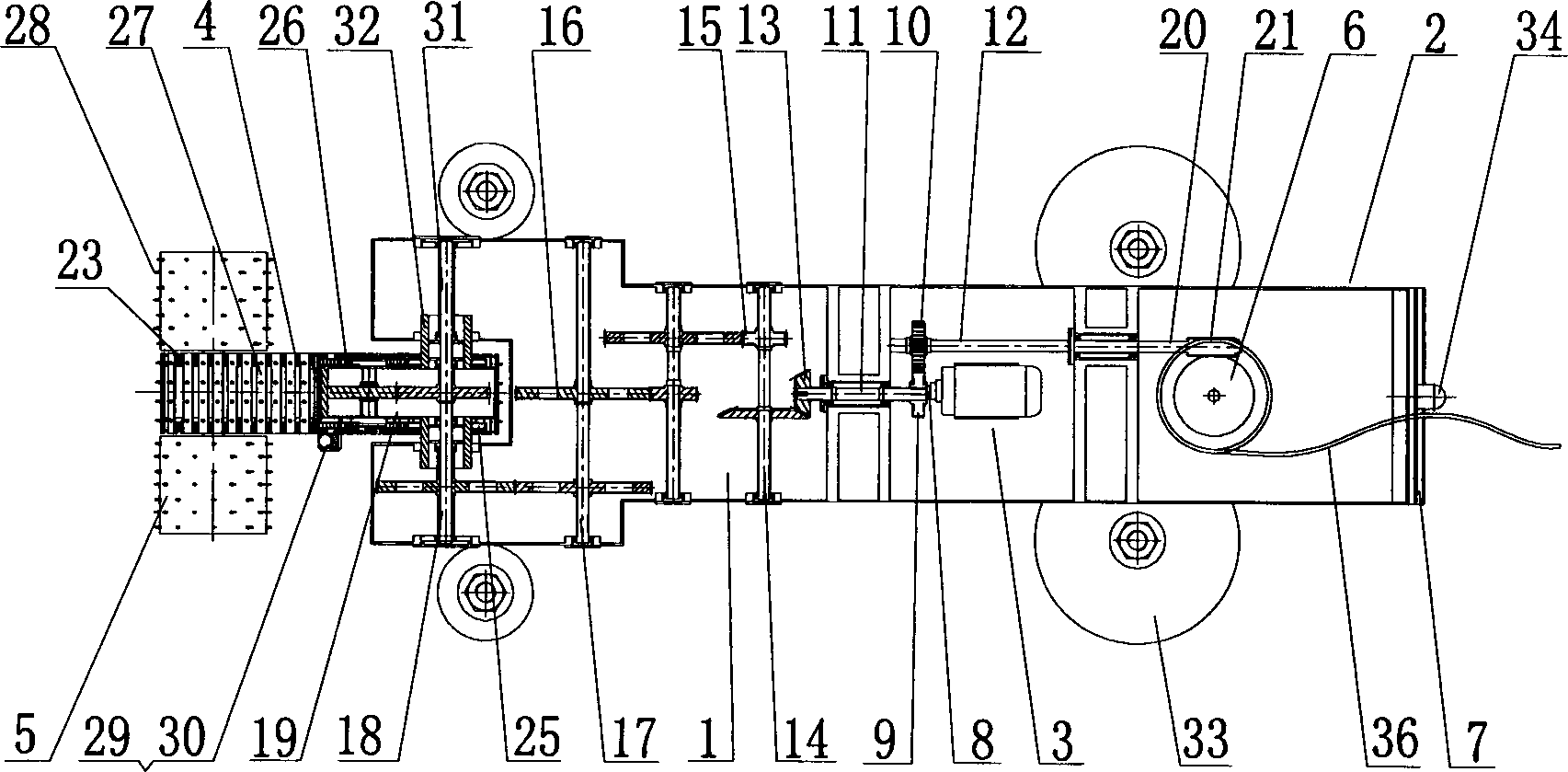

Rocker-type transverse shearer

Owner:HUNAN UNIV OF SCI & TECH

A loop heat pipe geothermal mining system with adjustable working fluid circulation flow

ActiveCN107144035BAchieve miningMaximize heat transfer efficiencyGeothermal energy generationGeothermal collectorsThermal insulationEvaporation

The invention discloses a loop heat pipe type terrestrial heat exploitation system with adjustable and controllable working medium circular flow. The loop heat pipe type terrestrial heat exploitation system comprises a casing pipe type loop heat pipe, an earth surface heat exchanger and a liquid storage box. The earth surface heat exchanger and the liquid storage box are both located on the ground. The casing pipe type loop heat pipe comprises an evaporation section, a heat insulation section and a backflow section. The evaporation section is located in a high temperature heat reservoir. The earth surface heat exchanger is provided with a condensation section, and the condensation section and the outside carry out heat exchange. A one-way valve or a steam pump is arranged between the heat insulation section and the condensation section. A one-way throttle valve is arranged between the liquid storage box and the backflow section. The evaporation section, the heat insulation section, the condensation section, the liquid storage box and the backflow section are communicated in sequence end to end. Working medium fluid of the liquid storage box enters the evaporation section through the backflow section, and the liquid working medium fluid entering the evaporation section generates film boiling after absorbing heat. According to the loop heat pipe type terrestrial heat exploitation system, the working medium fluid of the liquid storage box passes through the backflow section, the liquid phase backflow mode and the boiling mode of the evaporation section are controlled, the effective filling factor of the terrestrial heat pipe can be adjusted in real time, and therefore terrestrial heat energy is stably and efficiently extracted.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com