Inspection and test method for modified polypropylene plastic cable protection pipe

A technology of cable protection tube and polypropylene plastic, which is applied in the direction of specific gravity measurement, measuring devices, and analysis materials, etc., can solve the problems of time-consuming and laborious, and achieve the effect of convenient and fast operation, reduce the risk of bidding, and improve the efficiency of circulation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

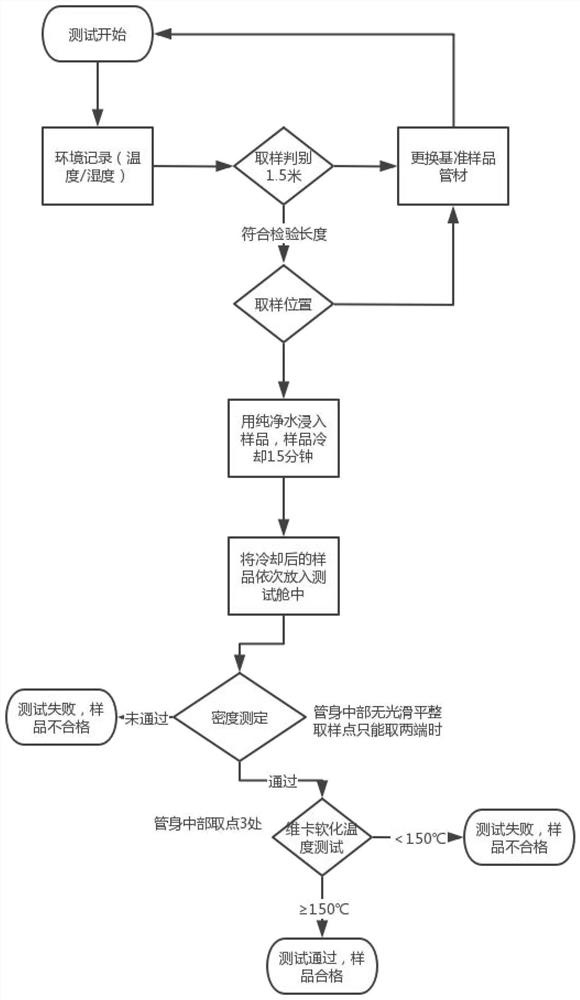

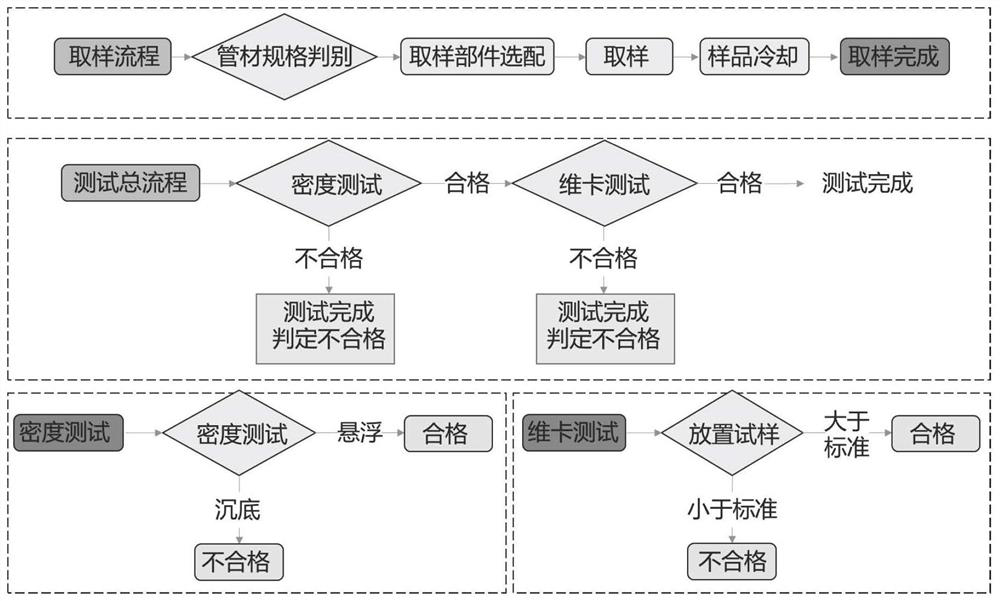

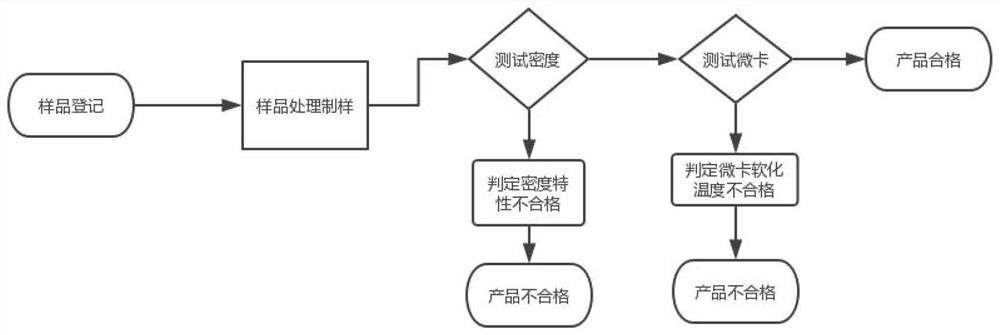

Method used

Image

Examples

Embodiment 1

[0101] The batch number of the material warehouse of the power grid company is 1903J0321101. The modified polypropylene plastic cable protection tube has a diameter of 100mm and a production date of 2019-12-09. The sample meets the basic requirements of the test. After sampling on-site testing, the TD solution sample sinks to the bottom and is determined to be unqualified.

Embodiment 2

[0103] The batch number of the material warehouse of the power grid company is 1903J0321502. The modified polypropylene plastic cable protection tube has a diameter of 200mm and a production date of 2019-10-12. The sample meets the basic requirements of the test. After sampling on-site testing, the TD sample sank to the bottom and was determined to be unqualified.

Embodiment 3

[0105] The batch number of the material warehouse of the power grid company is 1901J0650401. The modified polypropylene plastic cable protection tube has a diameter of 100mm and a production date of 2019-12-03. The sample meets the basic requirements of the test. After sampling on-site testing, the TD sample sank to the bottom and was determined to be unqualified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com