CFD-based prediction method of centrifugal pump cavitation performance

A prediction method and centrifugal pump technology, which are applied to the components, pumps, and pump components of the pumping device for elastic fluids, can solve the problems of long simulation time and difficulty in ensuring the simulation accuracy, so as to save the number of simulations and save Simulate the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

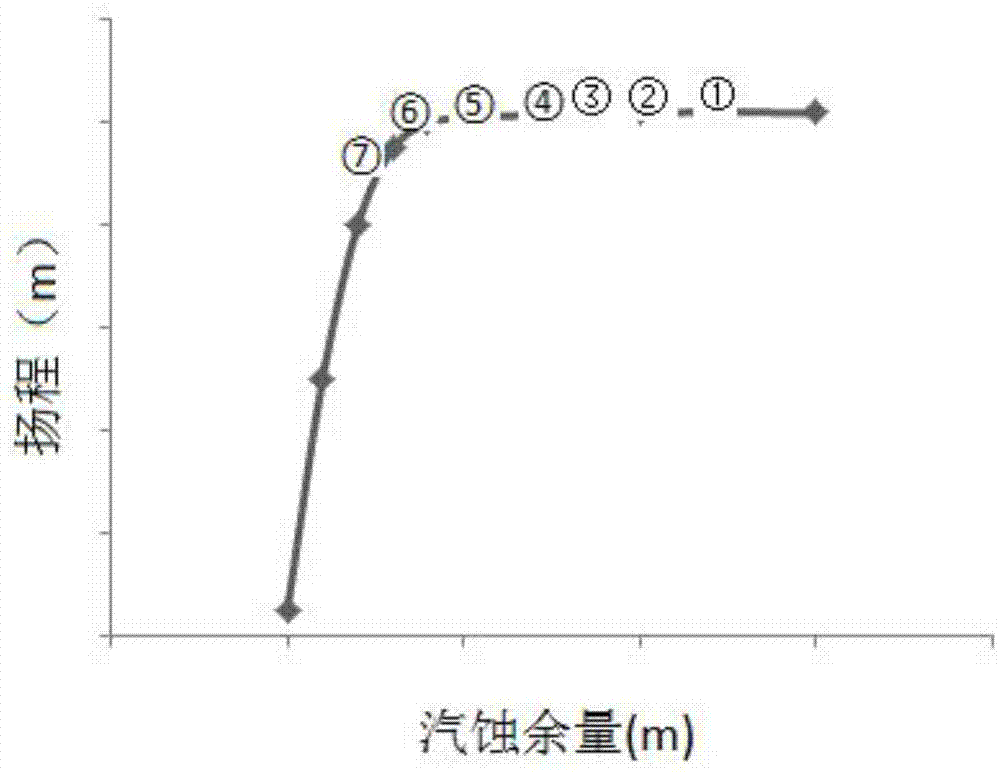

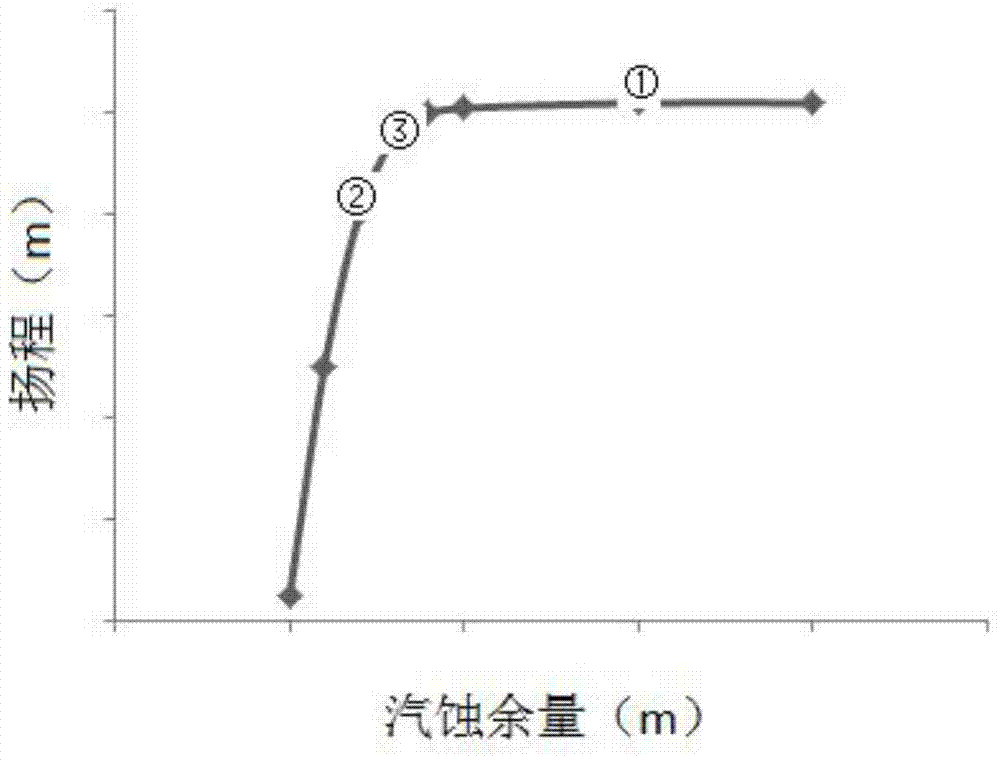

[0045] The purpose of the present invention is to use the CFD cavitation model to quickly predict the value of centrifugal pump NPSHr, this method is specifically carried out on the CFD software CFX, specifically as follows:

[0046] step one:

[0047] Purpose: Under the condition of given mass flow rate M*, when the pump is running normally, use CFX software to simulate and calculate the head H(0). Set the boundary conditions: the inlet is set to a fixed total pressure: PT in (0)=PT in *

[0048] The outlet is set to a fixed mass flow rate: M out (0)=M*

[0049] After the simulation calculation in CFX, the post-processing output is obtained: total outlet pressure: PT out (0),

[0050] Export static pressure: PS out (0),

[0051] Then the pump head and dynamic pressure can be obtained according to the calculation: head H(0)=PT out (0)-PT in (0),

[0052] Dynamic pressure DH (0) = PT out (0)-PS out (0)

[0053] Step two:

[0054] Objective: To obtain the full-loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com