Patents

Literature

155results about How to "Reduce the amount of excavation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

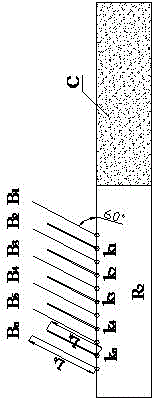

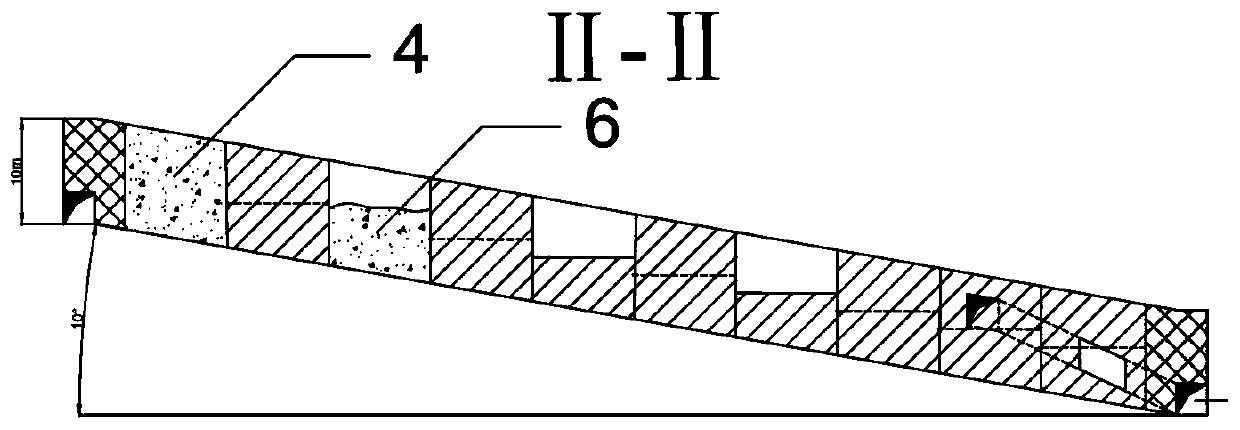

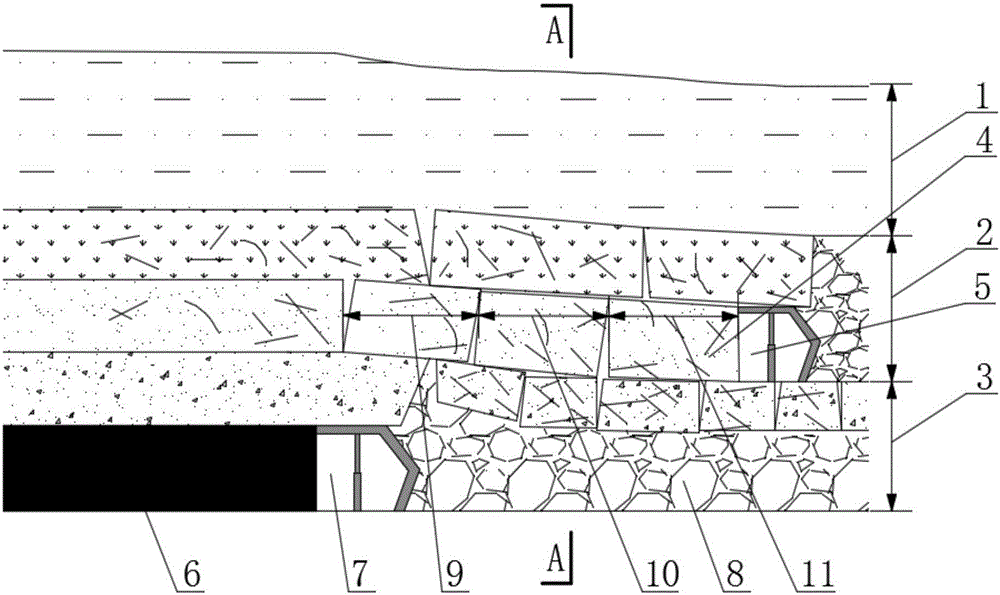

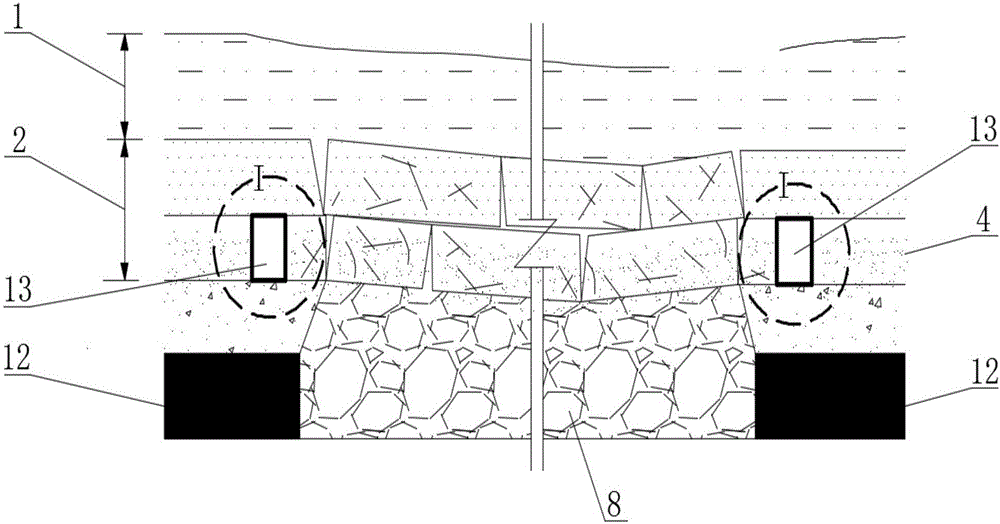

Roadside packing gob-side entry retaining top-cutting explosion pressure relief method

InactiveCN104790954ARelieve pressureEliminate problems such as support difficultiesUnderground miningSurface miningStructural engineeringDeep hole

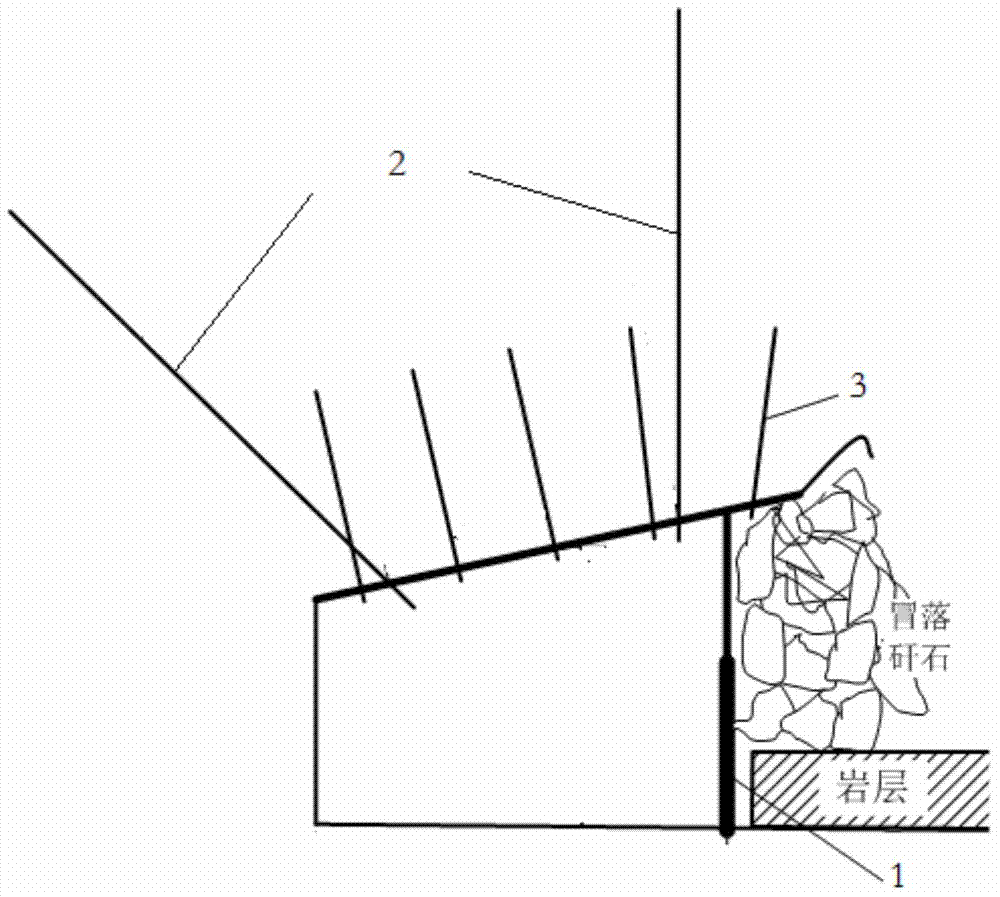

The invention discloses a roadside packing gob-side entry retaining top-cutting explosion pressure relief method which comprises the following four steps: I, confirming a top-cutting method, the drilling construction time and a drilling construction site; II, confirming top-cutting pressure relief explosion drilling parameters; III, drilling deep-hole explosion holes and explosive filling and sealing holes; IV, performing explosion top-cutting pressure relief. The roadside packing gob-side entry retaining top-cutting explosion pressure relief method is applied to roadside packing gob-side entry retaining top-cutting explosion pressure relief.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

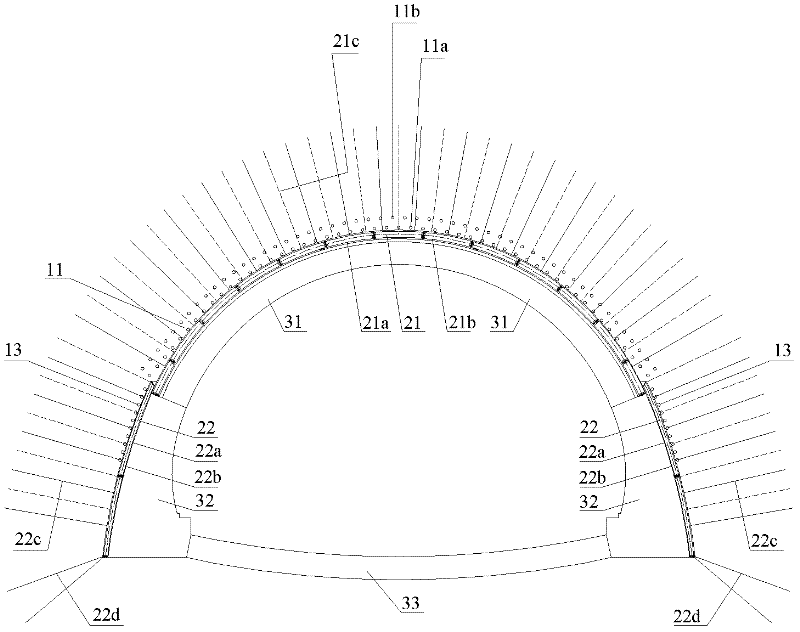

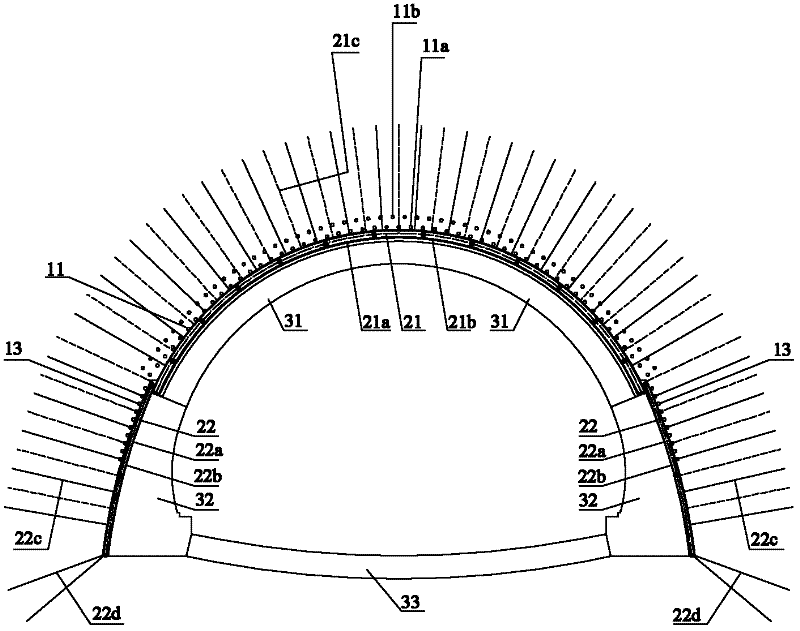

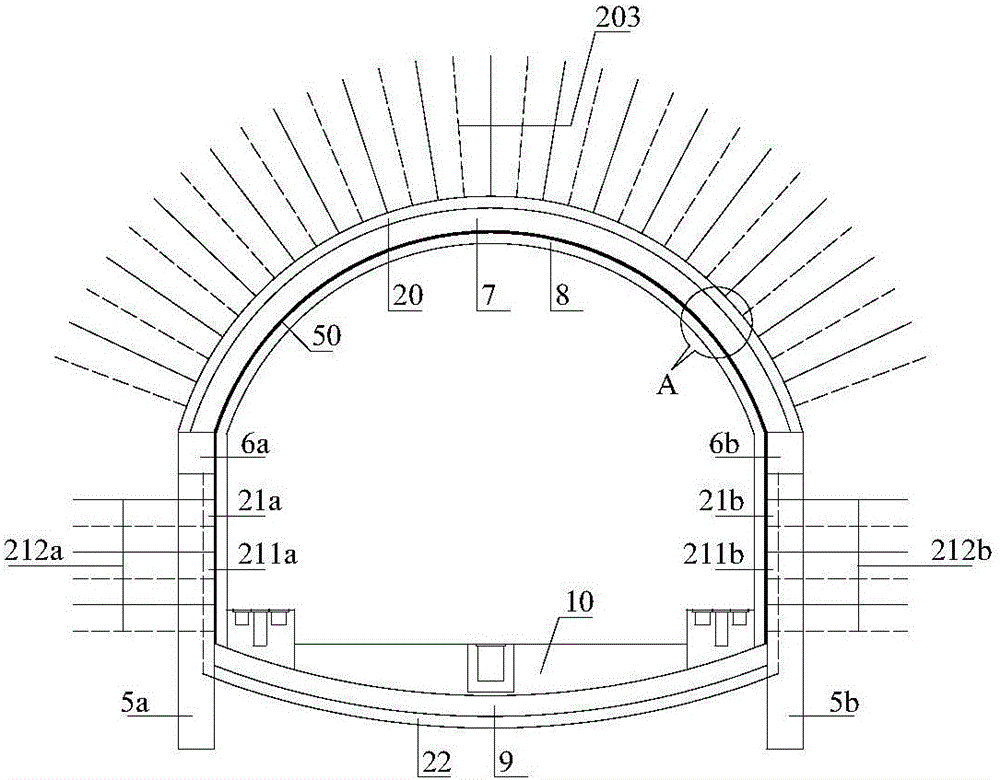

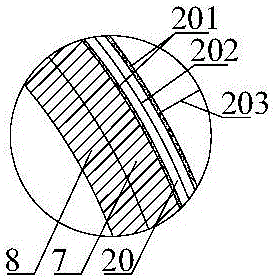

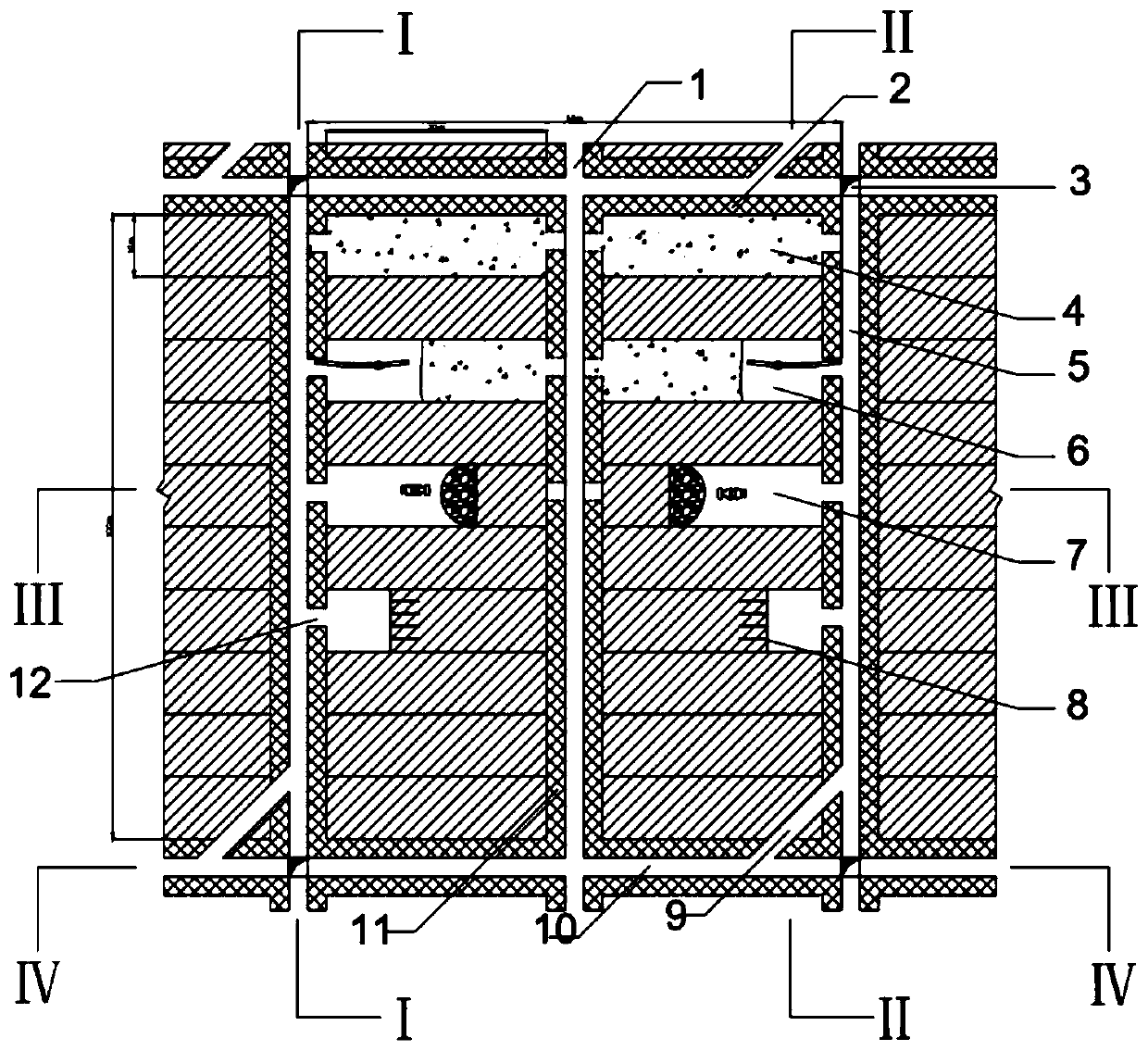

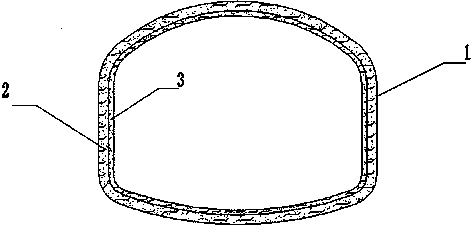

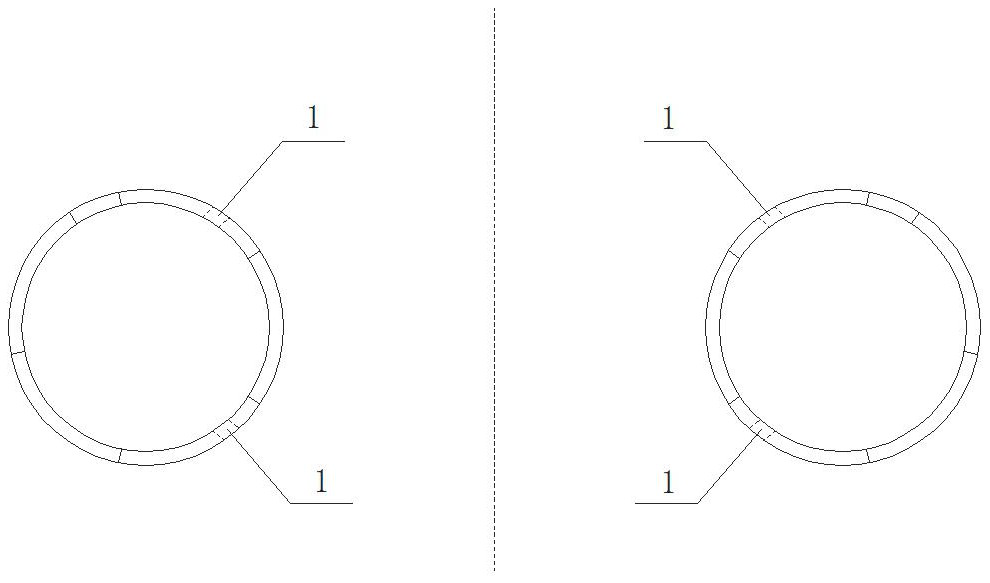

Composite liner structure of four-track large-span wall-foundation arched tunnel

InactiveCN102213099ASolve the problem of sinking deformationIncrease stiffnessUnderground chambersTunnel liningComposite linerSubsidence

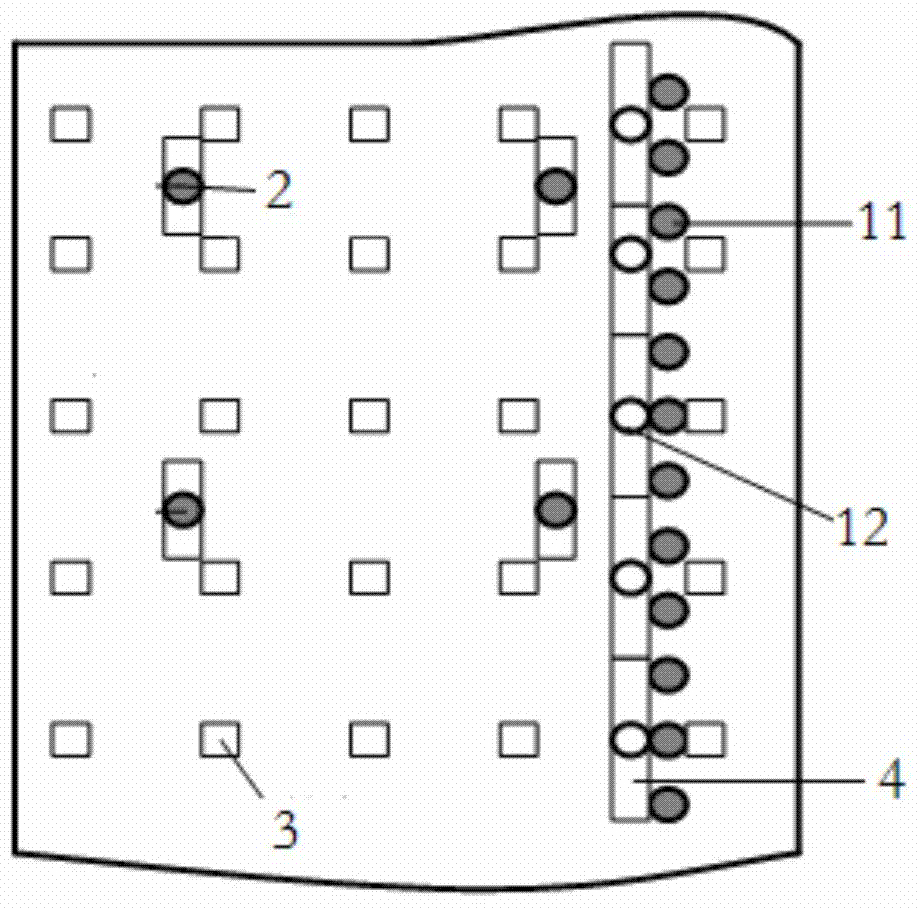

The invention relates to a composite liner structure of a four-track large-span wall-foundation arched tunnel. According to the composite liner structure provided by the invention, subsidence of an arch crown of a four-track large-span tunnel can be effectively controlled, and crack of a liner, even a tunnel collapse accident caused by subsidence of an arch springing and deformation of the arch crown can be avoided so that the stability and the safety of tunnel construction and operation are ensured. The composite liner structure comprises a forepoling structure, a preliminary poling structure and a secondary liner structure which are arranged from inside to outside. The secondary liner structure comprises a secondary liner structure (31) at an arch part, wall-foundation structures (32) at two sides of a tunnel and an inverted arch; the forepoling structure comprises a forepoling structure (11) at the arch part and forepoling structures (12) on the side walls of a wall foundation; the preliminary poling structure comprises preliminary poling structures (21) at the arch part and preliminary poling structures (22) on the side walls of the wall foundation; and the lower ends of the preliminary poling structures (21) at the arch part and the secondary liner structure (31) at the arch part are respectively supported at the upper ends of the wall-foundation structures (32) at two sides of the tunnel.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

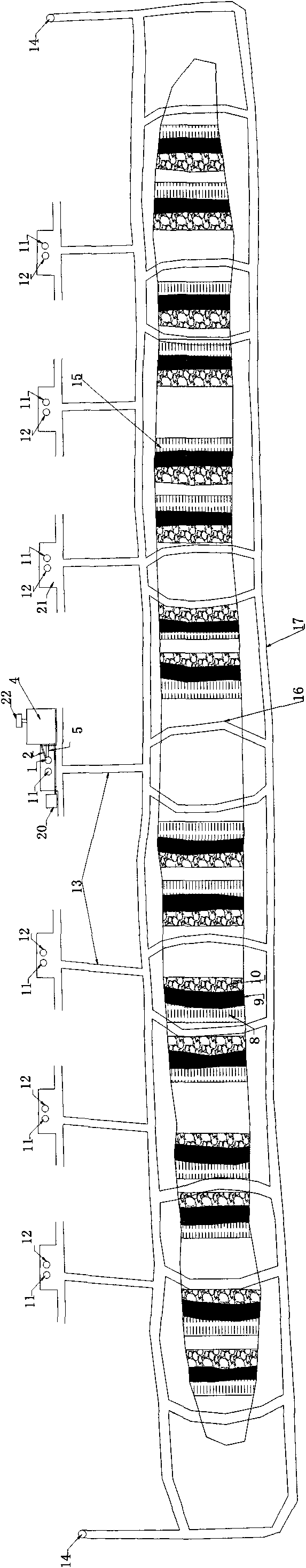

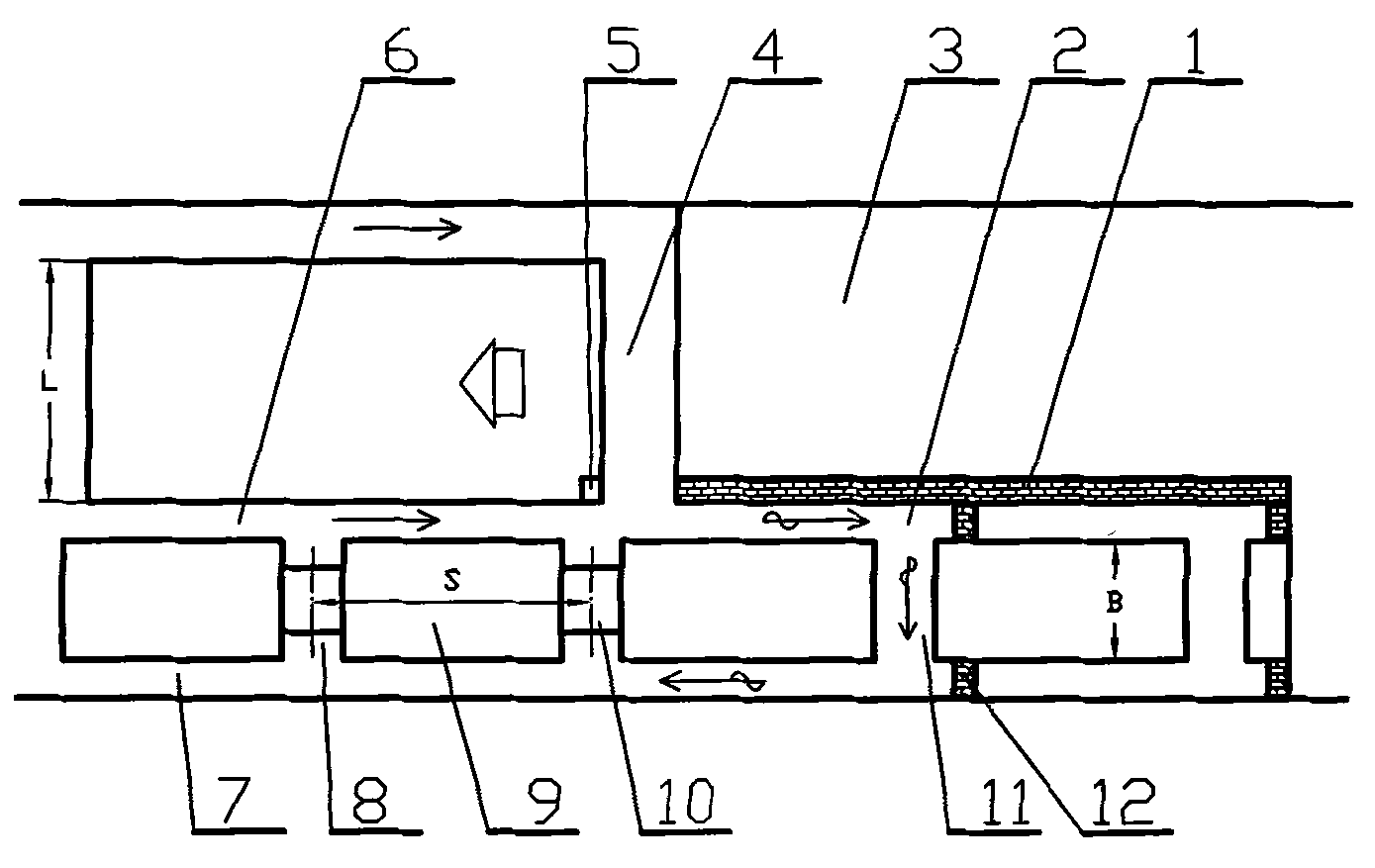

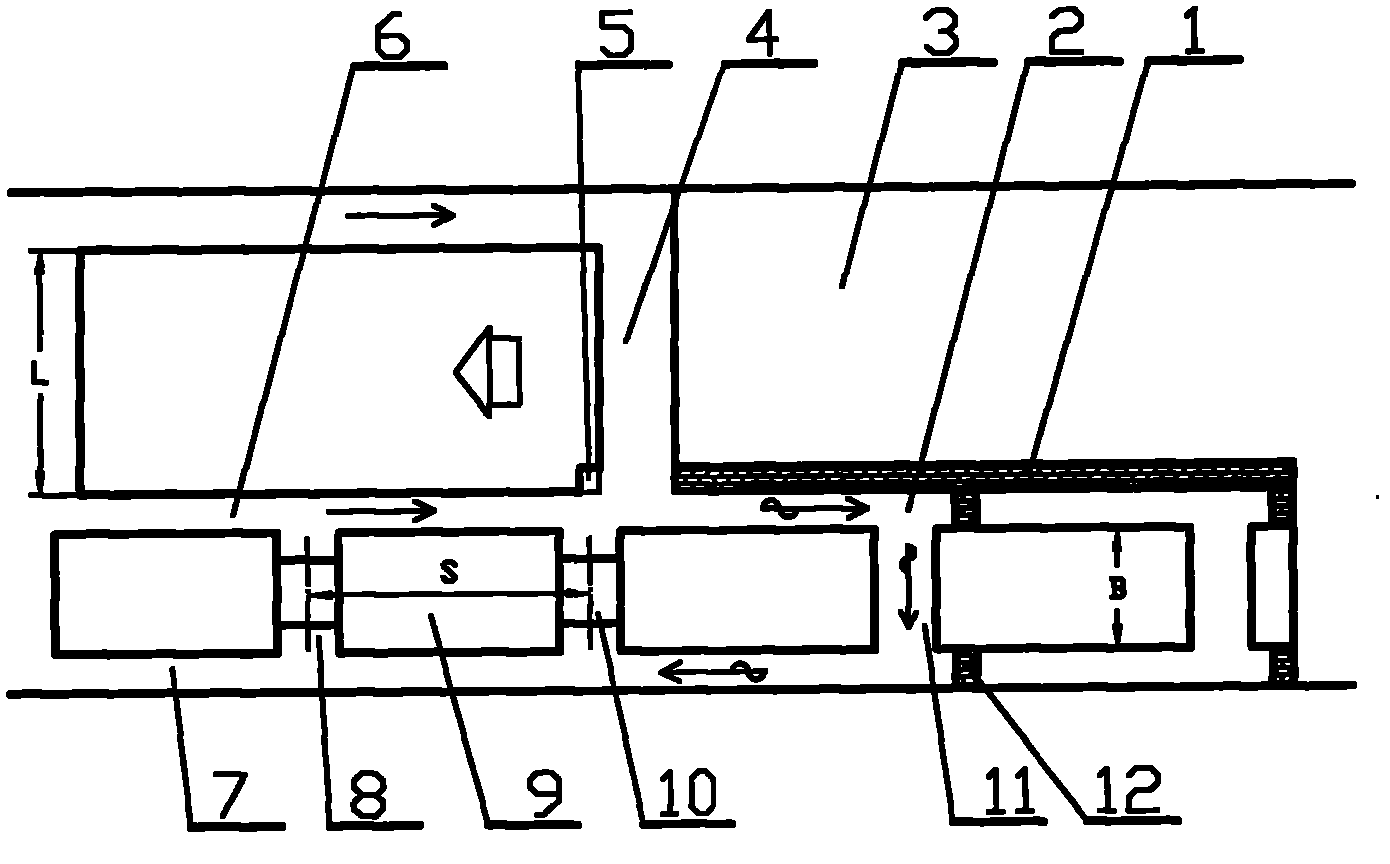

Deeply buried iron mineral resource underground mining and concentrating integration system

ActiveCN101775985AReduce the amount of excavationAchieve short-distance liftsUnderground chambersUnderground miningEcological environmentMineral Sources

The invention relates to a deeply buried iron mineral resource underground mining and concentrating integration system, which is characterized in that only one main hoisting shaft is arranged, positions adjacent to the main hoisting shaft are provided with an underground concentrating mill, an underground filling station and an underground water sump; the left side and the right side of the main hoisting shaft are uniformly provided with at least one blind shaft, and positions adjacent to the main hoisting shaft and the blind shaft are both provided with a main orepass; the footwall side of the top of an ore body is provided with a main horizontal haulage roadway, and both ends of the roadway are provided with air shafts; and the underground concentrating mill comprises a cycle chamber, a conical chamber, a screening chamber, a powder ore chamber, a grinding chamber, a sorting chamber and a product delivery chamber. The invention has the main characteristics that the concentrating mill, the underground filling station and the under water sump are arranged underground so as to realize short-distance hoisting of mined deeply buried mineral resources, the concentrated tailings and waste rocks are directly used underground, the overall mining cost can be reduced by 10 to 30 percent without damaging the earth surface, environment pollution is reduced, and the ecological environment is protected.

Owner:NORTHEASTERN UNIV

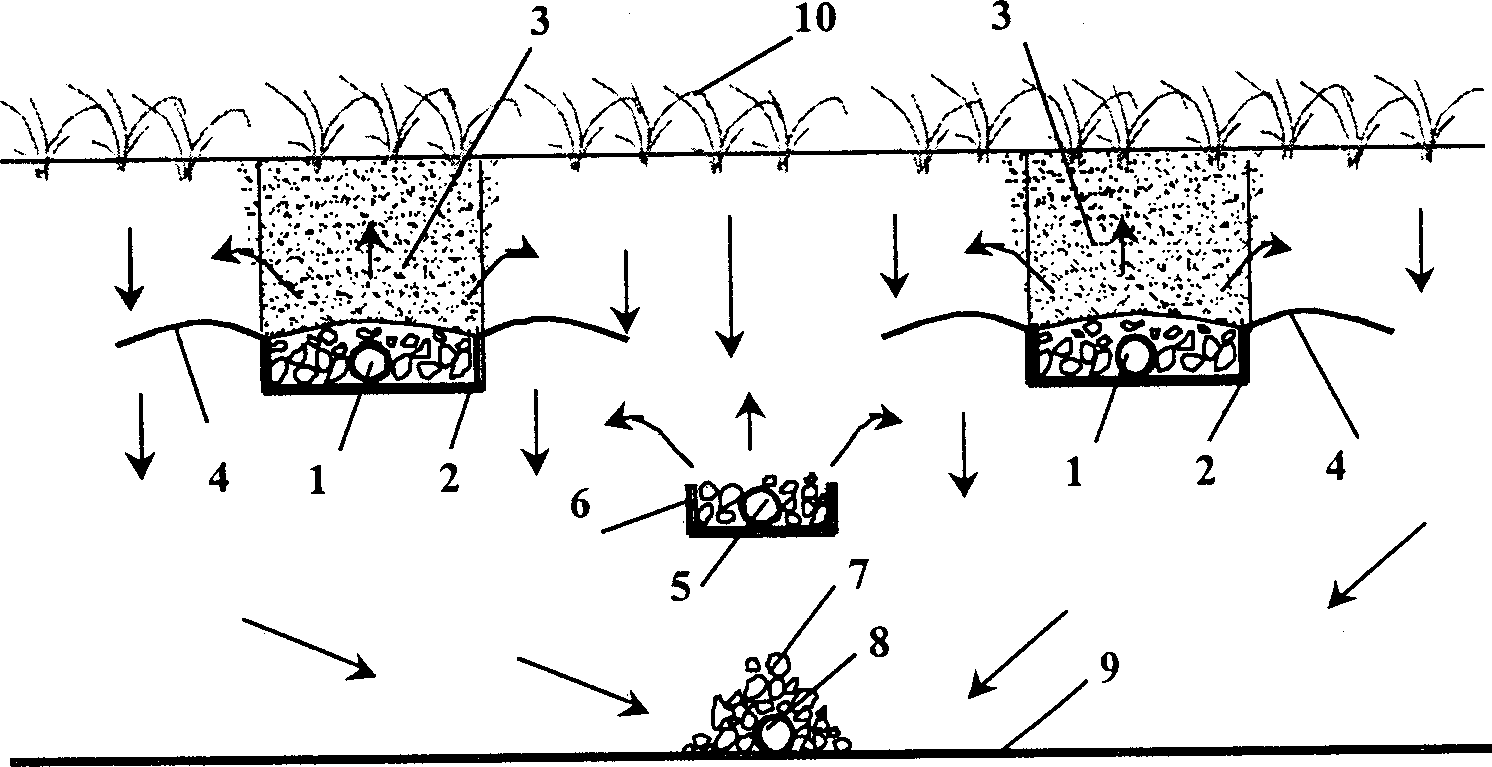

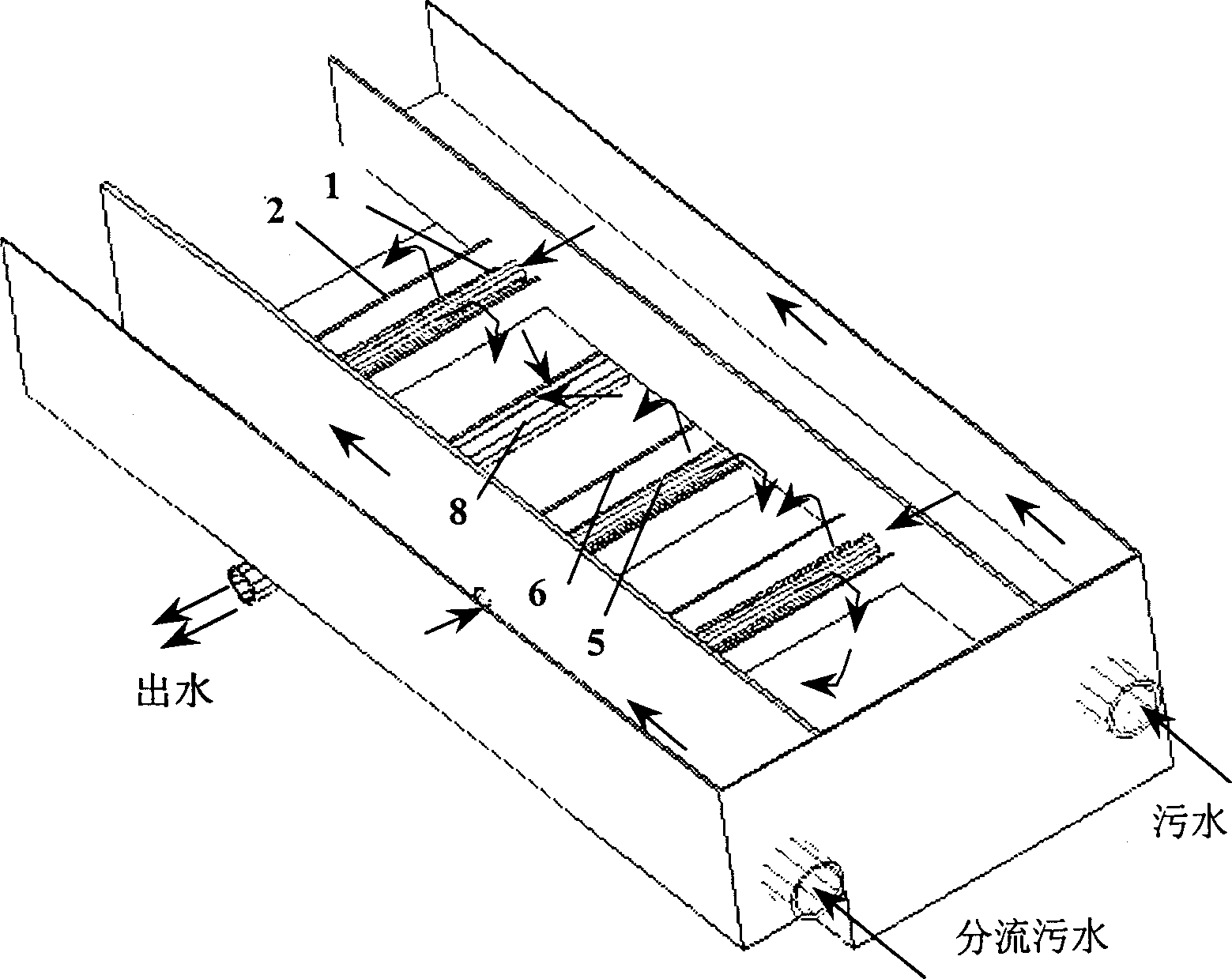

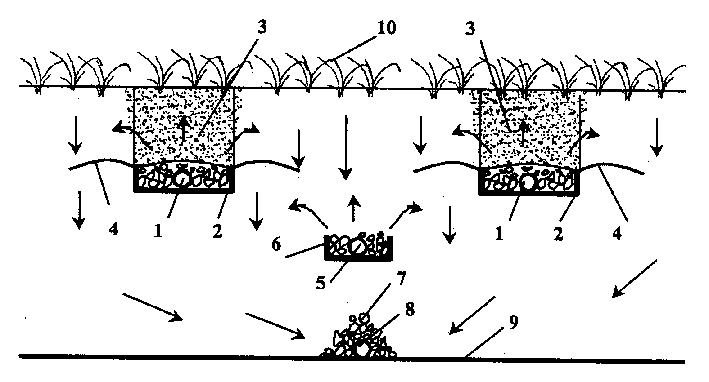

Intensified water-layout underground infiltration water treatment method and system

InactiveCN1405096AReduce the amount of excavationLow infrastructure costTreatment using aerobic processesSustainable biological treatmentTotal phosphorusPiping

Under the surface plants several percolating channels and water-distributing grooves are set, the interior of percolating channel is filled with artifically-made speciall soil, and at two sides of water-distributing groove the reinforced water-distributing material can be set, under the action of comprhensive cleaning function of soil, microorganism and plant system, the sewage can be cleaned, the cleaned water can be collected by a water-collecting channel set on the impervious layer of its bottom portion, and discharged out by a water-collecting tube. Said invention can make removing rate of COD, amino nitrogen, total nitrogen and total phosphorus being in domestic sewage by up to above 90%.

Owner:TSINGHUA UNIV

Coal mine gob-side entry retaining side supporting method

InactiveCN103758529AImprove resource recoveryImprove damageUnderground chambersTunnel liningSupporting systemCoal

The invention discloses a coal mine gob-side entry retaining side supporting method. The coal mine gob-side entry retaining side supporting method comprises the following steps of supporting the coal mine gob-side entry retaining side through intensive individual hydraulic supporting columns; constructing anchor cable supports for the gob-side entry retaining top plates based on the original rocker bolt supports, enabling the gob-side entry retaining to adopt double-line rocker bolt supports, enabling the distance between the rocker bolts to be 2 m and the row distance to be 2.2 m and enabling the anchor bolts which are close to one side of the coal wall to be installed along a certain inclination angle and the anchor bolts which are close to one side of a gob to be installed perpendicular to the top plates; constructing a row of single hydraulic supporting columns on the inner side of the intensive single hydraulic supporting columns after the designed pretress of the anchor bolts is achieved and enabling the column distance to be 1.2 to 1.5 m; enabling the insensitive single hydraulic supporting columns to be out successively from back to front and enabling supplement single hydraulic supporting columns and the installed anchor bolts to be formed into a gob-side entry retaining side auxiliary supporting system. The coal mine gob-side entry retaining side supporting method solves the problem that the gob-side entry retaining side supporting is difficult.

Owner:BEIJING HAOHUA ENERGY RESOURCE

Non-coal-pillar double tunneling method

ActiveCN104763434AAvoid interferenceIncrease productivityUnderground chambersTunnel/mines ventillationSurface recoveryEngineering

The invention discloses a non-coal-pillar double tunneling method. The non-coal-pillar double tunneling method includes that retaining a separating wall width tunneling tail roadway when performing working surface air return way and tail roadway tunneling, after delaying a tail roadway tunneling working surface, constructing a concrete pier and a concrete separating wall with a connected channel at the inner coal wall of the tunneled roadway, pre-embedding a gas discharge pipe, after the wall body intensity reaches the standard, using the wall body as one coal wall of the working surface air return way and tunneling, temporarily closing the front channel after forming the next connected channel, wherein the double tunneling ventilation effect is formed between the tail roadway and air return way through the connected channels. The non-chain-pillar double tunneling method uses the isolating wall as the protection coal pillar, the bad influence of a traditional roadway retaining method to the working surface recovery is radically solved, the one-time tunneling section of the roadway is small, the tunneling construction and roadway support are easy to perform, the cost is low, and the operation is safe and effective.

Owner:TAIYUAN UNIV OF TECH

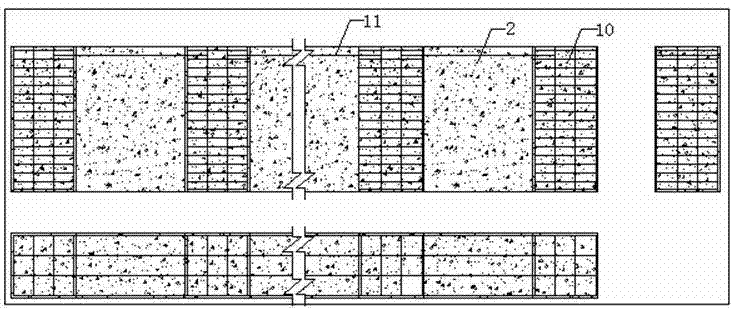

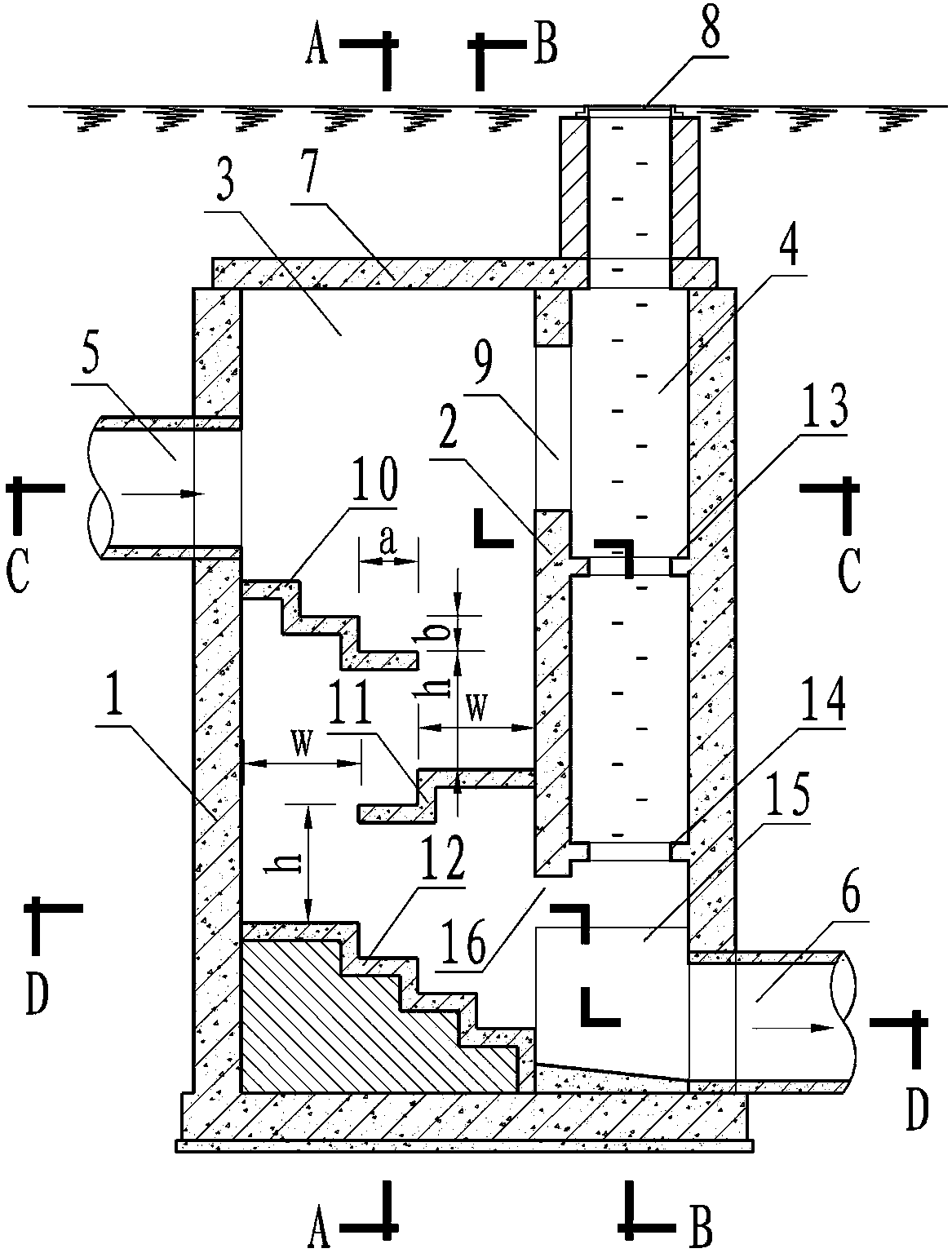

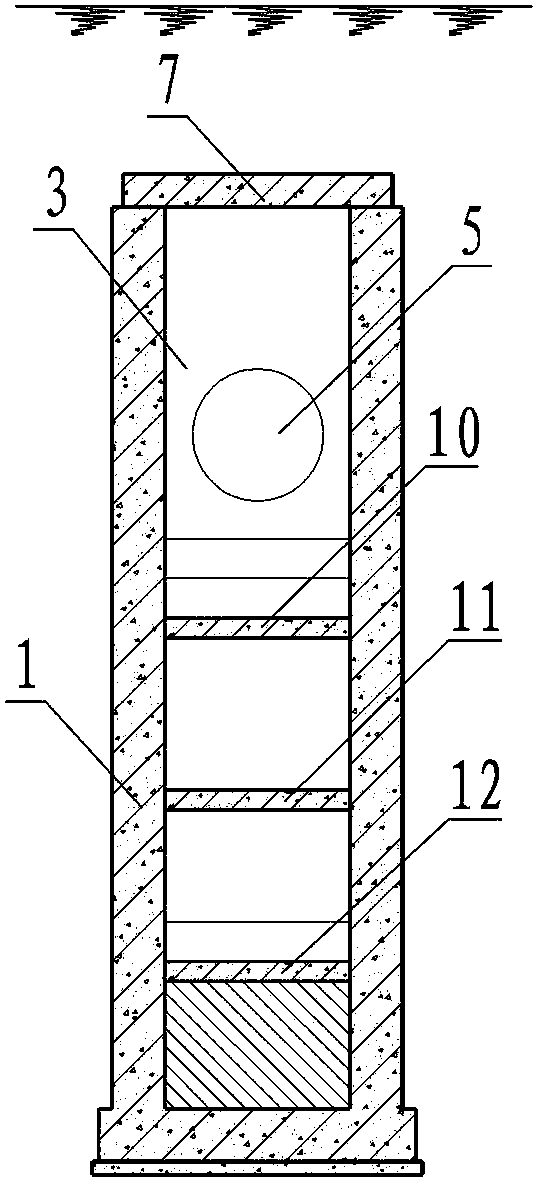

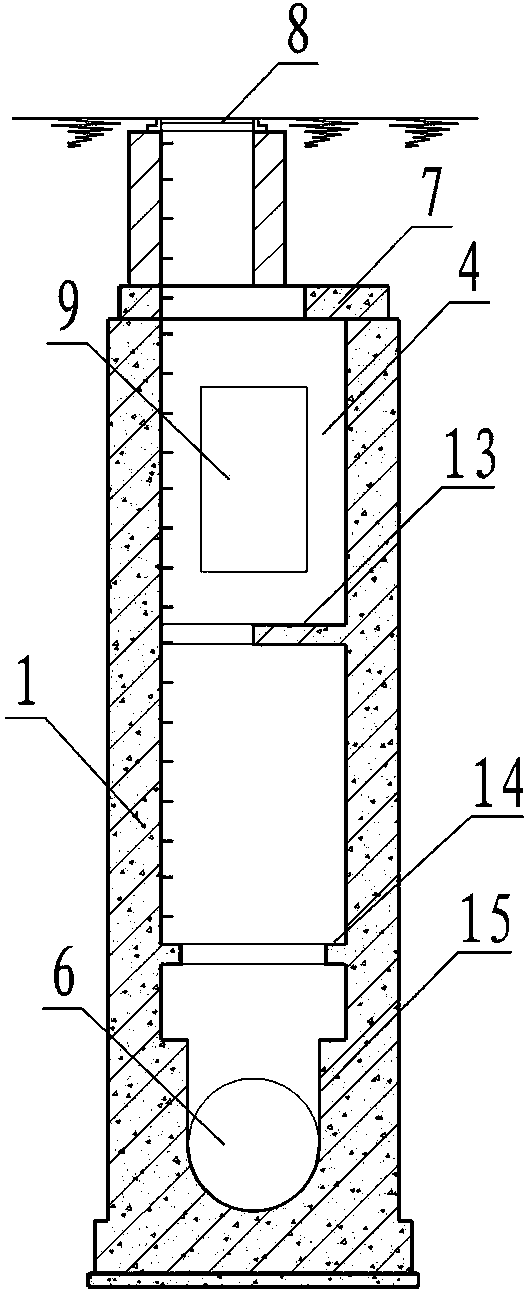

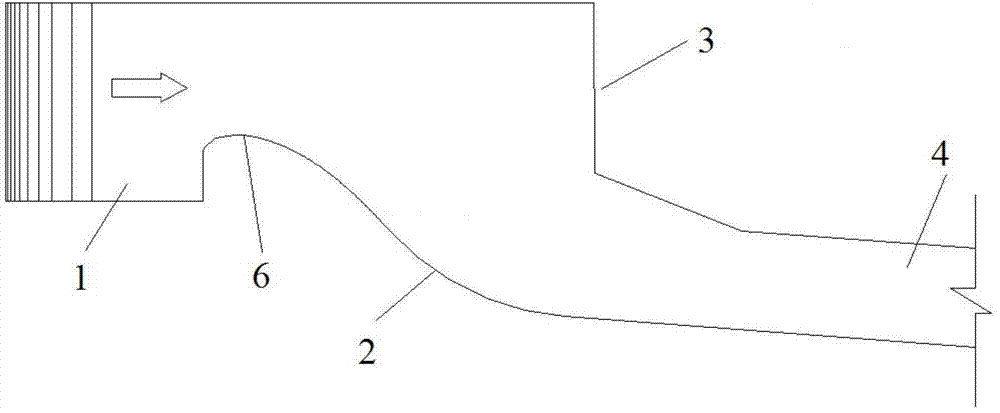

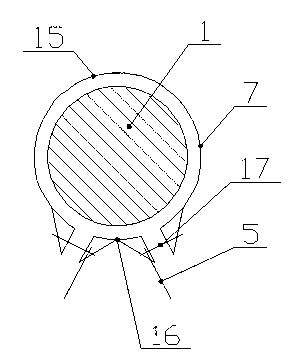

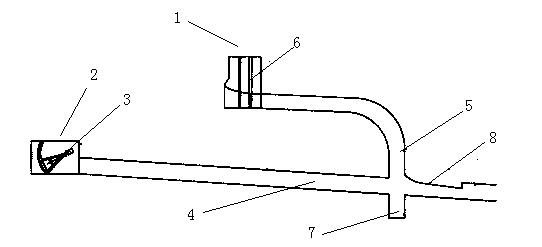

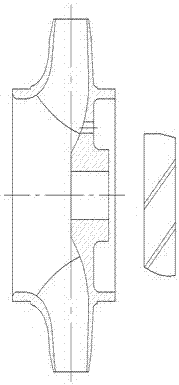

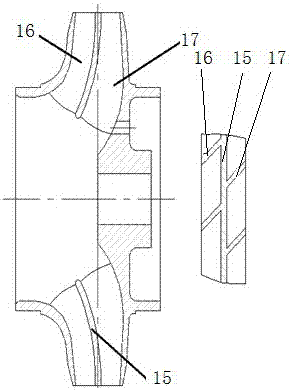

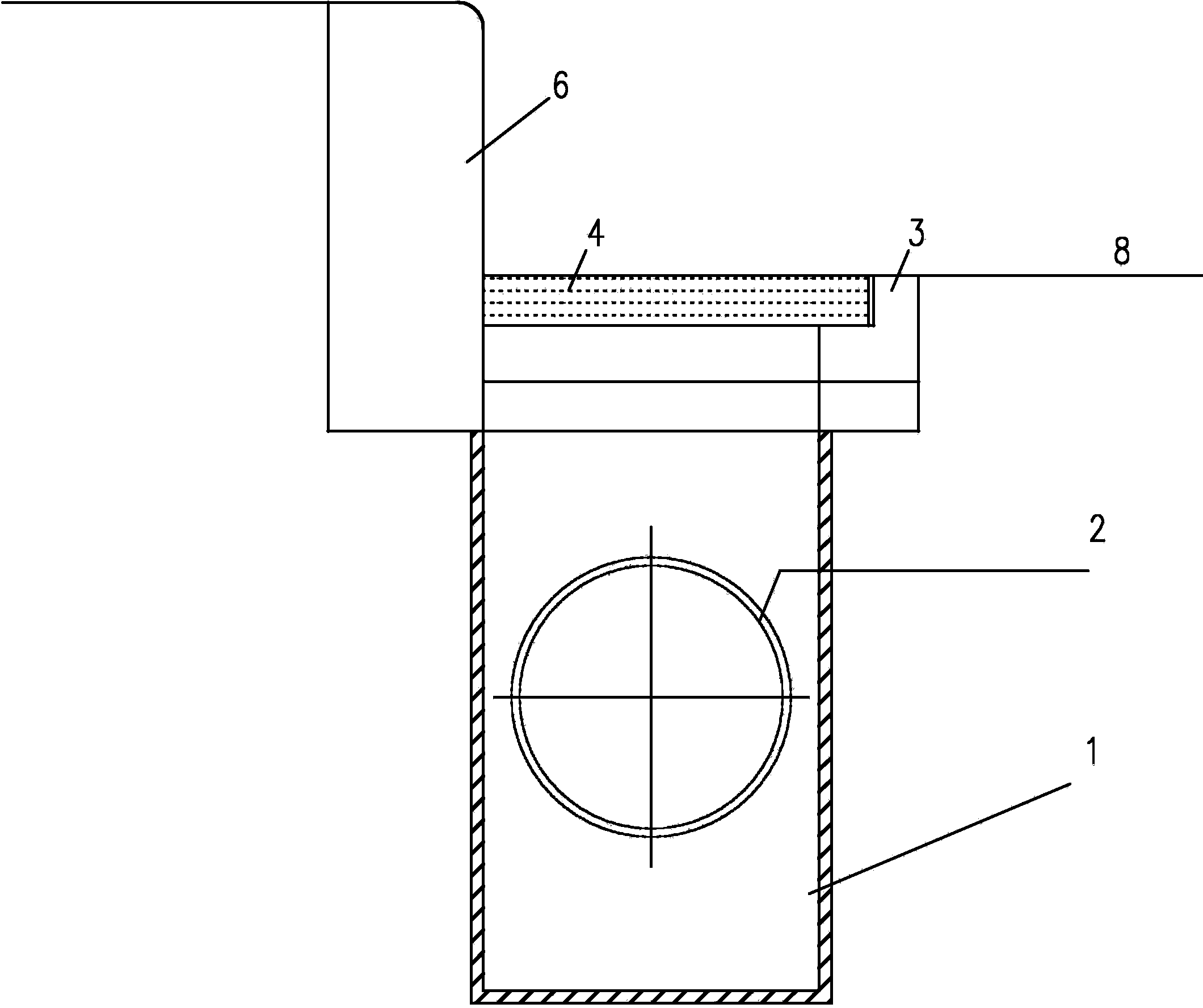

Turn-back type stepped drop well

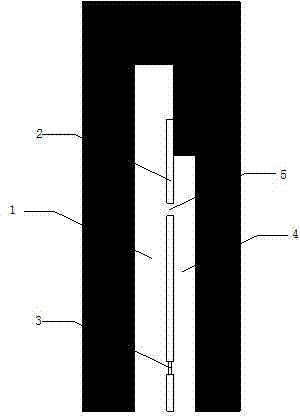

InactiveCN104372844AOvercome the defect of small dropSmall sizeSewerage structuresSewer pipelinesBrickEngineering

The invention discloses a turn-back type stepped drop well and relates to the field of drainage engineering, in particular to a structure of hydraulic drop of urban drainage pipelines, wherein the structure is applicable to rainwater pipes or sewage pipes with the diameter d being 700 mm-1650 mm and the drop difference being 2 m-6 m. The drop well is mainly composed of a well body, a partition wall, a hydraulic drop chamber, an operation chamber, a water inlet pipe and a water outlet pipe. An upper stepped plate, a middle stepped plate and a lower stepped plate are arranged in the hydraulic drop chamber and are mutually arranged in a turn-back mode, and therefore the size of the drop well can be effectively reduced. The defect that in the prior art, the drop difference of a drop well with a big pipe diameter is small is overcome; the stepped plates are arranged in the turn-back mode, so that the size of the drop well is reduced; the space below the stepped plates are effectively utilized, the size of filled concrete or brick setting is reduced, and the work amount of foundation pit excavation is reduced, and therefore the construction cost is lowered; the hydraulic drop chamber is separated from the operation chamber, so that maintenance operations in the well are facilitated.

Owner:洛阳城市建设勘察设计院有限公司

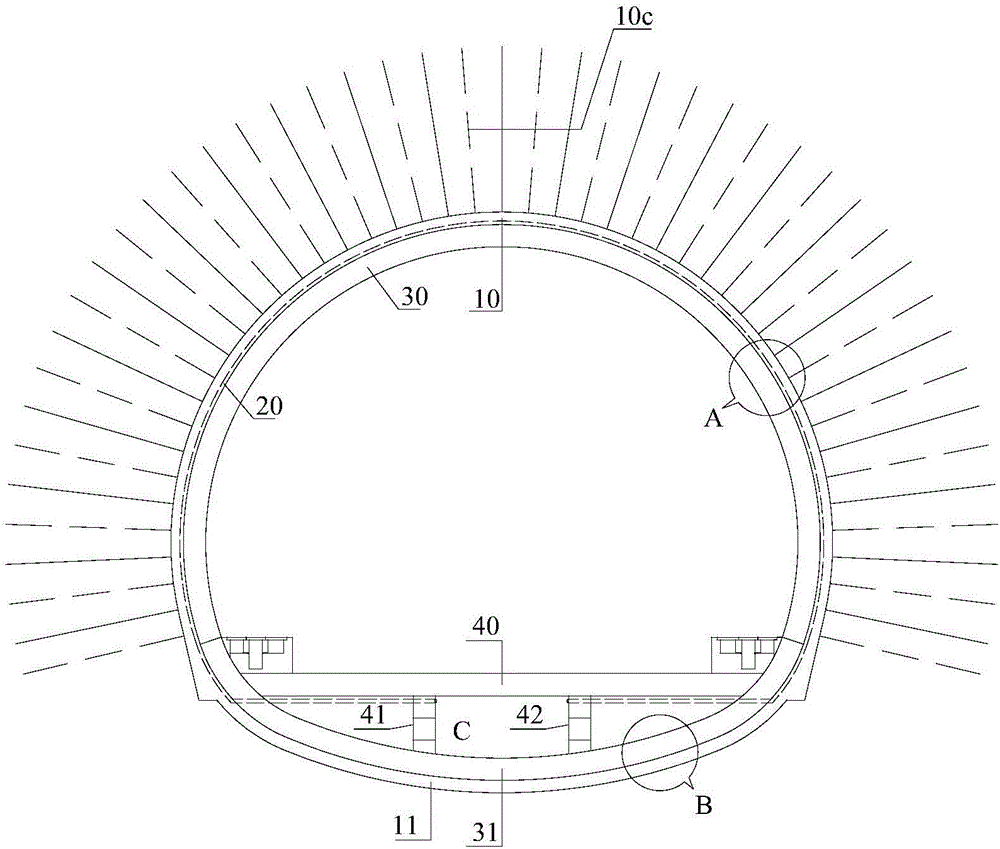

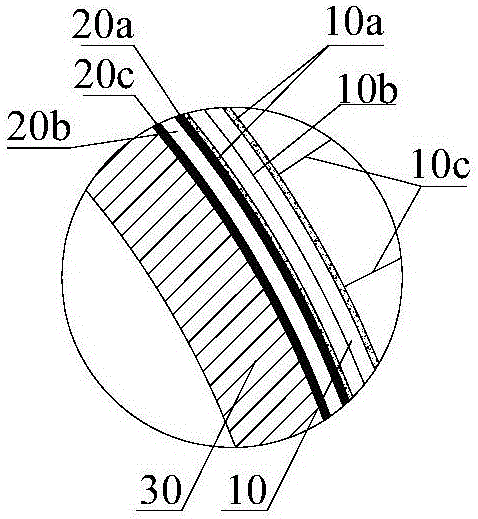

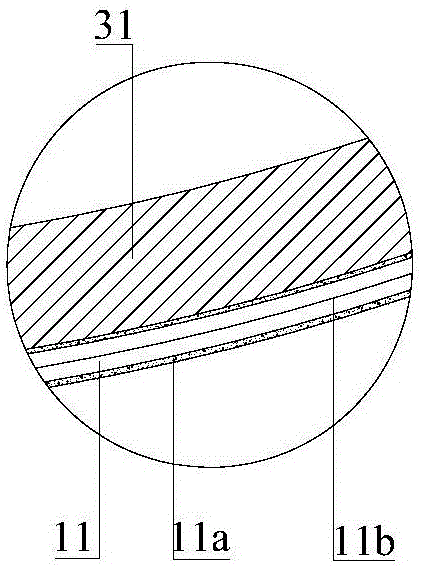

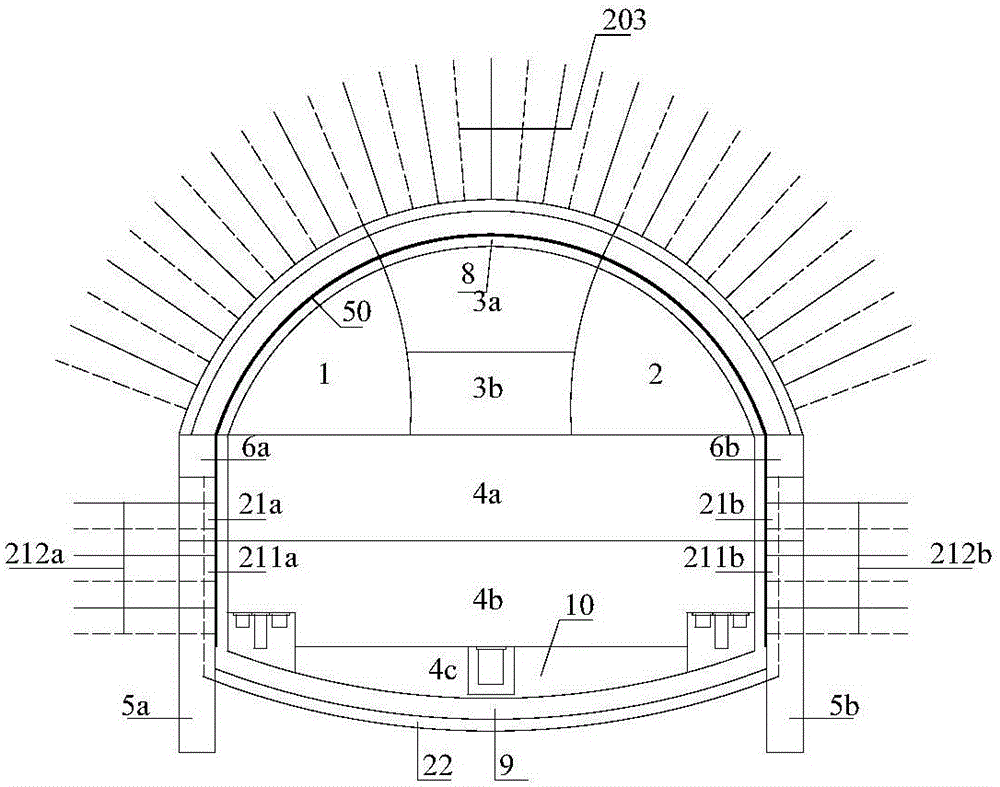

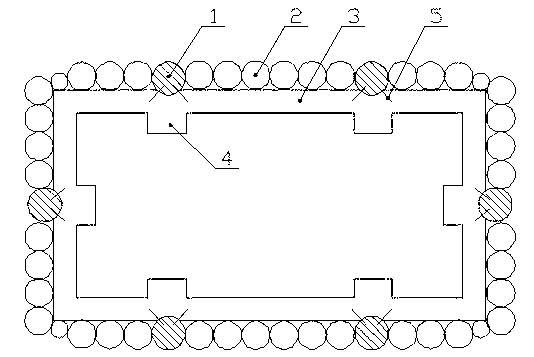

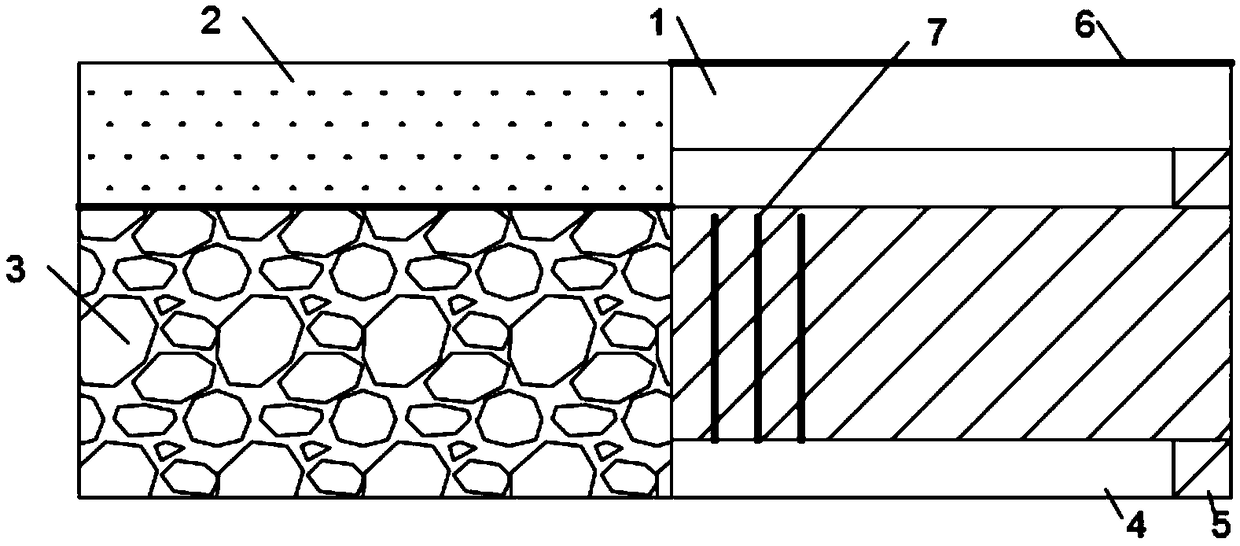

Pi-shaped plate and inverted arch combined tunnel bottom lining structure

InactiveCN105840211AEasy to excavateReduce the amount of excavationUnderground chambersDrainageWall segmentLine structure

The invention relates to a pi-shaped plate and inverted arch combined tunnel bottom lining structure. By transforming the traditional tunnel lining tunnel bottom structure style, the stress performance of a lining structure, especially a tunnel bottom structure, under the action of high water pressure or high ground stress is improved, and meanwhile, a drainage system in a tunnel is optimized, the drainage capacity of the tunnel is increased, and the water disaster risk of rainfall flood seasons during operation is reduced by combining the lining tunnel bottom structure. The pi-shaped plate and inverted arch combined tunnel bottom lining structure comprises an initial support structure, a secondary lining structure and a waterproofing and drainage system, wherein the secondary lining structure consists of a secondary lining arch wall segment and a secondary lining tunnel bottom structure, and the secondary lining tunnel bottom structure consists of an inverted arch and a pi-shaped plate arranged on the inverted arch; the pi-shaped plate consists of a top plate, a left-side vertical plate and a right-side vertical plate, and the upper ends of the left-side vertical plate and the right-side vertical plate and the top plate are fixedly combined together; the lower ends of the left-side vertical plate and the right-side vertical plate and the inverted arch are fixedly combined, and the two transversal ends of the top plate and the two ends of the inverted arch are fixedly combined; a corridor formed among the left-side vertical plate, the right-side vertical plate, the top plate and the secondary lining inverted arch can be used as a longitudinal drainage channel of the tunnel.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

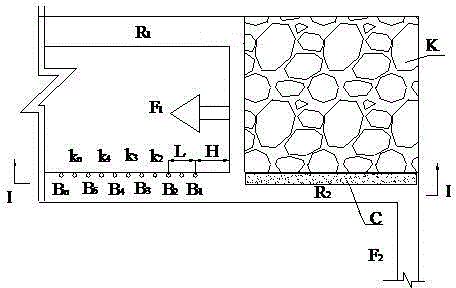

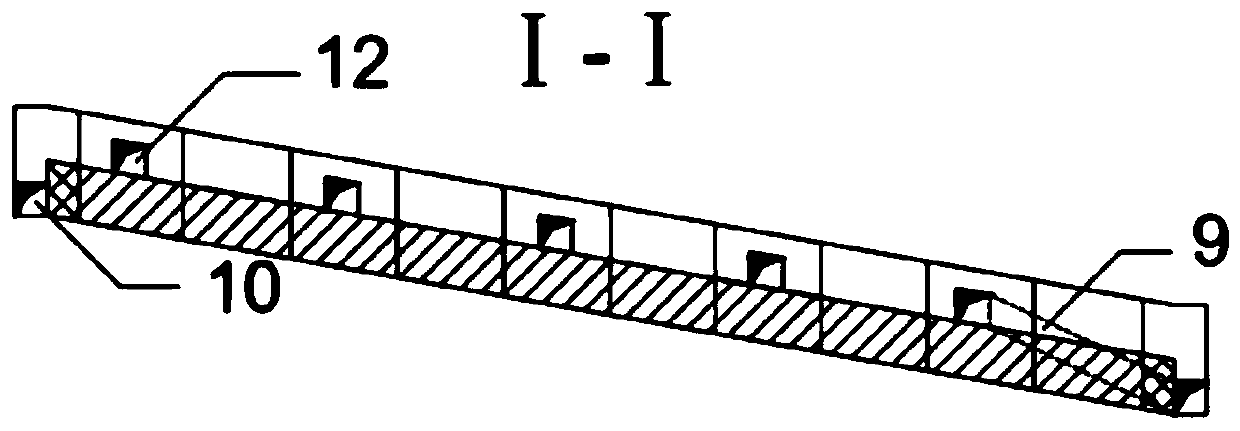

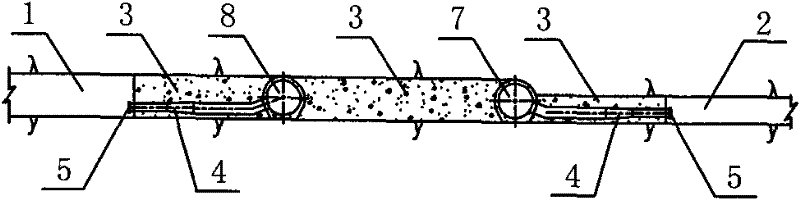

Short-section temporary gob-side entry retaining method

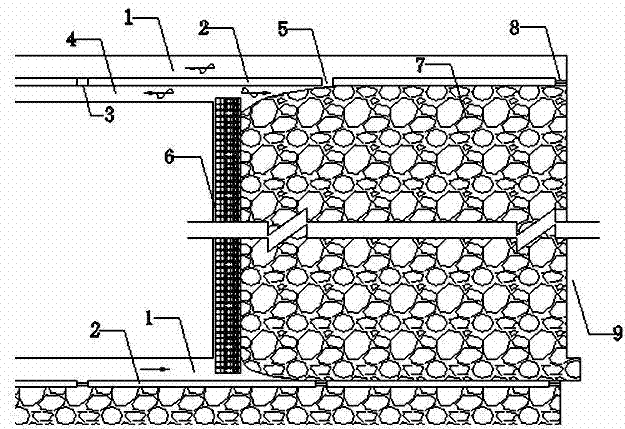

InactiveCN102146797ASimplify technical difficultyReduce the amount of excavationMining devicesUnderground chambersHigh strength concreteHigh intensity

The invention relates to a short-section temporary gob-side entry retaining method which comprises the following steps: step 1, prefabricating a high-strength concrete block on the ground for reservation; step 2, forming a rectangular notch on a working surface coal wall at the side of an air inlet entry and carrying out the anchor rod (cable) support to a top plate; step 3, transporting the high-strength concrete block to the position of an entry retaining and establishing an entry-side wall body with the high-strength concrete block on the edge of a gob, so that the air inlet entry behind the working surface forms a gob-side entry retaining; step 4, constructing and establishing a closed wall at the position 1-2 m away from the rear part of a return air contact entry to seal the gob-side entry retaining and the return air contact entry and ensuring that the length of the gob-side entry retaining entry does not exceed the spacing of the contact entry; and step 5, carrying out repeated operation according to the steps (2)-(4) in the recovery process of the working surface. The short-section temporary gob-side entry retaining method greatly simplifies the technical difficulty of the entry remaining, provides the extraction space for the gas control, reduces the entry tunneling quantity, greatly reduces the preparation time of the working surface and avoids the later entry maintenance work required by the prior gob-side entry retaining.

Owner:CHINA UNIV OF MINING & TECH +1

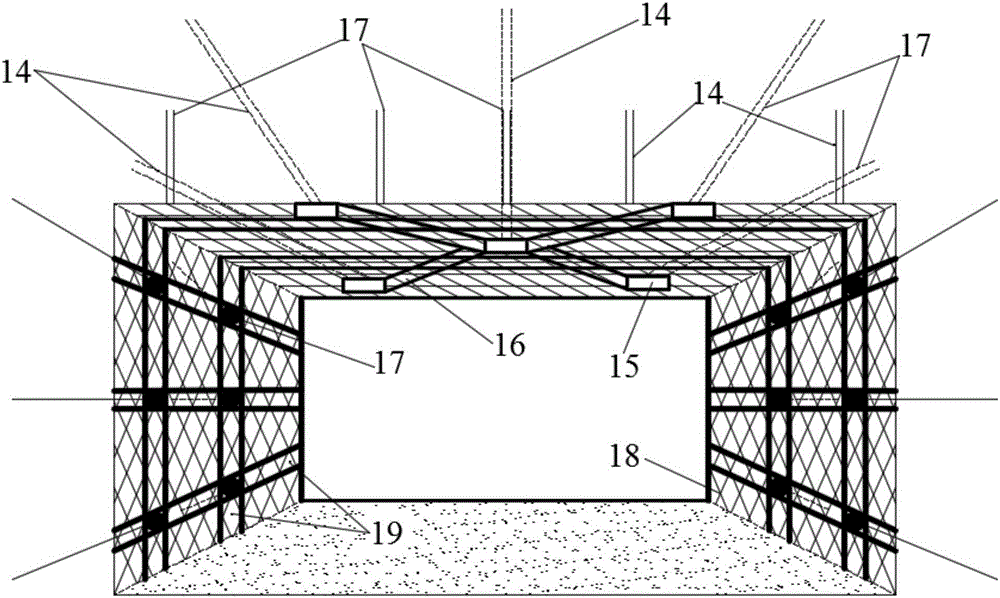

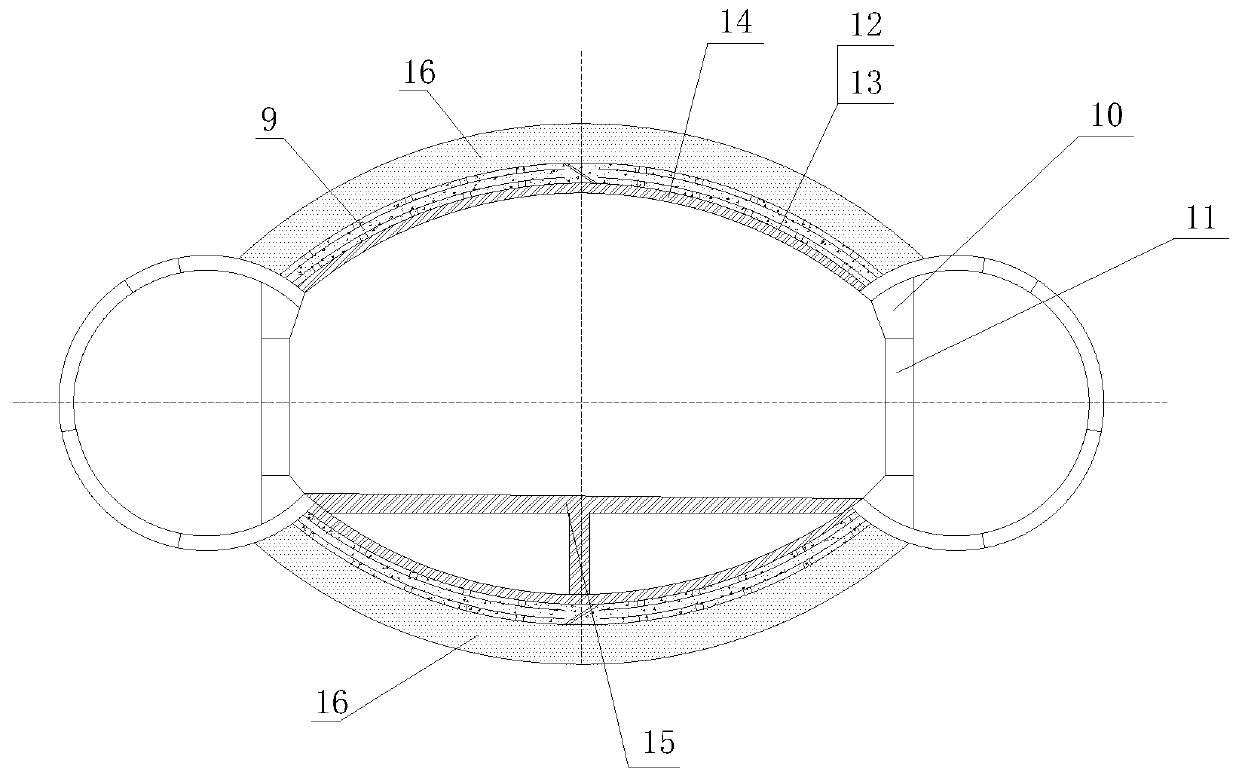

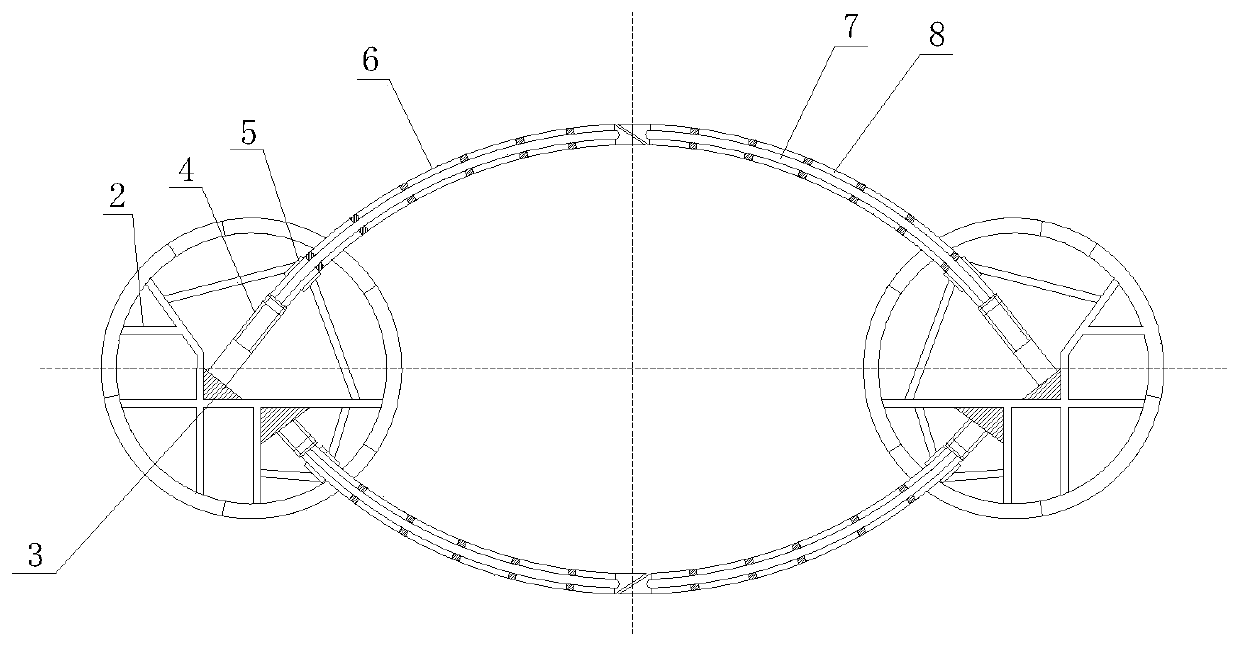

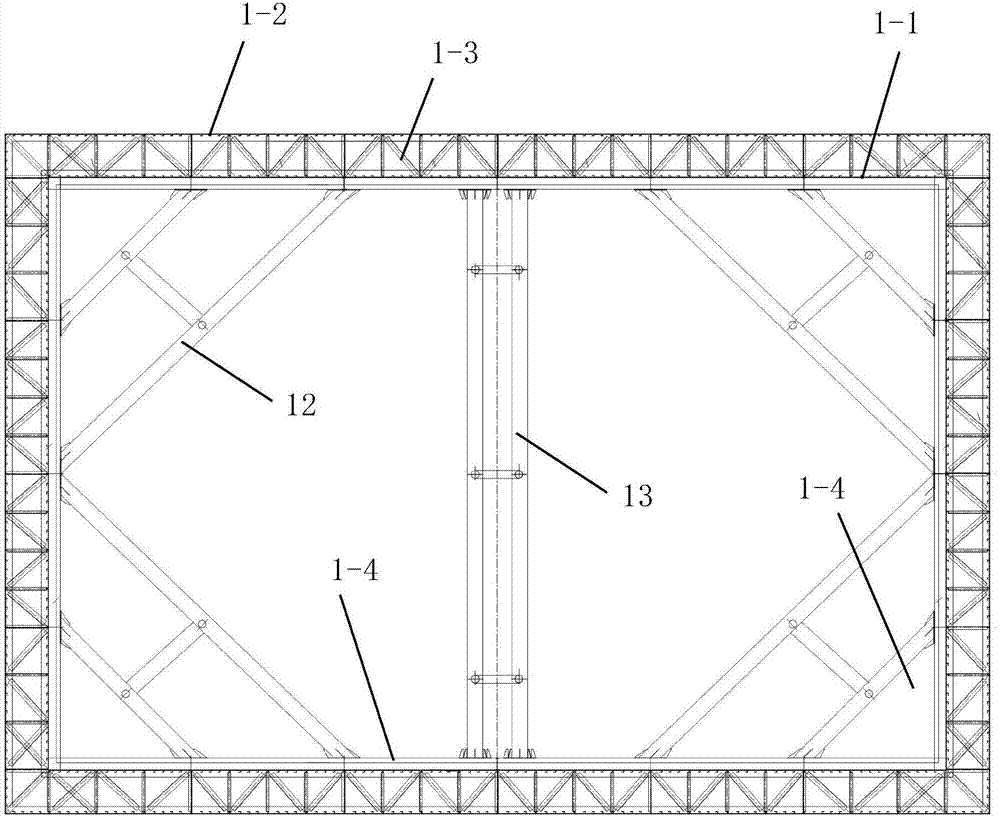

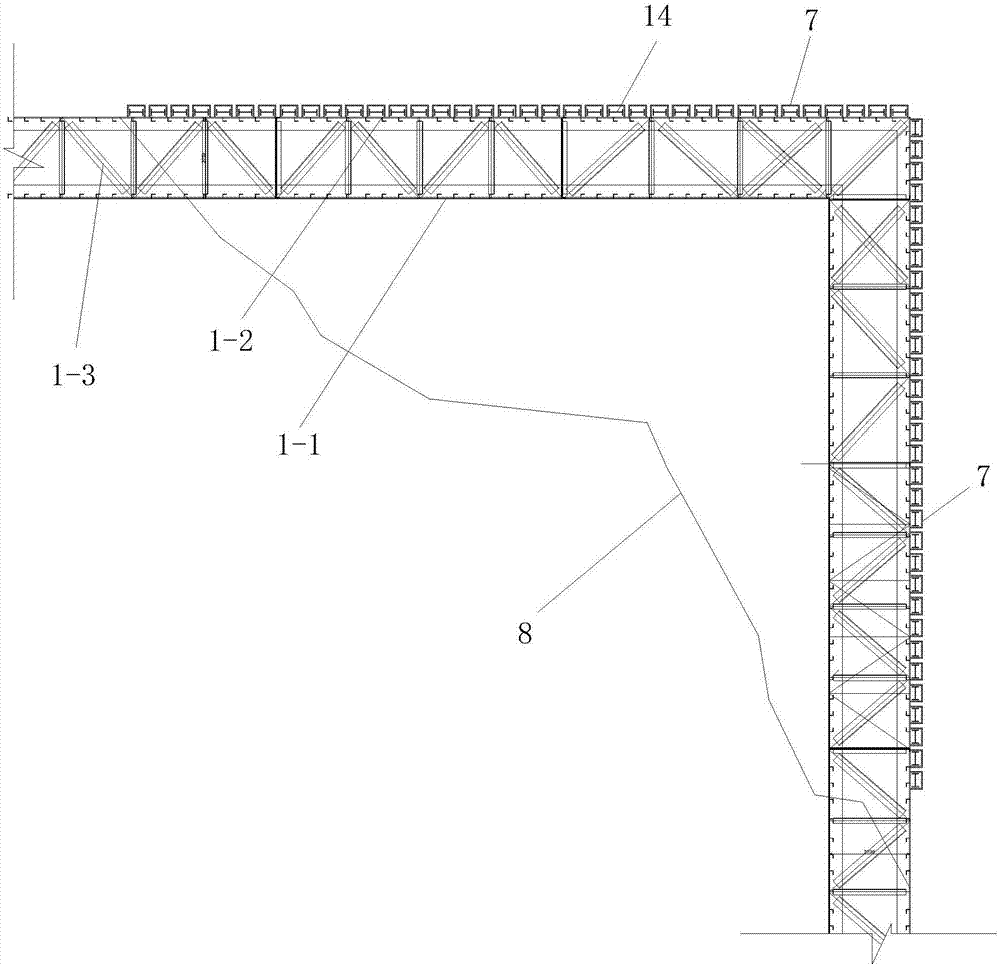

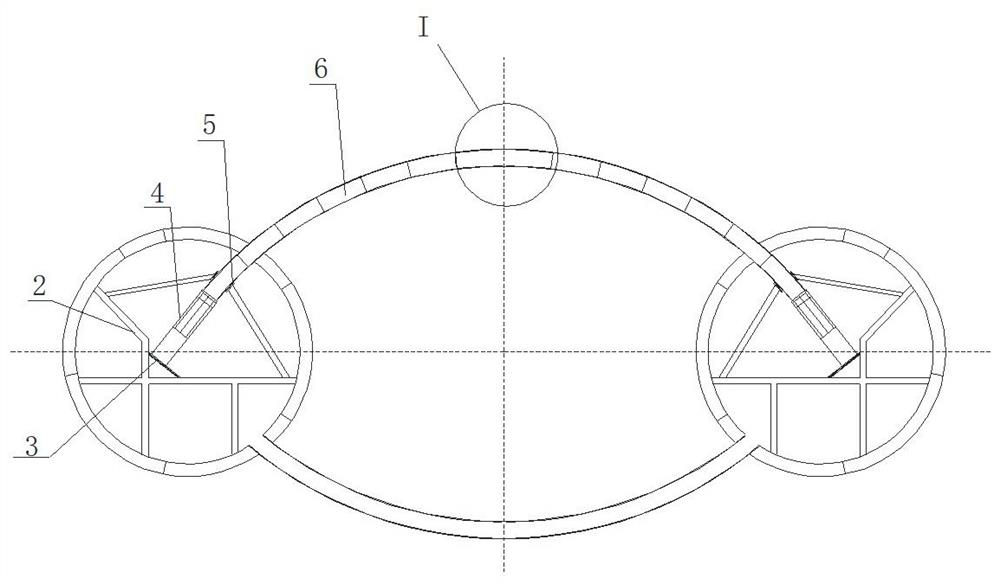

Composite lining structure for super-large-span pile-foundation-joist-based bearing arched tunnel and construction method thereof

InactiveCN106050262ASolve the problem of easy sinking deformationEliminate risk of landslidesArtificial islandsUnderground chambersJoistEngineering

The invention provides a composite lining structure for a super-large-span pile-foundation-joist-based bearing arched tunnel and a construction method thereof. With the structure, the force-bearing state is clear and construction becomes convenient; and a problem of lining cracking caused by excessive arched structure sedimentation because of difficult control of super-large-span tunnel arch springing displacement on the complicated geological condition can be solved, so that stability and security of tunnel construction and operation can be guaranteed. The structure comprises a forepoling structure, a preliminary bracing structure, and a secondary bracing structure that are arranged from inside to outside. Left-side arch springs of the preliminary bracing structure and the secondary bracing structure are supported on a left-side joist and are connected with the left-side joist and right-side arch springs of the preliminary bracing structure and the secondary bracing structure are supported on a right-side joist and are connected with the right-side joist. A left-side pile foundation and a right-side pile foundation are arranged at an interval under the left-side joist and the right-side joist along an extending direction of the tunnel; and the upper ends of the left-side pile foundation and the right-side pile foundation are fixedly connected with the left-side joist and the right-side joist and the lower ends are arranged in a stable rock and soil strata of a foundation.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

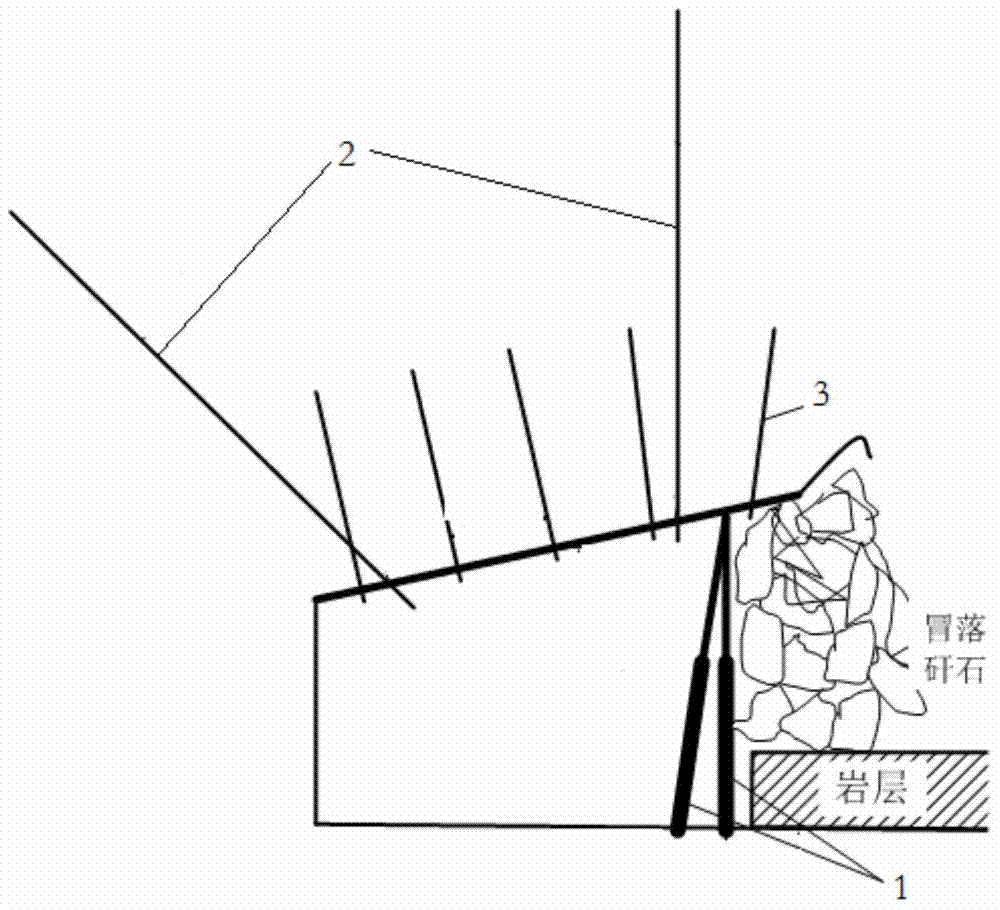

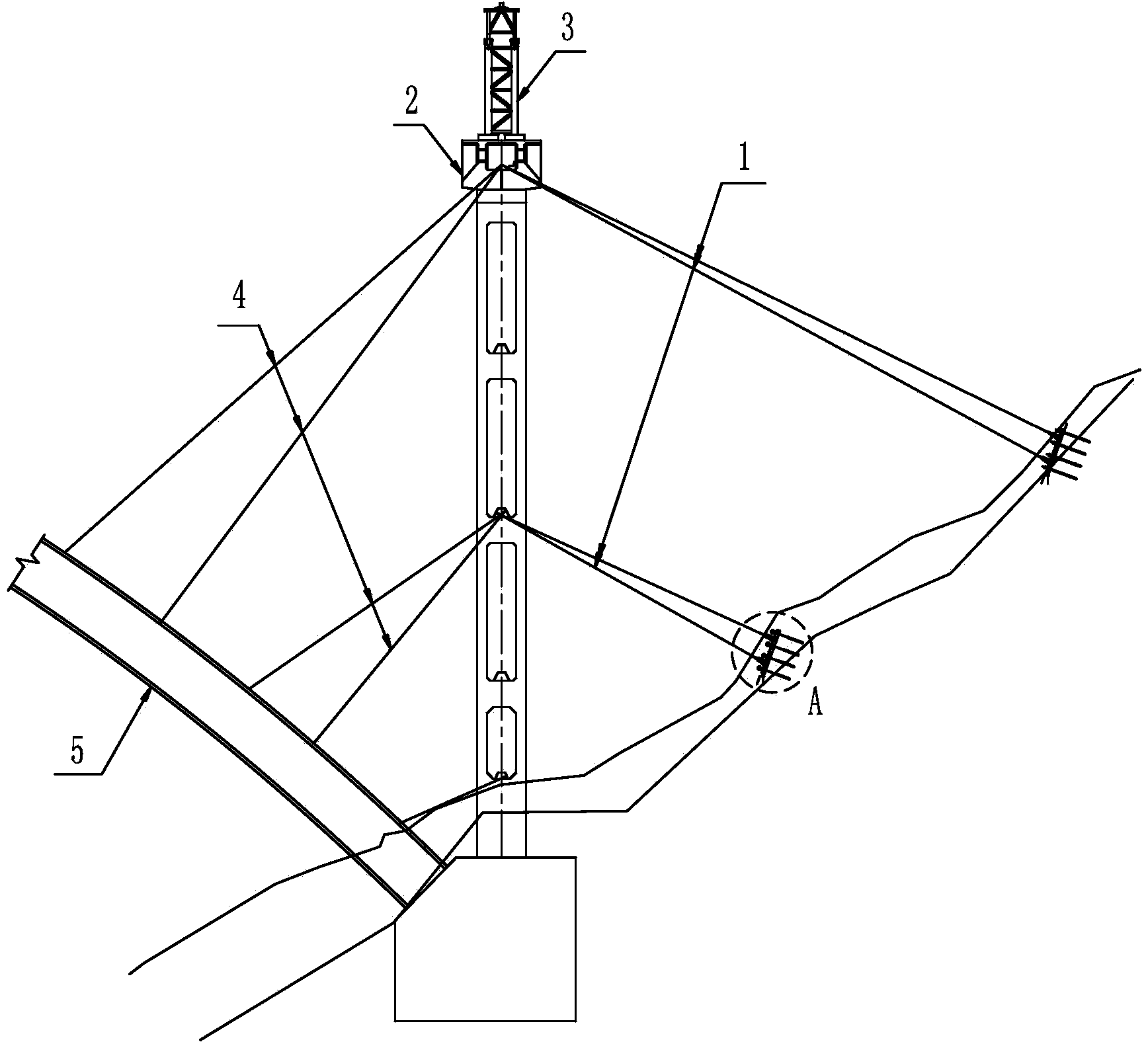

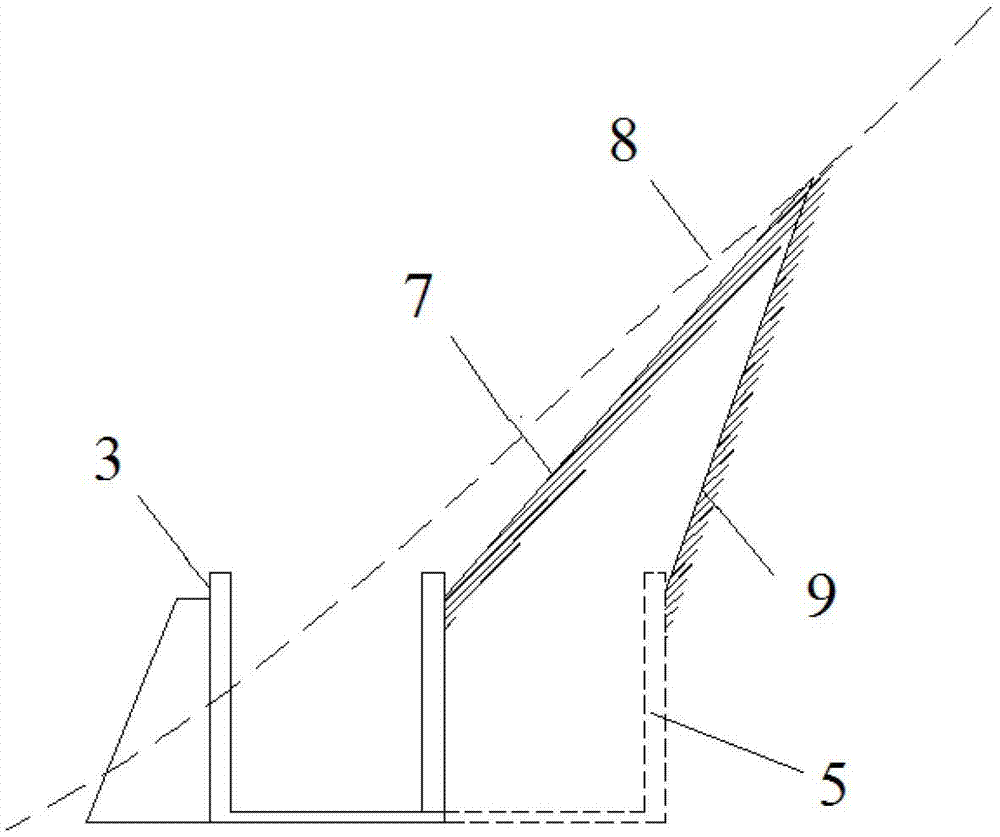

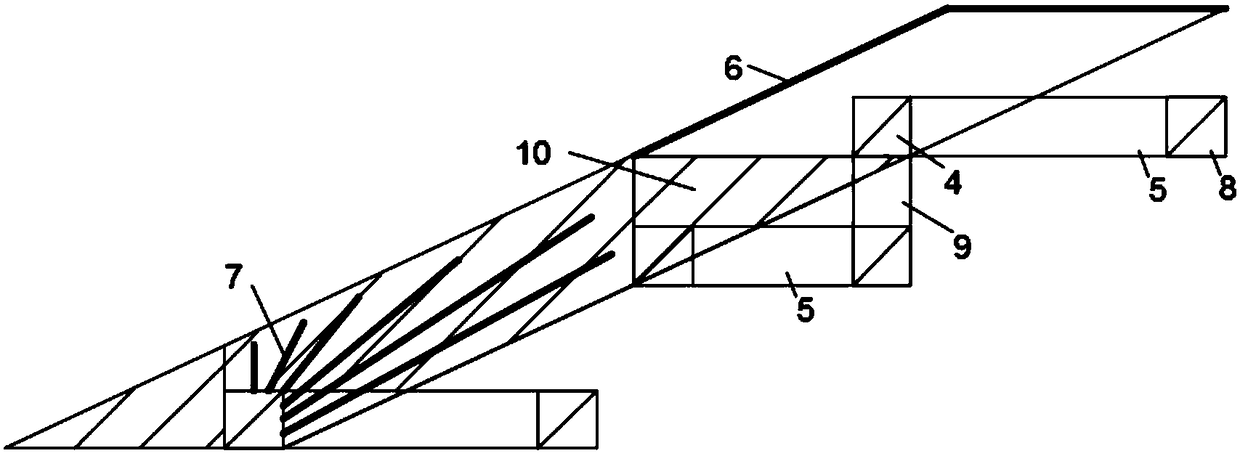

Large-tonnage combination anchoring system and method for rocky slope

ActiveCN103397597AUniform force transmissionClear forceBridge structural detailsBridge erection/assemblyPre stressRock body

The invention discloses a large-tonnage combination anchoring system and method for a rocky slope and relates to the field of bridge construction. The large-tonnage combination anchoring system comprises at least one vertical distribution beam, a plurality of transverse distribution beams and a plurality of bundles of longitudinal prestress anchorage cables, wherein the vertical distribution beam is arranged along the rocky slope, the lower part of the vertical distribution beam is close to a rock surface, and the upper part of the vertical distribution beam is anchored with a backstay; the plurality of transverse distribution beams are fixed above the vertical distribution beam; one end of each bundle of longitudinal prestress anchorage cable extends into a rock body and is anchored, and the other end of the each bundle of the prestress anchorage cable is anchored to the transverse distribution beams via an anchorage; each bundle of the longitudinal prestress anchorage cable is vertical to the transverse distribution beam; the tail end of the longitudinal distribution beam is connected with a small distribution beam, and a cushion layer. According to the system and the method, under conditions of rocky slope and the like, large-tonnage anchoring force is provided for stay cables, dig engineering quantity is effectively decreased, and construction difficulty and construction risks are lowered.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

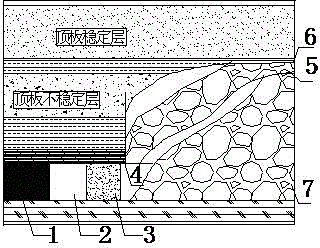

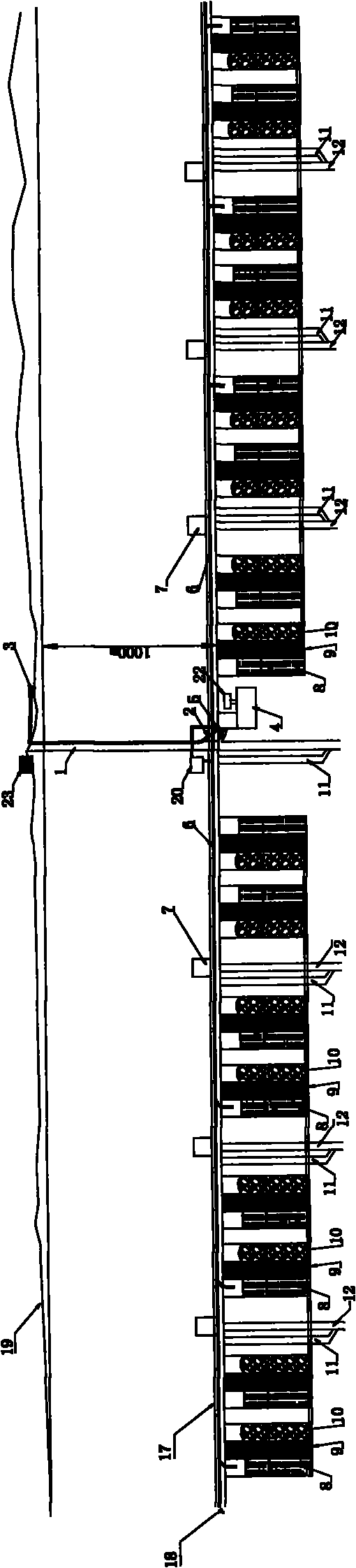

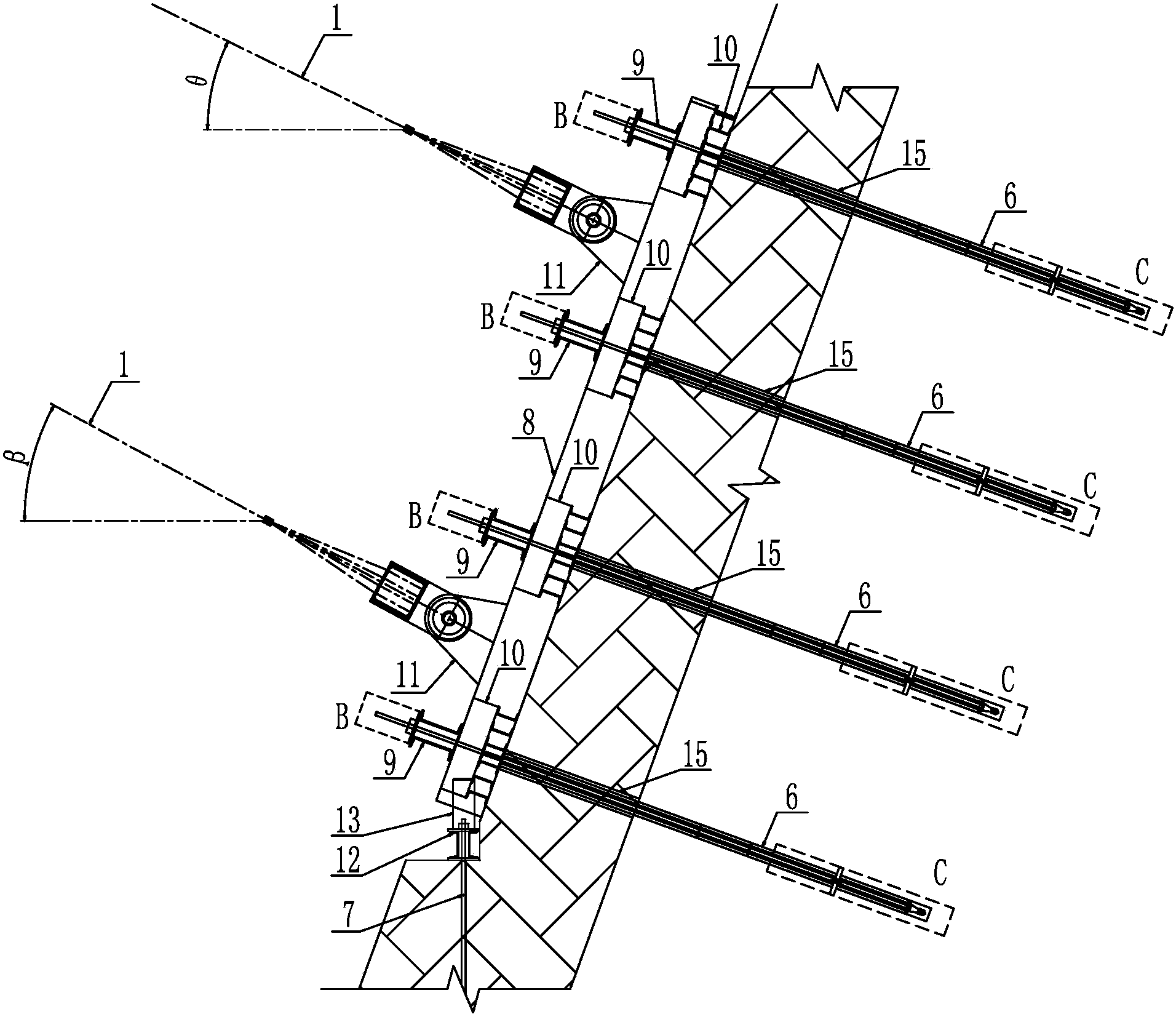

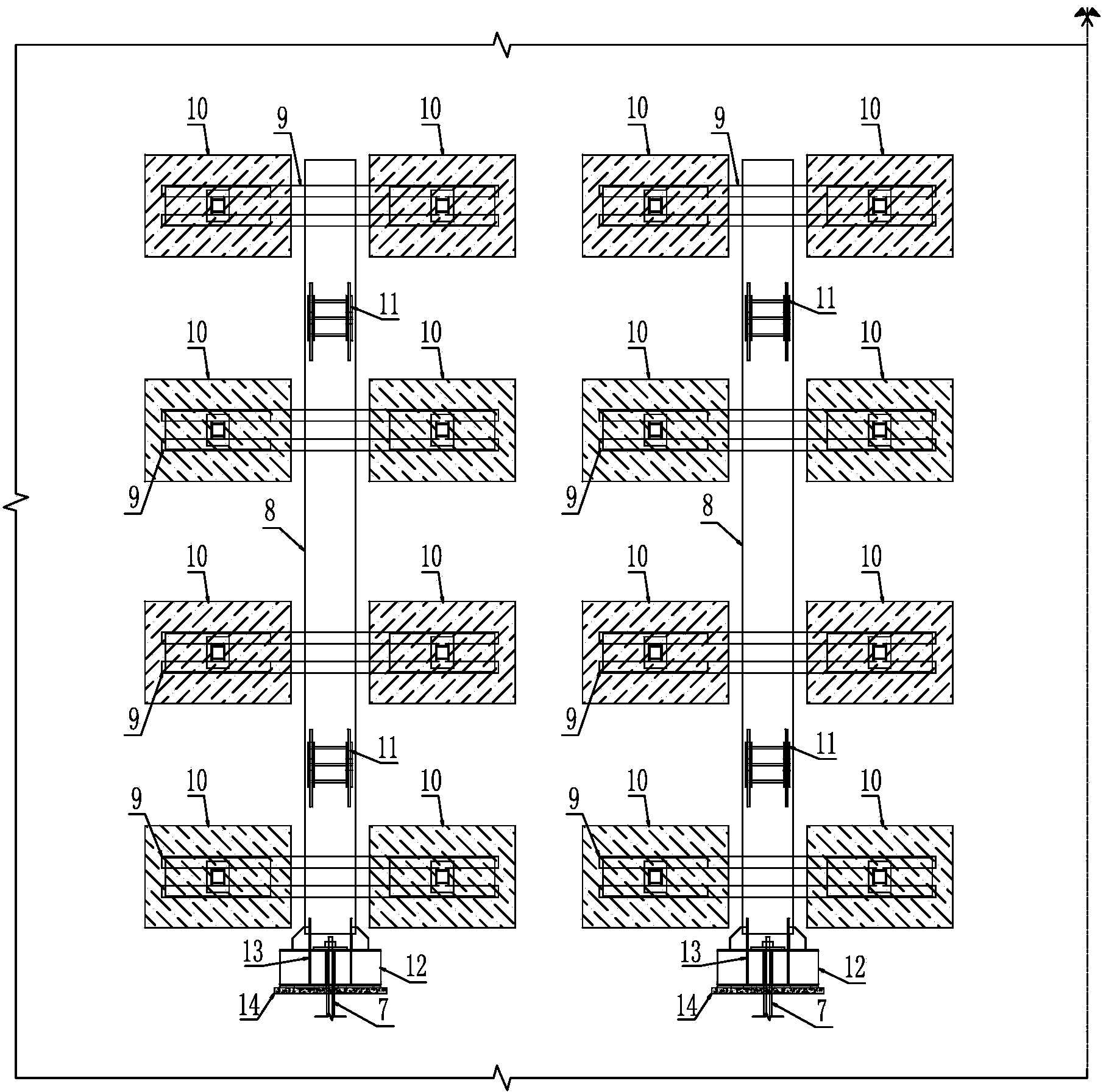

Layered strip mining method for gently inclined ore body

ActiveCN111550244AReasonable divisionHigh recovery rateUnderground miningSurface miningStopingMechanical engineering

The invention relates to a layered strip mining method for a gently inclined ore body. According to the technical scheme, the mining method aims at the gently inclined ore body, and comprises the steps of ore block division and layout of stope preparation cutting, blasting, ventilation, mining and filling and transporting. The step of ore block division is that different panels are divided at eachstage, the panels are arranged along the ore body trend, a stage transportation roadway is excavated along the ore body trend, and the same number of ore rooms are divided on the left and right sideswith a floor rise in the middle of each panel as a boundary. Mining and filling have three steps that 1, ores in the upper layers of the ore rooms are stoped; 2, ores in the lower layers of the ore rooms are stoped; and 3, after the ore rooms are subjected to cemented filling, inter-columns in the panels are stoped, and the inter-columns are subjected to cemented filling after stoping. In the panels, the stoping of the step 1 and the stoping of the step 2 are sequentially conducted from top to bottom, and the principle of stoping every other ore room is strictly met; and after the mining of asingle ore room is completed, the approach road of the floor rise is closed, the ore rooms are filled by the approach road of a roof rise, after the ore rooms in a single panel are all mined and filled, the inter-columns in the panels are stoped, the mining mode is that mining is conducted from top to bottom, and filling is conducted after mining. The layered strip mining method has the characteristics that the mining cost is low, the ore stoping rate is high, and the mining efficiency is high.

Owner:WUHAN UNIV OF TECH

Method for combined exploitation of coal and its associated oil shales

ActiveCN106337685AReduce mining difficultyEnsure rock breaking efficiencyUnderground miningSurface miningResource utilizationOil shale gas

The invention provides a method for combined exploitation of coal and its associated oil shales. The method comprises the construction steps that when the coal and its associated oil shales are located in a reasonable exploitation bed separation distance range, coal resources located at the lower portion are firstly exploited, a mine bearing pressure is fully utilized to destroy associated oil shales located in an overlying rock layer and reduce the strength; then, the associated oil shales at the upper portion are exploited later to achieve combined exploitation of coal and its associated oil shales. Therefore, the shortcoming that when oil shales are independently exploited, the oil shale strength is higher and accordingly a coal cutter difficultly break rocks can be overcome. According to the exploitation method, existing infrastructures and sinking and driving engineering can be fully utilized, the roadway tunneling amount can be decreased, investment can be reduced, the costs are low, the phenomenon that the oil shales associated with coal are severely abandoned can be effectively completely eradicated or decreased, the resource utilization rate can be improved, an economic value is huge, and the method has the important practical significance on relieving of conventional energy source supply and demand pressure, energy structure adjustment and energy guaranteeing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

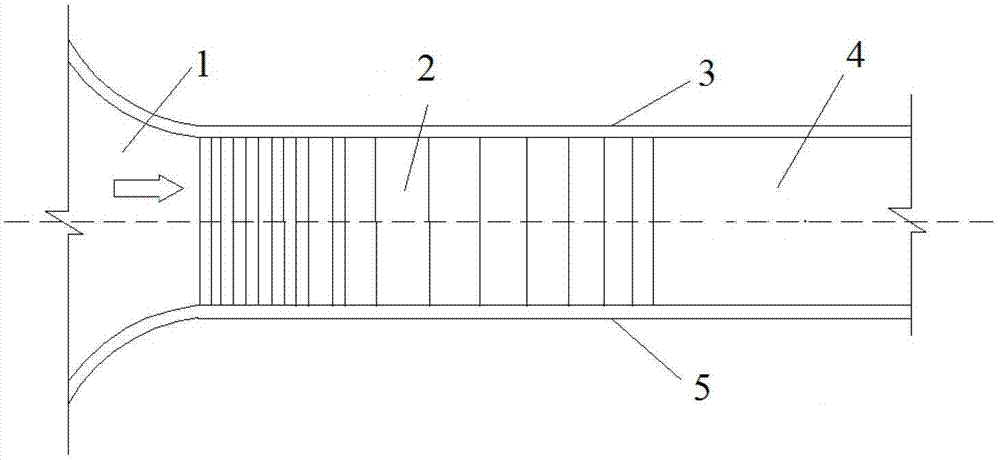

Lateral-inflow and rolling-energy-dissipation bank spillway

InactiveCN103195029AReduce difficultyNo increase in engineering excavationBarrages/weirsEngineeringSpillway

The invention discloses a lateral-inflow and rolling-energy-dissipation bank spillway which comprises a spillway inlet portion, a spillway discharge chute and a spillway energy-dissipating and discharging outlet portion. The spillway inlet portion comprises an approach channel section and a WES (waterway experiment section) practical weir section, the axis of the spillway inlet portion is intersected with the axis of the spillway discharge chute at an angle of not less than 45 degrees, and a lateral chute which is composed of a WES practical weir, a chute bottom and an opposite side wall of a spillway inlet is designed behind the WES practical weir section and enables waterflow to rollingly enter the spillway discharge chute. The mode of bank spillway inlet portion of the lateral-inflow and rolling-energy-dissipation bank spillway is a complete change for the mode of a traditional bank spillway inlet portion, so that a series of problems such as the engineering quantity of the excavation of transverse and longitudinal mountain of the inlet is large and that the spillway inlet portion cannot dissipate the energy of the waterflow in the traditional spillway inlet portion can be solved.

Owner:SICHUAN UNIV

Hot-melt connection method of PE (polyethylene) water supply and drainage pipe

ActiveCN103231511AHigh strengthReduce the amount of excavationTubular articlesButt weldingEngineering

The invention discloses a hot-melt connection method of a PE (polyethylene) water supply and drainage pipe. The hot-melt connection method comprises the following steps of: (1) cleaning the surface of a heating plate, removing dust and impurities on the surface of the heating plate so as to clean the surface, plugging in a socket after the cleaning is finished, and electrifying for heating; (2) installing a clamping apparatus and a side wing bracket matched with a PE pipe to be welded; and (3) placing the PE pipe to be welded on a special hot-melt butt welding machine of a PE water drainage pipe on the same layer, clamping by using the clamping apparatus, and the like. The method has the advantages that the PE tube hot-melt butt welding connection technology suitable for engineering practice is summarized through continuous summarization, analysis and comparison, unnecessary idling and reworking are greatly reduced through PE pipe construction, the labor force is saved, and the economic cost is reduced, so that the method can be widely popularized.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

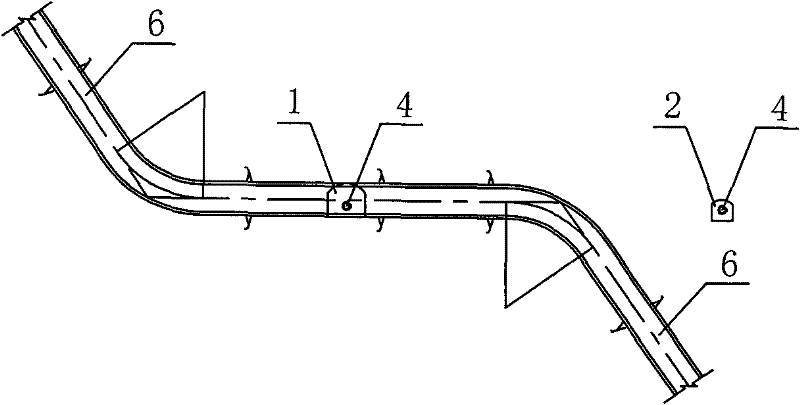

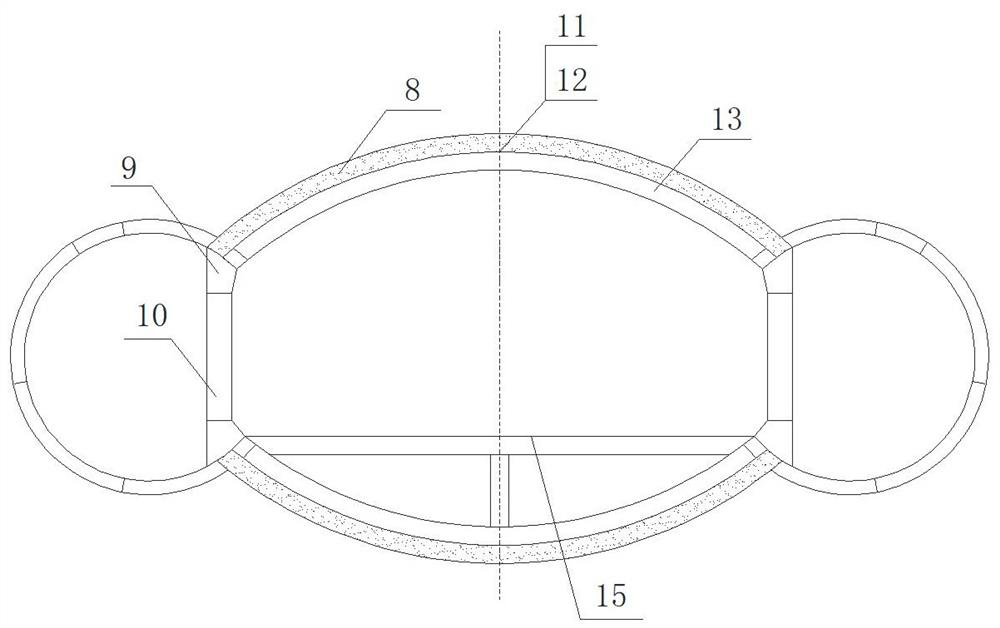

Soft soil stratum subway station expansion method and structure based on inserted beam freezing method

ActiveCN111305851AStabilized soil structureImprove construction efficiencyUnderground chambersTunnel liningSoil scienceStructural engineering

The invention provides a soft soil stratum subway station expansion method and structure based on an inserted beam freezing method. The soft soil stratum subway station expansion structure comprises shield tunnels, a middle platform connected between the two parallel shield tunnels and communicating with the shield tunnels, and frozen soil layers wrapping the outer side of the middle platform; themiddle platform comprises a top lining unit, a bottom lining unit, side columns and a structural bottom plate, the top lining unit and the bottom lining unit are arranged between the shield tunnels and are symmetrical up and down, and the frozen soil layers are distributed along the arched outer surfaces of the top lining unit and the bottom lining unit; the two side ends of the bottom lining unit and the two side ends of the top lining unit are connected and supported through the side columns; and the structural bottom plate is arranged above the bottom lining unit and is kept on the same horizontal plane with the two ends of the bottom lining unit. The method solves the problem of large deformation of subways and surrounding soil caused by serious soil moving in an expansion mode, and has the advantages of being high in construction efficiency, short in construction period and high in safety.

Owner:SHIJIAZHUANG TIEDAO UNIV +1

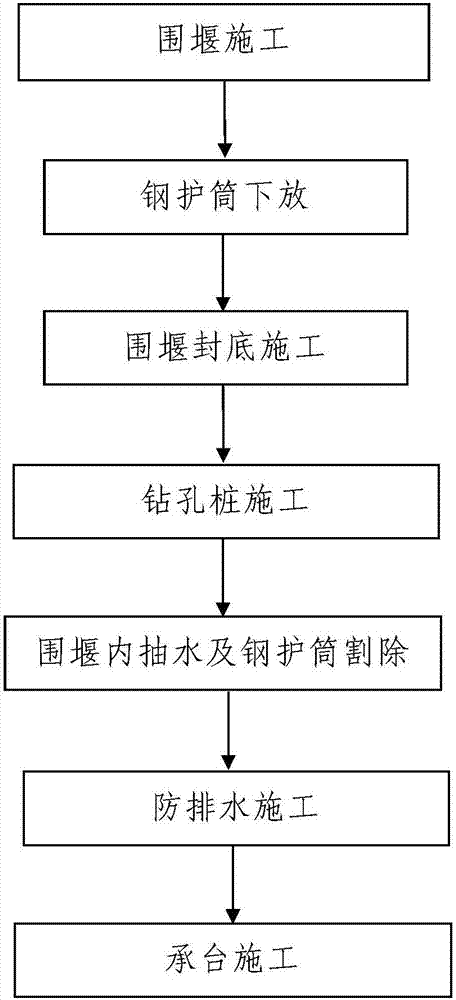

Construction method for rock riverbed bearing platform in water

ActiveCN107489106AThe method steps are simpleEasy constructionFoundation engineeringBridge erection/assemblyCofferdamBottom water

The invention discloses a construction method for a rock riverbed bearing platform in water. The construction method includes the steps of construction of a cofferdam, transfer of protective steel canisters to a lower level, bottom sealing construction of the cofferdam, construction of drilling piles, water extraction inside the cofferdam and excision and removal of the protective steel canisters, anti-drainage construction and construction of the bearing platform, wherein during the anti-drainage construction, an anti-drainage structure is constructed inside the steel cofferdam, the anti-drainage structure includes a water-permeable layer, a bottom water-separating layer and lateral water-separating layers, and the bottom water-separating layer is connected with the four lateral water-separating layers to form an integrated type water separating layer; during the construction of the bearing platform, molding construction is conducted on the bearing platform in the water inside the integrated type water separating layer. According to the construction method for the rock riverbed bearing platform in the water, by drilling multiple guide holes in hard rock where the drilling piles are located from top to bottom, sifter holes are formed in the hard rock where the drilling piles are located to increase a rock fissure surface; moreover, by adopting a prestress anchor device to fixedly connect the steel cofferdam with the drilling pies in an integrated mode, so that the pile foundation construction progress and construction quality can be effectively ensured, and meanwhile, the integrated type water separating layer is arranged on the molding pile foundation after construction and can effectively ensure the concrete pouring quality of the bearing platform.

Owner:CHINA RAILWAY 20 BUREAU GRP +1

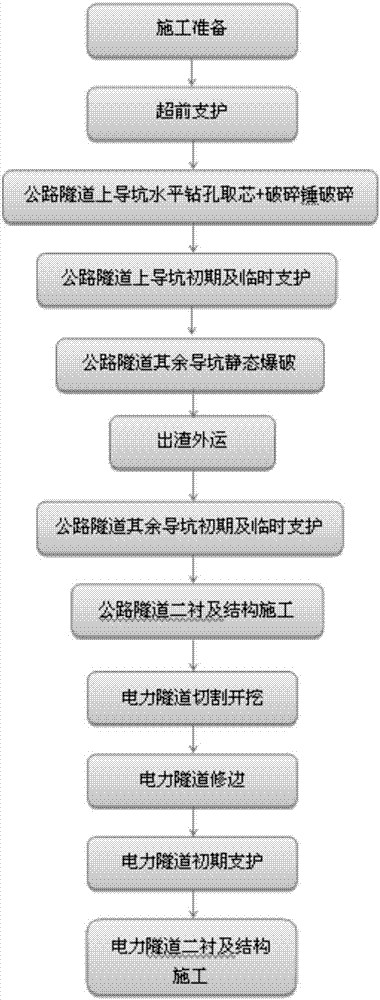

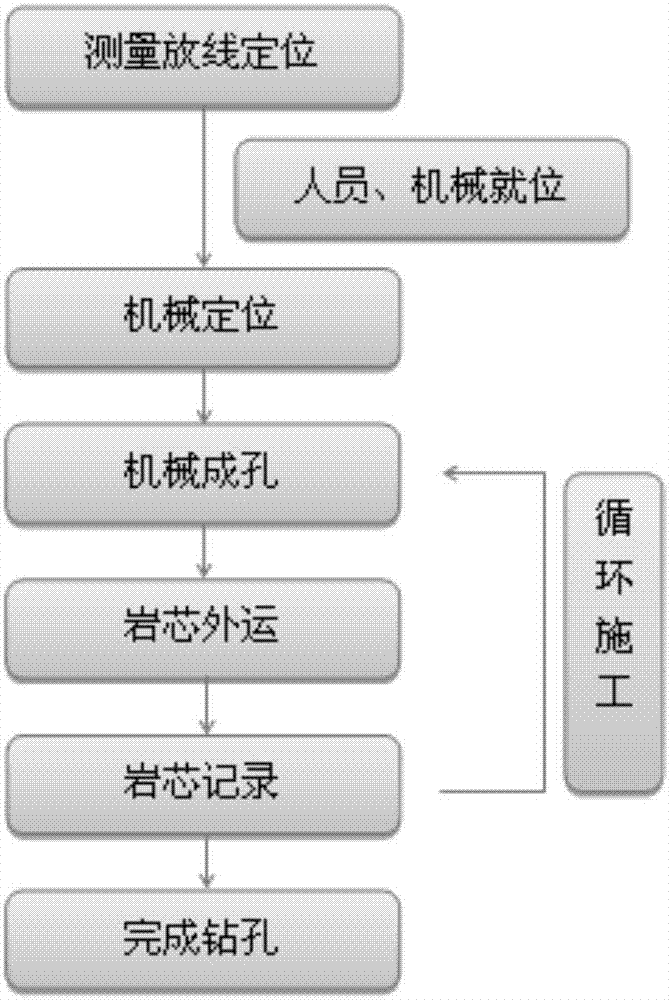

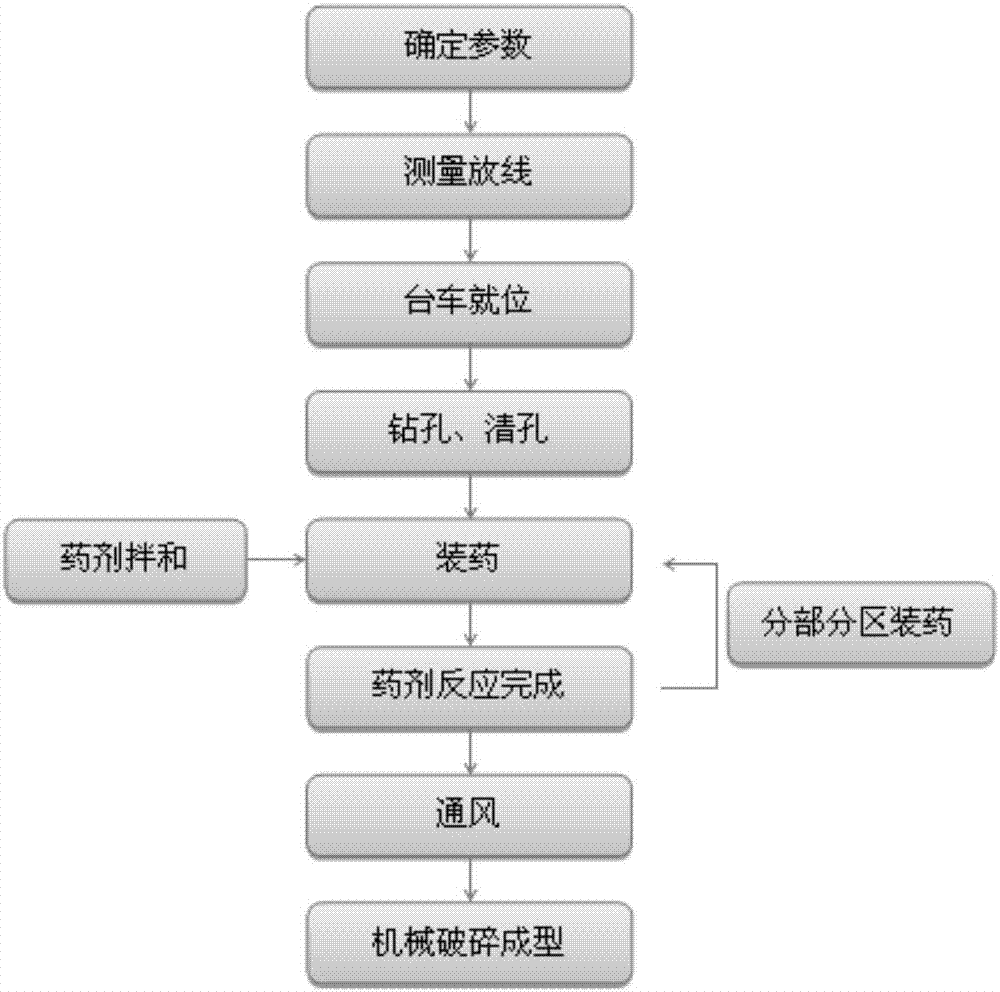

Urban overlapped tunnel excavating construction method under shallow-buried condition

ActiveCN107327306AEnough free surfaceEasy to controlUnderground chambersTunnel liningSquare meterDrilling machines

The invention discloses an urban overlapped tunnel excavating construction method under a shallow-buried condition, and relates to the technical field of tunnel construction methods. Excavating of an upper layer main tunnel is constructed by adopting a CRD method, the left side and the right side of the upper layer main tunnel are sequentially divided into at least two pilot tunnels from top to bottom, excavating is sequentially conducted from top to bottom at each side, and essential primary bracing and temporary bracing are conducted; the left side and the right side of the upper layer main tunnel are constructed one after another, excavating for the upper pilot tunnel of each side is conducted by adopting modes of hole drilling machine horizontal drilling and core-taking and quartering hammer crushing, and excavating for the rest of the pilot tunnels is conducted in a static blasting mode; the upper layer main tunnel is excavated first, and then a lower layer tunnel is excavated, and excavating for the lower layer tunnel is conducted by adopting modes of mechanical cutting and quartering hammer crushing. The urban overlapped tunnel excavating construction method under the shallow-buried condition is applicable to the shallow-buried tunnels without disadvantageous geology conditions (faults, crushed zones and the like) with the buried depth being not less than 5 meters and the area of the excavated section being not greater than 150 square meters, the requirement for surrounding environment is high, vibration-free protective construction is required, and the construction process is fast.

Owner:中铁十一局集团第五工程有限公司 +1

Tunnel lining construction method

ActiveCN103670439AImprove adhesionSimple processSolid waste managementUnderground chambersFiberShotcrete

The invention discloses a tunnel lining construction method which includes the following steps: constructing full-fracture-surface steel arches along the longitudinal surrounding rock excavation face of a tunnel at intervals, spraying two layers of low-carbon type fiber concrete layers at the position, between adjacent steel arches, of the surrounding rock excavation face at a high speed with a wet spraying machine depending on air pressure, and forming a tunnel lining structure until the tunnel is through. The tunnel lining construction method is simple in construction process and safe in construction procedure, the sprayed concrete rebound rate can be lowered, the spraying performance is improved, the energy consumption is reduced, and the formed tunnel lining structure is high in toughness, good in anti-permeability, good in durability and particularly suitable for weak surrounding rock tunnel supports constructed with the mining method.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

Tube-jet combined pile supporting underground wall structure and construction method for same

InactiveCN103195050AReduce construction costsReduce the amount of excavationBulkheads/pilesRebarFastener

The invention discloses a construction method for the tube-jet combined pile supporting underground wall structure. The underground wall structure comprises prestressed pipe piles pressed in soil at intervals, wherein the prestressed pipe piles are encircled along the periphery of a to-be-constructed basement; a high-pressure rotary-jet cement-soil pile is closely arranged between every two adjacent prestressed pipe piles in parallel, so as to form a combined pile; earthwork is segmentally excavated from top to bottom, and a reinforced concrete basement annular wall body is segmentally poured at the inner side of the combined pile from top to bottom; the upper layer of the annular wall body is connected with the lower layer of the annular wall body by means of instant grouting, so that a basement continuous wall is formed by each layer of the annular wall body; and an attached wall column can be arranged in the annular wall body, anchor lacing bars or pile hoops are arranged on the prestressed pipe piles at intervals along the length direction, the anchor lacing bars or the pile hoops are connected with the lacing fasteners of the basement continuous wall, so that the basement continuous wall and the prestressed pipe piles form a waterproof integer. The underground wall structure is simple, convenient and reliable to construct, capable of saving temporary supporting expense, free from adverse influence on environment, free of earthwork backfilling, and short in construction period.

Owner:福州市第三建筑工程公司

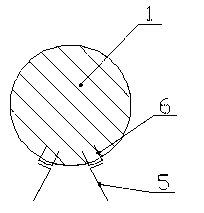

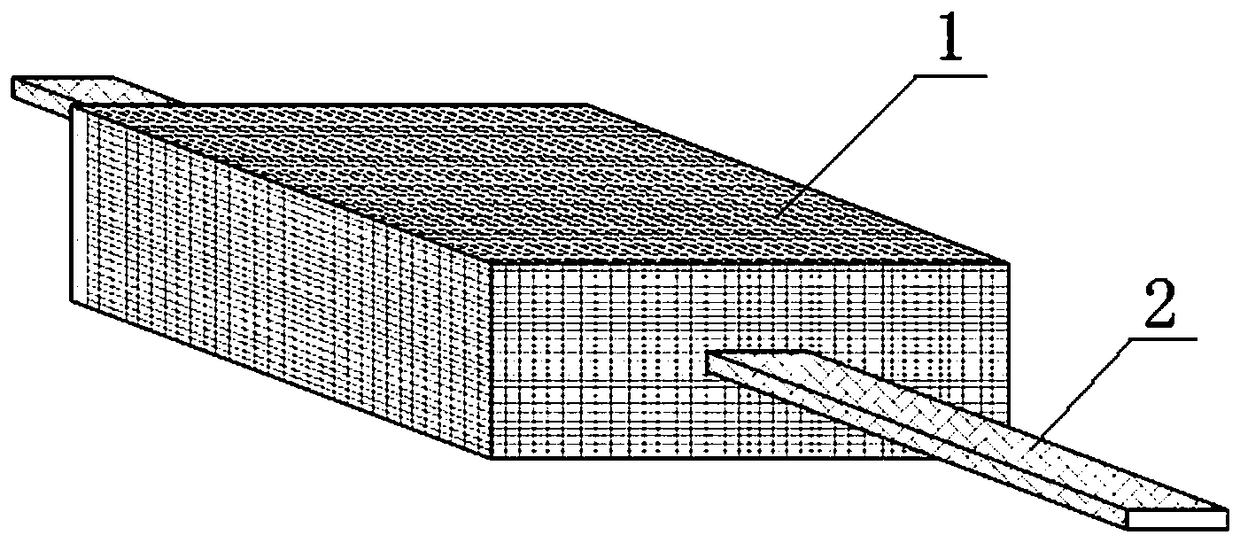

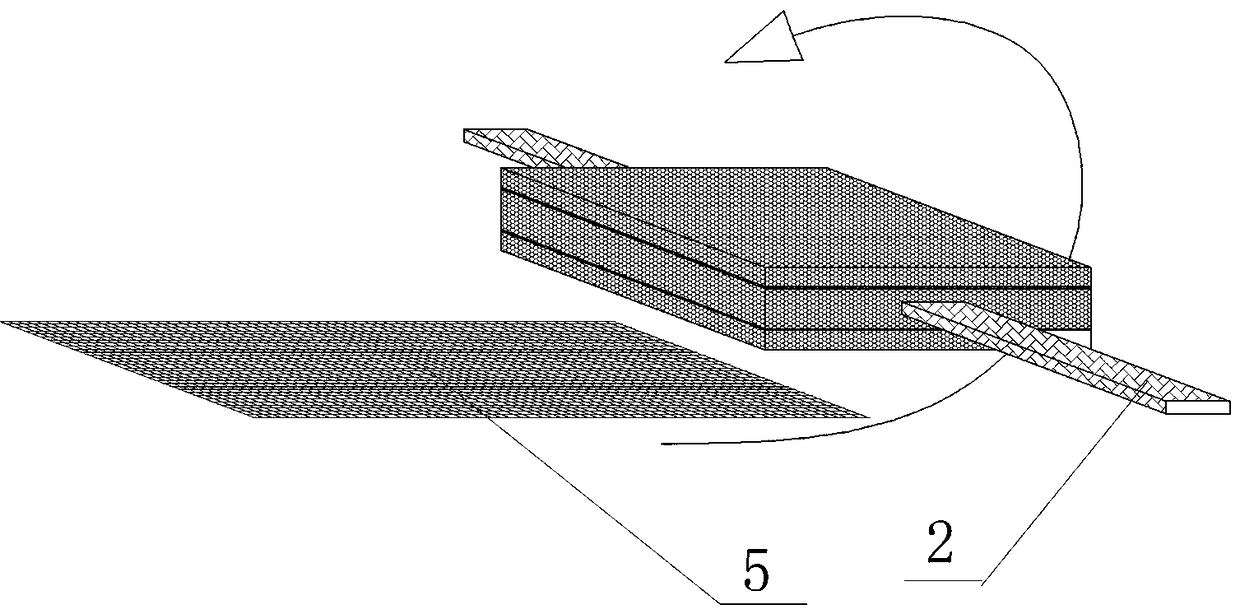

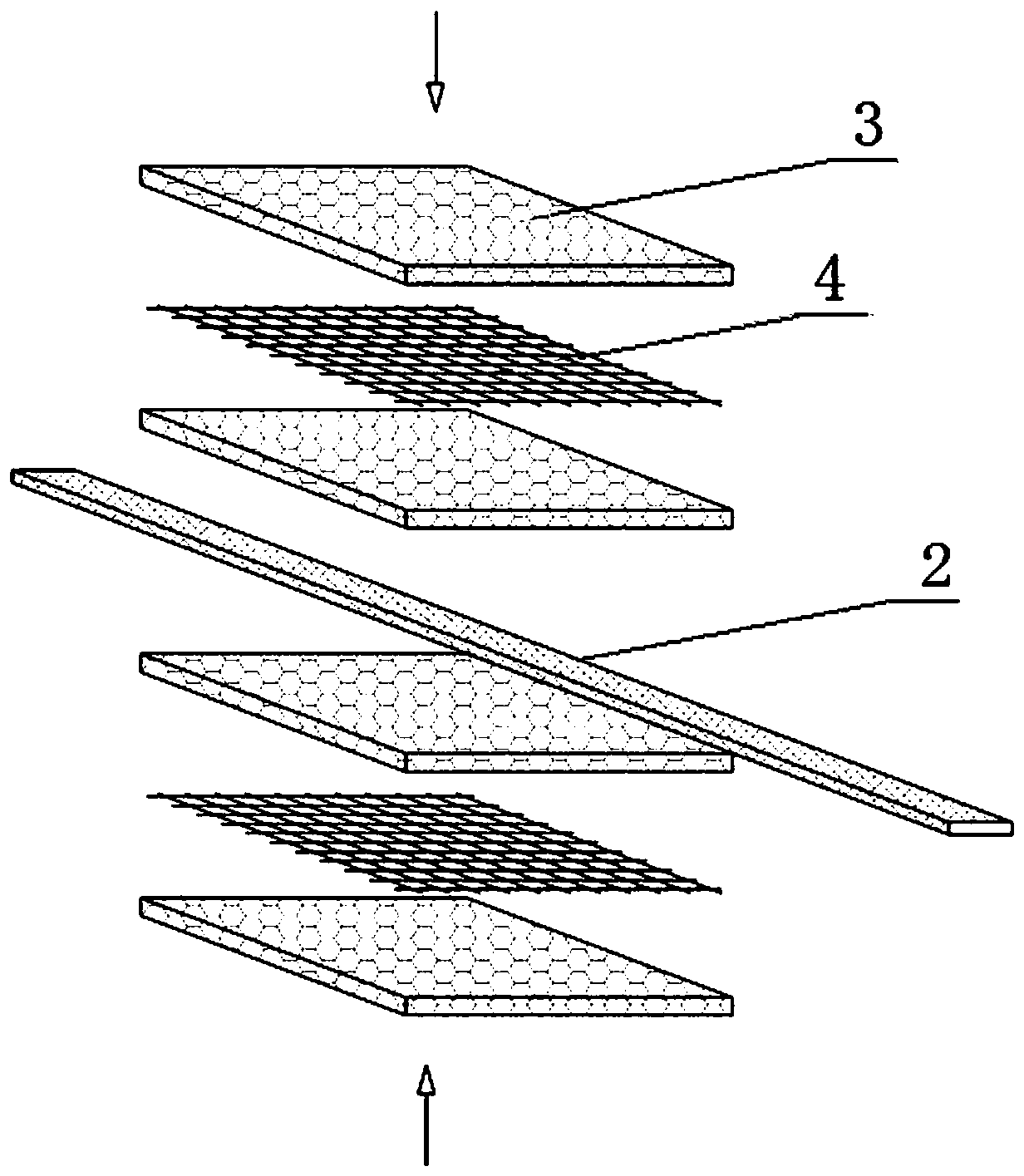

Lightweight graphite resistance reduction module and preparation method thereof

PendingCN108155489AImprove conductivityStrong moisture absorption and moisturizing abilityLine/current collector detailsConnection contact member materialGlass fiberGraphite

The invention discloses a lightweight graphite resistance reduction module and a preparation method thereof. The lightweight graphite resistance reduction module is prepared form expanded graphite, glass fiber mesh cloth, graphite resistance reduction cloth and graphite woven belt material. The lightweight graphite resistance reduction module can be made into a block shape, a plate shape or a cylindrical shape and is high in plasticity and structural strength. The preparation method includes the processes of laying, fixing, pressing, coating and re-pressing. The lightweight graphite resistancereduction module has the advantages of being small in density, light in weight, high in strength, good in water absorption, excellent in electrical conductivity and the like.

Owner:XIXIAXIAN JINFANGYUAN SEALING MATERIAL

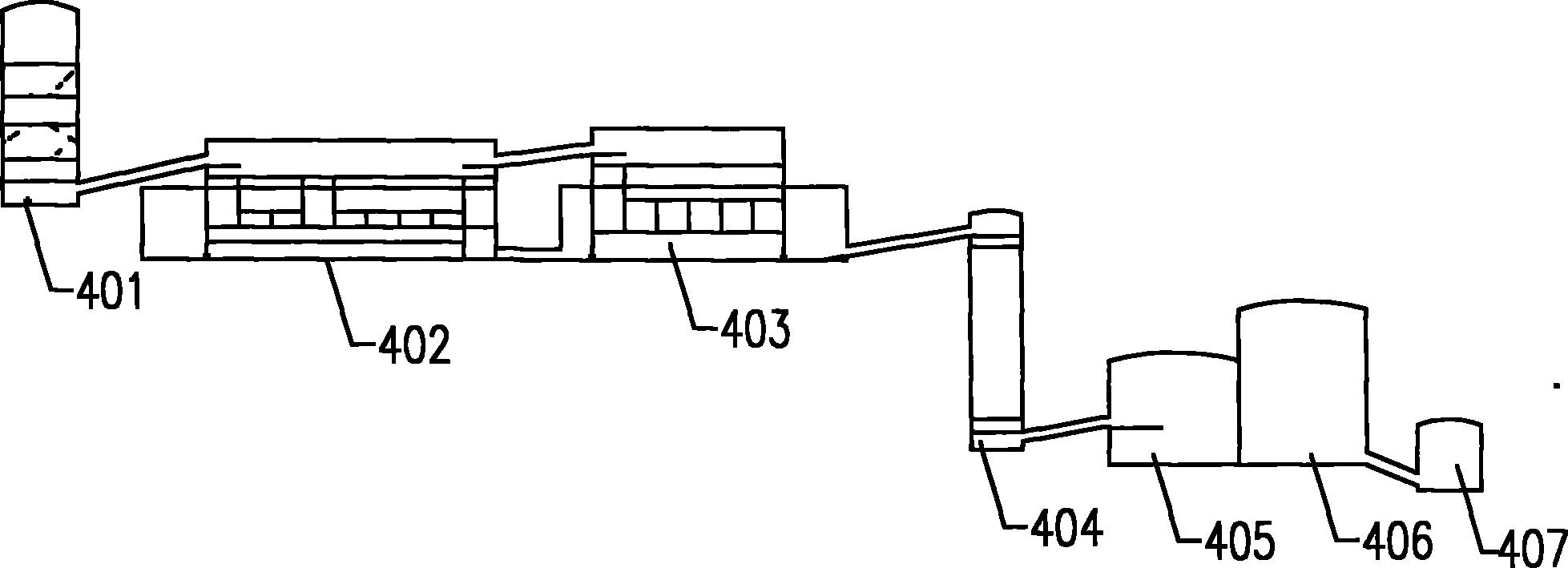

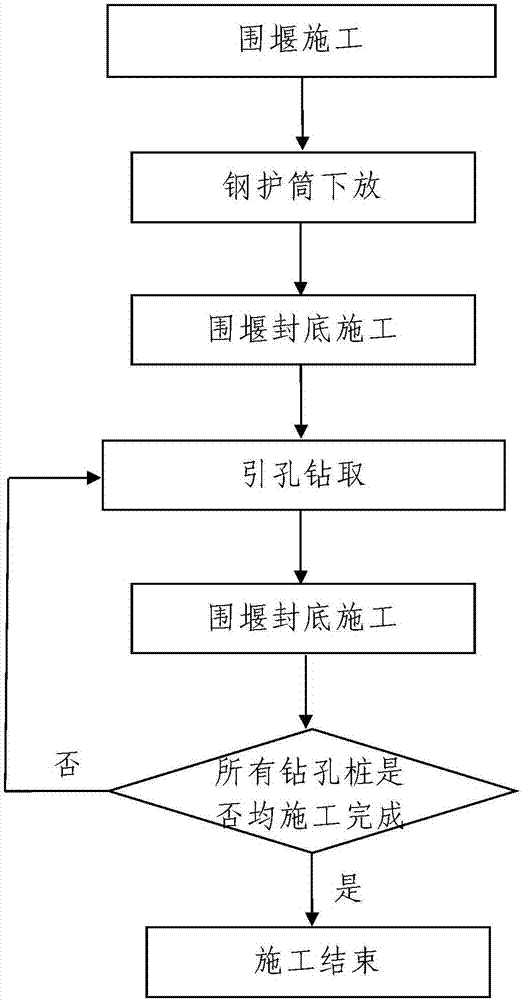

Construction method for large-size deep water foundation of rock riverbed

ActiveCN107620316AThe method steps are simpleEasy constructionProtective foundationCofferdamLarge size

The invention discloses a construction method for a large-size deep water foundation of a rock riverbed. The construction method comprises the following steps of: step I, cofferdam construction; stepII, steel casing dropping; step III, cofferdam bottom-sealing construction; step IV, drilling pile construction, wherein when any drilling pile is constructed, the step IV comprises the following steps of: 401, lead-hole drilling; and 402, drilling pile construction; step V, water pumping in cofferdam and steel casing cut-off; step VI, bearing platform construction; and step VII, concrete pier construction. According to the construction method disclosed by the invention, a plurality of lead holes are drilled in a hard rock on which the drilling pile is located from top to bottom, so that the hard rock on which the drilling pile is located forms sieve holes for increasing rock crack surfaces, and therefore, a deep water foundation construction process can be simply and quickly completed.

Owner:NO 1 ENG LIMITED OF CR20G

Construction technology for deep water foundation pile foundation

ActiveCN107503345AThe method steps are simpleEasy constructionBulkheads/pilesMultiple edgesCofferdam

The invention discloses a construction technology for a deep water foundation pile foundation. The construction technology includes the following processes that firstly, a cofferdam is constructed; secondly, a steel protection cylinder is put down; thirdly, bottom sealing construction is conducted on the cofferdam; and fourthly, drilling piles are constructed, wherein the multiple drilling piles are constructed respectively. Construction of the drilling piles includes the steps that 401, lead hole drilling is conducted, wherein multiple lead holes are drilled from top to bottom in hard rock where the currently-constructed drilling piles are located, and the 8-10 lead holes are vertically arranged and include multiple edge holes and one middle hole; 402, the drilling piles are constructed; and 403, the step 401 and the step 402 are repeated multiple times till the construction process of all the drilling piles is completed. By means of the construction technology, due to the fact that the multiple lead holes are drilled from top to bottom in the hard rock where the drilling piles are located, the number of the lead holes and the arrangement positions of all the lead holes are limited so that screen holes can be formed on the hard rock where the drilling piles are located and rock fracture planes can be increased, and the problem that due to the fact that the rock is hard and complete and the drilling construction progress of the drilling piles is affected can be effectively solved.

Owner:CHINA RAILWAY 20 BUREAU GRP

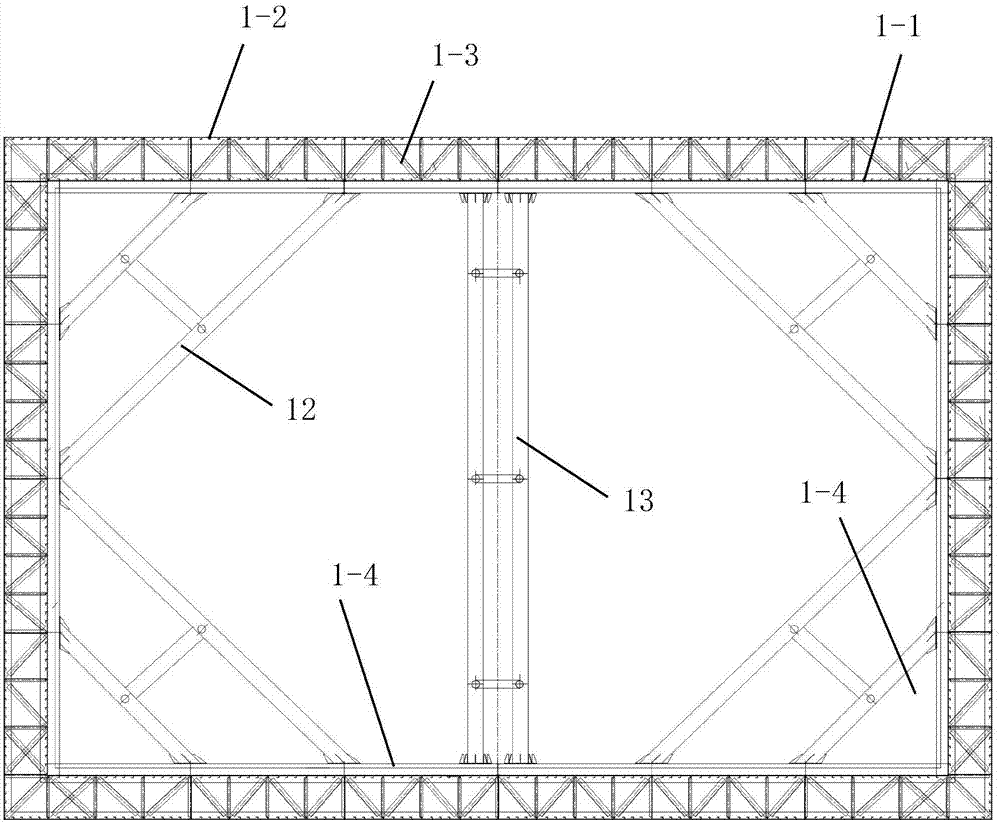

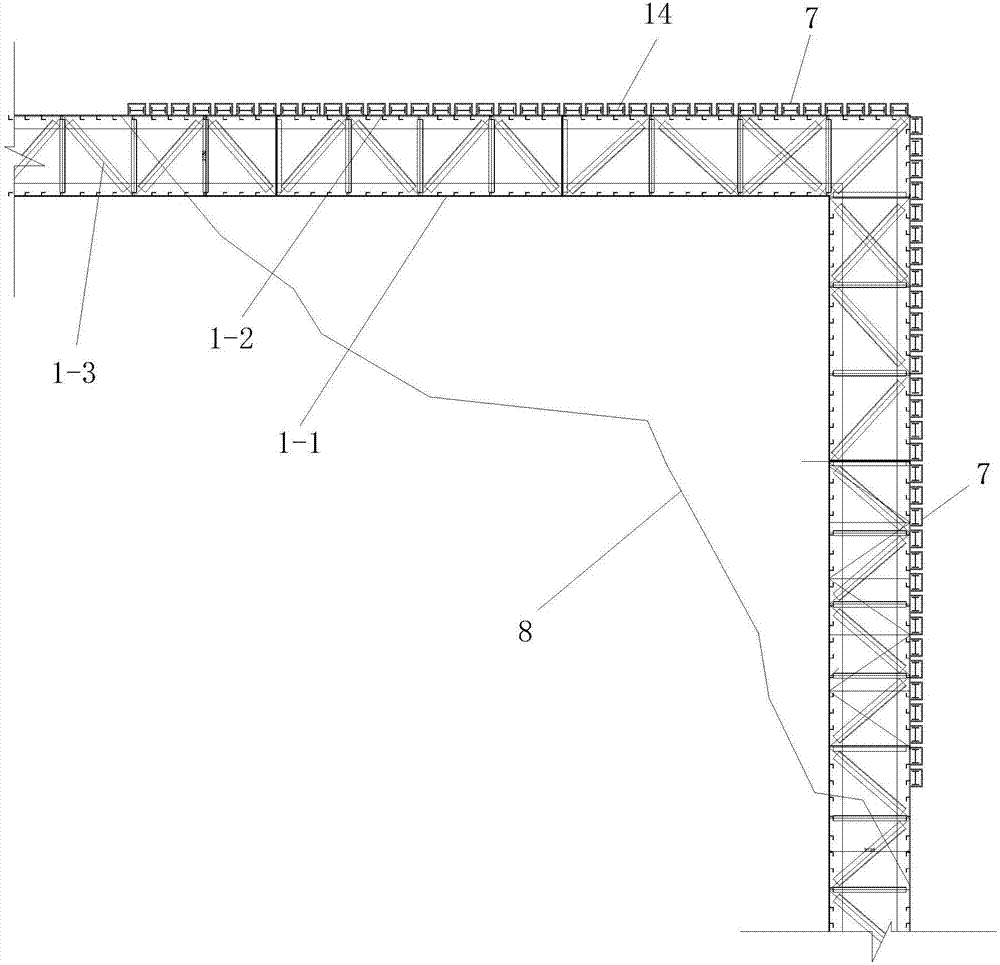

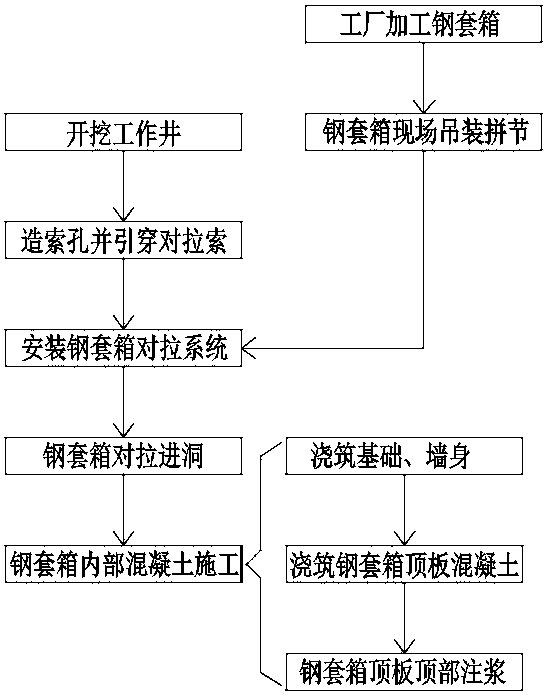

Method for carrying out opposite-pull construction on pipe ditch through steel jacket box

ActiveCN109024669ADense enoughShort construction timeArtificial islandsUnderwater structuresSteel jacketArchitectural engineering

The invention discloses a method for carrying out opposite-pull construction on a pipe ditch through a steel jacket box. Hidden penetration construction of the pipe ditch is completed through the method that an opposite-pull rope and an opposite-pull system cooperate to carrying out opposite-pull jacking on the steel jacket box and then soil is excavated. The method comprises the following steps that A, the opposite-pull rope is lead after a rope hole is formed through a method of arranging a rope hole PE pipe in a coarse hole during headwork; B, the opposite-pull system of the steel jacket box is mounted; C, the steel jacket box enters a hole in an opposite-pull manner; and D, concrete construction in the steel jacket box is carried out. Compared with a traditional pipe ditch constructionmethod, pipe ditch ground construction is carried out by adopting the method for carrying out opposite-pull hidden penetration on the pipe ditch through the steel jacket box, and the method has the advantages of being low in construction cost, ecological, environment-friendly and small in safety rick and not influencing ground facilities are achieved.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG

Dam drainage structure

InactiveCN103526732AMake full use of layout spaceFunctionalBarrages/weirsStructural engineeringBottom water

The invention discloses a dam drainage structure which comprises a surface drainage hole, a surface drainage hole gate well, a bottom evacuation hole, a bottom evacuation hole gate well and a bottom water reflow tunnel. The surface drainage hole and the surface drainage hole gate well are formed in the upper portion of a dam, the bottom evacuation hole and the bottom evacuation hole gate well are formed at the bottom of the dam, and the bottom water reflow tunnel is communicated with the bottom evacuation hole gate well. A vertical well penetrating the bottom water reflow tunnel vertically is formed at the downstream of the bottom water reflow tunnel, and the vertical shaft is communicated with the surface drainage hole. By sufficiently utilizing limited building arrangement space, flood drainage and evacuation are realized; the surface drainage hole and the bottom evacuation hole share the same water reflow tunnel, so that the drainage structures of the surface drainage hole and the bottom evacuation hole do not have to be arranged separately, and excavating workload, supporting workload and occupation space are reduced.

Owner:POWERCHINA ZHONGNAN ENG

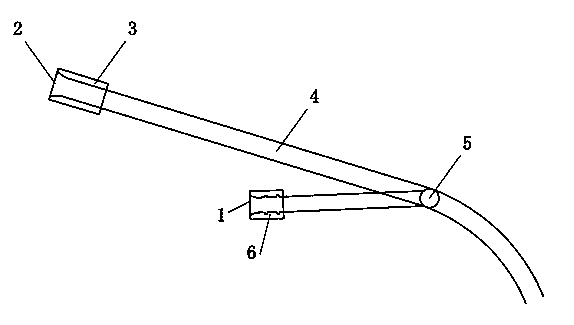

Pressure steel pipe overhaul access passage structure of high-water head hydropower station and construction method thereof

ActiveCN102251506AEasy accessReduce the amount of excavationWater-power plantsConventional hydroenergy generationWater diversionHydropower

The invention relates to a pressure steel pipe overhaul access passage structure of a high-water head hydropower station and a construction method thereof. The invention aims at realizing the purposes of being capable of arranging overhaul access passages on two or more parallel pressure steel pipes and simultaneously reducing the excavation of an overhaul access hole with single function, further facilitating the reduction of the hole chamber excavation engineering quantity and the shortening of the construction period and simultaneously creating convenience for daily management and maintenance. In the technical scheme of the invention, a construction adit and a pressure steel pipe at the tail end are in T-shaped arrangement, the construction adit and other pressure steel pipes are in cross arrangement and a steel climbing ladder is erected at the upper parts of the other pressure steel pipes; and the overhaul access passage is arranged on the boundary of each pressure steel pipe andthe construction adit and at the inlet end, and an access door is arranged on the outer side of the passage.The invention is applicable to water diversion buildings of the hydropower stations.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Low dilution mining method suitable for flat and thinner orebody

ActiveCN108952725AReduce the amount of excavationReduce mixUnderground miningBlastingEngineeringPermeation

The invention provides a low dilution mining method suitable for a flat and thinner orebody. A plurality of stopes are arranged along the trend of the orebody, and each stope corresponds to a to-be-mined chamber; the height of an initial mining layer of each chamber is 5 m, and the layer is mined by means of an open-stope method, after initial layer is mined, a jacking plate is supported by usinga low permeation supporting structure, and after the initial layer of each chamber is mined, the to-be-mined area in the bottom of the chamber is exploded by fan-shaped middle depth; after explosion,a shoveling and loading operation is carried out by means of a carry-scraper and a trackless transport vehicle, spallation rock strata on the upper part are reduced continuously, and the ground pressure is managed by means of the spallated ores, and the ground pressure of the jacking plate is managed by means of a filling body between the low permeation supporting structure and the jacking plate of the chamber. By designing a stope structure parameter of a relatively great dimension in the thin orebody, managing the ground pressure of the jacking plate by means of the spallated ores and the filling body and drilling the ores by means of a drill jambo and discharging the ores by means of the carry-scraper, a mining mode of a scaled operation is achieved, and the labor productivity is improved.

Owner:WUHAN UNIV OF TECH

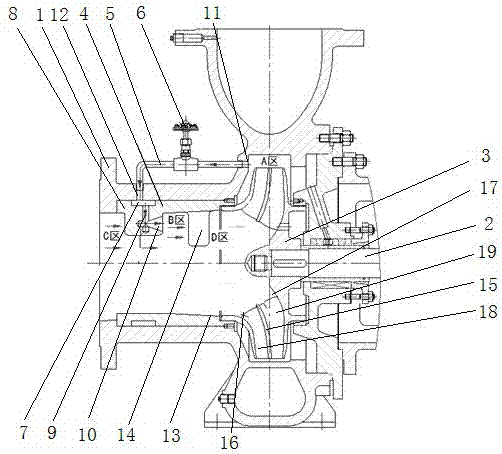

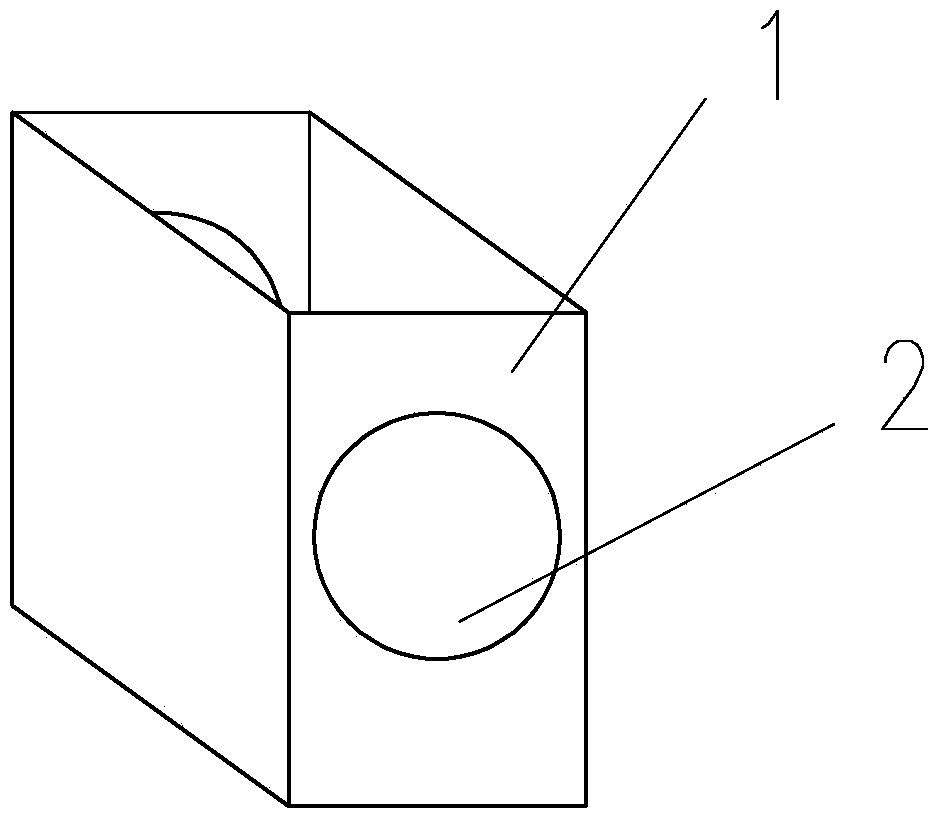

Low-cavitation-allowance low-pressure pulsation centrifugal pump

PendingCN107956737AReduce the amount of excavationExtended service lifePump componentsPumpsCavitationHigh-pressure area

The invention discloses a low-cavitation-allowance low-pressure pulsation centrifugal pump. The low-cavitation-allowance low-pressure pulsation centrifugal pump mainly comprises a pump body, a pump shaft and an impeller and is characterized in that a unique runner structure and a unique blade arrangement manner are adopted in the impeller, an energy conversion device is arranged on an inlet of theimpeller, and comprises an energy conversion component, a liquid guide pipe and an adjusting valve, a liquid guide groove is formed in the outer wall of the energy conversion component, jet flow ribplates are arranged on the circumference of the inner wall of the energy conversion component in an array manner, the outer wall of the energy conversion component is fixedly connected with the innerwall of a suction chamber of the pump body, the front end of the energy conversion component is fixedly connected with the pump body, a liquid outlet through hole is formed in the high-pressure area side wall of the pump body, a liquid inlet through hole is formed in the side wall of the low-pressure area, one end of the liquid guide pipe is communicated with the liquid outlet through hole, the other end of the liquid guide pipe is communicated with the liquid inlet through hole, the adjusting valve is arranged on the liquid guide pipe, and the liquid inlet through hole is communicated with the liquid guide groove. The centrifugal pump has the beneficial effects of being high in cavitation resistance capacity, stable and reliable in running, capable of prolonging the service life and reducing vibration and noise and the like.

Owner:SHANDONG SHUANGLUN

Novel catch-basin removing accumulated water on road surface and construction method

ActiveCN103526822ASolve road surface waterSimple construction methodSewerage structuresFiberArchitectural engineering

The invention relates to a novel catch-basin removing accumulated water on the road surface and a construction method. The novel catch-basin comprises a catch-basin body, a connecting pipe, a steel fiber grate well base and a steel fiber well grate cover. The side face of the catch-basin body is provided with two round holes used for installing the connecting pipe. The connecting pipe is laid under a road flat side stone. The catch-basin is communicated with a built catch-basin through the connecting pipe. The steel fiber grate well base is arranged on the catch-basin body. The steel fiber well grate cover covers the steel fiber grate well base. C15 concrete is backfilled into the portion of the connecting pipe to the bottom of the flat stone, then the flat side stone is installed, and the rest construction requirements are the same as the prior art. According to the novel catch-basin, the catch-basin is additionally arranged on the road section with the accumulated water and connected to an existing nearby catch-basin, and therefore the problem of the accumulated water on the road surface can be well solved. As the size of the catch-basin additionally arranged is only 12% that of a traditional catch-basin, the excavated earth volume of the novel catch-basin is less, and influence on the structure of the road surface is little as the catch-basin and the connecting pipe are located under the road flat side stone.

Owner:华昕设计集团有限公司

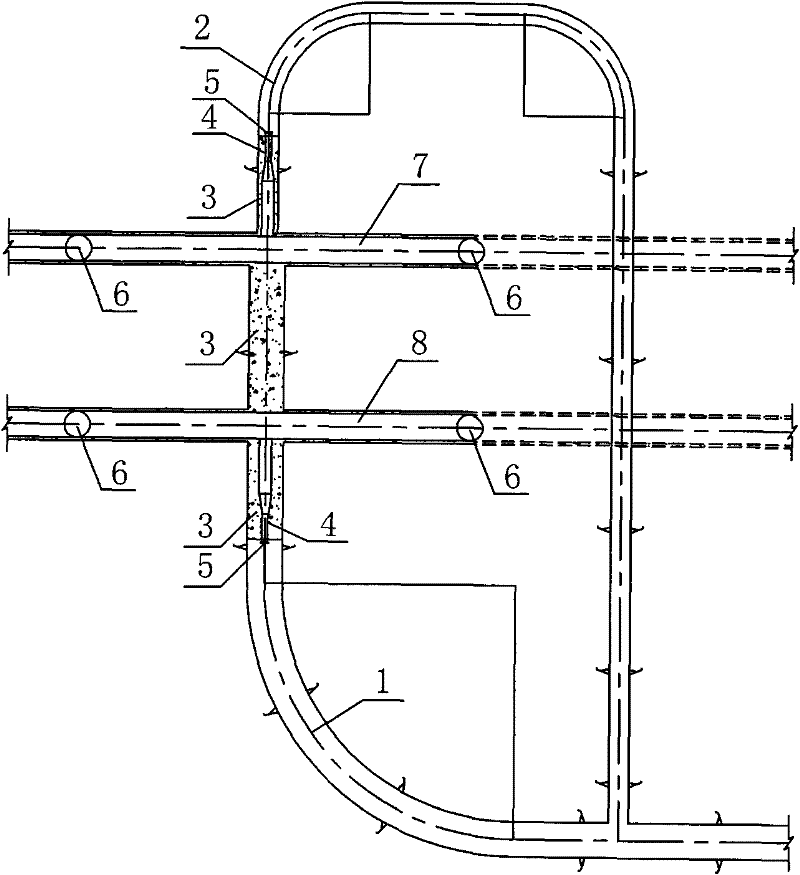

Subway station extension method and structure based on concrete-filled steel tube beam insertion method

InactiveCN112302666AImprove construction efficiencyImprove securityUnderground chambersTunnel liningArchitectural engineeringEngineering

The invention relates to a subway station extension method and structure based on a concrete-filled steel tube beam insertion method. The subway station extension method comprises the steps that a transverse through middle platform is built between existing bidirectional parallel shield tunnels to form an extension structure; and corresponding upper through holes and lower through holes are obliquely formed in segments of the two shield tunnels, jacking bent steel pipes are inserted from the through holes to be transversely connected to serve as external supports, a lining structure is constructed after soil is excavated on the inner side, and through connection is achieved after the segments at shield tunnel connectors are detached. Small expansion, downward storey addition and step-by-step expansion can be achieved, and the subway station extension method is suitable for expansion of subway stations with strict control over ground displacement and ground surface settlement and construction of shallow soil, soft stratums and large-span underground spaces.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com