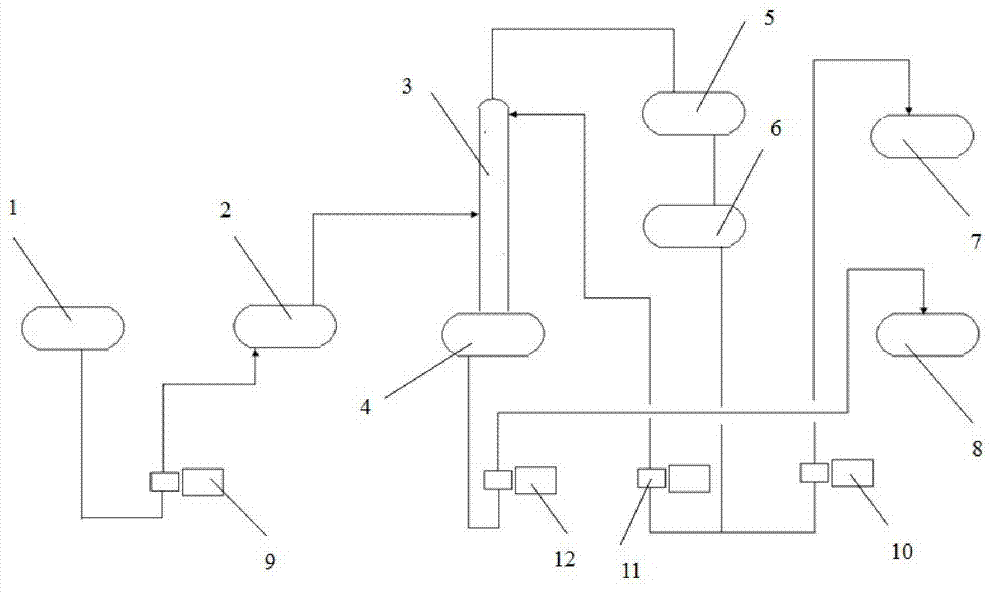

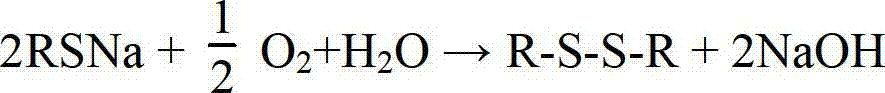

Technology and system for preparing vulcanizing agent by using sweetening waste of lye regenerated byproducts

A technology for removing thiols and vulcanizing agents, applied in the preparation of organic compounds, catalyst activation/preparation, catalysts for physical/chemical processes, etc., can solve problems such as environmental pollution, save the vacuum system, simplify the production process, and avoid decomposition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

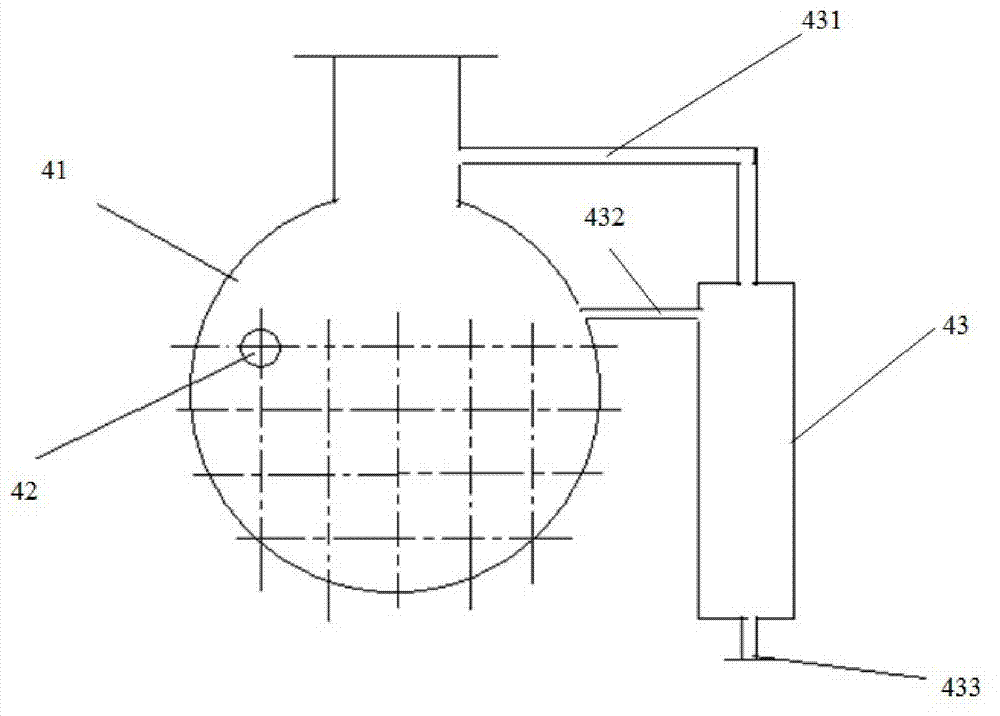

Method used

Image

Examples

Embodiment 1

[0035] The outlet temperature of the raw material preheater is 135°C, that is, the feed temperature is 135°C.

[0036] Tower top temperature: 130°C

[0037] Tower kettle temperature: 155°C

[0038] Reflux ratio: 1:1

[0039] The pressure at the top of the column is normal pressure, and the number of theoretical plates in the rectification column is 5

[0040] 5 tons of raw materials were processed, and 4.88 tons of vulcanizing agent products were obtained, with a product yield of 97.6%. The properties of the products are as follows:

[0041]

[0042]

[0043] It is determined by experiments that the sulfur decomposition temperature of each component in the obtained vulcanizing agent is ≯230°C, and the content of dimethyl disulfide is ≮35%. The effect of using the vulcanizing agent is equivalent to that of pure dimethyl disulfide. At 230°C, some sulfur-containing components do not decompose, and the content of dimethyl disulfide is more than 35%, so it meets the qualit...

Embodiment 2

[0045] The outlet temperature of the raw material preheater is 125°C, that is, the feed temperature is 125°C.

[0046] Tower top temperature: 120°C

[0047] Tower kettle temperature: 140°C

[0048] Reflux ratio: 1:1

[0049] The pressure at the top of the column is normal pressure, and the number of theoretical plates in the rectification column is 5

[0050] Treat 5 tons of raw materials, obtain 4.53 tons of vulcanizing agent products, and the product yield is 90.6%. The properties of the products are as follows:

[0051]

[0052]

[0053] It is determined by experiments that the decomposition temperature of sulfur in each component of the vulcanizing agent is ≯230°C, and the content of dimethyl disulfide is ≮35%. The effect of using the vulcanizing agent is equivalent to that of pure dimethyl disulfide. The components are similar to the vulcanizing agent in Example 1, so some sulfur-containing components do not decompose at a temperature of 230°C, and the content of...

Embodiment 3

[0055] The outlet temperature of the raw material preheater is 130°C, that is, the feed temperature is 130°C.

[0056] Tower top temperature: 126°C

[0057] Tower kettle temperature: 150°C

[0058] Reflux ratio: 1:1

[0059] The pressure at the top of the column is normal pressure, and the number of theoretical plates in the rectification column is 5

[0060] 5 tons of raw materials were processed, and 4.77 tons of vulcanizing agent products were obtained, with a product yield of 95.4%. The properties of the products are as follows:

[0061]

[0062] It is determined by experiments that the decomposition temperature of sulfur in each component of the vulcanizing agent is ≯230°C, and the content of dimethyl disulfide is ≮35%. The effect of using the vulcanizing agent is equivalent to that of pure dimethyl disulfide. The composition of the vulcanizing agent is similar to that of the vulcanizing agent in Example 1, so there is no case that some sulfur-containing components ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com