Low-cavitation-allowance low-pressure pulsation centrifugal pump

A NPSH and low pressure technology, applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problem of the ability of the inducer to reduce NPSH, the large range of pressure and speed changes, and the reduction of NPSH To reduce the amount of excavation, smooth flow, and reduce infrastructure investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

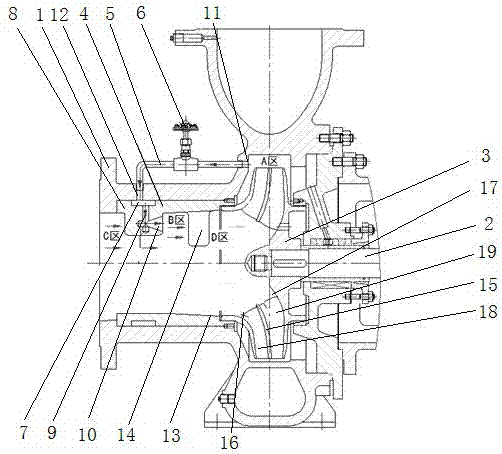

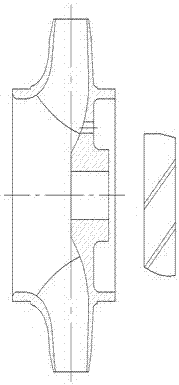

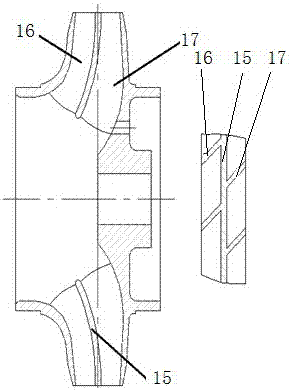

[0023] As shown in the drawings, a low NPSH low pressure pulsation centrifugal pump mainly includes a pump body 1, a pump shaft 2, and an impeller 3. The connection relationship between the pump body 1, pump shaft 2, and impeller 3 is similar to that of the existing The technology is the same, so I won’t go into details here. It is characterized in that an energy conversion device is provided at the entrance of the impeller 3, which includes an energy conversion component 4, a catheter 5 and a regulating valve 6, and the outer wall of the energy conversion component 4 is provided with a fluid guide. Groove 7, the inner wall of the energy conversion component is provided with a jet rib 8 in a circumferential array, and the jet rib 8 is provided with a liquid inlet hole 9 in the radial direction corresponding to the liquid guide groove 7, and a jet hole 10 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com