Subway station extension method and structure based on concrete-filled steel tube beam insertion method

A technology for concrete filled steel tubes and subway stations, which is used in earth-moving drilling, underground chambers, wellbore linings, etc., can solve the problems of short division of shield construction sections, deformation of subway and surrounding soil bodies, and damage to existing operating subways. Achieve the effect of good deformation control effect, short engineering period and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

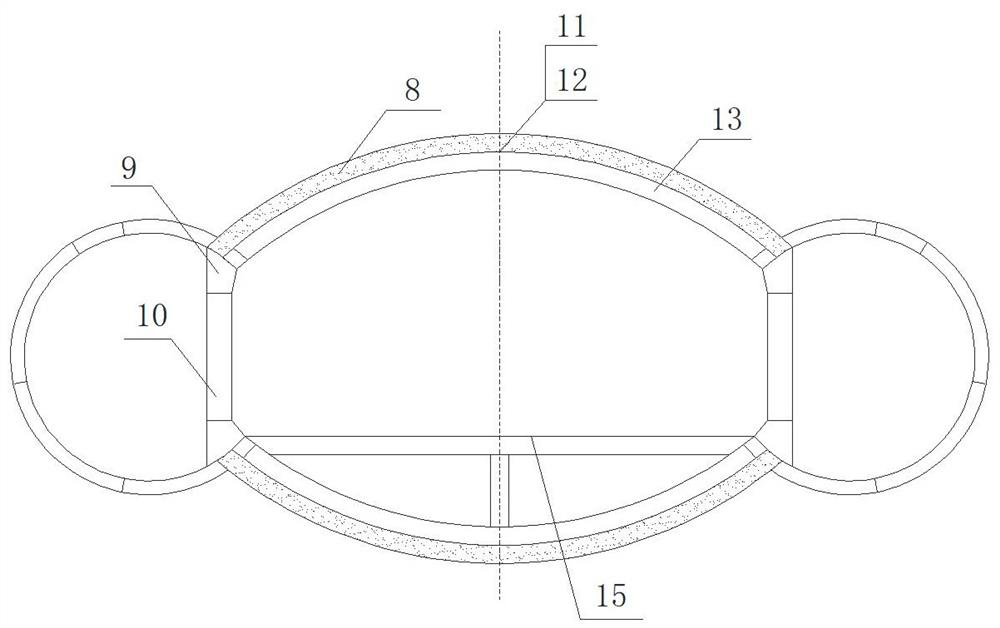

[0072] Such as figure 1 As shown, the subway of the present embodiment, the extension structure of the station comprises a shield tunnel and an intermediate platform connected between two parallel shield tunnels and communicated with the shield tunnel;

[0073] Wherein, the intermediate platform includes a top lining unit and a bottom lining unit, side columns and a structural floor 15, and the top lining unit and the bottom lining unit are arranged between the shield tunnels and are symmetrical up and down, and both the top lining unit and the bottom lining unit include outer The curved steel pipe layer distributed at intervals, the waterproof layer and the station lining 13 arranged in sequence inside the curved steel pipe layer. The diameter of the curved steel pipe in the curved steel pipe layer is 40cm, the radius of curvature is 700~1200m, preferably 900cm, and the length of each section of the curved steel pipe is 0.8~1.0m. Adjacent steel pipes are connected by welding...

Embodiment 2

[0086] The subway of present embodiment, station extension structure are identical with embodiment 1.

[0087] The subway and the station expansion method based on the steel pipe concrete beam insertion method of the present embodiment are specifically realized by the following steps:

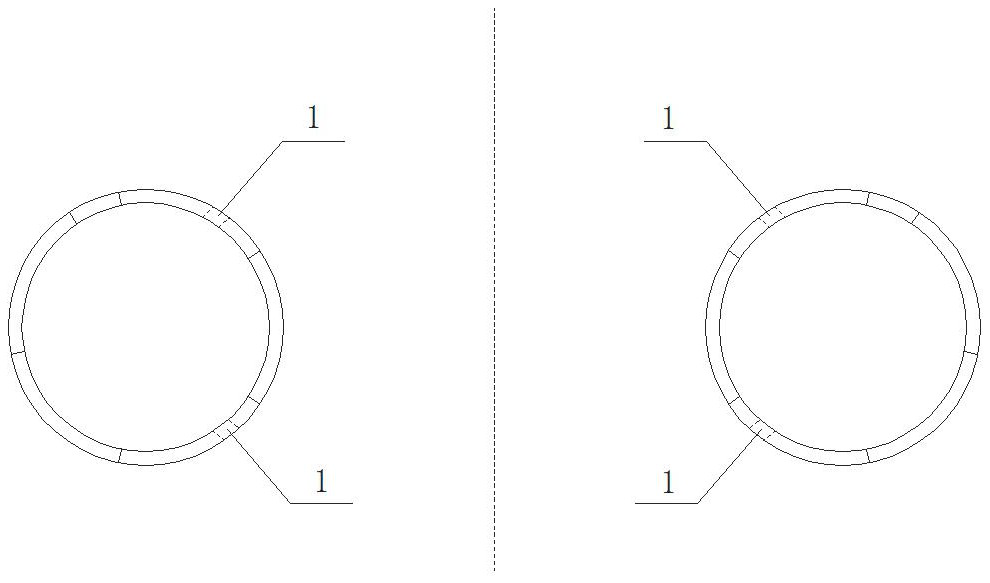

[0088] (1) Upper and lower perforations 1 are respectively set on the opposite positions of the shield segments of the two parallel shield tunnels. The diameter of the perforations is greater than the diameter of the curved steel pipe by ±3mm, so that the curved steel pipe can be jacked smoothly.

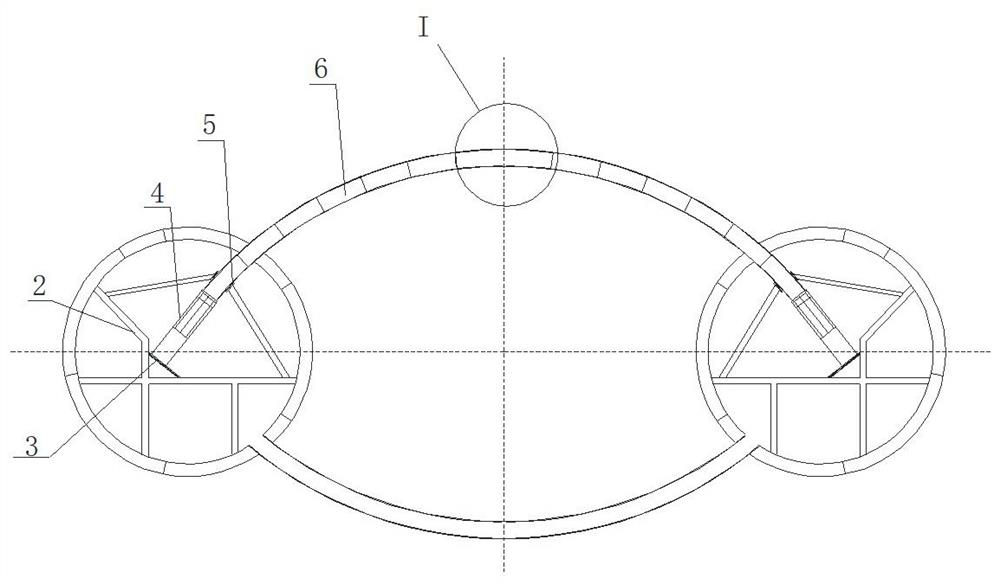

[0089](2) Set up the reaction force frame 2 in the shield tunnel on both sides, fix the reaction force support 3 and the guide frame 5 on the reaction force support 2, set the jacking oil cylinder 4 on the reaction force support 3, so that the jacking The telescopic rod of the oil cylinder 4 coincides with the central axis of the perforation 1 in step (1), and the guiding direction of the guide frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com