Method and apparatus for preparing microsphere silicon dioxide carrier on gas-phase fluidized bed by polyvinyls catalyst

A gas-phase fluidized bed and ethylene polymerization technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of high energy consumption, long process, and long roasting time, and achieve low energy consumption and process The effect of short and prolonged residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Refer to the method described in CN1657571A to prepare modified sol, take 10.7 kilograms of pure water and add to 80 liters of stainless steel comprehensive kettle 1 that is provided with electric stirrer and steam jacket, add 1% in this still After adding 0.5 kg of surfactant aqueous solution (modifier, the same below) and 25% to 28% chemically pure ammonia water in Pingping, start the electric stirrer, and make 6.67 kg of silicon dioxide by weight percentage 15% wet After the silicone gel is slowly added to the above kettle, turn on the steam switch for regular constant temperature heating. The temperature of the constant temperature timer controller is set to 90°C and the time is set to 4 hours (this process is automatically completed). Lower the temperature of the material liquid in the kettle to ≤50°C, then add 1.5 kg of acrylic acid solution (modifier) with 80-90% modifier (modifier) into the reaction kettle, stir the material for a short time, put the mate...

Embodiment 2

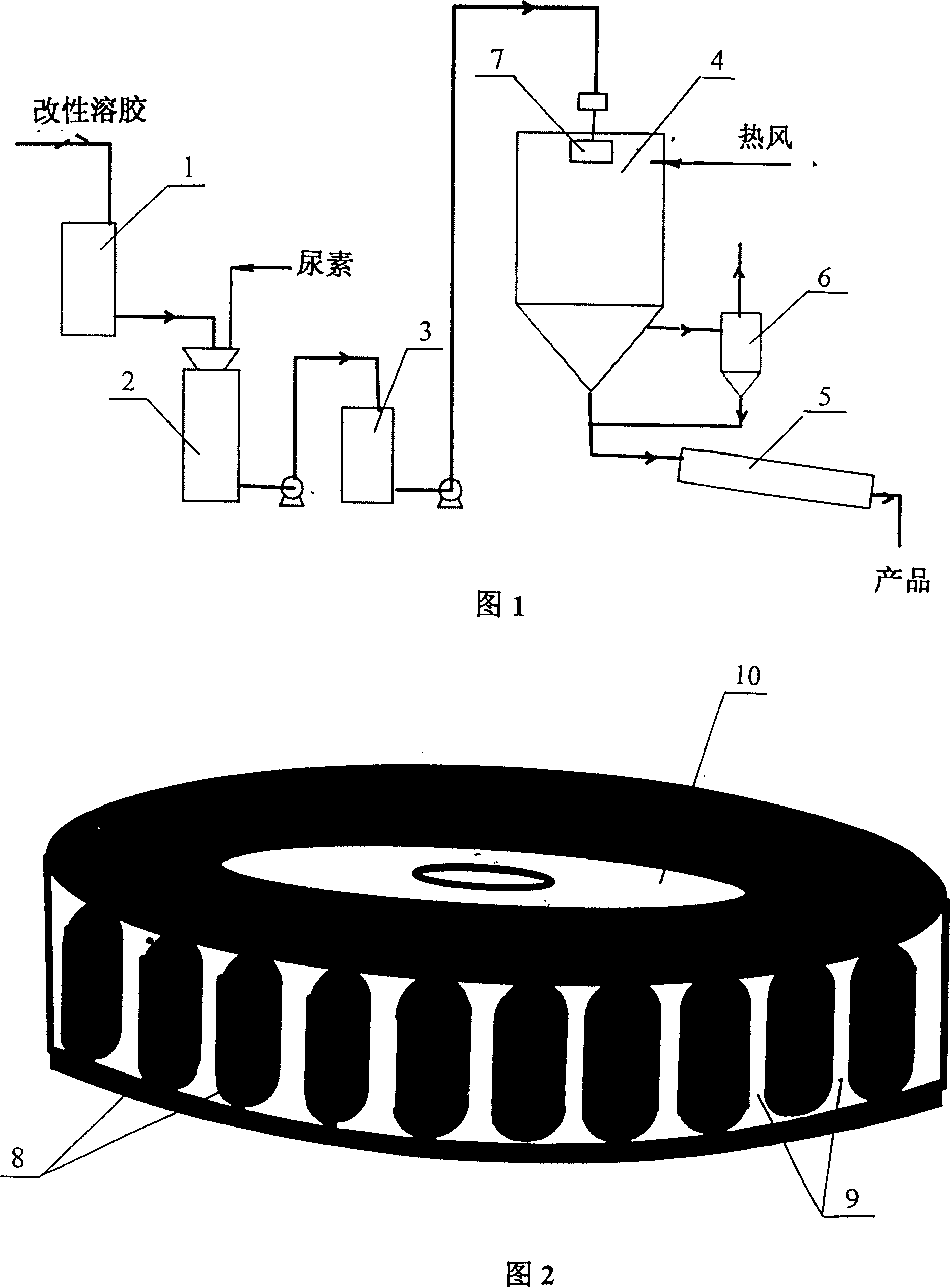

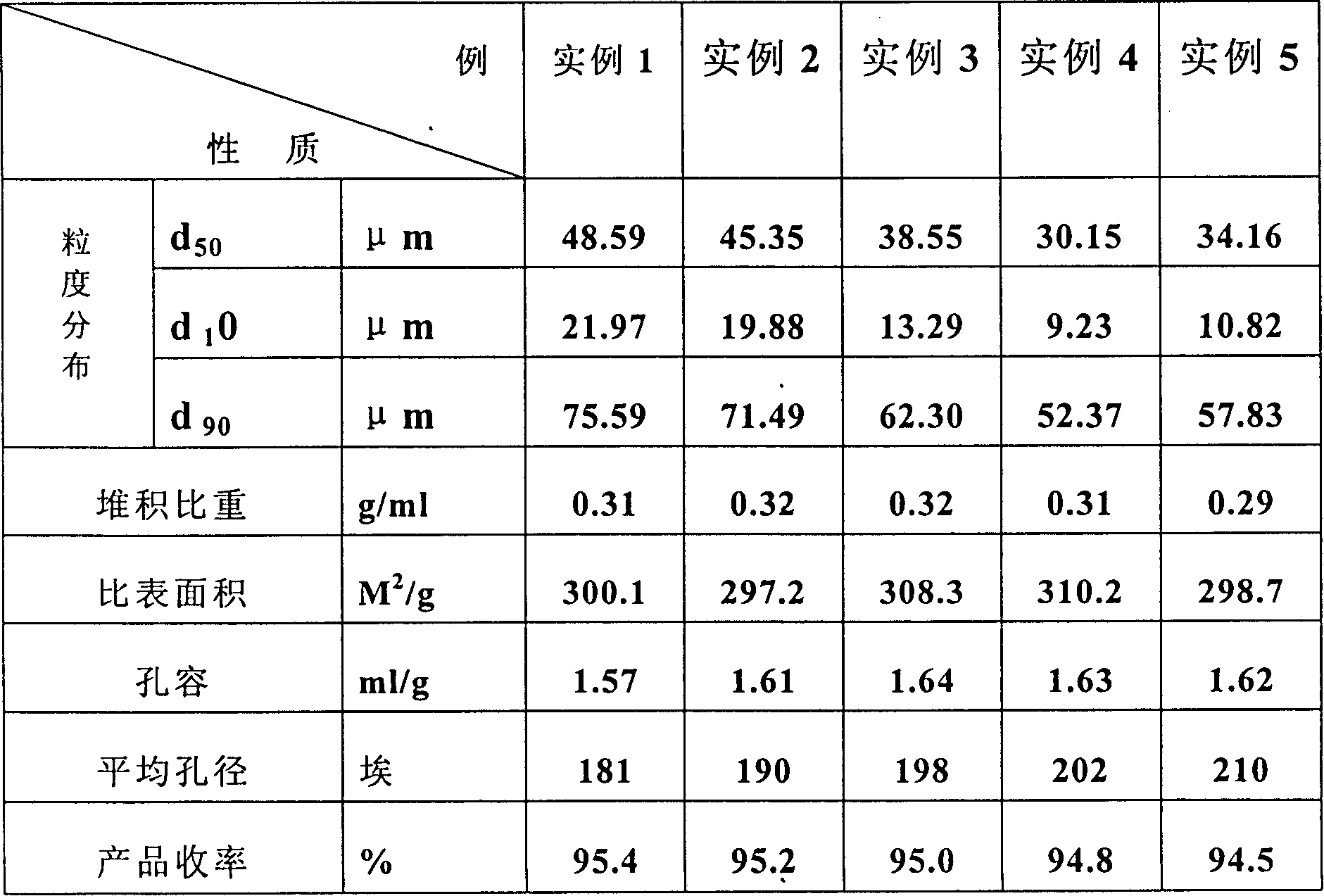

[0040] (1) refer to the step (1) of embodiment 1 and prepare SiO 2 20 kg of sol with a solid weight percentage of 9%.

[0041] (2) 20 kilograms of 9% solid silicon dioxide sols obtained in the above step (1) are added to the colloid mill 2 through the comprehensive kettle 1, and then 100 grams of urea modifiers are added, and then crushed, refined and emulsified After 5 minutes, it is sent to the slurry tank 3, and then sent to the atomizing disc 7 of 10 to 12 curved cylinders 8 provided on the top of the spray dryer 4 through the inlet 10 by the pump (the rotating speed is 9000 rpm). , the slurry is from the gap 9 between the atomized coiled cylinders 8 at a linear velocity of 58.9 m / s, and the temperature at the upper tangent inlet of the spray drier 4 sides from below (below the atomizing disc 7) is The hot air at 370°C (exhaust air temperature 160°C) rotates downwards in the same direction at high speed, and the fine particles enter the first-stage cyclone separator 6 thr...

Embodiment 3

[0043] (1) refer to the step (1) of embodiment 1 and prepare SiO 2 20 kg of sol with a solid weight percentage of 10%.

[0044] (2) 20 kilograms of above-mentioned sols with a percentage by weight of 10% solid silicon dioxide are added to the colloid mill 2 through the comprehensive kettle 1, and then 120 grams of urea modifier are added, and then crushed, refined and emulsified Send in the slurry tank 3 after 10 minutes, add 10 by the pump again and send into the atomizing disc 7 of 10~12 curved cylinders 8 that are provided with at the center of the spray drying machine 4 top (its rotating speed is 10000 rpm) , the slurry is from the slit 9 between the curved cylinders 8 of the atomizing disc 7 at a linear velocity of 72 m / s, and from the bottom of the atomizing disc (below the atomizing disc) at the upper tangent inlet of the spray drier 4 sides The hot air with a temperature of 380°C (exhaust air temperature 170°C) rotates downwards in the same direction at high speed, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com