Belt type screening and conveying device for vibrating screen

A technology of conveying device and vibrating screen, which is applied in the direction of filter screen, solid separation, grid, etc., which can solve the problems of fast wear of the sieve plate, achieve the effects of reducing the vibration quality, increasing the service life, and saving energy consumption in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063]The present invention will be further described below with reference to the accompanying drawings and specific examples.

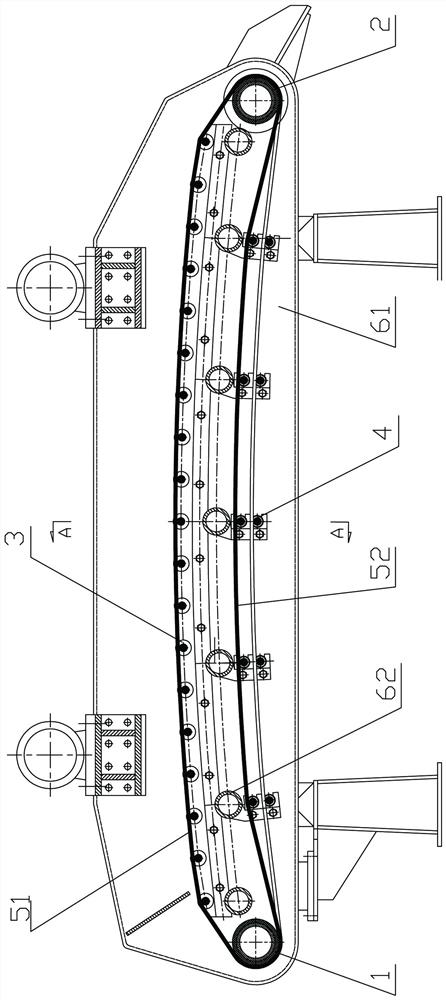

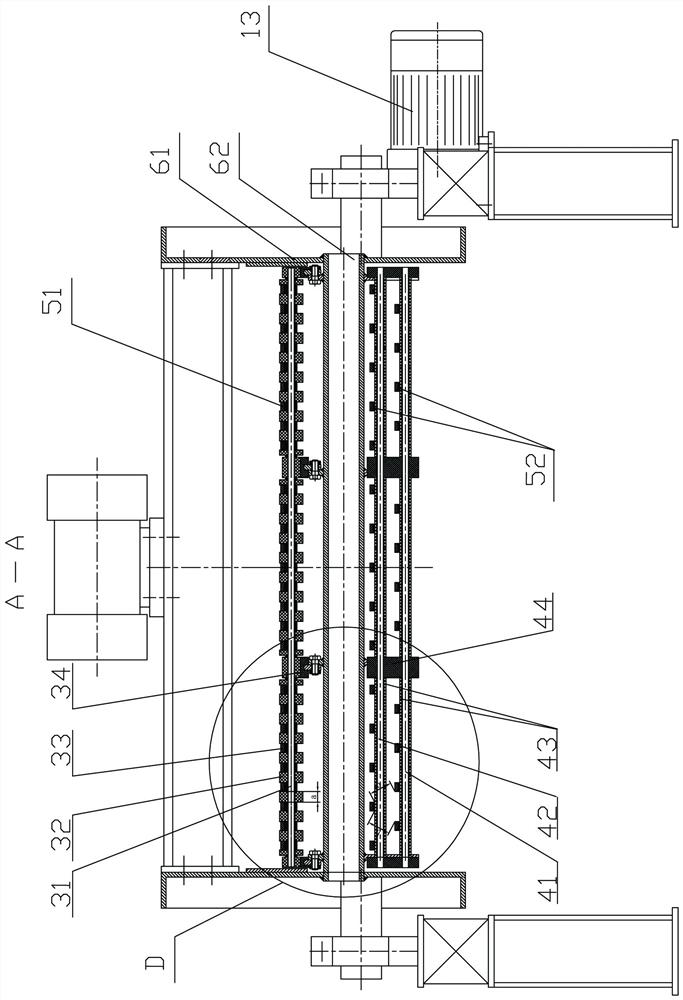

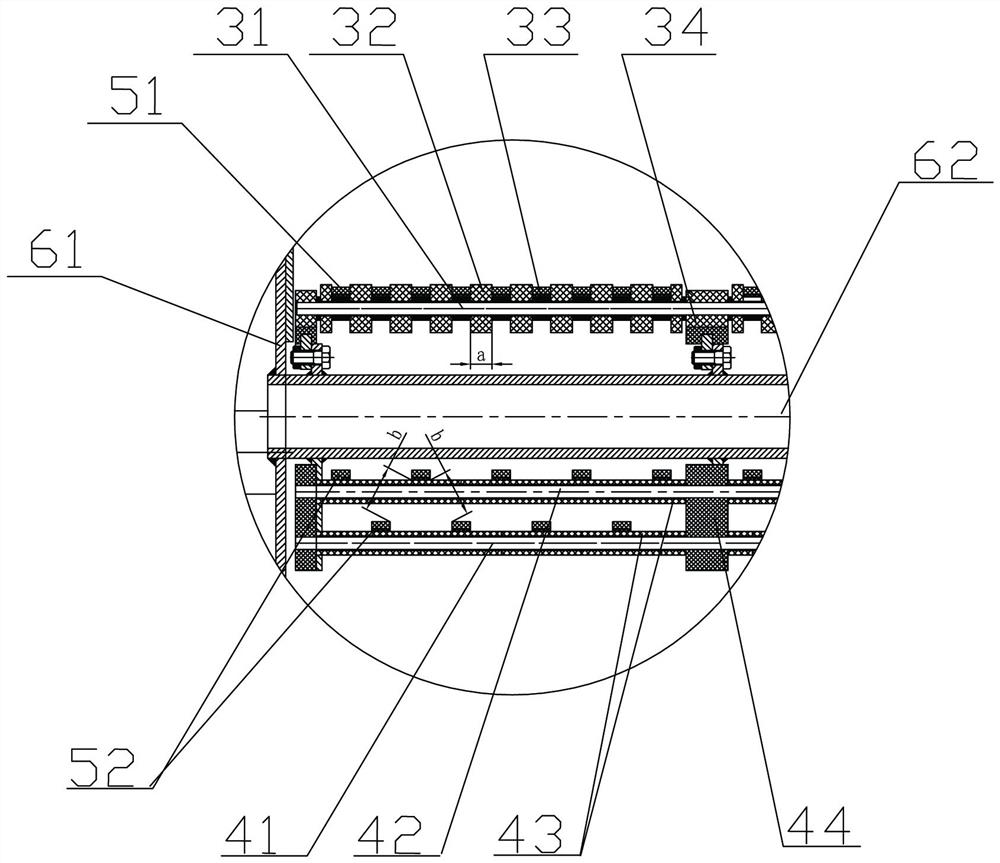

[0064]Such asFigure 1 - Figure 4 As shown, a belt screen conveying device for a vibrating screen is fixedly mounted on a screen box of a vibrating screen, characterized in that the active roller 1, the driven roller 2, several upper support The roller assembly 3 and the plurality of pieces of screen separation belt, the drum shaft 21 at both ends of the movable drum is fixed to the roller shaft 11 at both ends of the active drum on the side plate 61 of the vibrating screen sieve discharge end. On the side panel 61 of the screen sieve box feed end, drive is driven by an external motor 13, a speed reducer, and a synchronous belt 12 or a chain or an axis 2 and the active roller 1 can also be interchangeable. The active drum 1 is also The electric drum can be employed, the tensioning device 22 can be mounted on the driven roller 2 or the active drum 1 according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com