Non-coal-pillar double tunneling method

A technology without coal pillar and end road, which is used in earth-moving drilling, wellbore lining, tunnel lining and other directions, can solve the problems such as failure of road retention work to achieve the expected goal, difficulty in ventilation in single road tunneling, and excessive roadway deformation, and achieve improvement. The effect of roadway maintenance, reducing the amount of roadway excavation and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

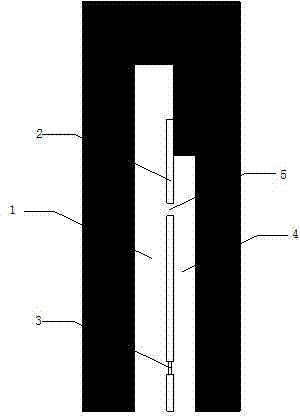

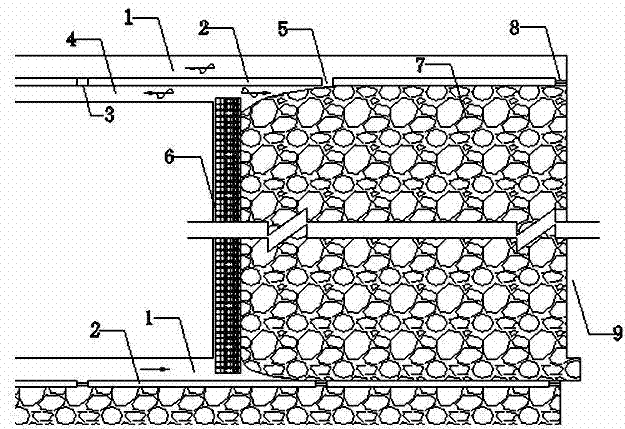

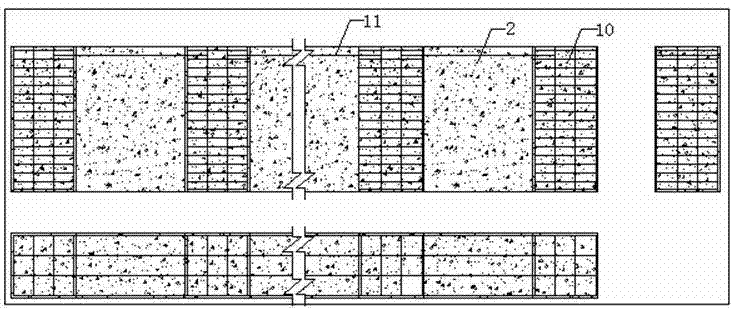

Image

Examples

Embodiment 1

[0036] Yiyang Coal Group Pingshu Coal Mine 8 1 Take No. 6 coal as an example, the coal is located at the top of Taiyuan Formation, about 15m away from No. 6 coal. The thickness of the coal seam is 0.90-2.50m, with an average of 1.67m. The structure is simple, without or with a layer of gangue. The lithology of the roof is mostly mudstone and sandy mudstone, with a compressive strength of 20.0-49.2 MPa and a tensile strength of 0.5-2.1 MPa, and the roof has good stability; the lithology of the floor is mostly sandy mudstone and mudstone, with a compressive strength of 26.1-86.2 MPa, tensile strength 0.6 ~ 5.2MPa. According to underground pair 8 1Observation of the roof and floor of the No. coal seam shows that the roof is black mudstone and sandy mudstone with well-developed dense and fine joints. The roof in the roadway has good stability and is easy to maintain. Its floor is made of black mudstone and sandy mudstone, and there is no phenomenon such as bottom drum, which h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com