Patents

Literature

63 results about "NPSH" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

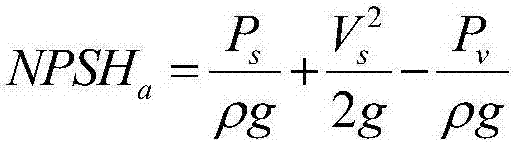

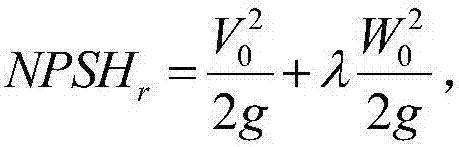

In a hydraulic circuit, net positive suction head may refer to one of two quantities in the analysis of cavitation: The Available NPSH: a measure of how close the fluid at a given point is to boiling, and so to cavitation. The Required NPSH: the head value at a specific point required to keep the fluid from cavitating. NPSH is particularly relevant inside centrifugal pumps and turbines, which are parts of a hydraulic system that are most vulnerable to cavitation. If cavitation occurs, the drag coefficient of the impeller vanes will increase drastically - possibly stopping flow altogether - and prolonged exposure will damage the impeller.

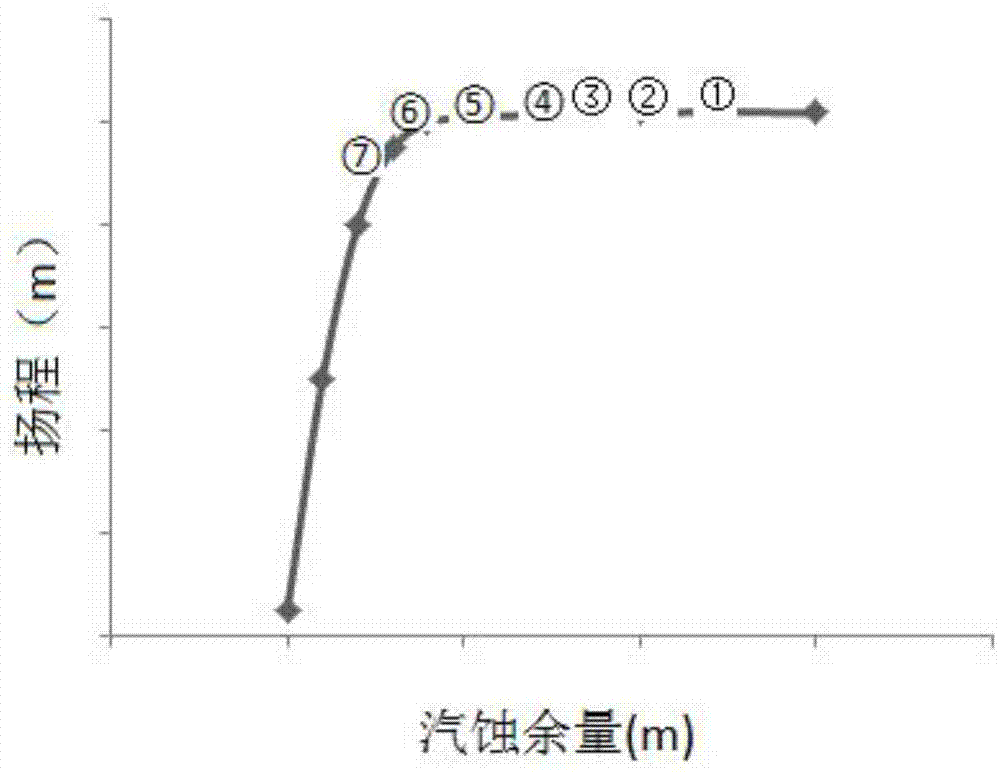

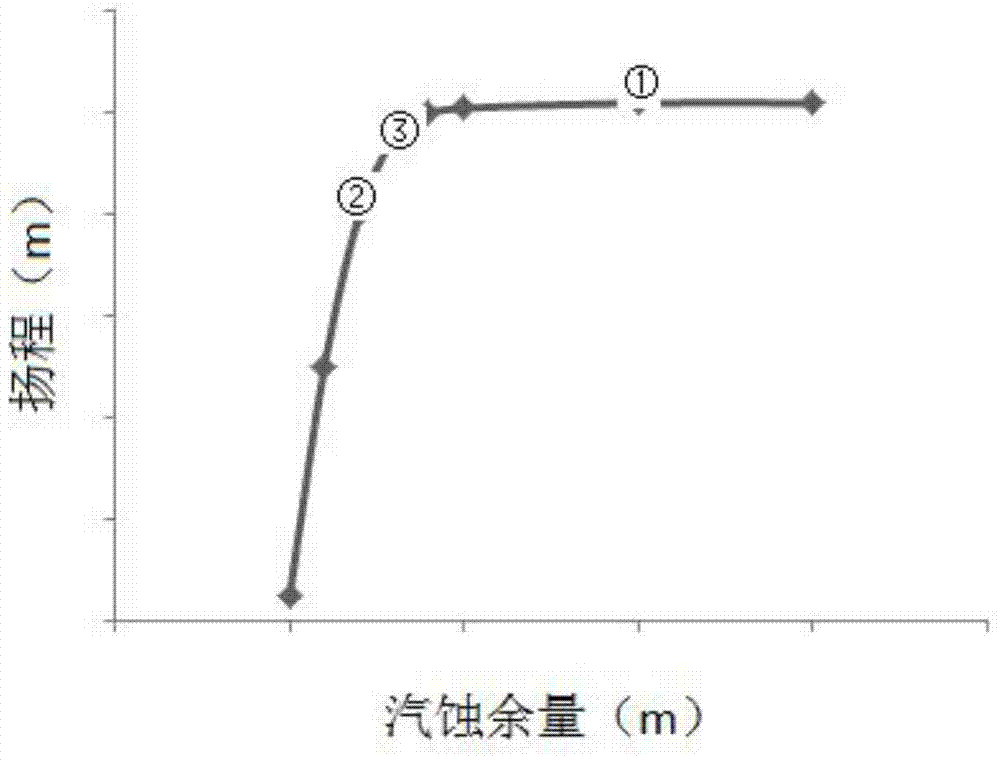

CFD-based prediction method of centrifugal pump cavitation performance

ActiveCN104504219ASave simulation timesSave simulation timePump componentsEngine fuctionsCavitationPredictive methods

The invention provides a CFD-based prediction method of a centrifugal pump cavitation performance and relates to a method for predicting centrifugal pump net positive suction head required (NPSHr) by a CFD cavitation model. The method mainly includes the following steps that boundary conditions in CFX software are set as inlet fixed total pressure and outlet fixed mass flow rate and rapid numerical simulation calculation is performed to estimate pump lift; under novel boundary conditions, the pump lift is calculated again in the CFX software; in the CFX software, the boundary conditions are inlet fixed mass flow rate and outlet fixed static pressure, and simulation computation is performed to obtain a NPSHr estimated value that is close to a true value; the boundary conditions are set as inlet fixed mass flow rate and outlet fixed static pressure, a point that is quite close to 3% reduction of lift is obtained by simulation computation in the CFX software, and an obtained NPSHr value is quite close to the true value; if a calculated result in the last step is in an accuracy range, the process is finished, and otherwise, the content of the last step is repeated. The CFD-based prediction method of the centrifugal pump cavitation performance is a predictable and controllable simulation method, and simulation times and time can be saved.

Owner:JIANGSU UNIV

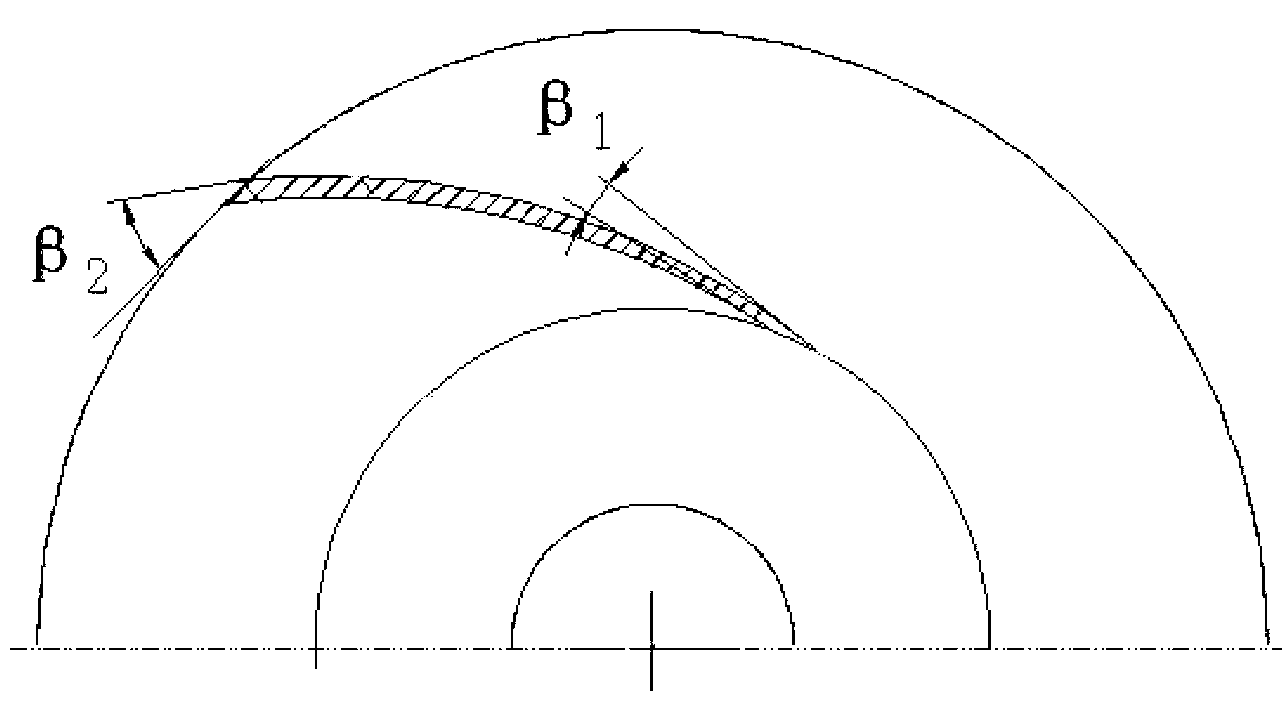

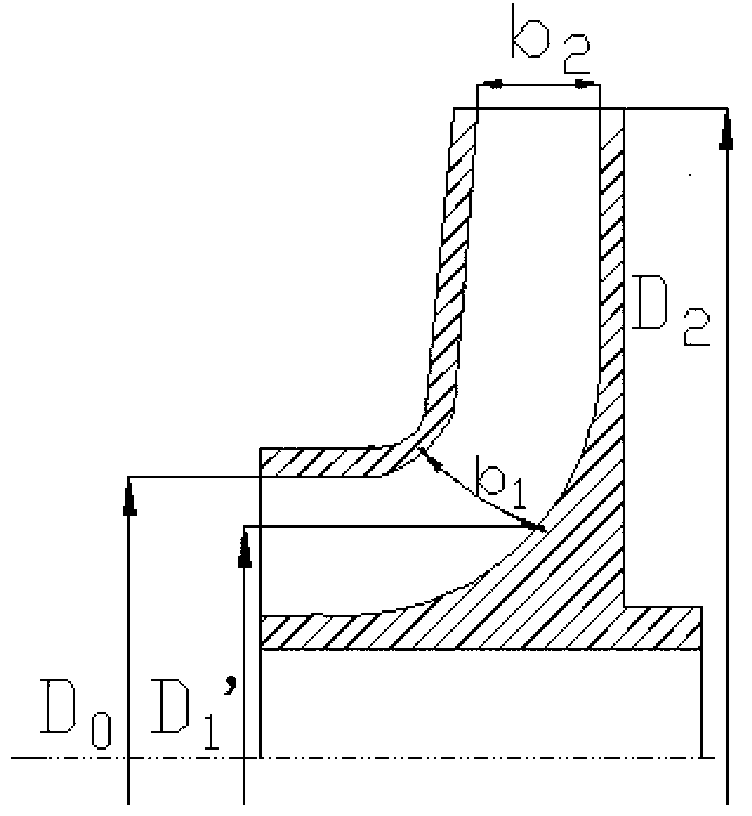

Centrifugal pump design method based on matrix laboratory (MATLAB) genetic algorithm

InactiveCN103020345AOvercome the unsolvable global optimal solution problemImprove adaptabilitySpecial data processing applicationsGenetic algorithmEngineering

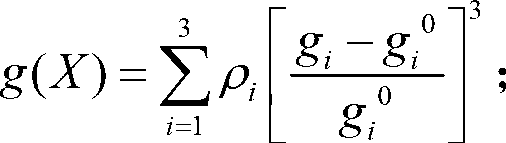

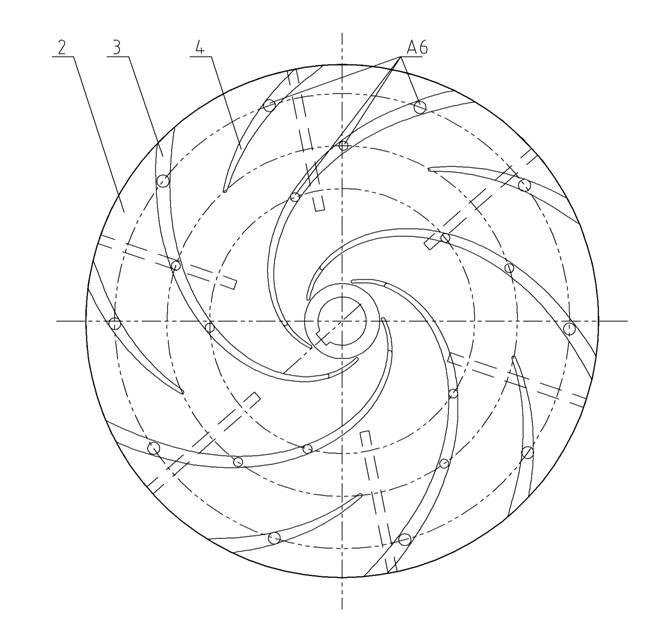

The invention discloses a centrifugal pump design method based on matrix laboratory (MATLAB) genetic algorithm, and the method is characterized by comprising the following steps of firstly selecting the diameter of an inlet and an outlet of an impeller of a centrifugal pump, positions of an inlet and an outlet of blades, a placement angle of the inlet and the outlet of the blade, the width of the inlet and the outlet of the blade and the quantity of the blades as optimized variables, establishing a branch objective function of overall loss power of the centrifugal pump, a branch objective function of net positive suction head and a branch objective function of centrifugal pump stability; respectively acquiring a minimal initial value of each branch objective function, allocating a weight pho i for each branch objective function, and establishing a uniform objective function g(X); setting a restraint condition of the optimized variable according to a speed coefficient method result; and finally adopting an MATLAB genetic algorithm tool box to obtain a minimal value of the g(X) as well as the value of each variable. Compared with the prior art, the design period is shortened, the optimization process is simplified, and the stability also can be guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

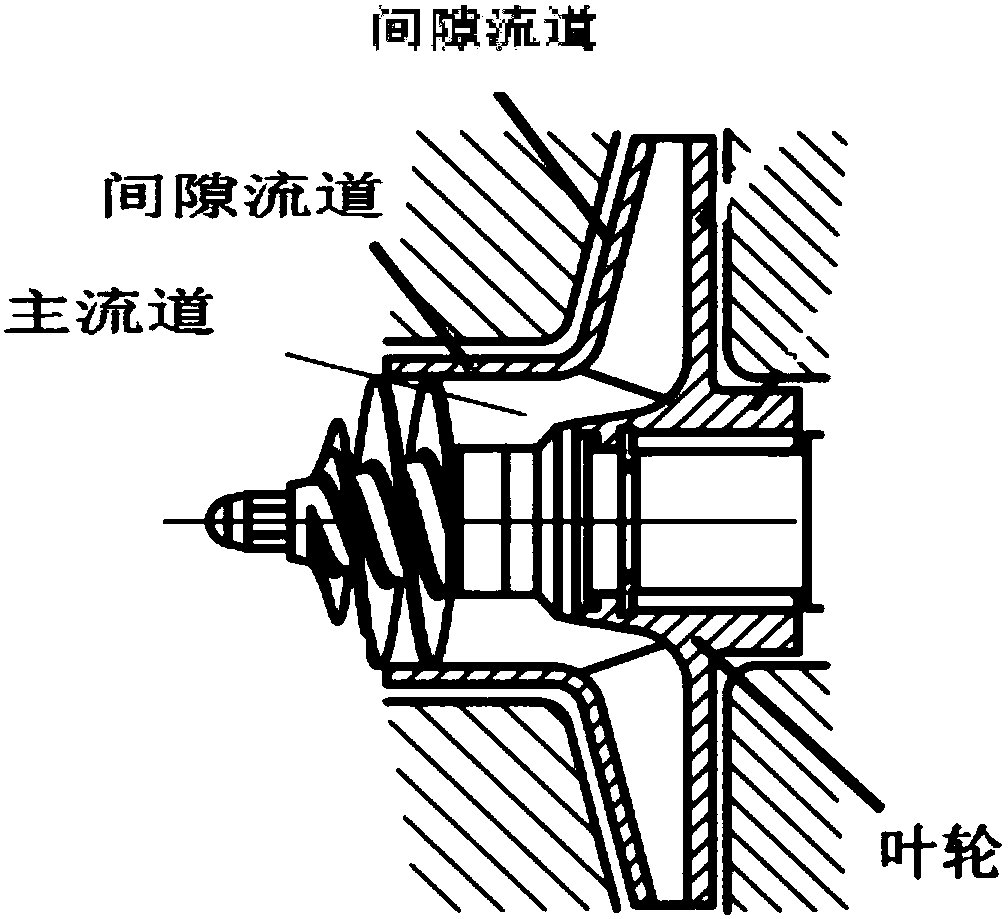

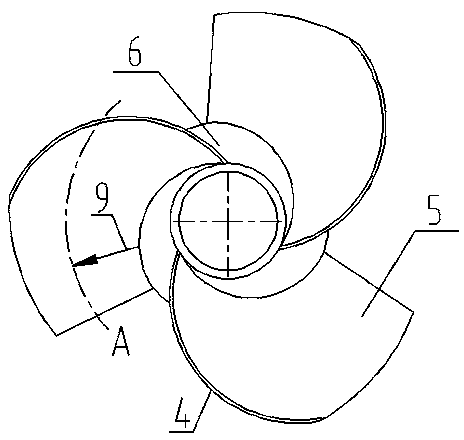

Inducer designing method based on centrifugal pump

ActiveCN102678617AGood cavitation performanceImprove performancePump componentsPumpsSpecific speedNPSH

The invention relates to an inducer designing method based on a centrifugal pump, which belongs to the technical field of pumps. The method is characterized in that an inducer is designed based on a given centrifugal pump device. According to the inducer designing method based on the centrifugal pump, the inducer is designed by determining the flow, the pump lift, necessary net positive suction head and other experimental data at a point of the centrifugal pump with the highest efficiency, based on an external characteristic experiment according to the conditions of an existing water pump device. Consequently, the inducer acquires higher cavitation specific speed under the conditions of an outer diameter of a rim, inlet hub ratio and optimal inlet flow coefficient. Not only can the inducer be enabled to have good cavitation performance, but also the inducer has good energy matching relationship with a pump impeller, the performance of the inducer is improved, the operation stability of a system is enhanced, assembly difficulties caused by size difference between the pump and the inducer due to an original designing method can be prevented, the inducer designing efficiency is improved, and popularization value is realized.

Owner:JIANGSU UNIV

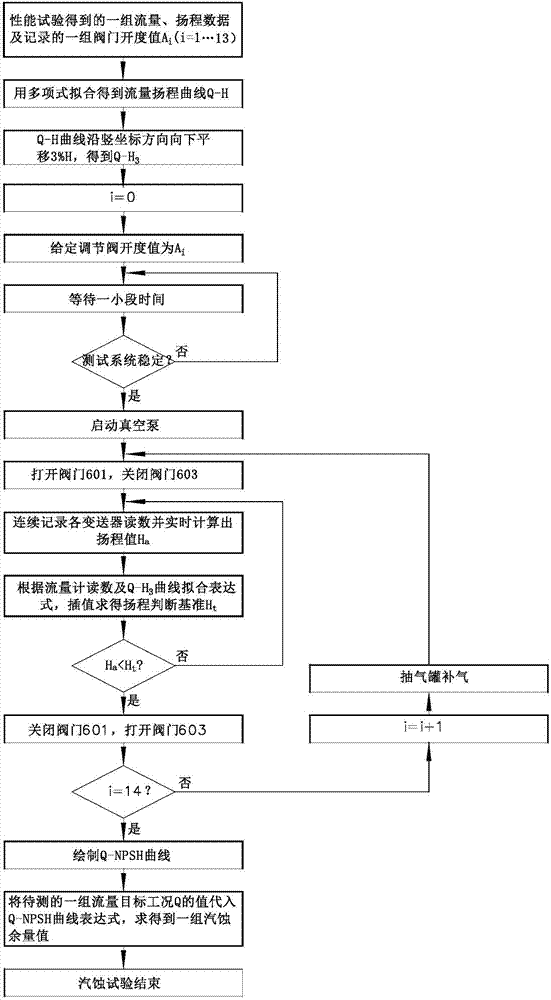

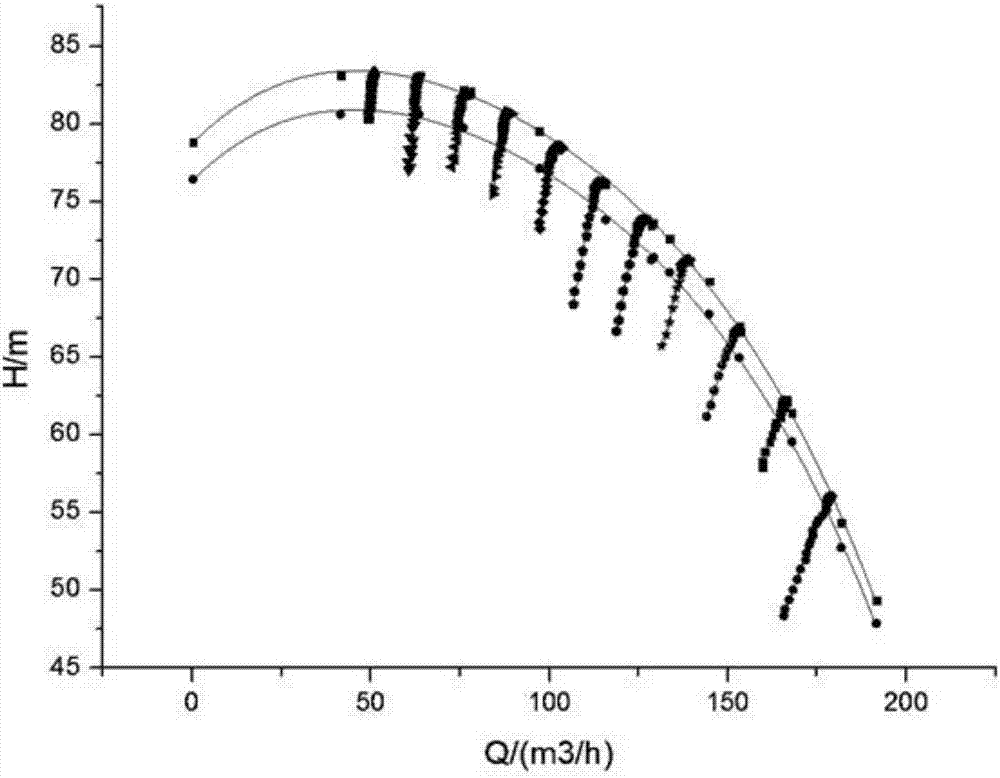

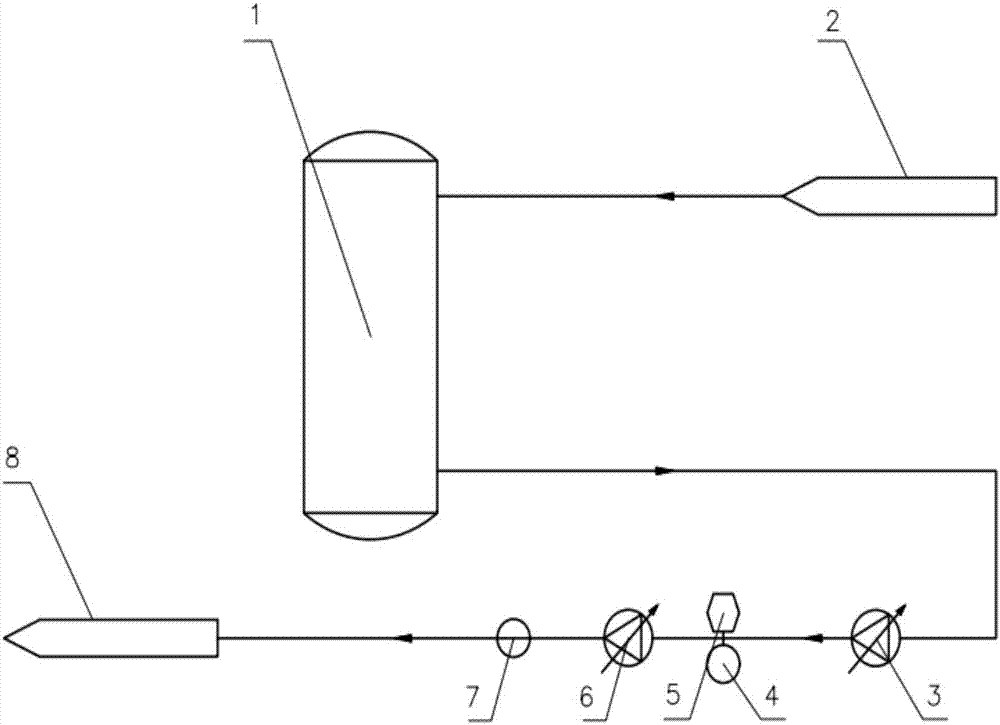

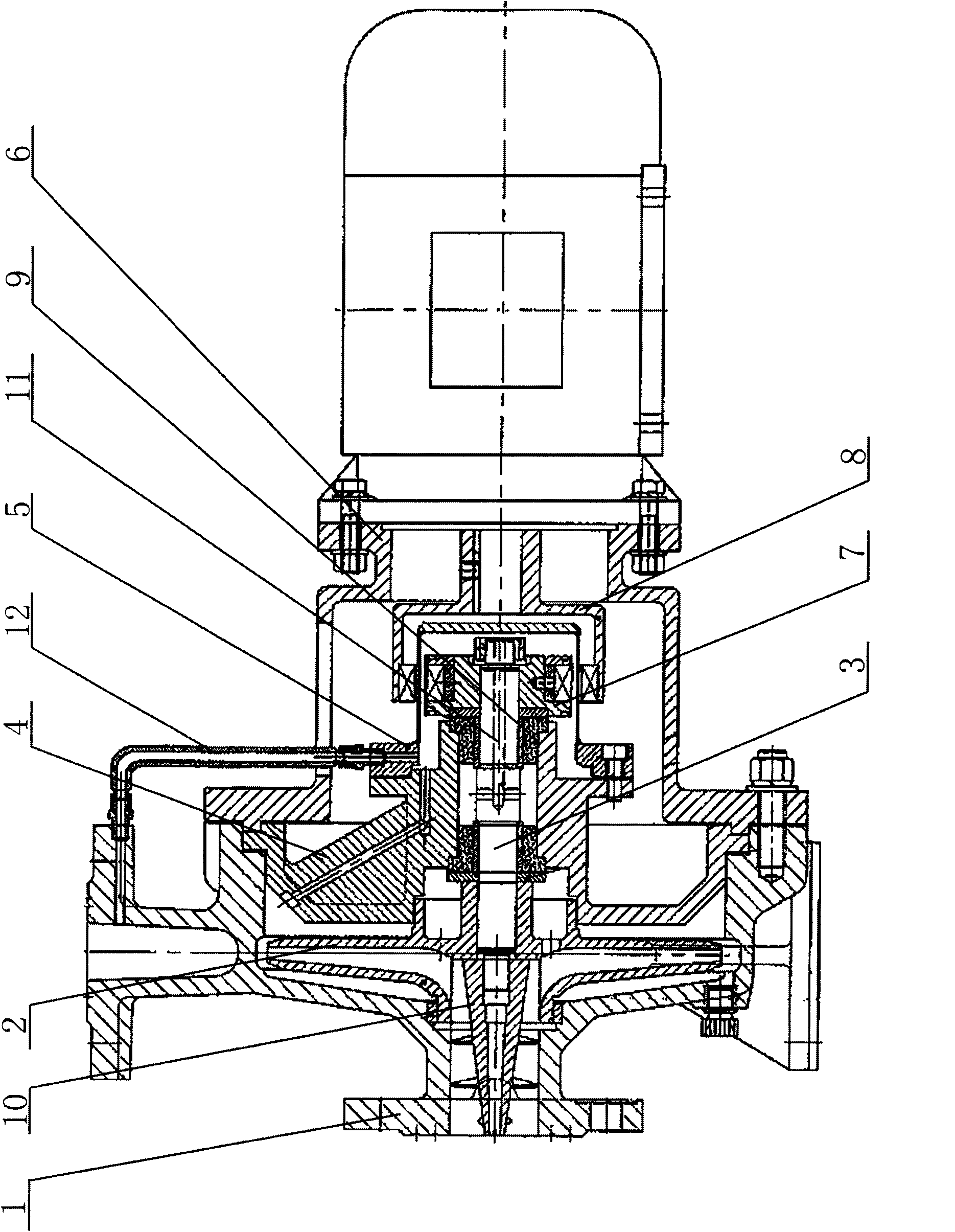

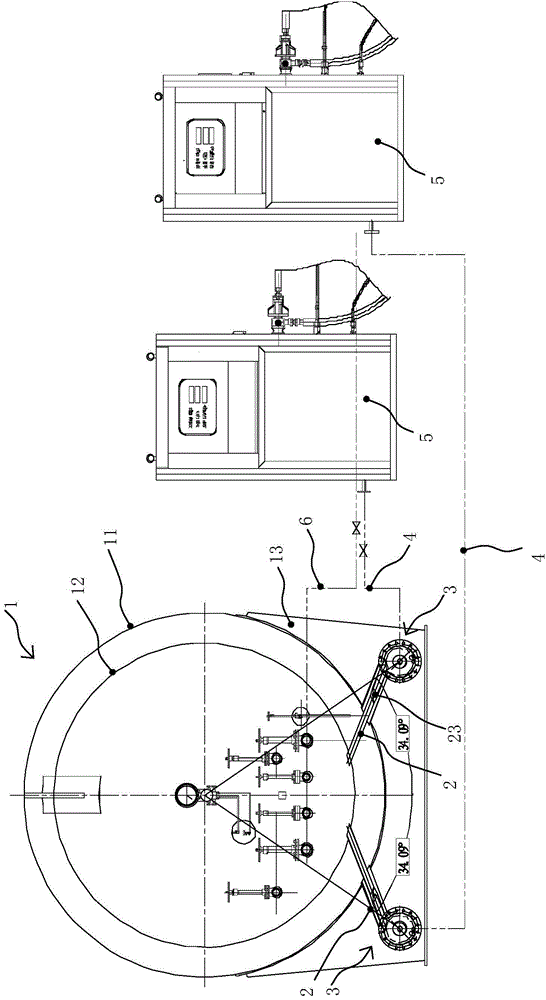

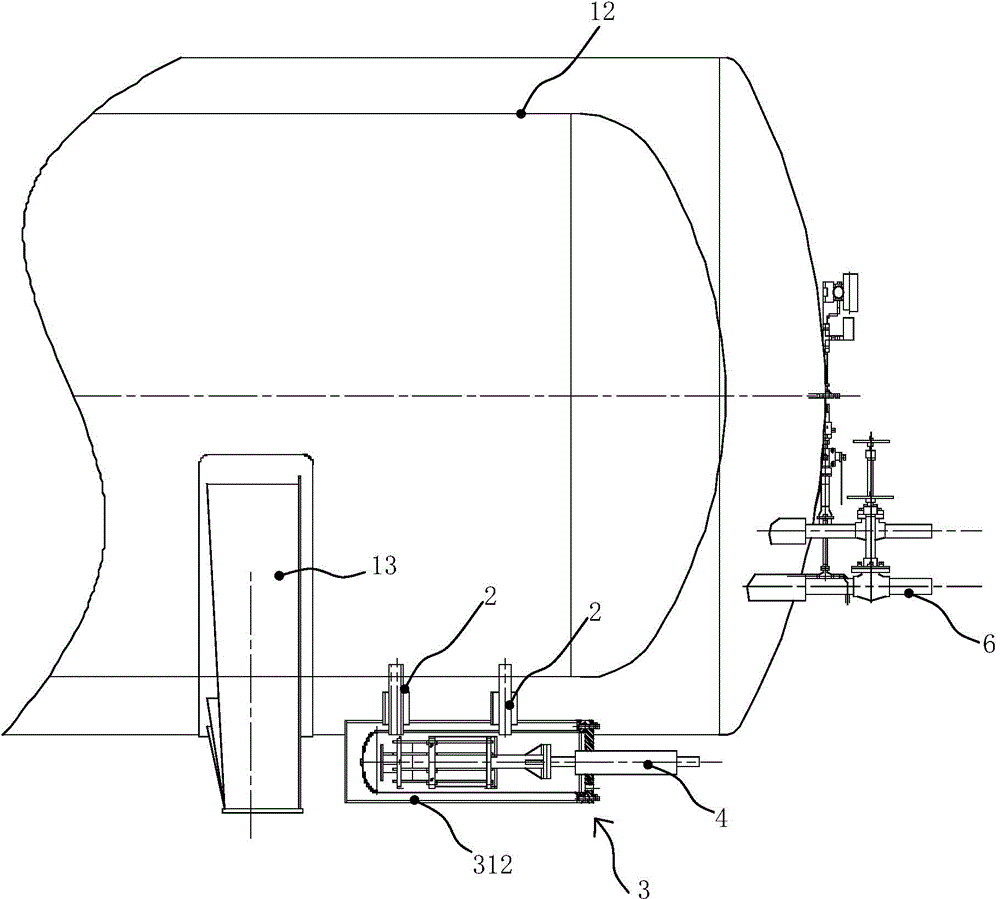

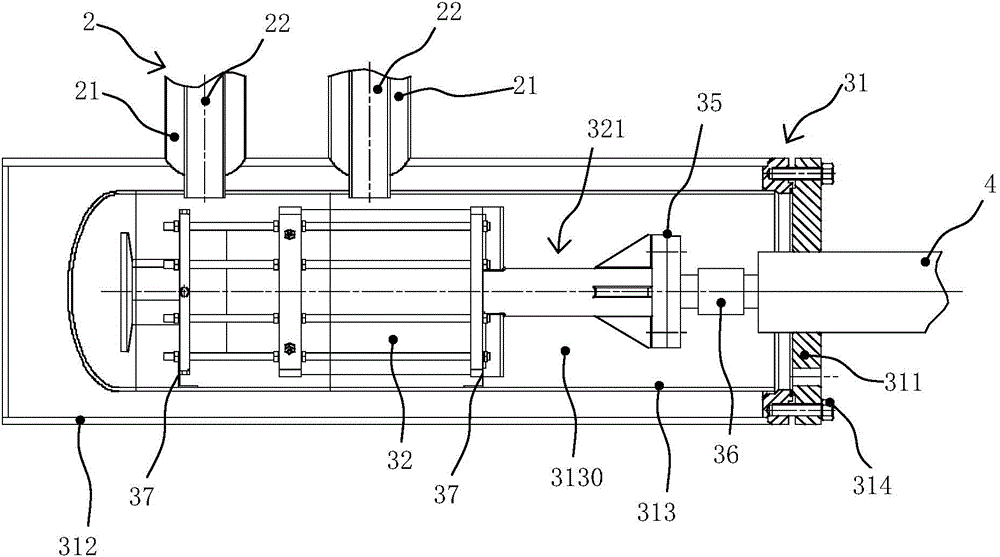

Automatic testing system and method for water pump net positive suction head

ActiveCN106968934ATest Process AutomationQuick testPump testingPositive-displacement liquid enginesWater storage tankNetwork output

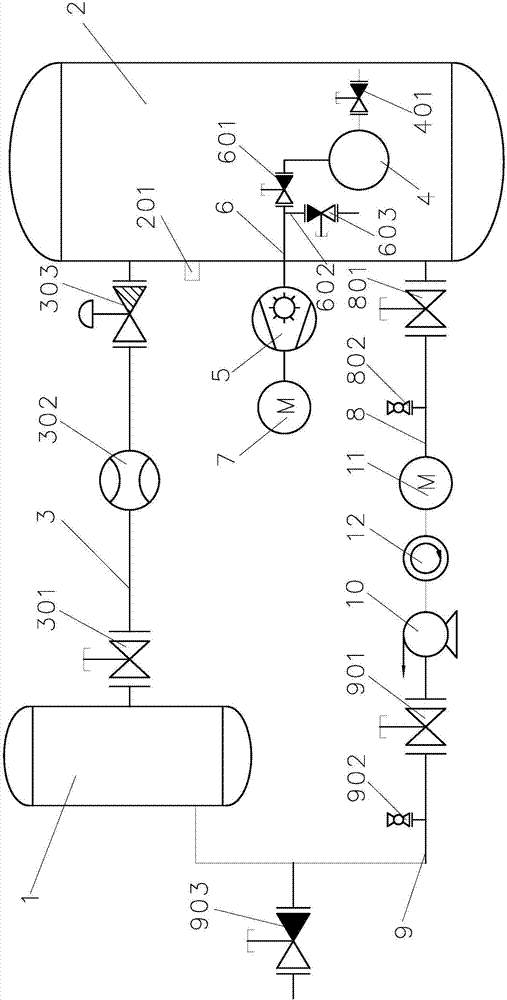

The invention discloses an automatic testing system and method for the water pump net positive suction head. The automatic testing system comprises a discharging tank, a water storage tank, a flow adjusting pipeline connecting the discharging tank with the water storage tank, an air extraction tank arranged on the water storage tank, a vacuum pump, an air extraction pipeline, a branch pipeline of the air extraction pipeline, a motor, a water inlet pipeline, a water outlet pipeline, and a measurement and control cabinet, wherein the flow adjusting pipeline is provided with an electric gate valve, a flow meter and a pneumatic adjusting valve. The vacuum pump communicates with the air extraction tank through the air extraction pipeline, and the air extraction pipeline is provided with a switch valve. The motor is electrically connected with the vacuum pump. The water inlet pipeline is provided with an electric gate valve and a pressure transmitter and communicates with a water inlet of a tested water pump. The water outlet pipeline communicates with a water outlet of the tested water pump and is provided with an electric gate valve, a pressure transmitter and a switch valve. The measurement and control cabinet integrates a data collecting module and a data control module, is connected with the electric gate valves, the pressure transmitters and other components through signal lines and is further provided with a network output interface used for communicating with an industrial personal computer provided with testing programs. By means of the automatic testing system and method for the water pump net positive suction head, the water pump net positive suction head can be automatically, rapidly and accurately tested.

Owner:GUANGDONG KENFLO PUMP CO LTD

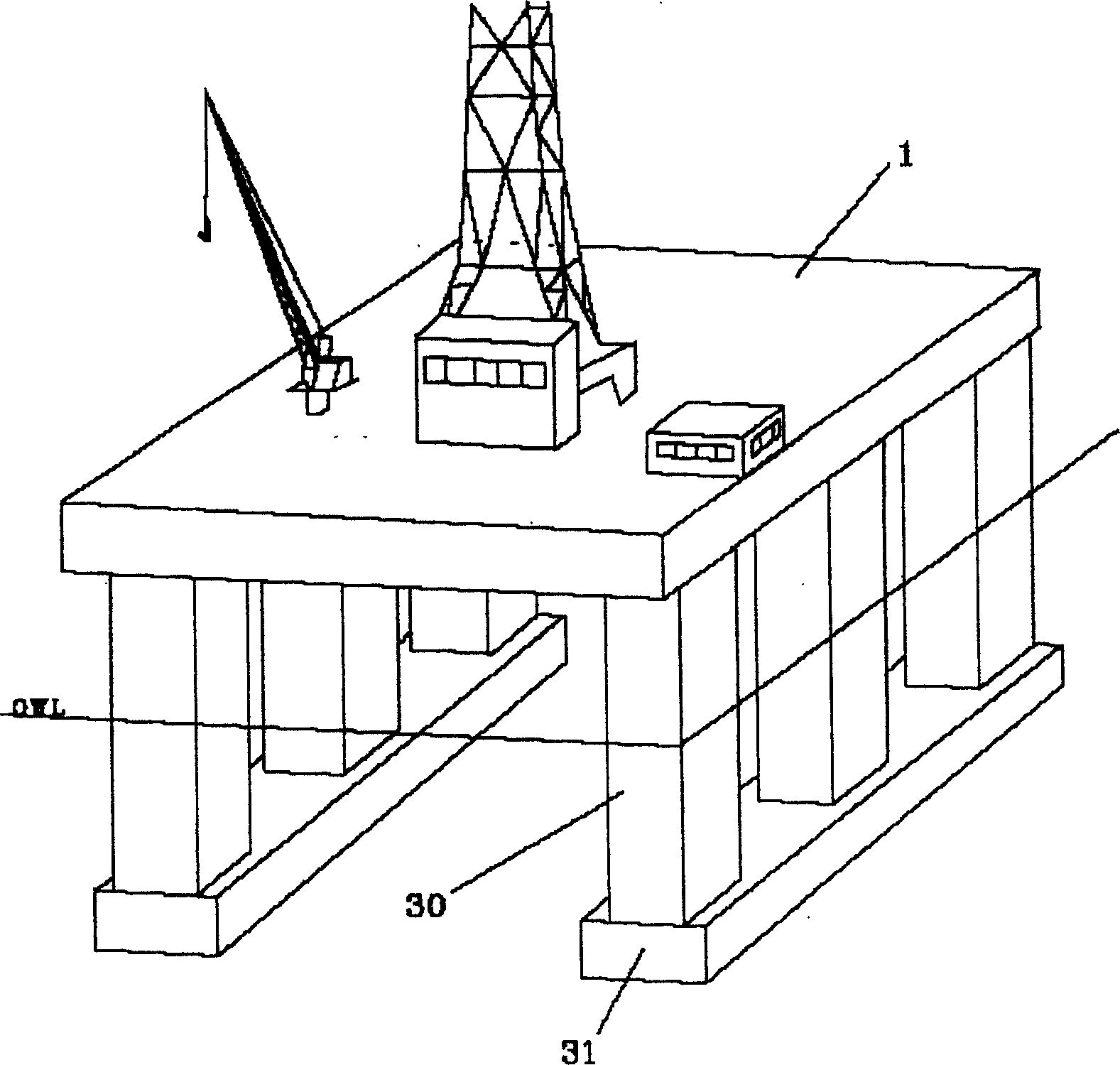

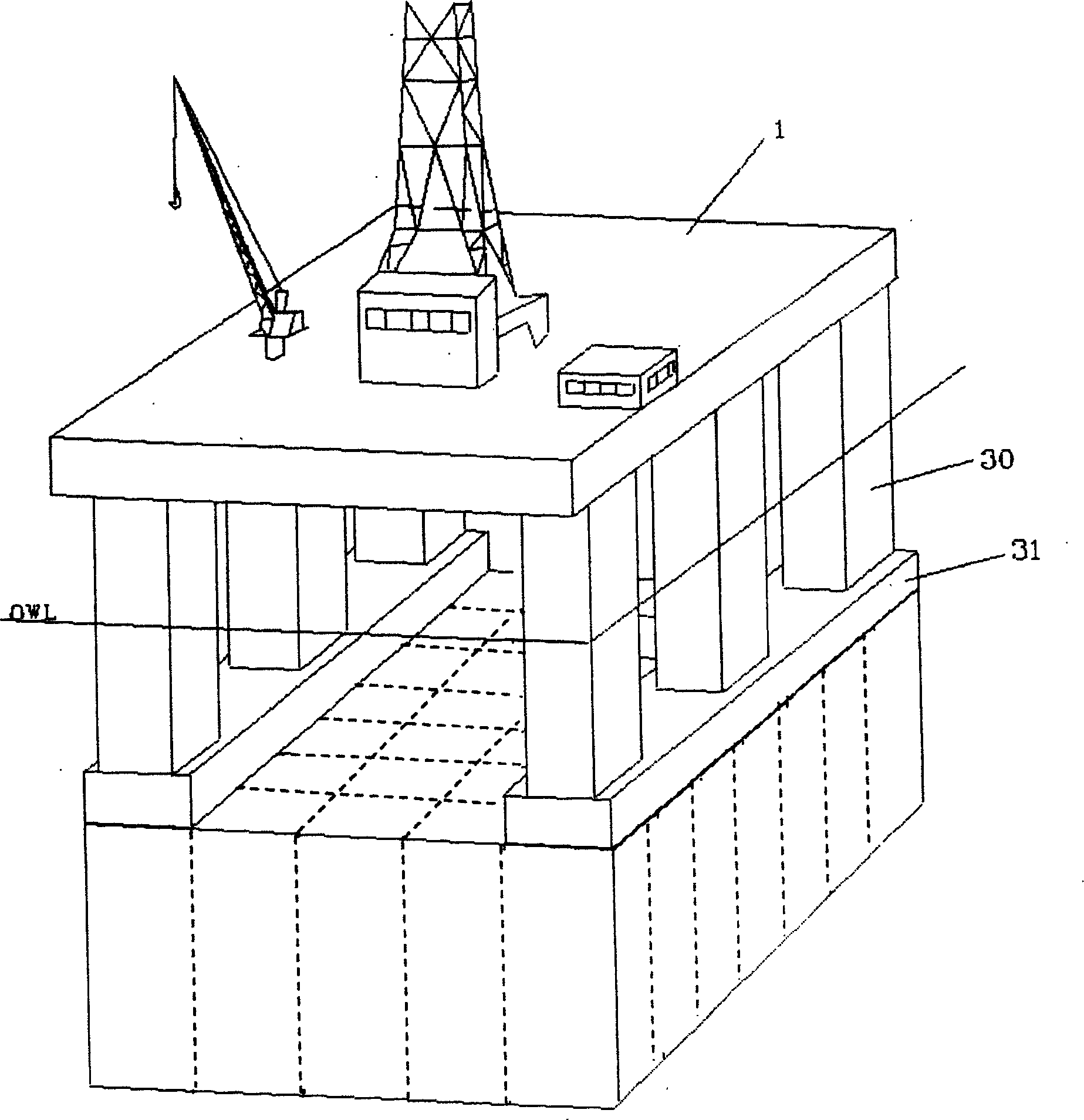

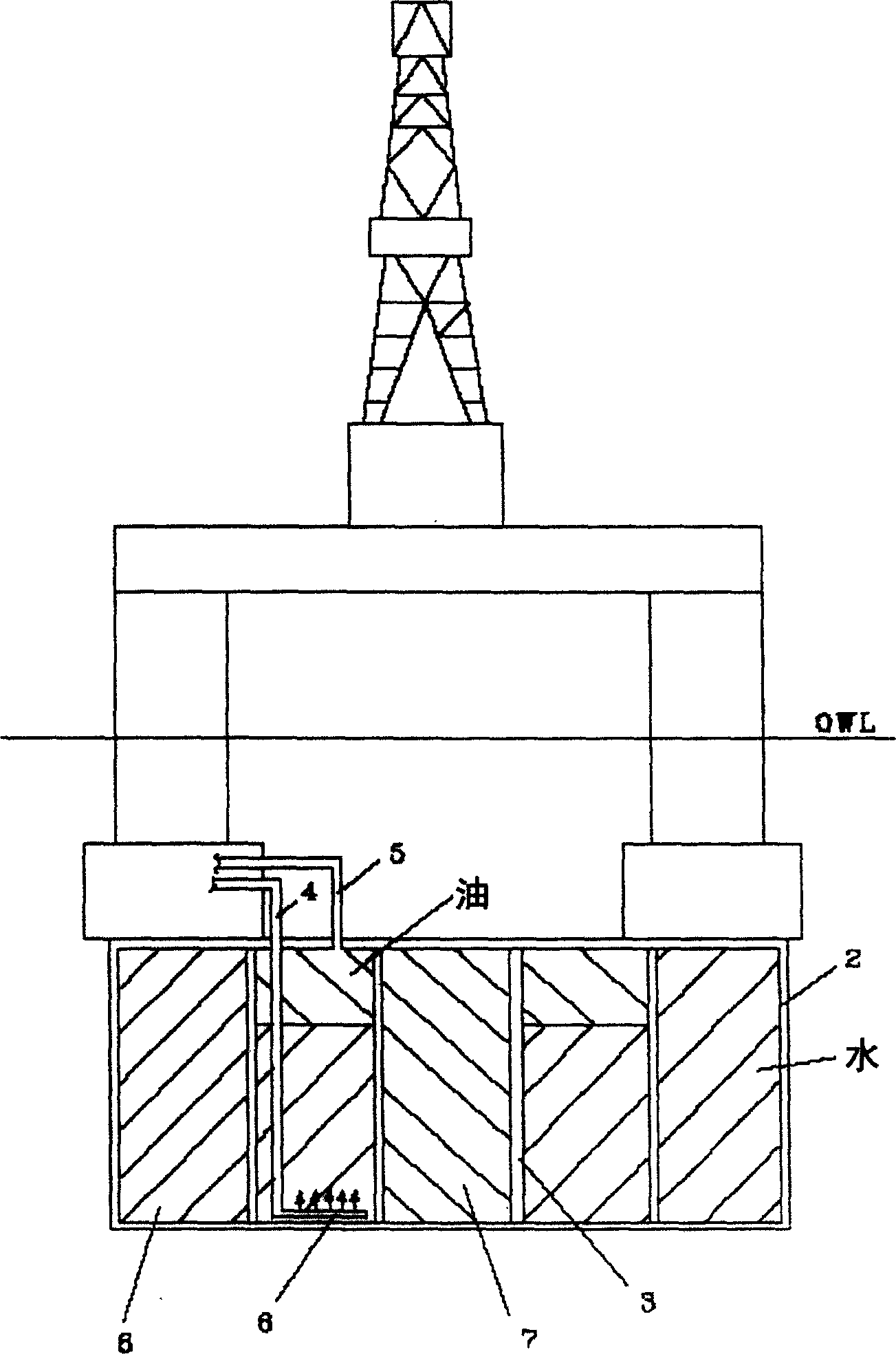

Floating semi-submersible oil production and storage arrangement

InactiveCN1646362AImprove anti-overturn performanceEasy maintenanceWaterborne vesselsFloating buildingsGravity centerOil production

An arrangement for the storage of marketable quantities of crude oil at a semi-submersible floating production vessel. The storage is achieved by hanging a segmented reinforced concrete tank (2) to the underside of the semi-submersible vessel. The semi-submersible vessel can be an existing semi-submersible drilling rig. By maintaining the mass of the tank and contents slightly greater than the displacement of the tank and by arranging the centre of gravity of the tank below its centre of buoyancy, the metacentric height of the semi-submersible vessel is approved. The storage arrangement for the oil provides the necessary maintenance of mass by either storing approximately 4 / 5 of the oil in oil-over-water chambers and approximately 1 / 5 in gas-over-oil chambers or by using a gas-over-oil-over-water arrangement in all the chambers. The piping arrangements minimize the free surface of liquids in the tank. The design ensures the internal pressure in the tank can be less than the external pressure which minimizes required reinforcement. The design provides a net positive suction head to oil export pumps located above the storage tank in a location which allows easy maintenance. The design allows all pumps, valves and instrumentation necessary for handling ballast water to be maintained within the hull of the semi-submersible where they can be easily maintained. The design allows all the valves, pumps and instrumentation necessary for handling oil to be in locations where they can be easily maintained.

Owner:PS COMTEK LTD

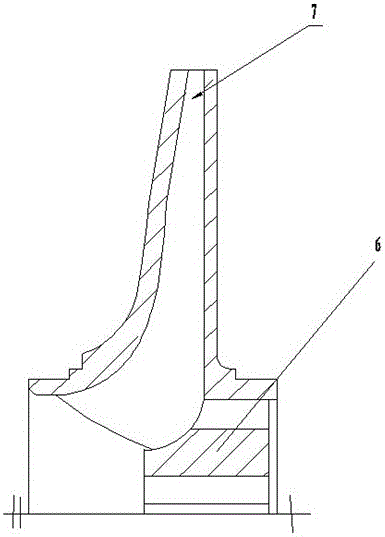

Top-level impeller on condensate extraction pump for nuclear power station

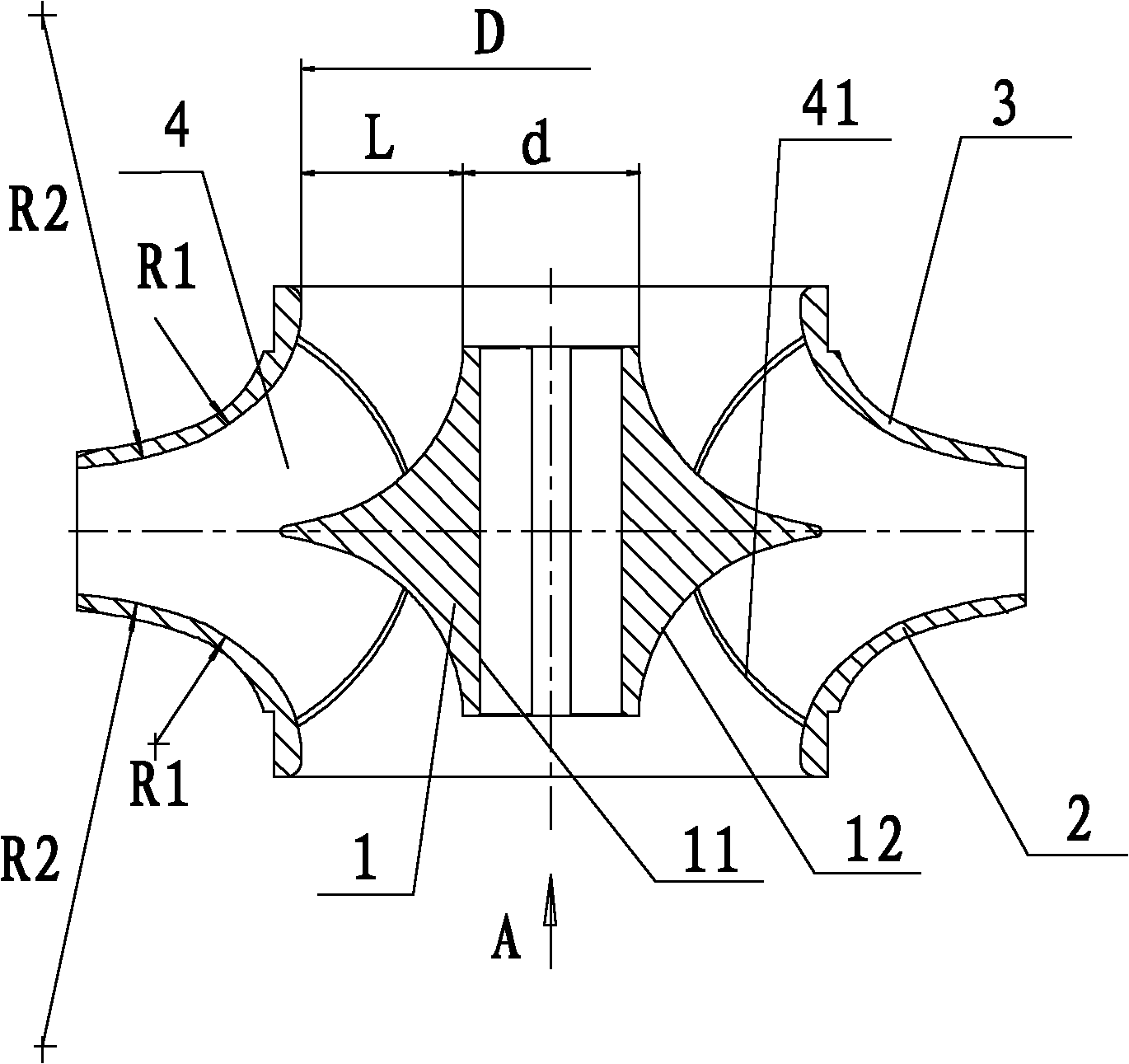

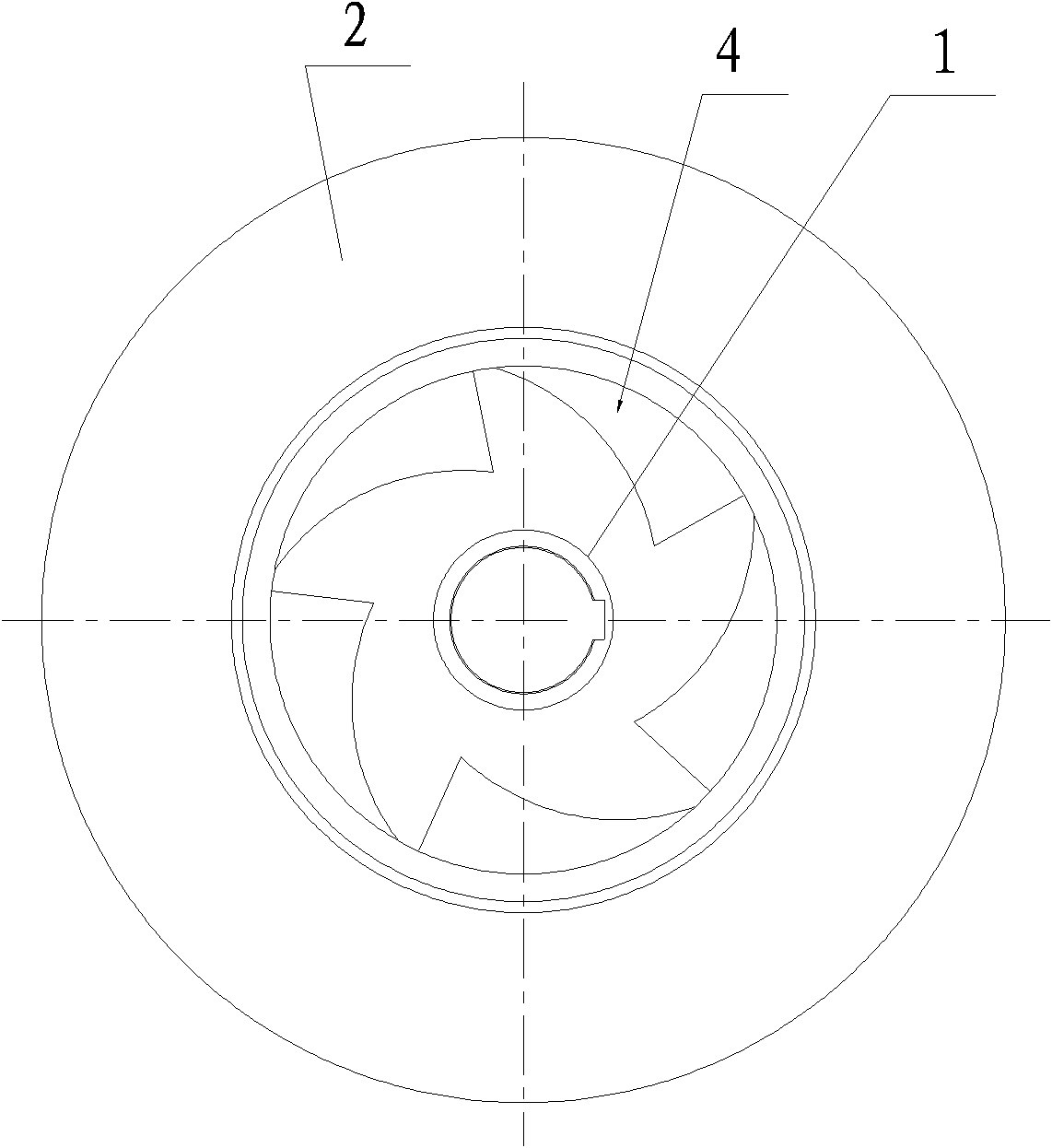

InactiveCN102116311AReduce NPSHImprove anti-cavitation performancePump componentsPumpsImpellerCavitation

The invention discloses a top-level impeller on a condensate extraction pump for a nuclear power station, which comprises a hub, a front cover plate, a rear cover plate and a plurality of blades, wherein the inner end surface of the hub is a cylindrical surface, and the outer end surface of the hub is formed by connecting two sections of trumpet-shaped curved surfaces which are in the same shape and have the same size back to back; the front cover plate and the rear cover plate are trumpet-shaped curved plates which are in the same shape and have the same size; the inner end surface of the front cover plate and the rear cover plate are formed by sequentially connecting a small section of straight surface, a section of first curved surface of which the curvature radius is R1 and a second curved surface of which the curvature radius is R2; the R2 is more than R1; the front cover plate and the rear cover plate are coaxially arranged at the periphery of the hub back to back to ensure that the inlet diameter and the outlet diameter of the top-level impeller are the same as each other; the front edge and the rear edge of each blade are connected on the inner end surfaces of the front cover plate and the rear cover plate respectively; and a V-shaped inner edge formed in the middle of each blade is connected on the outer end surface of the hub to form a double-suction impeller. The top-level impeller can reduce necessary net positive suction head of a small pump and has higher cavitation resistance.

Owner:SHANGHAI APOLLO MACHINERY

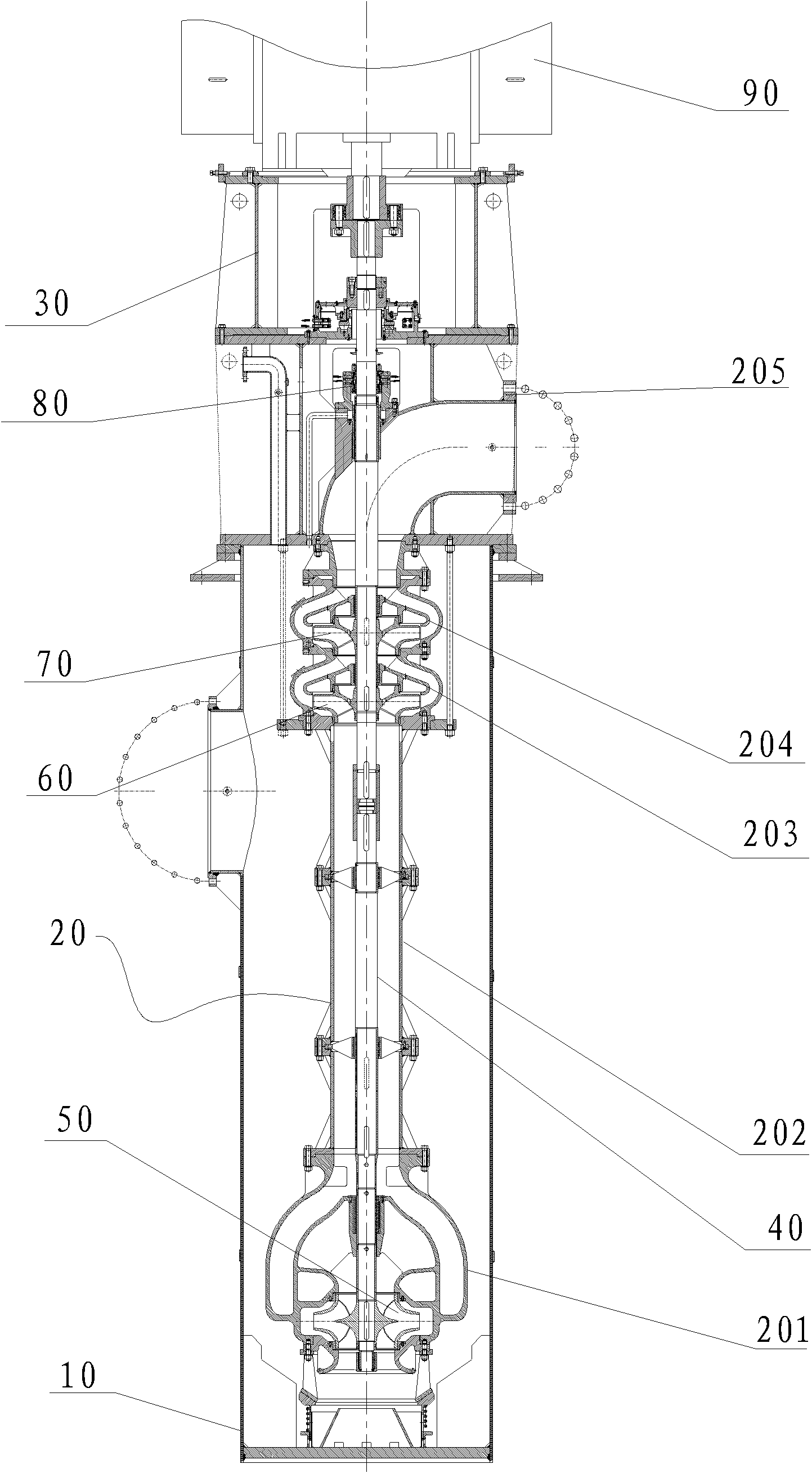

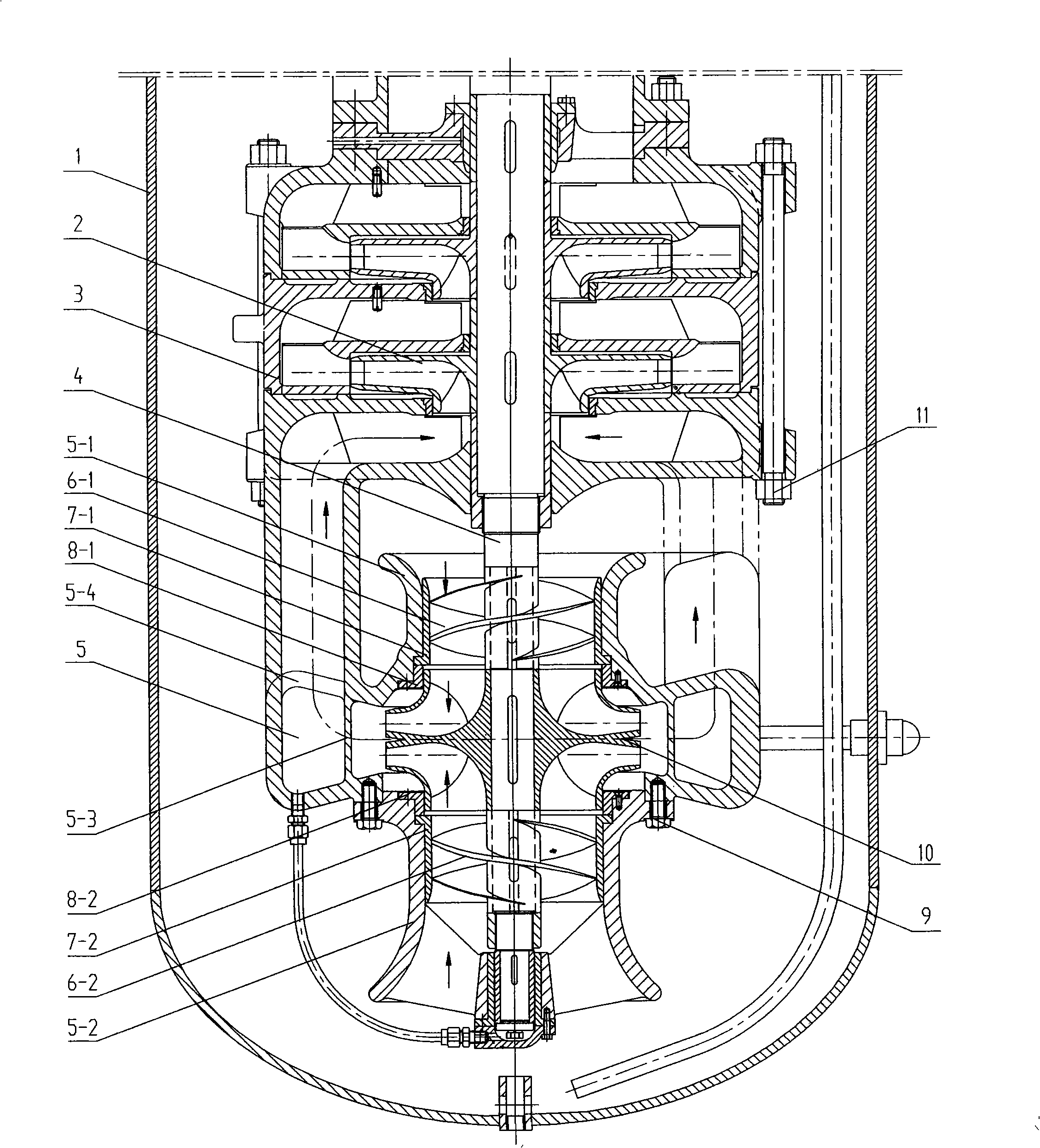

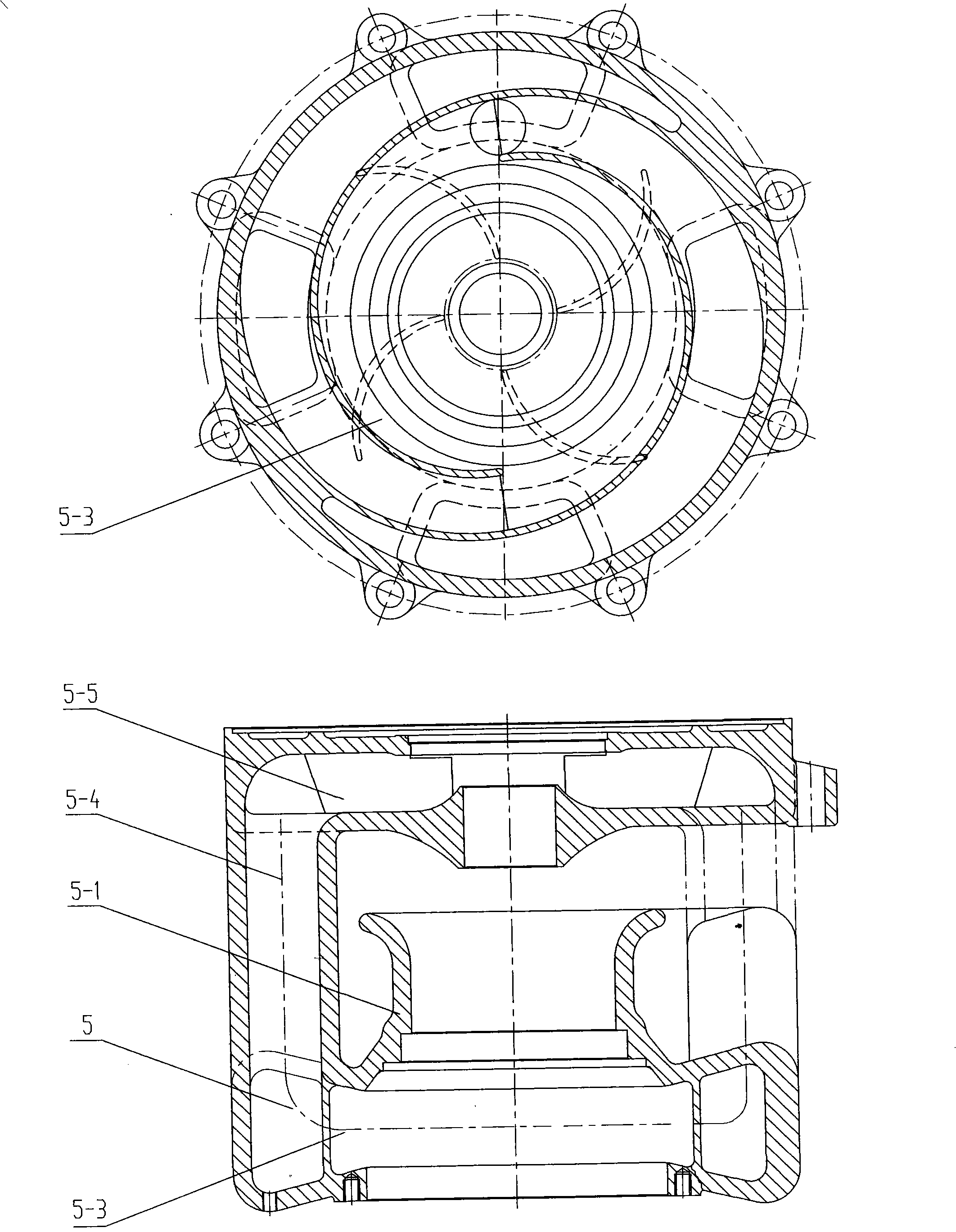

Vertical type multilevel barrel bag pump

InactiveCN101303027AReduce the overall heightReduce volumePump componentsRadial flow pumpsImpellerCavitation

The invention discloses a vertical multi-level barrel pump which is characterized in that a first level absorption section of the barrel pump adopts a dual absorption impeller and a first level pump body matched with the dual absorption impeller and provided with a dual channel and a radial volute shell; the rotating shafts above and under the dual absorption impeller are respectively provided with a preposed inducer and an absorption guide pipe matched with the preposed inducer so as to realize the dual absorption of pumped fluid. Under the condition that the flow is limited, the value r of net positive suction head (NPSH) can be reduced by more than 1.5m, namely the cavitation corrosion performance is remarkably improved, thereby not only reducing the height and volume of the barrel and the manufacturing cost, but also improving the efficiency and the operation reliability of the pump and bringing convenience for the installation and the maintenance of the pump.

Owner:ZHEJIANG PUMP GENERAL WORKS

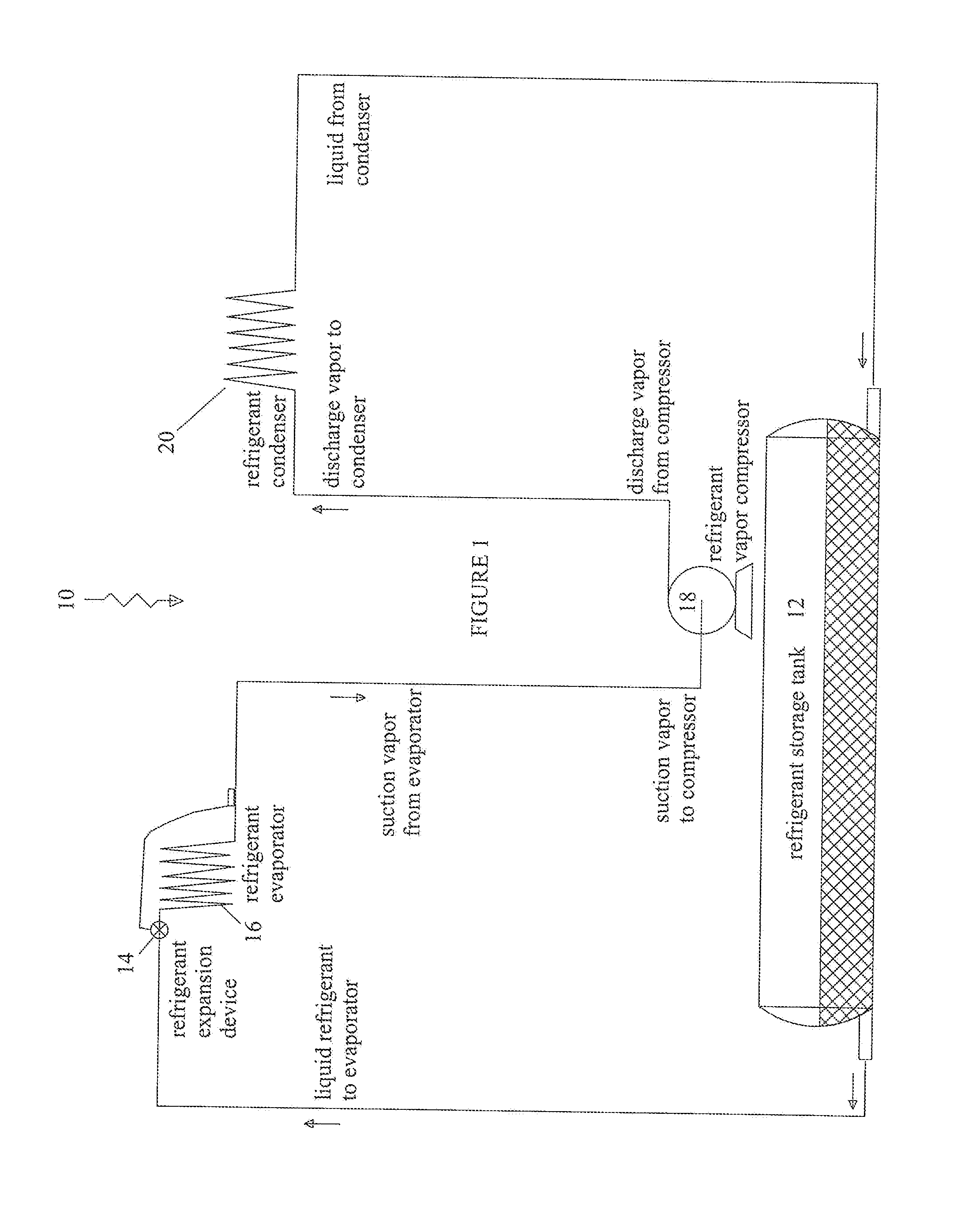

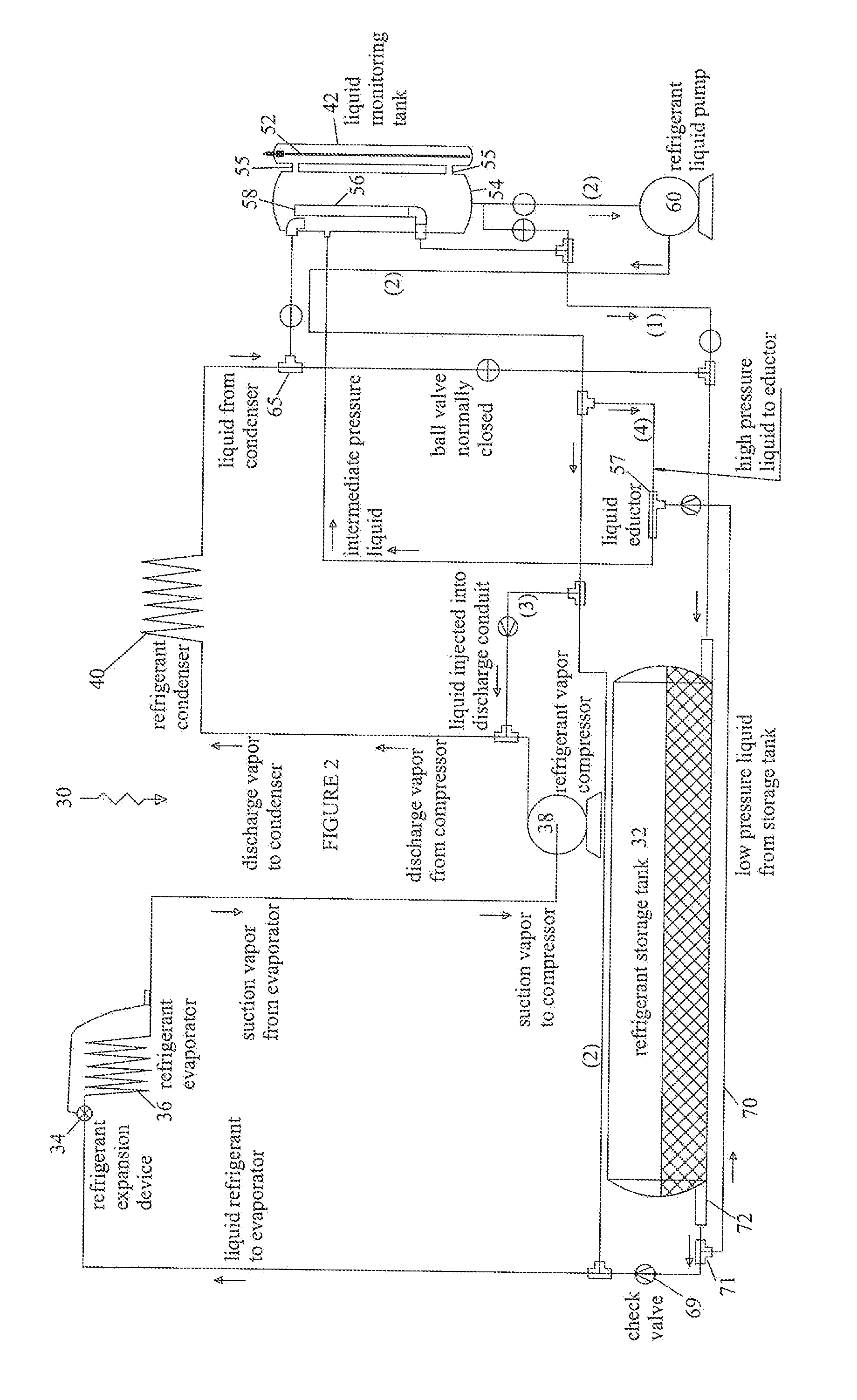

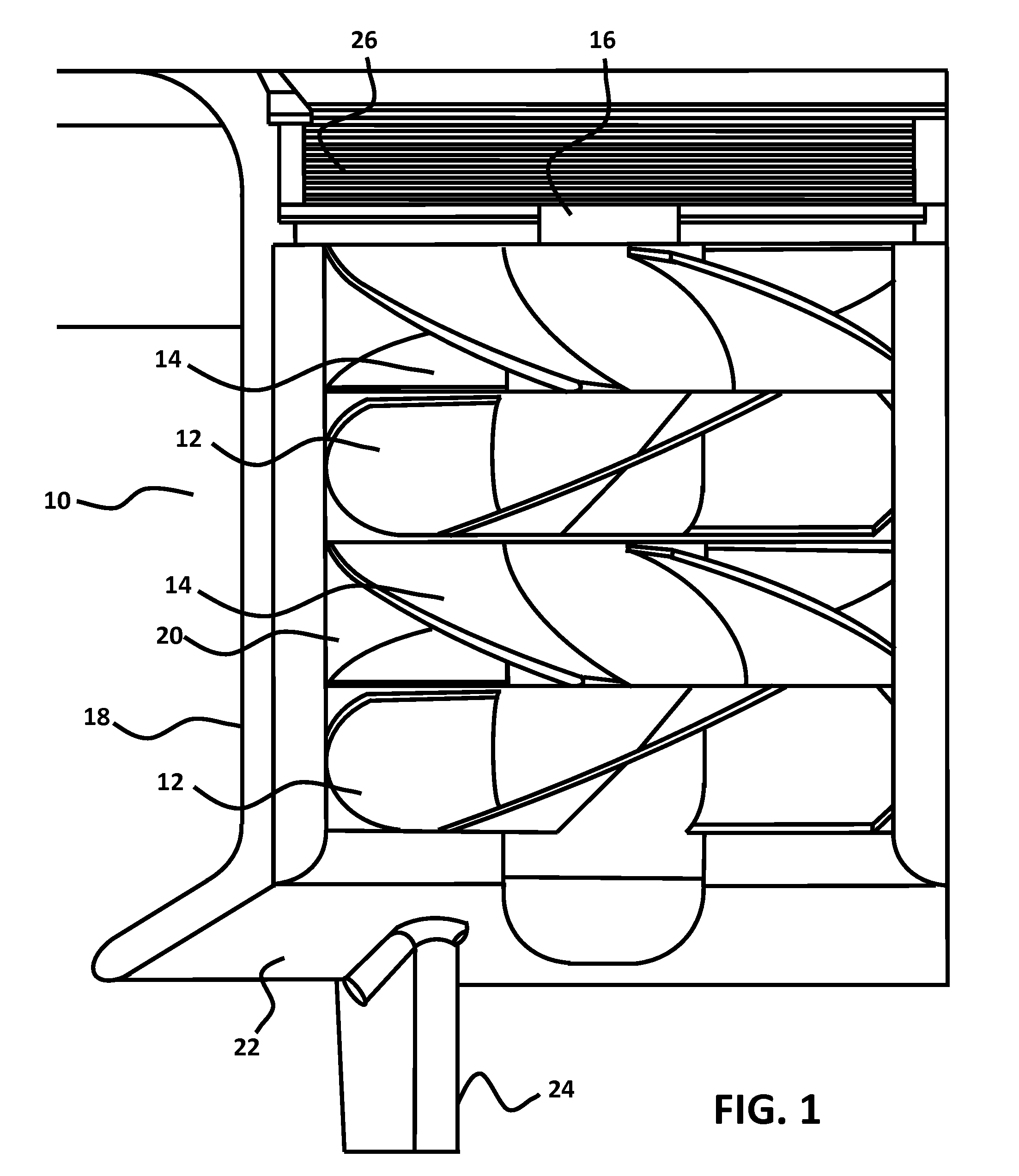

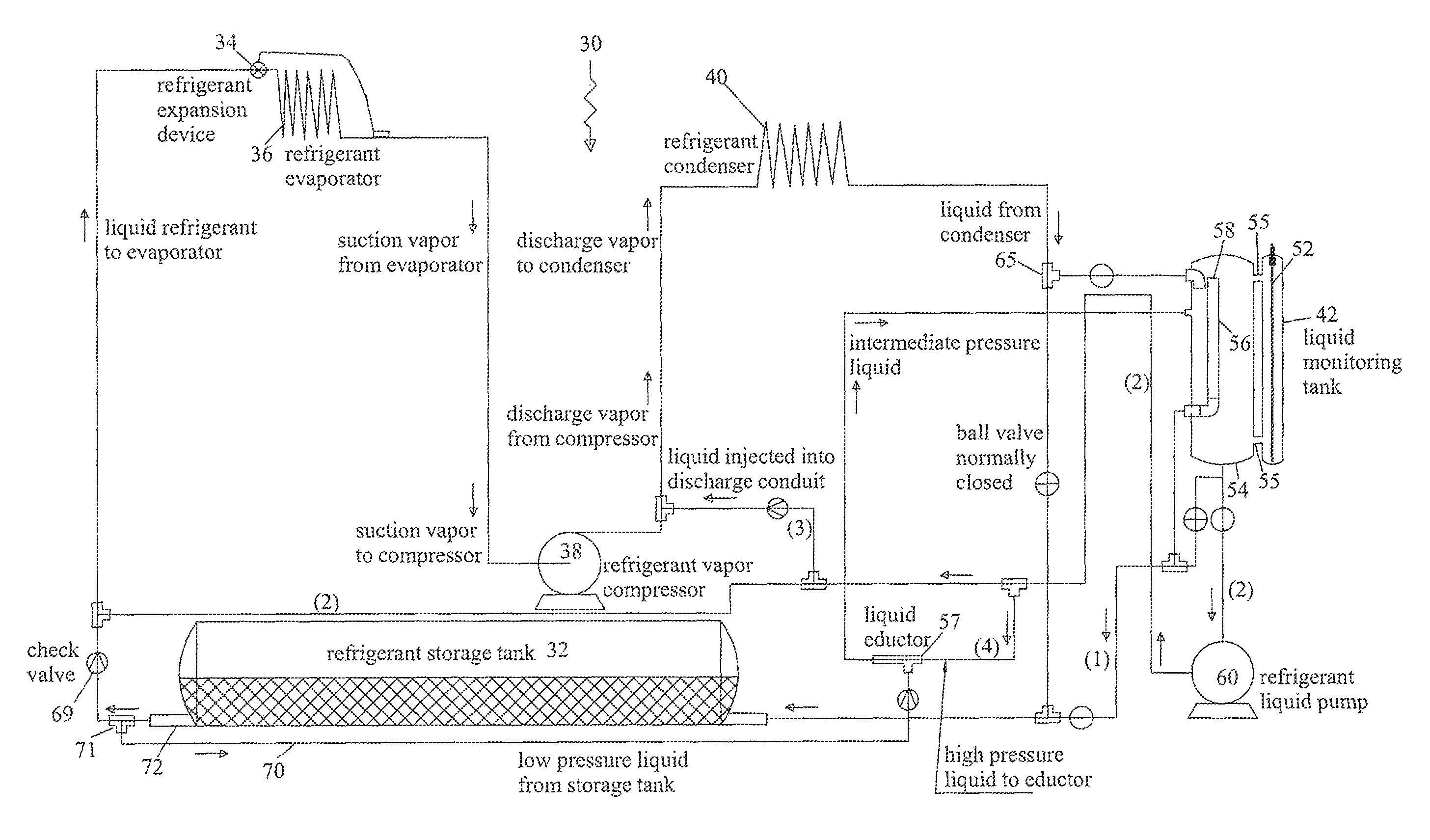

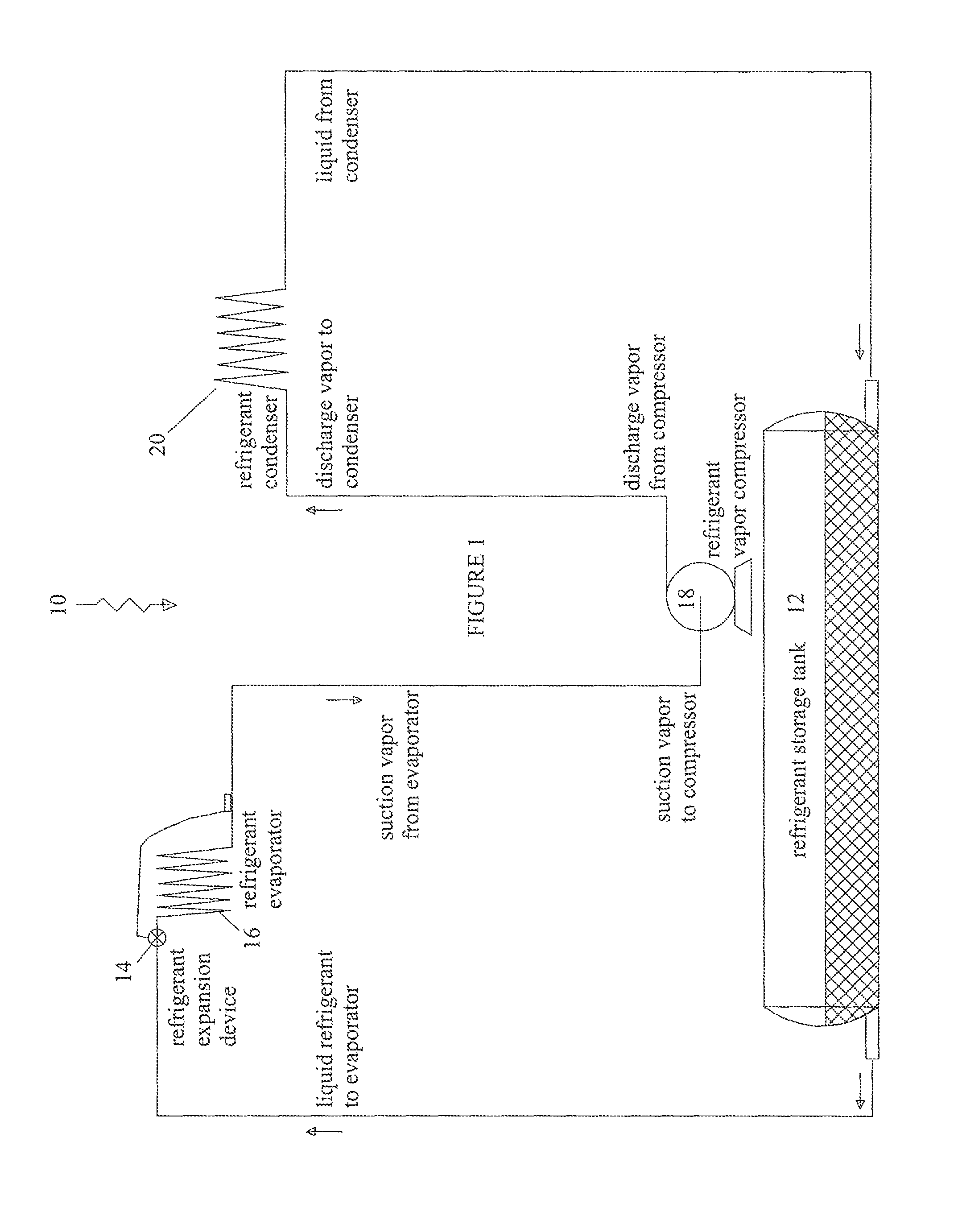

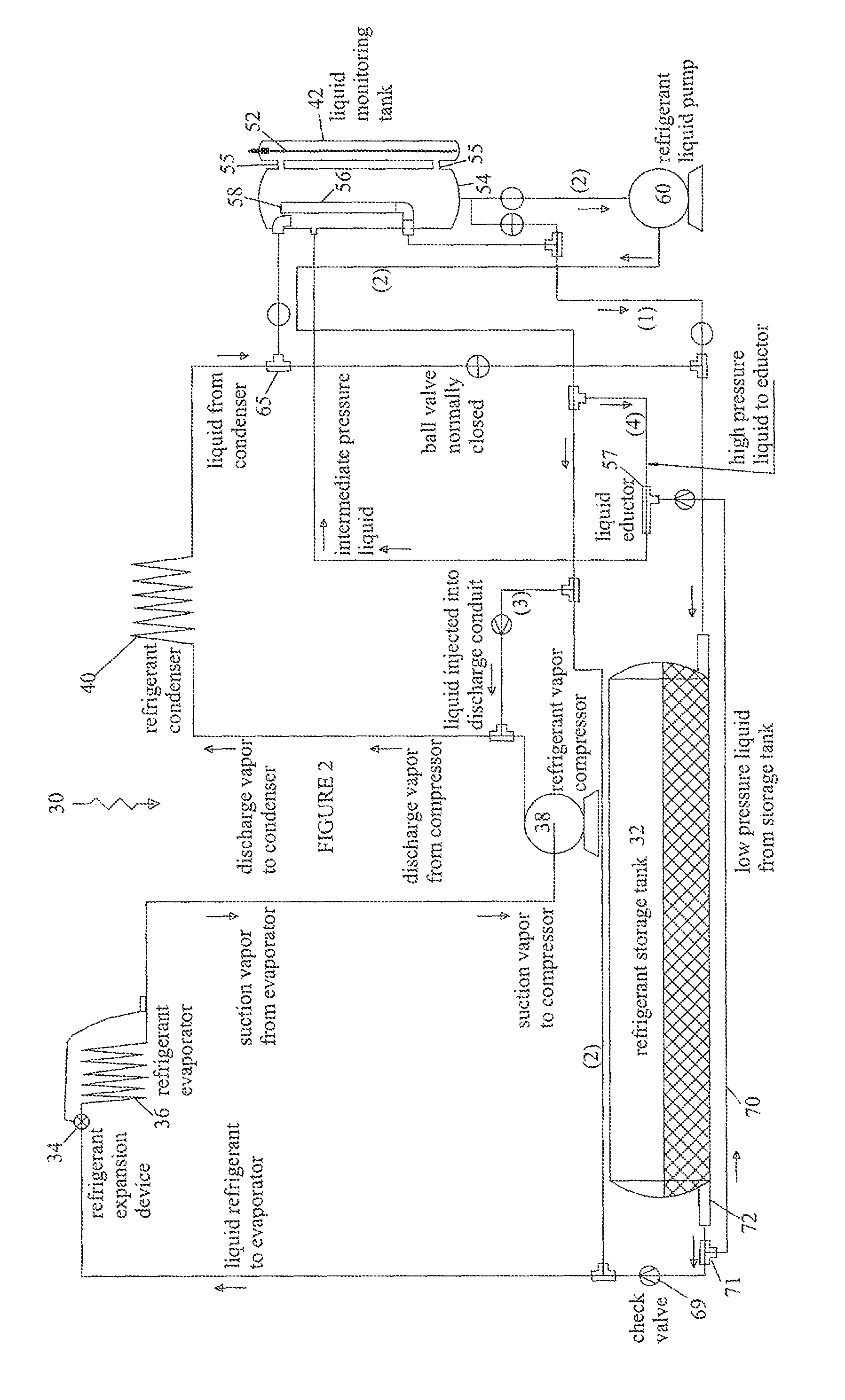

Apparatus for Improving Refrigeration Capacity

ActiveUS20140047855A1Improve efficiencyMaximize capacityFluid circulation arrangementThermometer applicationsEngineeringAir conditioning

A refrigeration, air conditioning or other cooling system is disclosed. The refrigeration system includes a refrigerant storage tank fluidly connected to a refrigerant expansion device which is fluidly connected to a refrigerant evaporator for absorbing ambient heat, a refrigerant vapor compressor fluidly connected to the refrigerant evaporator and a refrigerant condenser fluidly connected to the refrigerant compressor and the refrigerant storage tank. A liquid refrigerant pump and eductor are included in the system along with a refrigerant receiving tank and associated controls that maintain the appropriate Net Positive Suction Head at the inlet to the pump along with proper flow and pressure control in the system.

Owner:KOLARICH ROBERT

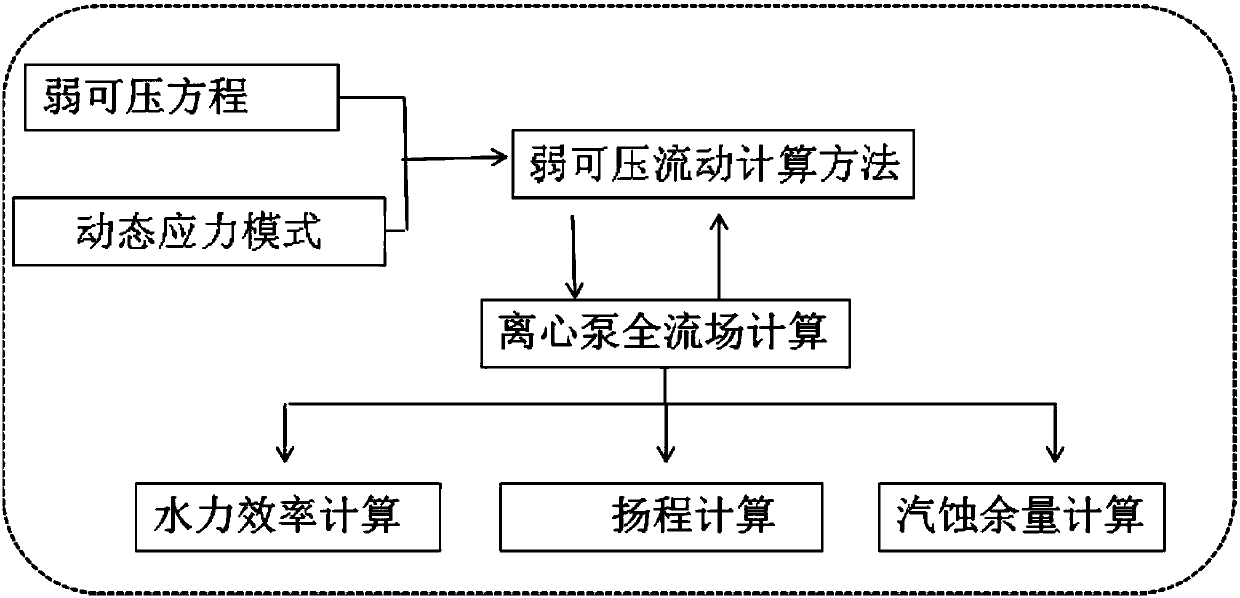

High-power centrifugal pump hydraulic performance prediction method based on weak compressible flow analysis

ActiveCN108506223AAccurate Numerical PredictionFeasible ideasPump componentsDesign optimisation/simulationHelicity basisEngineering

The invention provides a high-power centrifugal pump hydraulic performance prediction method based on weak compressible flow analysis. The method comprises the following steps that (1) a new sub-gridstress model is determined; (2) numerical calculation of a total flow field in a pump is carried out to obtain basic data of hydraulic performance prediction; and (3) the lift, the hydraulic efficiency and the net positive suction head are calculated according to the basic data of hydraulic performance prediction. According to the method, for the inner flow characteristic of a high-power highs-speed flow centrifugal pump and the defects of a dynamic sub-grid stress mode, the dynamic sub-grid mode with helicity constraints is constructed, the numerical simulation method of an in-pump weak compressible high-rotating-speed flow field is set up, and accurate numerical prediction of the hydraulic performance of the centrifugal pump is achieved.

Owner:ZHEJIANG SCI-TECH UNIV

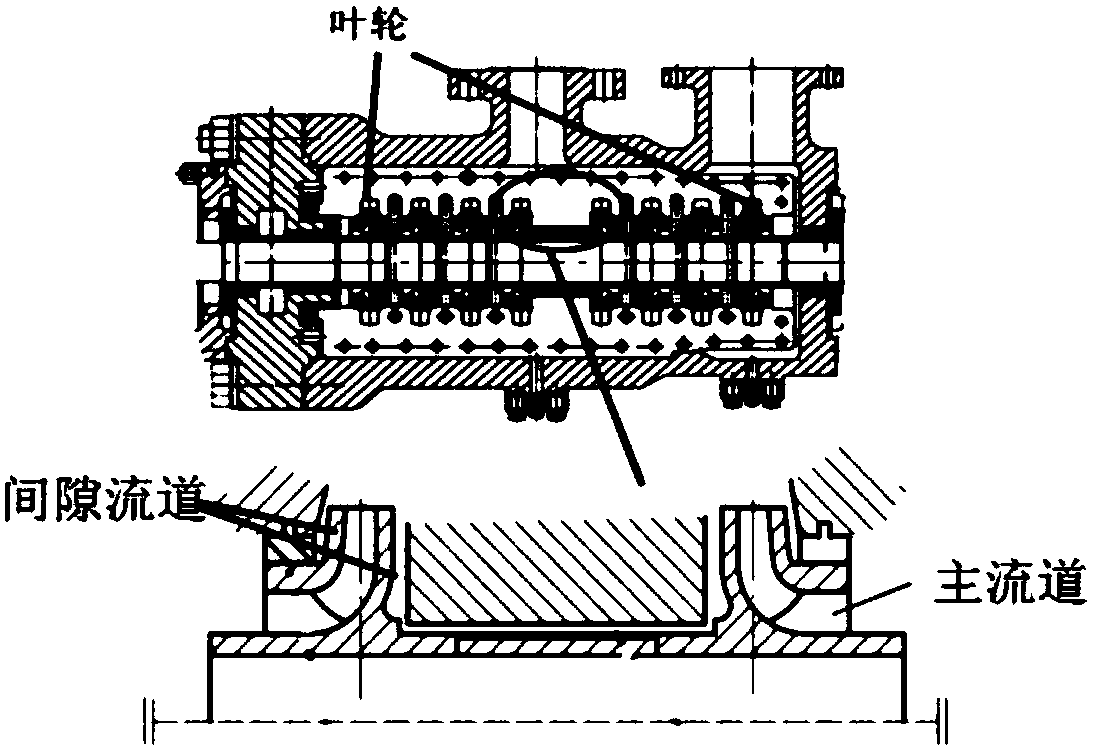

Optimal design method for inducer with varying pitch of centrifugal pump

The invention discloses an optimal design method for an inducer with a varying pitch of a centrifugal pump, belonging to the technical field of pumps. The optimal design method is characterized by comprising the following steps: when designing the inducer with the varying pitch, firstly, determining data such as flow of a peak efficiency point of the central pump, a necessary net positive suction head, a device net positive suction head and the like through experiments, and then determining geometric sizes of diameters of an inlet and an outlet of a rim of the inducer and a rim folding lead according to the experimental data and a flow condition of the inlet of a main impeller of the pump. According to the optimal design method for the inducer with the varying pitch of the centrifugal pump provided by the invention, the inducer and the main impeller of the pump have good energy matching relationship, the performance of the inducer is improved, the operation stability of the system is enhanced, difficulty in selection of a lift coefficient of the inducer according to experience is avoided, and the efficiency for designing the inducer is improved. The optimal design method has a certain popularization value.

Owner:JIANGSU UNIV

Device and method for pumping a cryogenic fluid

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

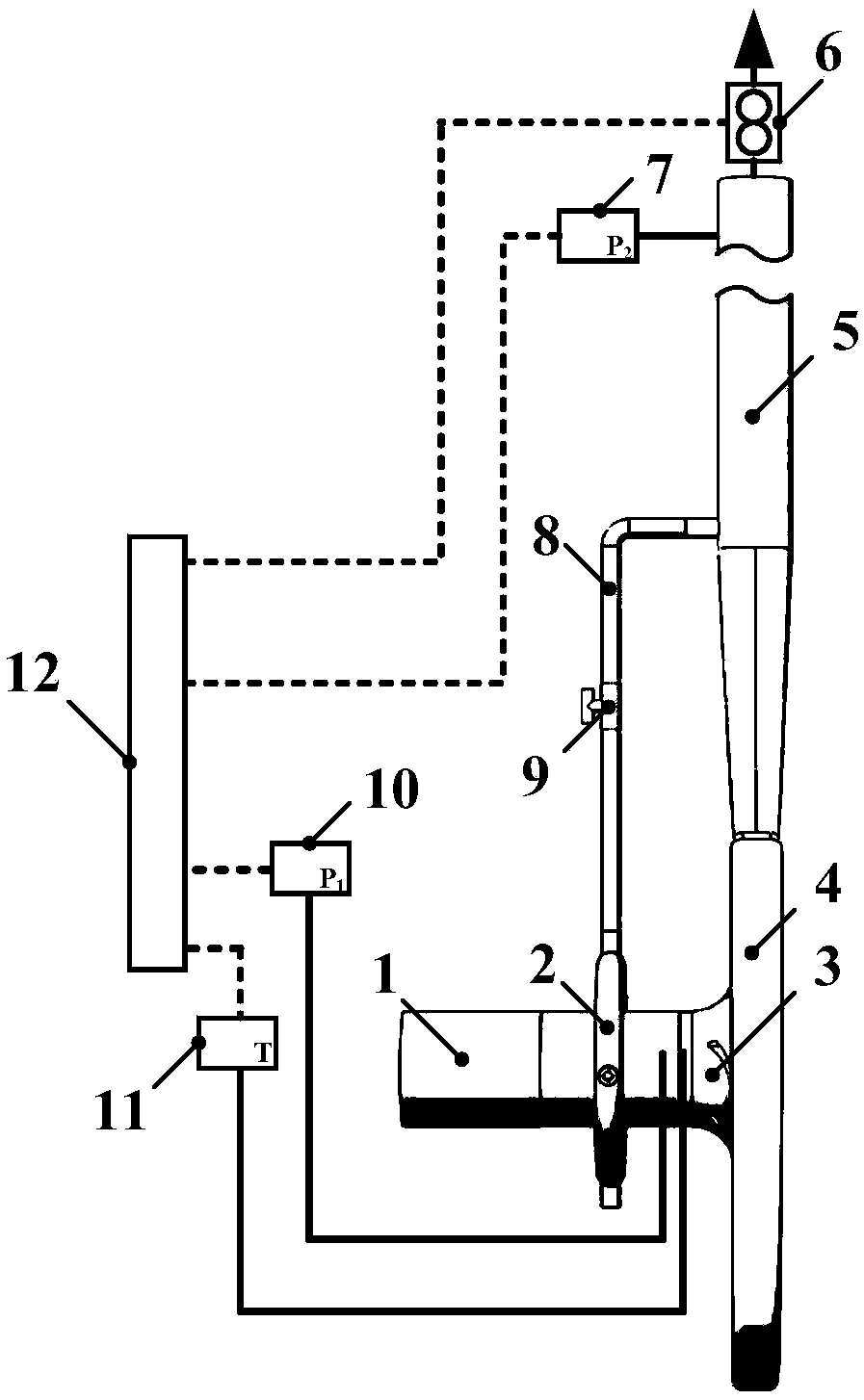

Device for solving pump cavitation of ORC power generating system by use of booster pump and use method of device

ActiveCN107061370ASolve the problem of cavitationAvoid restrictionsPump componentsEngine controlThermodynamicsLiquid storage tank

The invention relates to a device for solving pump cavitation of an ORC power generating system by use of a booster pump and a use method of the device. The device comprises a working medium fluid reservoir, the booster pump and a working medium pump, wherein the working medium fluid reservoir is in pipeline connection with a system working medium side inlet; the working medium fluid reservoir is also sequentially connected with the booster pump and the working medium pump through a pipeline; and the working medium pump is connected with a system working medium side outlet through a pipeline, a set of temperature detection unit and a set of pressure detection unit are arranged on the pipeline between the booster pump and the working medium pump, and a set of flow detection unit is arranged on the pipeline between the working medium pump and the system working medium side outlet. The frequency of the booster pump is adjusted to change the working medium pressure at the inlet of the working medium pump to realize control of the effective net positive suction head available (NPSHa); and owing to rise of the working medium pressure at the inlet of the working medium pump, rise of the NPSHa is guaranteed, the problem of cavitation of the pumps is solved, and limitation on space transformation is avoided.

Owner:GRAND NEW POWER

Automatic adjusting device and method for inhibiting cavitation of centrifugal pump

ActiveCN109681474AHigh trafficImprovement of cavitation statePump componentsPump controlCavitationInlet pressure

The invention discloses an automatic adjusting device and method for inhibiting cavitation of a centrifugal pump. The cavitation state of the centrifugal pump is judged in real time by monitoring theflow, the inlet and outlet pressure and the inlet temperature of the centrifugal pump in real time, a control unit calculates the device net positive suction head NPSHa and the required net positive suction head NPSHr through the temperature and the inlet pressure, and if NPSHa is smaller than or equal to NPSHr, an electric control valve is controlled to be continuously opened and stops acting till NPSHa is larger than NPSHr. High-pressure fluid is guided to a centrifugal pump inlet on a centrifugal pump outlet pipe according to the requirement, automatic adjustment can be achieved through theelectric control valve arranged on a liquid supplementing pipe, and the effects of increasing the centrifugal pump inlet pressure and improving and inhibiting cavitation are achieved. According to the automatic adjusting device and method for inhibiting cavitation of the centrifugal pump, different working condition requirements can be effectively met for automatic adjustment and inhibition on cavitation, the stable running range of the centrifugal pump is greatly widened, the cavitation state of the centrifugal pump can be effectively improved, and the wide application value is achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

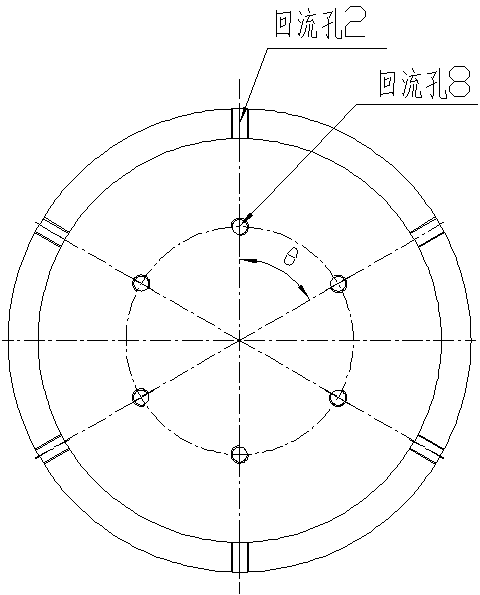

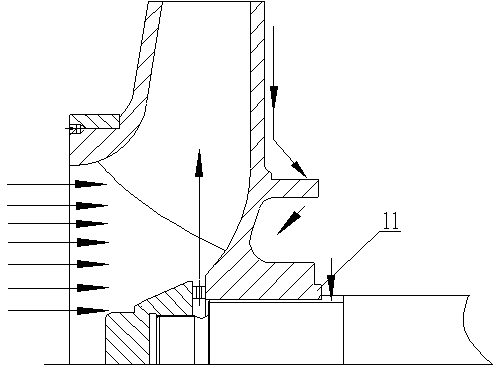

Flow backing device of nuclear power centrifugation type excess heat discharge pump

The invention discloses a flow backing device of a nuclear power centrifugation type excess heat discharge pump. By means of a mode of backflow formed by a flow backing hole (2) opened on a front cover (1), a flow backing hole (8) opened on a pump body (3) and a flow backing pipeline (9), the problem of flow turbulence at the position of an impeller inlet caused by the fact that a liquid flow backing direction and an impeller incoming flow direction are opposite due to traditional impeller equalizing orifices is solved, so that the efficiency of the pump is improved, the critical net positive suction head of the pump is reduced, conditions of pressure pulsation at the position of an impeller outlet can be effectively improved, and optimal effects of improving performances are achieved by changing the position, size and number of the opened flow backing holes.

Owner:JIANGSU UNIV

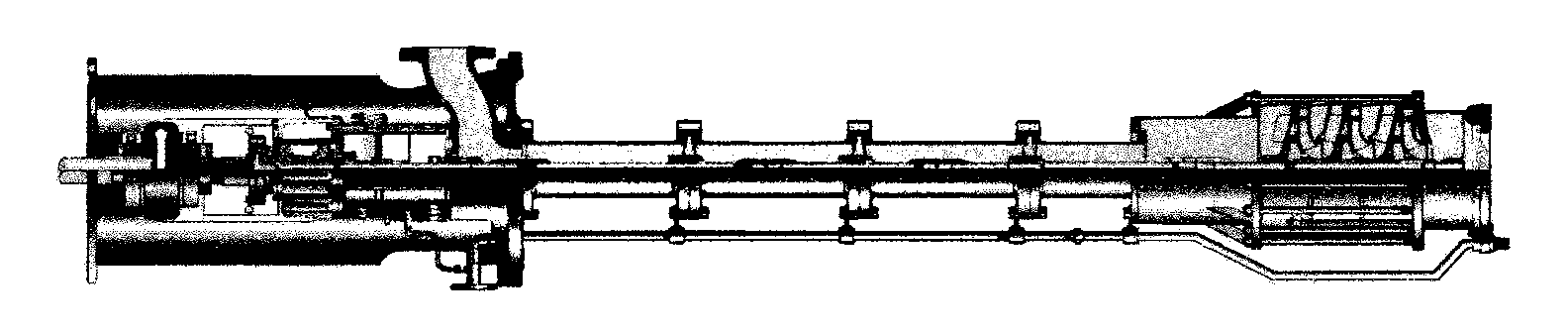

Low-temperature deep-well pump

The development trend of a marine low-temperature deep-well pump is that the marine low-temperature deep-well pump is reliable at low temperature, necessary net positive suction head is low, efficient and energy-saving effects are achieved, and maintaining is convenient. According to the current status and the development trend, the structural design is broken through for the SCW low-temperature deep-well pump, a high-pressure self-tightening structure design is adopted, and magnetic suspension bearings are adopted. New material, such as high polymer material, is used so that the characteristics of safety, reliability, corrosion and leakage resistance and vibration and noise reduction of the marine low-temperature deep-well pump can be enhanced. In detail, a multi-stage impeller structure is adopted for achieving high lift, a mature inclined outlet deep-well pump hydraulic model is adopted, and a pump inlet is matched with an inducer, so that an expected hydraulic performance is achieved; a stainless steel casting, a stainless steel shaft, a PTFE sealing element, a graphite sliding bearing and other materials are used for being adaptive to the low-temperature environment below 104 DEG C; a mechanical seal cavity is matched with a booster, meanwhile, the gas pressure reduction effect of an upper sliding bearing is used so that it can be guaranteed that pumped liquid does not leak outwards in the high-pressure operation process of the pump, and safety can be guaranteed; a shutdown seal design is adopted so that the pumped liquid can not leak outward in the maintaining process of the pump, and then environment safety can be guaranteed. Pipe segmenting, pipe flange connection and shaft hard coupler connection are used for reaching the 5 m-22 m depth below the liquid.

Owner:TIANJIN SHICANG IND EQUIP

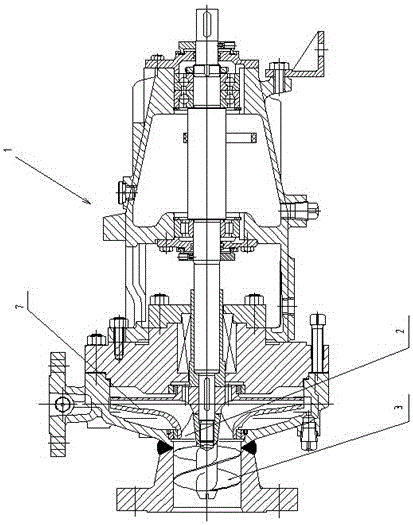

Magnetism forle pump of low cavitation belt variable pitch preposition wheel

InactiveCN101666318AImprove cavitation performanceExtended service lifePump componentsPump installationsCavitationEngineering

The invention relates to a magnetism forle pump of a low cavitation belt variable pitch preposition wheel, mainly solving the problems that the net positive suction head (NPSH) of the existing magnetism forle pump is a little higher, the cavitation resistance is poor, and the occasion requirements on conveying vaporizable medium and plural low entrance pressure in fields of petrifaction, refrigeration and the like cannot be satisfied. The invention is characterized in that: the entrance of a pump body (1) is provided with a variable pitch preposition wheel connected to a pump spindle (3), a bearing body (4) and the pump body (1) are respectively provided with a liquid flow inner circulating system and a liquid flow outer circulating system. The magnetism forle pump of the low cavitation belt variable pitch preposition wheel, in virtue of the reasonable cooperation between the reposition wheel and the liquid flow inner circulating system and the liquid flow outer circulating system, reduces the NPSH of the pump, effectively improves cavitation resistance of the pump, features high reliability and long service life, and can satisfy the use in special occasions of requiring low entrance pressure and conveying all the vaporizable mediums in fields of petrifaction, refrigeration and the like.

Owner:浙江腾宇泵阀设备有限公司

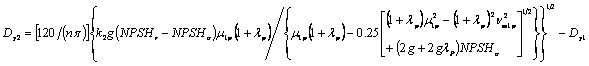

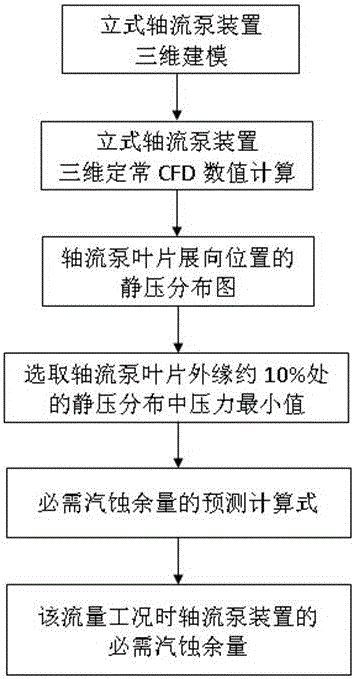

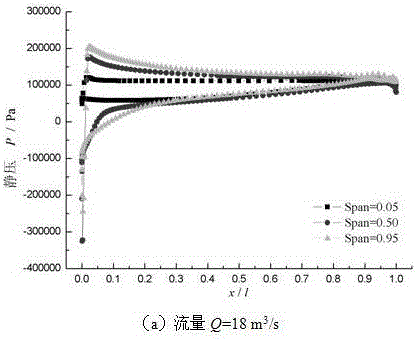

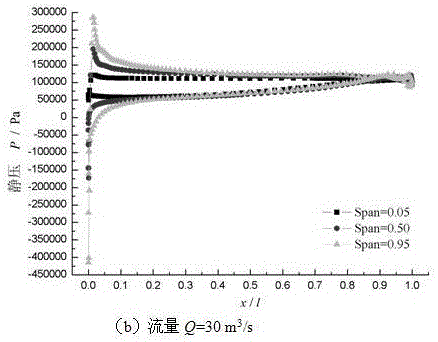

Method for predicting necessary net positive suction head of axial flow pump based on pump unit

ActiveCN106383970ASafe and stable operationSpeed up the progress of the projectDesign optimisation/simulationSpecial data processing applicationsAxial-flow pumpCavitation

The invention provides a method for predicting a necessary net positive suction head of an axial flow pump based on a pump unit, and belongs to the technical field of pumping station projects. Based on the calculation of a three-dimensional steady numerical value of an axial flow pump device, a numerical solution method is adopted to predict the necessary net positive suction head of the axial flow pump of the pump unit under multiple working conditions; the method is simple and convenient, the cost is low, the time-consuming is short, and the necessary net positive suction head of an axial flow pump station under any working condition can be predicted, so that the accidental working condition that the physical model test is not measured or the pump station is running can be made up. The method for predicting the necessary net positive suction head of the axial flow pump based on the pump unit provided by the invention helps to compare the cavitation performance of the axial flow pump device under different hydraulic models, helps to the safe and stable operation of an actual pumping station, avoids cavitation of the axial flow pump station, and achieves the purpose of ensuring the safe and stable operation of the axial flow pump.

Owner:YANGZHOU UNIV

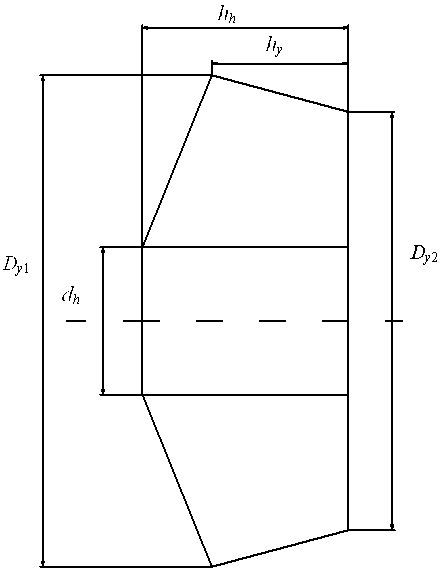

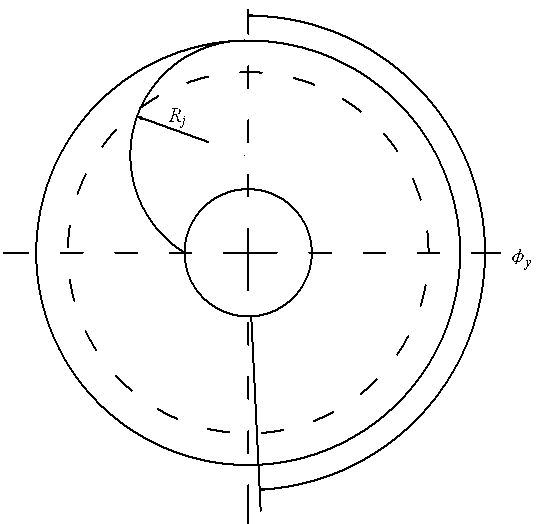

Design method of axial flow type low-lift prepositioned inducer

ActiveCN104047890AGood hydraulic efficiencyGuaranteed uptimePump componentsPumpsEngineeringSolid particle

The invention provides a design method of an axial flow type low-lift prepositioned inducer. The inducer is suitable centrifugal pump units with medium-low specific speed which are widely used in the fields such as petrochemical industry, smelting industry and power plants. The invention gives a design formula for the main geometric size parameters of the inducer, wherein the parameters are as follows: the outer edge diameter of the inducer is D, the middle diameter of the hub of the inducer is Dh, the inlet edge inclining angle of a blade is alpha, the outlet edge outer edge diameter of the inducer is Do, the inducer hub conical angle of the inducer is theta, the radius of a wing type work surface of a flow surface A is Rp, a wing type outlet placing angle is beta and a wing type cord length is l. The flow field distribution at the inlet of the centrifugal pump can be improved by the low-lift prepositioned inducer, the centrifugal pump is suitable for the medium occasions containing solid particles, and the operation stability and suction performance of an impeller of the centrifugal pump are effectively improved under the condition of a low net positive suction head of the device.

Owner:江苏双达泵业股份有限公司

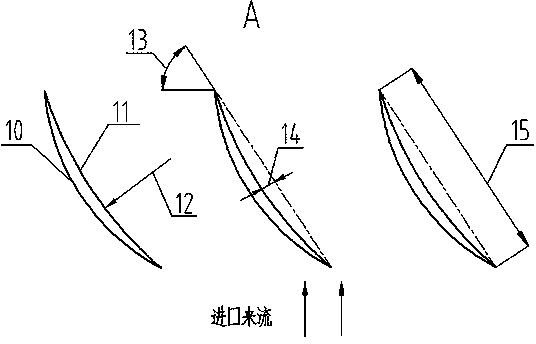

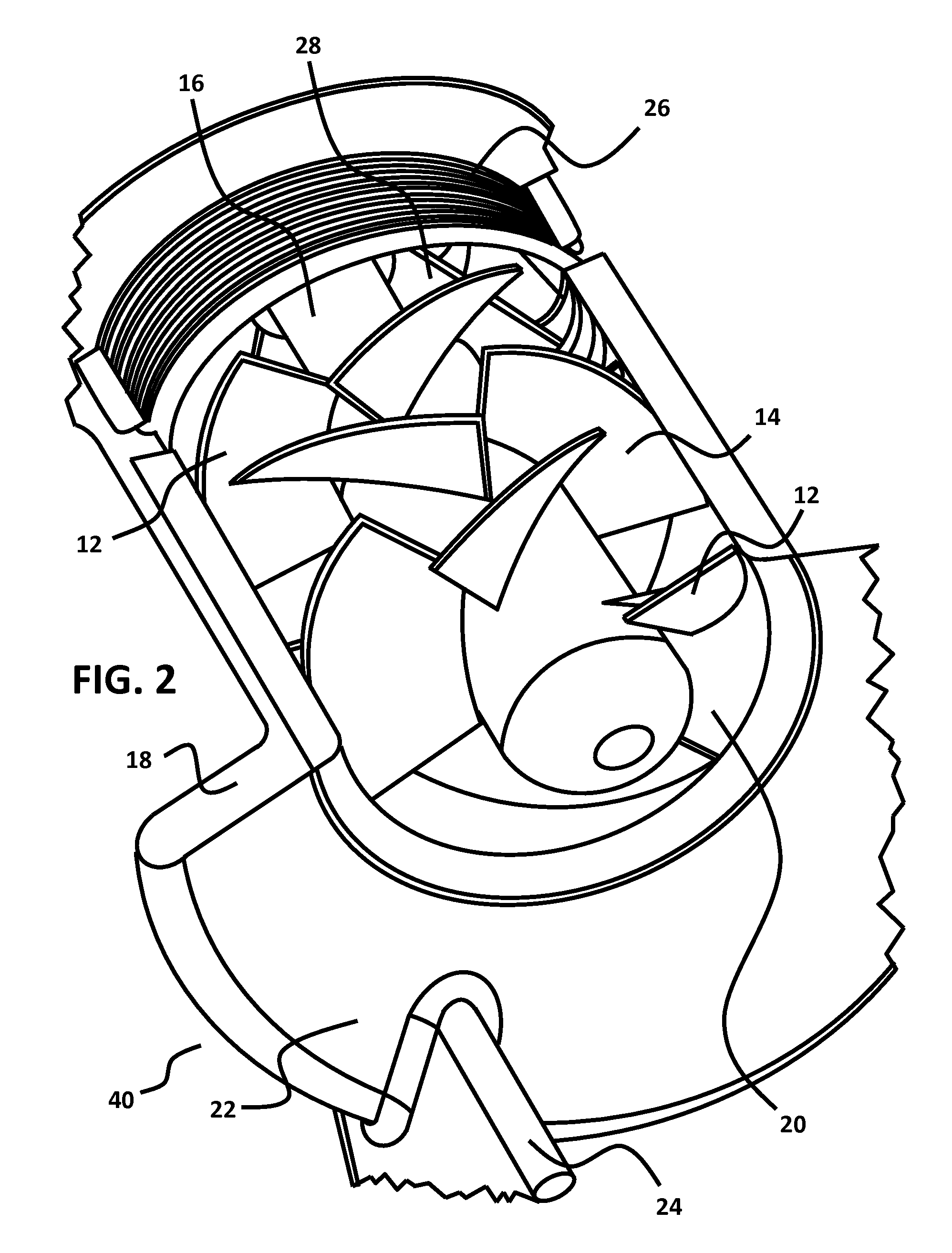

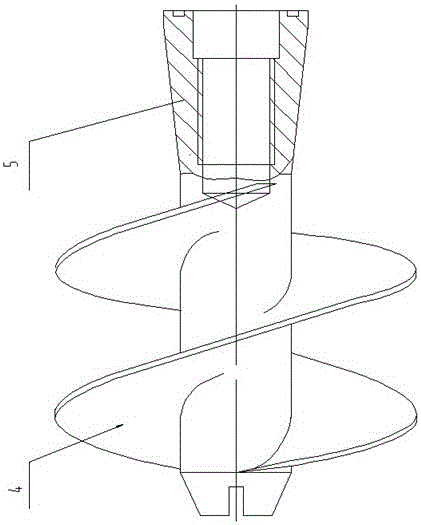

Multi-stage inducer for centrifugal pumps

An inducer assembly comprising at least two sets of rotating and non-rotating helical inducer vanes. As the fluid enters the inducer, the fluid moves up through a first set of rotating vanes, and gains rotational momentum. The fluid then enters a second set of non-rotating vanes that use the rotational momentum of the fluid to progress the fluid forward while removing the rotation and consequently decreasing the net positive suction head required. The inducer is positioned at the inlet of a cryogenic centrifugal pump. Embodiments of the cryogenic centrifugal pump use a vertical rotational axis and include a thrust equalizing mechanism device to balance hydraulic thrust.

Owner:ELLIOTT CO

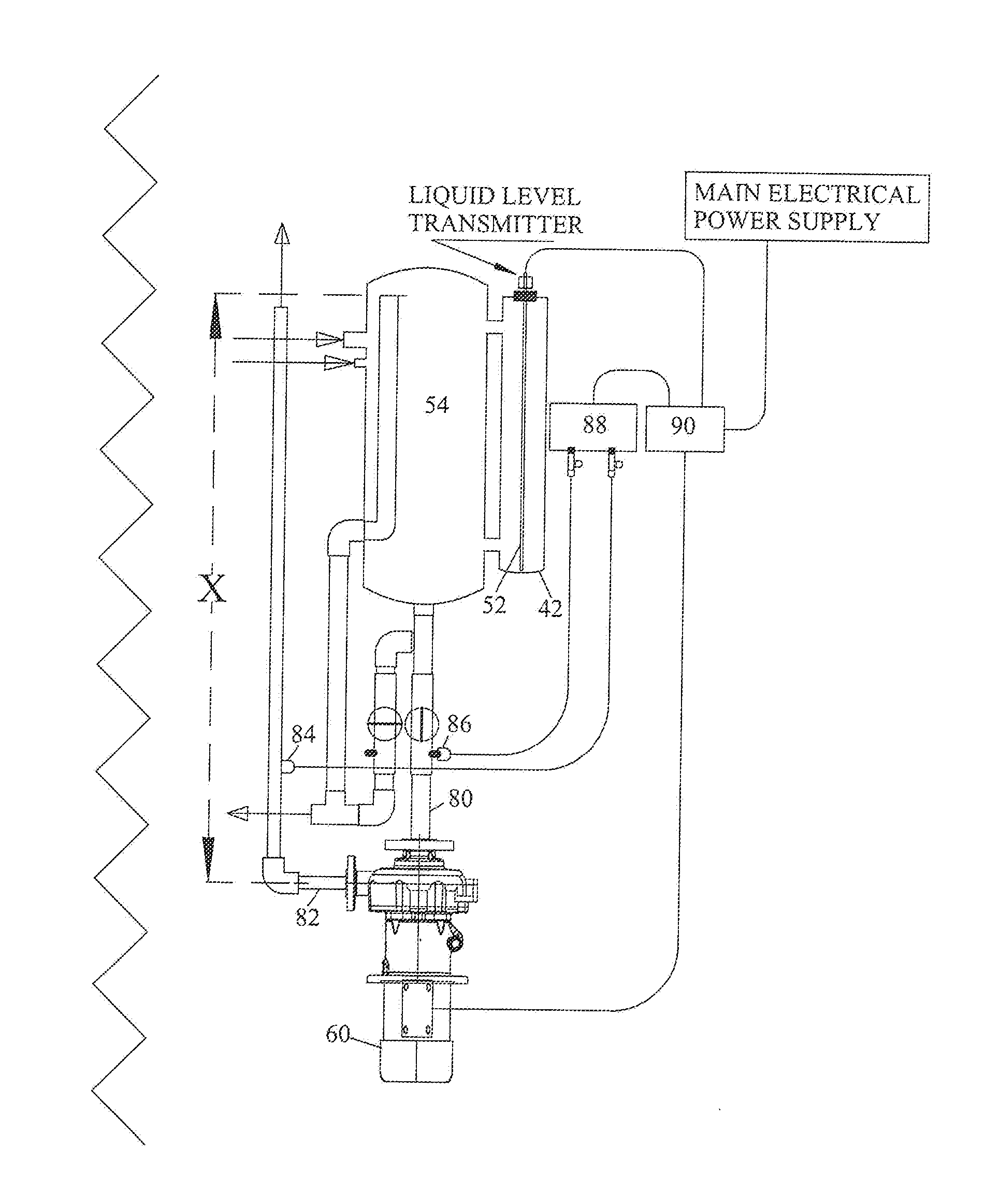

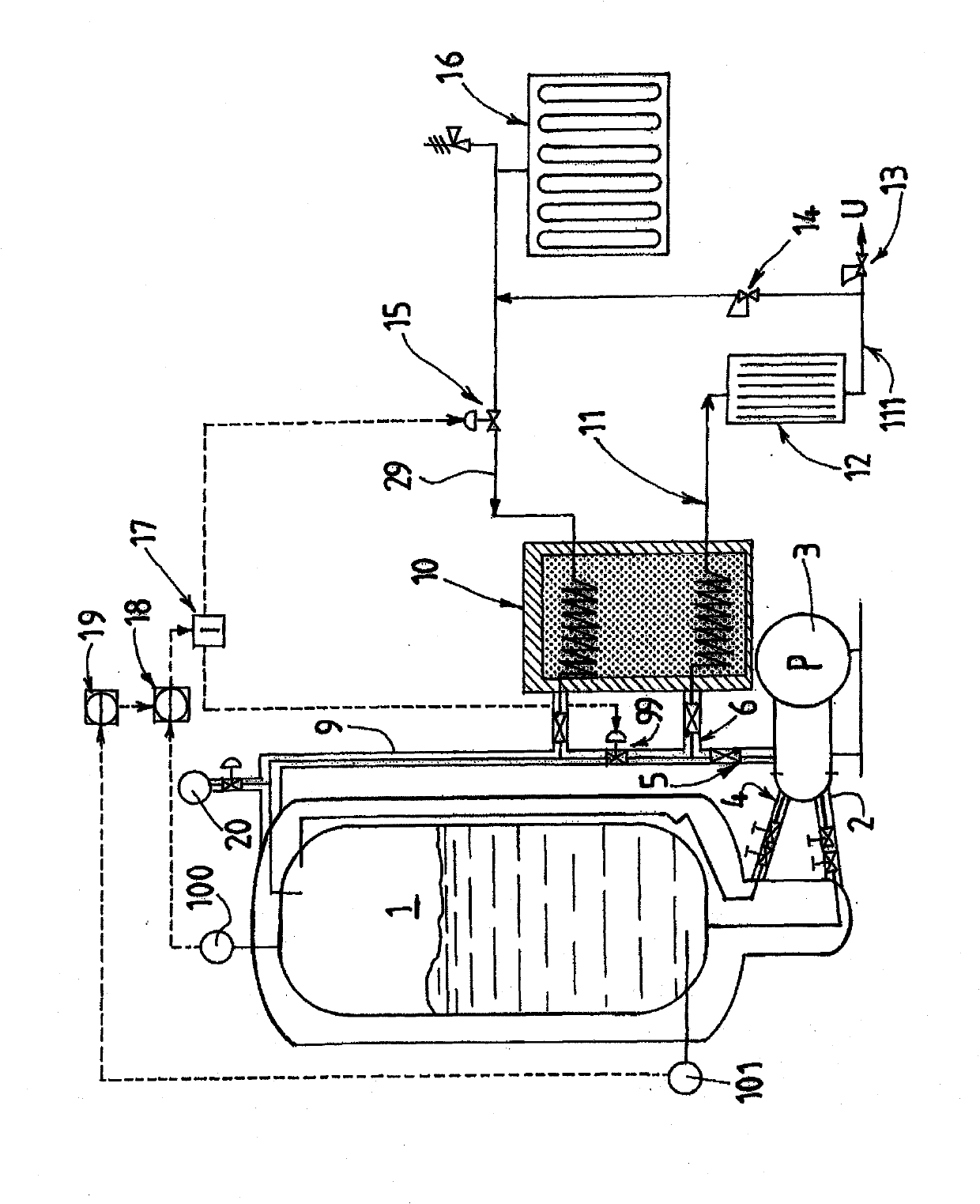

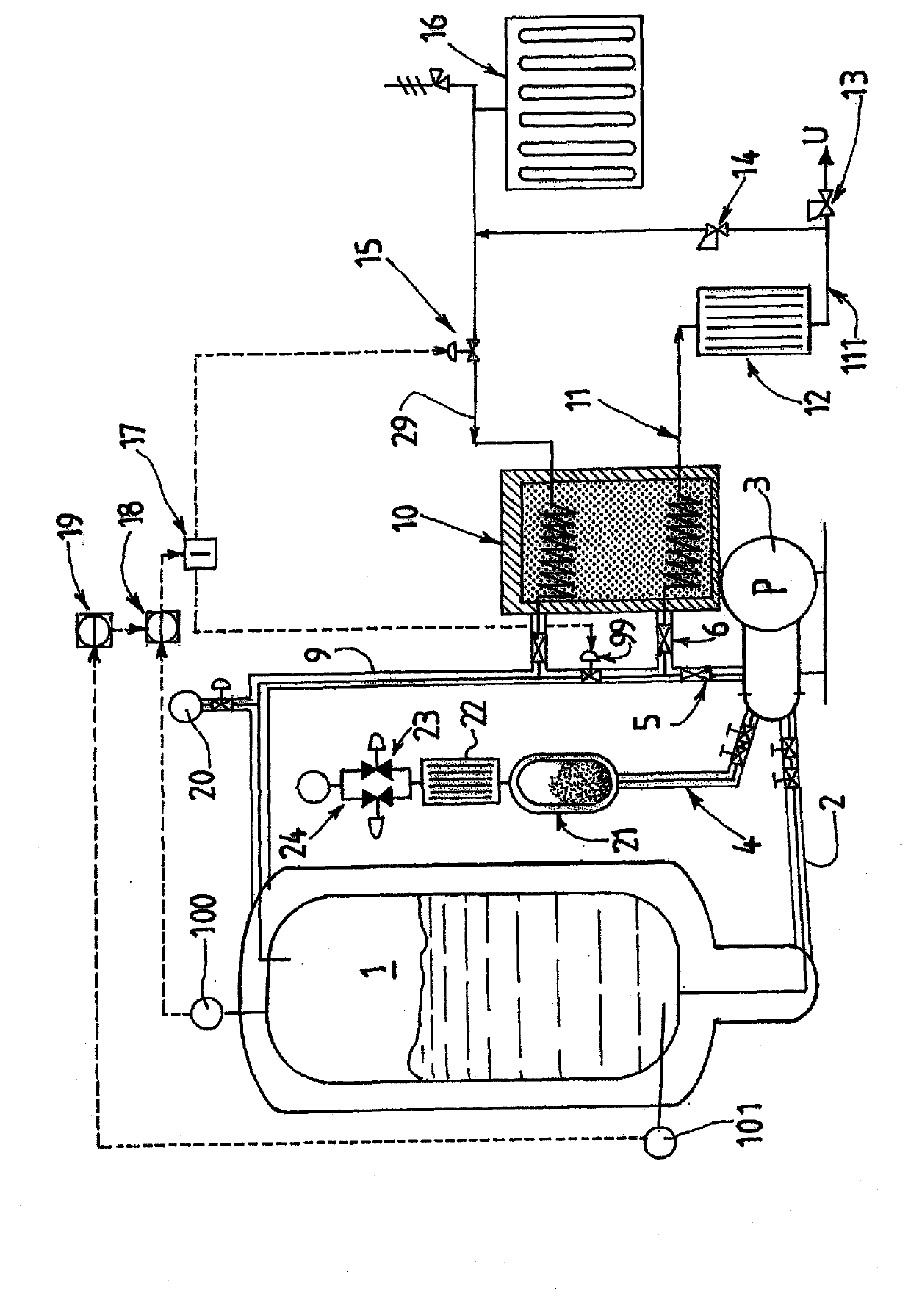

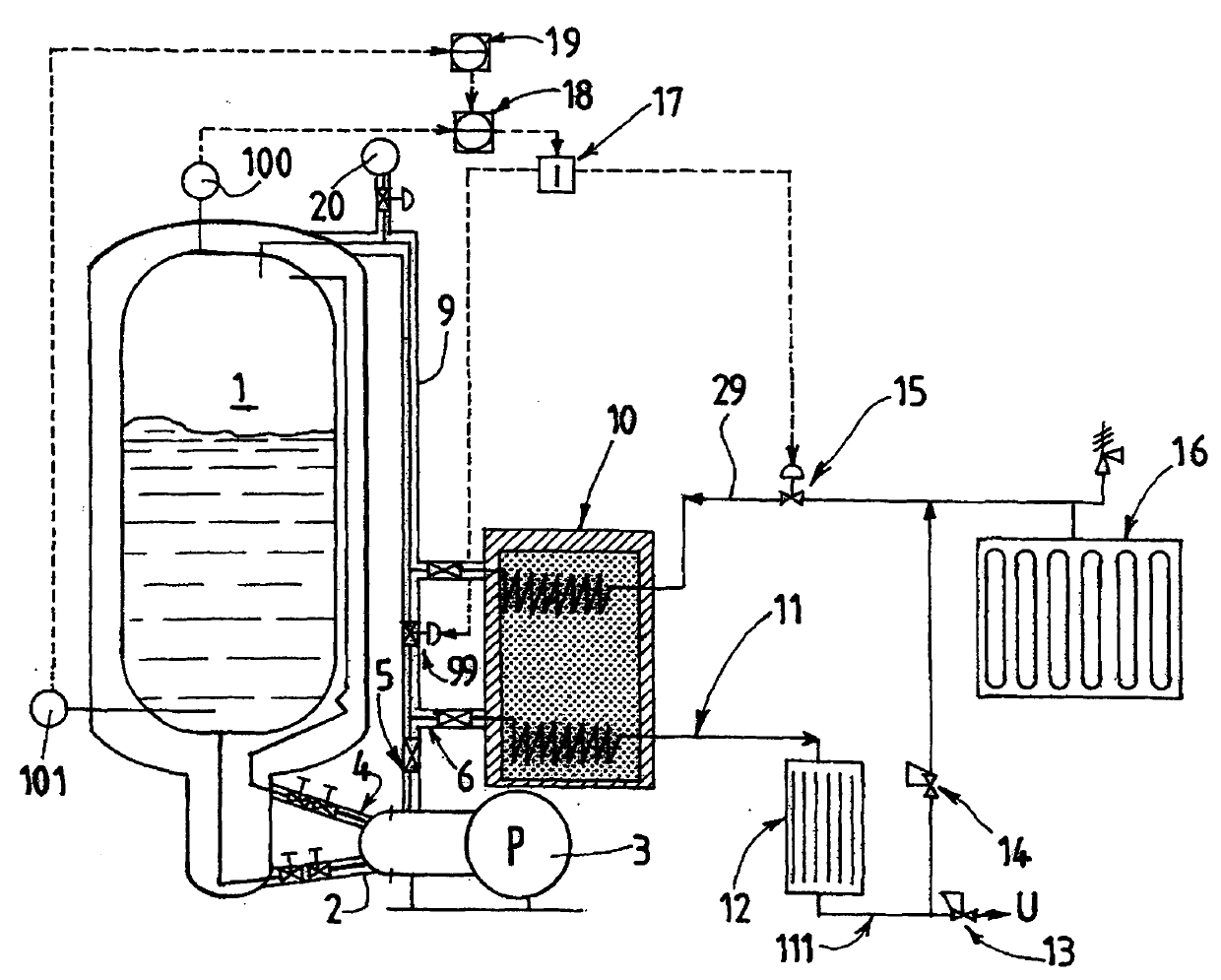

Apparatus for improving refrigeration capacity

ActiveUS9303909B2Improve efficiencyMaximize capacityFluid circulation arrangementRefrigeration safety arrangementEngineeringAir conditioning

A refrigeration, air conditioning or other cooling system is disclosed. The refrigeration system includes a refrigerant storage tank fluidly connected to a refrigerant expansion device which is fluidly connected to a refrigerant evaporator for absorbing ambient heat, a refrigerant vapor compressor fluidly connected to the refrigerant evaporator and a refrigerant condenser fluidly connected to the refrigerant compressor and the refrigerant storage tank. A liquid refrigerant pump and eductor are included in the system along with a refrigerant receiving tank and associated controls that maintain the appropriate Net Positive Suction Head at the inlet to the pump along with proper flow and pressure control in the system.

Owner:KOLARICH ROBERT

LNG liquid adding system

ActiveCN105318180AReduce the impactImprove the efficiency of LNG bunkeringContainer filling under pressurePulp and paper industryPre cooling

The invention provides an LNG liquid adding system comprising a low temperature storage pot, a liquid phase pipeline, an immersed pump system, a liquid discharge pipeline and a liquid adding machine. The immersed pump system includes a pump tank and an immersed pump. The pump tank includes a sealing cover, a shell and an inner container. The immersed pump is installed in the inner container. The pump tank and the immersed pump are both installed horizontally. The liquid phase pipeline is connected between the low temperature storage pot and the pump tank. The pump tank is arranged on the lower part of the low temperature storage pot. The low temperature storage pot is communicated with LNG liquid in the pump tank. The immersed pump system conveys the LNG liquid to the liquid adding machine through the liquid discharge pipeline. The LNG liquid in the low temperature storage pot is communicated with the LNG liquid in the pump tank. The immersed pump is immersed in the LNG liquid in the pump tank all the time so that the immersed pump can be started without pre-cooling. Meanwhile, net positive suction head of the immersed pump can be satisfied completely, so that influence on the immersed pump due to cavitation erosion can be reduced and LNG addition efficiency is increased.

Owner:ENRIC (LANGFANG) ENERGY EQUIP INTEGRATION CO LTD +3

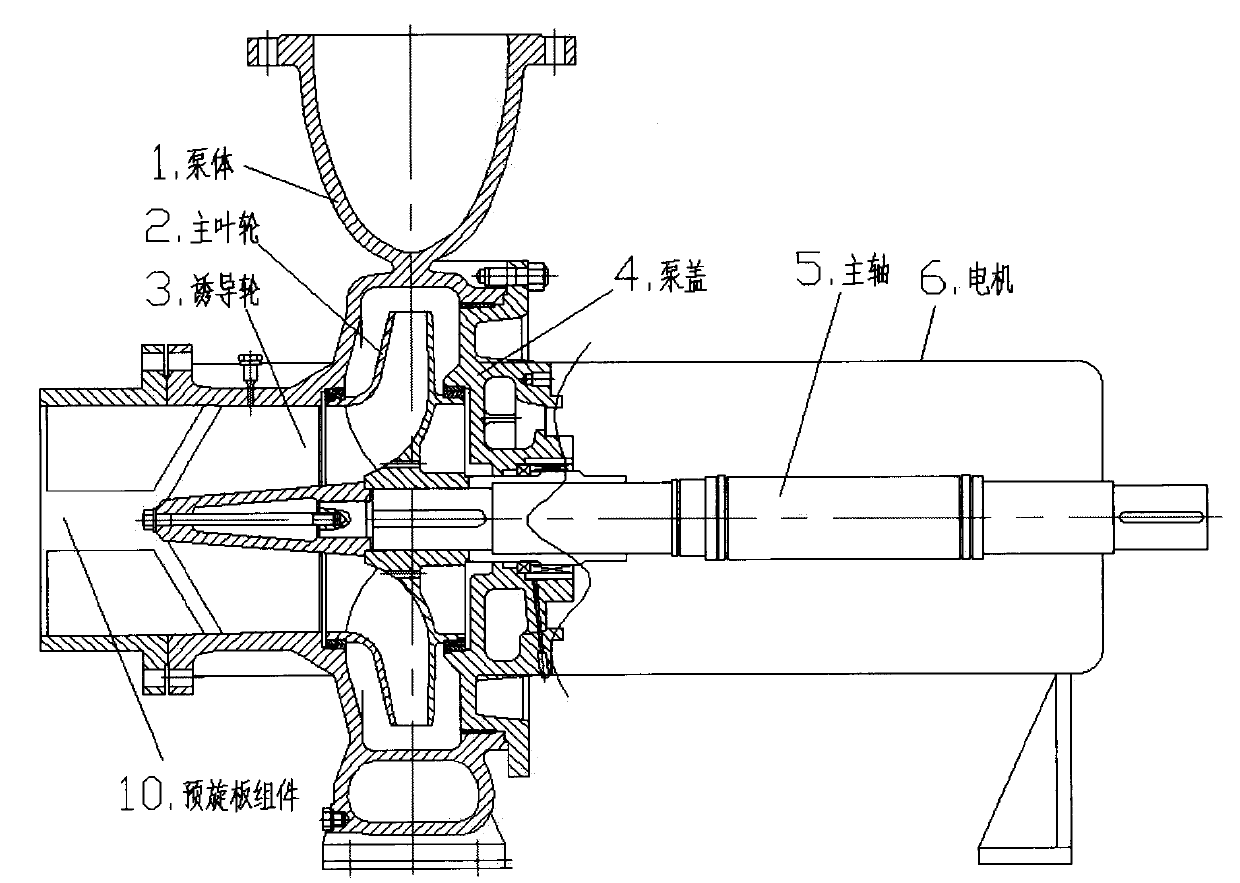

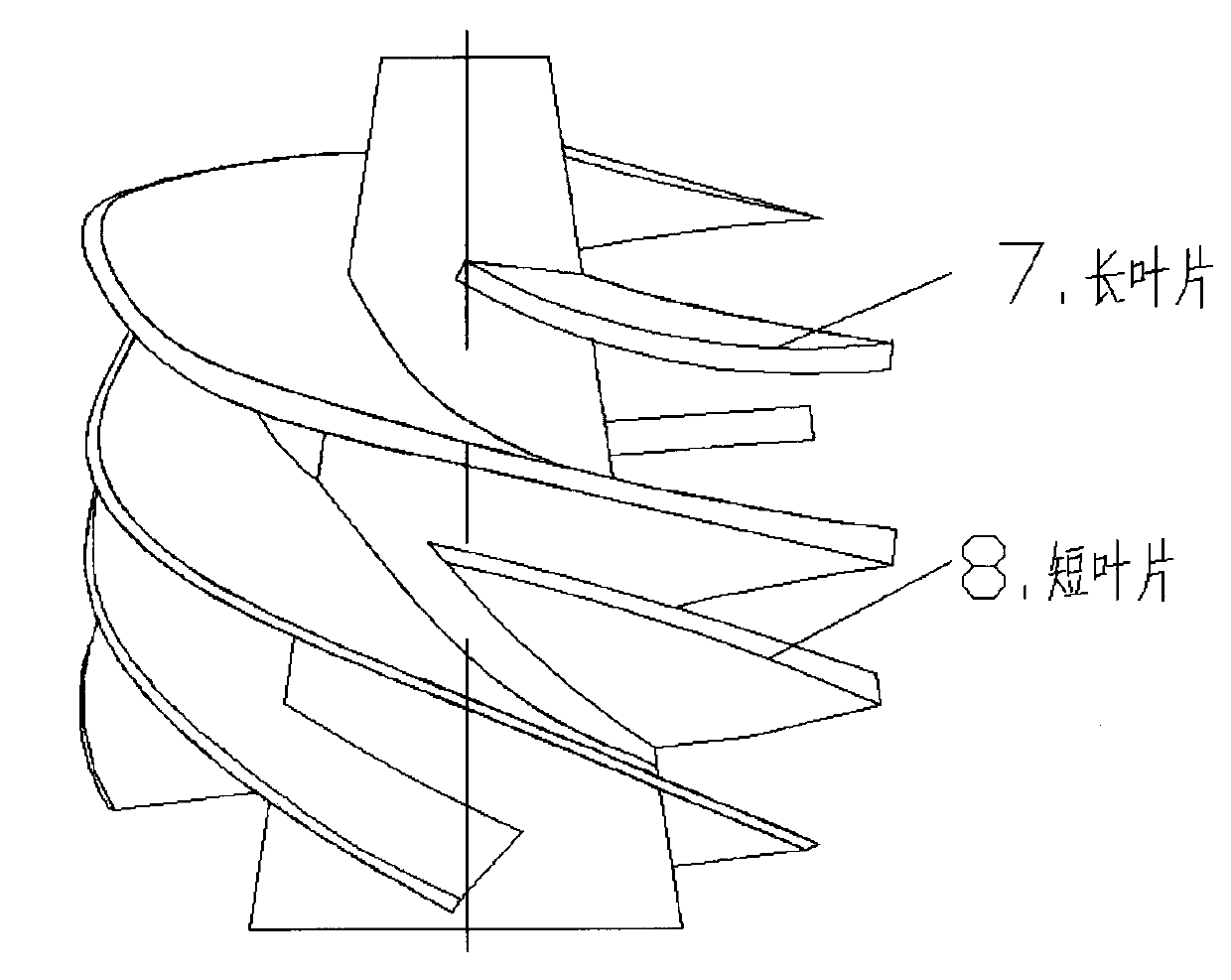

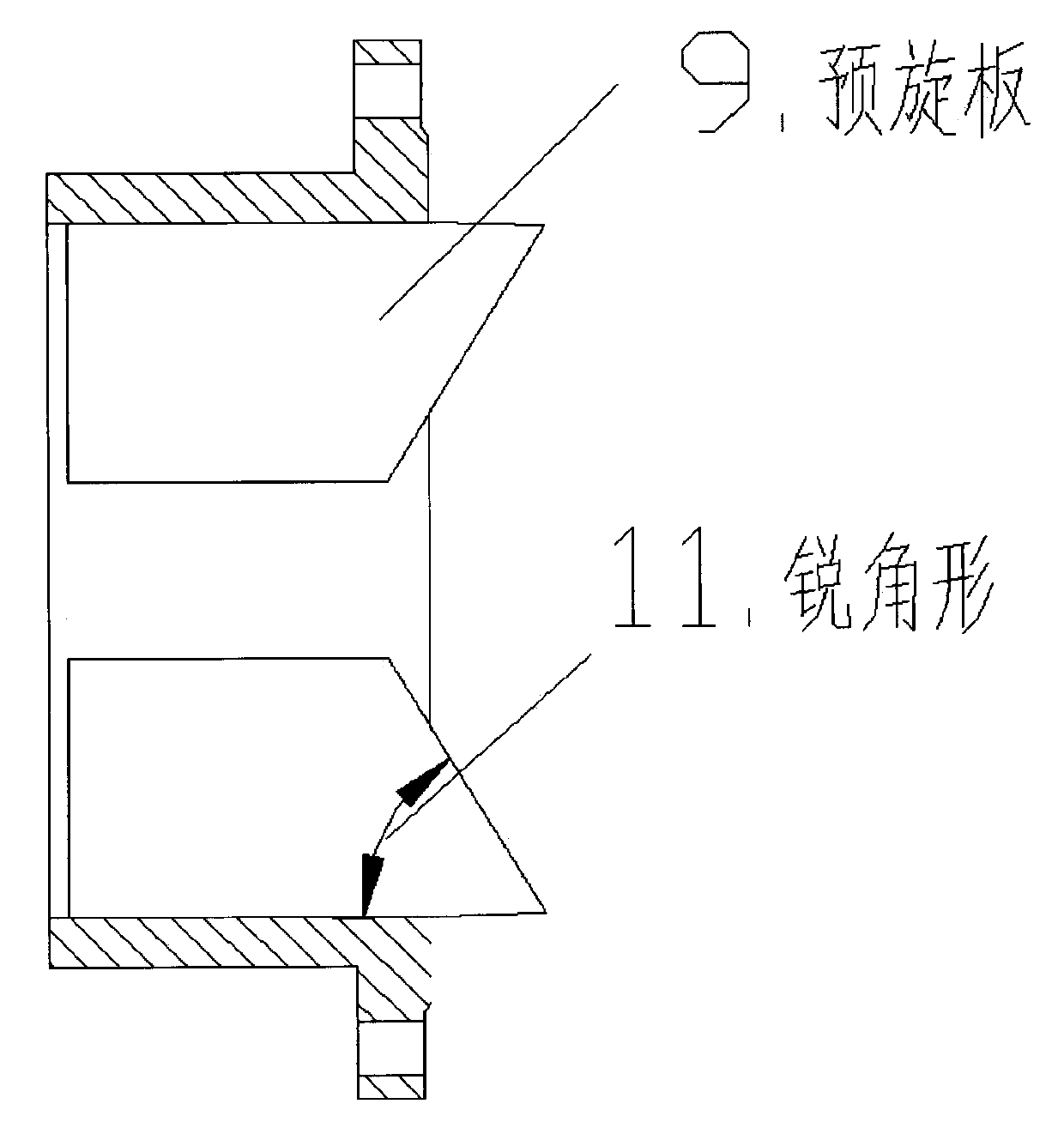

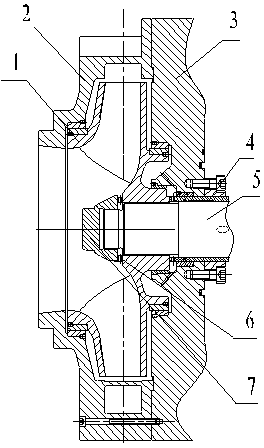

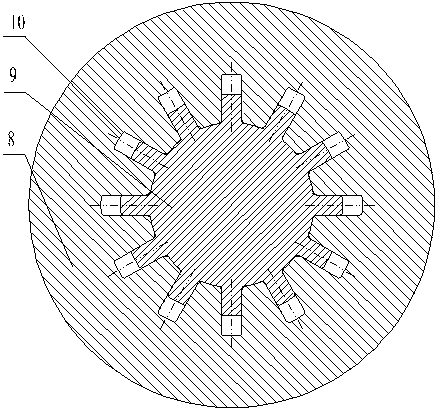

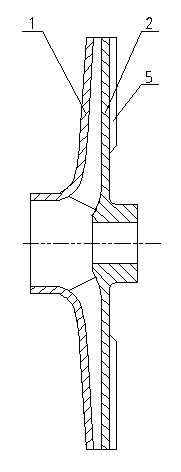

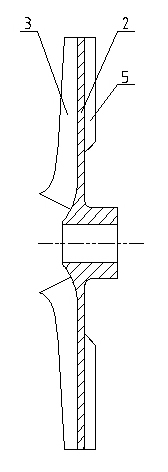

Structural design of pump with front preswirl plate of inducer having long and short vanes

InactiveCN103133404AImprove cavitation resistanceAvoid cavitationPump componentsPumpsImpellerCavitation

The invention relates to structural design of a pump with a front preswirl plate of an inducer having long and short vanes. The inducer is provided with two long vanes and two short vanes. According to the design, the long and short vanes are spaced, the short vanes are located at the tail of the inducer, and the short vanes are disposed between the long vanes. Therefore, occurrence and development of flow separation are prevented effectively. The inducer is fine in cavitation resistance, so that inlet flow field of an impeller can be improved. In addition, formed lift enables net positive suction head to be lowered, and prevention on impeller cavitation is promoted. The tail of the preswirl plate extends to the inducer at an acute-angle, the tail is kept equal to an inlet edge of the inducer with long and short vanes in edge distance, the inlet flow field can be improved effectively, and pre-whirling is prevented.

Owner:JIANGSU UNIV

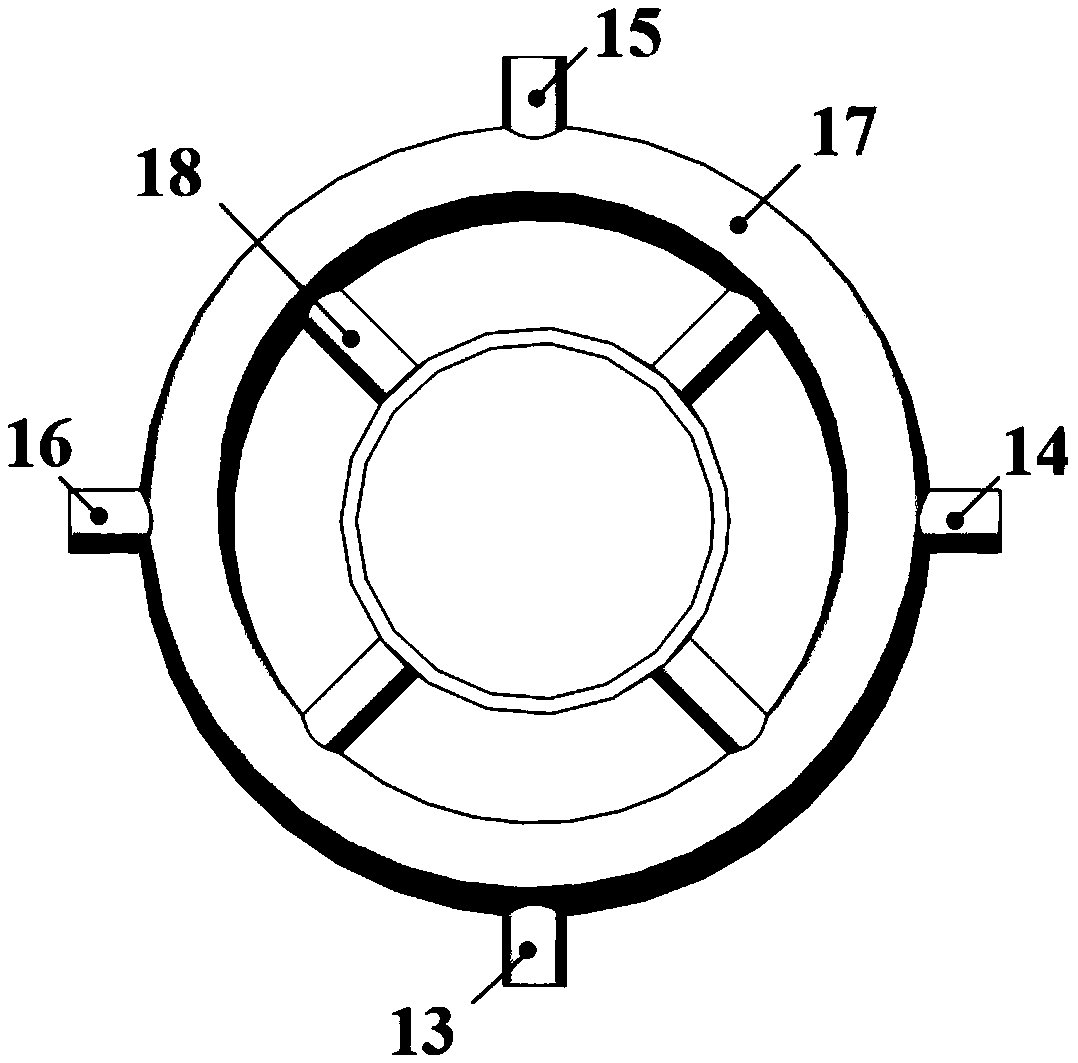

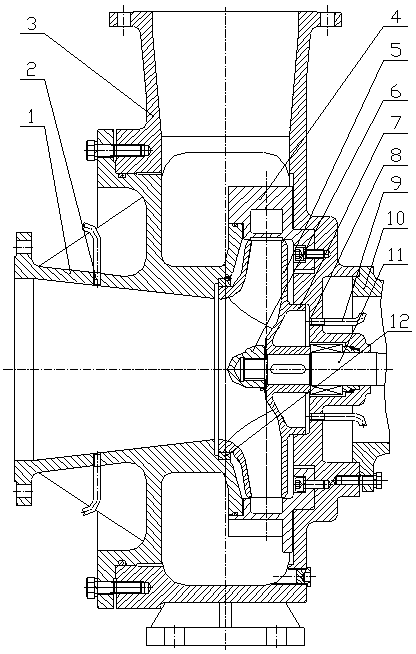

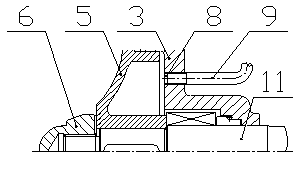

Axial force balance device for centrifugal residual heat removal pump for nuclear power

The invention discloses an axial force balance device for a centrifugal residual heat removal pump for nuclear power. The axial force balance device comprises an impeller (1), guide vanes (2), a pump cover (3), a shaft sleeve (4), a spline shaft (5), a locking gasket (6) and an impeller nut (7). Through radial flow return, pump efficiency is improved, critical net positive suction head of the pump is reduced and pressure fluctuation of an outlet of the impeller is improved effectively. Through impeller hub 'gear grooves', fluid leakage can be reduced greatly and pump efficiency is improved. The spline shaft is high in strength, centering performance of the impeller is fine, and accordingly vibration of the pump is controlled effectively. Through the special design of the locking gasket, impeller nut loosening is eliminated effectively, and axial force can be regulated to the minimum by changing area and number of balance holes.

Owner:JIANGSU UNIV

Anti-cavitation cantilever centrifugal pump and manufacturing method thereof

InactiveCN105822588AImprove cavitation resistanceGuaranteed uptimePump componentsPumpsCavitationSheet steel

The invention provides an anti-cavitation cantilever centrifugal pump and a manufacturing method thereof, and aims at solving the following problem that when an existing standard centrifugal pump operates at a lower-capacity point and a net positive suction head of a device is extremely low, cavitation occurs in the pump to cause unstable running, serious vibration, and easy formation of pump curve humps, thus leading to a failure in meeting the technical requirements of stable running. The anti-cavitation cantilever centrifugal pump is technically characterized in that an inducer, which is a welded inducer, is arranged at an impeller inlet of a single-stage cantilever pump; an impeller of the inducer is formed by sheet steel with a thickness of 2mm, and welded on a hub of the inducer; and an impeller outlet is narrowed to improve the running stability of the centrifugal pump at the lower-capacity point. The anti-cavitation cantilever centrifugal pump has the following beneficial effects that the pump is excellent in anti-cavitation performance, and stable in running, and has the net positive suction head reduced by about 1.2mm as compared with that of the standard pump; moreover, the pump is, at lower capacity, stable in running, relatively high in efficiency and low in vibration value, such that the use and maintenance costs are reduced by about 1 / 5. The anti-cavitation cantilever centrifugal pump also has the characteristics of simple structure, simplicity and convenience in control, low costs, high reliability and the like.

Owner:沈阳市工业泵厂(有限公司)

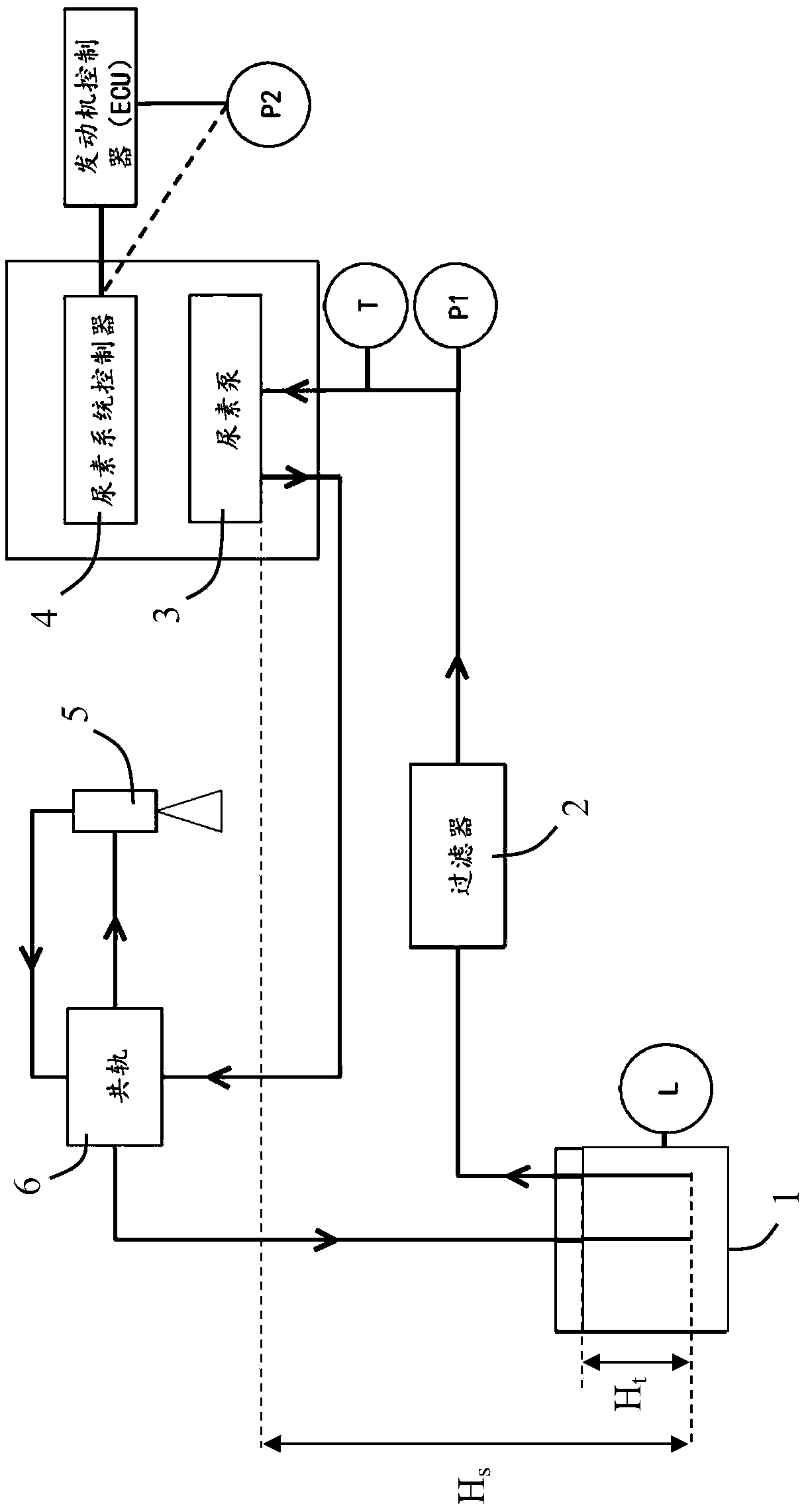

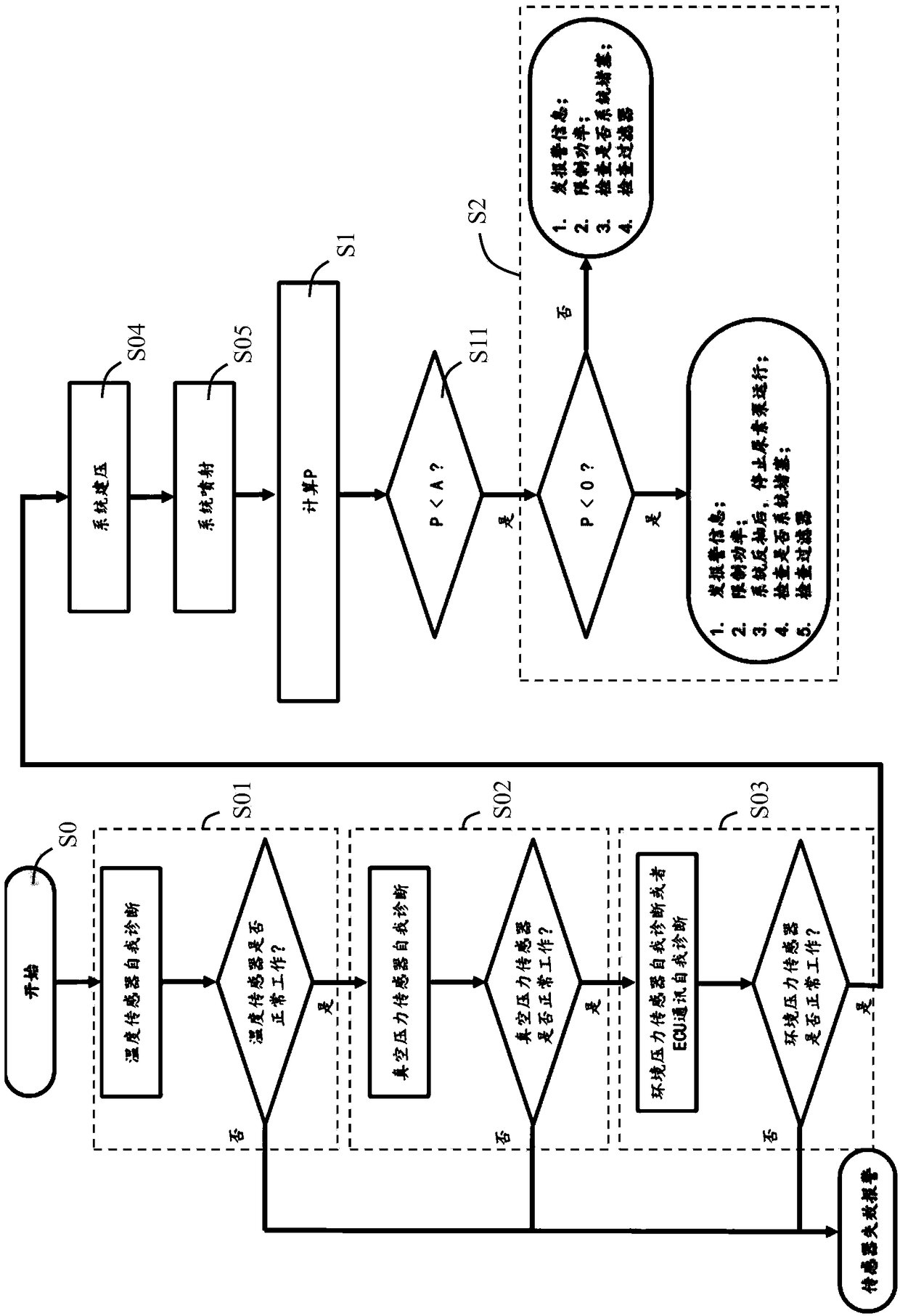

Method for preventing urea pump from cavitation corrosion in post-treatment system

ActiveCN109268111AAvoid cavitationInternal combustion piston enginesSilencing apparatusCavitationAmbient pressure

The invention relates to a method for preventing a urea pump from cavitation corrosion in a post-treatment system, which comprises a urea tank, a urea pump, a common rail, a urea nozzle, a temperaturesensor, a vacuum pressure sensor and a urea system controller. The method for preventing the urea pump from cavitation corrosion in the post-treatment system comprises the following steps: S0: starting; S1: a safe operating pressure value P of the urea pump is obtained by the following formula: P=PRho+Pu-Pv-Pho*g*(NPSHp+SF), wherein PRho represents a vacuum pressure detection value of the vacuumpressure sensor; Pu represents a ambient pressure value; Pv represents a urea vapor pressure value obtained from a detection value of the temperature sensor; g represents gravity acceleration; NPSHprepresents the net positive suction head of the urea pump; SF represents a security parameter; S2, judging whether P is less than 0 or not; if P is less than 0, the system back pumps and then stops operation of the urea pump to prevent cavitation of the urea pump.

Owner:TENNECO SUZHOU EMISSION SYST

Welded impeller of canned motor pump used for central air conditioner

The invention relates to a welded impeller of a canned motor pump used for a central air conditioner. The impeller comprises a front cover plate and a rear cover plate which are matched correspondingly, wherein long blades and short blades in spiral radial shapes are uniformly distributed on the inside surface of the rear cover plate; each short blade is positioned between two adjacent long blades; six straight blades are uniformly distributed on the outside surface of the rear cover plate; welding process holes are uniformly formed on the rear cover plate; the welding process holes are uniformly formed on the front cover plate correspondingly; the welding process holes on the front cover plate and the welding process holes on the rear cover plate are all provided with welding fluxes; and an integrated impeller is formed by welding. In the welded impeller, the front cover plate and the rear cover plate of the impeller are cast separately, which solves a difficult casting problem of the impeller with large impeller diameter and small egress width. The egress width of the impeller of the invention is only 3mm; the outside diameter of the impeller is over phi160mm; the efficiency of a pump is up to 20 percent; and the net positive suction head is below 0.45mm. The welded impeller improves the efficiency of the pump greatly. A small-flow high-lift lithium bromide canned motor has the characteristics of high efficiency and anti-cavitation performance.

Owner:HEFEI XINHU CANNED MOTOR PUMP

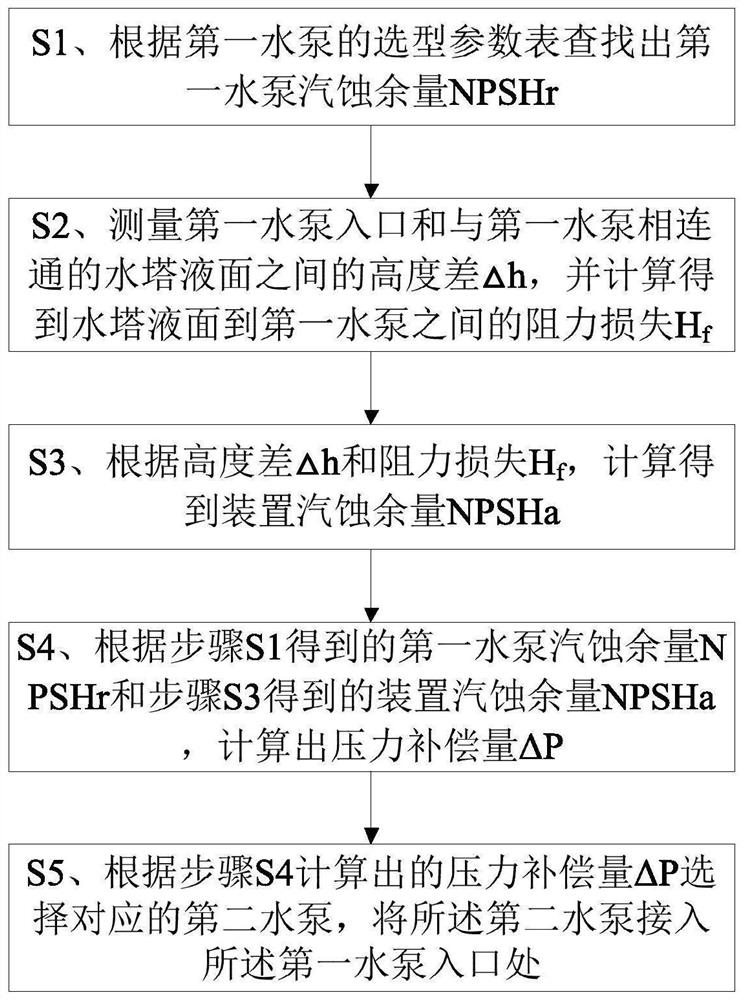

Method for effectively preventing water pump from generating cavitation phenomenon

The invention relates to the technical field of water pumps, in particular to a method for effectively preventing a water pump from generating a cavitation phenomenon. The method comprises the following steps of finding out the first water pump net positive suction head NPSHr according to a model selection parameter table of a first water pump; measuring the height difference delta h between an inlet of the first water pump and the liquid level of a water tower communicated with the first water pump, and calculating the resistance loss Hf between the liquid level of the water tower and the first water pump; according to the height difference delta h and the resistance loss Hf, performing calculation to obtain the device net positive suction head NPSHa; and calculating a pressure compensation amount delta P according to the first water pump net positive suction head NPSHr and the device net positive suction head NPSHa. The device net positive suction head of the first water pump is calculated in detail according to the operation conditions of the first water pump under various working conditions, so that the pressure compensation amount is calculated, the pressure value of the firstwater pump is supplemented by assembling a corresponding second water pump, and the cavitation phenomenon of the first water pump is effectively avoided.

Owner:福建蓝海节能科技有限公司

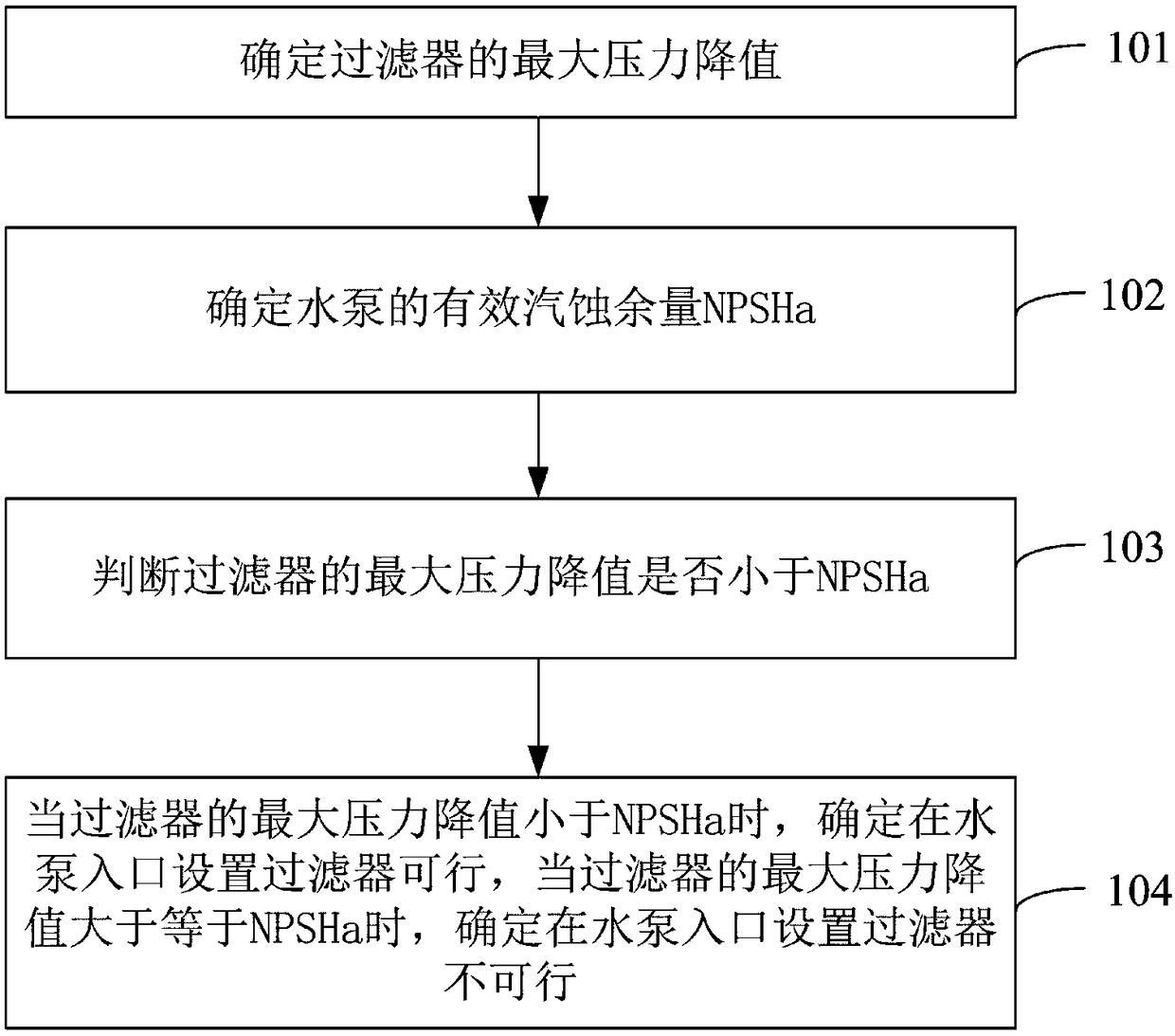

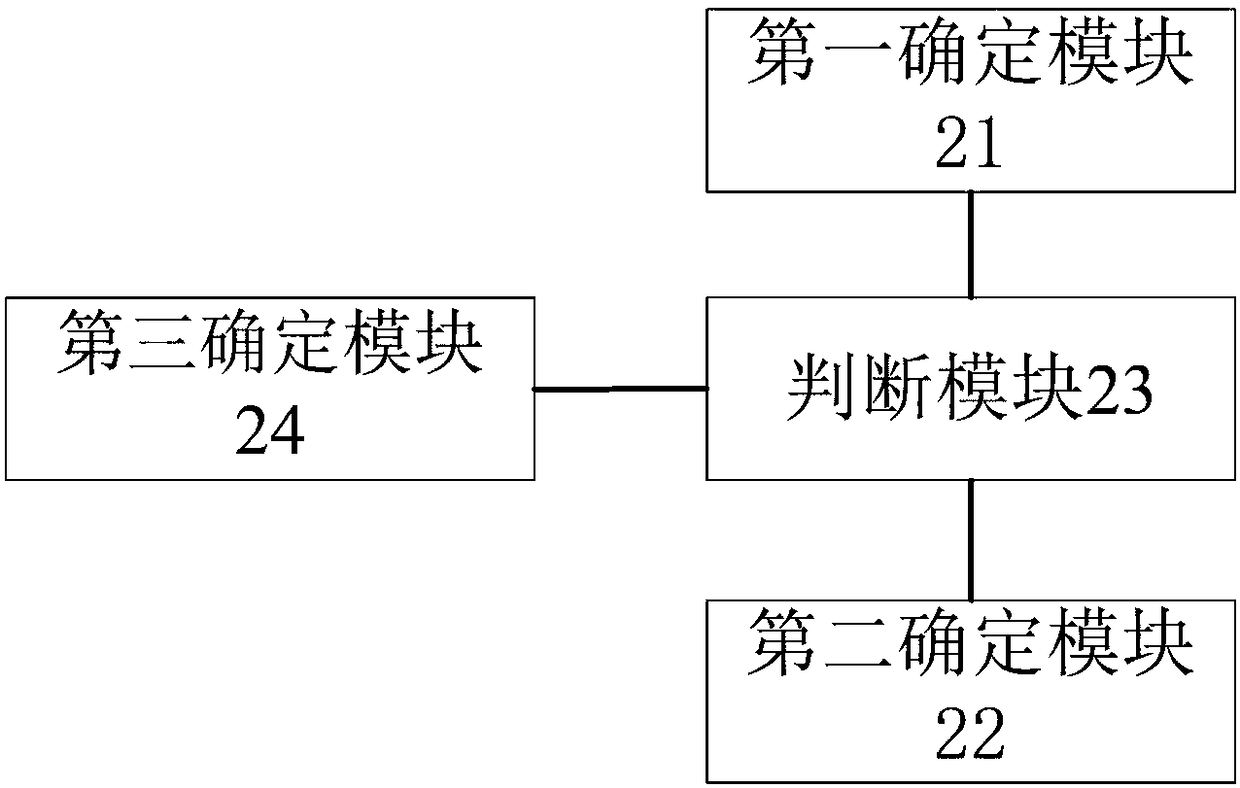

Method and device for determining feasibility of setting filters at inlet pipes of water pumps in nuclear power plants

ActiveCN108170869ASolve the problem of cavitationEasy to operateNuclear energy generationForecastingCavitationDifferential pressure

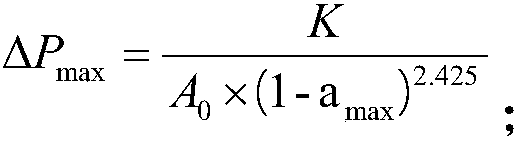

Embodiments of the invention provide a method for determining feasibility of setting filters at inlet pipes of water pumps in nuclear power plants. The method comprises the following steps of: determining a maximum pressure reduction value <delta>Pmax of a filter; determining an effective net positive suction head NPSHa of a water pump; judging whether <delta>Pmax is smaller than NPSHa or not; when <delta>Pmax is smaller than NPSHa, determining that the operation of setting the filter at the inlet of the water pump is feasible; and when <delta>Pmax is greater than or equal to NPSHa, determining that the operation of setting the filter at the inlet of the water pump is unfeasible. According to the method, the feasibility of setting corresponding filters at inlet pipes of water pumps can beassessed and determined through a simple and effective manner before setting the filters at the inlet pipes of the water pumps, and the determination manner is convenient and easy to operate, so thatthe problem that the water pumps generate cavitation due to filter differential pressure increase as the corresponding filters are additionally arranged can be effectively avoided.

Owner:GUANGDONG NUCLEAR POWER JOINT VENTURE +4

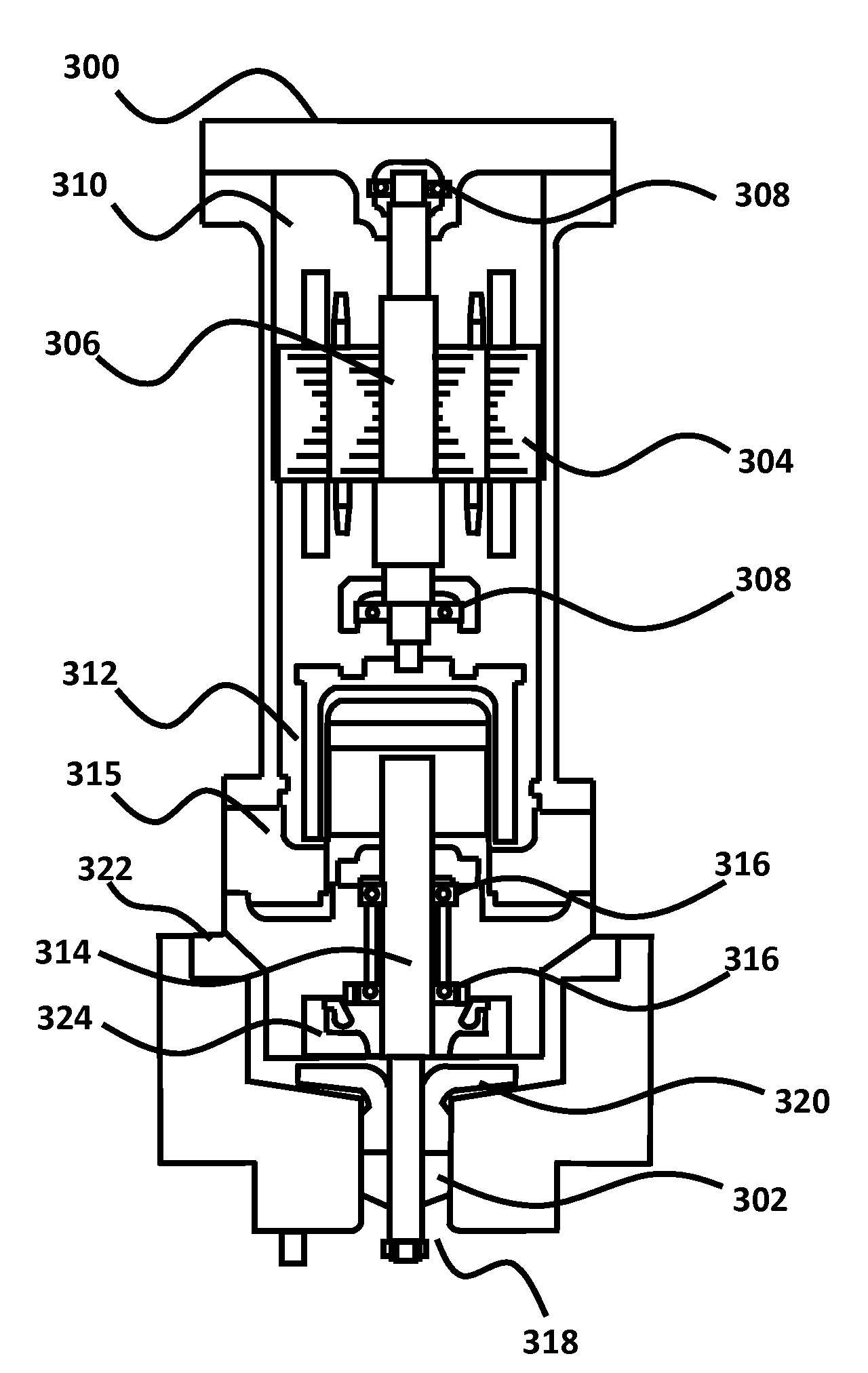

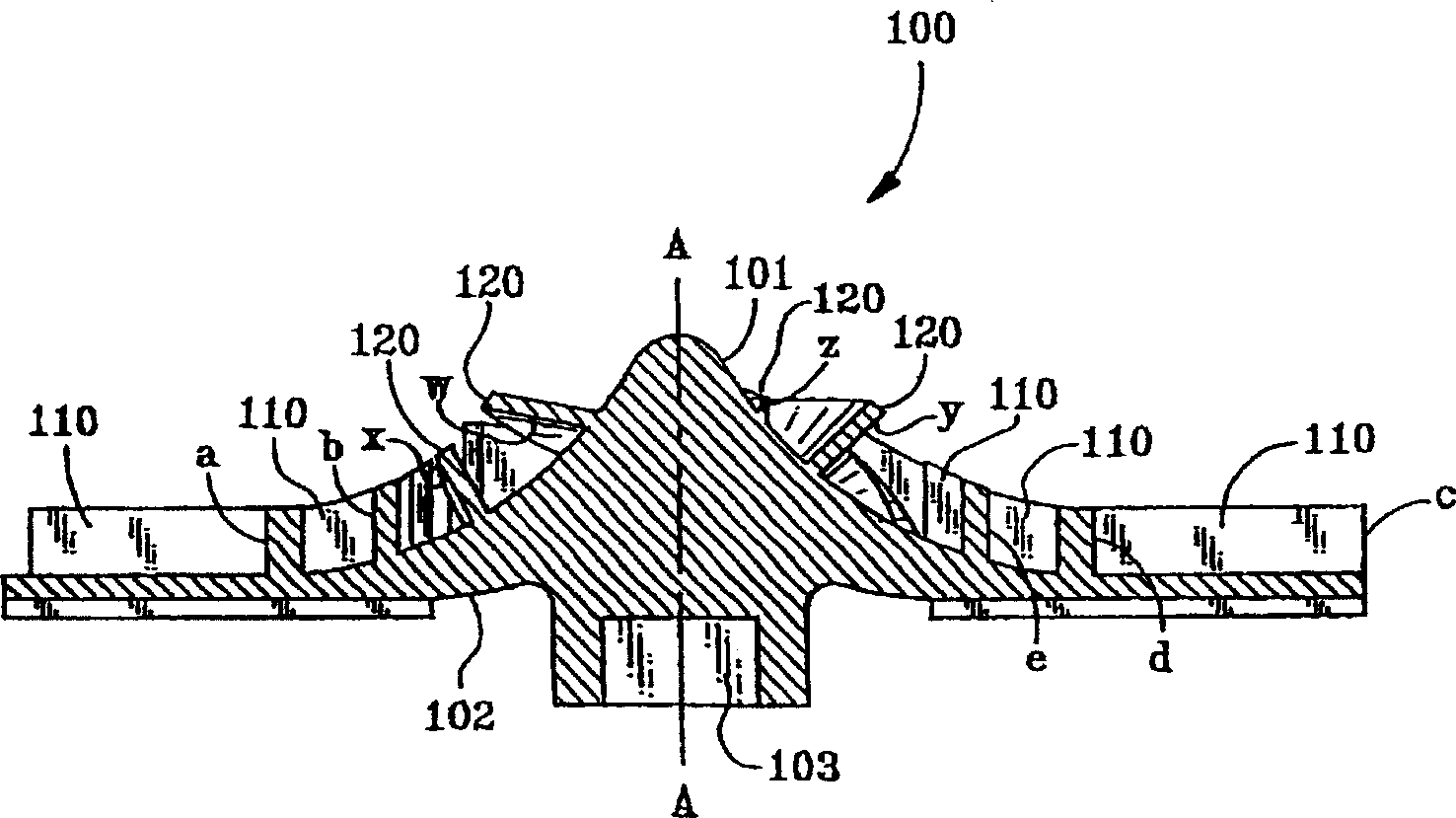

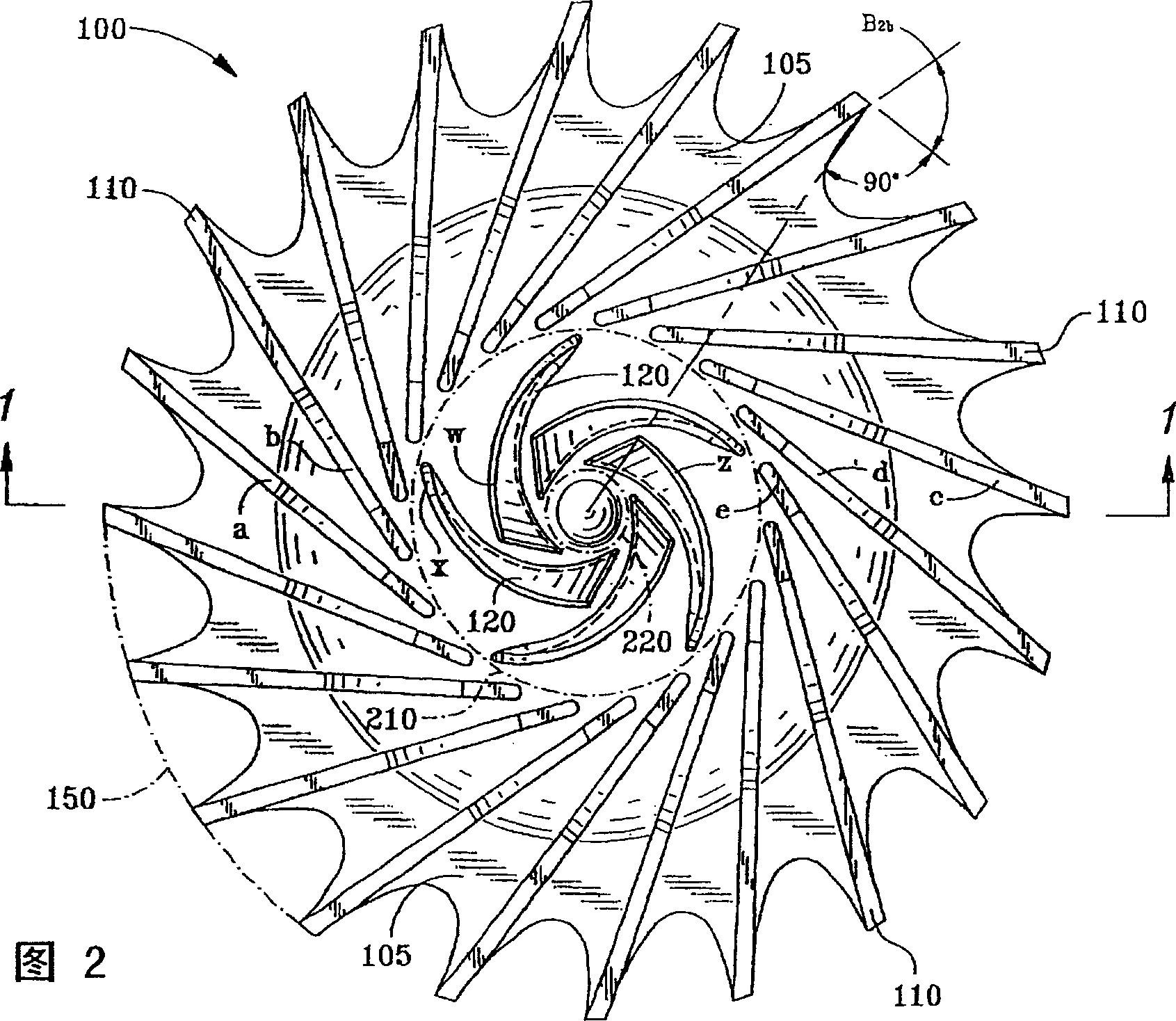

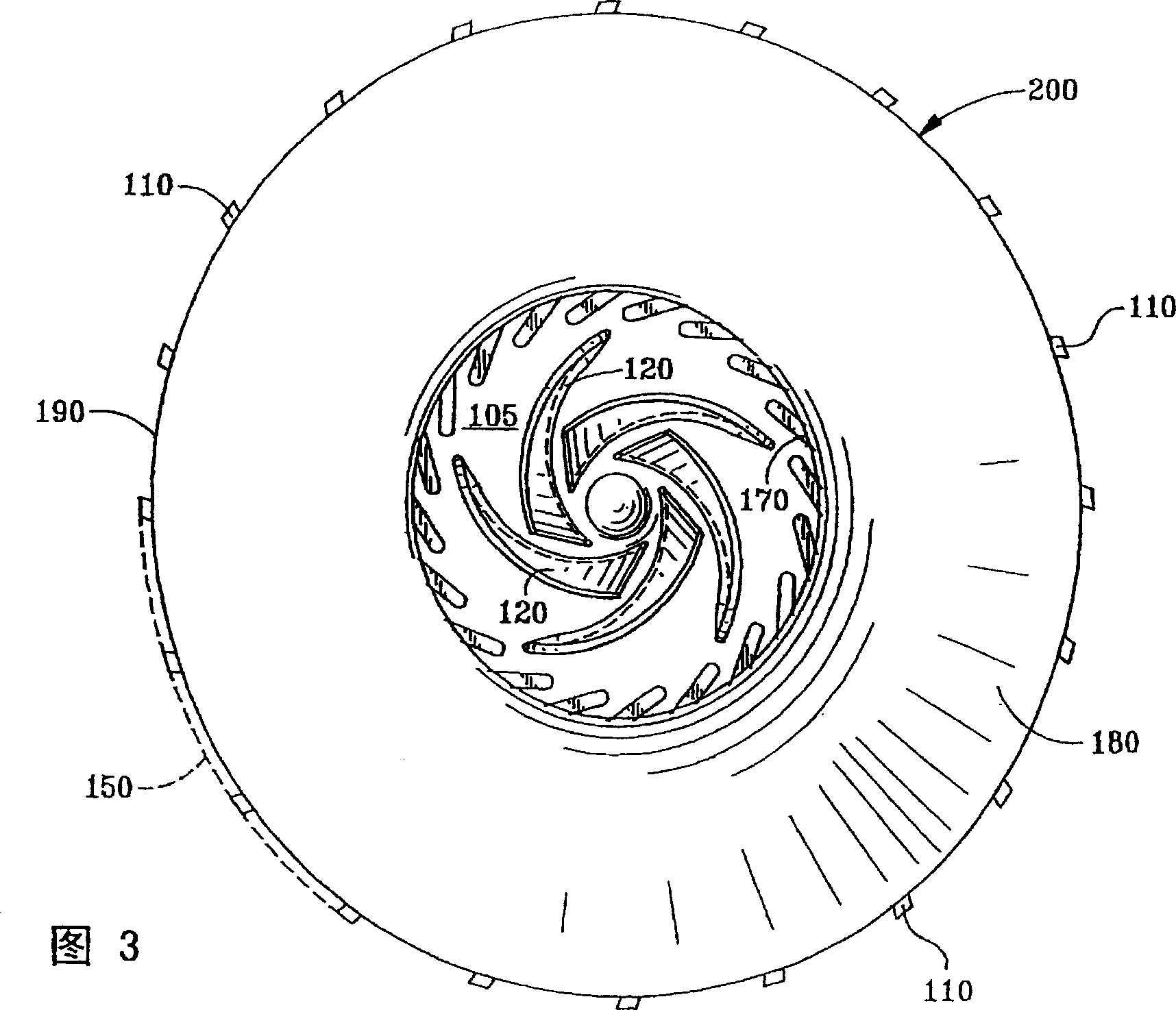

Pump impeller having separated offset inlet venes

A fluid impeller (100) for a centrifugal pump includes a hub (105) having a substantially disk-like form with a center and an edge, circular symmetry, and provosion for being rotatably driven. A first plurality of pumping vanes (110) projects substantially perpendicularly from a first surface of the hub and extends radially outwardly from a locus (210) near the center of the hub to another locus (150) near the edge of the hub. These vanes (110) provide a high pressure head with a small impeller diameter. A second plurality of separate and twisted inlet vanes (120) also projects substantially perpendicularly from the first surface of the hub and extends radially outwardly to the locus (210) near the center of the hub from another locus (220) nearer the center of the hub. The separate second plurality of vanes (120), by turning and pre-pressurizing the fluid, provides an impeller having capability of cavitation-free pumping at low net positive suction head (NPSH). A front shroud (180) can be used which partially or totally covers the first and / or second plurality of vanes.

Owner:FLOWSERVE MANAGEMENT CO

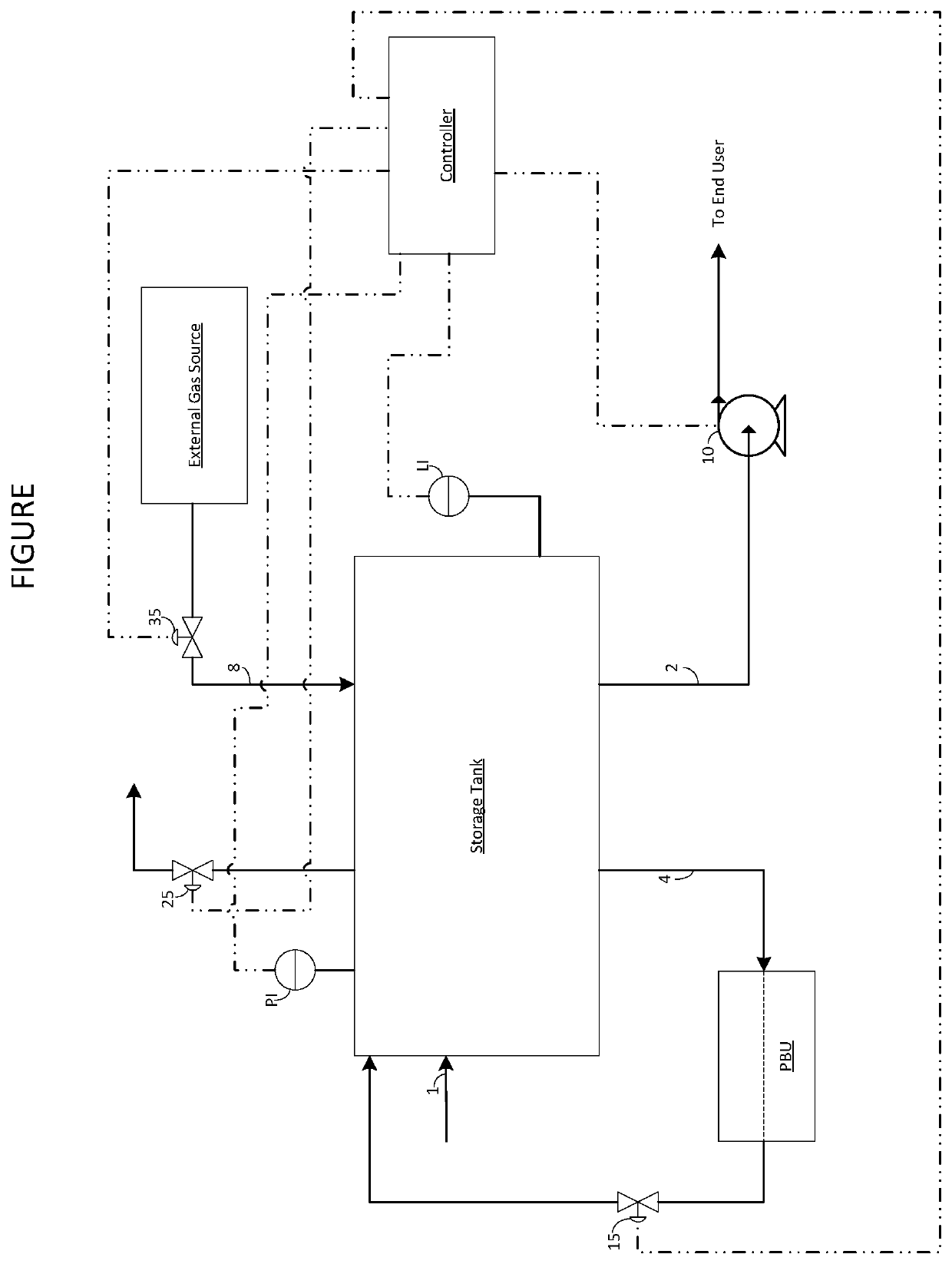

Method for increasing pump net positive suction head

InactiveUS20210199245A1Simple and cost-effectiveIncrease vapor pressureVessel mounting detailsFluid parameterLiquid storage tankEngineering

A method for increasing the available net positive suction head (NPSHa) for a cryogenic pump is provided. In one embodiment, the method can include the steps of: increasing a pressure within a liquid storage tank to at least a pumping set point, wherein the pumping set point is configured to cause the NPSHa to exceed the NPSHr; starting the cryogenic pump, thereby sending liquid from within the liquid storage tank through the pump and to an end user; stopping the cryogenic pump, thereby stopping flow of the liquid from the liquid storage tank; and resetting the pressure within the liquid storage tank to at least a storage set point.

Owner:AIR LIQUIDE GLOBAL E&C SOLUTIONS US

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com