Production method for realizing continuous casting with low superheat degree

A production method and technology of superheat, which is applied in the field of steelmaking and continuous casting, can solve the problems of ineffective continuous casting slabs over 300 mm thick, difficulty in large-scale promotion of industrial production, and slag removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

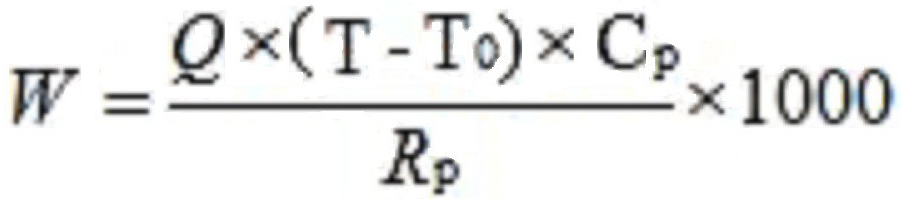

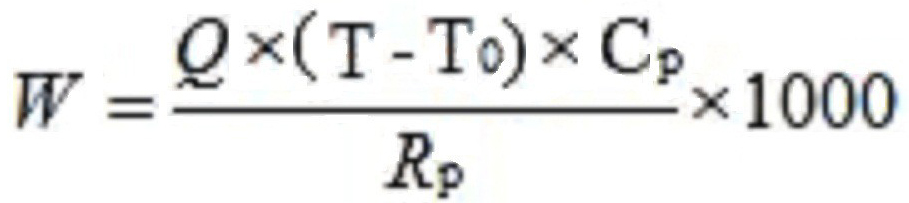

Method used

Image

Examples

Embodiment 1

[0025] A company’s 1# straight-arc single-point straightening continuous casting machine has a main radius of 9m for continuous casting, a tundish capacity of 30 tons, a depth of 0.8m, and no electromagnetic stirring and end pressing device. When using 250*1650mm section, the continuous casting speed is 0.75m / min and the continuous casting molten steel pouring speed is 2.37t / min; when pouring low alloy structural steel Q345B, the molten steel liquidus temperature is 1516℃, and the molten steel reaches the middle The initial temperature of the bag is 1548℃, and the set pouring temperature is 1528±3℃.

[0026] Using Φ10mm steel wire, the chemical composition content is: C: 0.16%, Si: 0.20%, Mn: 0.50%, P: 0.015%, S: 0.005%, Als: 0.020%, Cr <0.10%, Ni <0.05%, Mo <0.05%, Cu <0.05%, N <70ppm.

[0027] The first furnace of continuous casting billet pouring does not feed the wire. The second furnace starts to feed the wire at a speed of 31kg / min. The feeding position is located in the impa...

Embodiment 2

[0031] A company's 3# continuous casting 420*2700mm extra-thick section straight-arc continuous casting machine has a tundish capacity of 50 tons and a depth of 1.2 meters, equipped with electromagnetic stirring and light reduction devices. When the 400*2320 section is used for production, the continuous casting speed is 0.60m / min, the continuous casting molten steel pouring flow rate is 4.27t / min, when the general carbon structural steel Q235B is poured, the molten steel liquidus temperature is 1520℃, and the molten steel reaches the middle The initial temperature of the bag is 1550℃, and the pouring temperature is set to 1530±3℃.

[0032] Using Φ10mm steel wire, the chemical composition content is: C: 0.16%, Si: 0.20%, Mn: 0.50%, P: 0.015%, S: 0.005%, Als: 0.020%, Cr <0.10%, Ni <0.05%, Mo <0.05%, Cu <0.05%, N <70ppm.

[0033] The first furnace of continuous casting billet pouring does not carry out wire feeding. The second furnace starts to feed the wire at a speed of 60-65kg / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com