Polycrystalline silicon reduction furnace body

A polysilicon and reduction furnace technology, applied to silicon and other directions, can solve the problems of high energy consumption of polysilicon reduction furnace, difficulty in polishing the inner wall of the furnace, low polysilicon, etc., and achieve the effect of preventing high-temperature hydrogen chloride corrosion, ensuring service life and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

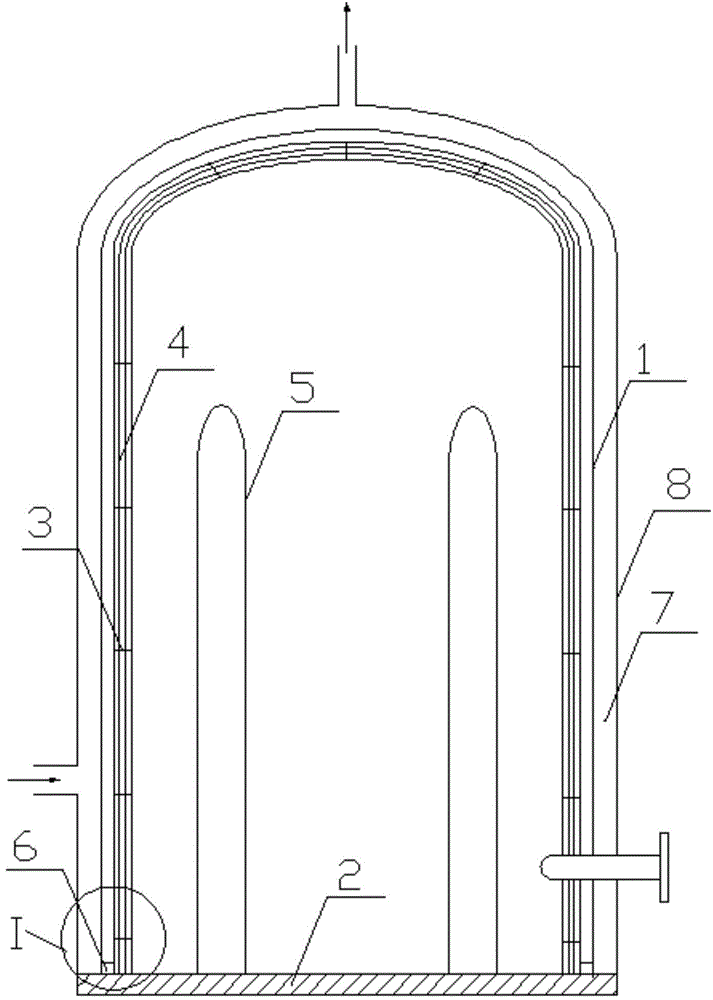

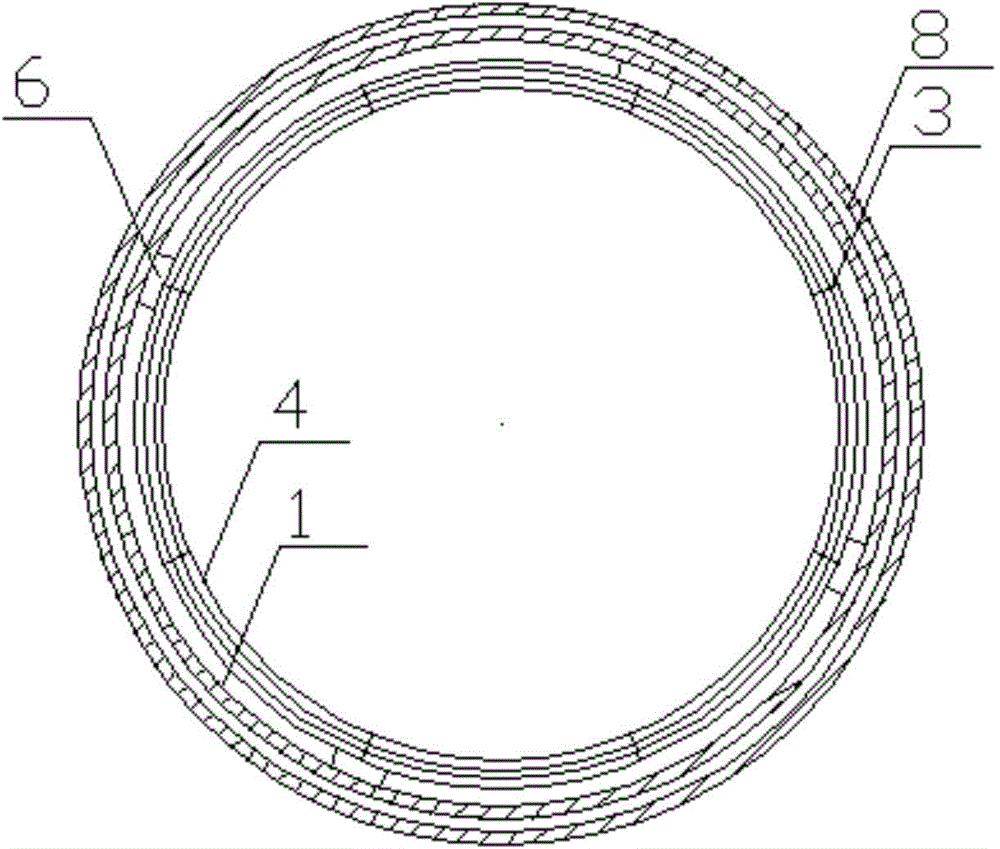

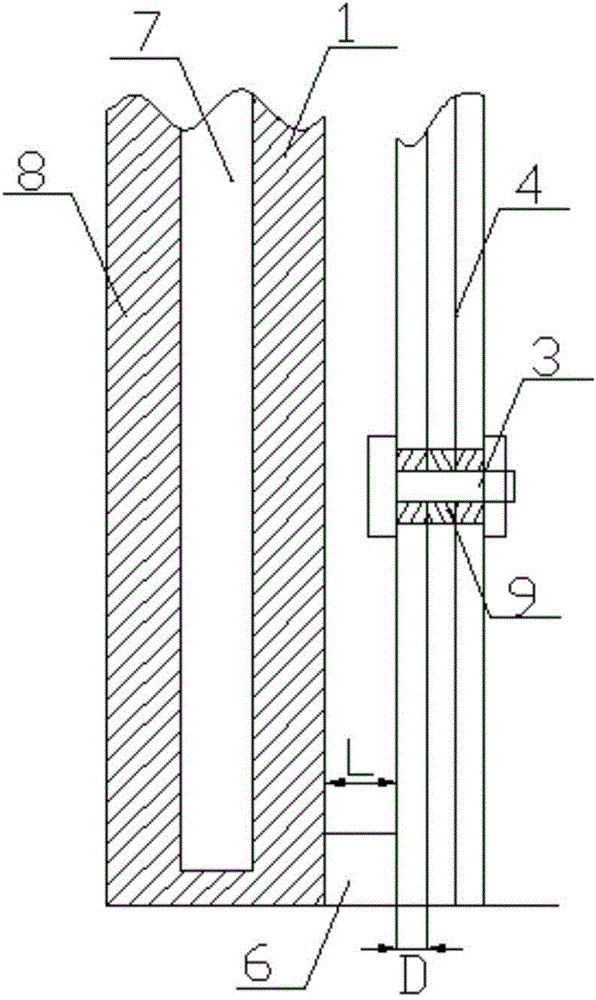

[0017] Embodiment 1: as figure 1 , 2 , Shown in 3, polysilicon reduction furnace furnace body comprises interlayer furnace inner wall 1; Chassis 2; Stainless steel bolt 3; Metal insulation plate 4; According to the proportion of the inner wall 1 of the interlayer furnace, the metal insulation board 4 is made to keep the same shape as the inner wall 1 of the interlayer furnace. For a small furnace body, the inner wall 1 of the interlayer furnace has a small area, and the radiation heat loss is relatively slow. The metal insulation board 4 with a thickness of 2.1 mm and 3 layers in total can be selected. The diameter of the bolt hole on the board is 10 mm, and the specification is M8. Stainless steel SUS316L bolts, the length of the screw rod is 30mm, by welding the stainless steel spacer 9 with a bolt hole thickness of 5mm on the outer side of the metal heat shield 4, the distance D of the heat insulation layer can be controlled = 5mm, and the distance between the multilayer m...

Embodiment 2

[0018] Embodiment 2: as figure 1 , 2 , Shown in 3, polysilicon reduction furnace furnace body comprises interlayer furnace inner wall 1; Chassis 2; Stainless steel bolt 3; Metal insulation plate 4; According to the proportion of the inner wall 1 of the interlayer furnace, the metal insulation board 4 is made to keep the same shape as the inner wall 1 of the interlayer furnace. For the medium-sized furnace body, the radiation heat loss of the inner wall 1 of the interlayer furnace is relatively fast, and the metal heat shield plate 4 with a thickness of 3 mm can be selected, with a total of 4 layers. The diameter of the bolt hole on the plate is 12 mm, and the stainless steel 304 bolts and screws with a specification of M10 are used. The length is 60 mm. By welding the stainless steel spacer 9 with a bolt hole thickness of 8 mm on the outer side of the metal heat insulation board 4, the distance D of the heat insulation layer can be controlled = 8 mm. The stainless steel bolts...

Embodiment 3

[0019] Embodiment 3: as figure 1 , 2 , Shown in 3, polysilicon reduction furnace furnace body comprises interlayer furnace inner wall 1; Chassis 2; Stainless steel bolt 3; Metal insulation plate 4; According to the proportion of the inner wall 1 of the interlayer furnace, the metal insulation board 4 is made to keep the same shape as the inner wall 1 of the interlayer furnace. For a large furnace body, the inner wall 1 of the interlayer furnace has a large area, and the radiation heat loss is very fast. A metal heat shield 4 can be selected, with a total of 5 layers, of which the thickness of the inner and outer layers is 5mm, and the thickness of the middle three layers is 2.2mm. Bolt holes are opened on the board. The diameter is 14mm, using stainless steel SUS316L bolts with specifications M12, the length of the screw rod is 90mm, by welding the stainless steel isolation gasket 9 with a bolt hole thickness of 10mm on the outer side of the metal heat insulation plate 4, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com