Optimal design method for inducer with varying pitch of centrifugal pump

An optimized design and technology of centrifugal pumps, applied to components, pumps, pump components, etc. of pumping devices used for elastic fluids, can solve problems such as increased unstable forces, decreased efficiency of inducers, and decreased hydraulic efficiency of pump main impellers , to achieve the effect of improving efficiency, enhancing operation stability and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

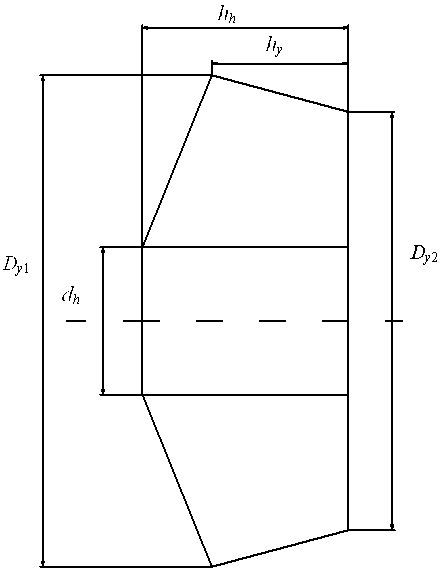

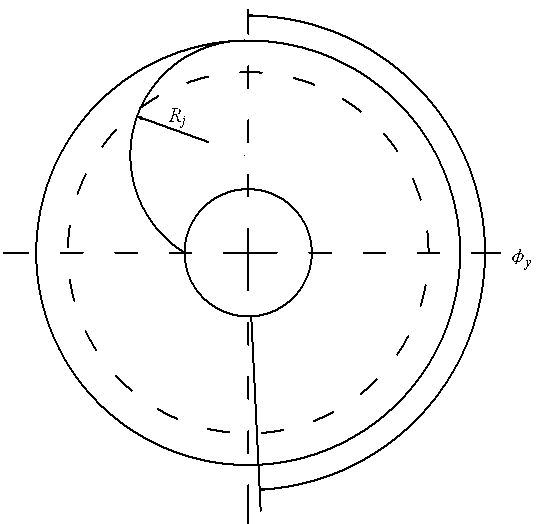

[0048] figure 1 and figure 2 Together determine the shape of this embodiment inducer. It is a cone-tipped inducer.

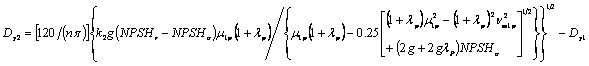

[0049] (1) Build a test bench for the external characteristics of the centrifugal pump, and the lift of the centrifugal pump H Measured by the pressure gauges at the inlet and outlet of the centrifugal pump; power P Measuring by electrometry; flow Q Read by the electromagnetic flowmeter on the centrifugal pump outlet piping system; efficiency n by the formula n = wxya / P Calculated; the vacuum pump is used to control the vacuum degree of the suction port, so that the centrifugal pump has cavitation, and the necessary NPSH of the centrifugal pump is measured NPSH r ; Calculate the NPSH of the centrifugal pump device according to the measurement of the built test bench NPSH a , NPSH a by the formula Calculated; through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com