Pressure steel pipe overhaul access passage structure of high-water head hydropower station and construction method thereof

A pressure steel pipe and channel structure technology, applied in hydropower stations, water conservancy projects, hydroelectric power generation, etc., can solve the problems of delaying the construction period, single function of the manhole for inspection and maintenance, and long tunnel lines, etc., so as to reduce the amount of excavation work, Ease of daily management and maintenance, and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

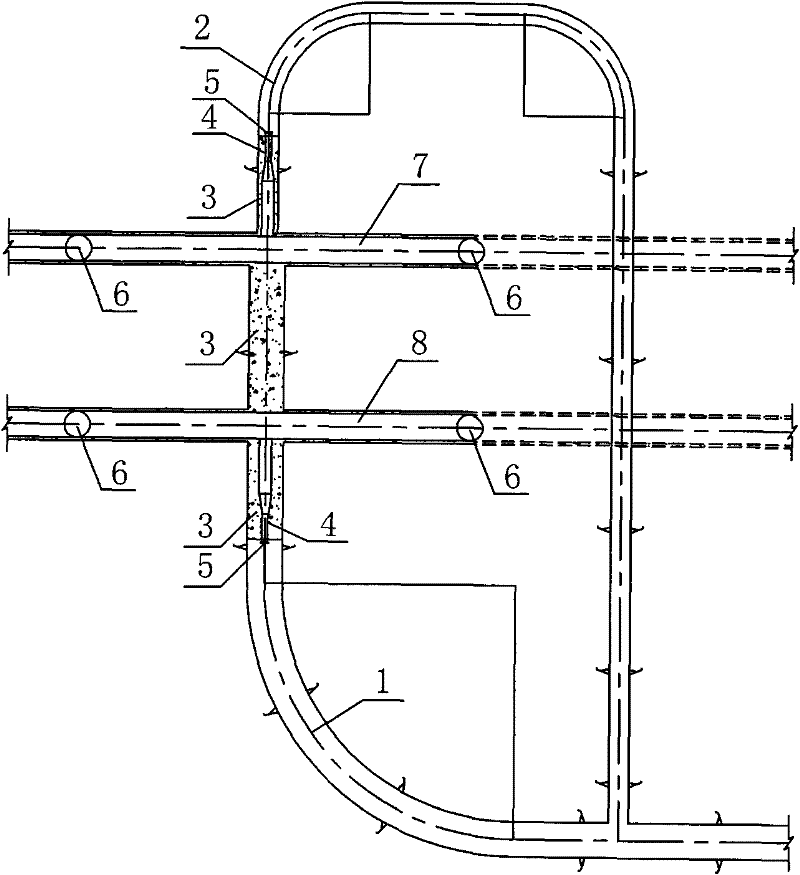

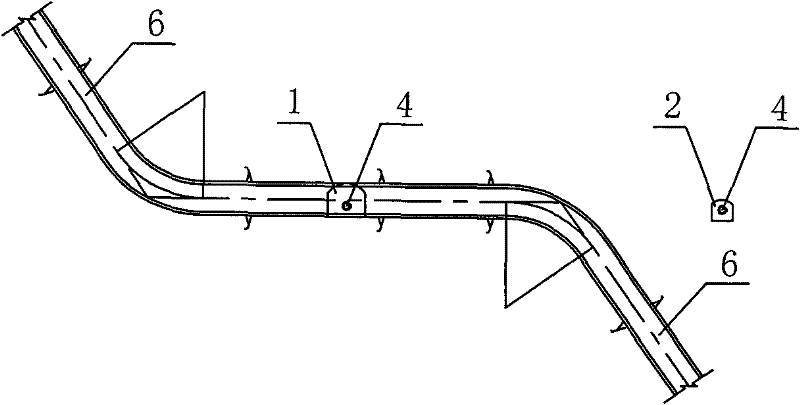

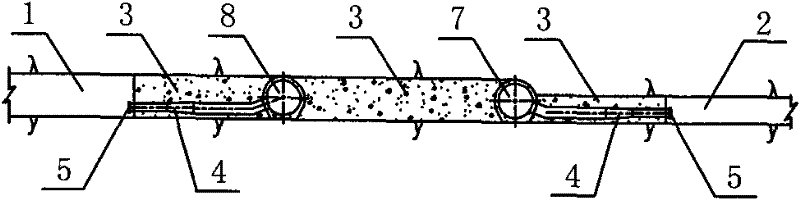

[0027] Such as Figure 4-6 As shown, in this embodiment, there is only one construction support tunnel 1 used to excavate a long tunnel to increase the construction working surface during the construction period. One end of the construction support tunnel is with two parallel penstocks (penstock I 7 and penstocks) as the main tunnel of the tunnel. II 8) Vertically intersecting arrangement, each penstock is connected with inclined shaft 6 (one upward, the other downward). The construction support tunnel 1 and the end penstock (penstock I 7) are arranged in a T shape, and the construction support tunnel 1 and the other penstock (penstock II 8) are arranged in a cross shape. In this example, the penstock I 7 is an embedded pipe. The plugging body 3 is poured at the end of the construction branch tunnel 1 at the junction with the penstock I. The maintenance access passage 4 is pre-embedded in the plugging body and in the channel Access door 5 is set on the outside. The penstock II...

Embodiment 2

[0033] Such as Figure 7-9 As shown, the basic structure of this example is the same as Example 1, except that the two penstocks are all exposed pipes, the steel is 600MPa or 800MPa grade steel, and the wall thickness is 30-50mm. (Under high internal water pressure, a certain thickness of the pipe wall needs to be increased, and it can also be skipped to a steel plate with higher strength).

[0034] The construction method of this example includes steps:

[0035] 1. The construction support tunnel 1 passes through two penstocks vertically, namely the penstock I 7 at the end of the construction tunnel and the penstock II 8 at the middle of the construction tunnel. Both penstocks are designed as exposed pipes. After the installation of I is completed (the section at the junction with the construction branch tunnel), directly set up an access passage 4 for the penstock I 7 and an access door 5 on the outside of the passage;

[0036] 2. After the installation of the penstock II 8 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com