Coal injection system for Maerz coal kiln

A Maerz and pulverized coal technology, which is applied in the field of pulverized coal injection system of coal-fired Maerz kiln in Switzerland, can solve the problems of increased initial investment and operating costs, energy waste, and complex pulverized coal injection system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

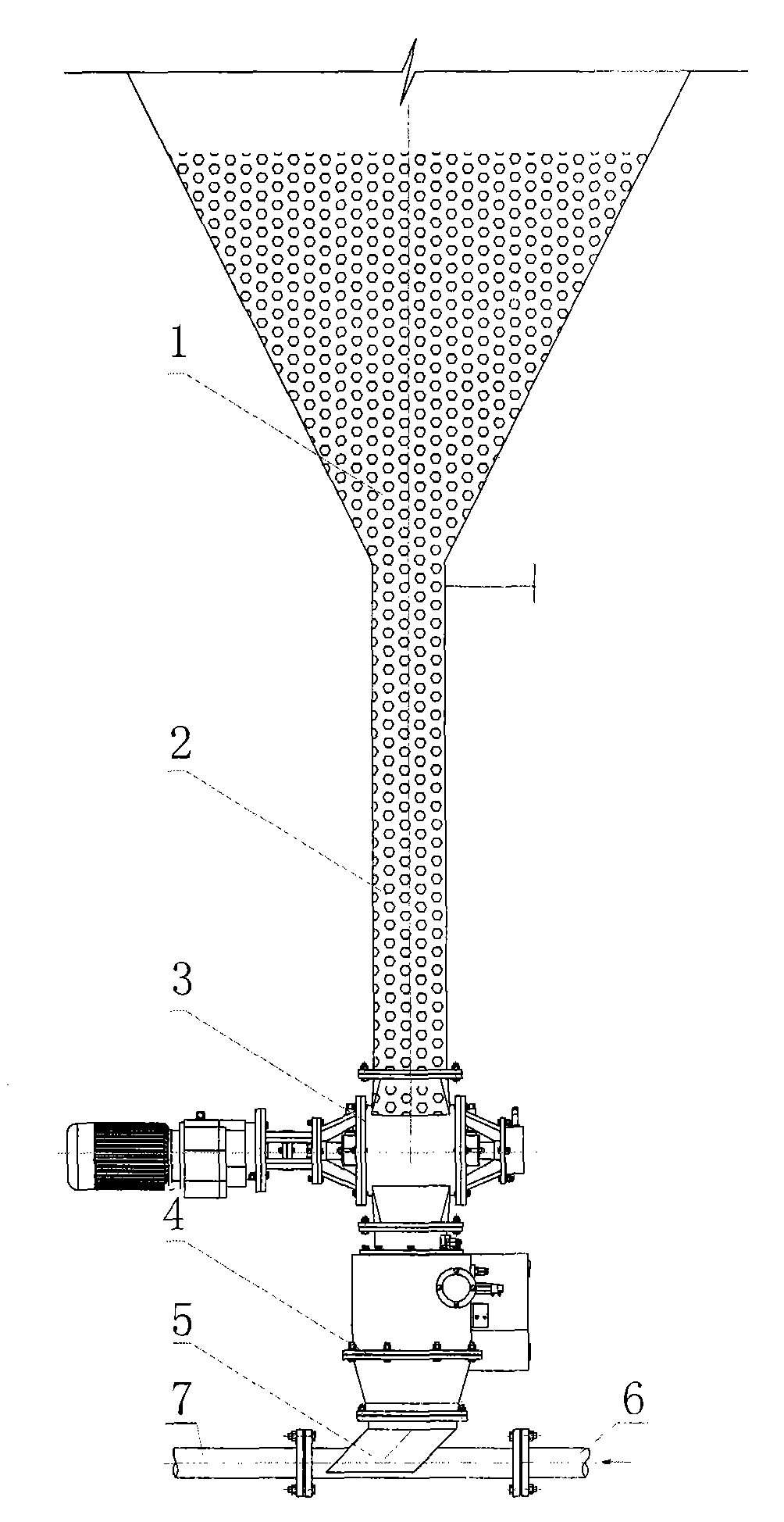

[0011] In the attached drawing, taking the 600t / d co-current regenerative double-chamber fine-grained Maerz kiln injection pulverized coal system as an example, its powder delivery is about 0.4-0.5kg / s, and its characteristic is that the powder delivery is small, Since the general impeller powder feeder cannot monitor the small flow of powder, it is necessary to integrate the rotary air-lock powder feeder (3) and the fine powder measurement device (4) to monitor the small flow of pulverized coal. Canceling the warehouse pump and its related valve accessories, and replacing it with a warehouse-free pump type conveying system can simplify the pulverized coal conveying system, and can continuously and safely convey, and can prevent the conveyed gas from going up, ensuring the safe operation of the dust collector, and can be online Real-time monitoring of the mass flow of pulverized coal fed into the coal-fired Maerz kiln and online display of instantaneous and cumulative average m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com