Full negative pressure short wall filling coal mining method

A technology of backfill mining and full negative pressure, which can be applied to backfills, safety devices, surface mining, etc., can solve the problems of heavy economic burden of coal mining enterprises, difficulty in land relocation, difficulty in maintenance and promotion, etc. The effect of less occupancy and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

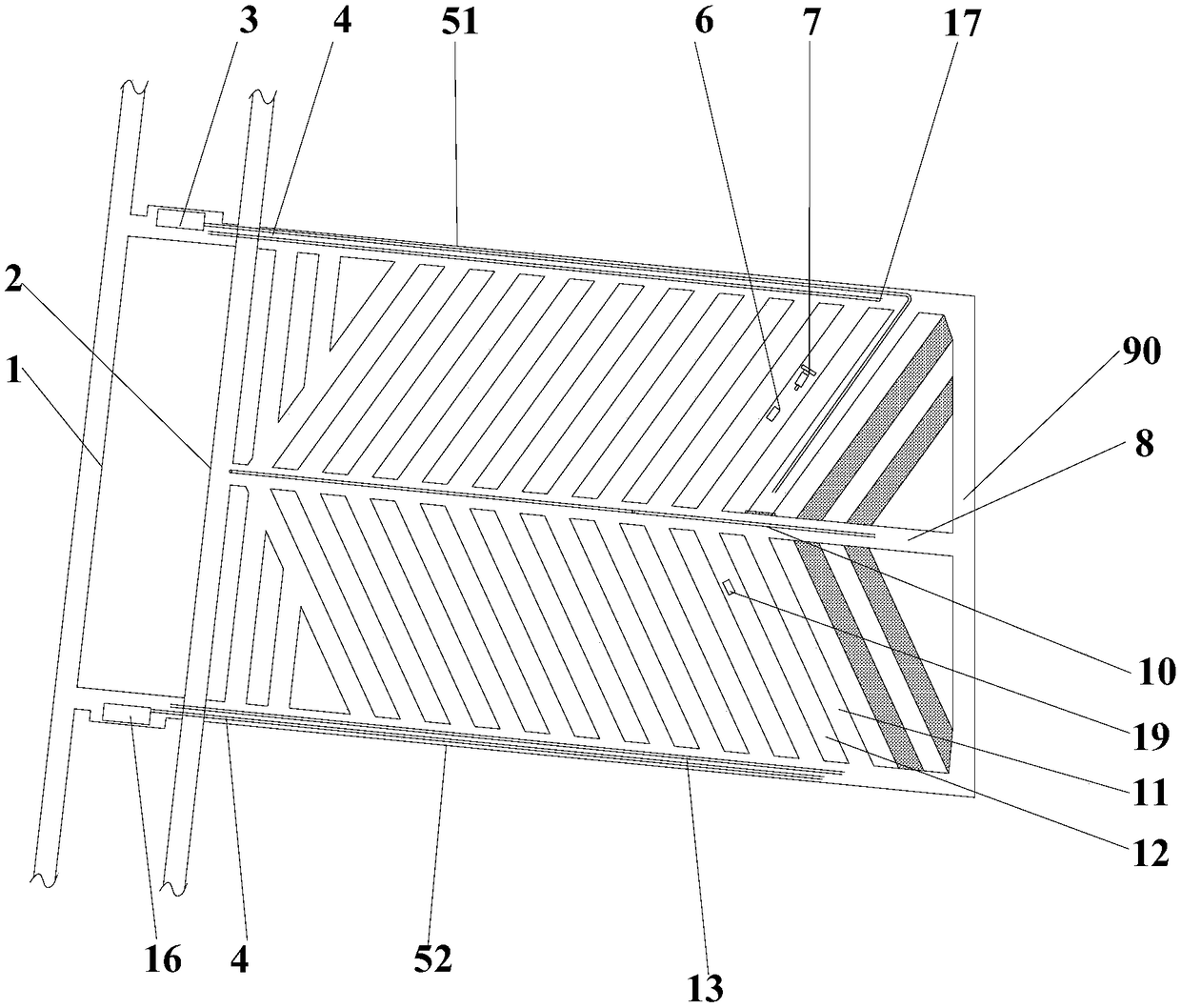

[0032] like figure 1 As shown, the present invention provides a kind of full negative pressure short-wall filling coal mining method, comprises the following steps:

[0033] Step 10: Determine the positions of the concentrated air return lane 1 and the centralized transport lane 2, and set up parallel and spaced transport troughs 8, first return air troughs 51, and second return air troughs 52 along the inclined direction of the working surface, so that The transportation chute 8 is arranged between the first return air chute 51 and the second return air chute 52, so that one end of the transportation chute 8 communicates with the centralized transportation lane 2, so that one end of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com