Five-cereal table vinegar brewing method and processing system

A processing system and vinegar technology, applied in the field of five-grain vinegar brewing method and its processing system, can solve the problems of long process cycle and complicated production system, and achieve the effect of simple production system, simple production process and improved filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

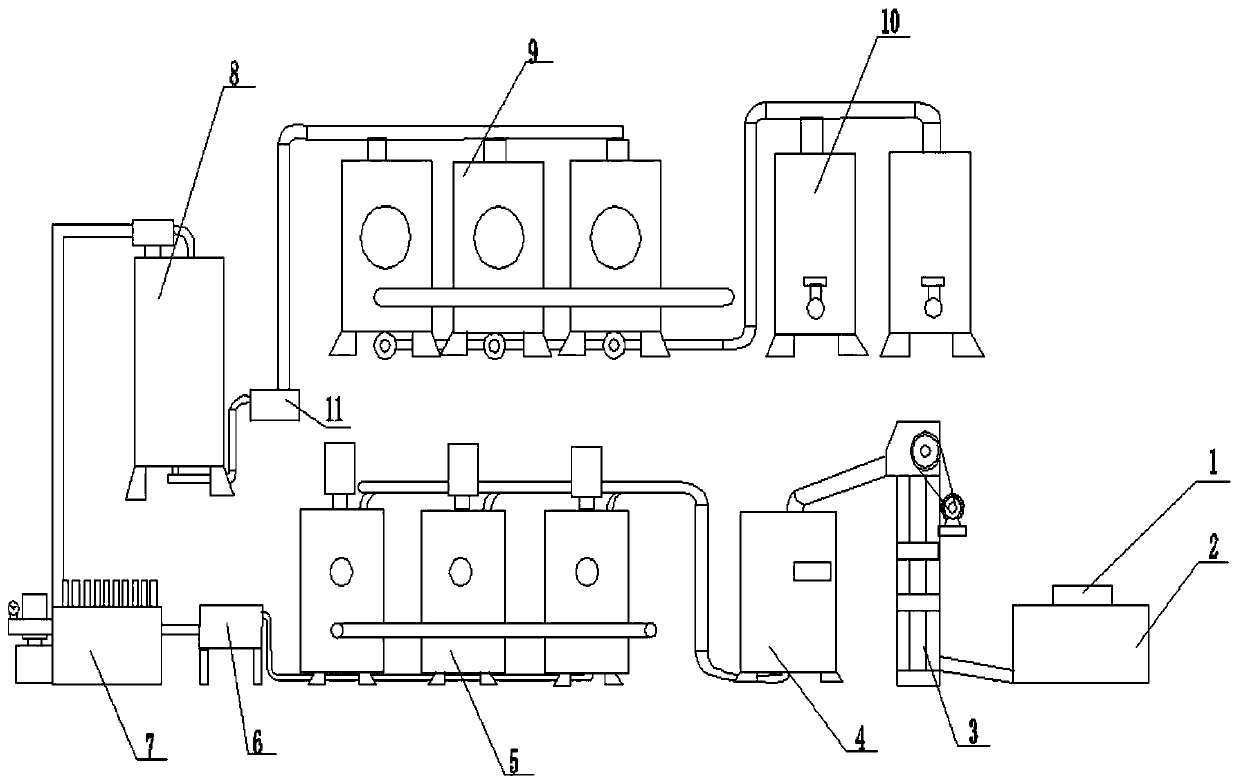

Image

Examples

Embodiment 1

[0024] A kind of five-grain vinegar brewing method comprises the following brewing steps:

[0025] The first step: crushing of raw materials: weigh 40% of corn, 15% of wheat, 15% of yellow rice, 15% of sorghum, and 15% of peas according to the mass ratio, stir them evenly and put them into a crushing device for crushing;

[0026] The second step: cooking and liquefaction: add the pulverized above-mentioned raw materials into the cooking tank, and add water twice the quality of the raw materials into the cooking tank, start the mixer and stir evenly, add α-amylase, stir evenly, and heat up to 85 ℃, heating for 25min; the dosage of α-amylase is 5u / g α-amylase per gram of raw material;

[0027] The third step: saccharification: reduce the temperature of the cooking tank after cooking and liquefaction to 50°C, add the saccharification agent, keep it warm for 30 minutes, add 20% water of the raw material mass into the cooking tank, and continue to lower the temperature of the cooki...

Embodiment 2

[0033] A kind of five-grain vinegar brewing method comprises the following brewing steps:

[0034] The first step: crushing of raw materials: weigh 48% of corn, 18% of wheat, 14% of yellow rice, 15% of sorghum, and 15% of peas according to the mass ratio, stir them evenly, and put them into a crushing device for crushing;

[0035] Step 2: Cooking and liquefaction: Add the pulverized above-mentioned raw materials into the cooking tank, and add water 2.5 times the quality of the raw materials into the cooking tank, start the mixer and stir evenly, add α-amylase, stir evenly, and heat up to 100 ℃, heating for 30min; the dosage of α-amylase is 5.5u / g α-amylase per gram of raw material;

[0036] The third step: saccharification: reduce the temperature of the cooking tank after cooking and liquefaction to 58°C, add a saccharification agent, keep it warm for 40 minutes, add water of 30% of the raw material mass to the cooking tank, and continue to lower the temperature of the cooking...

Embodiment 3

[0042] A kind of five-grain vinegar brewing method comprises the following brewing steps:

[0043] The first step: crushing of raw materials: weigh 50% of corn, 20% of wheat, 10% of yellow rice, 10% of sorghum, and 10% of peas according to the mass ratio, stir them evenly, and put them into a crushing device for crushing;

[0044] The second step: cooking and liquefaction: add the pulverized above-mentioned raw materials into the cooking tank, and add water 3 times the quality of the raw materials into the cooking tank, start the mixer and stir evenly, add α-amylase, stir evenly, and heat up to 110 ℃, heating for 35min; the dosage of α-amylase is 6u / g α-amylase per gram of raw material;

[0045] The third step: saccharification: lower the temperature of the cooking tank after cooking and liquefaction to 62°C, add a saccharification agent, keep it warm for 60 minutes, add water of 40% of the raw material mass to the cooking tank, and continue to lower the temperature of the coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com