Patents

Literature

32results about How to "Simple production system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

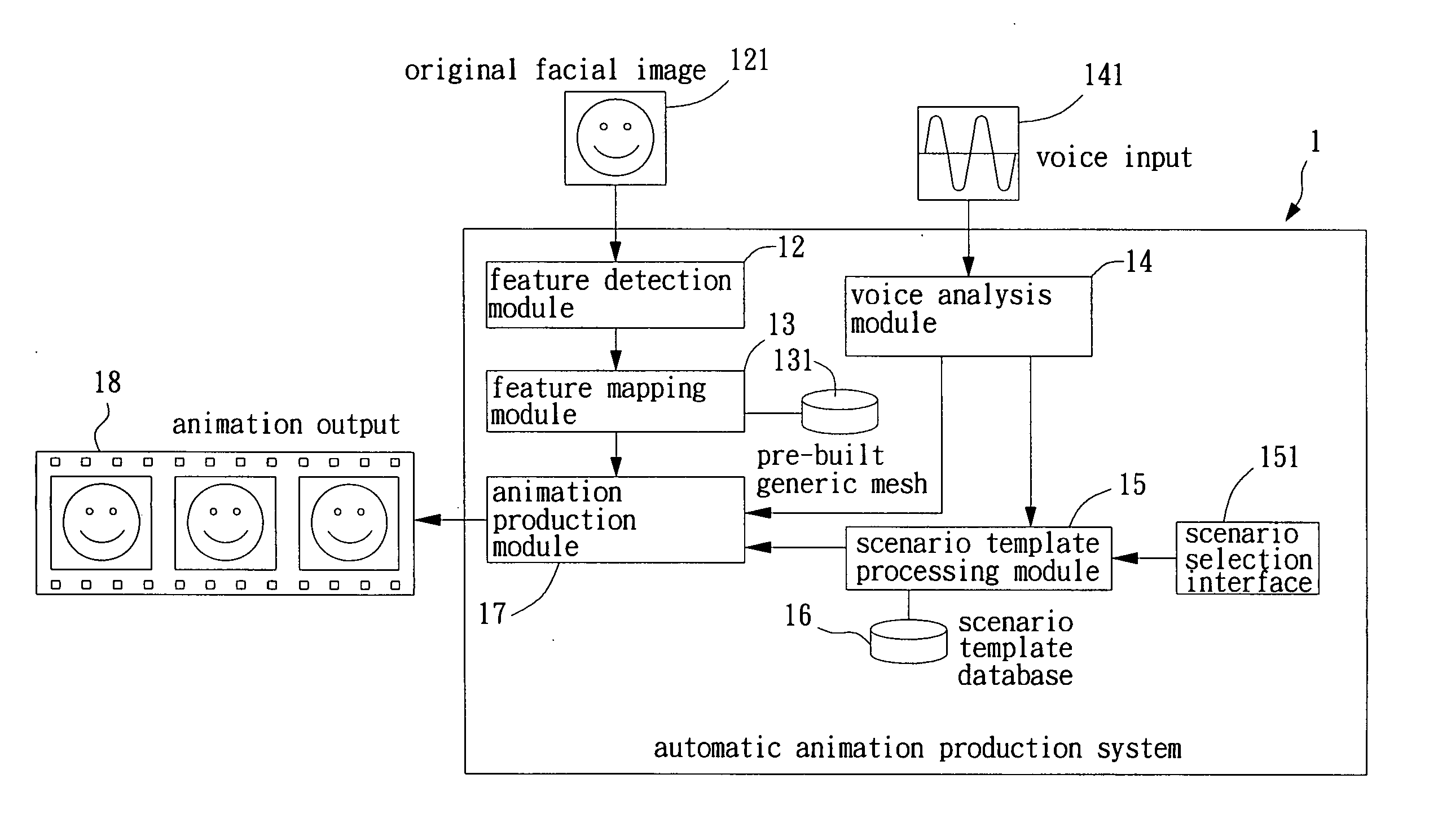

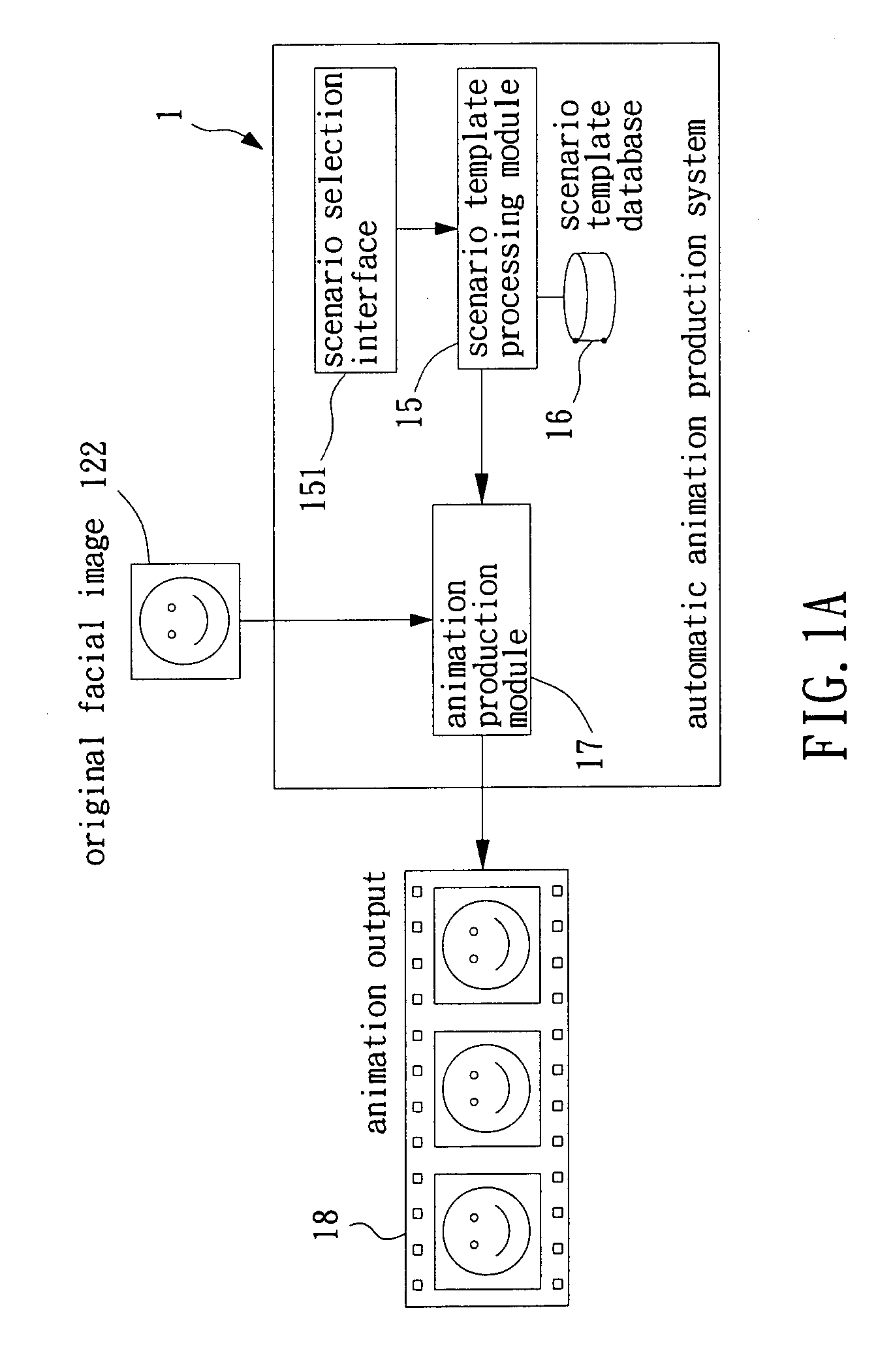

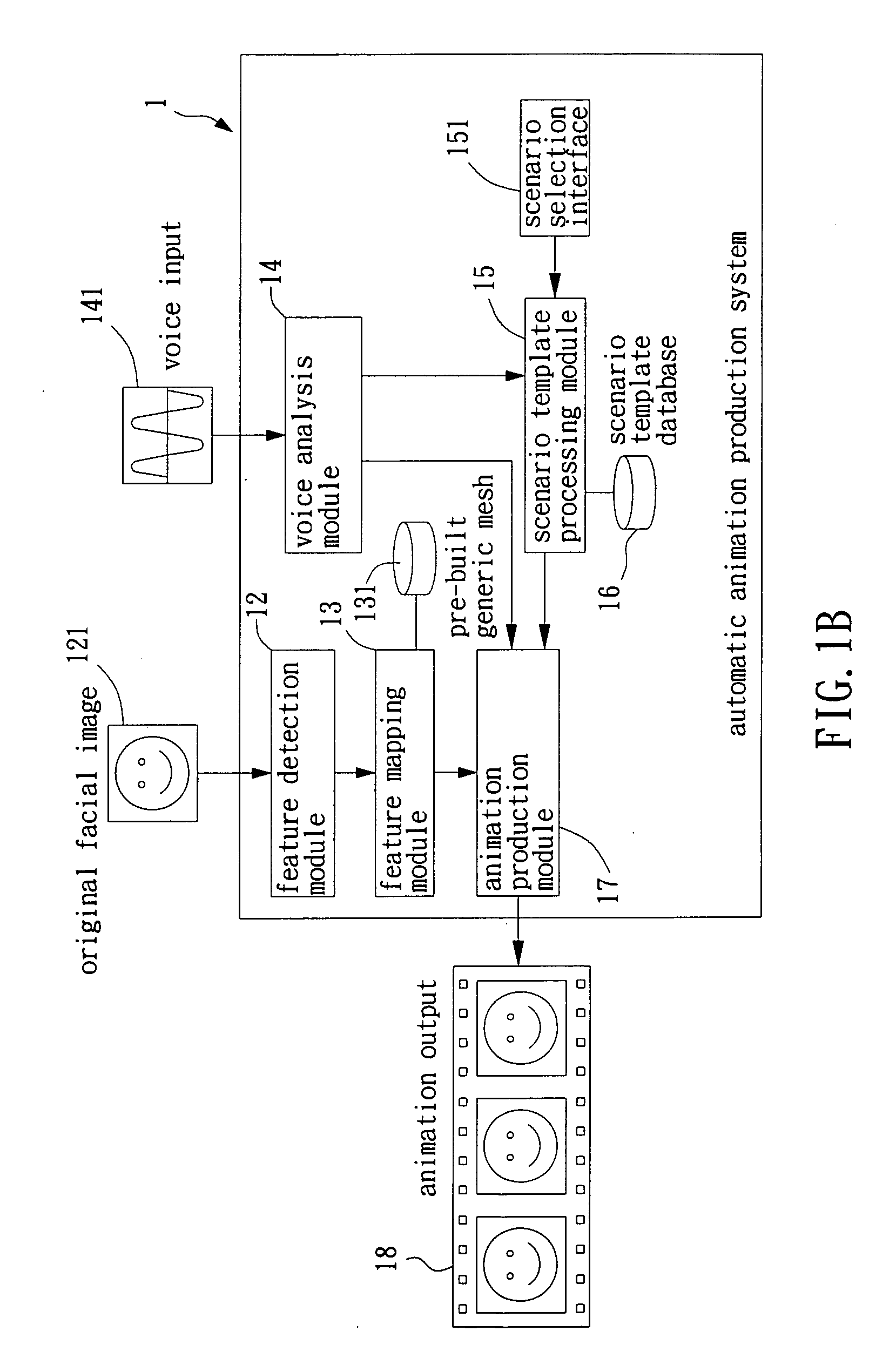

Automatic animation production system and method

InactiveUS20050273331A1Simple processSimple production systemCharacter and pattern recognitionAnimationAnalysis dataAnimation

The present invention provides an automatic animation production system and method. The automatic animation production system creates animations by synthesizing various facial features according to audio analysis. By expanding animation parameters in a scenario template database according to audio analysis data, facial features in an image are varied with time, thereby creating animation. The scenario template database comprises a plurality of animation parameters. Combinations of various animation parameters can create various facial expressions in an image, in accompany with variations of audio, enriched effects are available.

Owner:REALLUSION

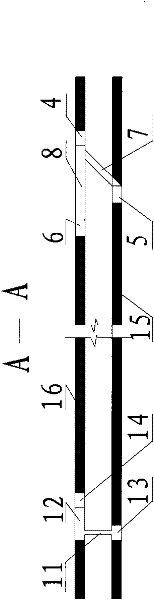

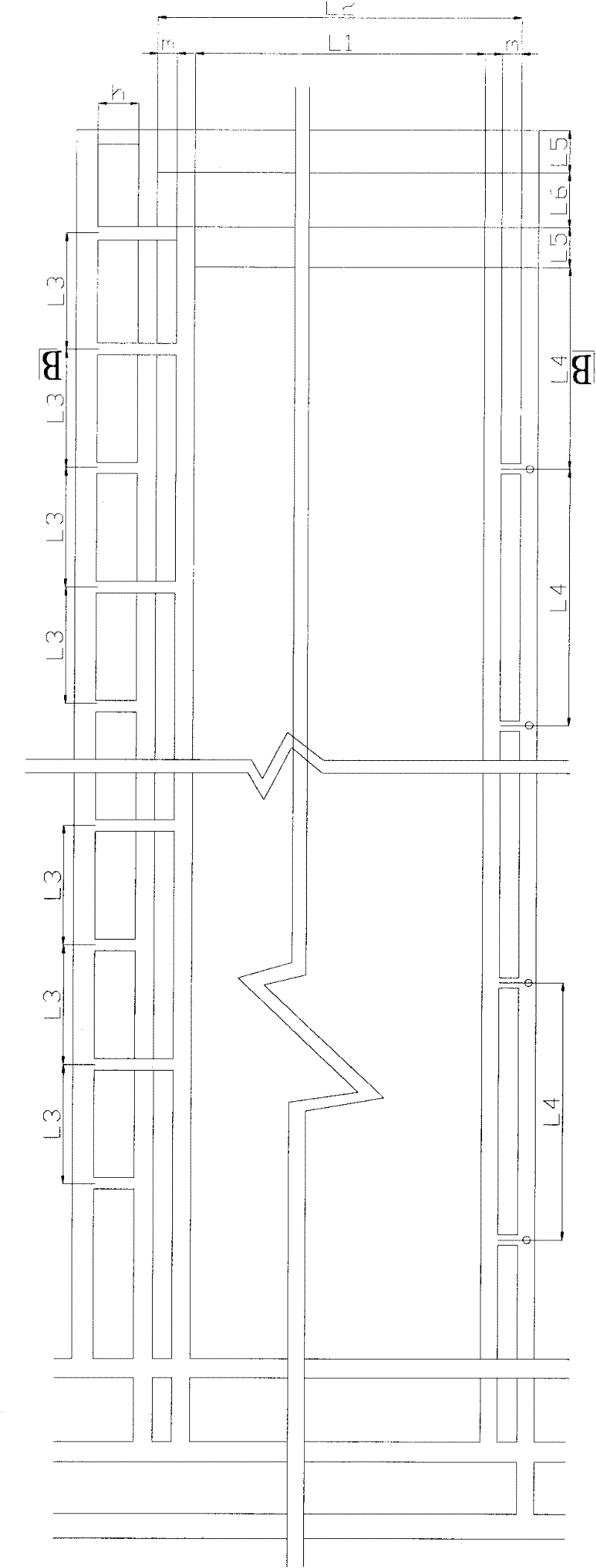

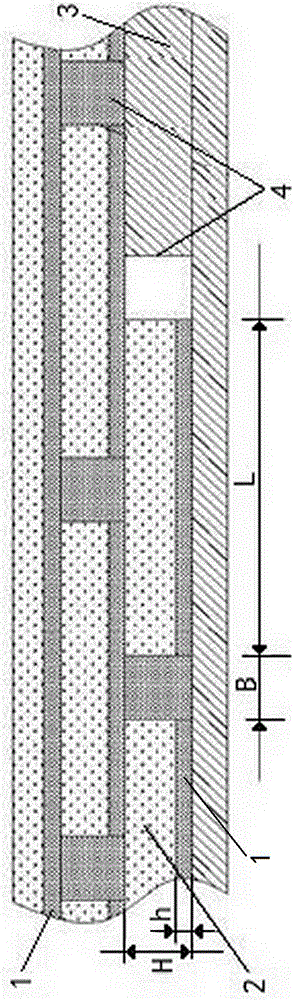

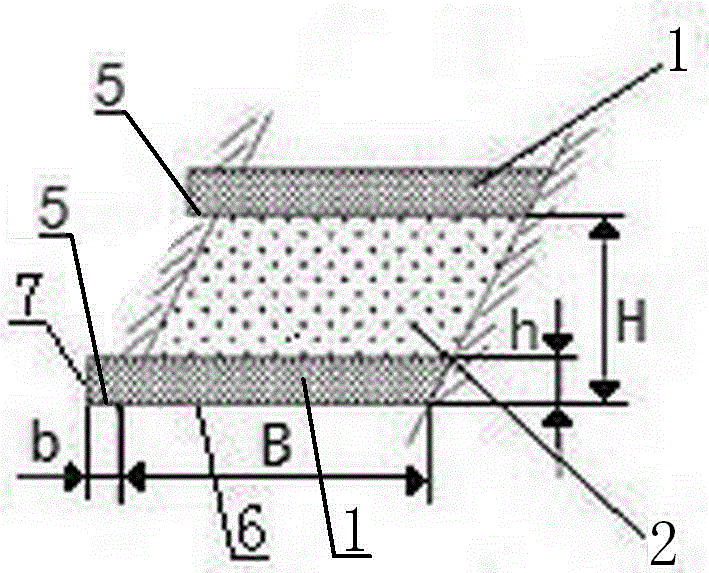

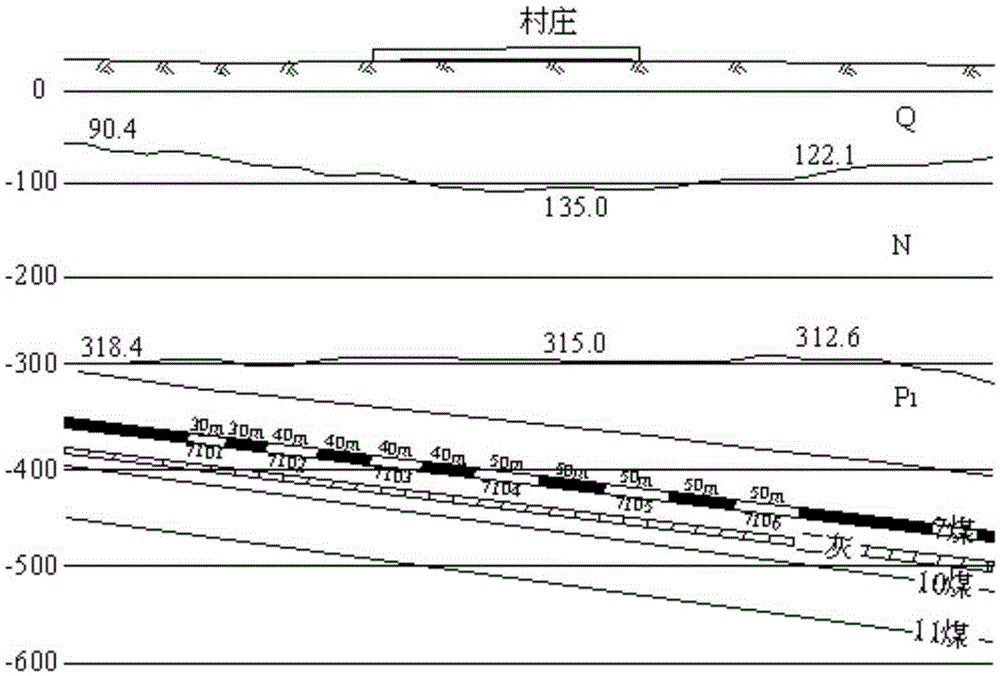

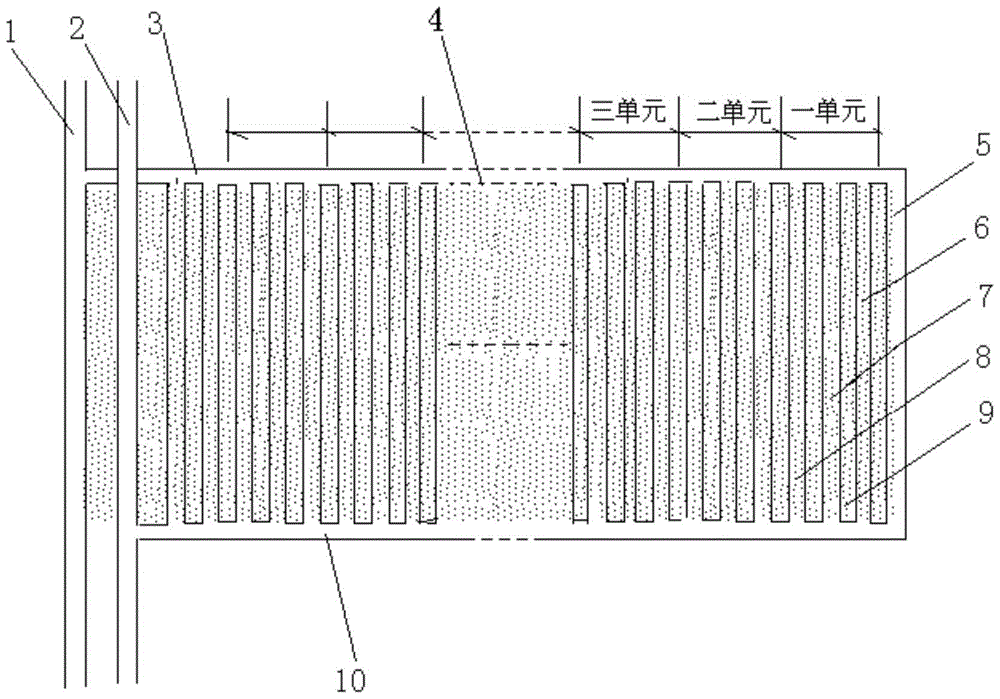

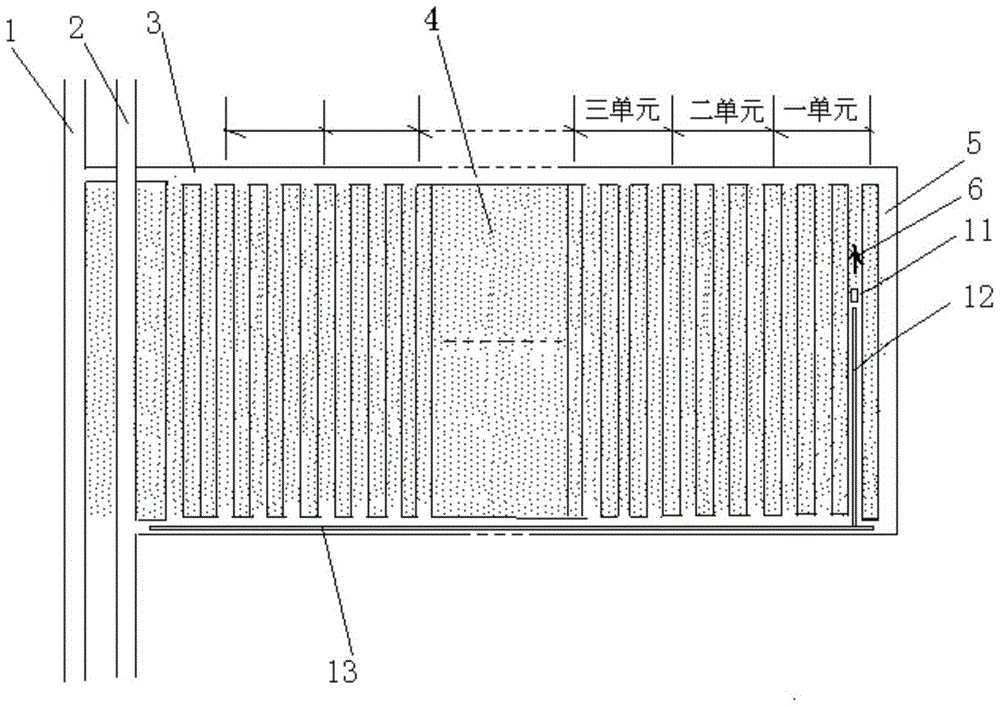

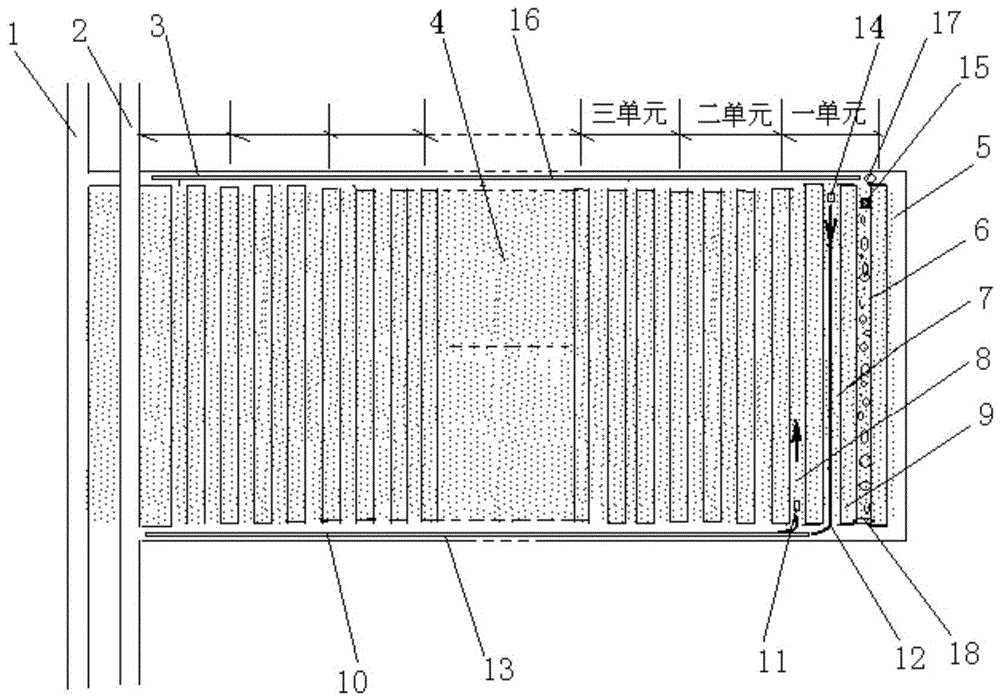

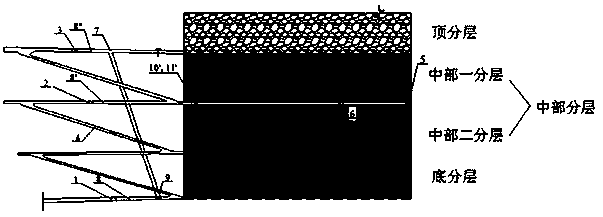

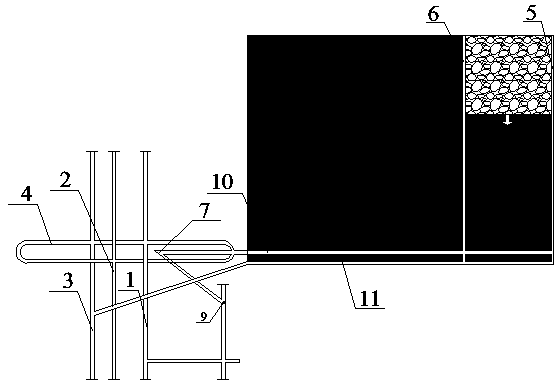

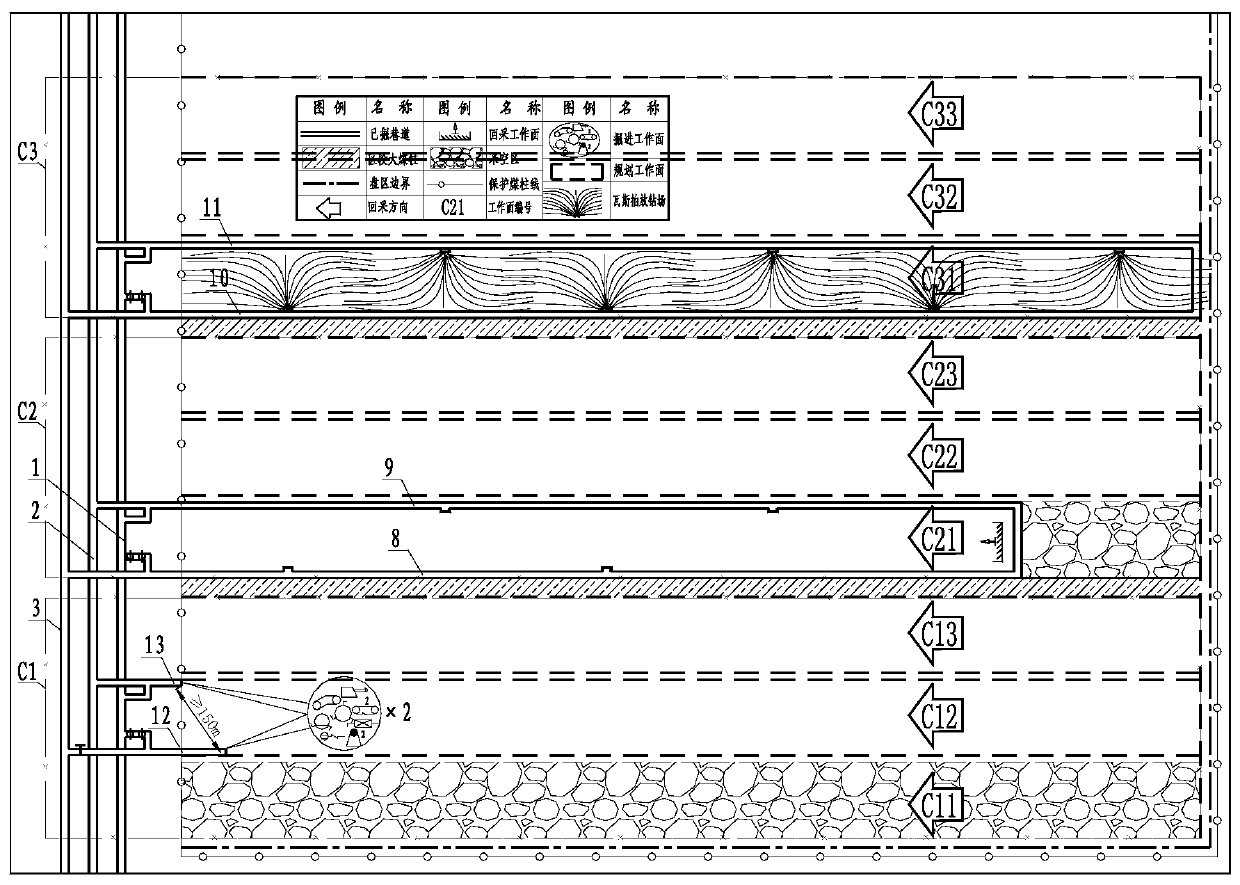

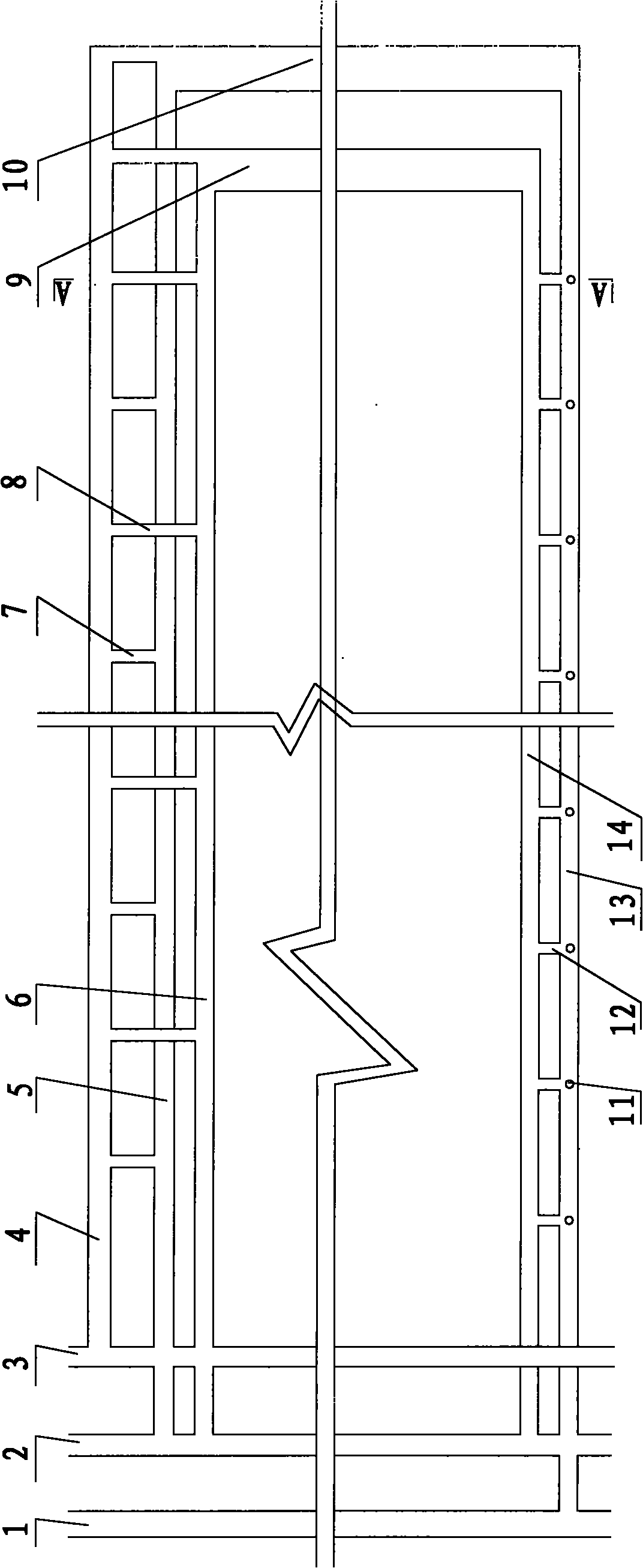

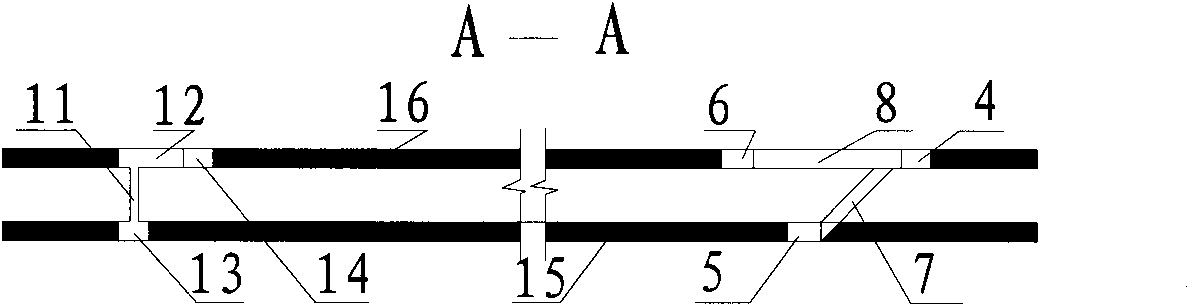

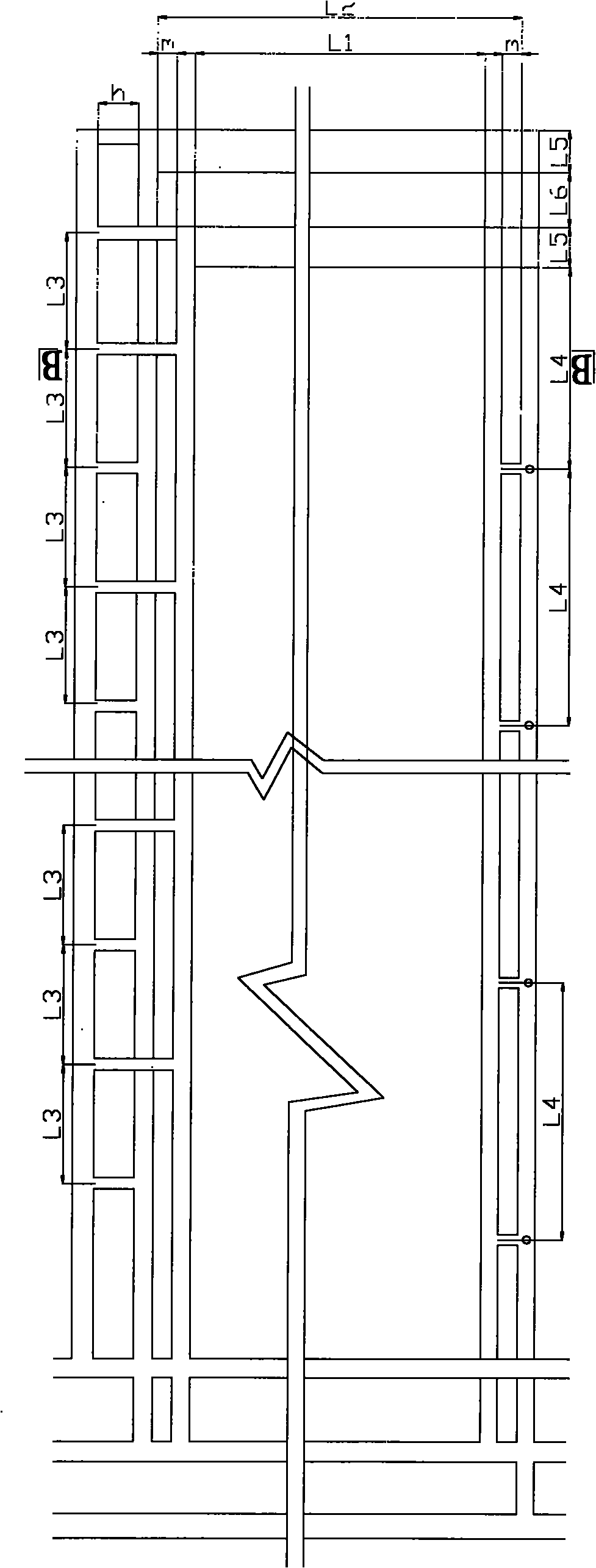

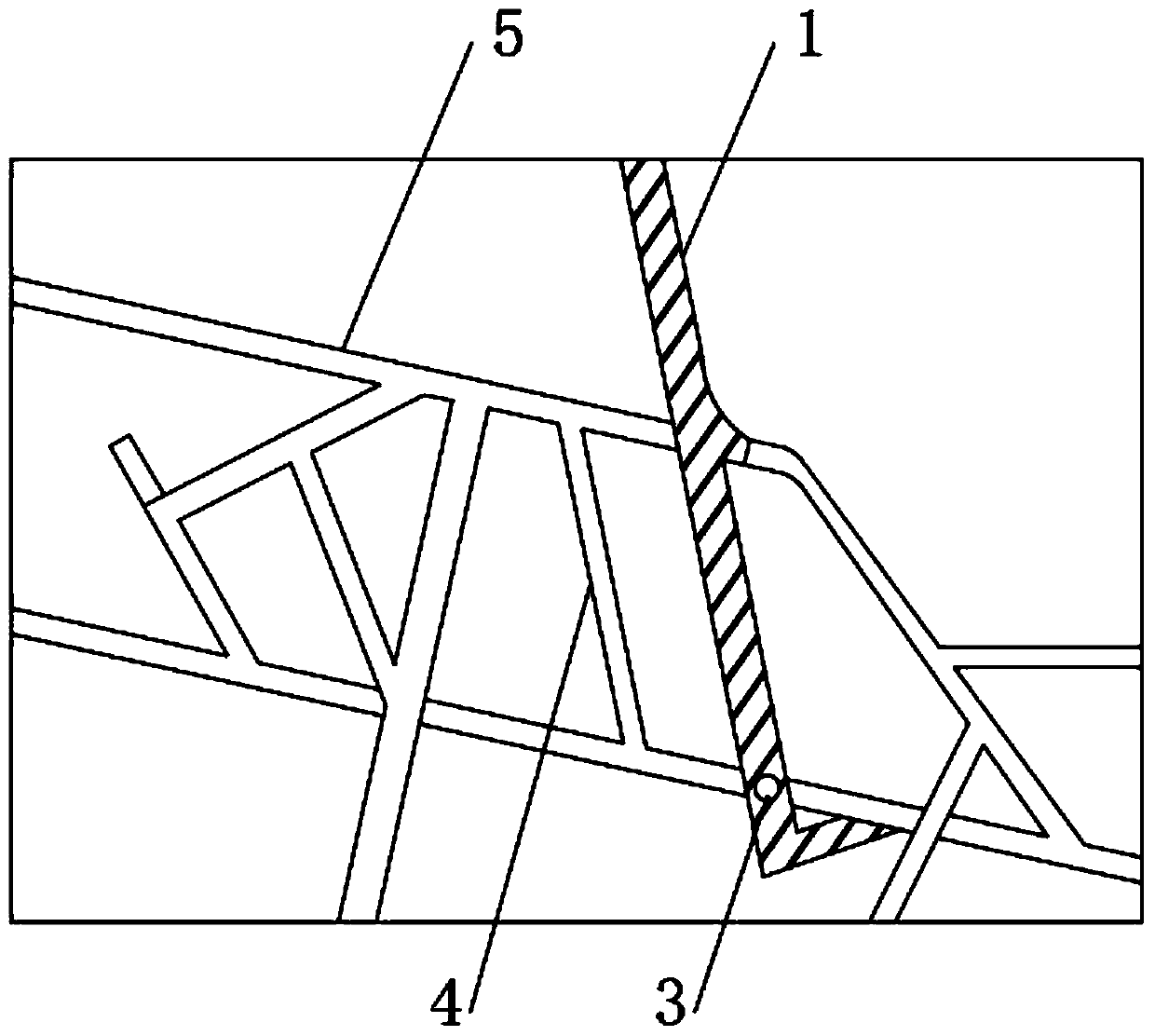

Close-range thin coal layer simultaneous mining and parallel transporting method

InactiveCN102392640AReduce the amount of excavation workIncrease productionUnderground miningSlitting machinesCentralized managementCoal

The invention discloses a close-range thin coal layer simultaneous mining and parallel transporting method, aiming to solve the problems caused by layer mining of the existing close-range thin coal layers, such as resource waste, serious flood, difficult mining distribution of lower layer coal, long mining period, low yield, high tunneling and supporting difficulties, high cost and the like. The method is characterized by arranging a centralized transport roadway, a centralized track roadway and a centralized air return roadway along the coal layers or top and bottom plates of the coal layers, simultaneously arranging two coal faces on the close-range thin coal layers and simultaneously mining and transporting coal. The method has the following beneficial effects: simultaneous mining and centralized transporting of the upper and lower coal layers are realized; relative to layer mining, by adopting the method, the tunneling quantities of the roadways are reduced, a belt conveyer can be simultaneously omitted, and the convenience is provided for centralized management of production; and especially for the close-range thin coal layers, the production system is simplified, the convenience is provided for centralized management, the production cost is lowered, and the mine output and the production efficiency are improved.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

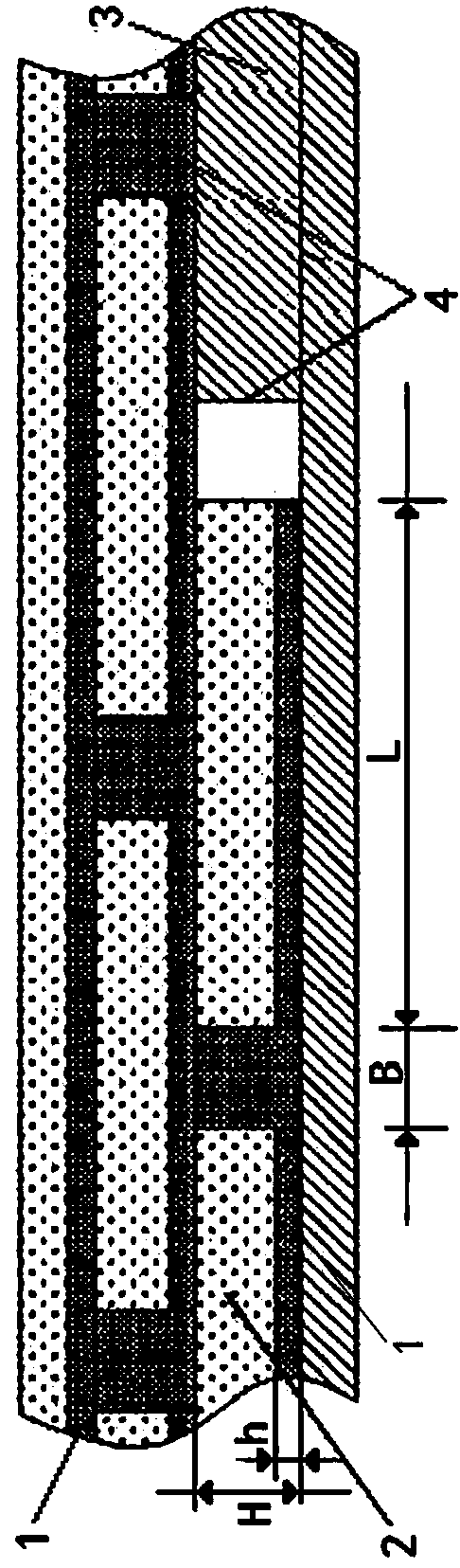

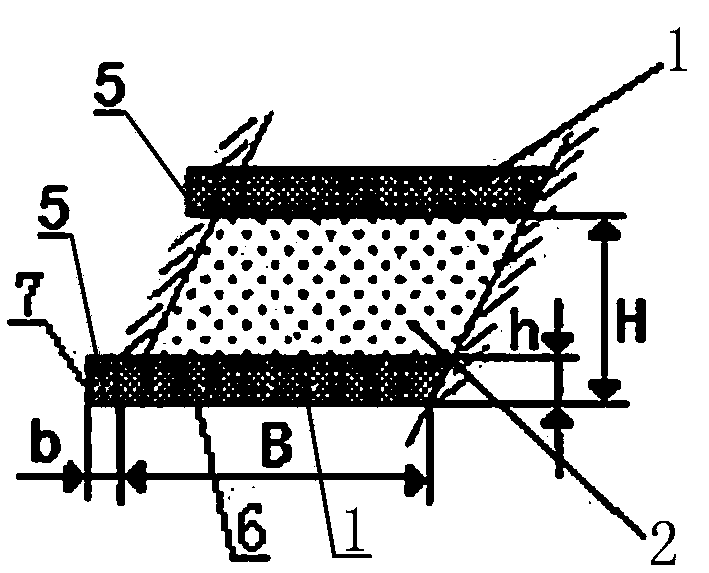

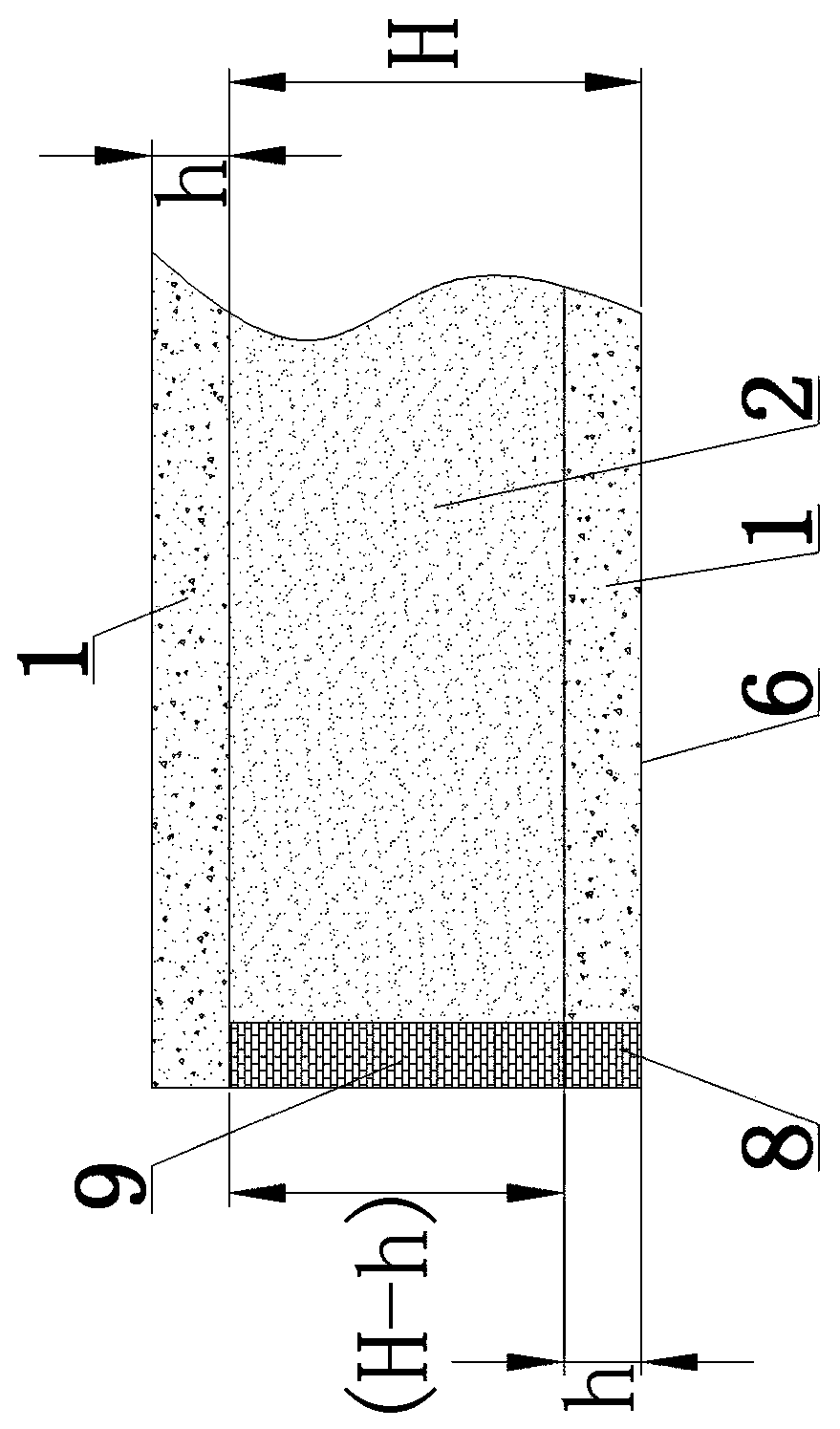

Drift type coal mining filling method

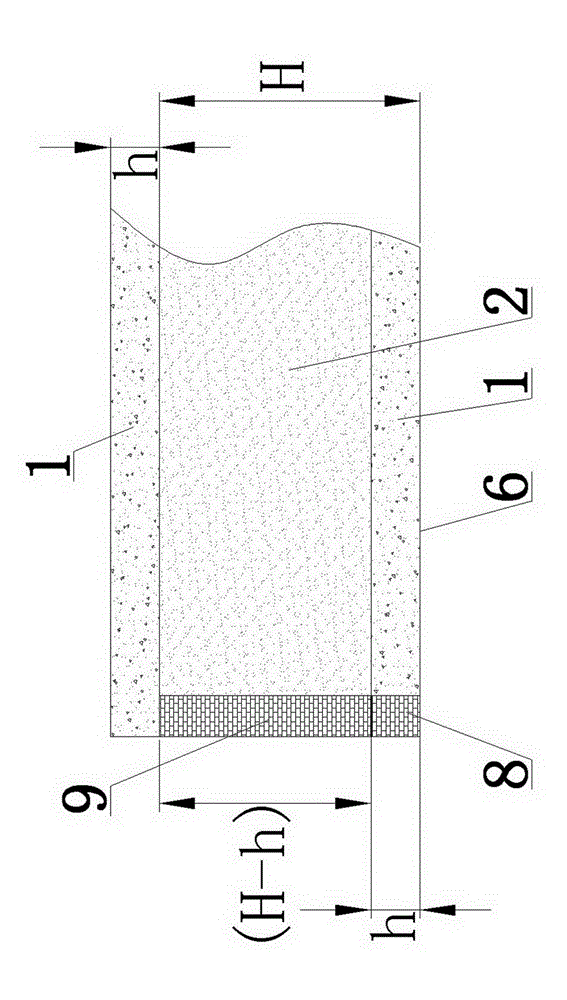

InactiveCN103147792AImprove mining efficiencyMeet stability and securityMaterial fill-upStopped workBrick

The invention discloses a drift type coal mining filling method. The method comprises the following steps of after one drift stoping work is completed, withdrawing a stoping machine, cutting and pulling a groove along a coal layer top plate at the lower side of a stope, cleaning the stope, building red bricks into a filling blockage wall at an entrance of the stope, enabling the filling blockage wall to be lower than the stope, pouring a cement mortar filling material into a filling area of the stope, solidifying the cement mortar to form a layer plate type adhesive body, then further upwards building the filling blockage wall to the height of the stope, and pouring the dewatered watery sand or yellow mud into a residual space above the layer plate type adhesive body of the filling area of the stope. The drift type coal mining filling method has the advantages that a production system of a coal mining well is simplified, the stoping rate of a working surface is favorably improved, the production is more safe and efficient, and the filling and production cost is saved.

Owner:贾巍

A method for recycling lead of abandoned lead acid accumulator

InactiveCN101188321ASimple production systemReduce energy consumptionWaste accumulators reclaimingBattery recyclingAuxiliary electrodeSulfur dioxide

The invention relates to a plumbum reclaiming method for a waste plumbum acid accumulator, and also relates to a method to process the waste plumbum acid accumulator, in particular to a method in which a wet method is used to reclaim plumbum from the material containing plumbum in the waste plumbum acid accumulator. The mixed material of the plate grid containing plumbum of the waste accumulator and plumbum paste is broken up to reach the granularity of 2 mm to 8 mm. The mixed material is filled in a column-shaped cloth bag to make a bag-shaped electrode and is put into the waste acid liquid of the waste accumulator to be electrolyzed. The plumbum material at the cathode is deoxidized into sponge plumbum, simultaneously the plumbum material at the anode is translated, desulfurized and oxygenated. A plurality of middle working procedures and assistant electrodes in the reclaiming using wet method at present are excused in the method of the invention, and the invention has better effect for improving production work efficiency and reducing reclaiming cost. The reclaiming is processed under the condition of moisture and normal temperature, and pollution of plumbum dust, plumbum vapor, plumbum residue and sulfur dioxide can not be generated. Water can be in recycling use. The invention is a clean and environmental protecting method for reclaiming the waste plumbum acid accumulator.

Owner:KUNMING UNIV OF SCI & TECH

Mining method of short- and long-wall portion of under-village coal

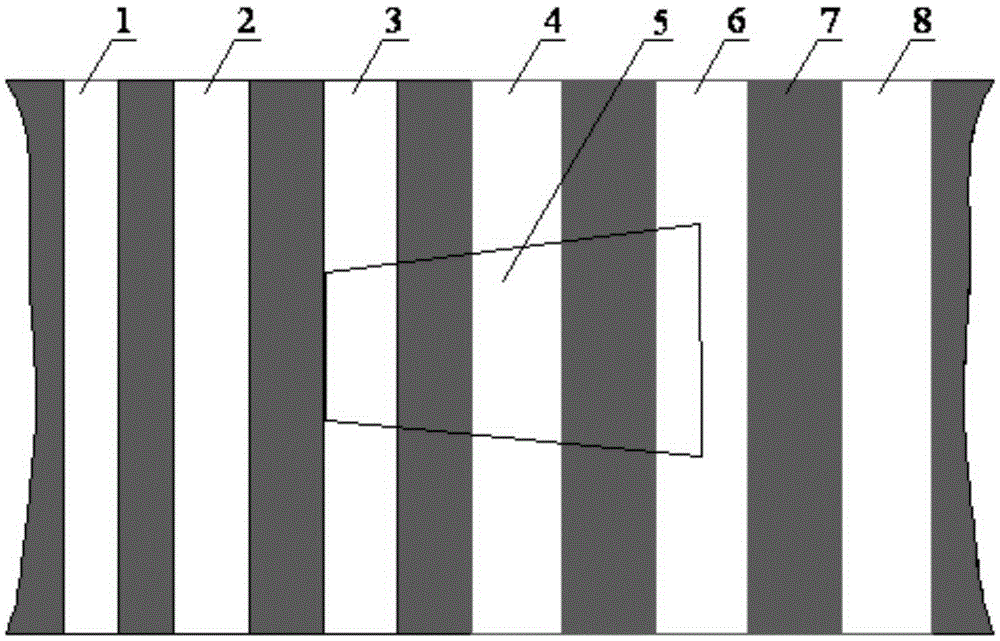

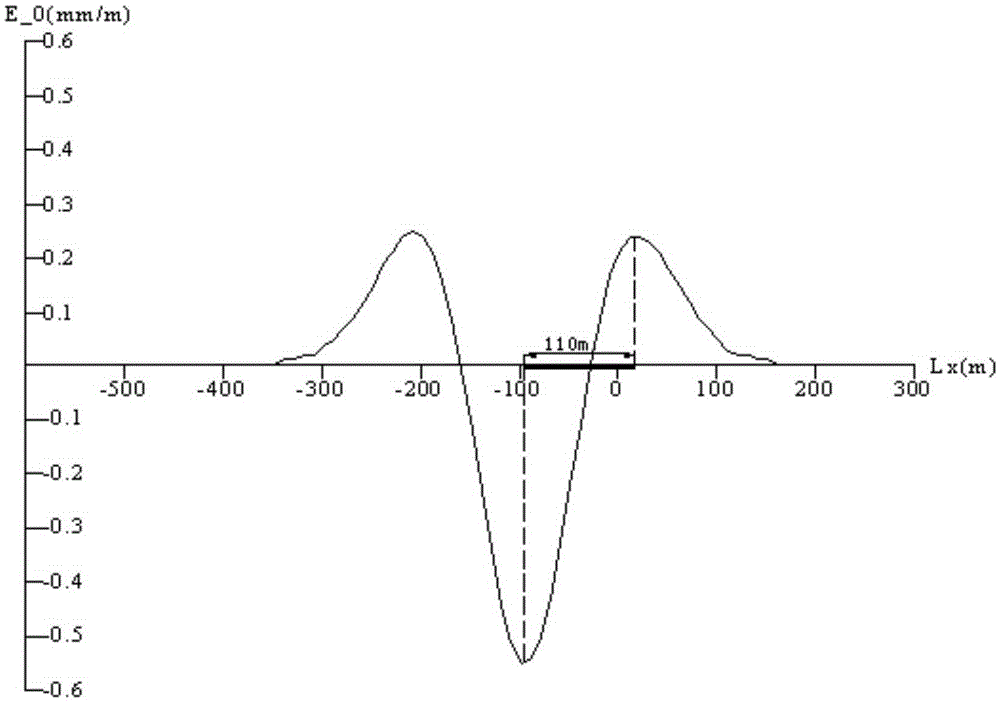

InactiveCN105332706AGood subsidence control effectProtect the safety of useUnderground miningSurface miningOrthogonal methodCoal

The invention discloses a mining method of a short- and long-wall portion of under-village coal, comprising steps: determining a face mining width extremum according to rock formation properties of a mining site in connection with face mining equipment supporting to obtain a face mining width range; determining an extremum of strip pillar reserved width between faces according to overlying stratum depth and overlying rock lithological conditions in connection with Wilson's theory, thus obtaining a strip pillar reserved width range; pairing face mining width and pillar reversed width by using an orthogonal method according to the face mining width range and isolation pillar reserved width range to form multiple schemes, and subjecting each scheme to pillar stability check and mining subsidence prediction to select optimal schemes; determining a mining sequence of strip multiple faces according to the principle of mining an area right under a building prior to lateral mining; the method has high operating efficiency, low cost and environmental friendliness.

Owner:TIANDI SCI & TECH CO LTD

Full negative pressure short wall filling coal mining method

PendingCN108301833AUndamagedEffective isolationUnderground miningSurface miningEngineeringStructural engineering

The invention provides a full negative pressure short wall filling coal mining method. The full negative pressure short wall filling coal mining method comprises the following steps that 10, positionsof a centralized return air lane and a centralized transportation lane are determined, and a transportation roadway, a first return air roadway and a second return air roadway are arranged; 20, tunneling is carried out on a branch lane in a first mining area, and after the branch lane is penetrated, tunneling is carried out on a branch lane in a second mining area, at the same time, supporting iscarried out on a penetrated branch lane, and a communication port between the penetrated branch lane and the transportation roadway is blocked; 30, the penetrated branch lane is filled after pluggingis finished; 40, tunneling is carried out on another branch lane in the first mining area, at the same time, supporting is carried out on a penetrated branch lane in the second mining area and a communication port between the penetrated branch lane and the transportation roadway is blocked; 50, the penetrated branch lane in the second mining area is filled after plugging is finished; 60, steps 10to 50 are cycled until the branch lane is completely filled; and 70, after filling is completed, reserved coal pillar lanes are successively mined according to the direction from the far end to the near end.

Owner:路彬

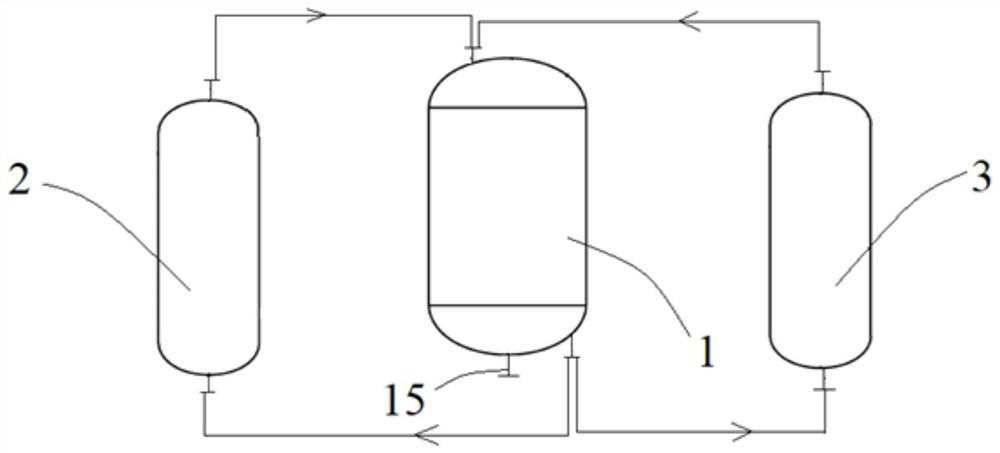

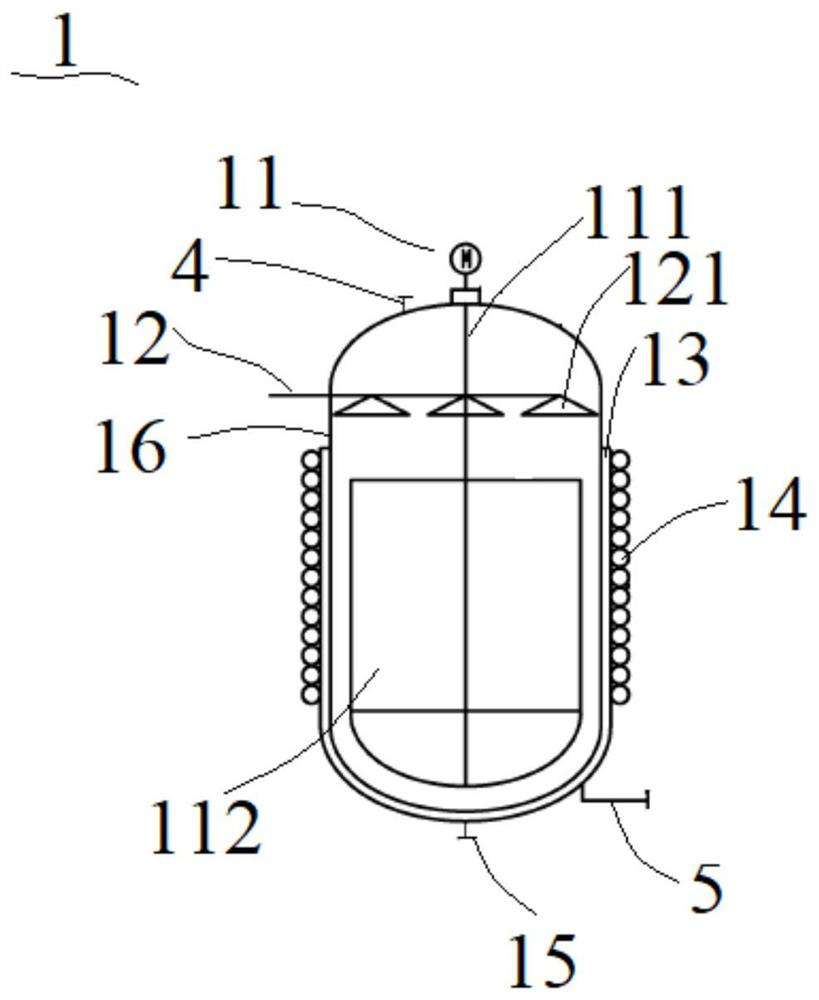

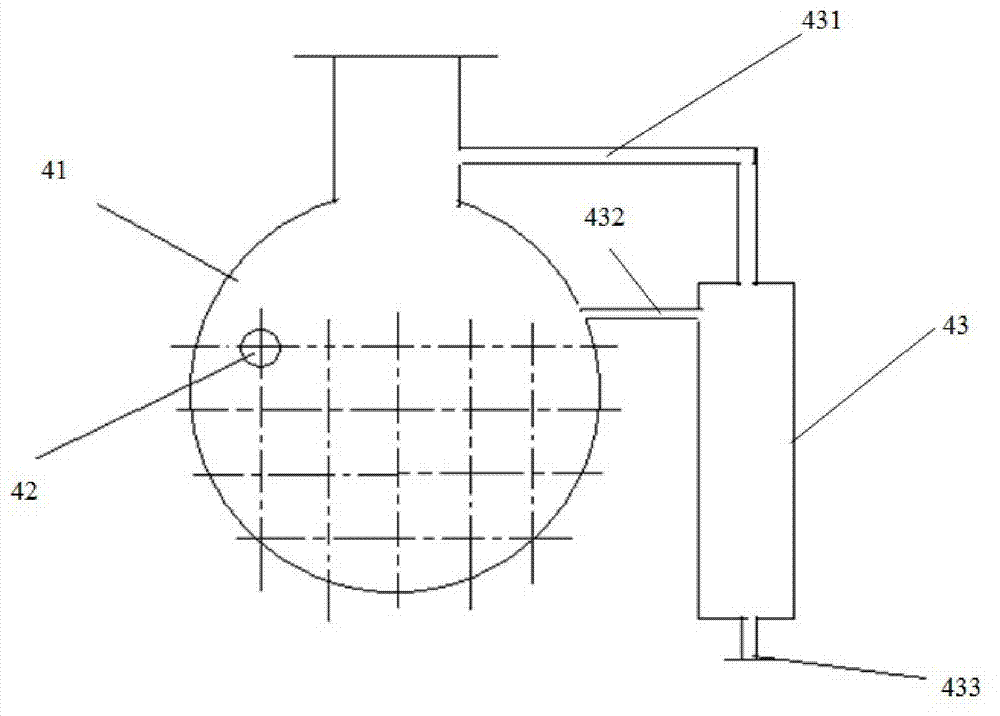

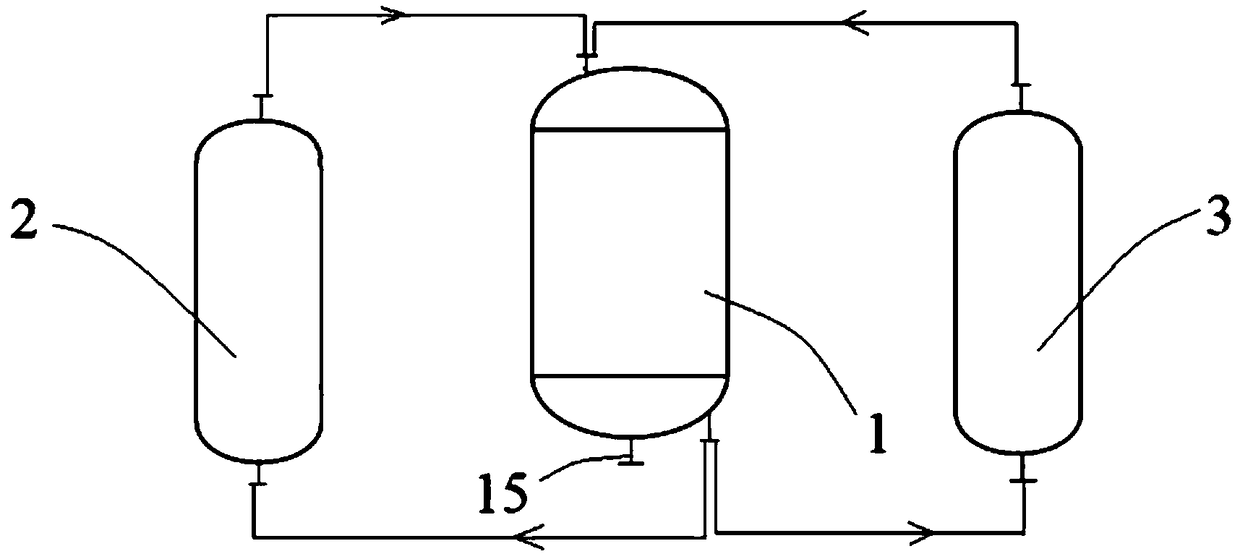

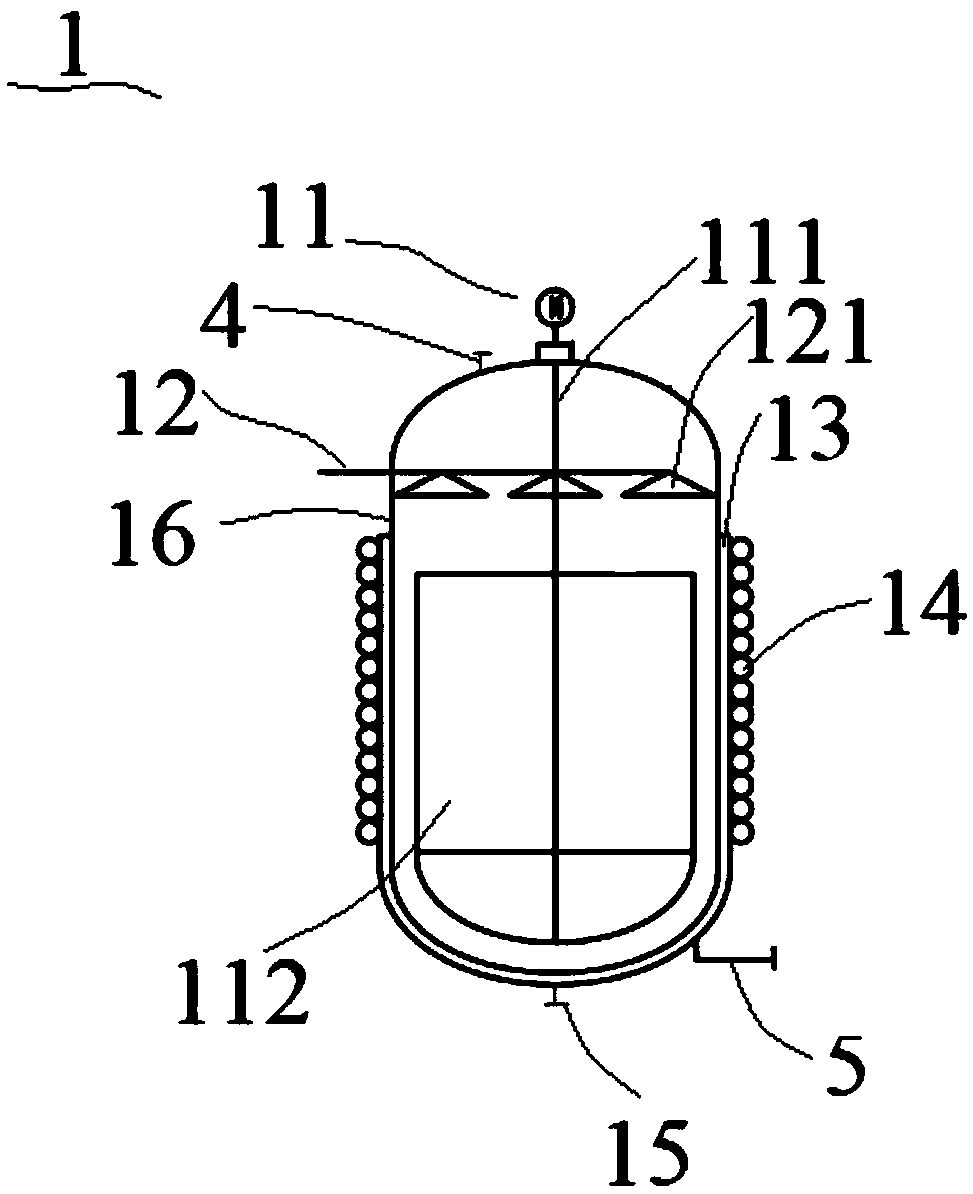

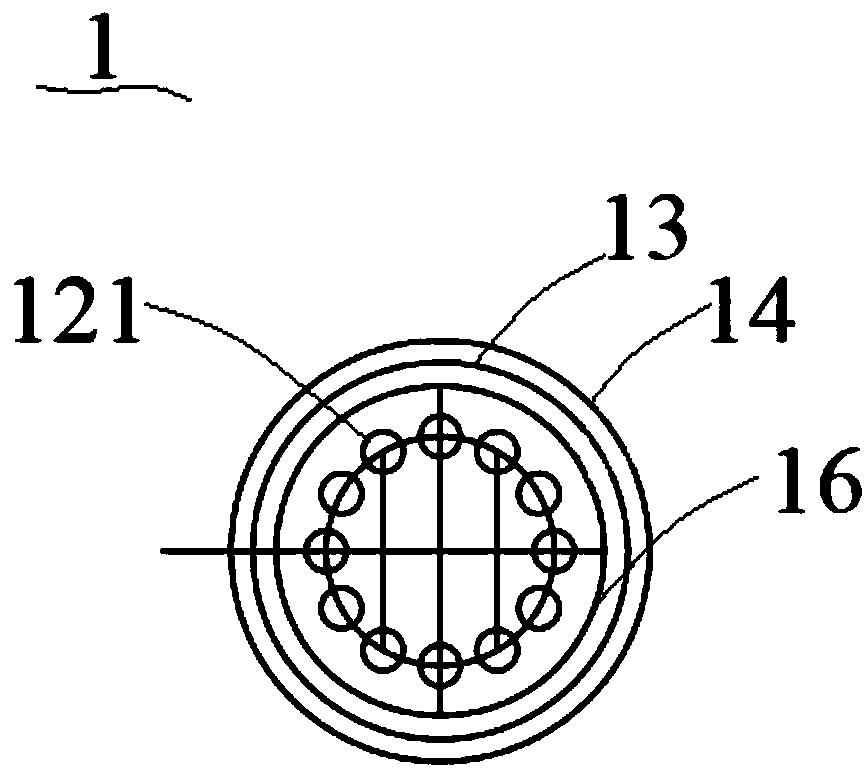

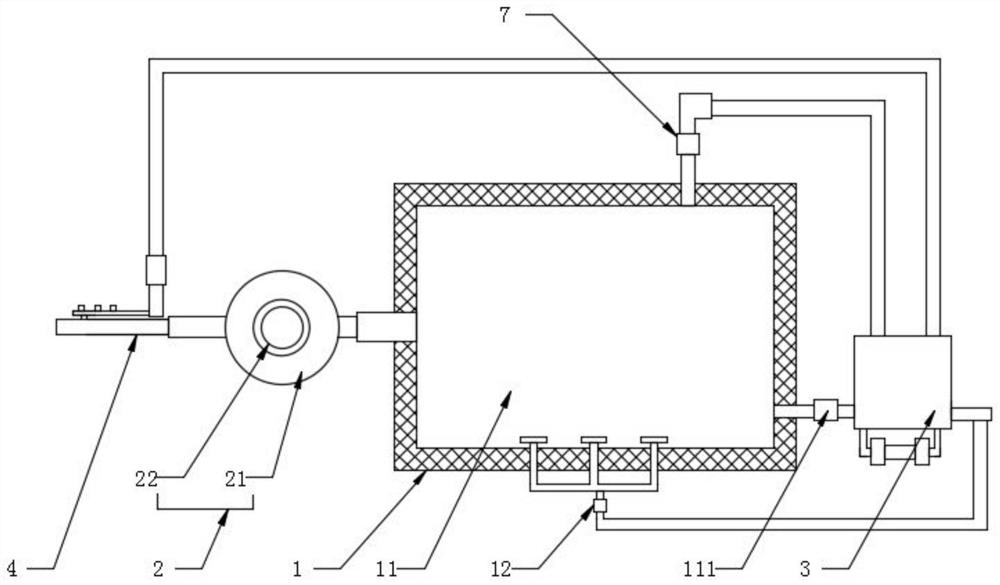

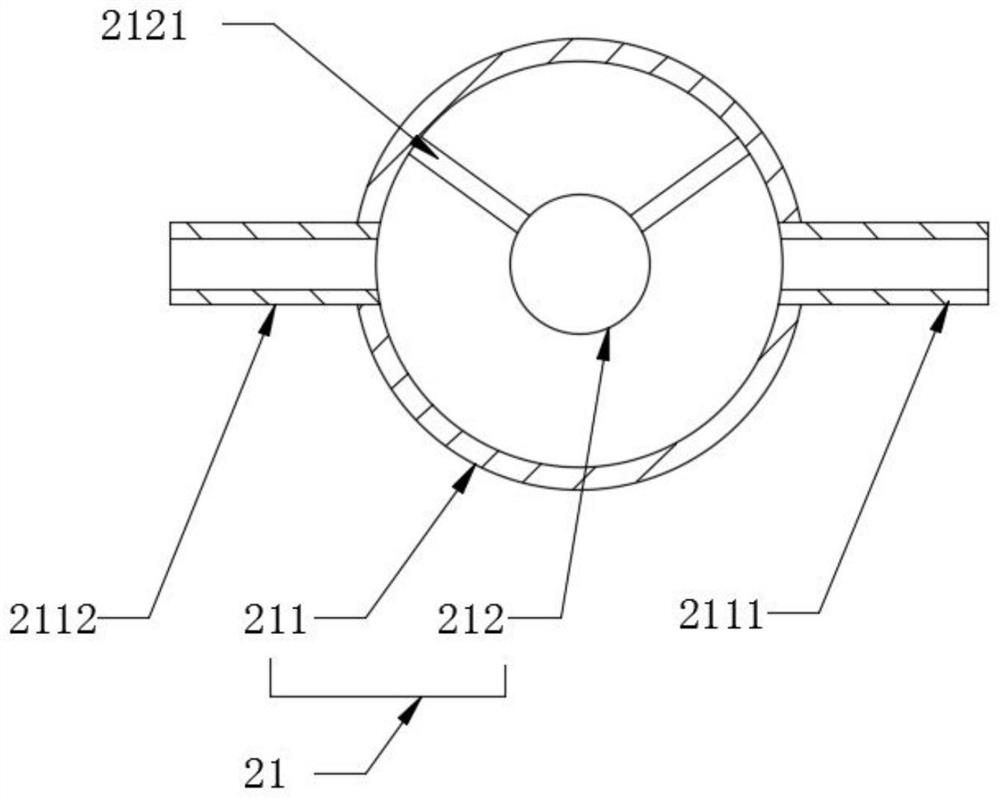

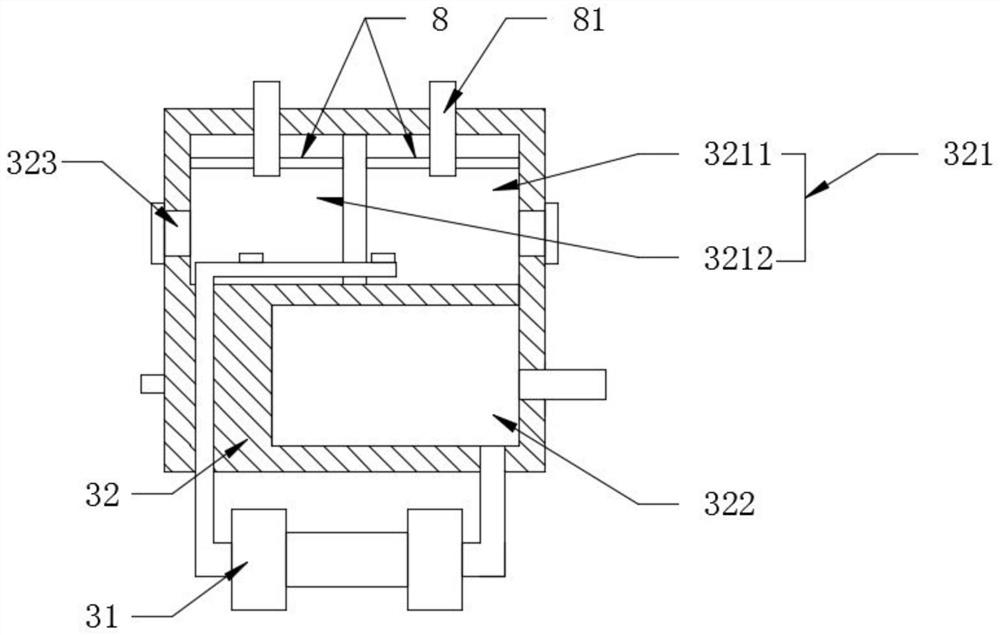

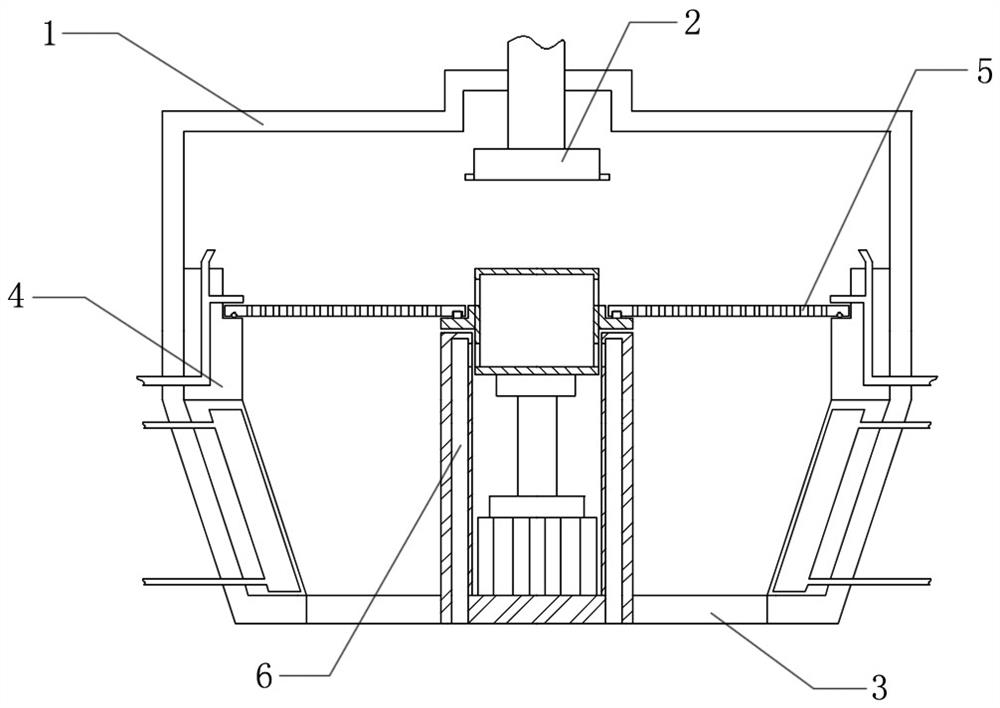

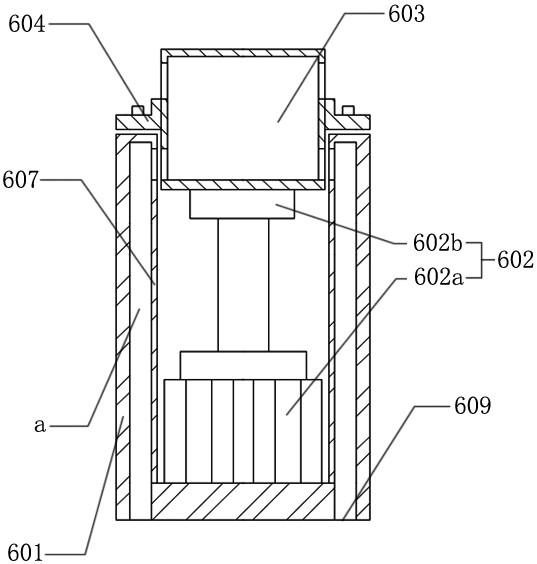

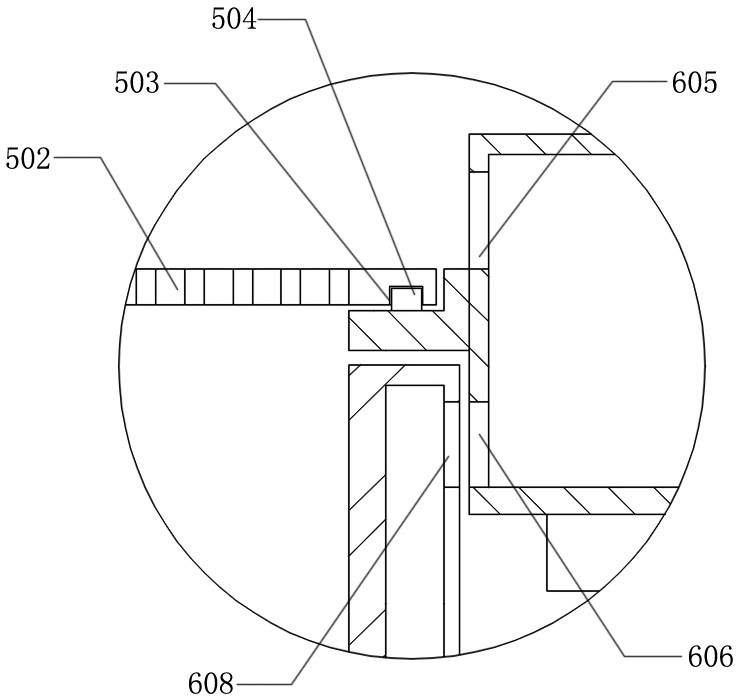

A production system and production method of nano biomedical materials

ActiveCN109351301BImprove purityReduce manufacturing costEnergy based chemical/physical/physico-chemical processesFeed devicesProcess engineeringIndustrial engineering

The invention provides a production system and method of a nano biomedical material. The production system comprises a reactor, a first membrane separator and a second membrane separator; a feeding port of the first membrane separator is communicated with a discharging port of the reactor, and a discharging port of the first membrane separator is communicated with a feeding port of the reactor; afeeding port of the second membrane separator is communicated with the discharging port of the reactor, and a discharging port of the second membrane separator is communicated with the feeding port ofthe reactor. According to the production system and method of the nano biomedical material, the nano biomedical material can be prepared simply through one reactor and two membrane separators, the whole production system is simple, related equipment in the production process of the nano biomedical material is reduced, then the possibility that medicine is contaminated is reduced, thus the improvement of the purity of the nano biomedical material is facilitated, the amount of equipment is reduced, and the reduction of the cost for producing the nano biomedical material is facilitated.

Owner:SEDIN NINGBO ENG +1

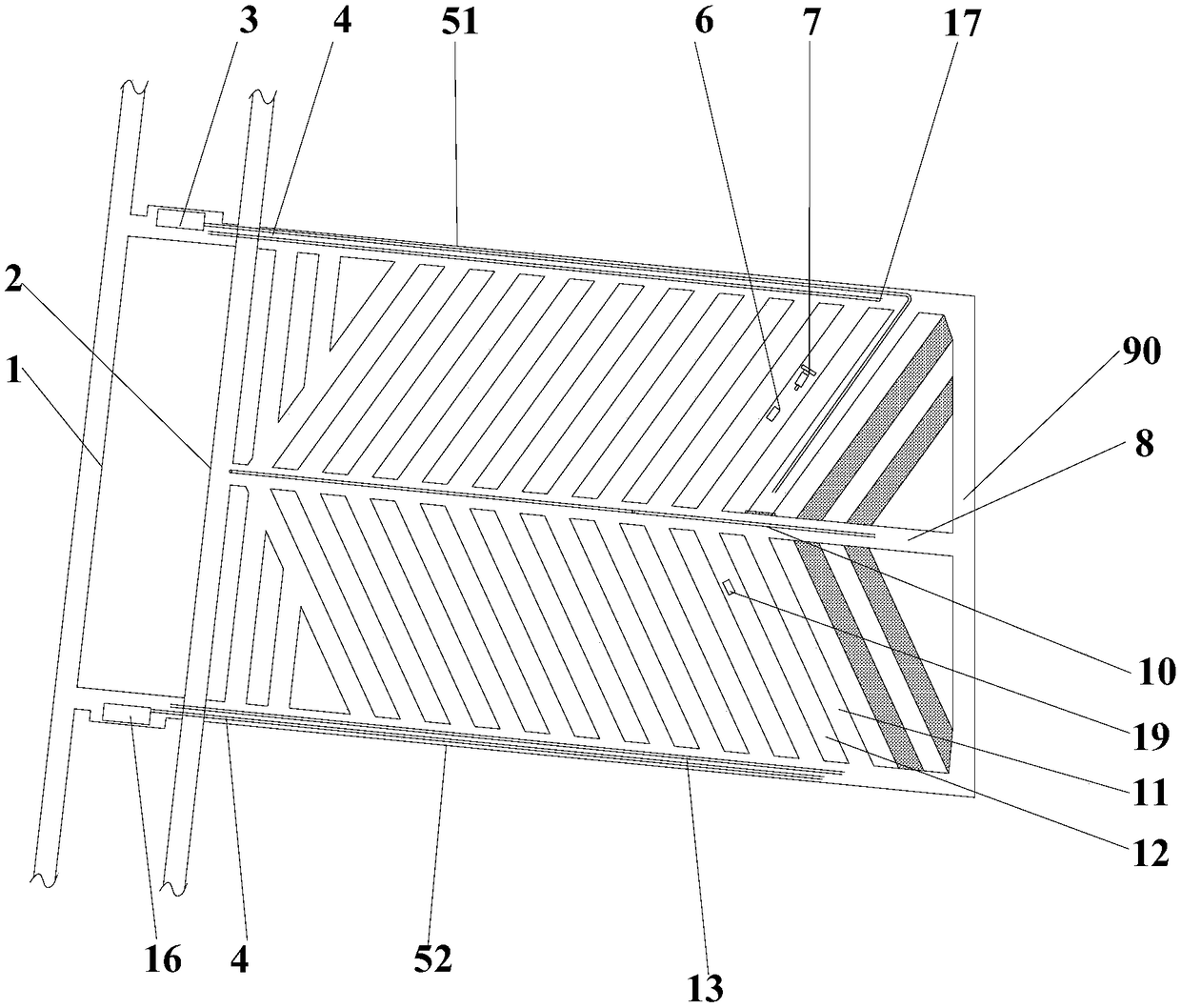

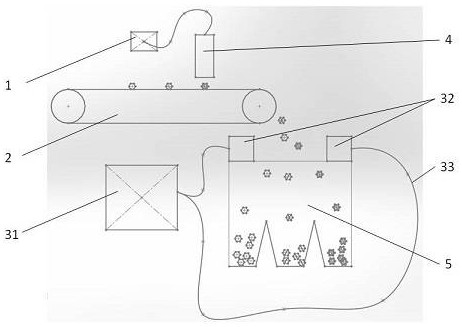

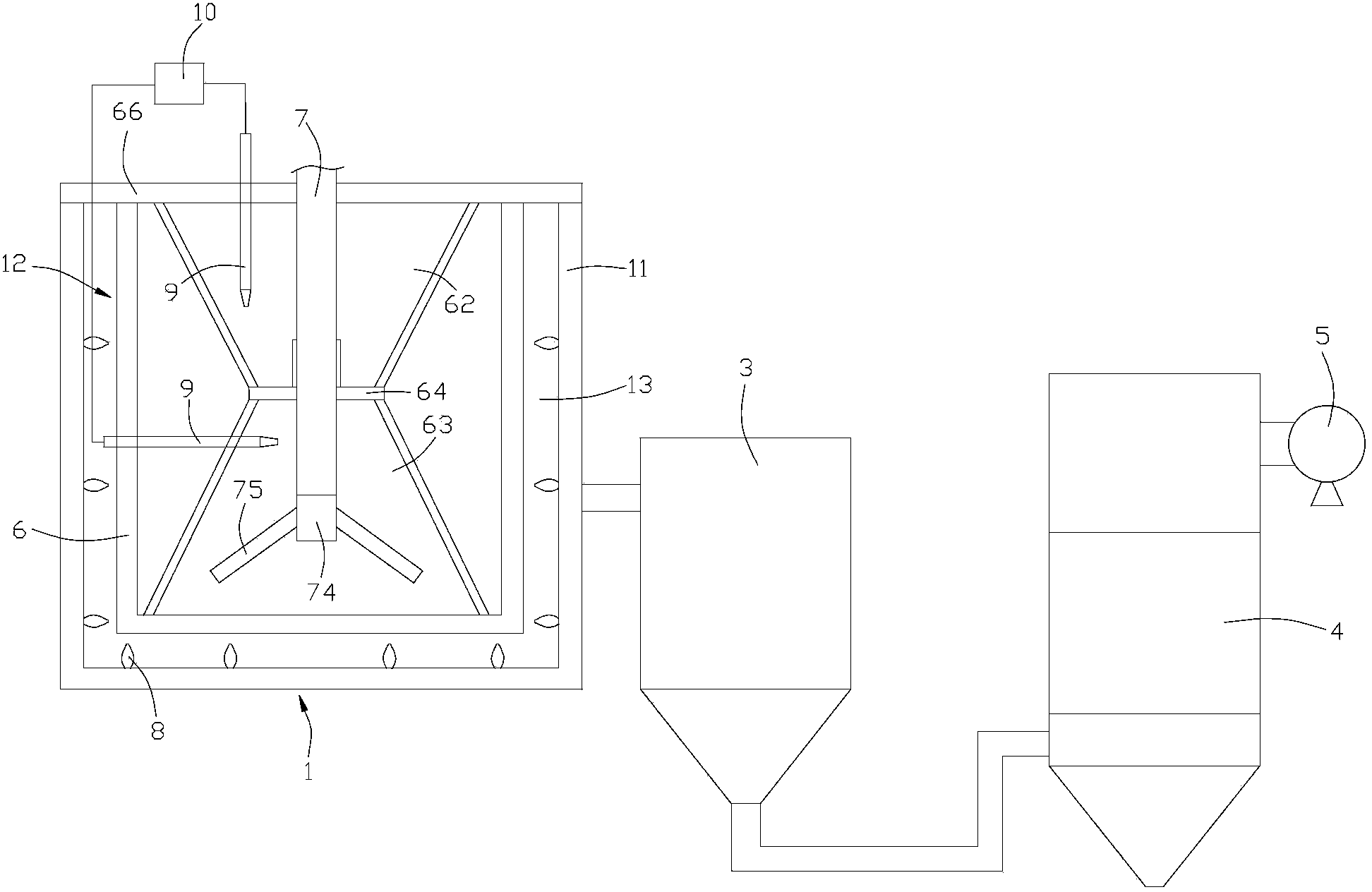

Mineral intelligent sorting system and method

The invention relates to an intelligent sorting system and method based on on-line coal quality detection technology, visual identification and positioning technology to detect the properties and positions of minerals, and to sort minerals according to categories of minerals with water jet. The intelligent sorting system and method are a fine process of identifying and sorting each material one byone, and are particularly suitable for sorting materials into a plurality of categories of products, and greatly improves the sorting accuracy. The sorting system of the present invention uses waterjet technology. Compared with a dry sorting injection technology in the prior art, the energy carried by the water jet is larger and more concentrated, and large materials which are difficult to be sorted in the technology in the prior art can be sorted. Compared with the dry sorting injection technology, water jet shooting target materials takes shorter time and achieves higher efficiency. The defects of interference of airflow on the running track of non-target materials caused by injecting materials with high-pressure gas in the current dry sorting technology and even inaccurate injection are avoided, and the sorting accuracy is improved. There is no coal dust caused by injecting materials by the dry sorting technology in the prior art, and there is no need for matched dust removal equipment.

Owner:爱读(天津)智能科技有限公司

Intelligent robot underground gangue removing system

PendingCN107413677AOptimize layoutReduce invalid transportationSievingScreeningIntelligent robotsClean coal

The invention discloses an intelligent robot underground gangue removing system. The intelligent robot underground gangue removing system comprises a front section main roadway belt, a roll screen, a rear section main roadway belt, an intelligent robot gangue picking system belt, an intelligent robot gangue picking system, an extremely-large clean coal returning belt and a gangue belt, wherein the front section main roadway belt, the roll screen and the rear section main roadway belt are sequentially arranged inside a main haulage roadway; the intelligent robot gangue picking system belt, the intelligent robot gangue picking system and the extremely-large clean coal returning belt are arranged inside an intelligent robot gangue picking chamber; and the gangue belt is arranged inside a gangue conveying roadway. The tail end of the front section main roadway belt is in lap joint with the front end of the roll screen, and the tail end of the roll screen is in lap joint with the front end of the intelligent robot gangue picking system belt and the front end of the rear section main roadway belt. The tail end of the intelligent robot gangue picking system belt and the front end of the extremely-large clean coal returning belt are both in lap joint with one end of the intelligent robot gangue picking system. The tail end of the extremely-large clean coal returning belt is in lap joint with the front section of the rear section main roadway belt. The other end of the intelligent robot gangue picking system is in lap joint with the front end of the gangue belt. According to the intelligent robot underground gangue removing system, an intelligent gangue picking robot is creatively selected, the process is simple, arrangement is reasonable, construction difficulties are reduced and investment is saved.

Owner:中煤能源研究院有限责任公司

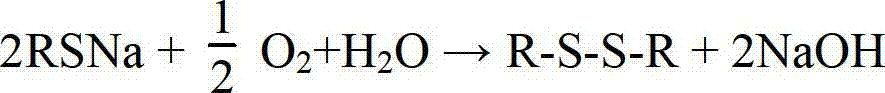

Technology and system for preparing vulcanizing agent by using sweetening waste of lye regenerated byproducts

ActiveCN102964281AAvoid pollutionMeet the indicator requirementsOrganic chemistryOrganic compound preparationLiquid wasteReflux

The invention discloses a technology for preparing a vulcanizing agent by using a sweetening waste of lye regenerated byproducts. The sweetening waste of the lye regenerated byproducts is continuously sent into a rectifying tower through a charging pump for fractionation. Non-metallic compounds in the waste are heated and evaporated into steam which rises to a tower top as an overhead fraction; the overhead fraction enters a top condenser and is condensed into liquid which then enters a reflux tank; a part of the liquid in the reflux tank is sent into a product tank and used as the finished vulcanizing agent; and the other part of the liquid in the reflux tank, as a reflux liquid, is sent back to the rectifying tower by a reflux pump to join the waste liquid entering the tower for further fractionation, until the sweetening waste of the lye regenerated byproducts of a same batch is completely processed. The technology has advantages of suitably controlled fractionation condition and high yield of the vulcanizing agent.

Owner:CHINA PETROLEUM & CHEM CORP

Full Negative Pressure Continuous Mining Continuous Full Step Replacement "Three Down" Coal Mining Method

ActiveCN104775817BUndamagedRealize full negative pressure ventilationUnderground miningTunnel/mines ventillationEngineeringProduction unit

Owner:路彬 +1

Five-cereal table vinegar brewing method and processing system

The invention belongs to the technical field of table vinegar brewing, and particularly relates to a five-cereal table vinegar brewing method and processing system. The brewing method comprises the following brewing steps: raw material crushing, cooking and liquefying, saccharifying, alcoholic fermentation, filtering, and acetic fermentation. The production process is simple, and the method is simple to operate and suitable for large-scale and small-scale production. Corn, wheat, millet, sorghum and pea are adopted as ingredients, and the taste and nutritional value are improved. The vinegar brewing process is improved, the decomposition of raw materials and the synergistic effect of microbial communities are facilitated, the biochemical performance is improved, more metabolites are generated, the flavor can be improved, and the vinegar yield can be increased. The production environment is clean and safe, and the fermentation is stable. A production system is simple, and a groove typefilter and a plate-and-frame filter press are combined and installed. The filtering efficiency is improved, and the vinegar flavor is improved.

Owner:宁夏兴宇绿色粗粮加工有限公司

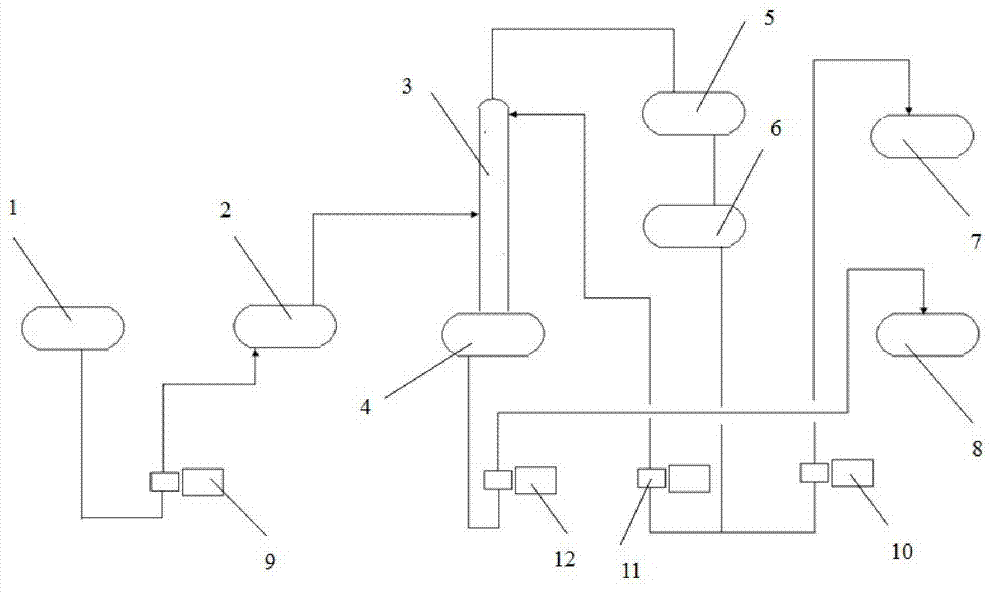

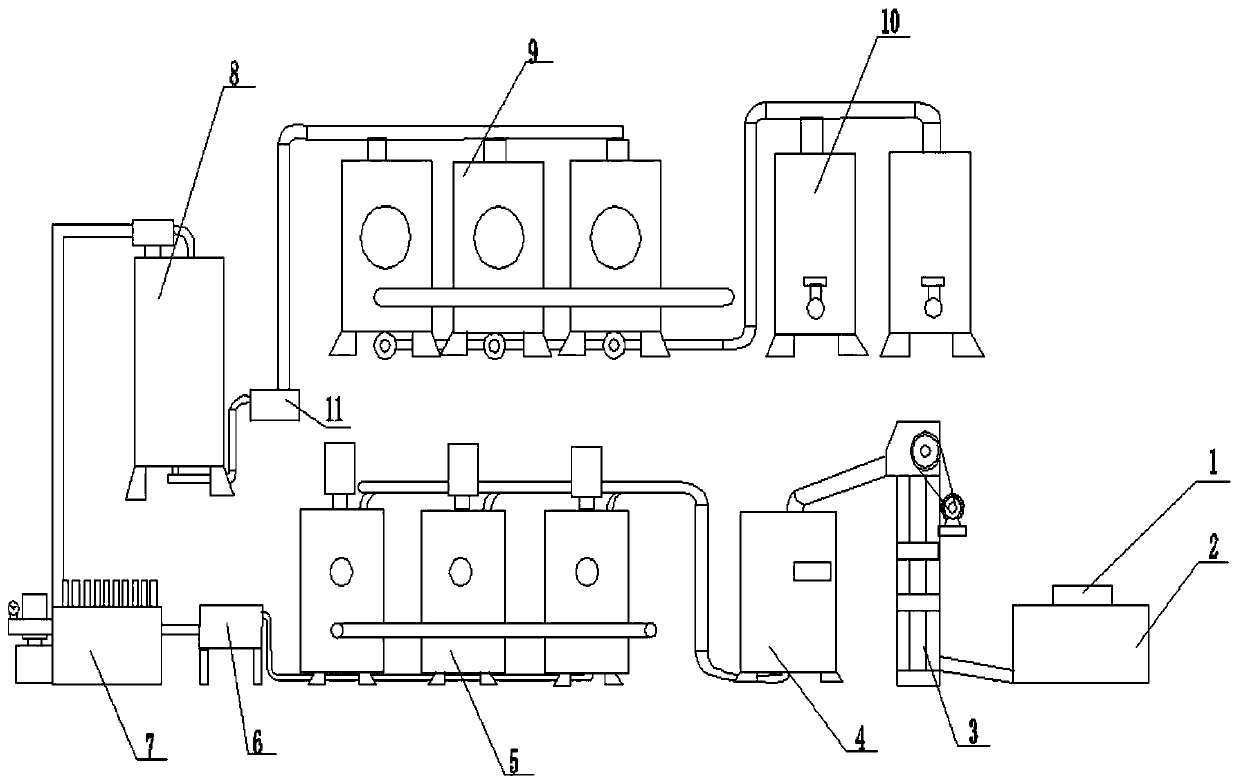

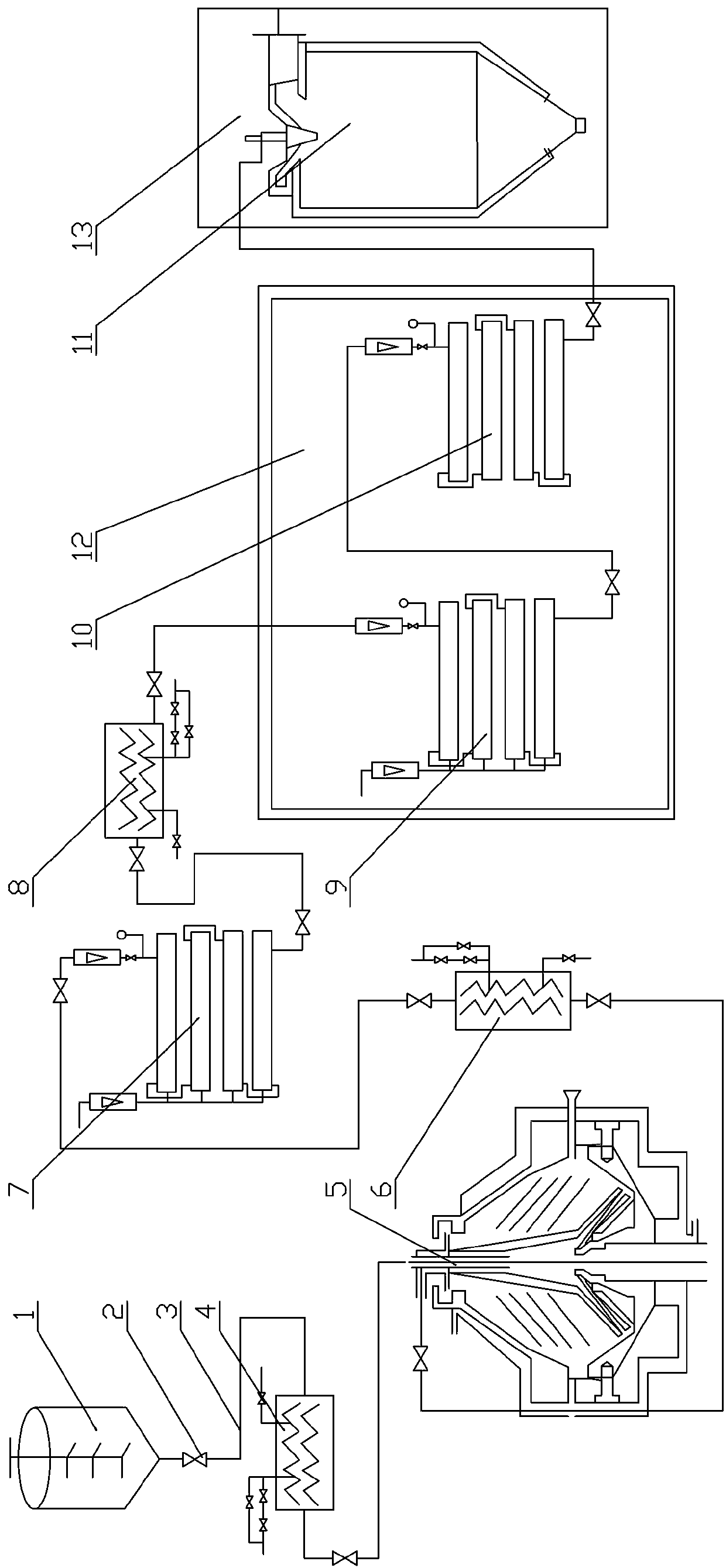

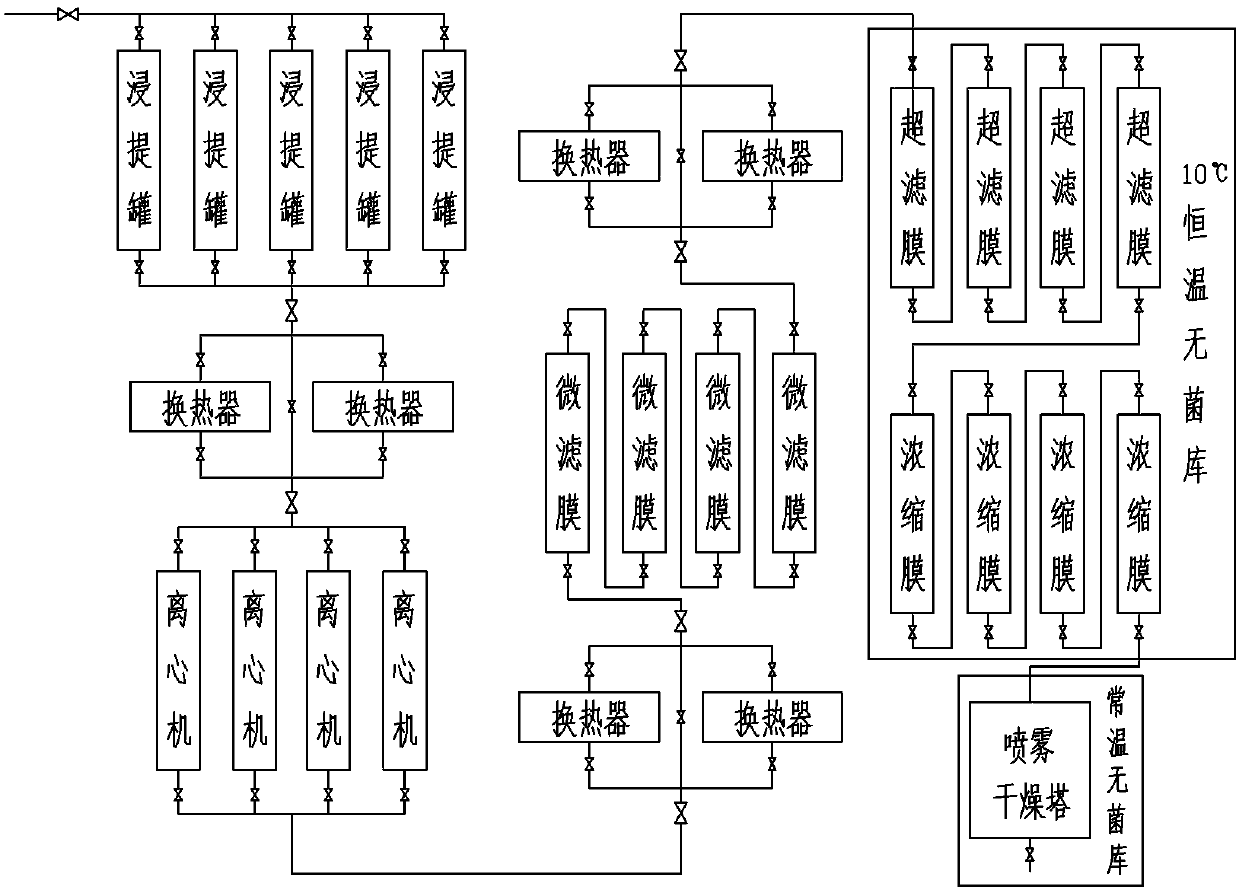

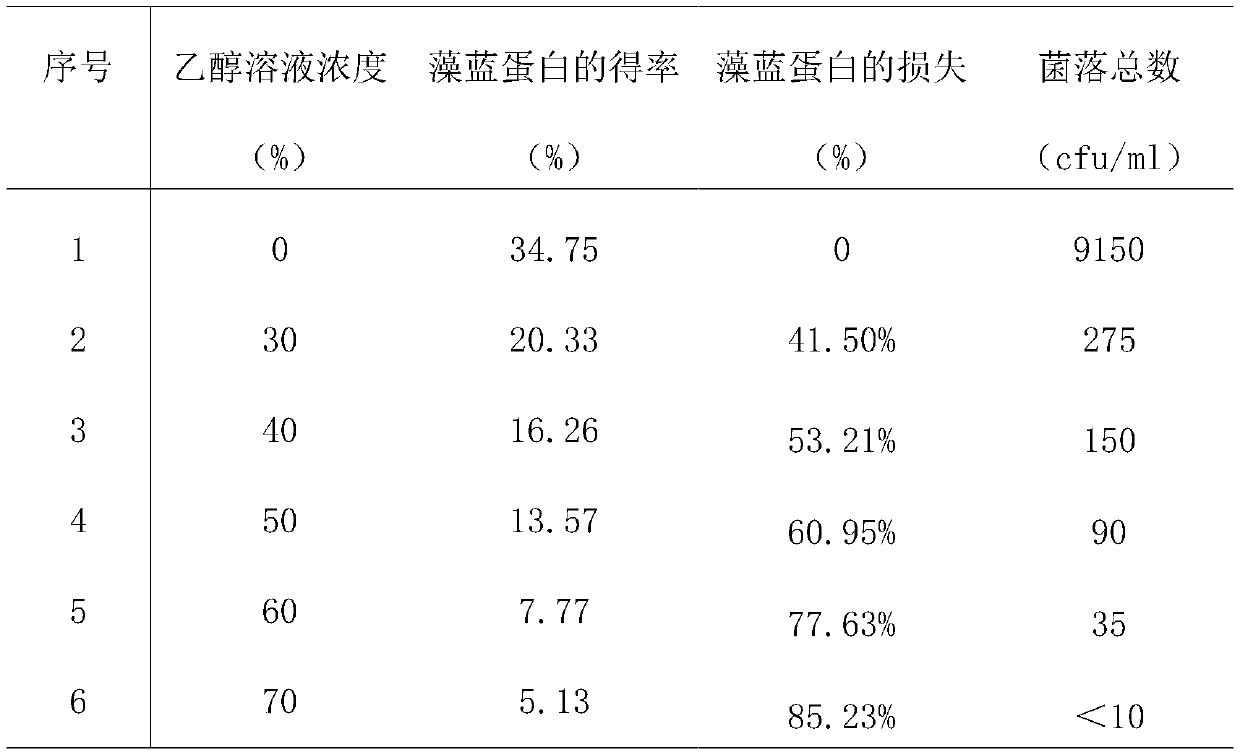

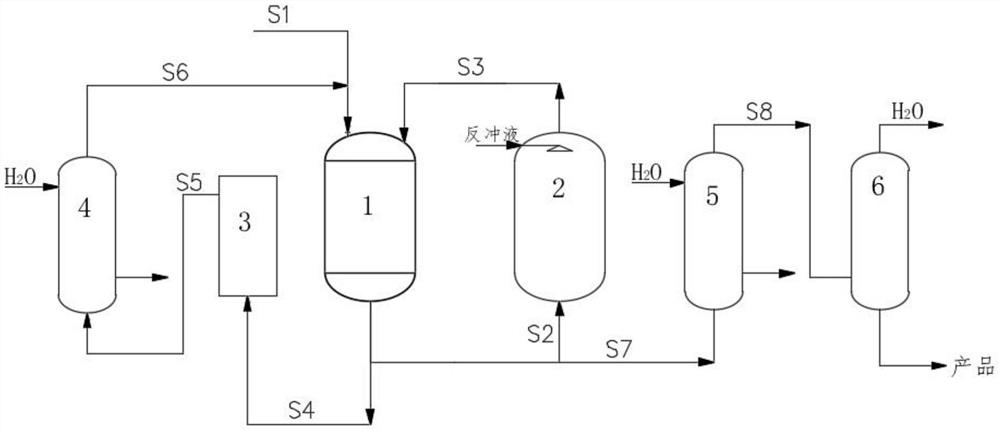

Production system for preparing phycocyanin through low-temperature alcohol extraction as well as process method

ActiveCN110713535AGrowth inhibitionReach the demand targetPeptide preparation methodsDepsipeptidesBiotechnologyUltrafiltration

The invention discloses a production system for preparing phycocyanin through low-temperature alcohol extraction as well as a process method. The production system provided by the invention comprisesan extraction tank; the extraction tank is connected in series with a first-stage cold circulation device, a cold circulation centrifugal machine, a second-stage cold circulation device, a first-stagemicro-filtration membrane filtering machine, a third-stage cold circulation device, a second-stage ultrafiltration membrane filtering machine, a third-stage concentration membrane filtering machine and a spray-drying tower sequentially through pipelines and valves; and the second-stage ultrafiltration membrane filtering machine and the third-stage concentration membrane filtering machine are positioned in a constant-temperature (10 DEG C) sterile library. According to the method provided by the invention, spirulina powder is extracted by a low-content alcohol-containing phosphate buffer solution, low-concentration ethanol helps to break walls of spirulina cells, the total number of microorganisms in material liquid is controlled, low-temperature separation and purification are conducted by controlling the temperature to be below 10 DEG C in the whole process after extraction, and the total number of microbial colonies in the phycocyanin can be controlled to be within 100 cfu / g under the condition of not influencing the yield of the phycocyanin, so the production process of the phycocyanin is greatly optimized and the quality of products is improved.

Owner:WUHAN GREEN FOOD BIOLOGICAL ENG

Production system and method of nano biomedical material

ActiveCN109351301ASimple production systemLess equipmentEnergy based chemical/physical/physico-chemical processesFeed devicesNanometreBiomedical engineering

The invention provides a production system and method of a nano biomedical material. The production system comprises a reactor, a first membrane separator and a second membrane separator; a feeding port of the first membrane separator is communicated with a discharging port of the reactor, and a discharging port of the first membrane separator is communicated with a feeding port of the reactor; afeeding port of the second membrane separator is communicated with the discharging port of the reactor, and a discharging port of the second membrane separator is communicated with the feeding port ofthe reactor. According to the production system and method of the nano biomedical material, the nano biomedical material can be prepared simply through one reactor and two membrane separators, the whole production system is simple, related equipment in the production process of the nano biomedical material is reduced, then the possibility that medicine is contaminated is reduced, thus the improvement of the purity of the nano biomedical material is facilitated, the amount of equipment is reduced, and the reduction of the cost for producing the nano biomedical material is facilitated.

Owner:SEDIN NINGBO ENG +1

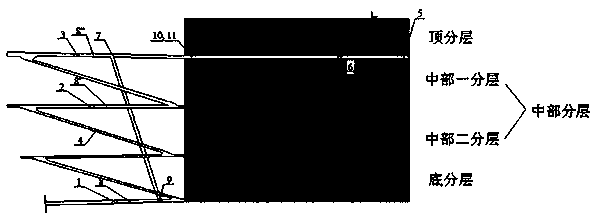

Multi-layer long-wall mining roadway arrangement method for extremely-thick coal seam

InactiveCN110630264AReduce the amount of excavationLow costUnderground miningSurface miningResource recoveryCross cut

The invention discloses a multi-layer long-wall mining roadway arrangement method for an extremely-thick coal seam, is mainly used for solving the problems of high roadway tunneling quantity, high maintenance cost and the like if traditional roadway arrangement modes are adopted for mining of extremely-thick coal seams, and belongs to the technical field of coal mining. The method specifically includes the following steps that the extremely-thick coal seam is layered from top to bottom according to the certain thickness, stoping is performed on the layers in the descending sequence, an air return main roadway, an auxiliary transportation main roadway and a transportation main roadway are arranged along the bottom levels of a top layer, a middle layer and a bottom layer respectively, in-seam cross-cuts are dug from the three main roadways or inclined connection roadways for entering of the layers and digging of stoping roadways, and a production system is formed. The three main roadwaysare connected by the aid of the inclined connection roadways, a chute is dug in a centralized transportation roadway connected with section transportation drifts to be connected with a mining area coal bunker, and stoped coal is transported from the chute to the mining area coal bunker and is transported out through the transportation main roadway. With the method, the roadway tunneling quantityis low, efficient auxiliary transportation is facilitated, the resource recovery rate is high, and the method is safe and reliable.

Owner:CHINA UNIV OF MINING & TECH

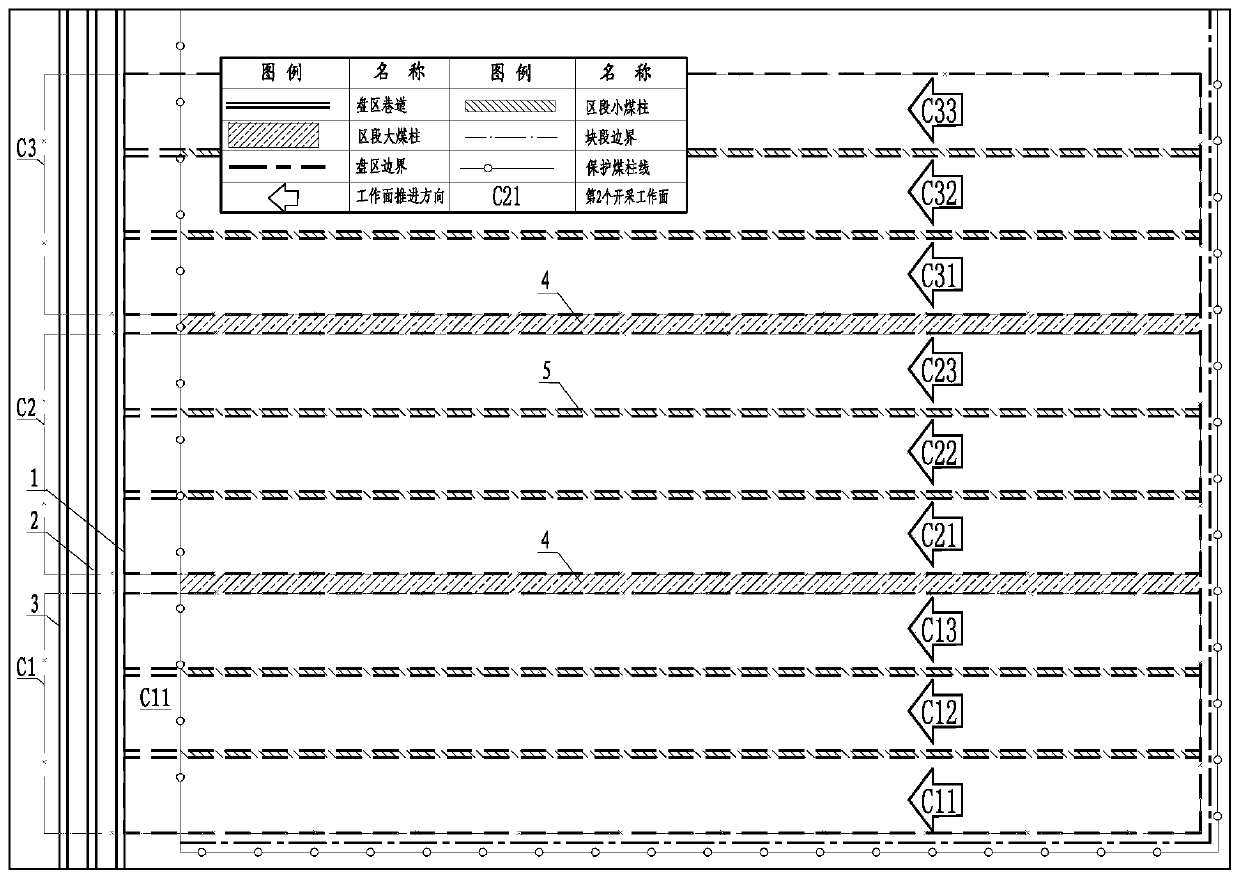

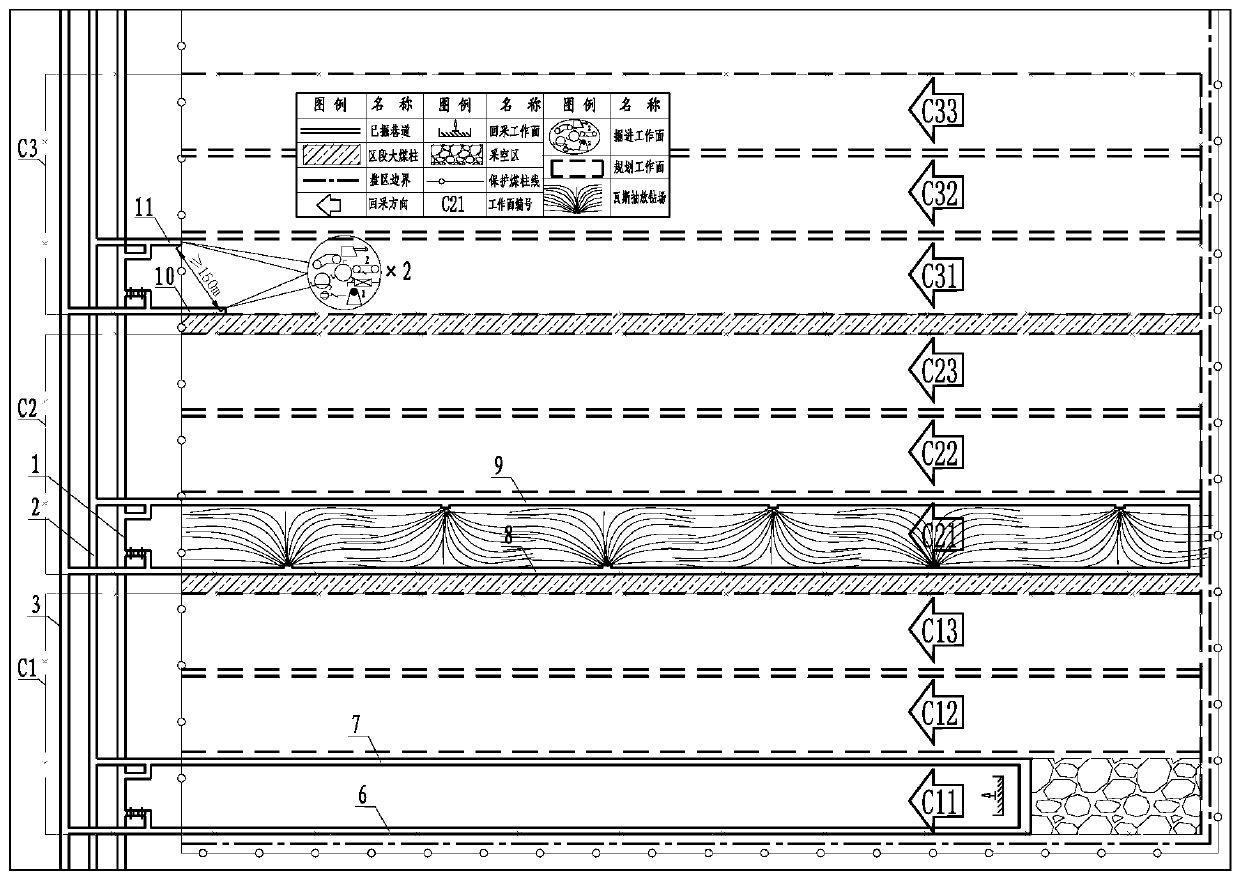

A method for continuous arrangement of working face in mining area of rock burst and high gas mine

ActiveCN108590658BConducive to cost reduction and efficiency increaseAchieving safe miningUnderground miningSurface miningStopped workStoping

The invention discloses a method for continued arrangement of a working face in a mining area of rock burst and high gas mine. The method comprises the following steps that the mining area is selectedand is divided into three zones, each zone is divided into a plurality of sections, and the mining sequence of the sections is determined; a first zone primary mining working face is mined firstly, and at the same time the second zone primary mining working face and third zone primary mining working face are separately subjected to gas pre-drainage and heading work; after stoping of the first zone primary mining working face is completed, a heading end of the third zone is moved to a second face of the first zone, and the roadway heading is carried out; the stoping of the second zone primarymining working face is carried out; the third zone primary mining working face is subjected to gas pre-drainage; and so on, the heading, pre-drainage and stoping work are separately carried out simultaneously in the three zones, and cycling is carried out until the next mining area continues. Linkage of mining, heading and pumping in the mining area is achieved, the method for continued arrangement of the working face in the mining area of rock burst and high gas mine has the advantages of less development (preparation), less investment, concentrated production, less occupancy of personnel andequipment, and the contradiction between rock burst and tight connection in the high gas mine can be can effectively alleviated.

Owner:中煤西安设计工程有限责任公司

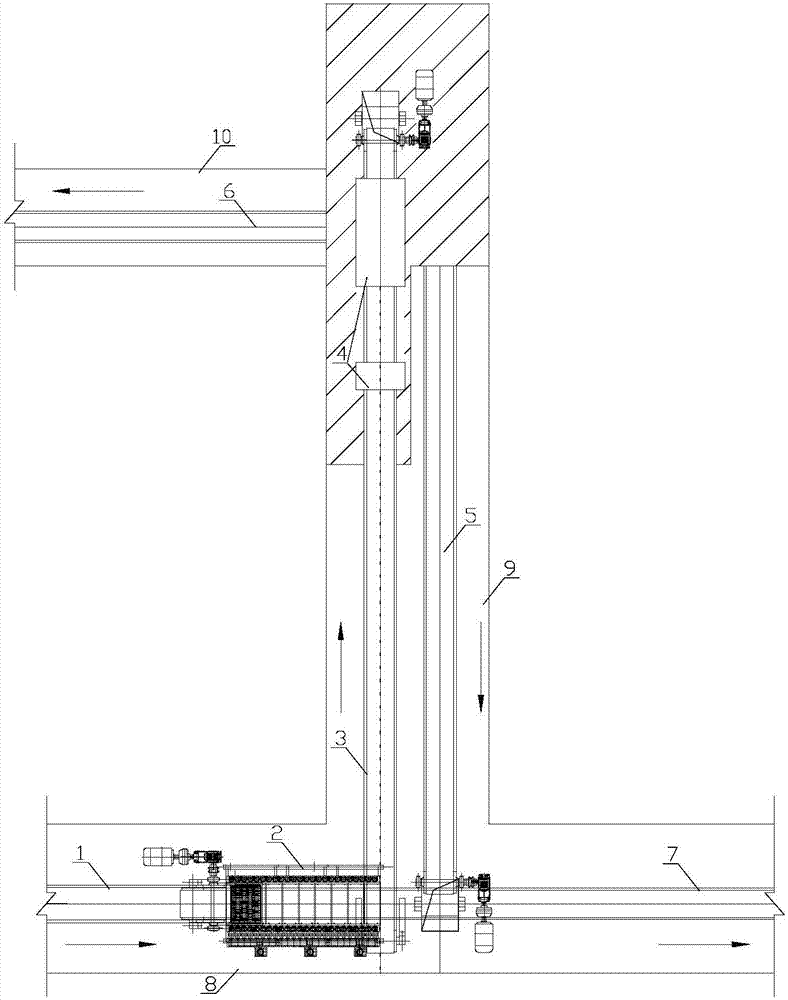

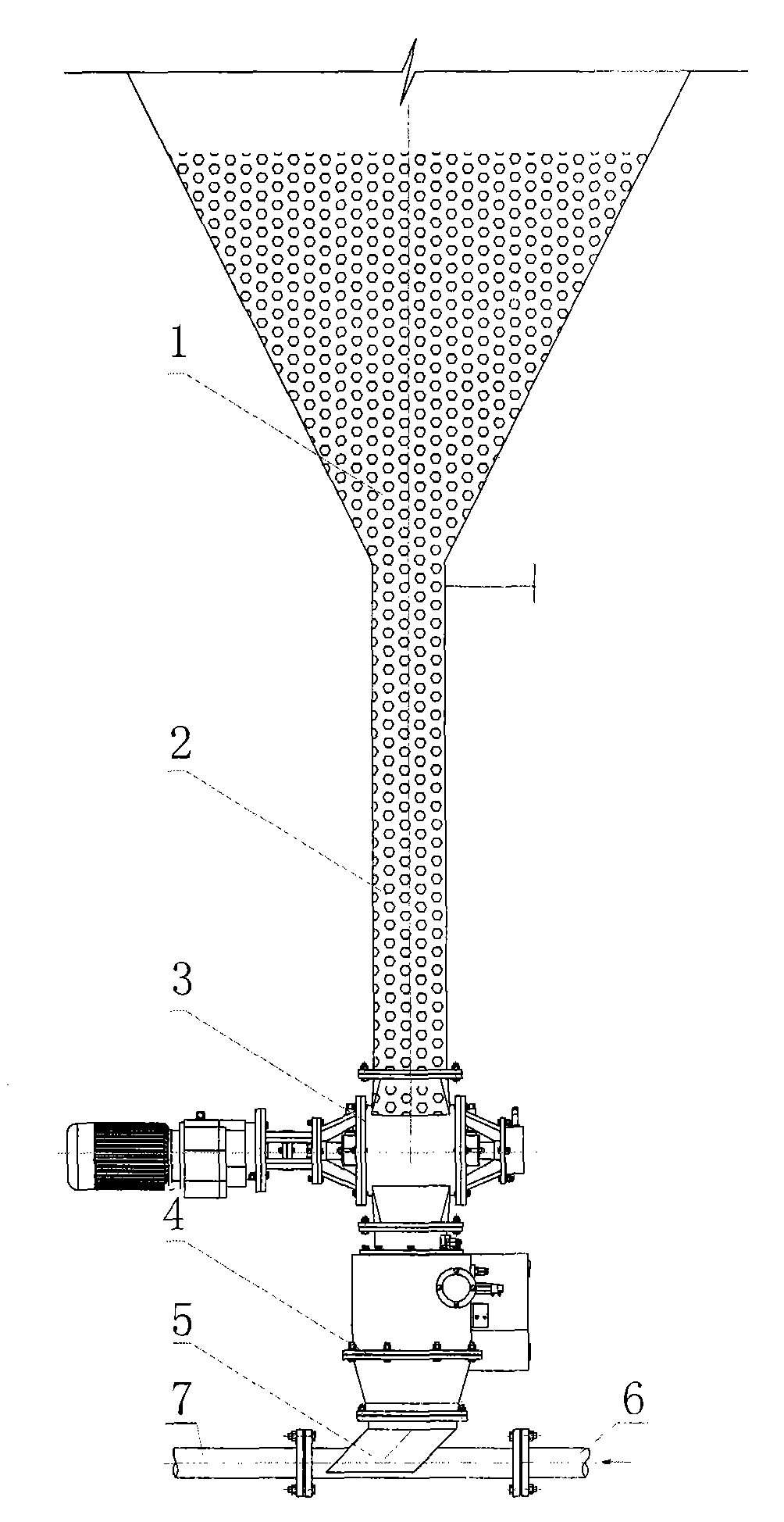

Coal injection system for Maerz coal kiln

InactiveCN103471128ANo plugging phenomenonContinuous and smooth deliveryLump/pulverulent fuel feeder/distributionEngineeringMechanical engineering

A coal injection system for a 600t / d Swiss Maerz coal kiln is transformed into a barn pump-free type energy continuous conveying system. A rotating air-locking type pulverized coal feeder is adopted by a sending system thereof for sending powder to a powder accurate measuring device; the instant and accumulated mean quality fluxes of small-flow coal powder can be monitored on-line; a coal powder conveying system is greatly simplified; more equipment and related accessories are saved; and the constructing, maintaining and managing costs are greatly lowered.

Owner:孙家鼎

Down filling system for doll production

The invention discloses a down filling system for doll production. The system comprises a down containing part, a pulse down discharging part, a vacuum pulse air supply part and a down discharging pipe, wherein the down containing part comprises a down containing cavity and an air valve communicated with the down containing cavity and the outside. The air valve is arranged in the down containing cavity, a positive pressure cavity is formed in an external vacuum box, the positive pressure cavity communicates with the air valve, the positive pressure cavity provides gas pressure for the interior of the down containing cavity through the air valve, down in the down containing cavity is inflated by airflow to fly, and a pulse opening and closing device is arranged outside the down containing cavity; the pulse opening and closing device achieves pulse opening and a high-pressure environment in the down containing cavity, flying down is discharged outwards through the pulse opening and closing device, the dolls are filled with down through the down discharging pipe, the whole process only needs to be matched with an external pulse control program, opening and closing of the pulse opening and closing device are controlled, down filling action is achieved, the whole production system is greatly simplified, and production investment is reduced.

Owner:湖南贝尔动漫科技有限公司

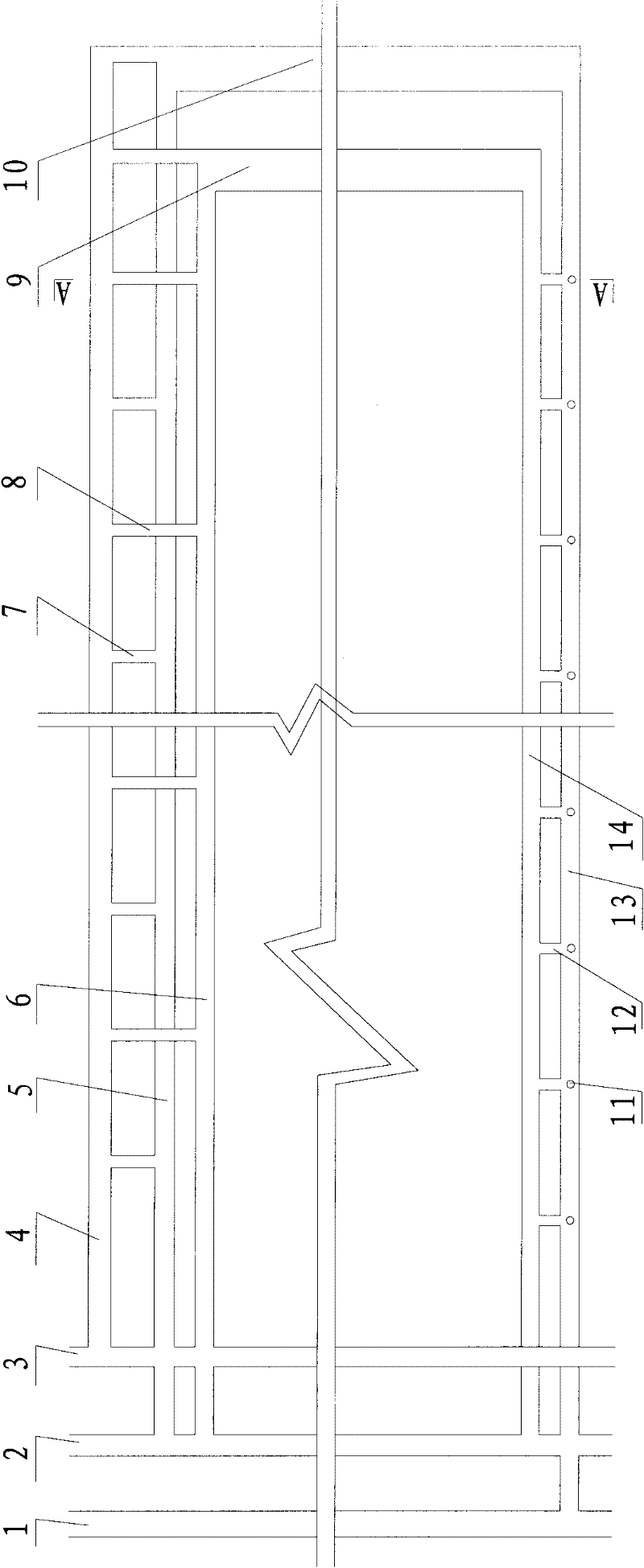

Close-range thin coal layer simultaneous mining and parallel transporting method

InactiveCN102392640BReduce the amount of excavation workIncrease productionUnderground miningSlitting machinesCentralized managementCoal

The invention discloses a close-range thin coal layer simultaneous mining and parallel transporting method, aiming to solve the problems caused by layer mining of the existing close-range thin coal layers, such as resource waste, serious flood, difficult mining distribution of lower layer coal, long mining period, low yield, high tunneling and supporting difficulties, high cost and the like. The method is characterized by arranging a centralized transport roadway, a centralized track roadway and a centralized air return roadway along the coal layers or top and bottom plates of the coal layers, simultaneously arranging two coal faces on the close-range thin coal layers and simultaneously mining and transporting coal. The method has the following beneficial effects: simultaneous mining and centralized transporting of the upper and lower coal layers are realized; relative to layer mining, by adopting the method, the tunneling quantities of the roadways are reduced, a belt conveyer can be simultaneously omitted, and the convenience is provided for centralized management of production; and especially for the close-range thin coal layers, the production system is simplified, the convenience is provided for centralized management, the production cost is lowered, and the mine output and the production efficiency are improved.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

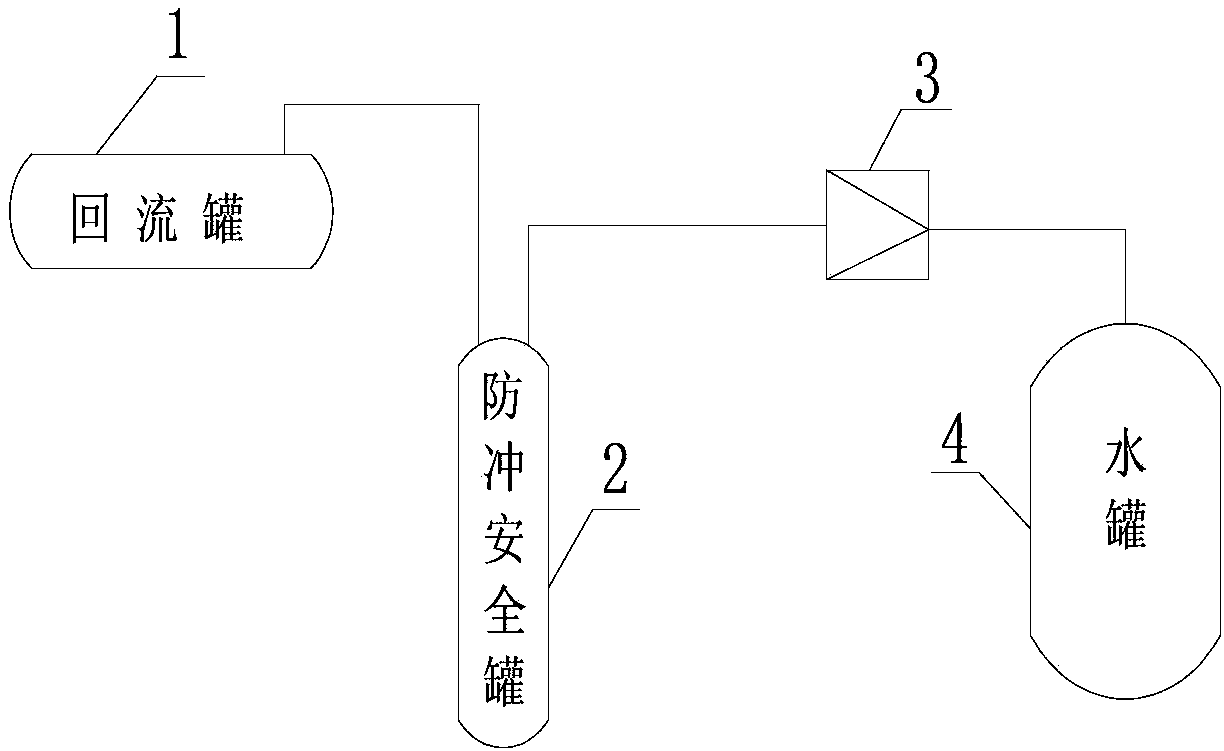

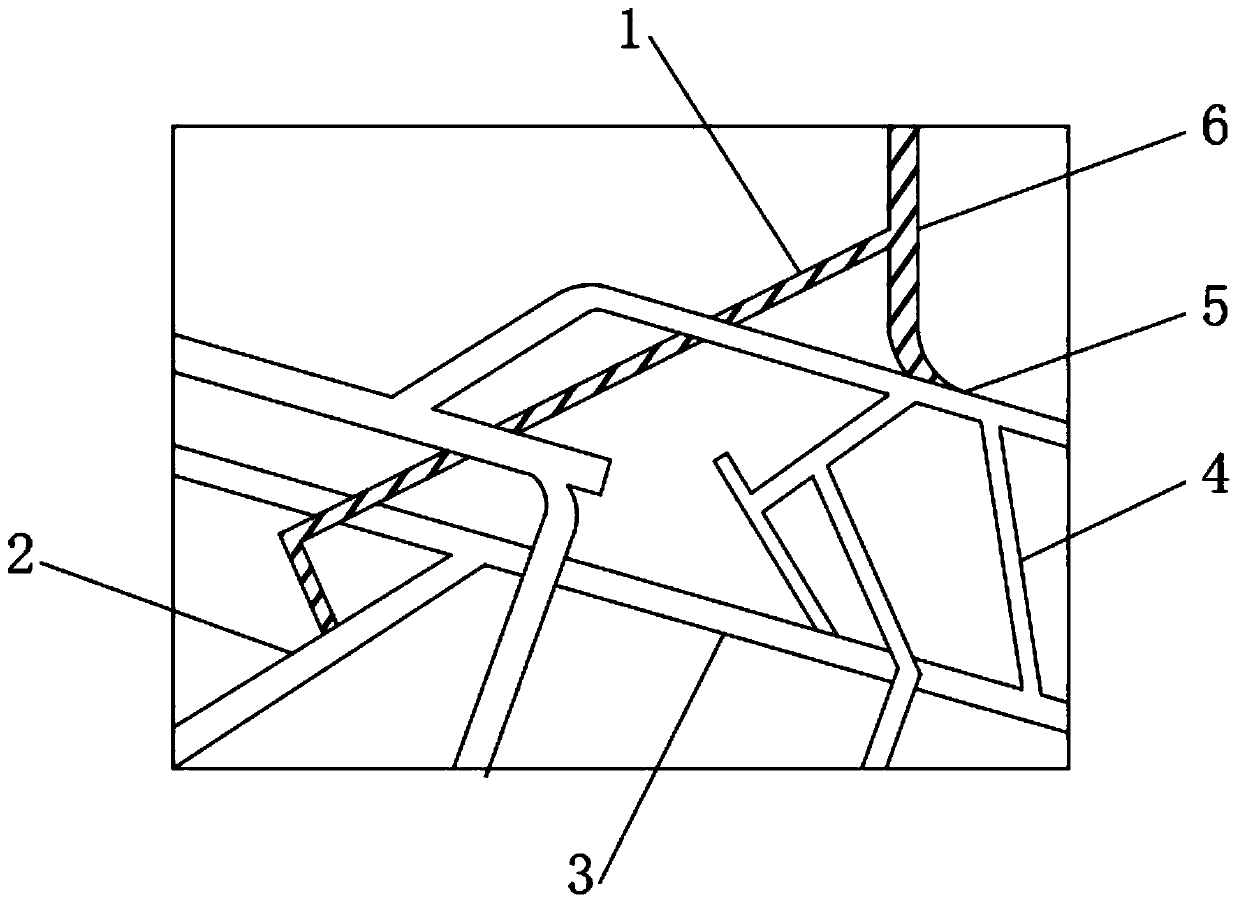

Rectification vacuum-pumping system of desulfurizer device

InactiveCN104096371ASafe and reliable operationSimple production systemVacuum distillation separationFractional distillationVacuum pumpingWhole systems

The invention relates to a rectification vacuum-pumping system of a desulfurizer device. The system comprises a reflux tank which is connected with an anti-impact safety tank through a pipeline. The anti-impact safety tank is connected with a dried screw vacuum pump through a pipeline. The dried screw vacuum pump is connected with a water tank through a pipeline. The system provided by the invention saves steam, and subsequent wastewater contains low content of monomethylamine, so that the whole system is simplified.

Owner:JIANGSU CHUANGXIN PETROCHEM

Drift type coal mining filling method

InactiveCN103147792BImprove mining efficiencyMeet stability and securityMaterial fill-upStopped workBrick

The invention discloses a drift type coal mining filling method. The method comprises the following steps of after one drift stoping work is completed, withdrawing a stoping machine, cutting and pulling a groove along a coal layer top plate at the lower side of a stope, cleaning the stope, building red bricks into a filling blockage wall at an entrance of the stope, enabling the filling blockage wall to be lower than the stope, pouring a cement mortar filling material into a filling area of the stope, solidifying the cement mortar to form a layer plate type adhesive body, then further upwards building the filling blockage wall to the height of the stope, and pouring the dewatered watery sand or yellow mud into a residual space above the layer plate type adhesive body of the filling area of the stope. The drift type coal mining filling method has the advantages that a production system of a coal mining well is simplified, the stoping rate of a working surface is favorably improved, the production is more safe and efficient, and the filling and production cost is saved.

Owner:贾巍

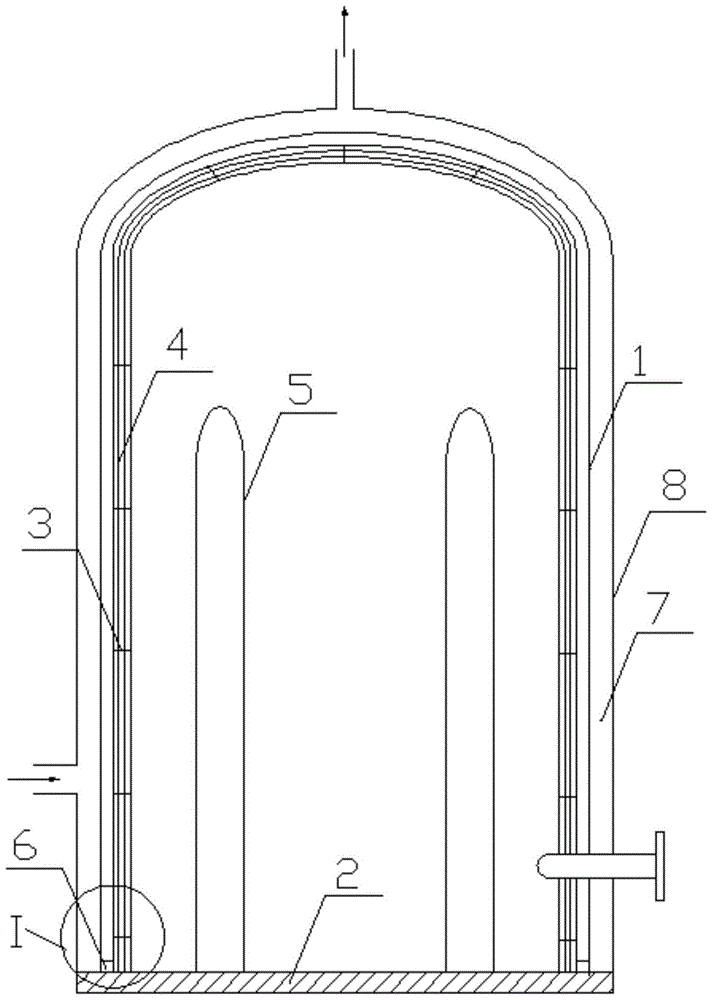

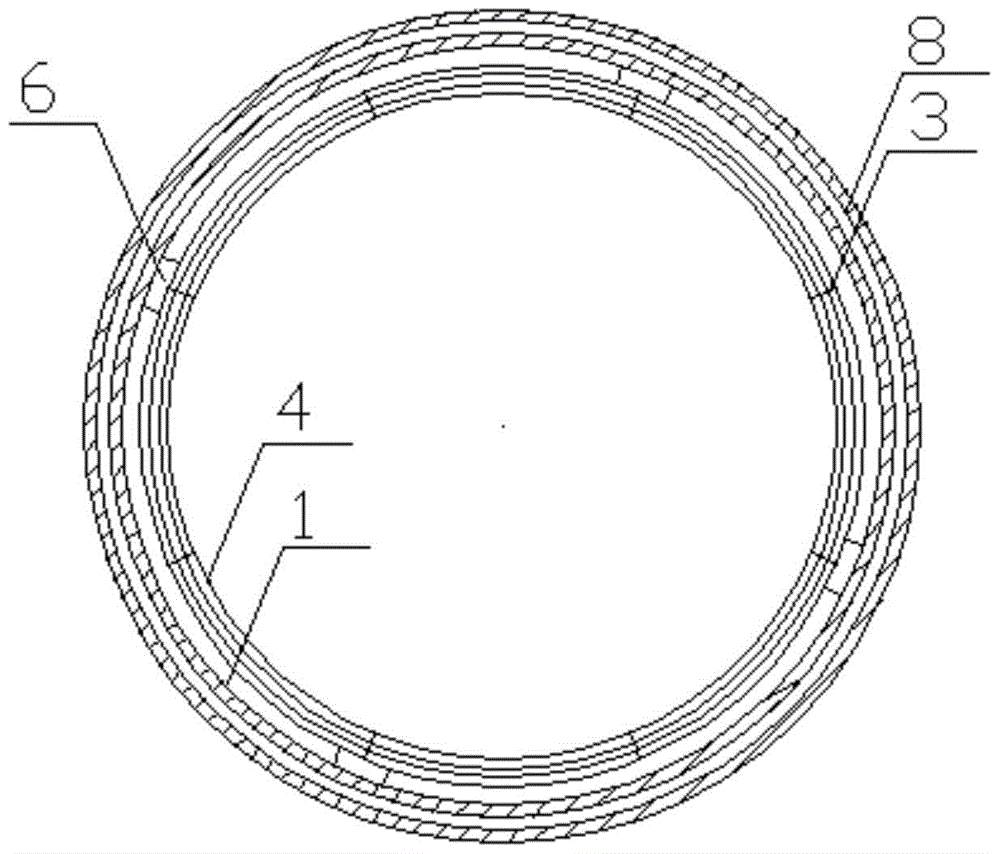

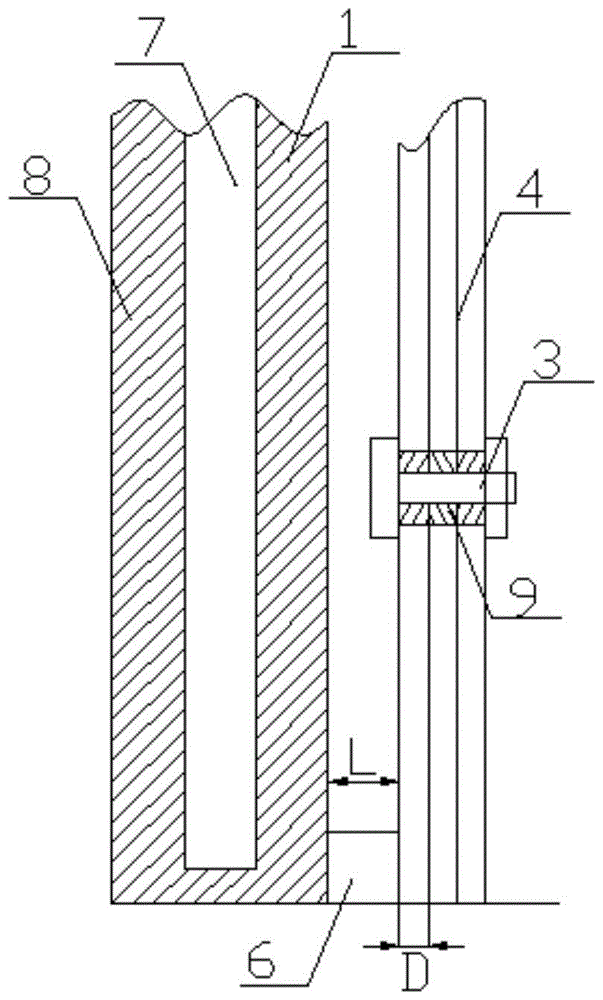

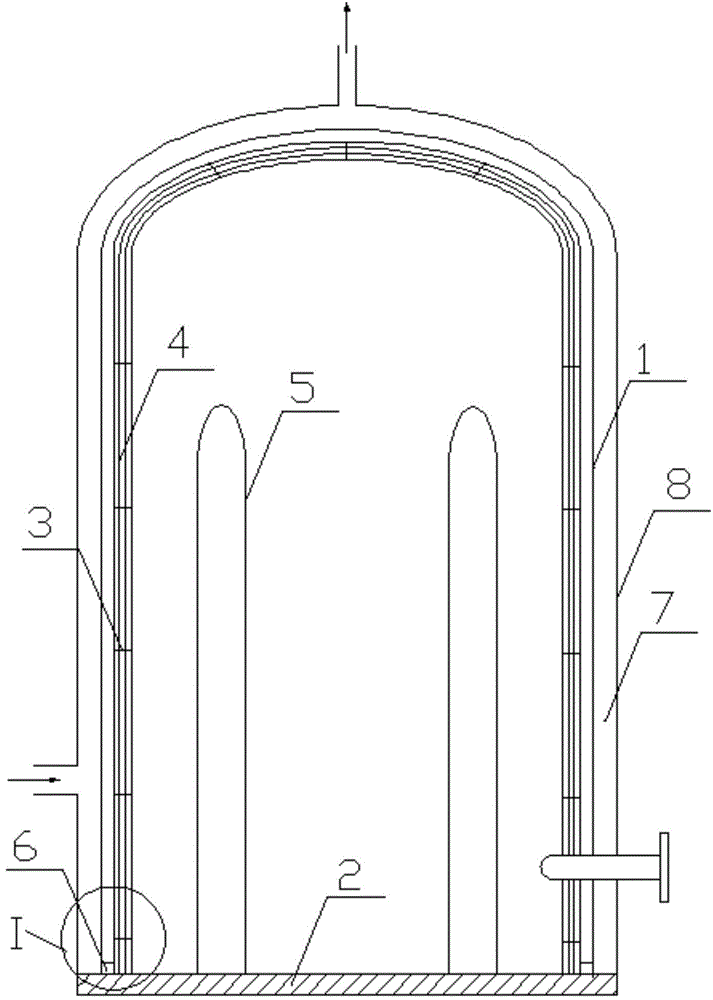

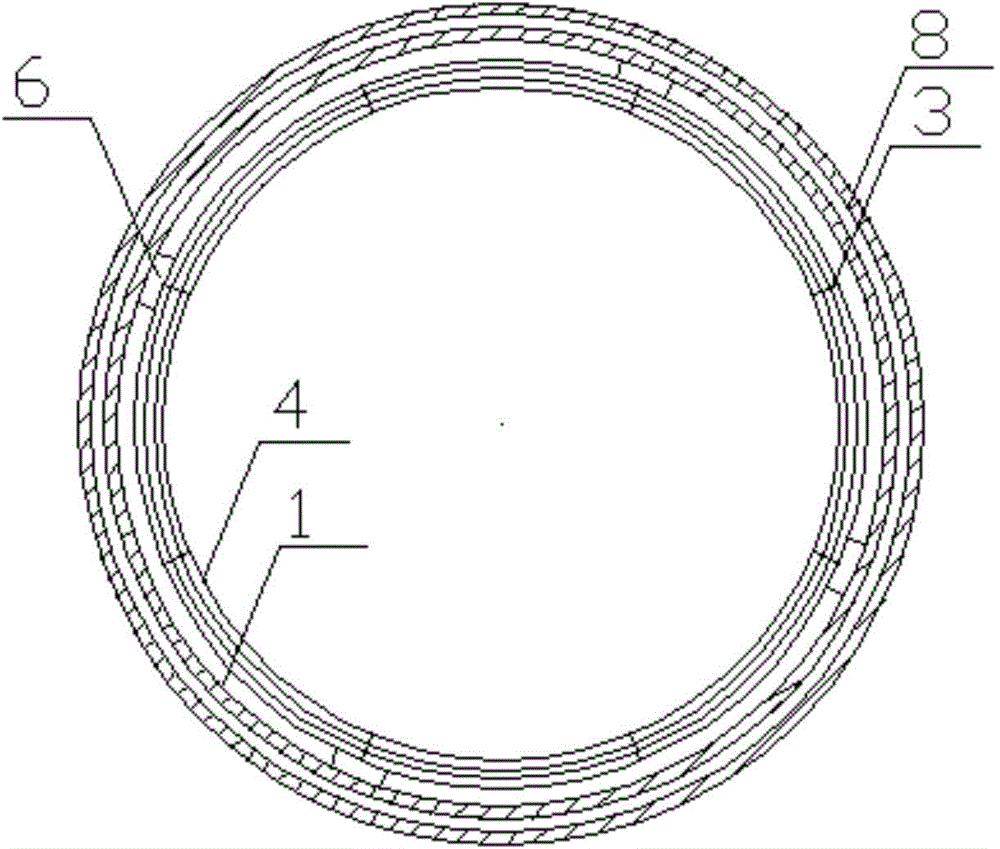

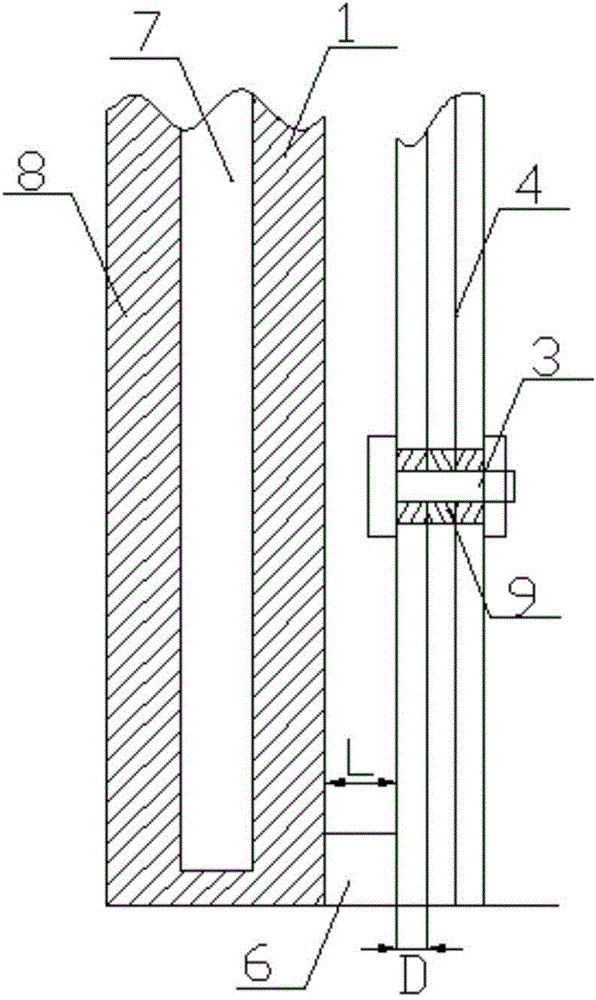

Furnace body of a polysilicon reduction furnace

The invention discloses a polycrystalline silicon reduction furnace body. 3-5 layers of metal thermal baffles are arranged in the furnace body; and the multiple layers of metal thermal baffles are fixedly connected together by virtue of stainless steel bolts and are fixed to the inner wall surface of the furnace body in a bolted connection mode. The thermal baffles are made of stainless steel, the shapes of the thermal baffles are consistent with the inner wall of the furnace body, and the interlayer of the thermal baffles is communicated with the inner cavity of the furnace body. According to the polycrystalline silicon reduction furnace body disclosed by the invention, the multiple layers of metal thermal baffles cover polycrystalline silicon bars, so that the heat loss can be greatly reduced, the utilization rate of heat energy in the furnace body is improved, the problem that energy waste is caused because the inner wall of the conventional furnace body is difficult to polish and the polishing effect is poor is solved, and the production cost of the polycrystalline silicon is reduced by virtue of low electric energy and an easily operated technology.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE +1

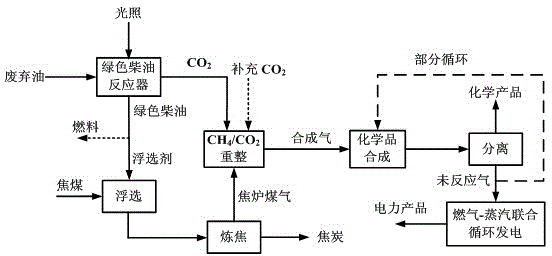

Method for comprehensively utilizing abandoned oil in coking industries

InactiveCN103497840BEasy to handleReduce manufacturing costFatty acid chemical modificationBiofuelsChemical industryThermodynamics

The invention provides a method for comprehensively utilizing abandoned oil in coking industries, and belongs to the technical fields of energy chemical industries and environments. The method is characterized by being a technical scheme of an application method of a poly-generation energy chemical engineering and power system combined with the comprehensive utilization of the abandoned oil in the coking industries. According to the method, an advanced photo-catalytic oxidation technology is used for transforming abandoned oil so as to produce environment-friendly diesel oil, the product treatment is convenient, raw materials are easy to purchase, and the production cost is low. A coke oven gas byproduct obtained by coking and CO2 generated in an environment-friendly diesel oil production process are exactly subjected to hydrocarbon complementation so as to produce a synthesis gas, so that the processes of using an additional gasification furnace for supplementing a carbon source and transforming water gas so as to adjust hydrogen are avoided; and the produced synthesis gas can be directly used for the synthesis of down-stream chemical products, so that a production system is simplified, and the production energy consumption is reduced. The method has the advantages that the conversion and utilization of CO2 are realized, the utilization rate of coke oven gas resources is realized, the CO2 emission is reduced, the whole production system is highly integrated, all production links are completely matched, elements are reasonably transformed and utilized in a classification manner, and a complete environment-friendly cycle production chain is formed.

Owner:TAIYUAN UNIV OF TECH

Polycrystalline silicon reduction furnace body

The invention discloses a polycrystalline silicon reduction furnace body. 3-5 layers of metal thermal baffles are arranged in the furnace body; and the multiple layers of metal thermal baffles are fixedly connected together by virtue of stainless steel bolts and are fixed to the inner wall surface of the furnace body in a bolted connection mode. The thermal baffles are made of stainless steel, the shapes of the thermal baffles are consistent with the inner wall of the furnace body, and the interlayer of the thermal baffles is communicated with the inner cavity of the furnace body. According to the polycrystalline silicon reduction furnace body disclosed by the invention, the multiple layers of metal thermal baffles cover polycrystalline silicon bars, so that the heat loss can be greatly reduced, the utilization rate of heat energy in the furnace body is improved, the problem that energy waste is caused because the inner wall of the conventional furnace body is difficult to polish and the polishing effect is poor is solved, and the production cost of the polycrystalline silicon is reduced by virtue of low electric energy and an easily operated technology.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE +1

Production system for preparing tin dioxide by gasification

The invention relates to a device for preparing stannic oxide with a gasification method, in particular to a production system for preparing stannic oxide with a gasification method. The system comprises a tin ingot melting and oxidizing integrated furnace and a secondary oxidation chamber which is connected with the integrated furnace and used for secondarily oxidizing oxide discharged from the integrated furnace, wherein the secondary oxidation chamber is communicated with a sedimentation and cooling barrel; and stannic oxide discharged from the cooling barrel is collected by a bag collector, and an exhaust fan is arranged on the collector. The melting and oxidizing integrated furnace and the secondary oxidation chamber are used for sufficiently oxidizing tin, and the quality of a produced product is better; secondarily, melting and oxidizing of tin are performed in the same furnace, and different burners can be arranged in burning space according to different temperatures required by melting and oxidizing, so that energy consumption is effectively saved; and again, the production system is simpler and can perform practice production.

Owner:GUANGXI HUAXI GRP CO LTD

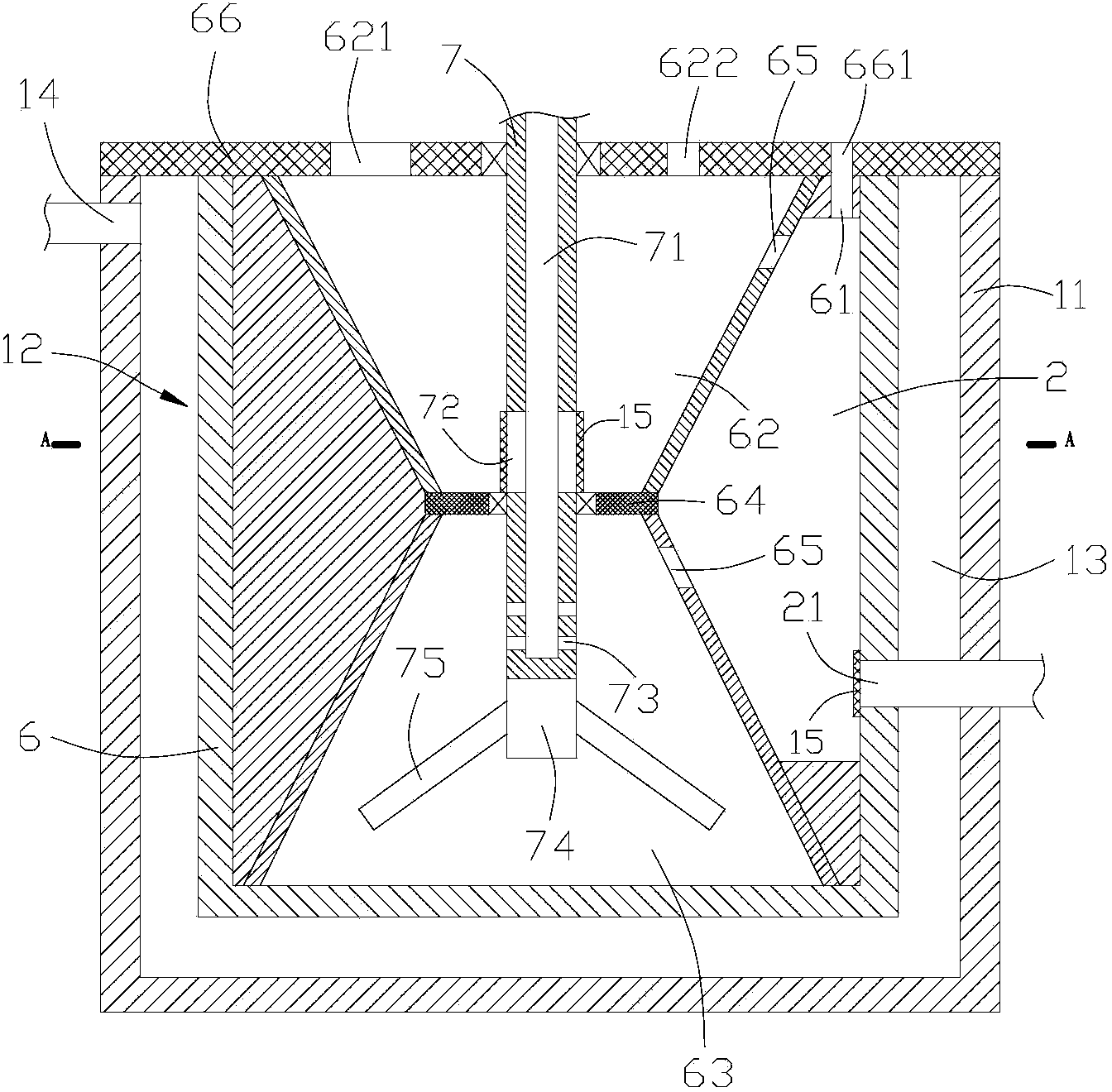

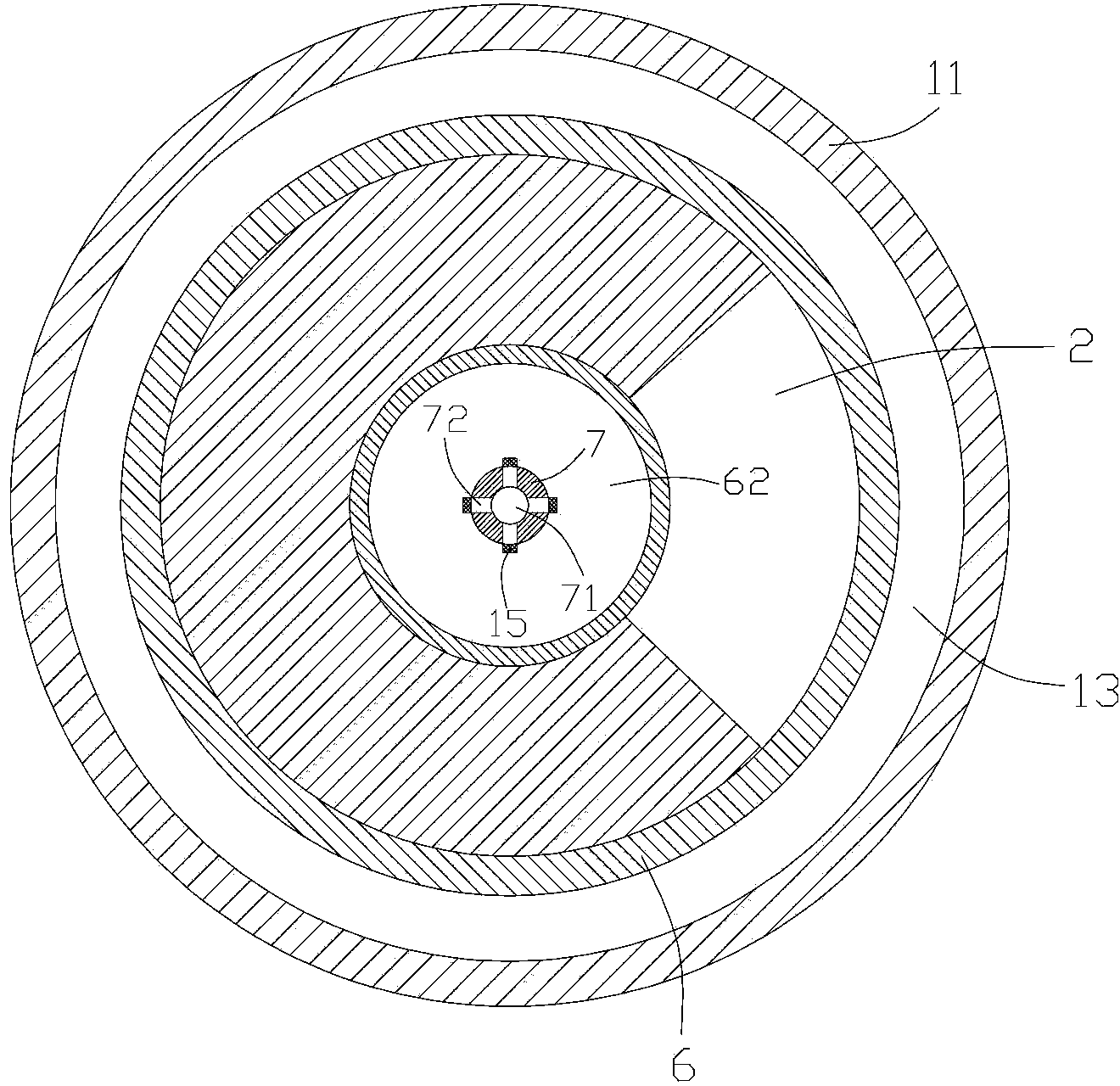

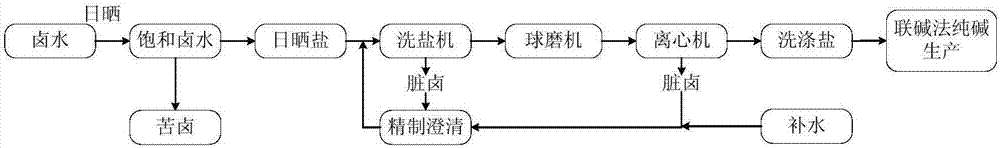

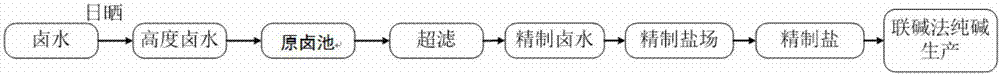

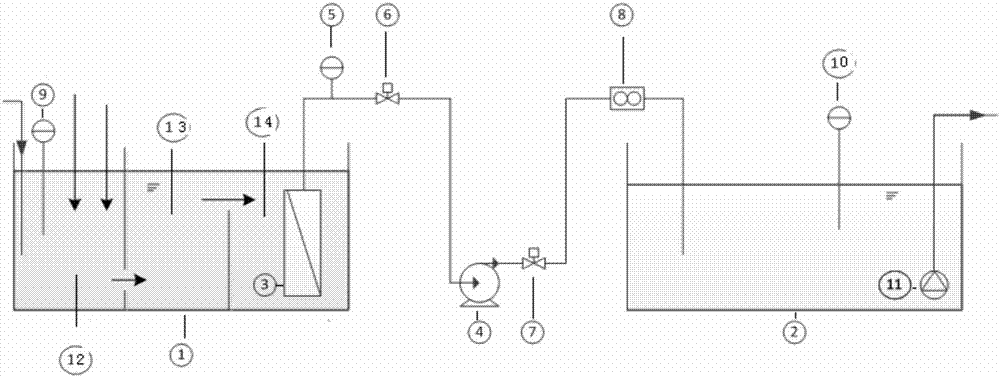

Preparation system of raw material salt in combined alkali production

ActiveCN106853978BGood removal effectHigh colloidal contentAlkali metal halide purificationAlkali saltBrine pool

The invention relates to the water treatment technology and soda ash production field, in particular to a preparation system of raw salt in combined alkali production. The system comprises a raw brine pool holding raw brine, an ultrafiltration membrane component, a refined brine pool and a combined alkali production system. The raw brine pool is internally provided with a reaction area for removing calcium and magnesium ions, a precipitation deslagging area for waste residue sedimentation, and a refining area holding the ultrafiltration membrane component. The precipitation deslagging area is communicated with the bottom of the reaction area, and the refining area is communicated with the top of the precipitation deslagging area. The refining area is communicated with a water inlet end of the ultrafiltration membrane component; a water outlet end of the ultrafiltration membrane component is connected to the refined brine pool. The refined brine pool is communicated with the combined alkali production system. The method involved in the invention eliminates a lot of tedious salt-leaching, salt-leaching refined brine refining processes in combined alkali production, lowers the investment cost of combined alkali production, simplifies the production system, and at the same time lowers the production cost.

Owner:TIANJIN MOTIMO MEMBRANE TECH +1

A method for improving transportation lane

ActiveCN109386294BSimple designSmall amount of workTunnelsArchitectural engineeringStructural engineering

The invention belongs to the technical field of transport connected roadways, in particular to a transport connected roadway improvement method. A transport connected roadway comprises a rock concentrated roadway and a rock rail roadway, wherein a tunneling stone gate is arranged on the rock concentrated roadway, and the transport connected roadway is arranged between the rock concentrated roadwayand the rock rail roadway; one end of the transport connected roadway is communicated with the tunneling stone gate. The tunneling transport connected roadway design of a working face is optimized, the transport connected roadway and the tunneling stone gate are designed on a straight line, a door poking position of the tunneling stone gate is designed to be a four-way door, the transport connected roadway is directly communicated with the concentrated roadway, the engineering quantity of the rock roadway is reduced, the roadway driving cost is reduced, the requirements of a mine for double effects, mechanization, automation, informatization, intelligentialization, level reduction, mining area reduction and staff reduction are met, the design concept of level, straight and simple roadwaydesign is fulfilled, the aim of achieving service and production in one step is achieved, the method is suitable for system optimization of newly prepared mining areas and working faces of the mine, and the method has good popularization value in the aspects of safety, economical efficiency, relieving of exploitation succession tension and the like.

Owner:HUAIBEI MINING IND

A production system and production process of nanometer biomedical materials

ActiveCN109382051BImprove quality pass rateLow costSemi-permeable membranesVacuum distillation separationMedicineBiochemical engineering

The invention discloses a production system of a nano biological medical material and a production process of the production system and belongs to the technical field of medical material production. The production system of the nano biological medical material comprises a reaction kettle, an electromagnetic separator, a tubular centrifuge, a first membrane separator, a second membrane separator and a vacuum distillation tower. By adopting the production system of the nano biological medical material and the production process of the production system disclosed by the invention, the produced nano biological medical material is not only safe and reliable, but also capable of effectively solving the problem that a corresponding nano medical biological material cannot be produced in China at present.

Owner:SEDIN NINGBO ENG +1

Machining device for metal powder production

PendingCN114229883AImprove molding rateAvoid the risk of being prone to impact on the inner wall of the tankSievingScreeningMetallurgyMetal powder

A machining device for metal powder production comprises a tank body, an atomization rotating disc arranged at the upper end of the tank body and a discharging opening formed in the lower end of the tank body. The cooling structure is arranged on the inner wall of the tank body and is used for cooling and solidifying metal liquid drops sprayed out of the atomizing rotating disc; the screening structure is arranged in the tank body and is used for screening cooled and solidified metal powder; and the recovery structure is arranged on the inner bottom surface of the tank body and is used for collecting the large-particle-size metal powder positioned at the upper end of the screening structure. By arranging the cooling structure, the screening structure and the recycling structure, the forming rate of the metal powder can be increased, the formed metal powder can be preliminarily screened, and meanwhile, the unqualified large-particle-size metal powder can be recycled; the device integrates forming, screening and recycling in one tank body, and has the advantages of simplicity in operation, high production efficiency, good powder forming rate, high economic benefit and the like.

Owner:HUIJIN ATOMIZING SCI

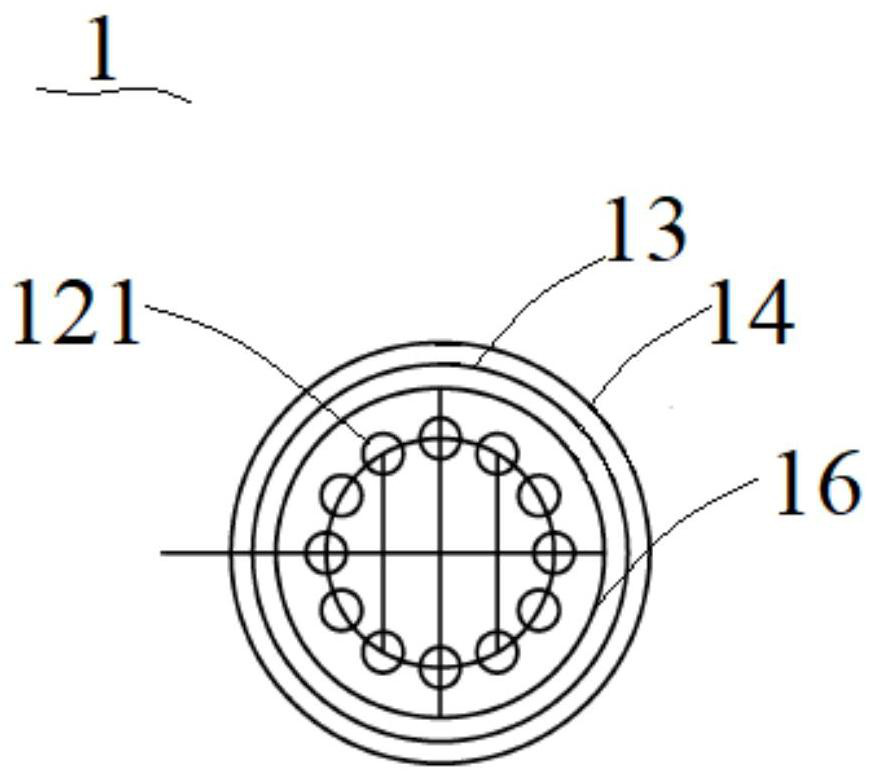

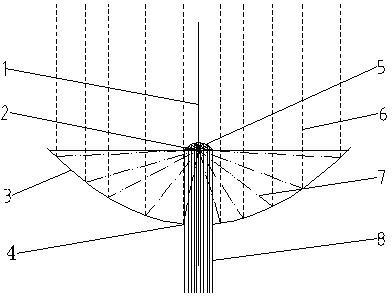

Cluster solar collector and cluster solar transmission system

InactiveCN102109669BEasy to track in all directionsHigh long-distance transmission efficiencyMountingsCondensersLight pipeLight energy

The invention provides a cluster solar collector and a cluster solar transmission system. The cluster solar collector consists of a large revolution paraboloid and a small revolution paraboloid, wherein, the two revolution paraboloids are oppositely arranged; the focal points of the two revolution paraboloids are superposed and the symmetric axes of the two revolution paraboloids are positioned on the same straight line; the center of the large revolution paraboloid is equipped with a through hole connected with a light pipe; and the aperture of the small revolution paraboloid is coincident with the diameter of the through hole. In the invention, a plurality of the cluster solar collectors are gathered into one place through a beam steering device and the light pipe, light in multiple paths are gathered into a light beam through a beam splitting and combining device, and the light beam is further clustered via a beam collecting and distributing device and then is output via the light pipe so as to form a light energy collecting and distributing unit; and a plurality of the light energy collecting and distributing units can form the cluster solar transmission system through the beam steering device, the beam splitting and combining device and the beam collecting and distributing device. By utilizing the cluster solar collector and the cluster solar transmission system, the problems such as high cost and low efficiency caused by direct access of solar energy in an application place are solved so as to realize separative and high-energy flow cluster solar transmission.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com