microwave heating device

A microwave heating device and microwave technology, applied in the direction of microwave heating, etc., can solve the problems of affecting power output, damage, uneven distribution of microwave electric field, etc., and achieve the effect of ensuring uniformity, safety, and microwave hygienic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

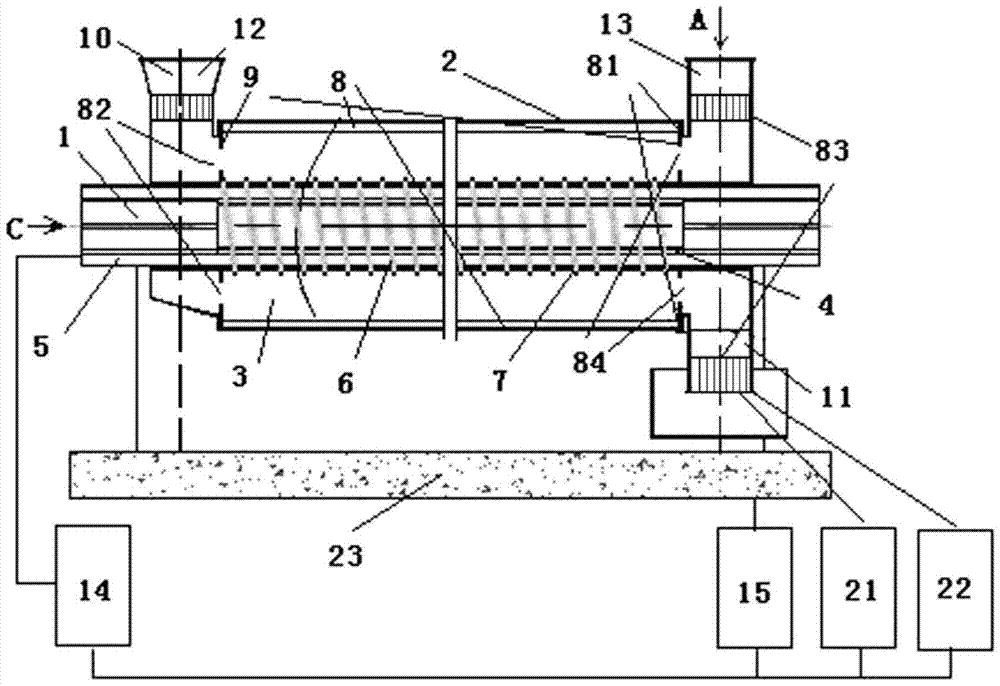

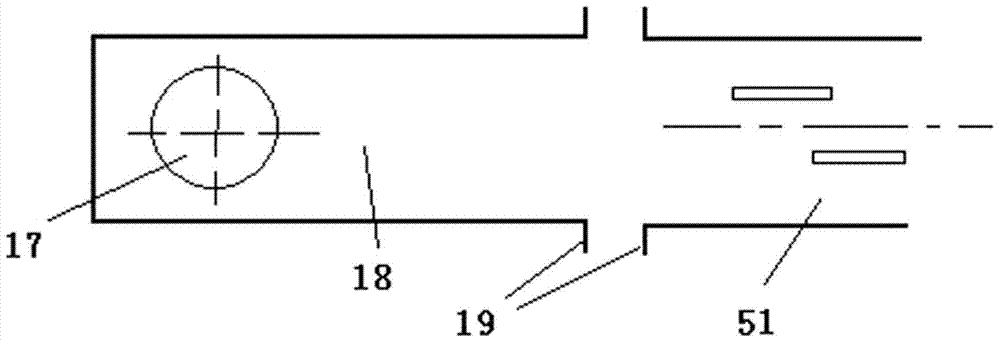

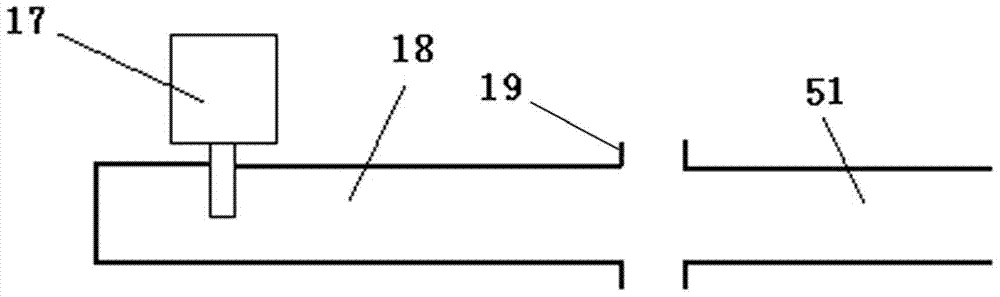

[0028] As a preferred embodiment of the present invention, such as figure 1 As shown, it includes a rotatable metal outer cylinder 2 and a metal inner cylinder provided with a microwave power radiation source 1. A coaxial annular cavity 3 is formed in the outer cylinder 2, and a support tube 4 is provided in the annular cavity 3. 4 is equipped with a microwave slot antenna group 5, the outside of the microwave slot group 5 is provided with a hollow dustproof sleeve 6 made of low-loss microwave dielectric, and the outside of the hollow dustproof sleeve 6 is provided with a dielectric spiral fin 7. The screw pitch is 30cm, the inner wall of the outer cylinder 2 is inlaid with a medium bracket 8 with a height of 40cm and a thickness of 10mm. The hollow dust-proof sleeve 6, the dielectric spiral fin 7 and the dielectric bracket 8 are all made of low-loss microwave dielectric materials, such as polytetrafluoroethylene or polypropylene, etc., which ensure good microwave penetration an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com