Low dilution mining method suitable for flat and thinner orebody

A mining method and thin ore body technology, applied in ground mining, mining equipment, underground mining, etc., can solve problems such as difficult scale and mechanized mining methods, waste rock falling into ore, and high ore dilution rate. Achieve the effect of reducing the amount of waste rock excavation, reducing surface subsidence and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

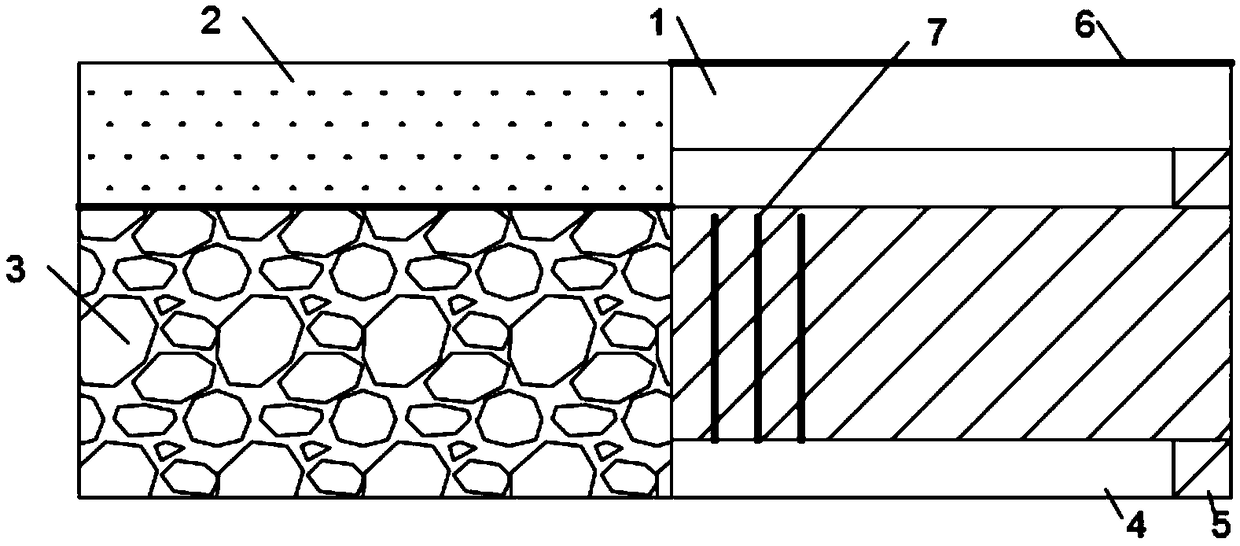

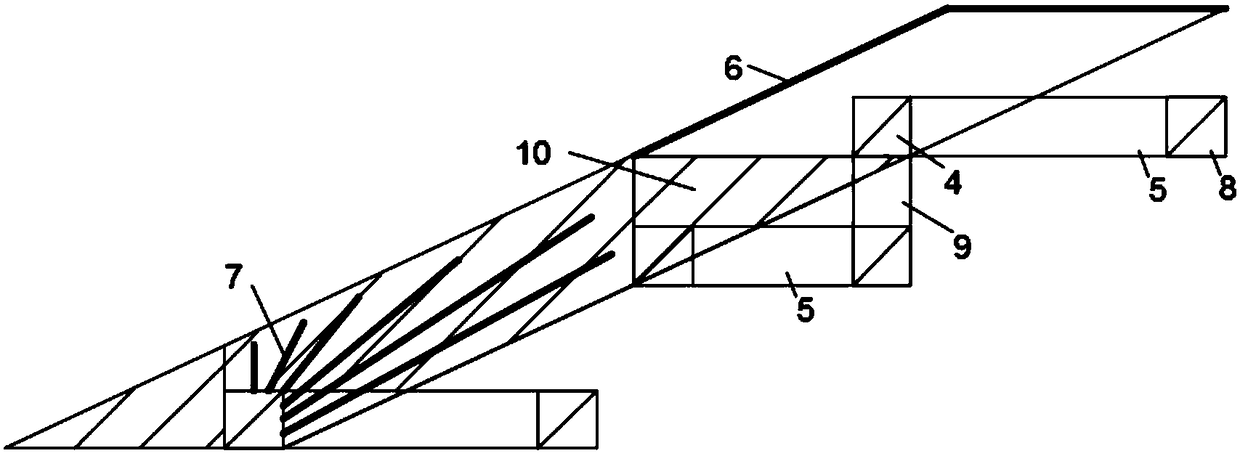

[0021] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as Figure 1-2 As shown, the inclined thin ore body applicable to the present invention mainly refers to the ore body whose inclination angle is less than 20° and the thickness is less than 8m. Several stopes are set along the ore body trend, and the length of each stope is 80-100m, and the width of the stope is ore body Design a section every 10-15m along the height direction of the ore body, design a middle transportation roadway 8 every 3-4 sections, design a vein-piercing roadway 5 at both ends of the mining stope, and excavate a roadway along the vein 4. Connect the vein-piercing roadways on both sides. When mining, dig a cutting groove at the end of one side of the ore body along the inclination direction of the ore body. The height is 13m, and a 2m roof is reserved for safety.

[0022] The height of the first mining layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com