Centrifugal pump design method based on matrix laboratory (MATLAB) genetic algorithm

A genetic algorithm and design method technology, applied in the field of centrifugal pump design based on MATLAB genetic algorithm, can solve problems such as not having the exact formula for pump loss, single-objective optimization of optimization goals, hindering engineering application promotion, etc., to overcome the global optimal solution. problems, reduce workload, and shorten the effect of design cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] In this embodiment, the design of a single-stage IS-type clean water centrifugal pump is taken as an example. The design parameters are as follows: flow rate 198m3 / h, head 50m, pump speed 2900rpm; perform the following steps:

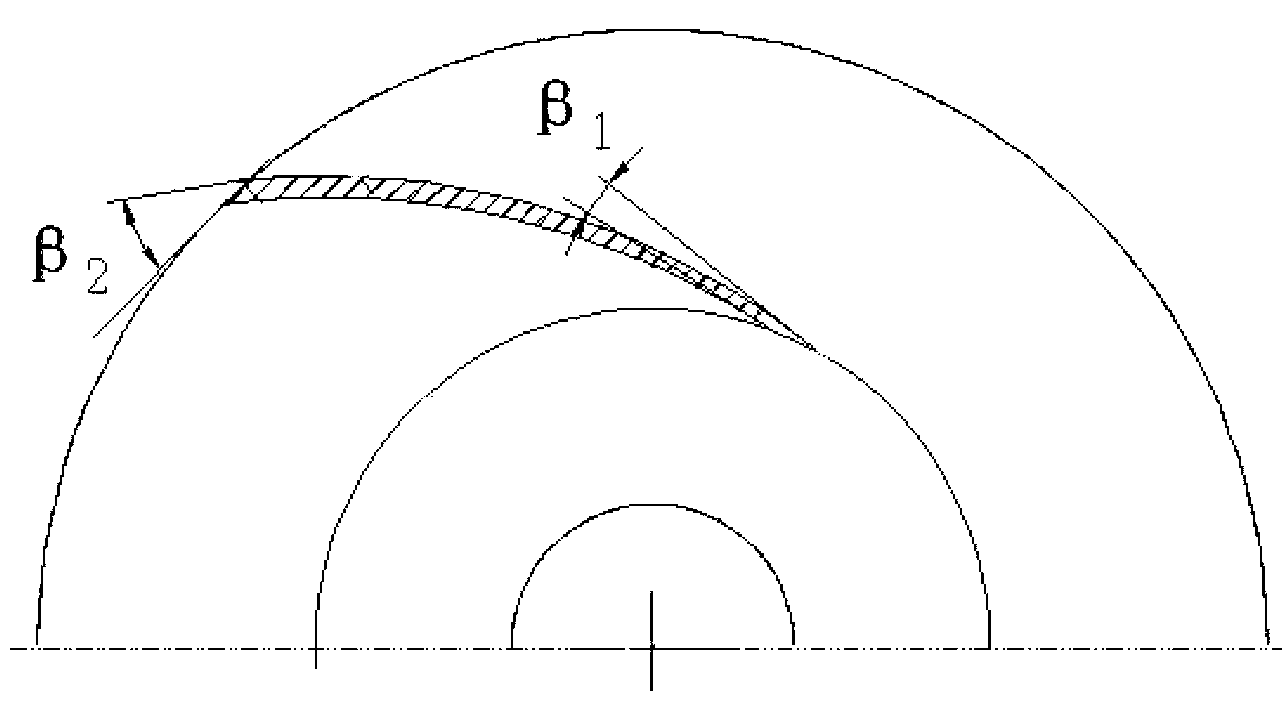

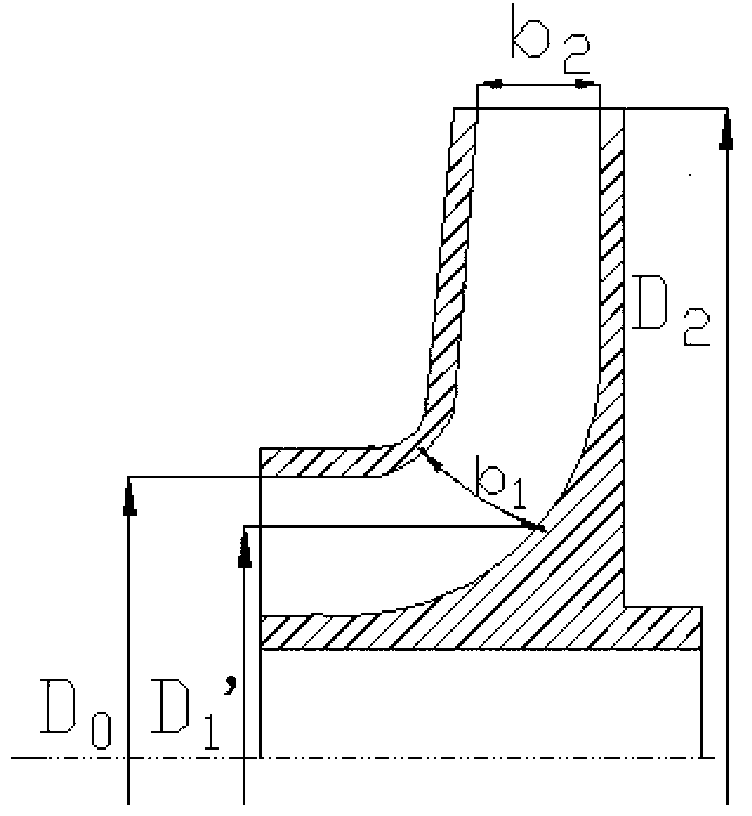

[0021] (1) Select centrifugal pump impeller inlet diameter D 0 , impeller outlet diameter D 2 , blade inlet position D′ 1 , blade inlet placement angle β 1 , blade outlet placement angle β 2 , blade inlet width b 1 , Blade outlet b 2 and the number of blades z as optimization variables to establish the sub-objective function g of the overall power loss of the centrifugal pump 1 (x), NPSH sub-objective function g 2 (x), centrifugal pump stability sub-objective function g 3 (x); Figure 1~2 Schematic diagram of the variables of the impeller.

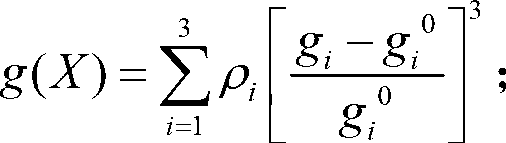

[0022] (2) Take the minimum initial value of each sub-objective function, and assign weights ρ to each sub-objective function i , to establish a unified objective function g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com