A production system and production process of nanometer biomedical materials

A biomedical material and production system technology, applied in the field of medical material production, can solve problems such as the lack of nano-biomedical materials, and achieve the effects of easy control, cost reduction, and simple production system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

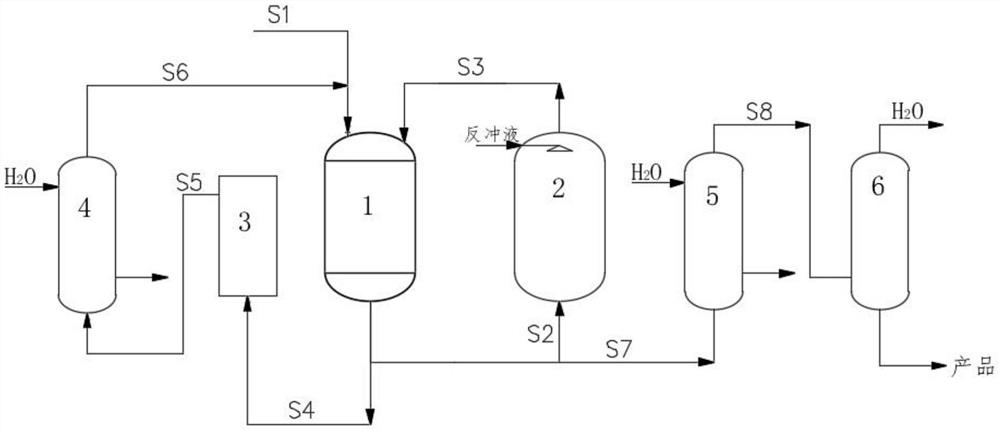

[0038] Such as figure 1 As shown, a production system for nano-biomedical materials includes a reactor 1, an electromagnetic separator 2, a tubular centrifuge 3, a first membrane separator 4, a second membrane separator 5, and a vacuum distillation tower 6.

[0039] Reactor 1, used for preparing magnetic particles (magnetic particles), refining the magnetic particles and organically coating the refined magnetic particles;

[0040] Electromagnetic separator 2: used to separate the magnetic particles prepared in the reactor 1 from the reaction solution;

[0041] Tubular centrifuge 3: used to remove magnetic particles that do not meet the particle size requirements after fine treatment; mainly used to remove magnetic nanoparticles larger than 12nm.

[0042] The first membrane separator 4: used to remove magnetic particles that do not meet the molecular weight requirement after fine treatment; mainly remove magnetic nanoparticles with molecular weight less than 3500.

[0043] Th...

Embodiment 2

[0052] The top of the electromagnetic separator 2 is also provided with a spraying device for washing the magnetic particles; the spraying device can accurately wash all the magnetic particles comprehensively, and can also save the washing liquid used in washing, effectively Reduce the cost of enterprises or users.

Embodiment 3

[0054] The electromagnetic separator 2 also includes an adjustable electromagnetic strength device. Users can adjust the electromagnetic intensity according to actual needs. The adjustable electromagnetic strength effectively meets the needs of users to set the electromagnetic strength by themselves, making the whole system convenient and fast to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com