Patents

Literature

72results about How to "Solve the problem of cavitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

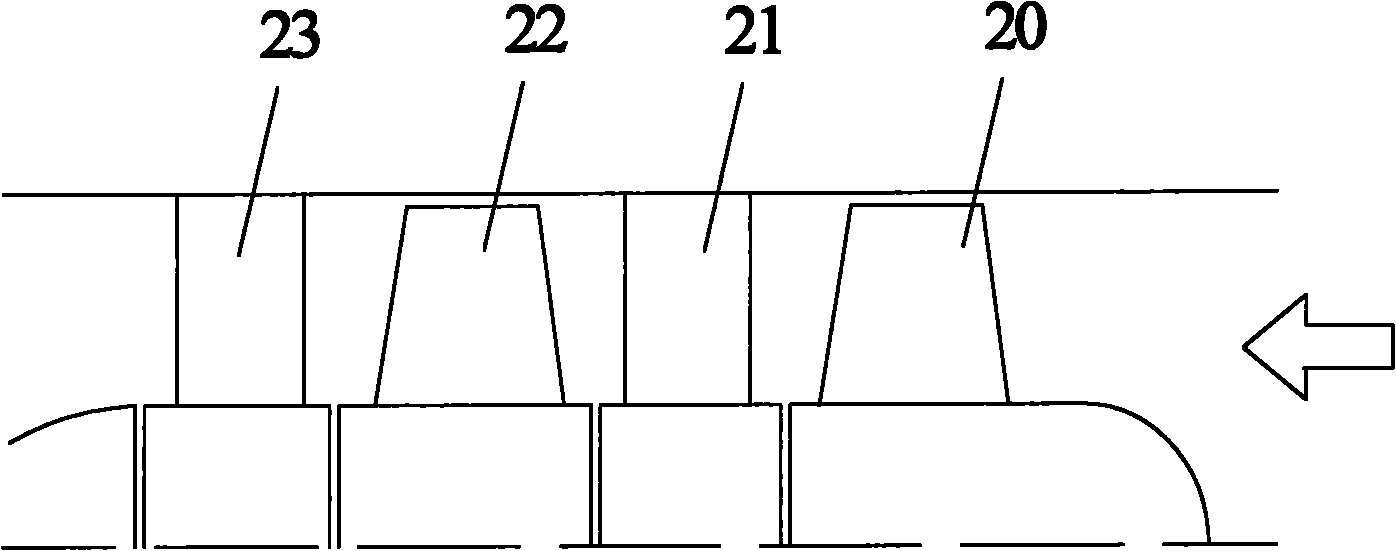

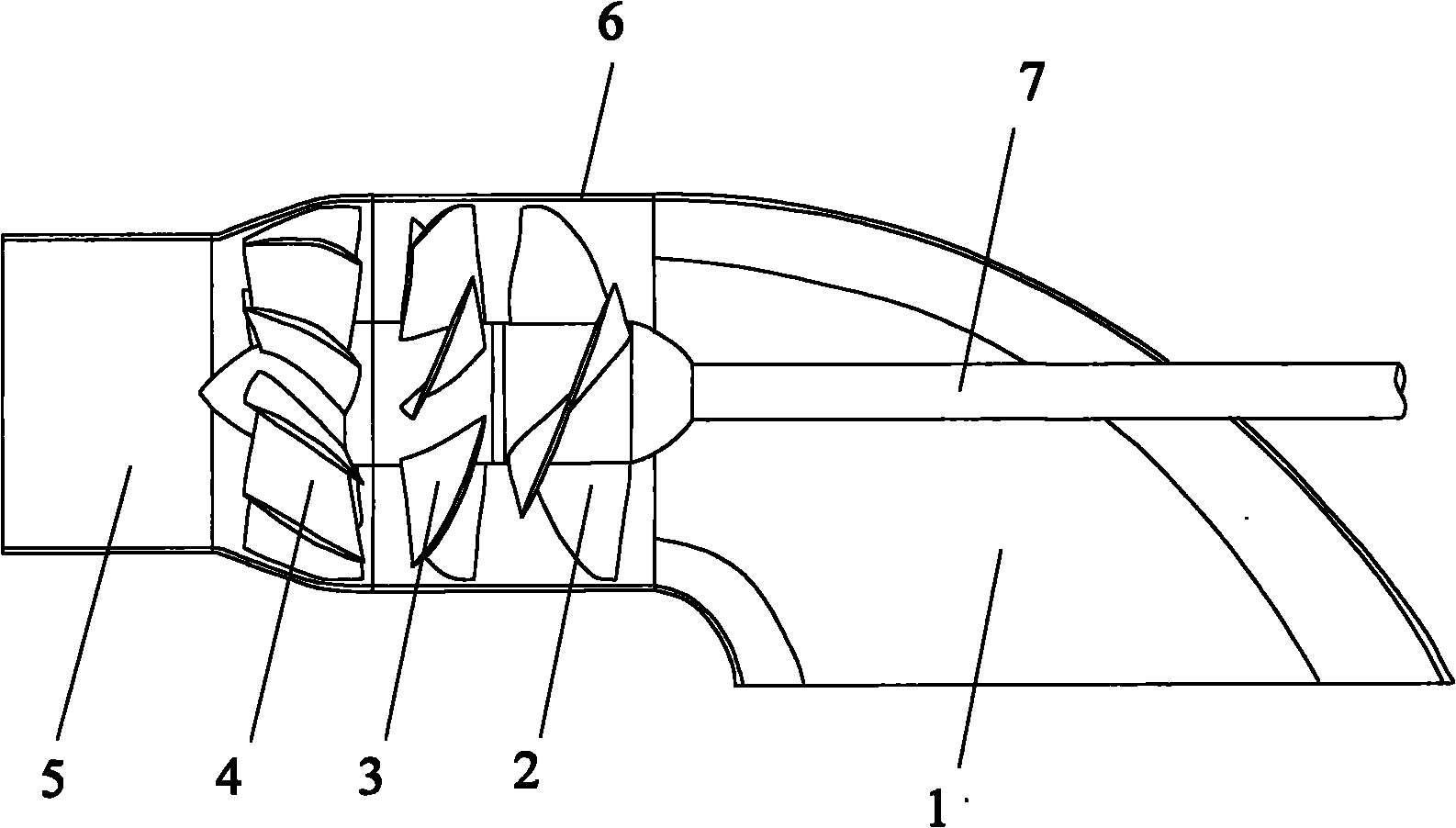

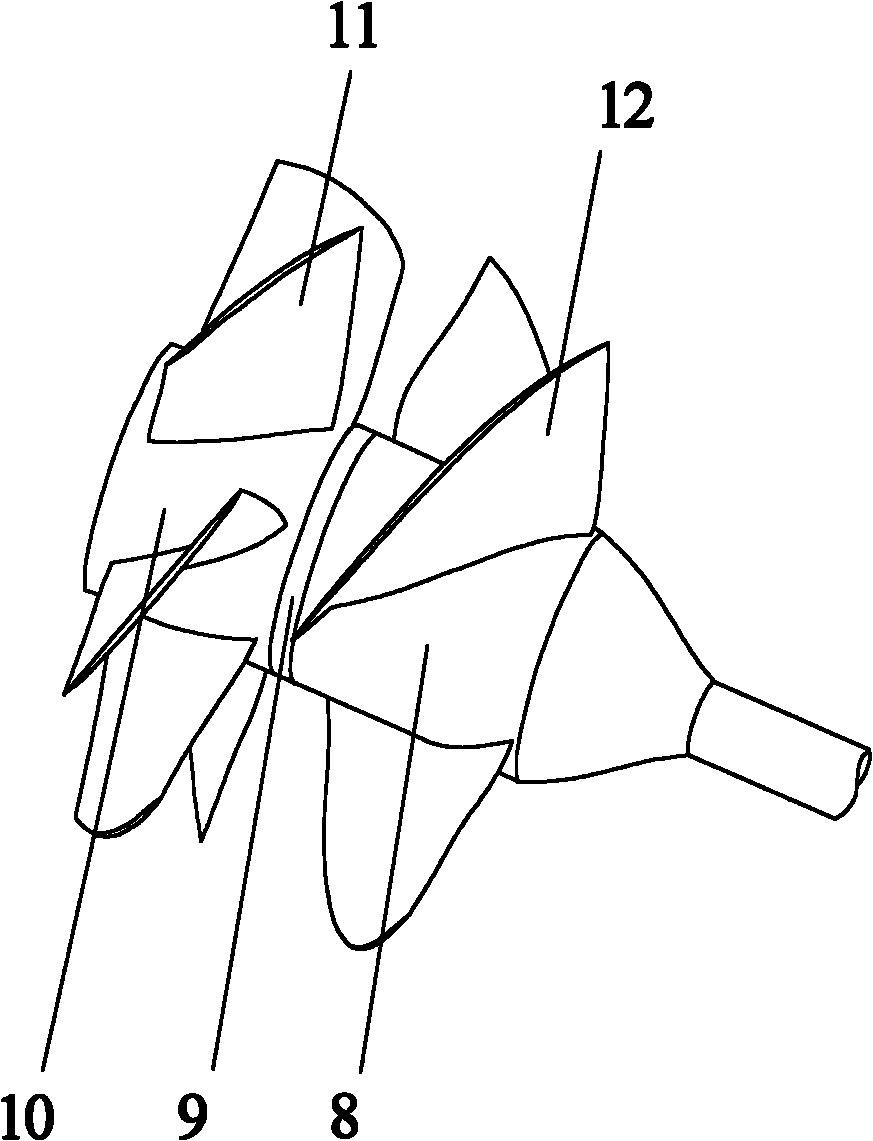

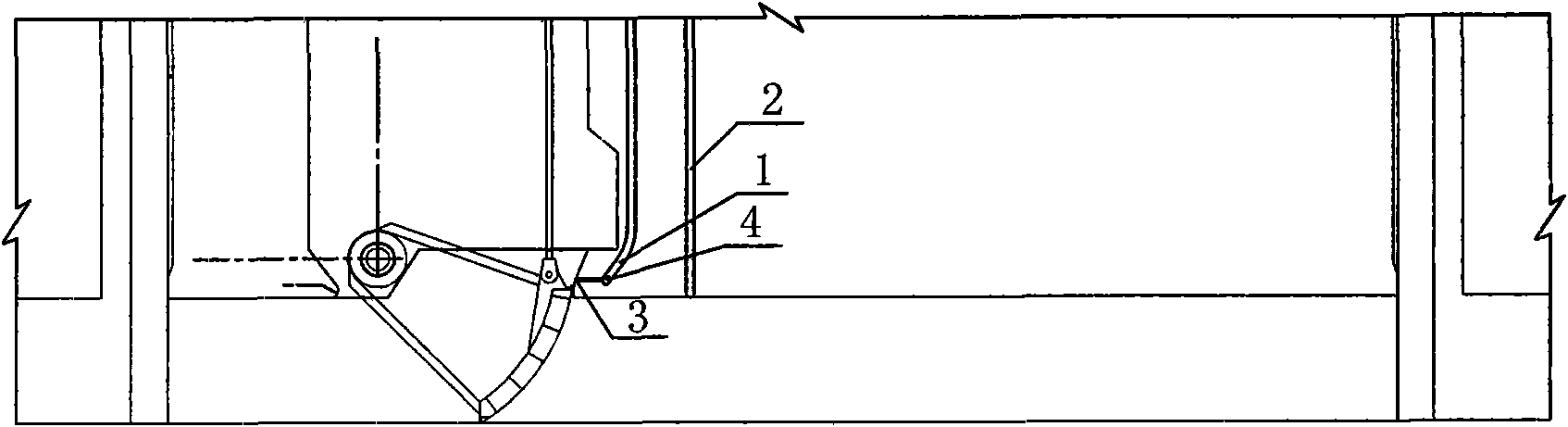

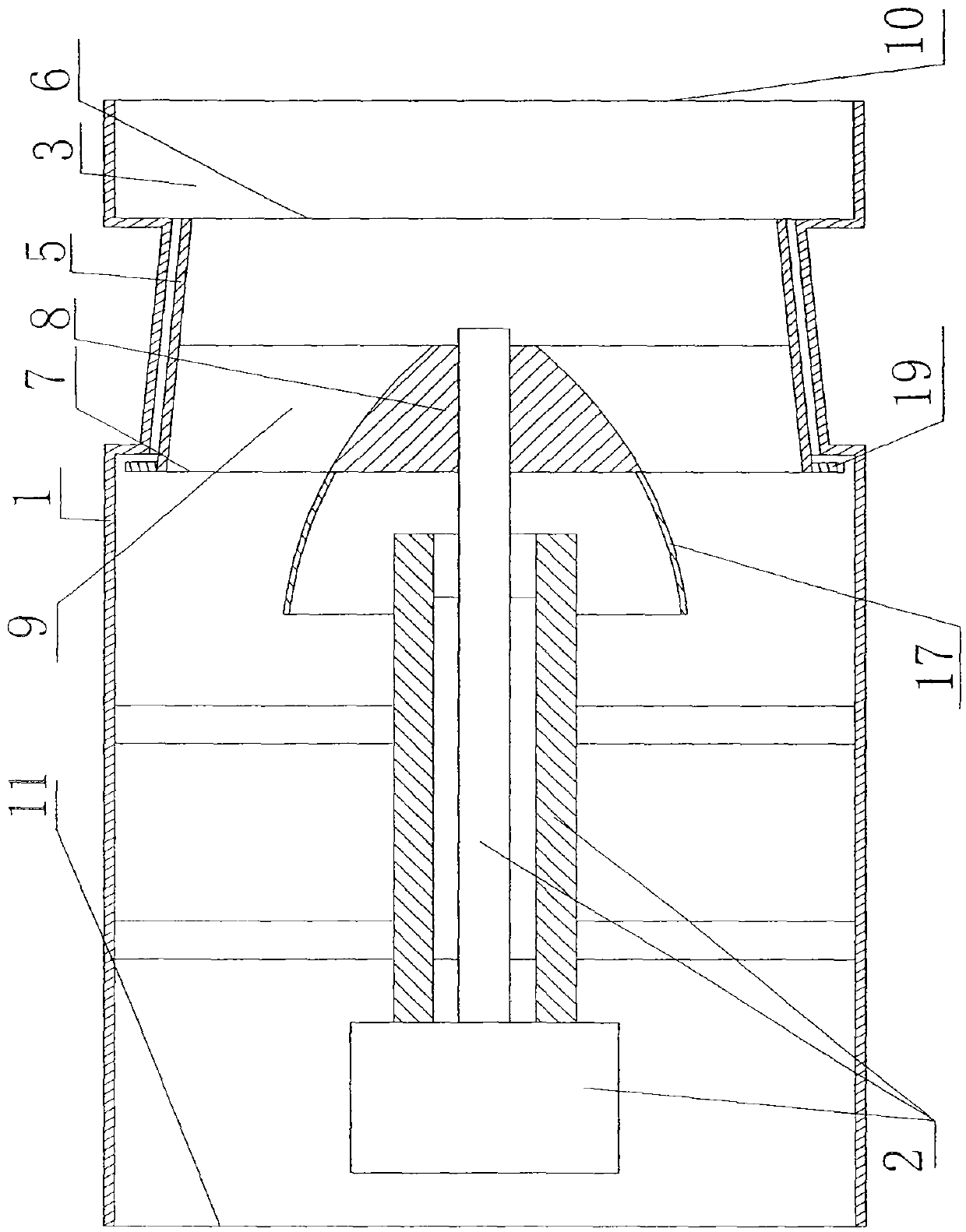

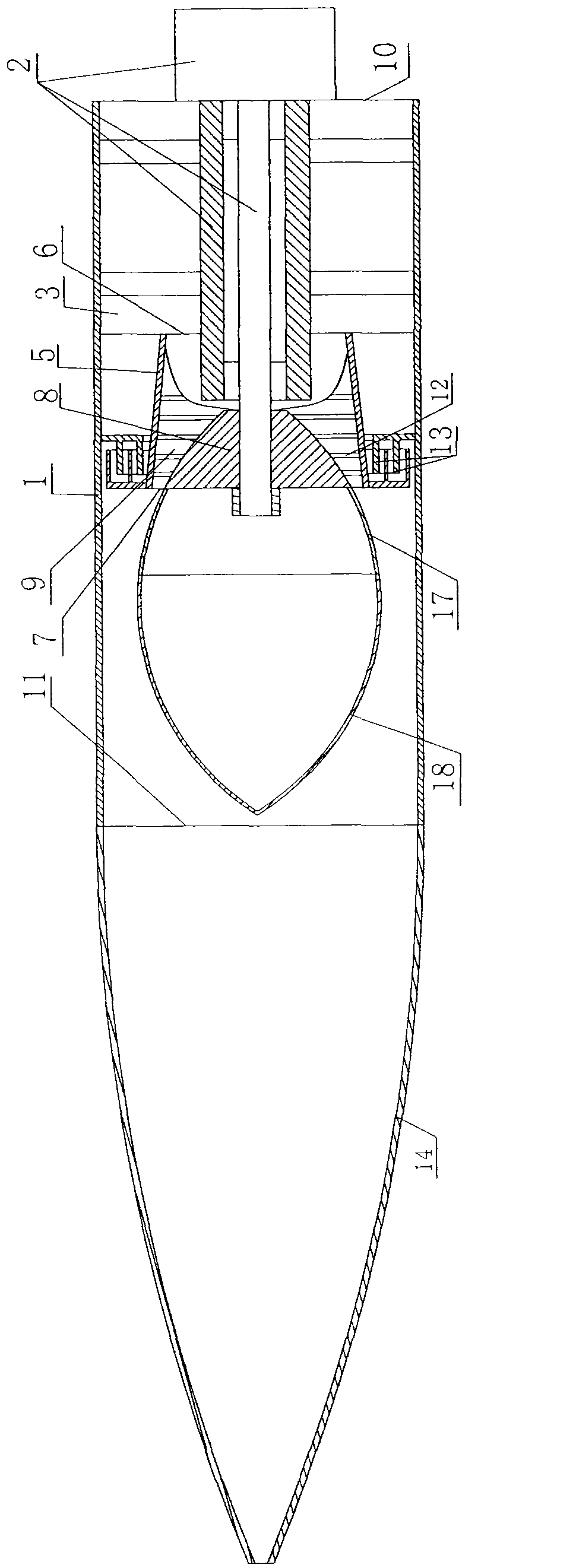

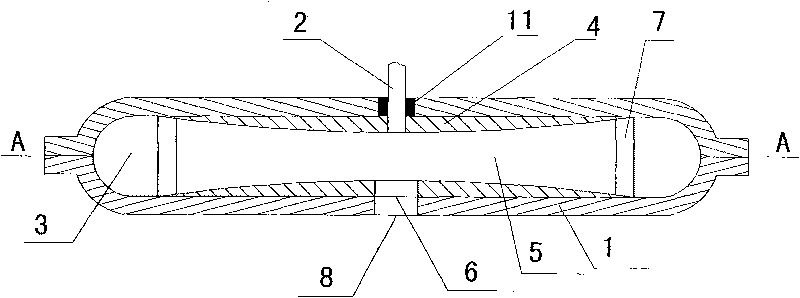

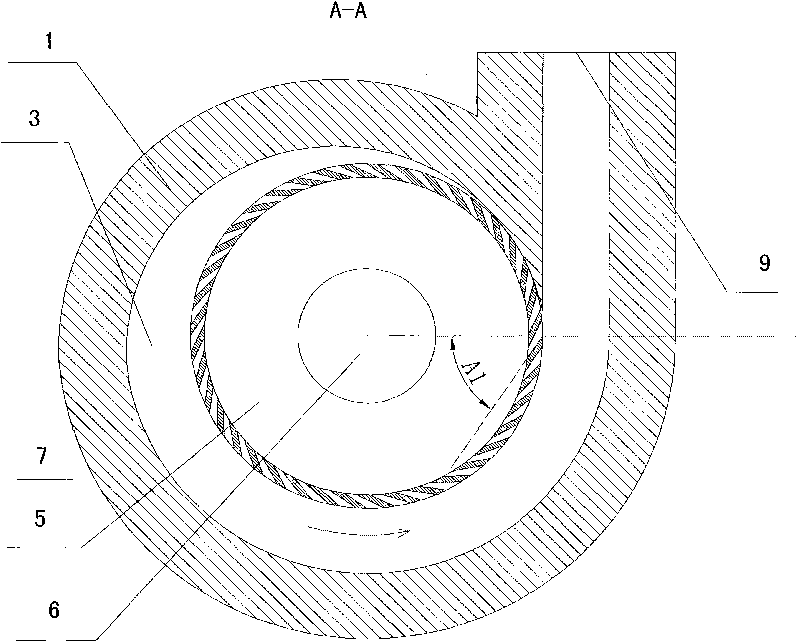

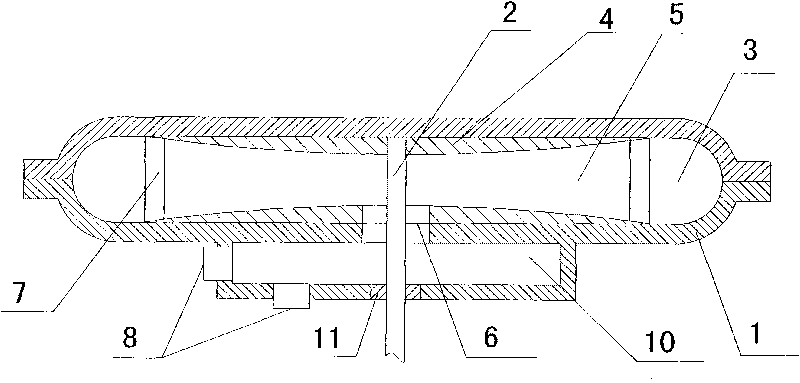

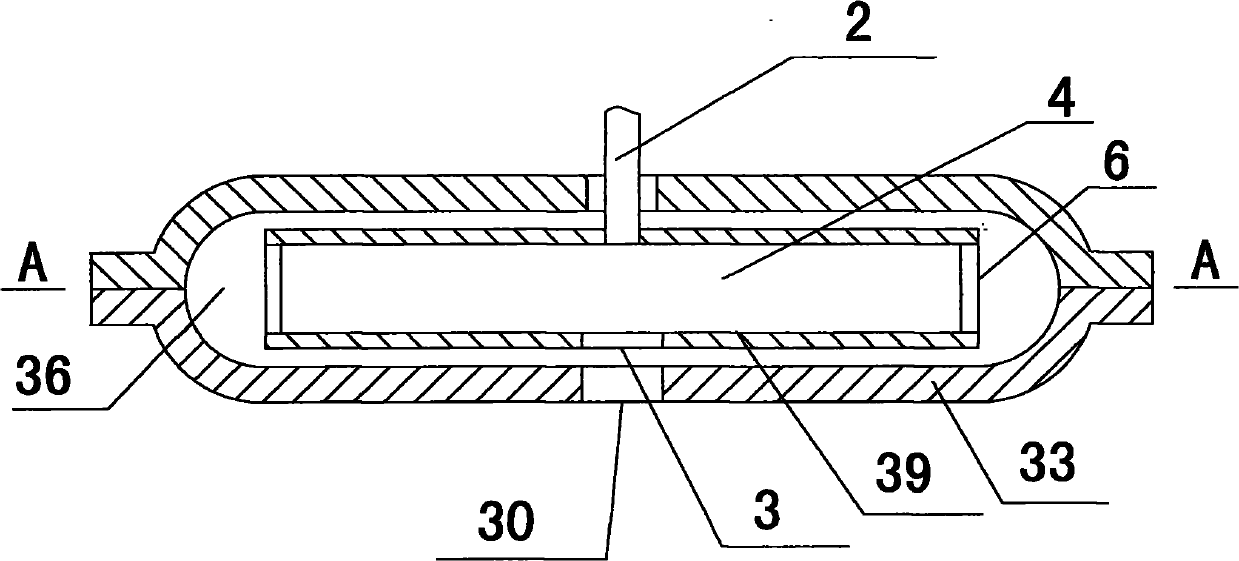

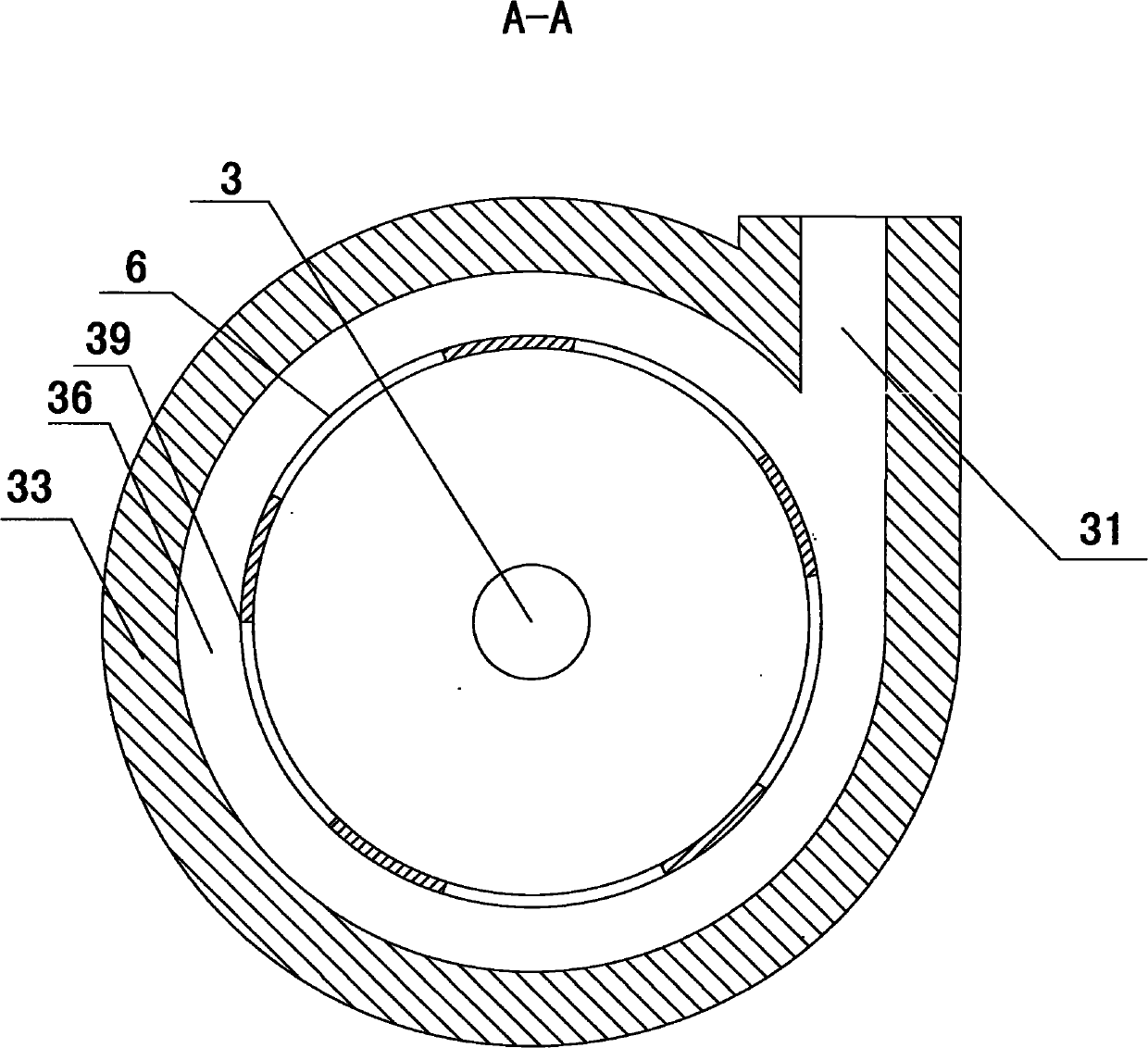

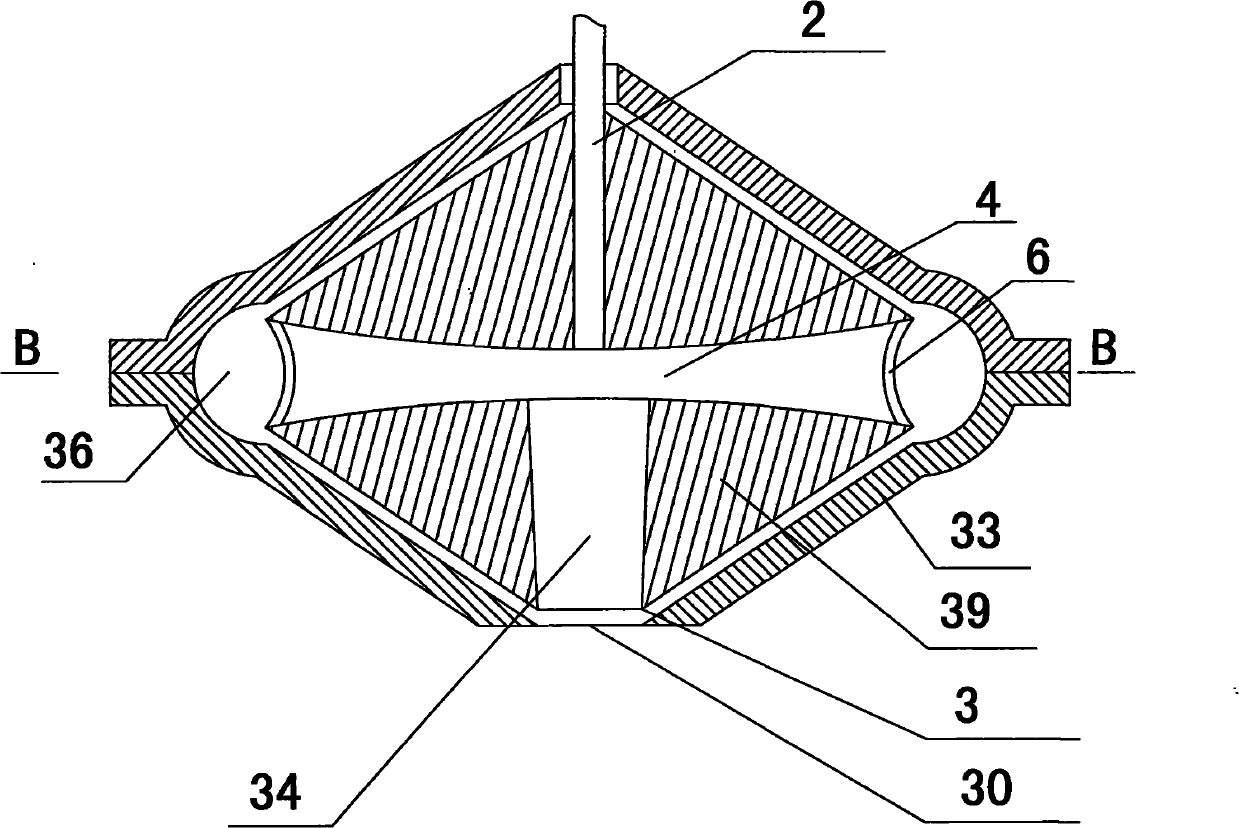

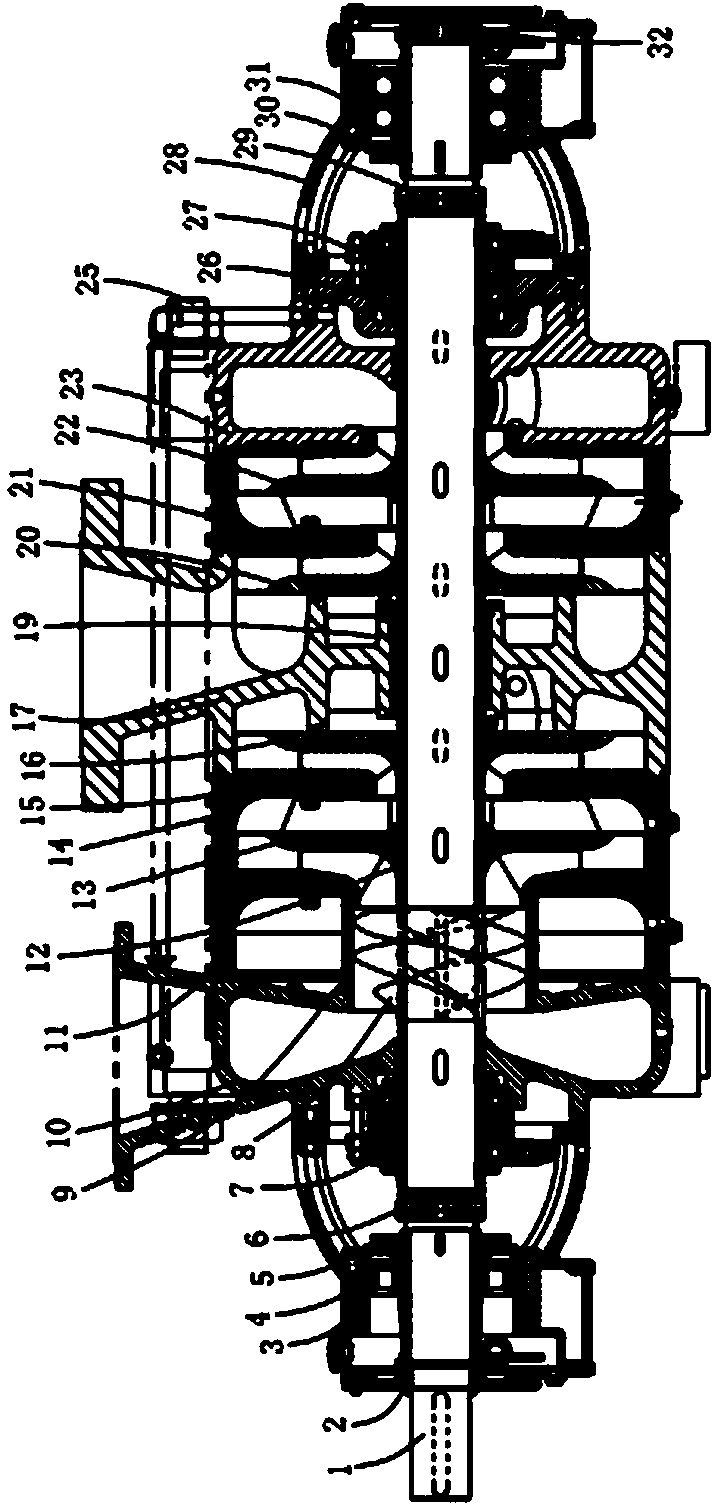

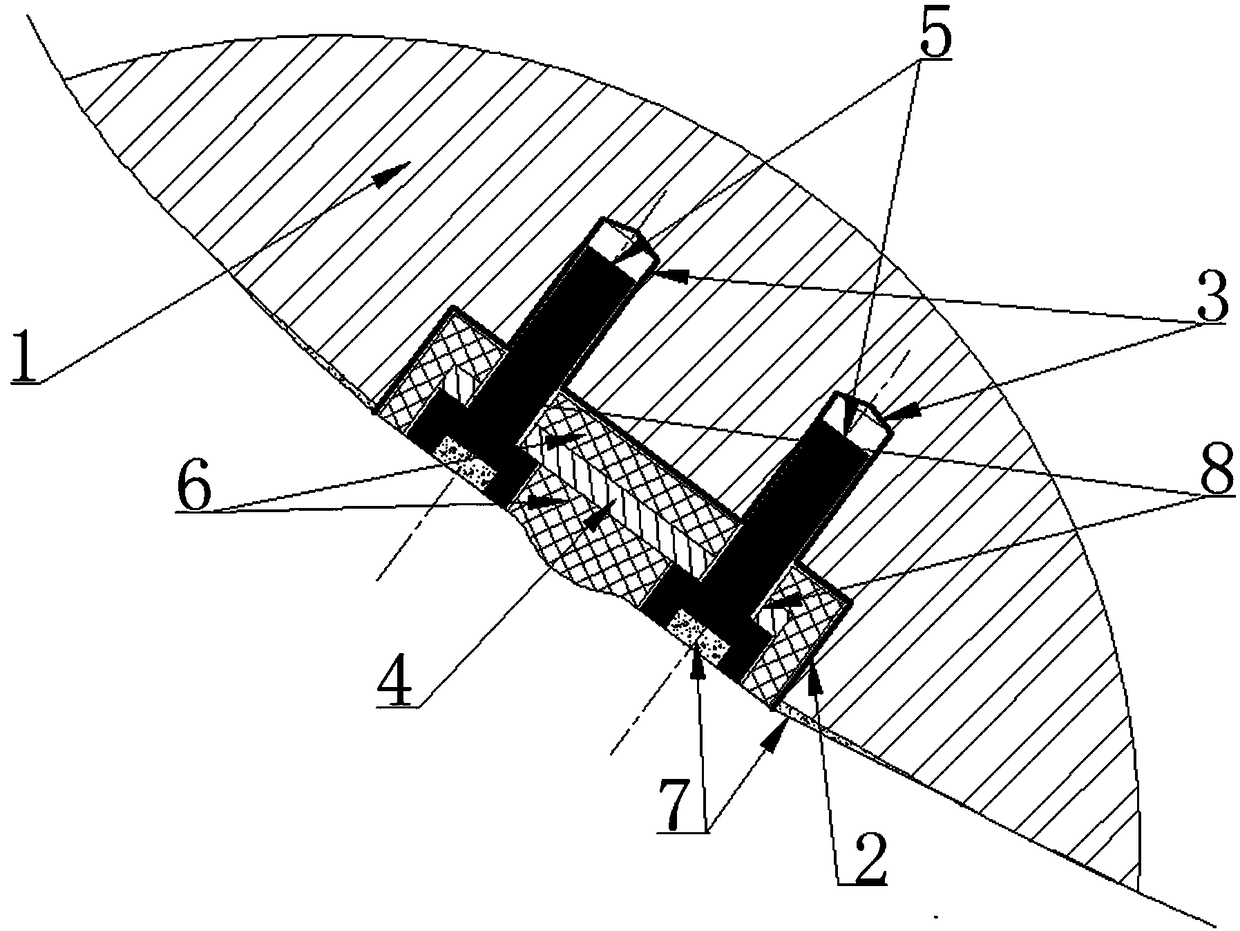

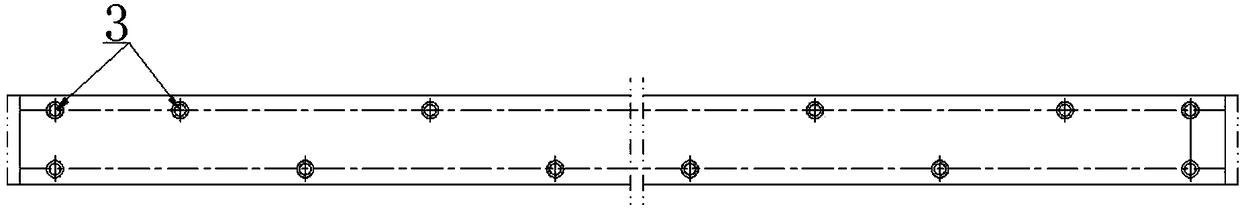

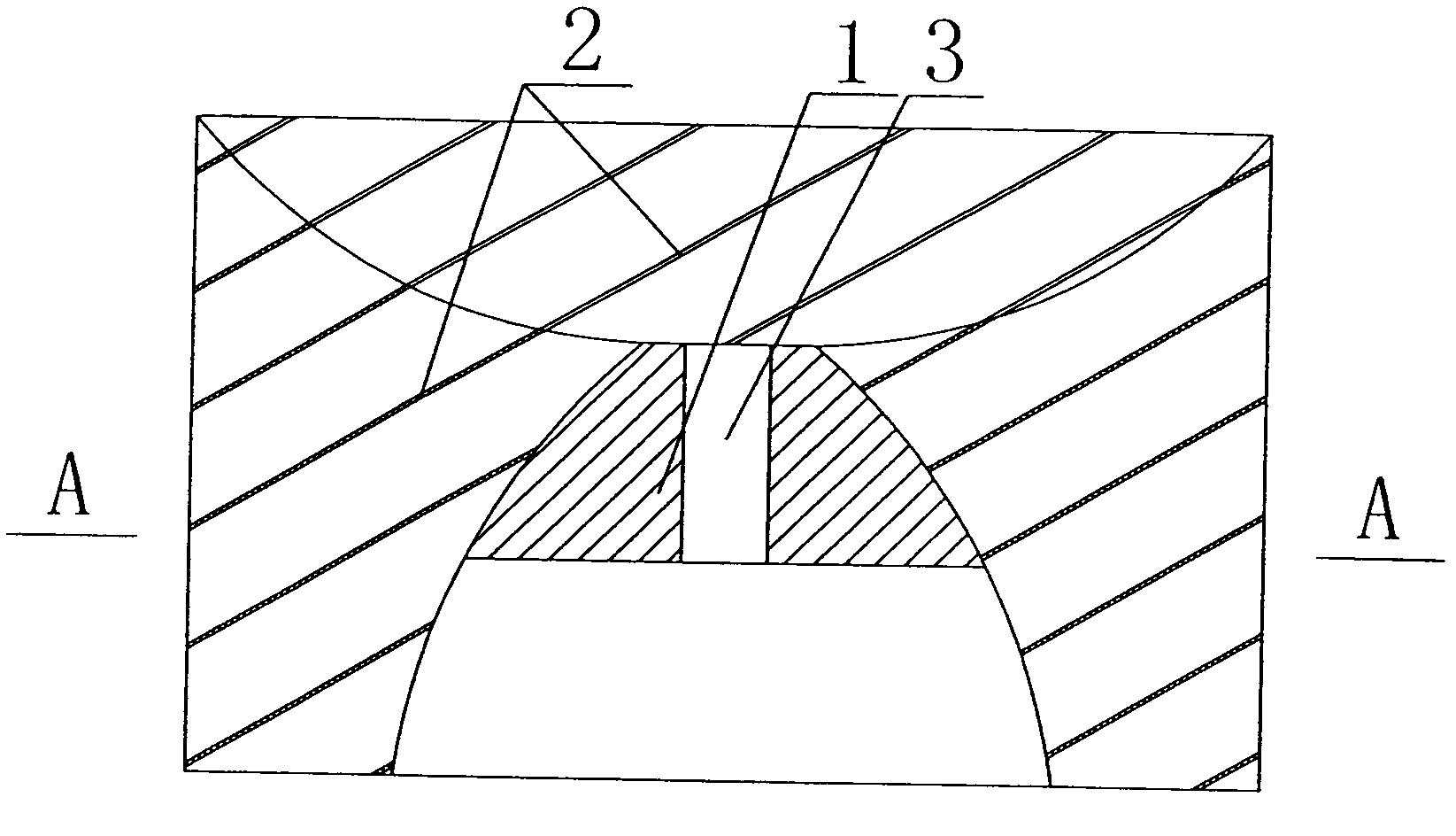

Serial axial-flow water jet propulsion pump

InactiveCN101830278AAvoid internal cavitationAvoid cavitationPump componentsPropulsive elementsImpellerCavitation

The invention discloses a serial axial-flow water jet propulsion pump which comprises a water suction elbow (1), a pump shaft (7), an impeller chamber (6), an inducer (2) and a main impeller (3), wherein the inducer (2) and the main impeller (3) are positioned in the impeller chamber (6); the pump shaft (7) is horizontally arranged; the inducer (2) and the main impeller (3) are fixed on the pump shaft (7) through keys; the outlet of the water suction elbow (1) is connected with the inlet of the inducer (2); the outlet of the main impeller (3) is orderly connected with a rectifier (4) and a jet pipe (5); and the area of the overflowing cross section gradually reduces along the central line of the flow channel to form a contracting flow channel. The invention avoids cavitation in the main impeller, solves the problems of cavitation under the operating conditions of large thrust and high speed of the water jet propulsion pump and reduces the axial size of the propulsion pump.

Owner:CHINA AGRI UNIV

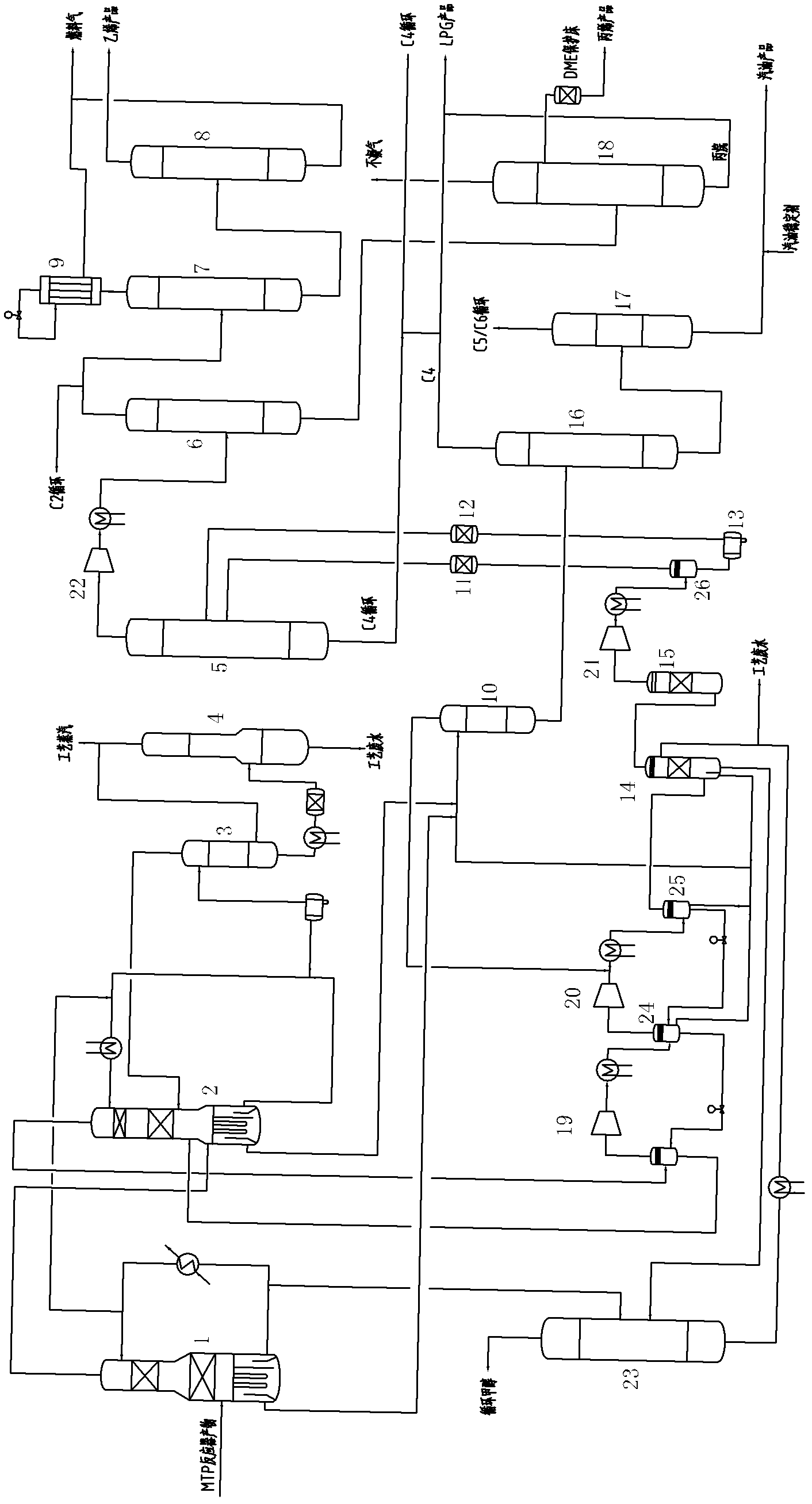

MTP (methanol to propylene) device and novel separation process thereof

ActiveCN105503492AReduce lossLess solvent absorptionDistillation purification/separationHydrocarbon from oxygen organic compoundsGas phaseSolvent

The invention relates to an MTP (methanol to propylene) separation device and a novel separation process adopted by the MTP device. The novel separation process comprises the steps that quenched reaction gas is pressurized by a compressor and undergoes washing and alkali wash treatment on a third compression section, a gas phase at the outlet of a fourth compression section goes to a depropanizer and a liquid phase goes to a debutanizer, water phases of separating tanks among the sections of the compressor return to a quench tower, and a hydrocarbon phase is sent to a separating tank at the outlet of the fourth compression section after being pressurized; the materials ejected from the debutanizer go to the depropanizer and the materials discharged from tower reactors enter a dehexanizer; a deethanizer compressor is arranged between a deethanizer and an oil absorption tower, the oil absorption tower adopts recycle propane or C4 as an absorbing solvent, fuel gas excluding C2 is obtained at the tower tops, the materials discharged from the tower reactors go to a stripping tower to recover the propane or C4 solvent, and the materials ejected from the stripping tower go to an ethylene rectification tower, thus obtaining the byproduct ethylene. The novel separation process has the effects that the process flow can be effectively optimized; the energy consumption of systems, the pipeline corrosion and the cost of investment can be effectively reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

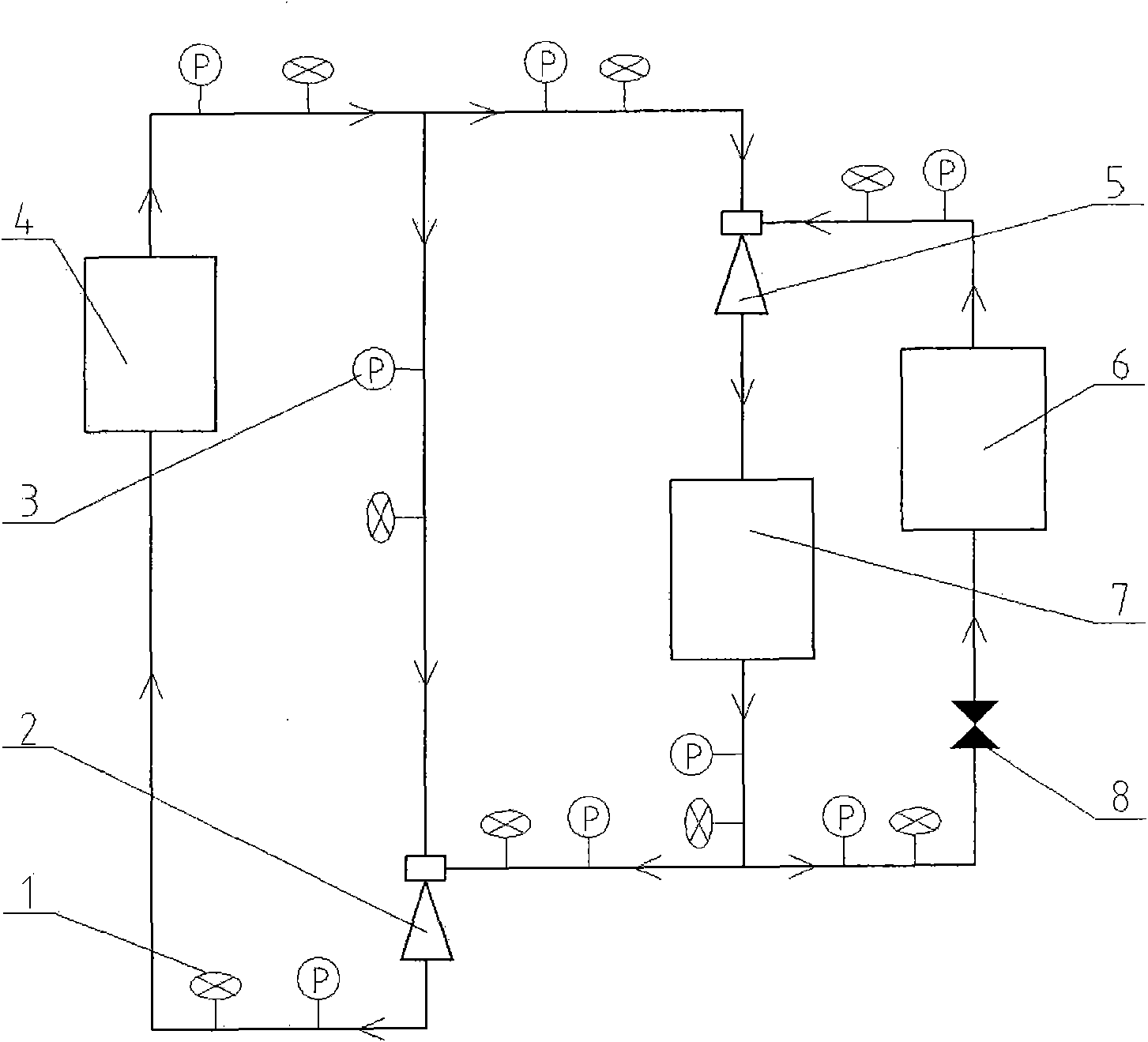

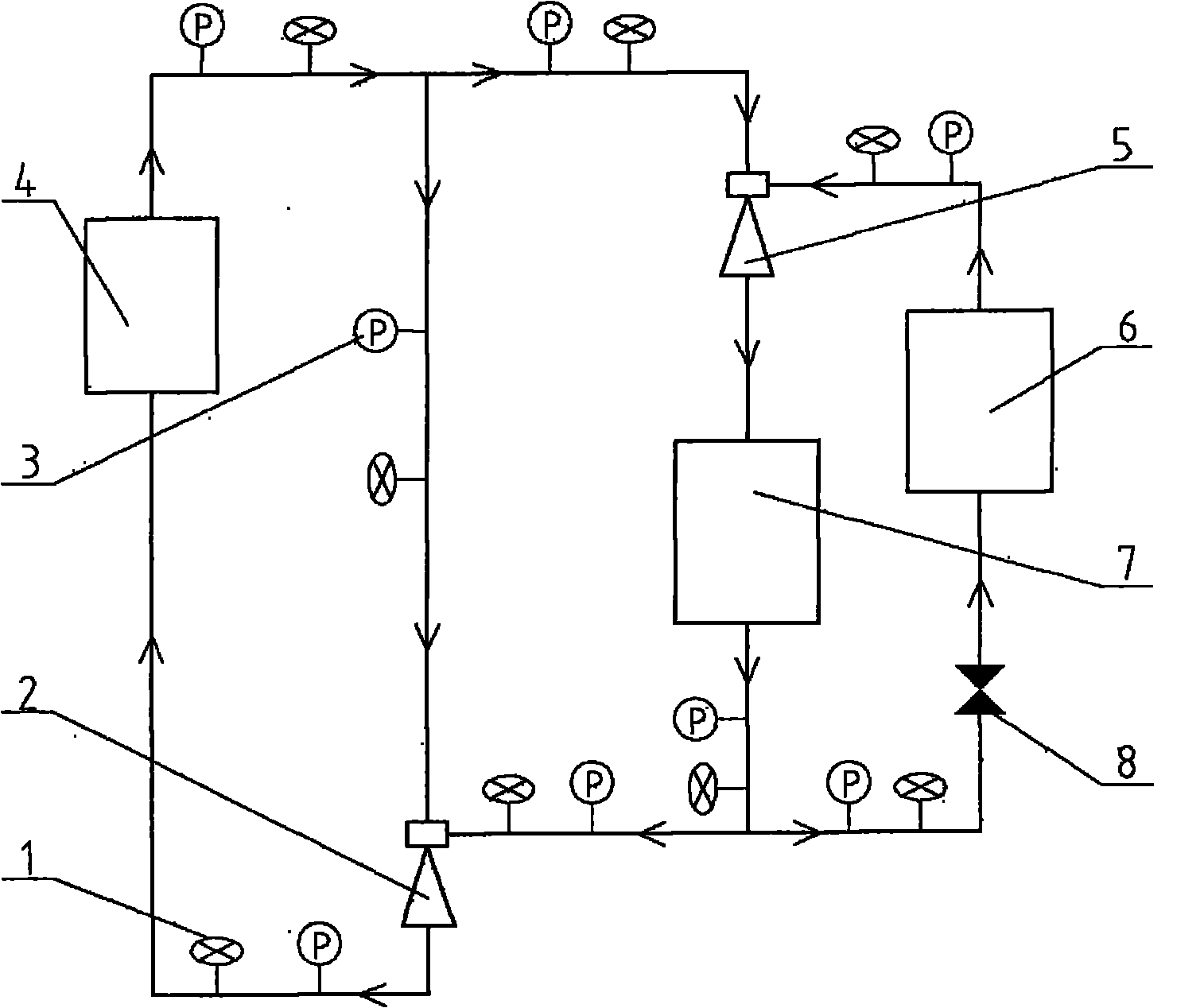

Double-jet refrigerating system

InactiveCN101818965ASolve the problem of cavitationIncrease pressureClimate change adaptationFluid circulation arrangementInjection portCavitation

The invention discloses a double-jet refrigerating system, belonging to the technical filed of energy and refrigeration. The system is characterized by replacing a mechanical pump with a steam-liquid injector on the basis of a traditional single jet refrigerating system. The outlet end of a generator 4 is respectively connected with the working steam inlet end of a steam-steam injector 5 and the working steam inlet end of the steam-liquid injector 2 through pipelines. The outlet end of a condenser 7 is divided into two paths to respectively connect with an expansion valve 8 and the injection port of the steam-liquid injector 2. The outlet of an evaporator 6 is connected with the injection port of the steam-steam injector 5. The fluid at the outlet of the steam-liquid injector 2 flows back to the generator 4 through pipelines. The invention has the effects and benefits of reducing moving parts, avoiding the cavitation corrosion problem of the mechanical pump and saving electric energy.

Owner:DALIAN UNIV OF TECH +1

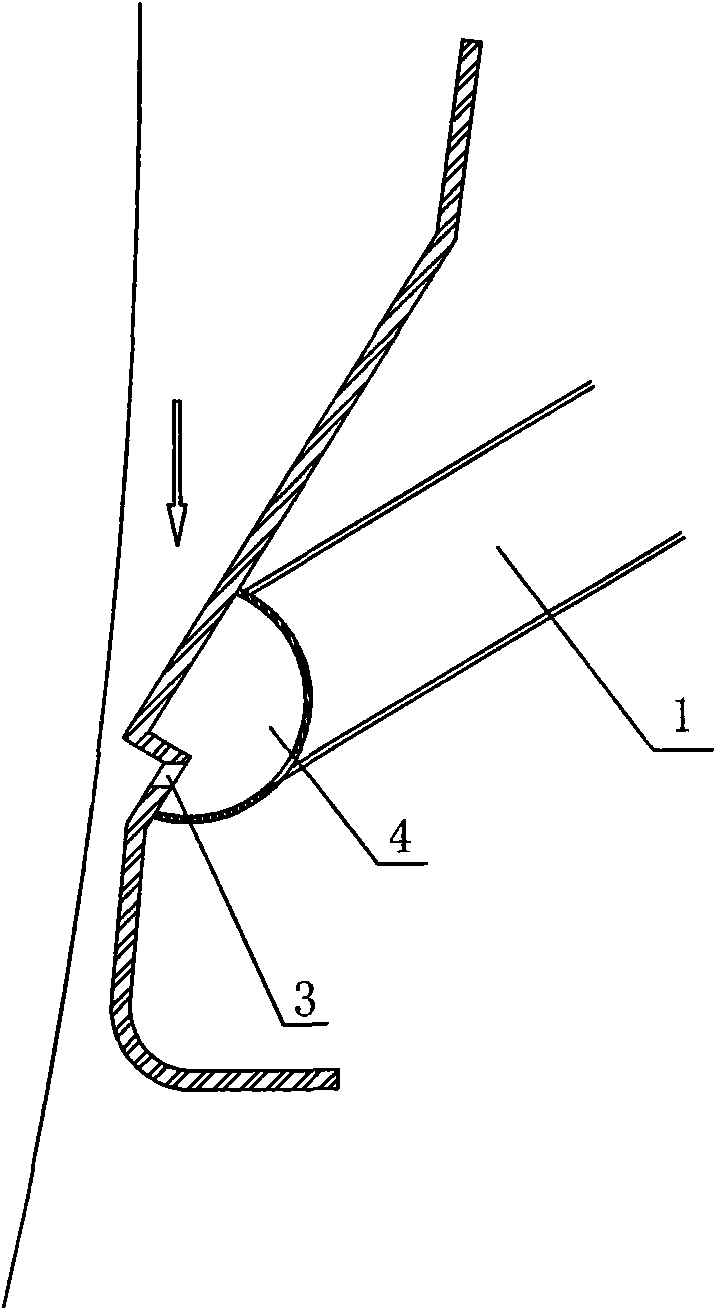

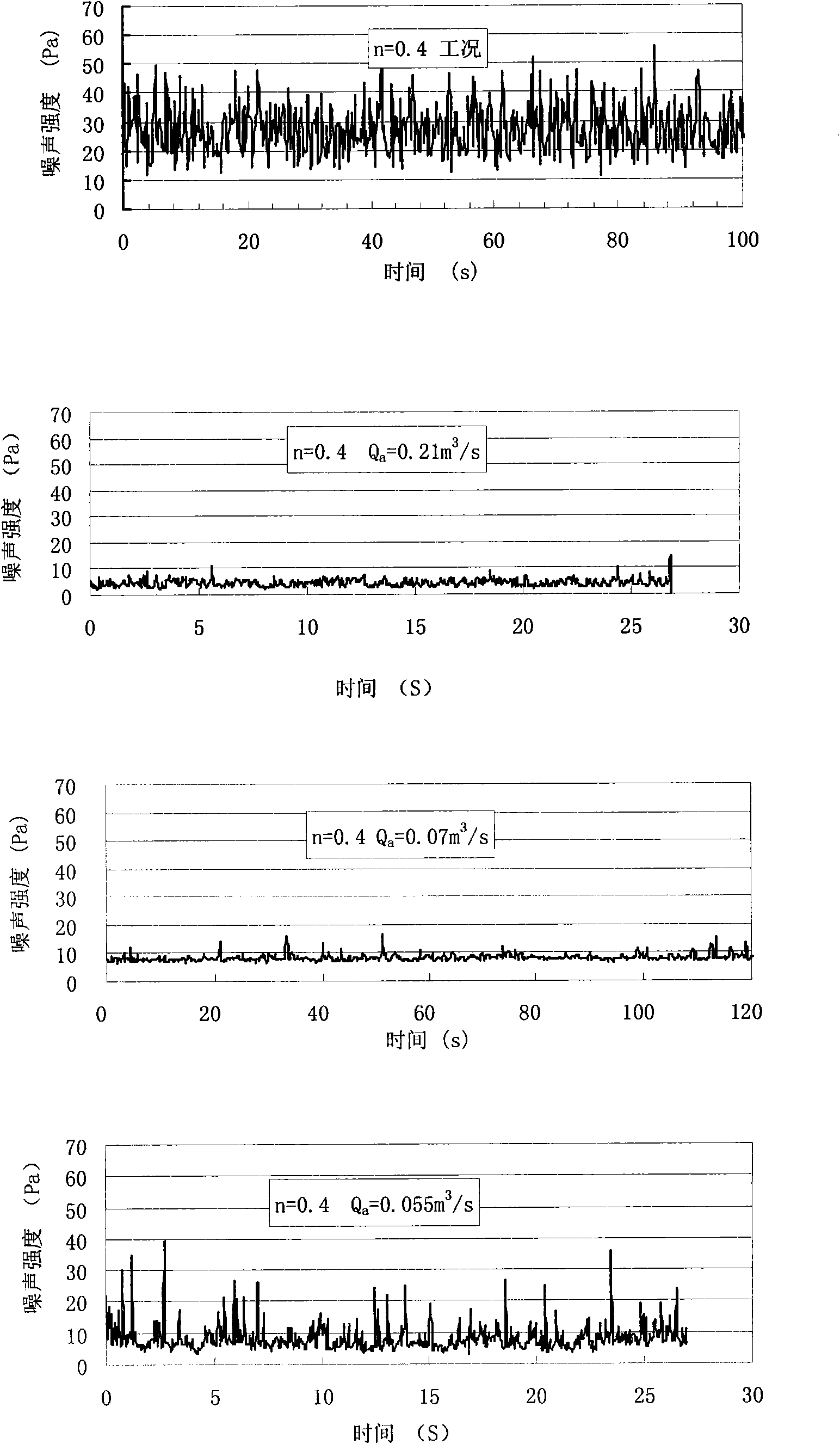

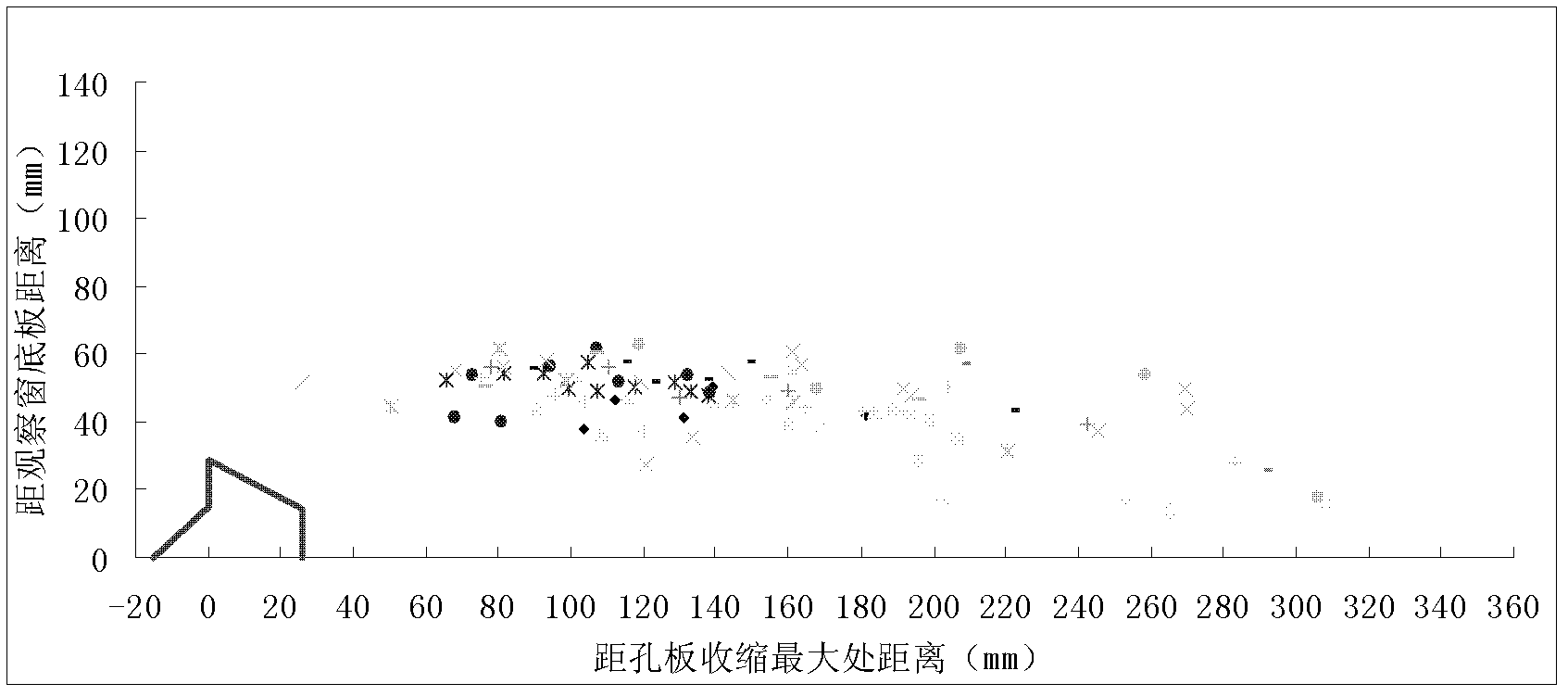

Combined ventilation method for relieving cavitation of large water-level amplitude high-lift ship lock valve

InactiveCN101603307ASimple structureReduce construction difficultyBarrages/weirsDry-docksCavitationNatural ventilation

The invention relates to a combined ventilation method for relieving cavitation of a high-lift ship lock valve, in particular to a combined ventilation method for relieving cavitation of a large water-level amplitude high-lift ship lock valve; by adopting a simple uniform cross section flat top type valve section gallery body type and shallow valve section gallery laying depth, in the design, the gallery is ensured to have a certain negative pressure when the high-level head of the ship lock is operated, the natural ventilation of a door head is used as a basic measure, and the natural ventilation of the top of the gallery is used as a supplement measure for the natural ventilation of the door head, by utilizing combined ventilation of the door head and the top of the gallery, cavitation is fully inhibited; when water level combination is changed, a water head is reduced, and negative pressure of the top of the gallery passes away and the natural ventilation can not be carried out, the natural ventilation of the door head is used for solving the problem of bottom flange cavitation of the valve. The method can well solve the problem of cavitation of the large water-level amplitude high-lift ship lock valve, and the construction difficulty of the valve section gallery is reduced, so as to be convenient for overhauling of the valve section gallery, save construction investment and reduce operation cost.

Owner:NANJING HYDRAULIC RES INST THE MINISTRY OF WATER RESOURCES THE MINIST

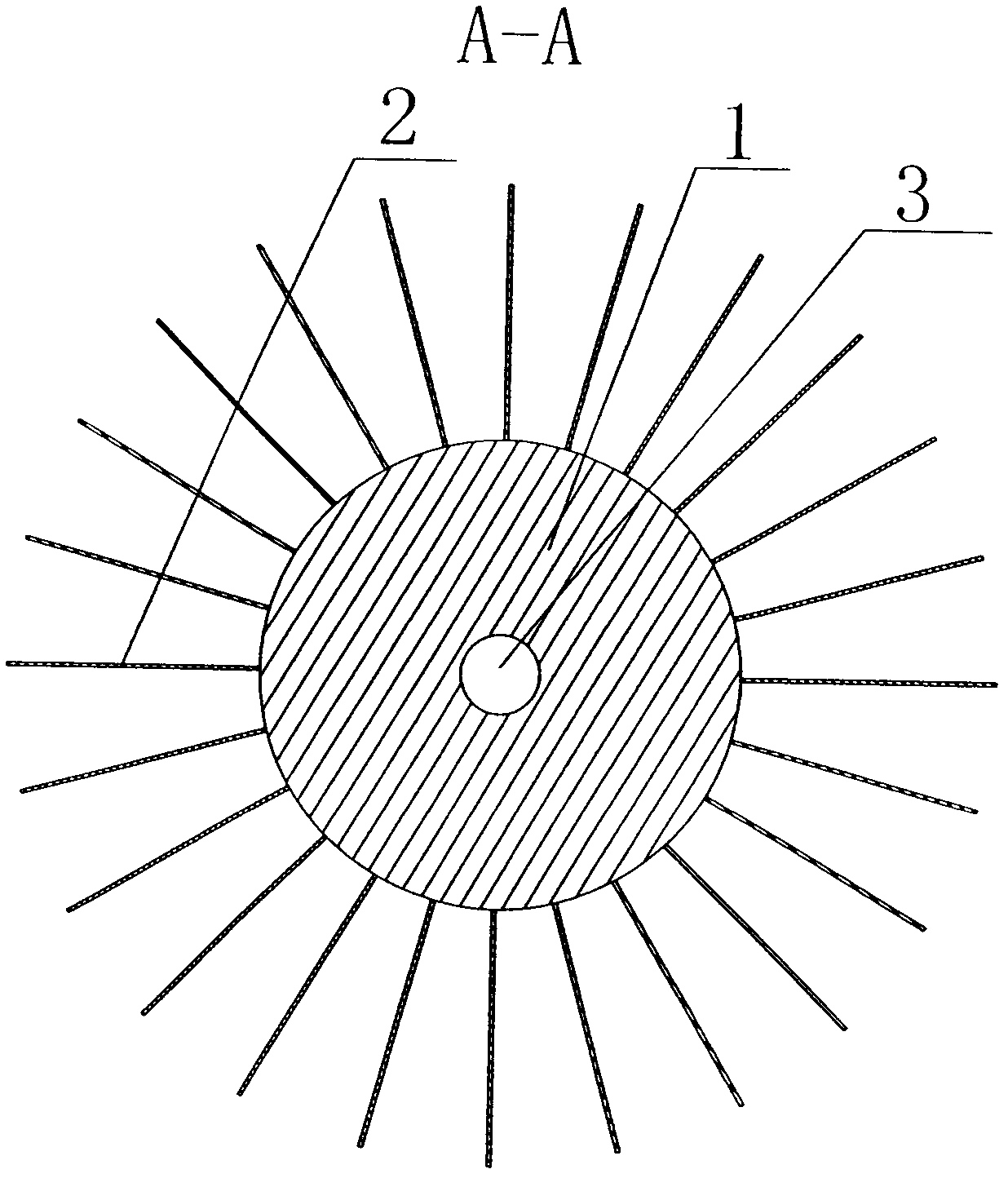

Axial flow device

InactiveCN102734175AUniform irrigationRealize micro-sprayPump componentsAxial flow pumpsImpellerSuction equipment

The invention provides an axial flow device comprising a shell and a transmission device. The shell is provided with the transmission device and is internally provided with a shell cavity; a vortex tube impeller is arranged in the shell cavity; the transmission device is connected with a vortex tube impeller; the vortex tube impeller is provided with a vortex tube which is provided with an impeller opening A and an impeller opening B and is internally provided with a wheel body, and the wheel body is provided with a guide blade; an inclined angle is formed between the guide blade and a rotating shaft of the vortex tube impeller; the guide blade is connected to the inner wall of the vortex tube; a shell cavity opening A is arranged at one end, which corresponds to the impeller opening A, of the shell cavity; and a shell cavity opening B is arranged at the other end of the shell cavity. The axial flow device is more energy-saving and can be used for pressurizing and conveying fluid. The axial flow device can serve as a water pump, vacuum equipment, air suction equipment, an air blower, a compressor, atomizing equipment, sprinkling equipment, a reactor, air blowing equipment, propelling equipment, a sewage processor, a dust remover, a dust collector, dressing equipment, a steam turbine, a water turbine, a wind turbine, a vortex pressurizing device utilizing residual heat of an engine, foam material manufacturing equipment, nano material manufacturing equipment and the like; and the axial flow device can be used for manufacturing a brand new foam material.

Owner:陈久斌

Method and system for separating MTP (Methanol to Propylene) reaction mixed gas

ActiveCN102304009BReduce corrosionReduce circulationChemical industryHydrocarbon purification/separationLoss rateQuenching

The invention relates to a method and a system for separating MTP (Methanol to Propylene) reaction mixed gas, wherein quenched water of a pre-quenching tower and a quenching tower kettle is respectively treated; gas hydrocarbon obtained at a compression II section is water-washed and alkali-washed and then enters a compression III section; the gas hydrocarbon obtained at the compression III section and liquid hydrocarbon not containing heavy hydrocarbons of C6 and more are respectively dried by the gas hydrocarbon, are flocculated by the liquid hydrocarbon and are dried, and then are conveyedinto a depropanization tower; a condensate stripping tower is arranged between the compression sections and is used for separating the condensate between the compression sections; light hydrocarbon components are returned back to the outlet of the compression II section and a heavy hydrocarbon components are respectively conveyed to a debutanization tower to be refined; the depropanization tower is arranged between the compression III section and a compression IV section and utilizes a regular rectification; the tower top of a demethanation tower is provided with a differential condenser for recycling refrigeration capacity thereof and reducing the loss rate of ethylene. The method and the system provided by the invention can effectively optimize technical flows, reduce system power consumption, reduce pipe corrosion and reduce investment cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

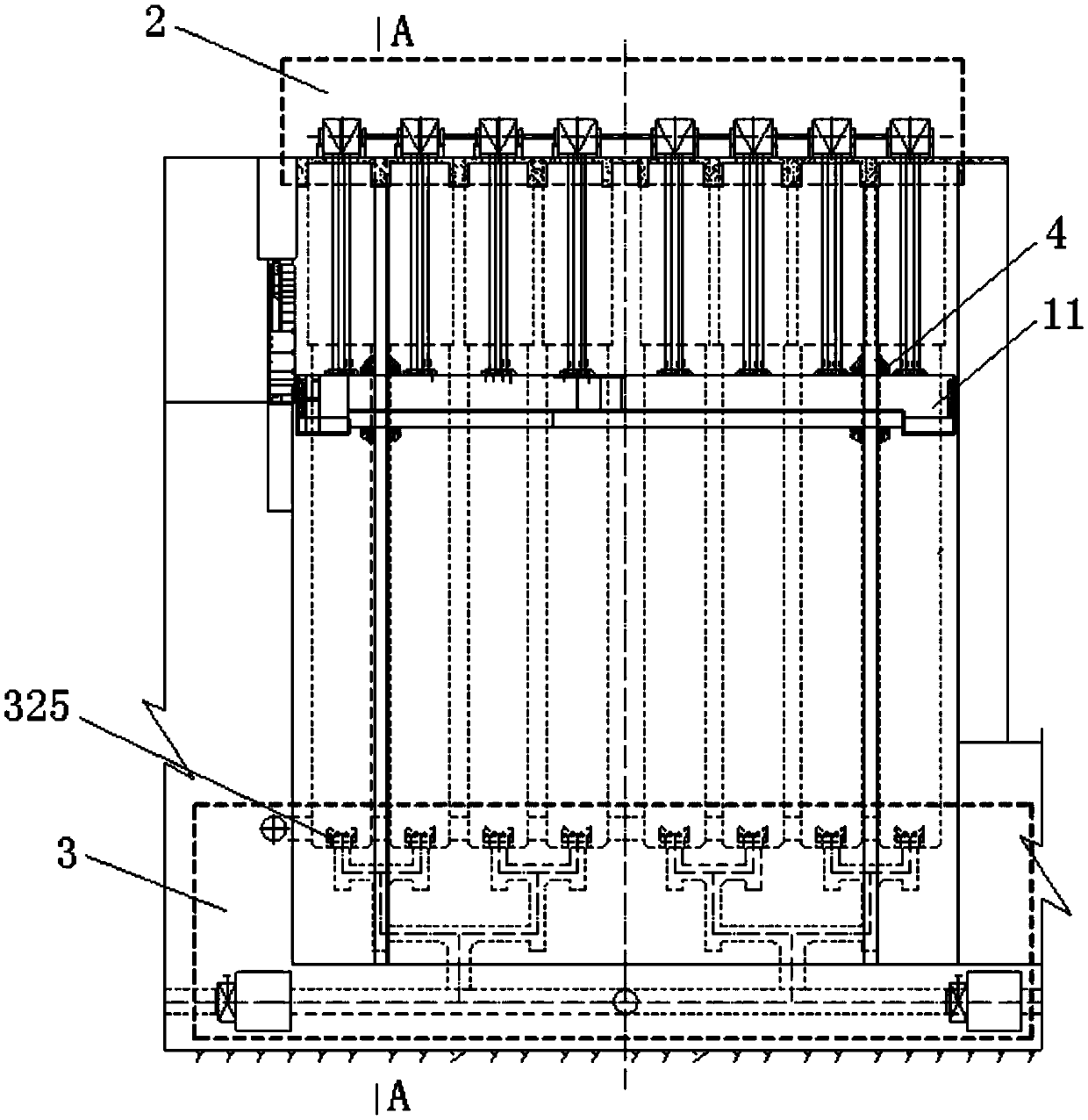

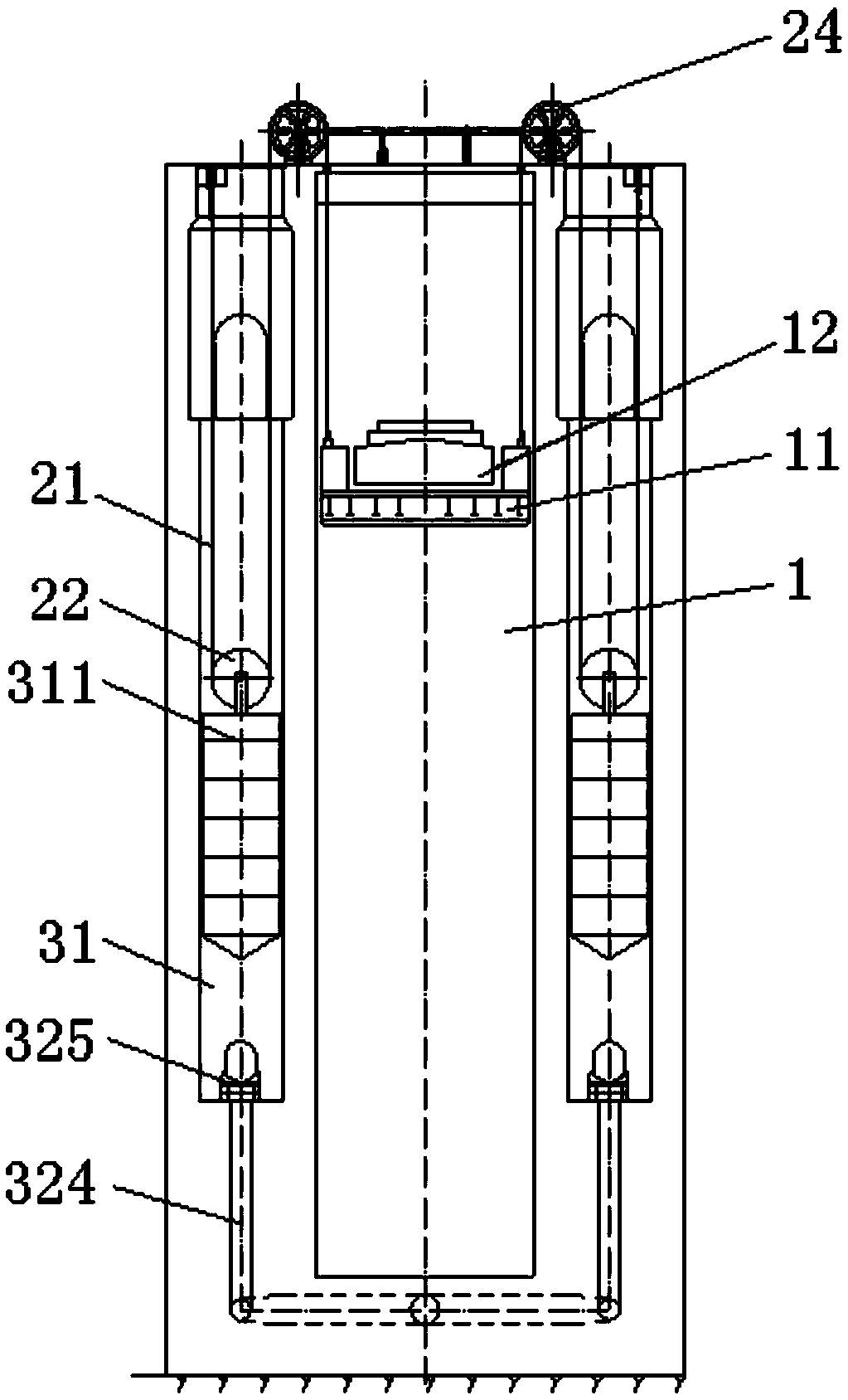

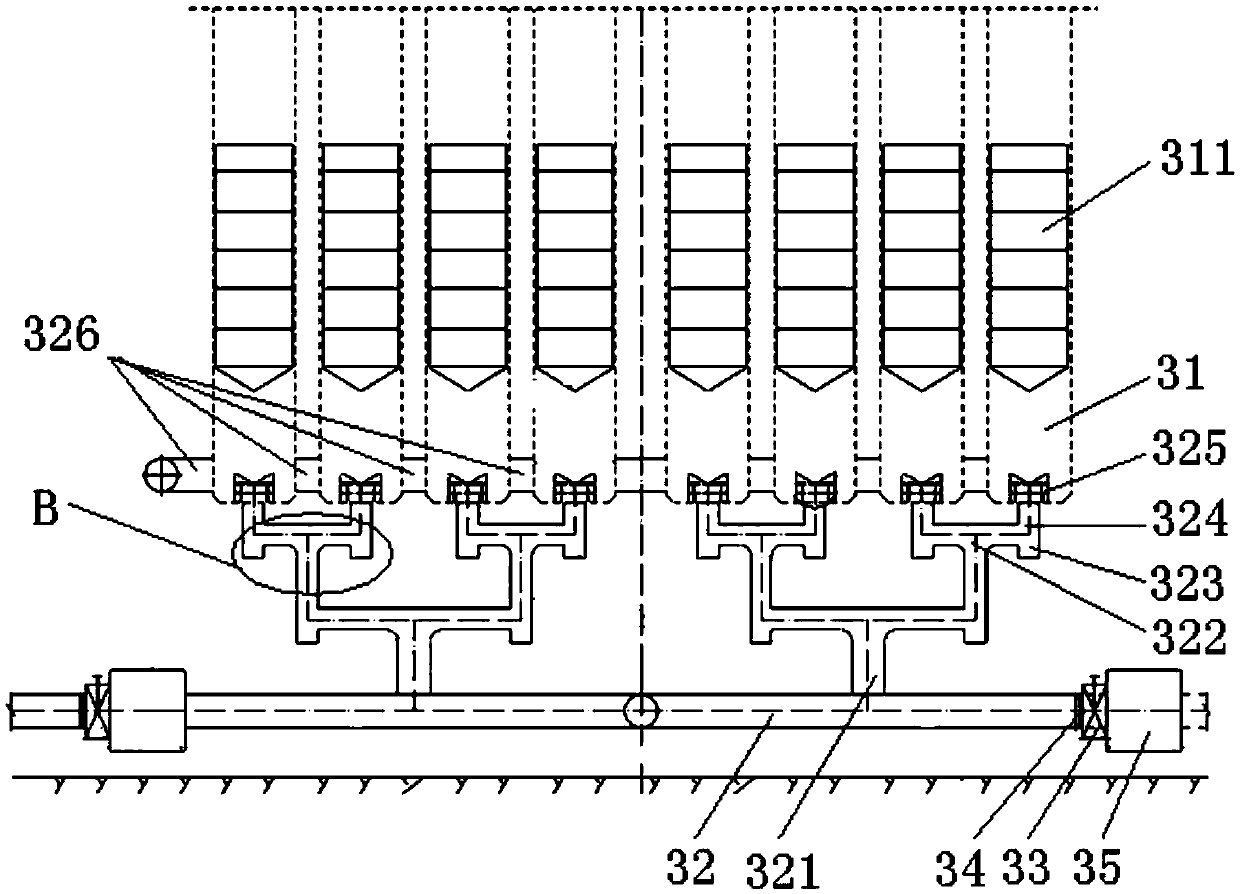

Capsizing-resistant hydraulic power type ship elevator with stable balanced hydraulic driving system

ActiveCN105507223AImprove operational efficiencyImprove distribution uniformityVertical ship-liftingMarine engineeringStraight tube

The invention provides a capsizing-resistant hydraulic power type ship elevator with a stable balanced hydraulic driving system. The ship elevator comprises a ship bearing compartment arranged in a lock chamber, a mechanical lifting system and the stable balanced hydraulic driving system, wherein the mechanical lifting system and the stable balanced hydraulic driving system are connected with the ship bearing compartment. The stable balanced hydraulic driving system comprises vertical shafts, float bowls arranged in the vertical shafts, a main water conveying pipe with a water conveying valve, and a plurality of branch water pipes with lower ends connected with the main water conveying pipe. Each branch water pipe is formed by a straight pipe of the lower portion, a corner pipe and / or a branch pipe in the middle, and a straight pipe of the upper portion, wherein the water outlet end of the straight pipe of the upper portion is arranged at the bottom of the corresponding vertical shaft, and an energy dissipater is arranged at the water outlet end of the straight pipe. All the vertical shafts are connected through a water level balance gallery. The ship elevator is characterized in that the stable balanced hydraulic driving system further comprises first resistance balancing parts arranged at the corners of the branch water pipes, or / and second resistance balancing parts arranged on the branch pipes, a circumferential direction reinforcing ventilating mechanism arranged in front of the water conveying valve of the main water conveying pipe, and a pressure stabilizing and vibration damping box arranged behind the water conveying valve of the main water conveying pipe. The ship elevator has a high capsizing-resistant ability.

Owner:HUANENG LANCANG RIVER HYDROPOWER +2

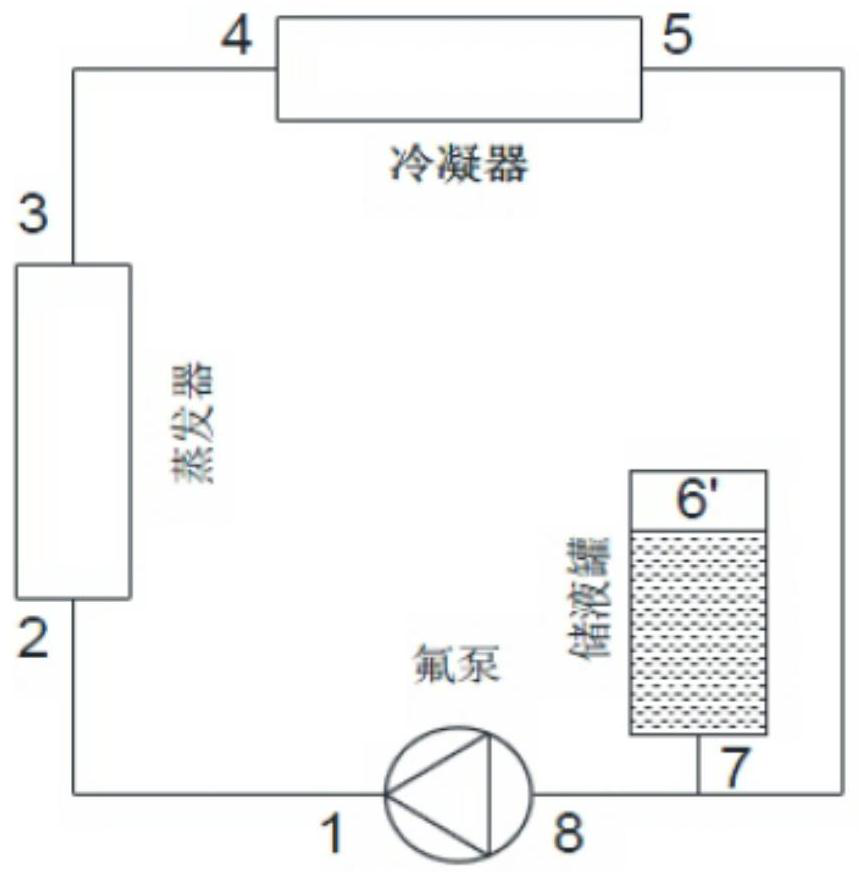

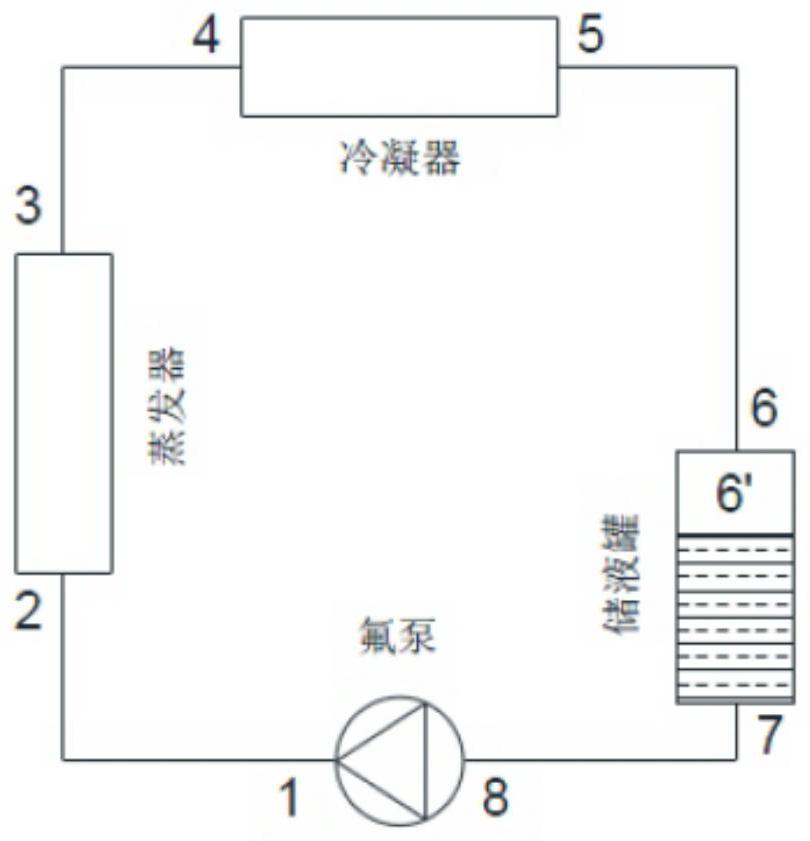

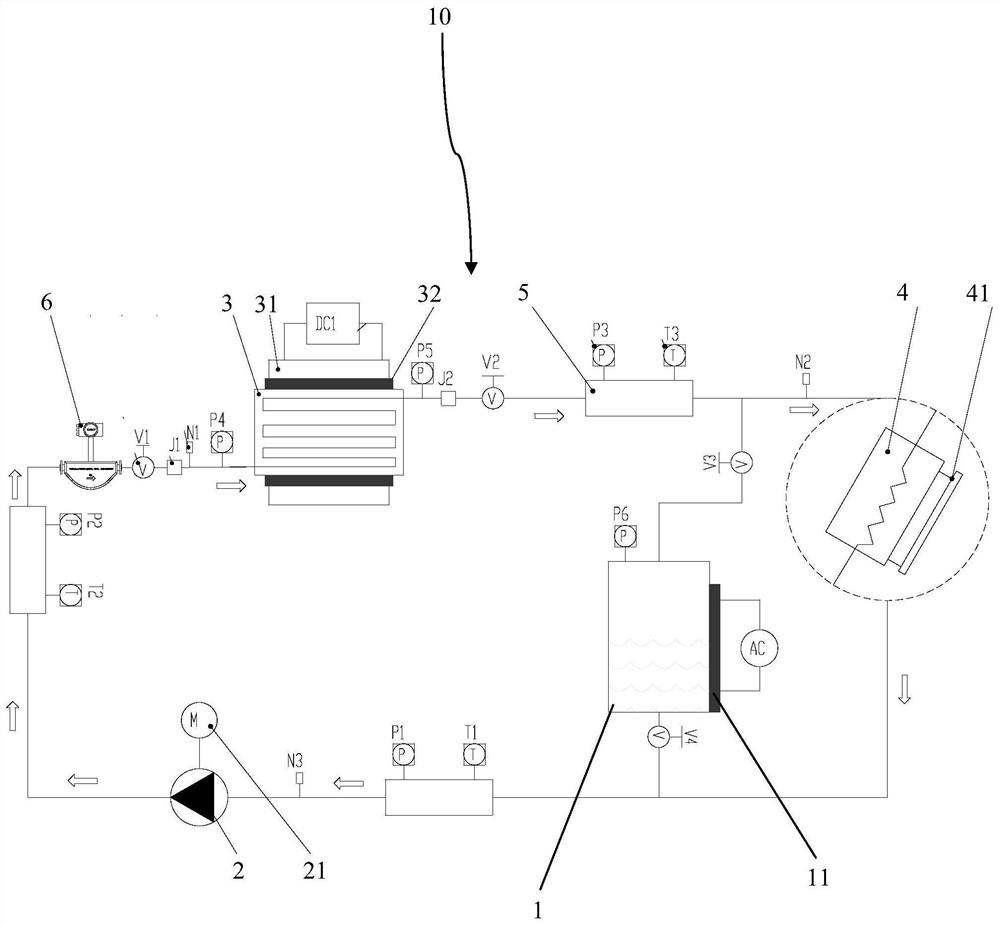

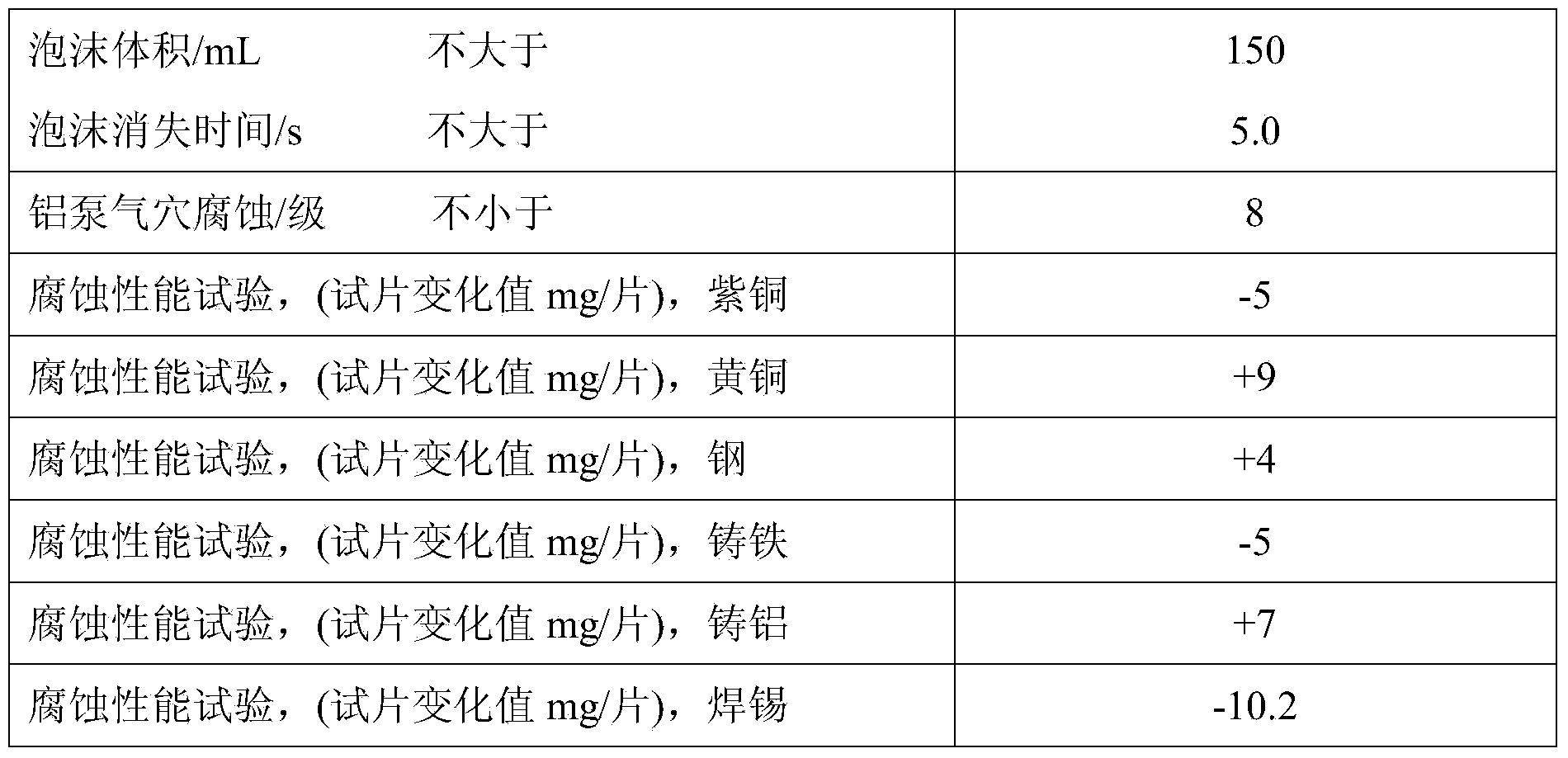

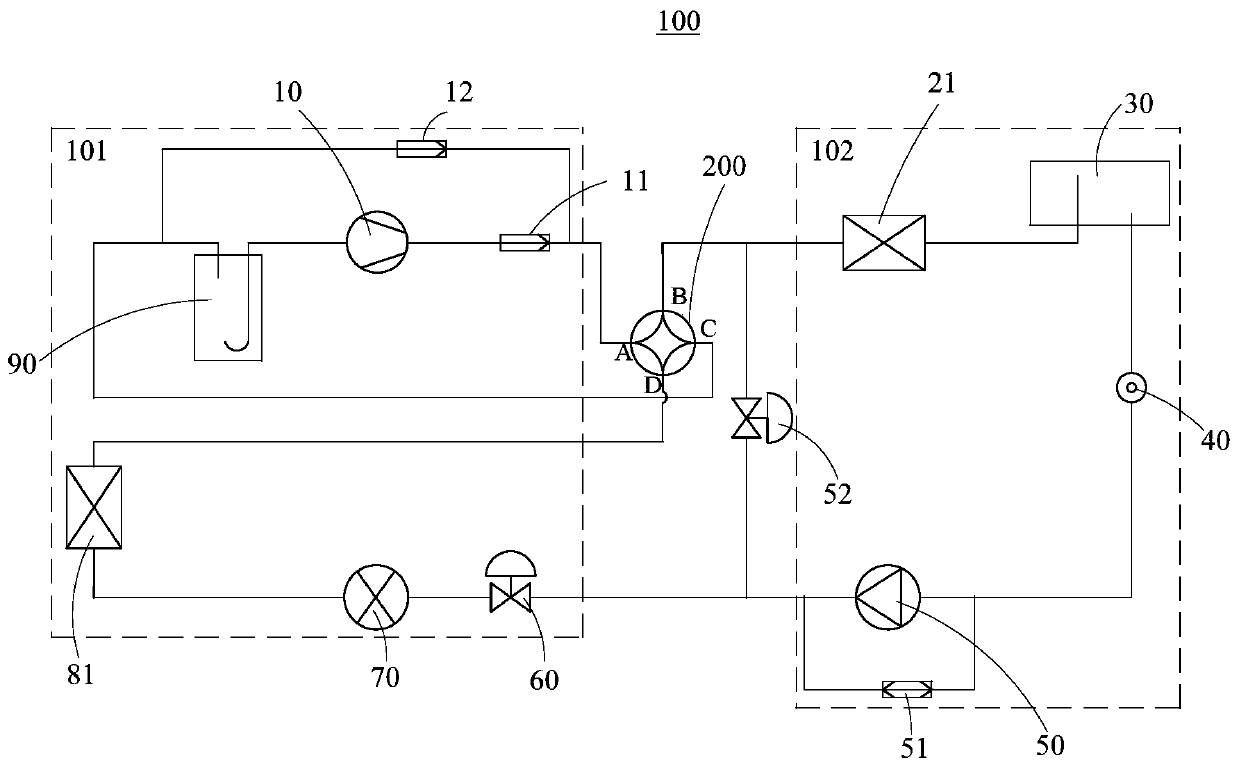

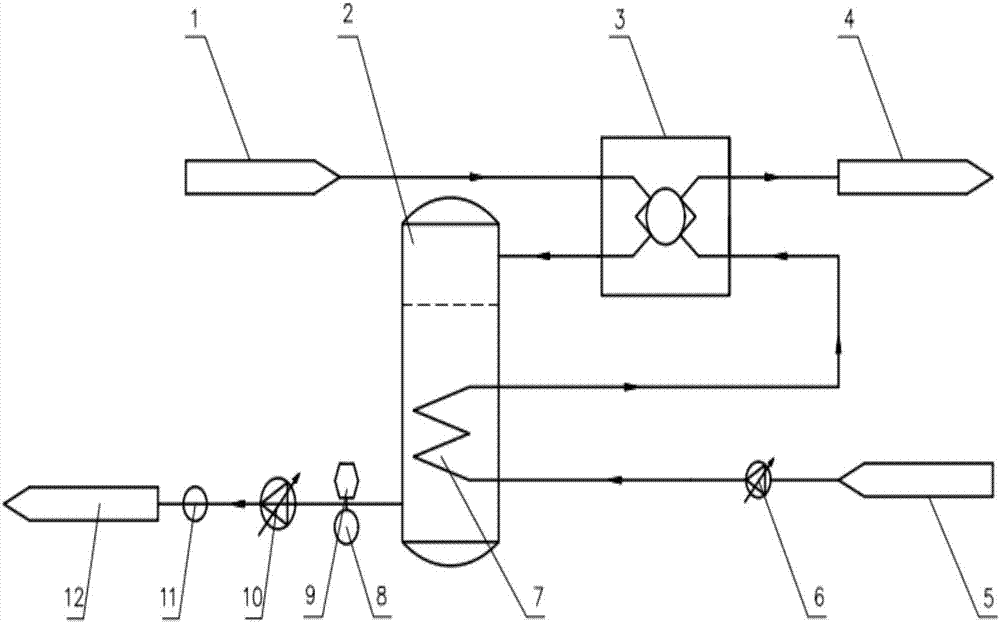

Pump-driven two-phase cooling system and working method thereof

ActiveCN112292004ASmall temperature fluctuationsImprove reliabilityModifications using liquid coolingLiquid level measurementFluid phase

The invention provides a pump-driven two-phase cooling system and a working method thereof, a heating device is arranged on a liquid storage tank of the system, a vapor phase area of the liquid storage tank is connected with an inlet of a condenser, and a liquid phase area of the liquid storage tank is connected with an inlet of a circulating pump. An evaporator is connected with an outlet of thecirculating pump and an inlet of the condenser, and an outlet of the condenser is connected with an inlet of the circulating pump. A temperature measuring device, a pressure measuring device and a control valve are arranged on connecting pipelines between the circulating pump and the liquid storage tank and between the circulating pump and the evaporator and between the condenser and the evaporator respectively; and a flow measuring device is arranged on a pipeline where the circulating pump and the evaporator are connected with each other. The pressure measuring device is arranged in a gas phase area of the liquid storage tank, and a liquid level measuring device is arranged in the liquid storage tank. The processing unit is electrically connected with the temperature, pressure, flow andliquid level measuring device and the control valve. According to the system and the working method thereof provided by the invention, the system control method can be simplified, and the reliabilityof the cooled equipment, the pump and the whole system is improved.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

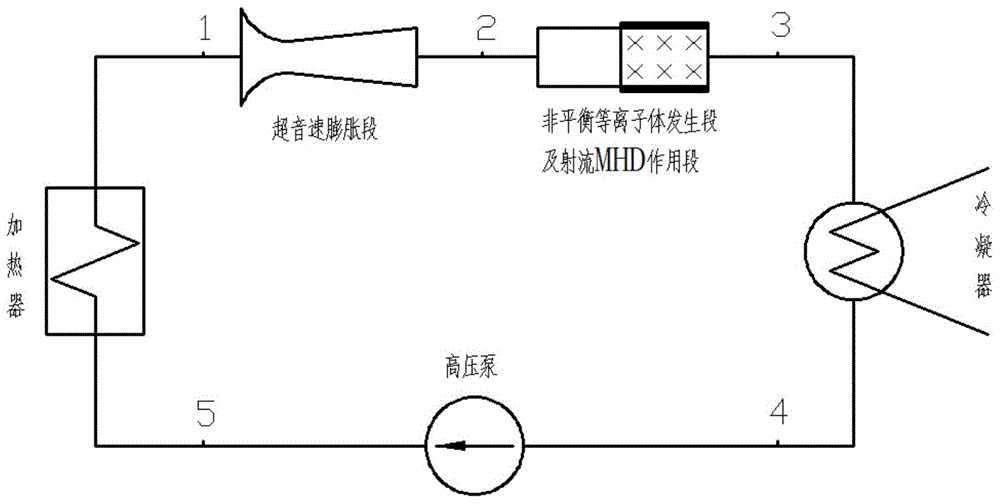

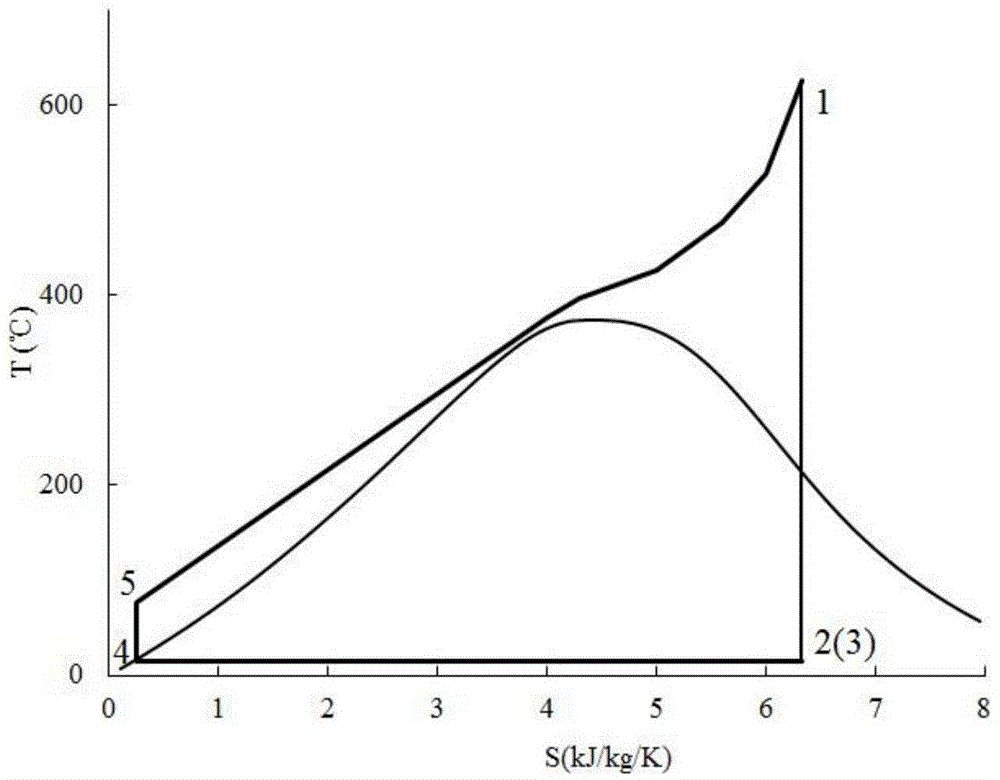

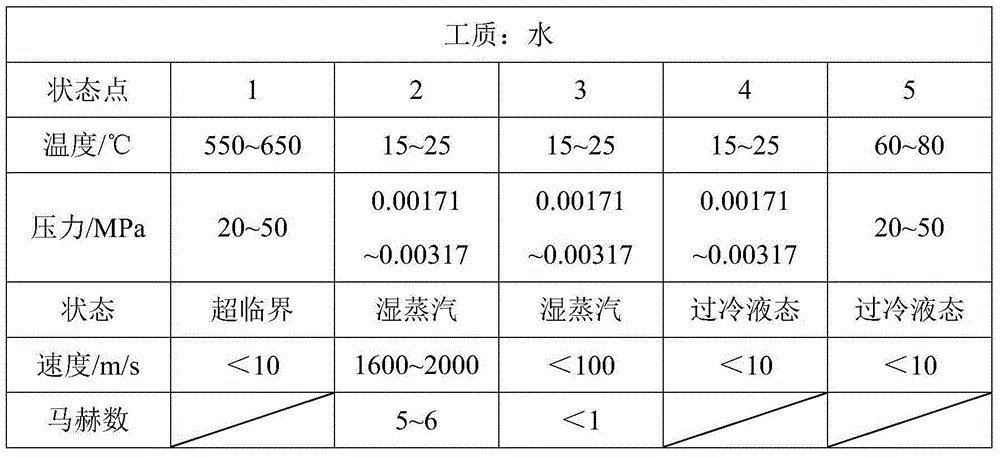

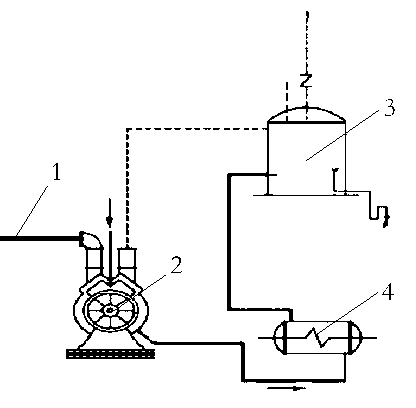

Method for closed-loop magnetic fluid power generation by making use of latent heat of vaporization and cyclic power generation system

InactiveCN104578682ASolve the problem of cavitationReduce the temperatureDynamo-electric machinesSteam condensationCavitation

The invention discloses a method for closed-loop magnetic fluid power generation by making use of latent heat of vaporization and a cyclic power generation system. A high-temperature high-pressure supercritical-state working medium is subjected to adiabatic expansion through a supersonic expansion passage, latent heat of condensation is released along with cluster type gas condensation to be further converted into fluid kinetic energy to finally obtain high-speed fluid, the high-speed fluid enters a plasma generation section to form conductive fluid which cuts magnetic induction lines to generate induced electromotive force for power generation, the fluid is condensed for recovery by a condenser after power generation, and the recovered fluid is pressurized by a high-pressure pump and heated by a heater to reach the high-temperature high-pressure supercritical state again to start a next cycle. Compared with a traditional power generation system, the cyclic power generation system has the advantages that a magnetic fluid power generation passage and a supercritical expansion passage for a steam turbine are replaced, the problem of compelled adoption of high steam discharge temperature due to blade cavitation caused by steam condensation in the steam turbine is solved, and accordingly the temperature of a cold source can be further lowered, and thermal cycling efficiency is improved.

Owner:SOUTHEAST UNIV

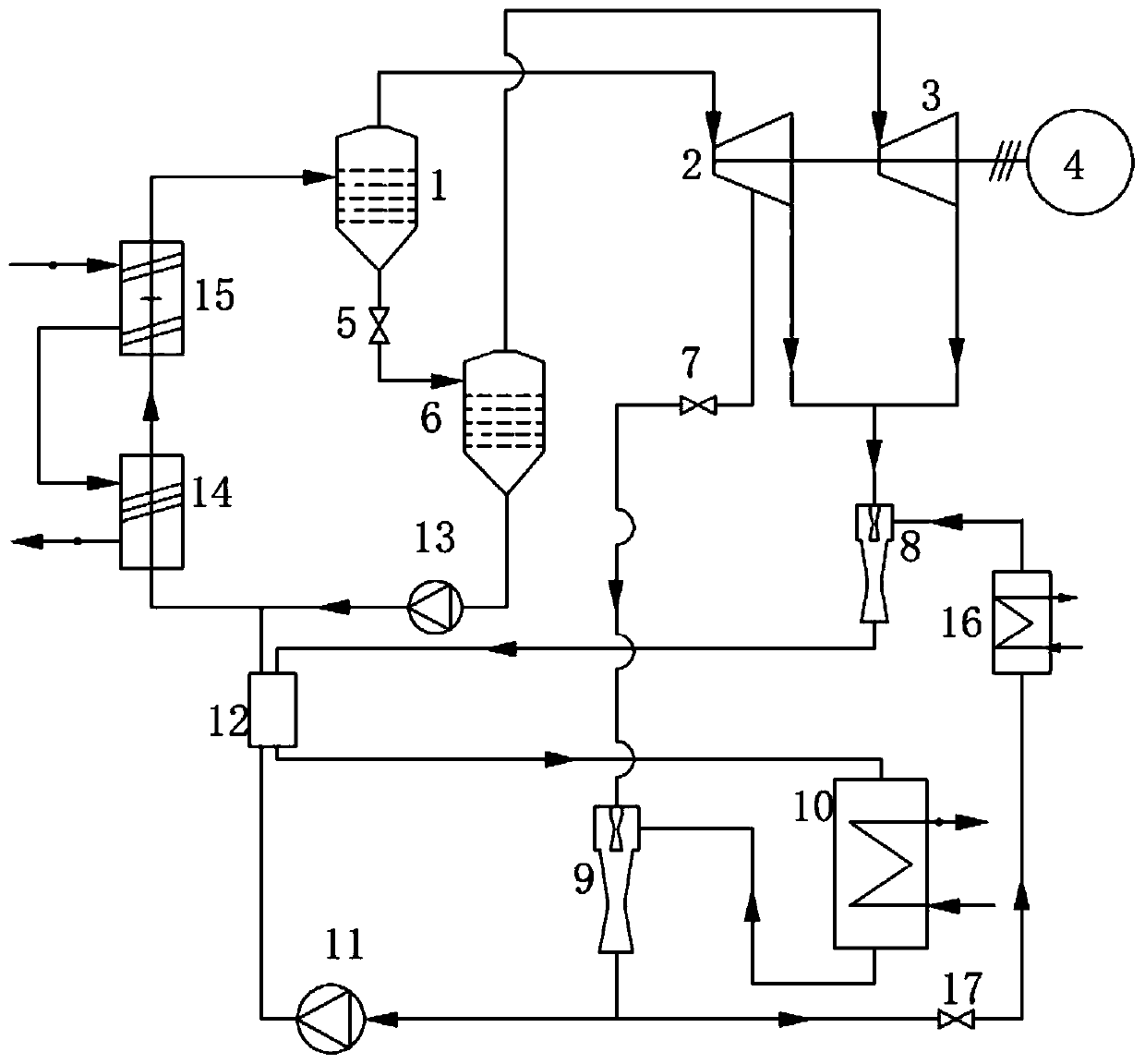

Injection organic Rankine flash evaporation combined cooling and power supply system

ActiveCN111306830AFully recycleRaise the evaporation temperatureCompression machinesSuperheatersVapor–liquid separatorProcess engineering

The invention discloses an injection organic Rankine flash evaporation combined cooling and power supply system. The system comprises a gas-liquid separator, a high-pressure expansion machine, a low-pressure expansion machine, a power generator, a pressure reducing valve, a flash evaporation tank, an extraction regulating valve, a refrigeration ejector, an injection regenerator, a condenser, a low-pressure working medium pump, a high-pressure working medium pump, a generator, an evaporator and a throttle valve; low-grade heat energy is connected with the generator, and a circulating working medium in the generator is heated; the high-pressure expansion machine, the low-pressure expansion machine and the power generator are coaxially connected to drive the power generator to generate electricity; and the circulating working medium evaporates and absorbs heat in the evaporator to obtain cold energy. An organic Rankine flash evaporation system, an injection regenerative system and an injection refrigeration system are coupled, so that the power consumption of the working medium pumps is reduced, the energy utilization efficiency is improved, and the system has the advantages of beingsimple in structure, remarkable in energy saving effect, convenient to control and the like.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

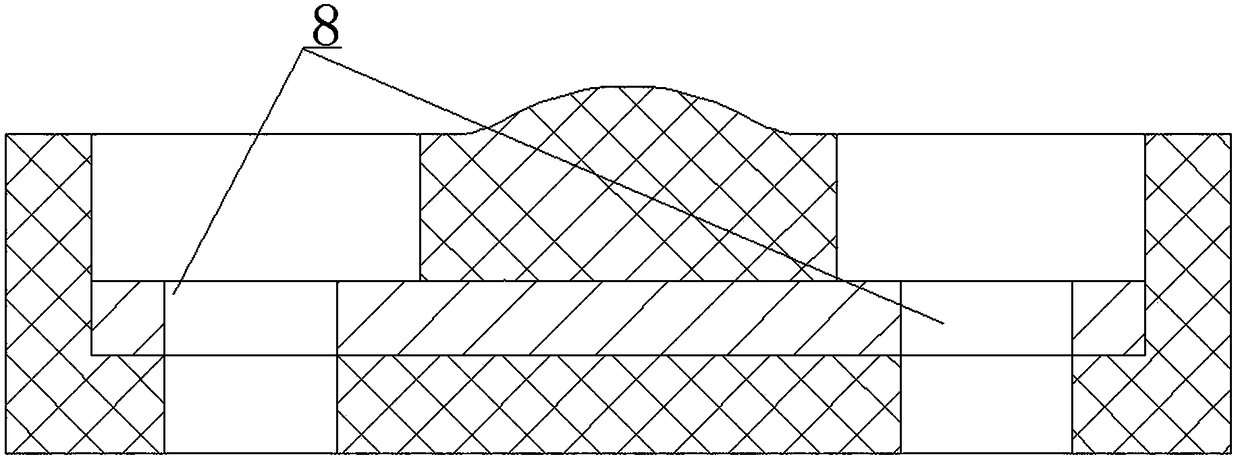

Sidestream shield pump for conveying gas-liquid mixing medium

ActiveCN108194430ALower device heightReduce construction costsPump componentsPump installationsImpellerSecondary stage

The invention discloses a sidestream shield pump for conveying a gas-liquid mixing medium, and relates to the technical field of shield pumps. The sidestream shield pump for conveying the gas-liquid mixing medium comprises a pump part and a motor, wherein the pump and the motor share one central shaft; a pump cavity communicates with a motor cavity; the pump part is provided with a suction section, a first stage impeller, a secondary stage impeller, a secondary guide vane and a discharging section; the suction section and the discharging section are located at the first end and the tail end ofthe pump part; and the secondary stage impeller and the secondary guide vane are fixedly arranged on the central shaft. The shield pump provided by the invention is provided with an impeller assemblycapable of conveying a liquid and conveying a gas, so that gas-liquid mixing conveying is realized; and meanwhile, a pressure flowing relationship of the gas and the liquid is utilized to enable theliquid to flow through the motor and be used as a circulating fluid for cooling the motor and lubricating a bearing.

Owner:HEFEI XINHU CANNED MOTOR PUMP

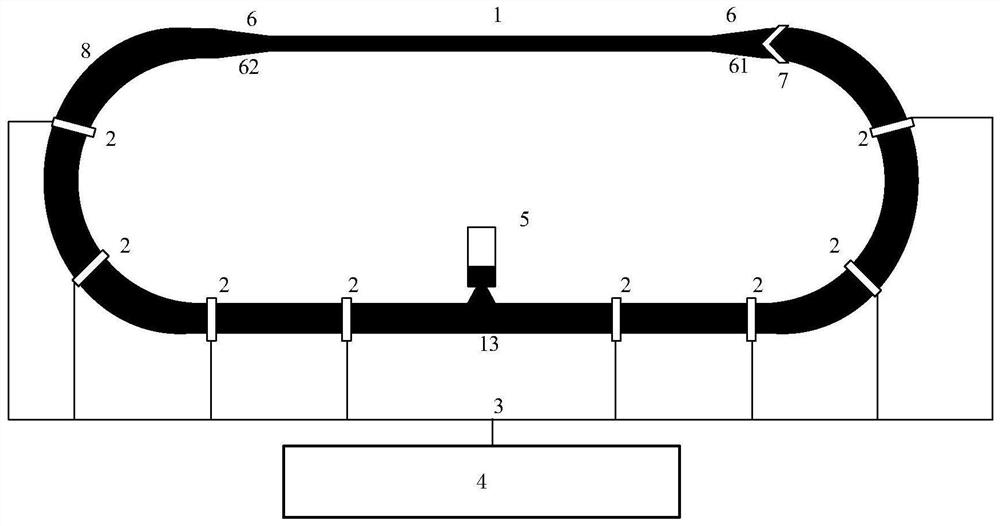

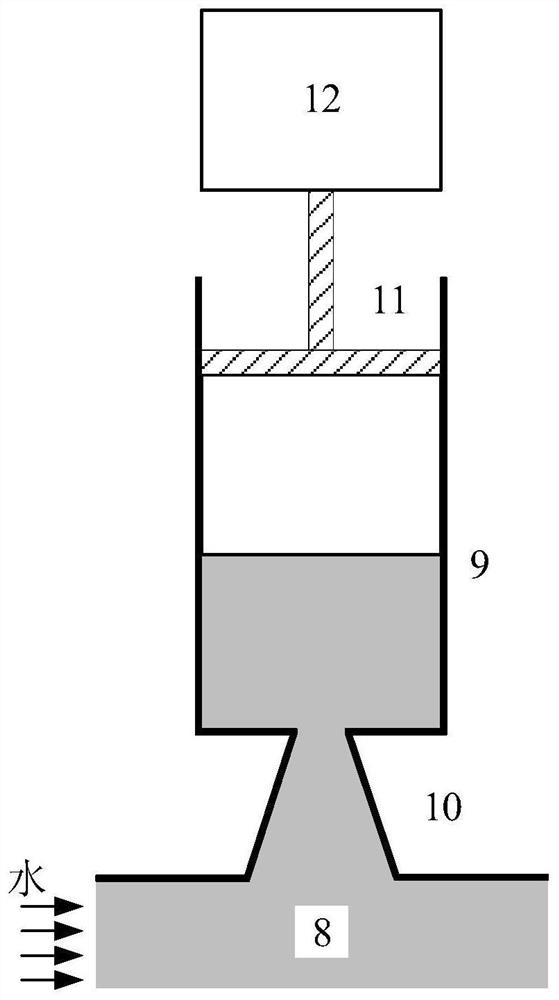

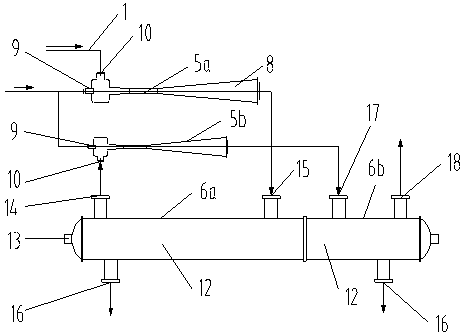

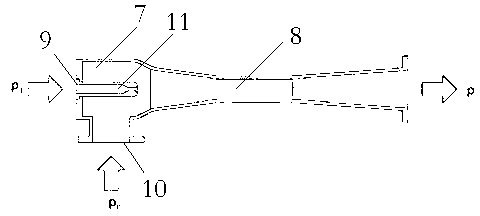

High-pressure water tunnel test device and test method thereof

The invention discloses a high-pressure water tunnel test device and a test method thereof. The high-pressure water tunnel test device comprises a water tunnel test section, a shaftless propelling device, an air supply pipeline, air supply equipment, a pressure-regulating cavitation-removing device, reducing and expanding sections and accelerating pipelines. The two ends of the water tunnel test section are respectively connected with a reducing pipeline and a expanding pipeline and are externally connected with the accelerating pipelines, and the pipelines form a closed loop. One or more shaftless propelling devices are dispersedly arranged on the water tunnel acceleration pipeline. If there are a plurality of shaftless propelling devices, the multiple shaftless propelling devices are dispersed and distributed in the whole course of the acceleration pipeline. The air supply equipment and the air supply pipeline are arranged outside a water tunnel pipeline to provide a power working medium for the shaftless propelling devices. According to the system, the flow and the flow speed of an existing water tunnel system can be remarkably improved, the energy supply problem of high-power equipment is solved, input energy is efficiently converted into the water flow speed, meanwhile, the high-pressure state under the deep sea condition can be simulated, and the cavitation problem caused by high-speed water flow is effectively solved.

Owner:XIAN THERMAL POWER RES INST CO LTD

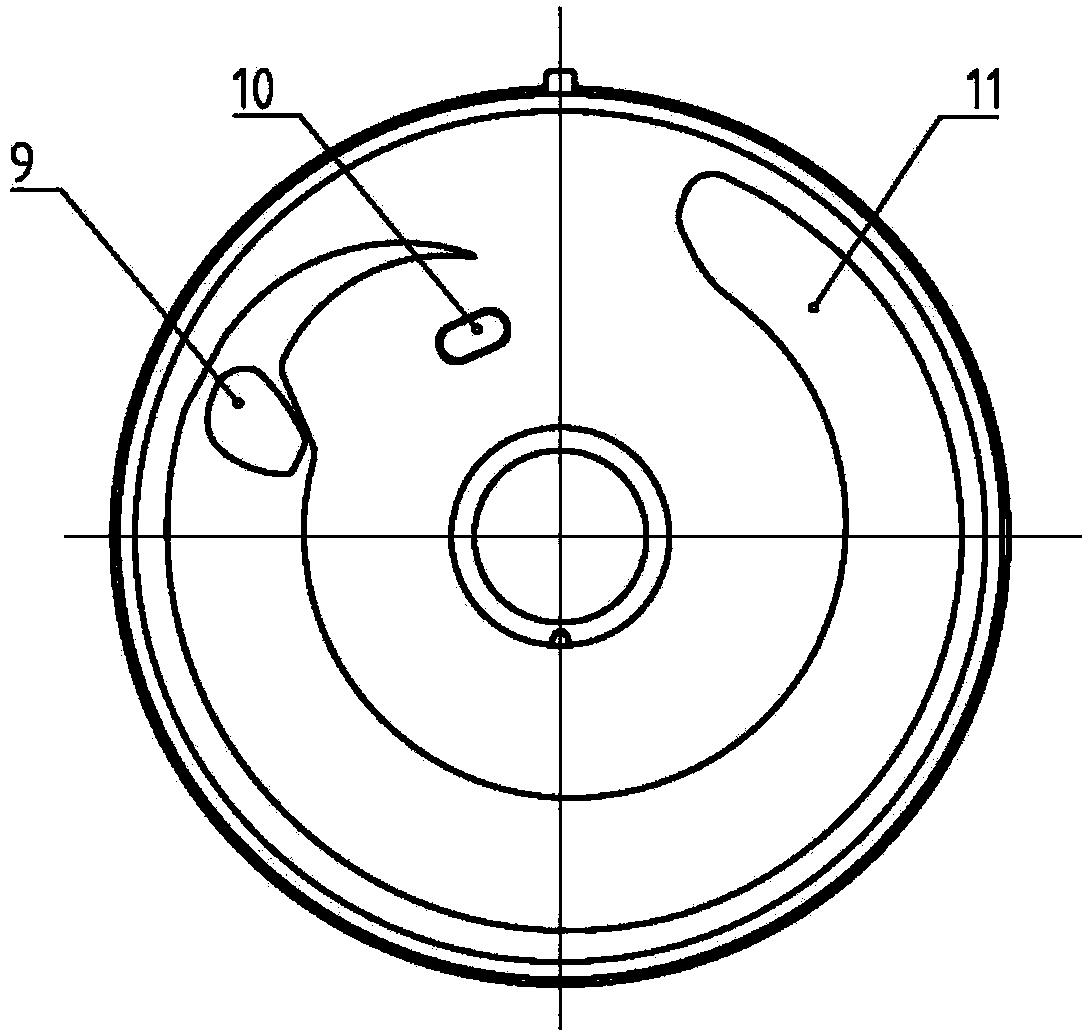

Swirler

InactiveCN101737334AReduce frictionSlow downRadial flow pumpsNon-positive displacement fluid enginesDrive shaftEngineering

The invention provides a swirler. The swirler comprises a shell and a transmission shaft, wherein the transmission shaft is arranged in the shell; at least one swirling wheel is arranged in the shell; the transmission shaft is connected with the swirling wheel; a swirling chamber is arranged in the swirling wheel; the middle part of the swirling chamber is provided with a swirling chamber inlet; the periphery of the swirling chamber is provided with a plurality of guide vanes; and the shell is provided with an inlet. The swirler makes full use of circumferential motion and fluid motion, causes fluid to be automatically sucked into eddy current from an eddy current central region by using the eddy current of which a rotational speed is steadily increased from a center to the periphery, produces a suction force by the center of the eddy current, produces high pressure at the periphery of the eddy current by the eddy current of which the rotational speed is gradually decreased from the center to the periphery, can be widely applied in the fields of fluid pressurizing, delivering and the like, can be used as a water pump, a vacuum pump, air suction equipment, a fan, a compressor and the like, and also can be used as spraying equipment, an atomizer, a reactor and the like.

Owner:陈久斌

Eddy current device

InactiveCN102086892AEasy to manufactureLow manufacturing costPump componentsFluid-pressure convertersCarbon dioxideEngineering

The invention discloses an eddy current supercharger. The eddy current supercharger comprises a shell and a transmission shaft, wherein a shell cavity is formed in the shell; the transmission shaft is arranged in the shell; an eddy current wheel is arranged in the shell cavity; the transmission shaft is connected with the eddy current wheel in which an eddy current chamber is formed; the middle part of the eddy current chamber is provided with an eddy current chamber inlet; the periphery of the eddy current chamber is provided with an eddy current chamber outlet; the shell cavity is provided with a shell cavity inlet; the eddy current chamber inlet is formed opposite to the shell cavity inlet; and the shell cavity is provided with a shell cavity outlet. In the eddy current supercharger, completely new supercharging principle and method are adopted, circular motion and fluid motion can be fully utilized, fluid is automatically sucked into an eddy current from an eddy current central region by using the eddy current of which the rotation speed gradually increases from the center to the periphery, super-high suction is produced by using the center of the eddy current, and super-high pressure is produced by using the periphery of the eddy current. The eddy current supercharger can be widely used in the fields such as fluid pressurizing, fluid conveying, air suction and the like, can be used as a water pump, a fan, a compressor, a vacuum machine and the like, and can also be used as spray equipment, a nanomaterial atomizer, purification equipment for processing carbon dioxide, sulfur oxide and nitric oxide, a special reactor, an air conditioner and the like.

Owner:陈久斌

Aqueous medium mining electromagnetic unloading valve

InactiveCN111219511AReduce usageWill not harmOperating means/releasing devices for valvesServomotor componentsMining engineeringAqueous medium

The invention relates to an aqueous medium mining electromagnetic unloading valve. The aqueous medium mining electromagnetic unloading valve comprises a valve body, a pressure increasing valve elementand an unloading valve element, wherein one side of the valve body is provided with a liquid inlet, and the other side of the valve body is provided with a liquid outlet and an unloading port; the valve body is internally provided with a first cavity communicating with the liquid inlet, a second cavity communicating with the first cavity and the liquid outlet and a third cavity communicating withthe first cavity and the unloading port; the pressure increasing valve element is arranged in the second cavity and is pushed by pressure of a medium in the first cavity to move to communicate with or close the liquid outlet; the unloading valve element is arranged in the third cavity; when the unloading valve element is in an opening state, the unloading valve element is pushed by the pressure of the medium in the first cavity to move to communicate with or close the unloading port; and the medium flowing in the valve body is water. The working medium of the aqueous medium mining electromagnetic unloading valve is water. On the one hand, application of emulsified liquid is avoided, and the cost is reduced; and on the other hand, water is adopted as the working medium, pollution can be avoided, and water does no harm to the environment.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD +1

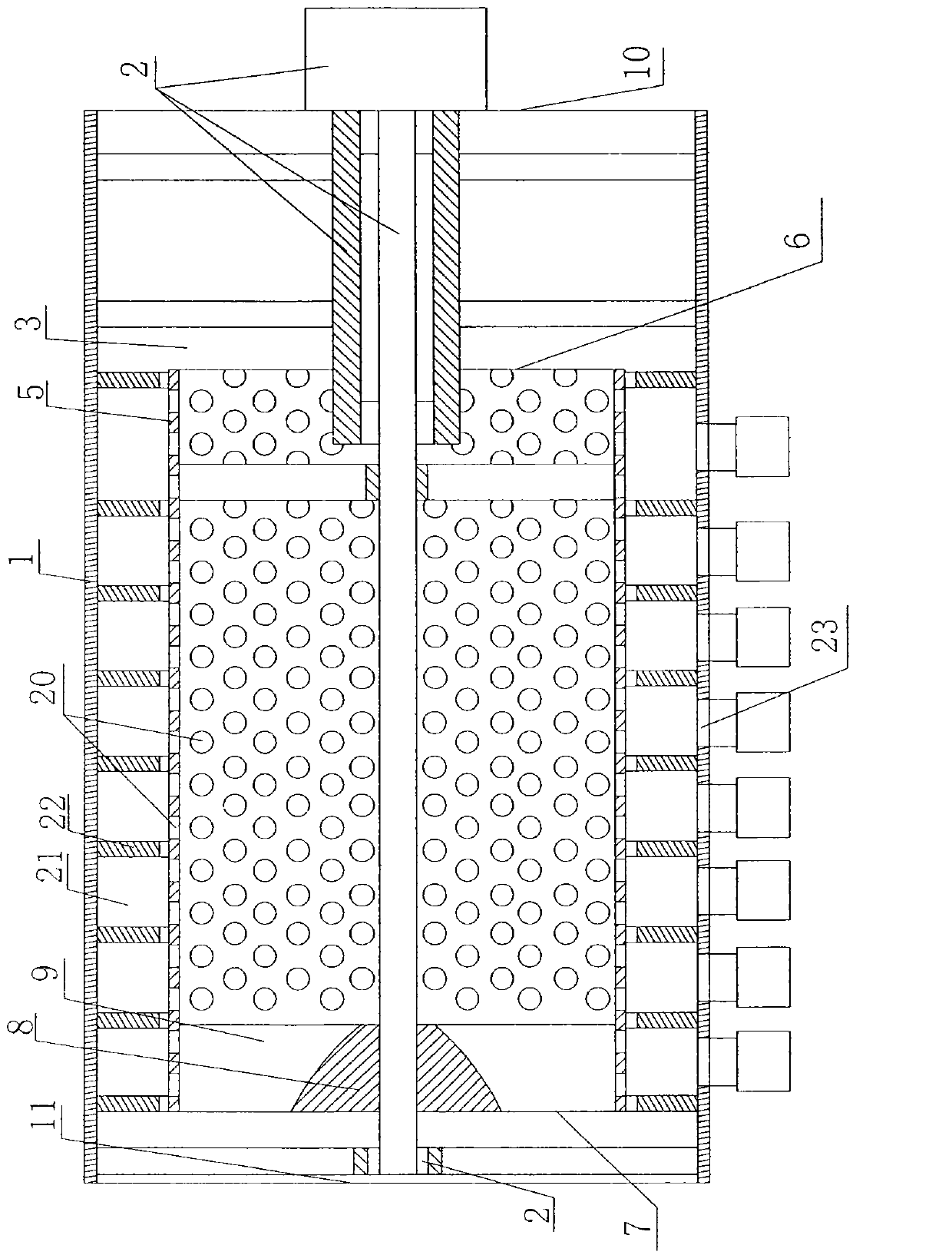

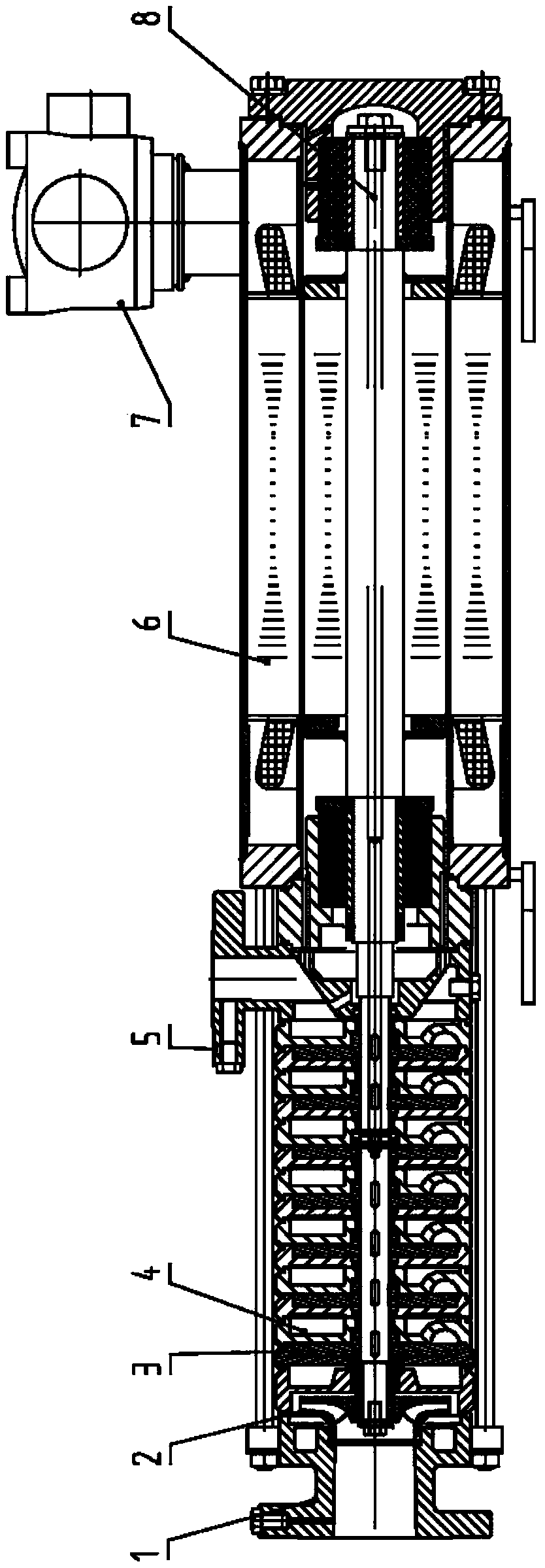

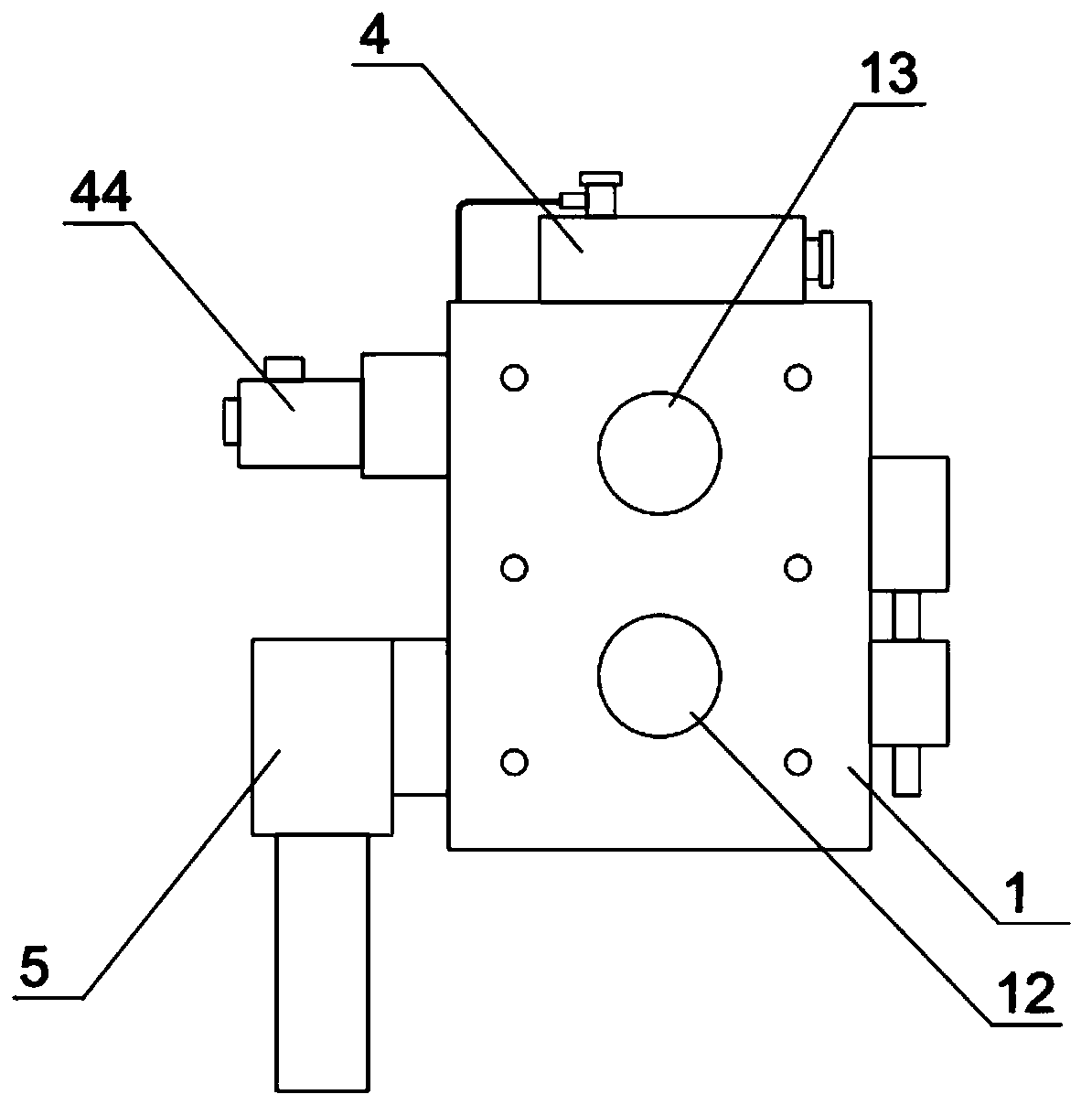

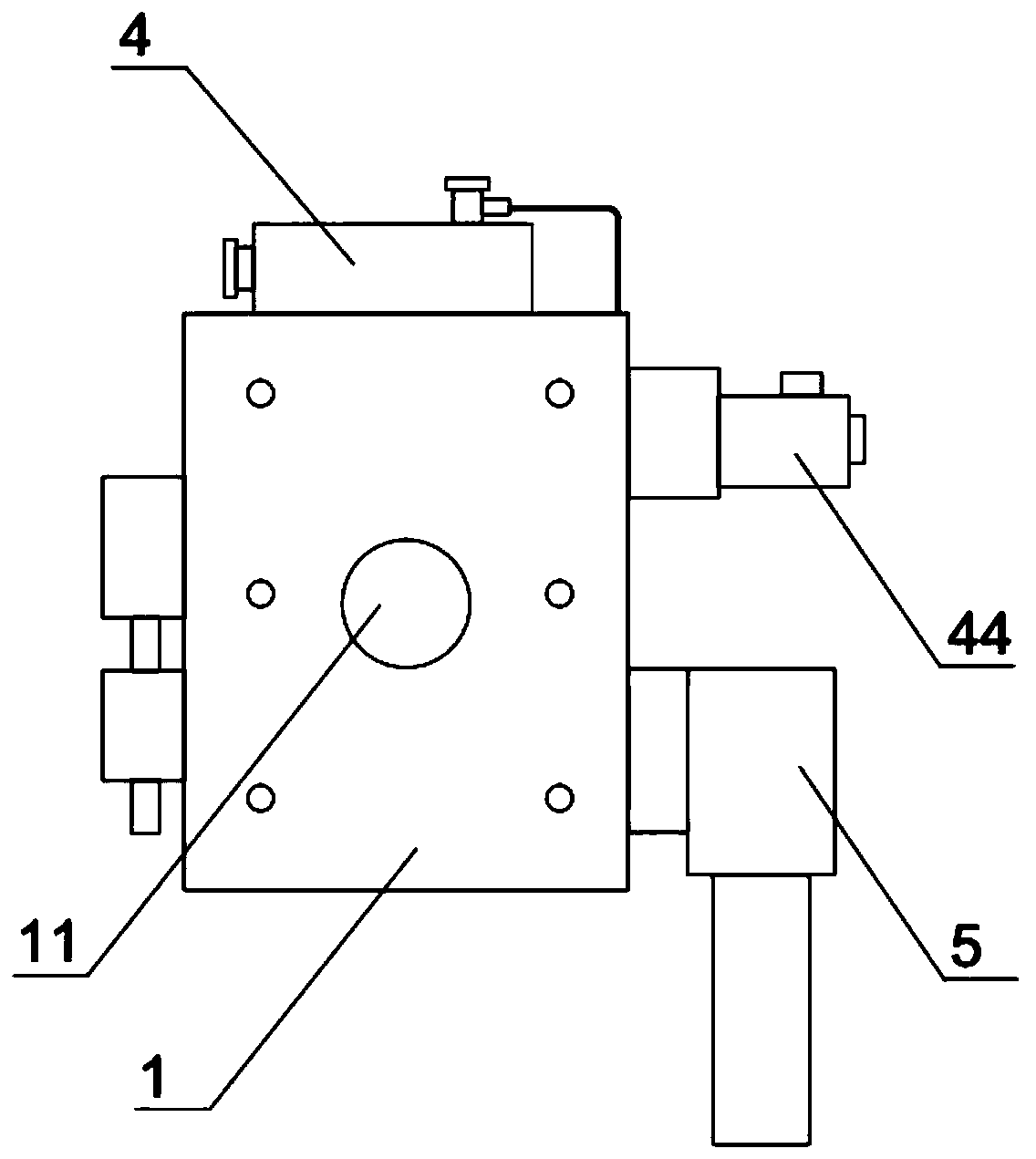

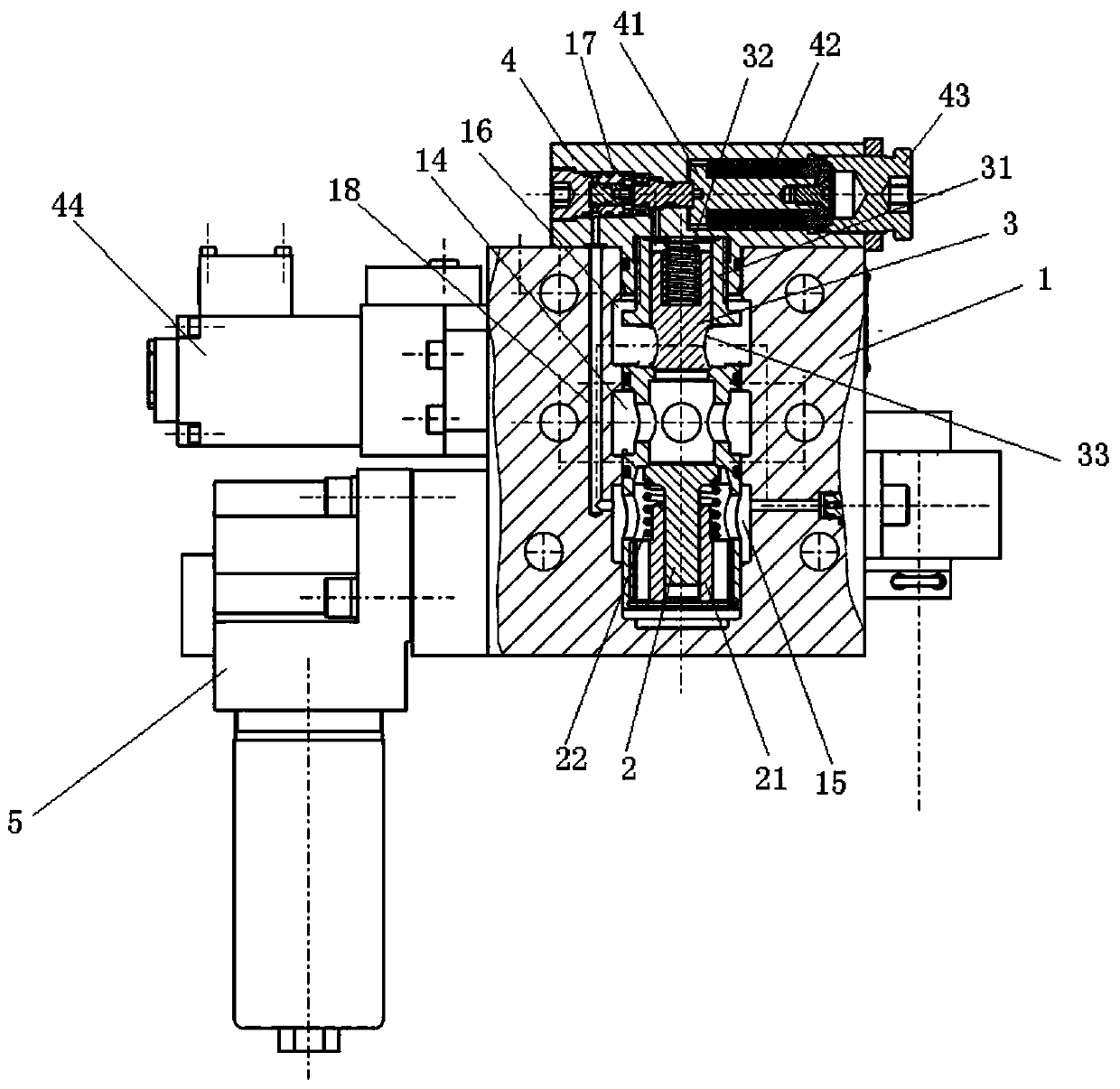

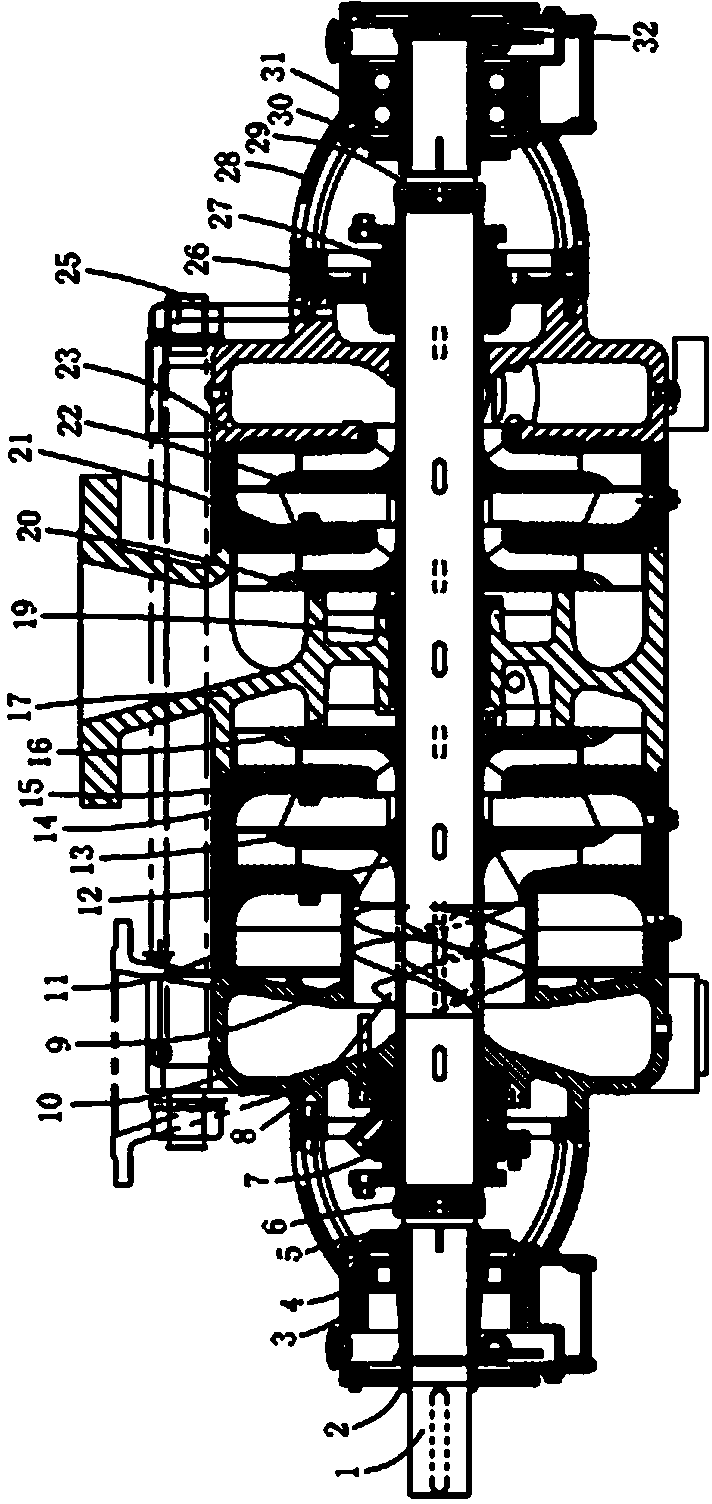

Horizontal type self-balancing multistage centrifugal pump with high cavitation resistance

InactiveCN103352875AAvoid damageSolve running problemsPump componentsRadial flow pumpsDrive shaftEngineering

A horizontal type self-balancing multistage centrifugal pump with high cavitation resistance comprises a stator component and a rotor component, wherein the stator component comprises a water inlet section, an inducer middle section, a flow guide sealing ring, a middle section, a front guide vane, a front final-stage guide vane, a water outlet section, a rear final-stage guide vane, a rear guide vane and a secondary induction section which are fixed through a tightening bolt assembly; the rotor component comprises a shaft, a shaft sleeve with two ends locked and fixed on the shaft through round nuts, an inducer, a first-stage impeller, a front impeller, an intermediate shaft sleeve, a rear impeller and a bearing and dirt blocking plate fixed through a bearing locking nut and a round nut; the first-stage impeller and the front impeller and the rear impeller are arranged symmetrically back to back; the inducer matched with the first-stage impeller is equipped in front of the first-stage impeller; the inducer and the first-stage impeller are fixed on a pump shaft and is connected with the shaft through keys for transmission; an axial direction fixes the inducer, the first-stage impeller, the front impeller and the rear impeller are fixed by the round nuts close to two ends in the axial direction; the flow guide sealing ring is arranged on the outer side of the inducer; and the two ends of the flow guide sealing ring are fixed at the inducer middle section and the water inlet section respectively.

Owner:SHANGHAI FIRST PUMP WORKS

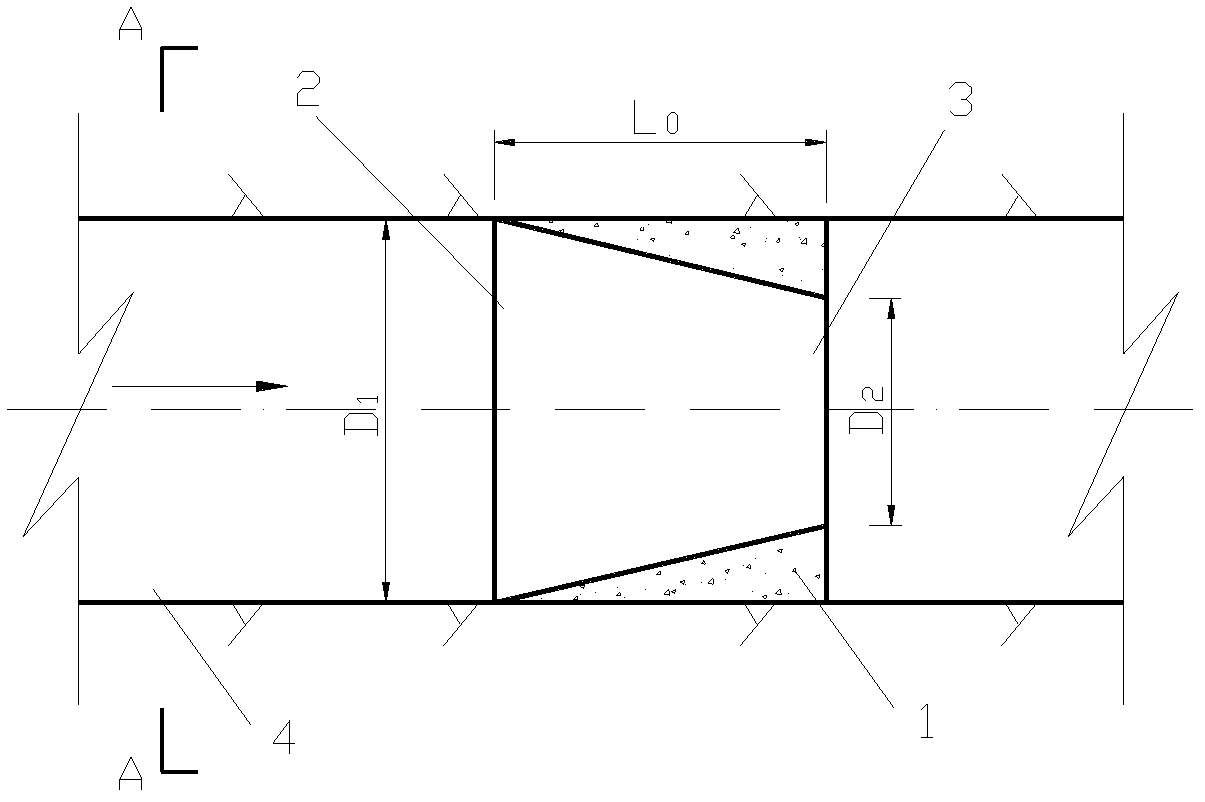

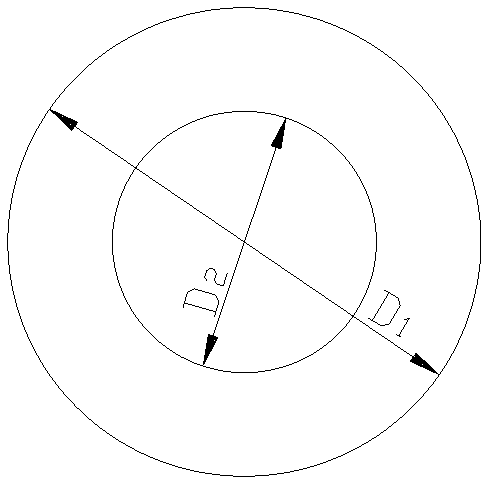

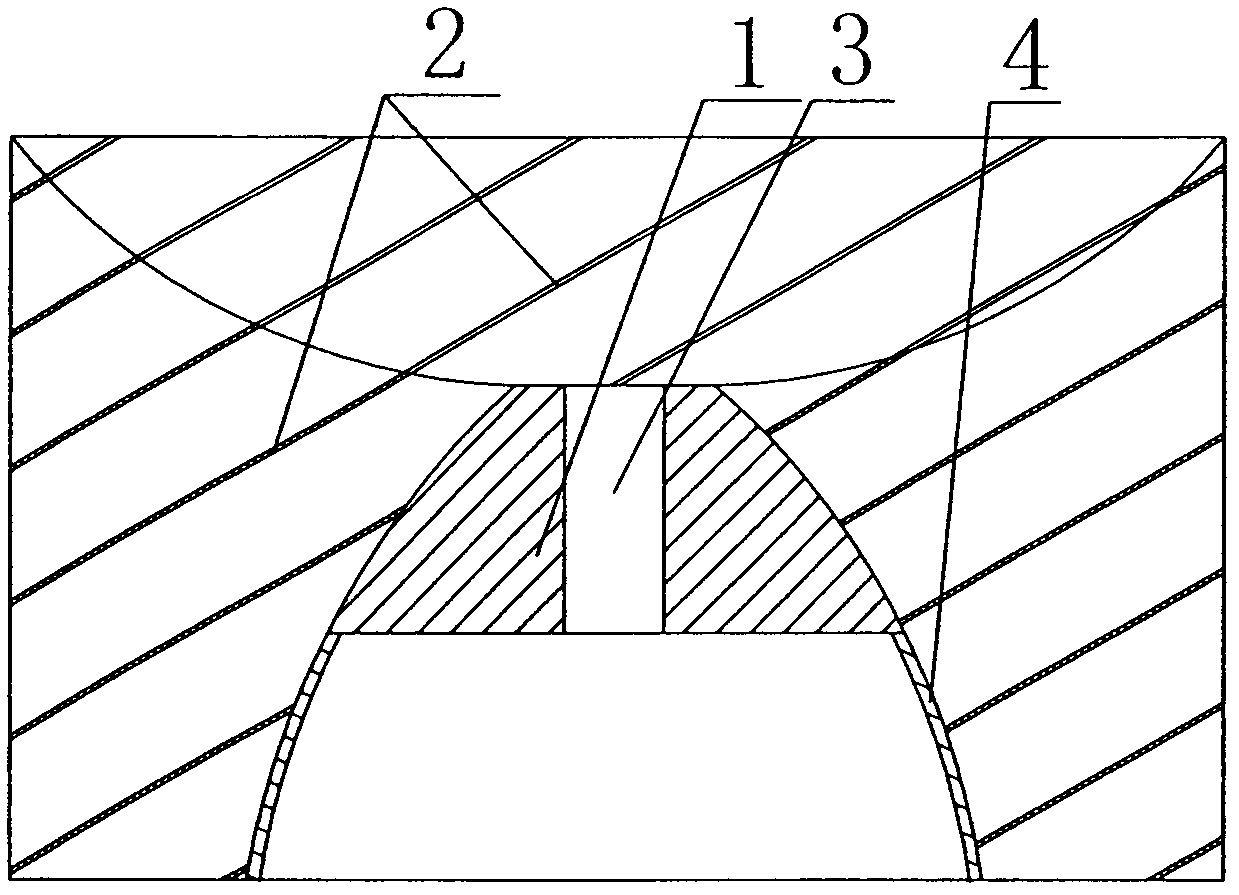

Reducing and sudden expansion type inner energy dissipator

InactiveCN102409642AReduce the impactImprove anti-cavitation performanceBarrages/weirsEngineeringFlood discharge

The invention provides a reducing and sudden expansion type inner energy dissipater. The energy dissipater consists of a matrix and an overflow hole arranged in the matrix, wherein, the overflow hole is in a contractible cone frustum shape, the inlet of the overflow hole is bigger than the outlet of the overflow hole, the diameter of the inlet of the overflow hole is equal to the diameter D1 of a flood discharge hole, the diameter D2 of the outlet of the overflow hole is equal to 0.1D1-0.7D1, and the overflow hole and the matrix have the equal length of L0 which is equal to 0.4D1-2.5D1. The reducing and sudden expansion type inner energy dissipater can be applied to energy dissipation in the pressured flood discharge hole; when in use, at least one reducing and sudden expansion type inner energy dissipater is arranged in the pressured flood discharge hole; and in the case of at least two reducing and sudden expansion type inner energy dissipaters, the distance between two neighboring energy dissipaters is at least 2D1, wherein, D1 is the diameter of the flood discharge hole.

Owner:SICHUAN UNIV

Circulator

InactiveCN102384091AImprove atomization effectSmall dropletPump componentsCircumferential flow pumpsChemical reactionWater turbine

The invention relates to a circulator, comprising a housing and a transmission gear, wherein a circulation cavity is arranged in the housing; a transmission gear is mounted on the housing; a rotating wheel is arranged in the housing; the transmission gear and the rotating wheel are connected with each other, the circulating cavity is internally provided with a circulating cavity inlet and a circulating cavity outlet; the circulating cavity expands gradually from one end to the other end, and an isolator is arranged in the housing between the circulating cavity inlet and the circulating cavity outlet. The circulator makes full use of circular motion and fluid motion, can better convert torsion force into pressure or thrust force through fluid, and better convert pressure or thrust force into torsion force through fluid. Moreover, particle mixing is realized through eddy flow, and chemical reaction becomes more sufficient by utilizing eddy flow. The circulator can be used as water pumps, slurry pumps, sewage pumps, blower fans, compressors, spraying equipment, atomizers, reactors, water turbines, steam turbines, wind turbines, vacuum equipment, foam material production equipment, nanometer material equipment and the like. The circulator provided by the invention has the advantages of high efficiency, low abrasion, etc., can be used for manufacturing fire-new foam material, and can usher in material revolution.

Owner:陈久斌

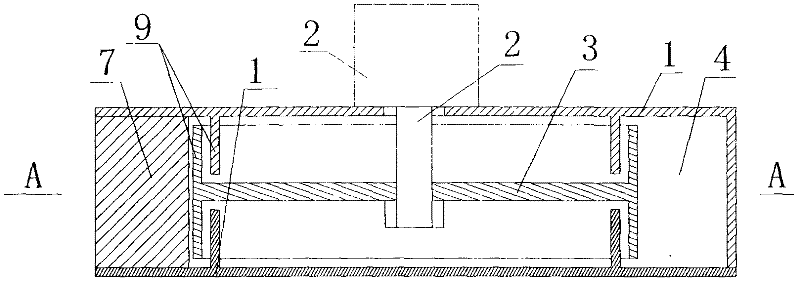

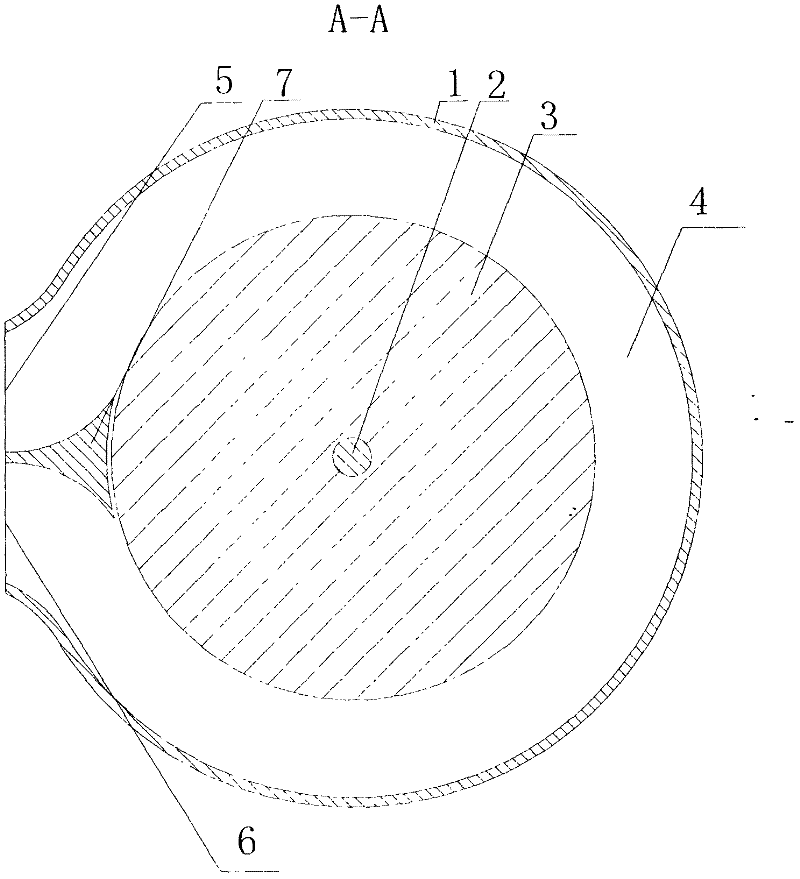

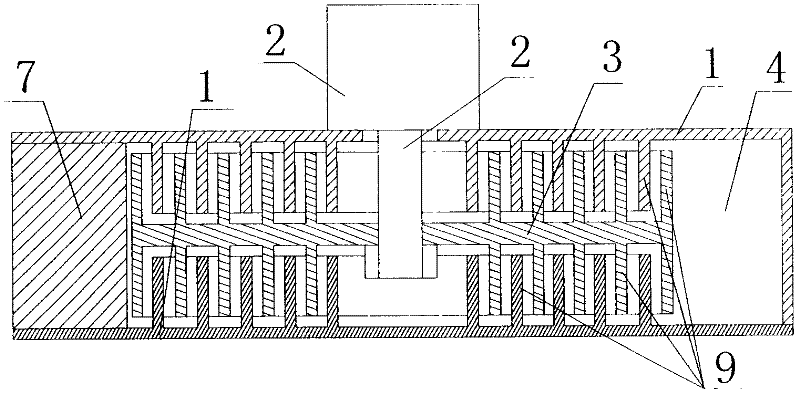

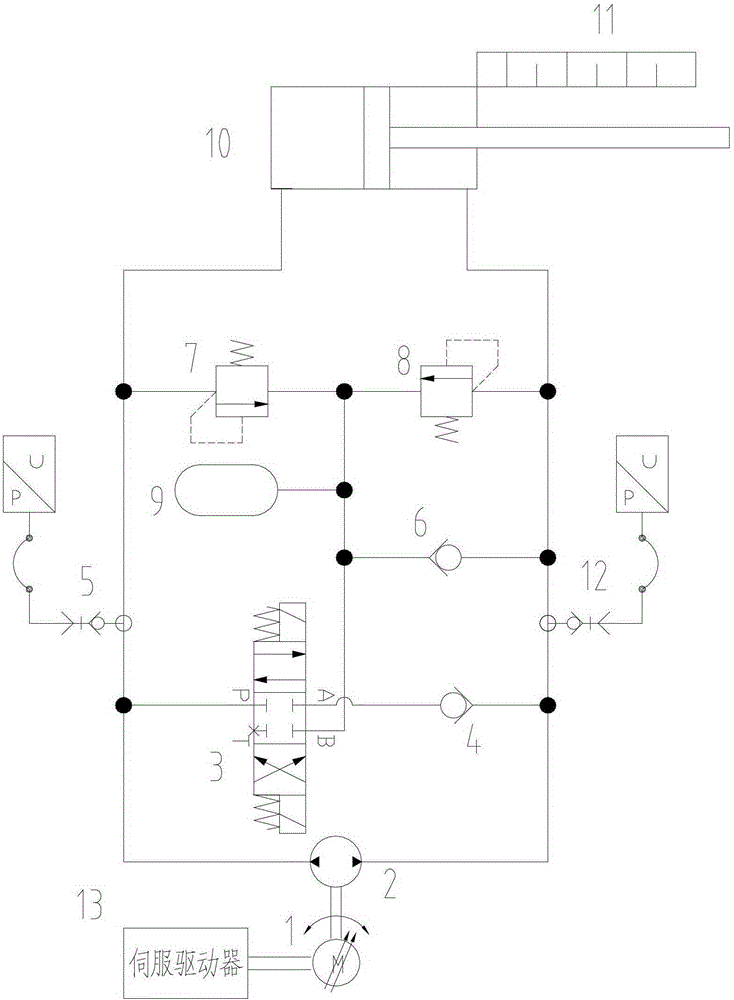

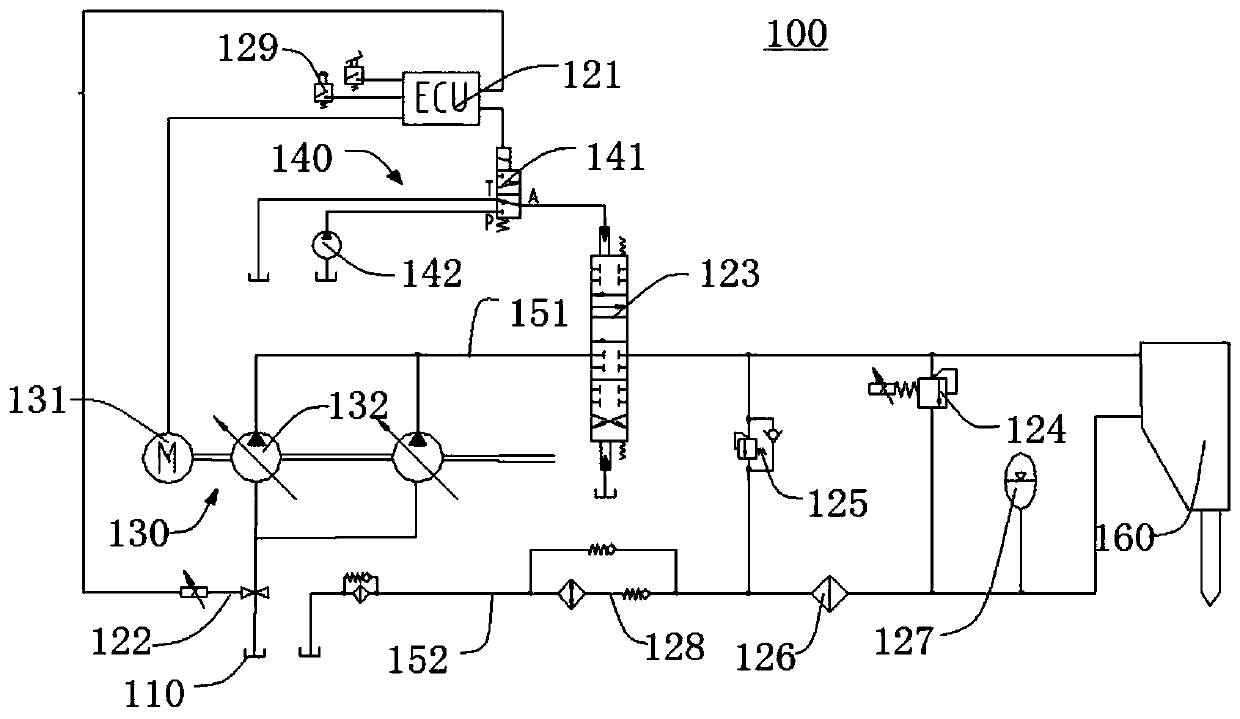

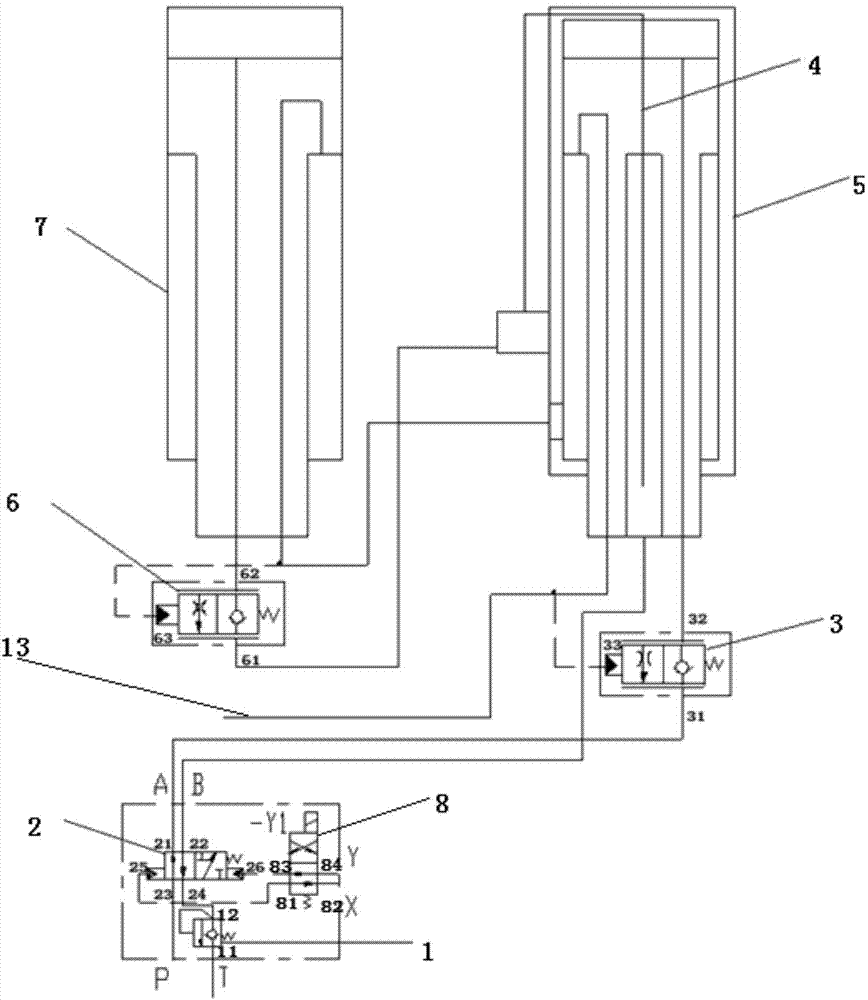

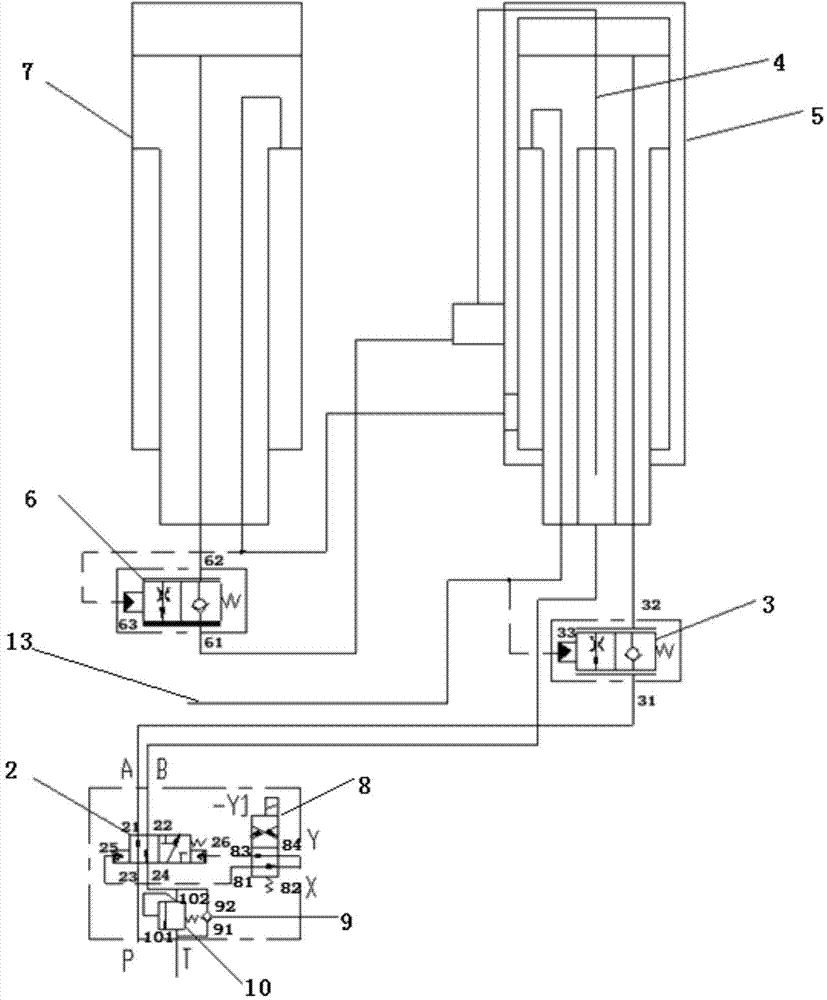

Hydraulic cylinder control system and control method for direct drive servo pump control electro-hydraulic hybrid drive

ActiveCN103307060BQuick responseExtend your lifeServomotorsFluid-pressure actuator componentsHydraulic cylinderDifferential pressure

The invention provides a direct drive type servo pump control electro-hydraulic combined driving hydraulic cylinder control system and a control method. The control system comprises a servo motor driver module, a pump controlled cylinder module and an auxiliary oil circuit module, wherein a servo driver controls a servo motor to drive a two-way pump for generating hydraulic energy, two oil circuits of the two-way pump are connected with a rod port and a head port of the hydraulic cylinder respectively, an oil tank is used for oil topping up and oil drainage when the flow quantity of the rod port and the head port is unbalanced, and the direction of motion of a piston rod of the hydraulic cylinder is controlled by the positive and negative rotation direction of the servo motor. The direct drive type servo pump control electro-hydraulic combined driving hydraulic cylinder control system provided by the invention has the advantages that the problem of asymmetric flow quantity existing in a pump control hydraulic control is solved effectively, the circulating oil consumption of the system and the pressure loss caused by oil flowing are reduced, the overall system is compact and easy to realize integration, and the pressure loss and heating of a conventional electro hydraulic servo system caused by the differential pressure discharge characteristic of a proportioning valve or a servo valve are reduced greatly.

Owner:NANJING ESTUN AUTOMATION CO LTD

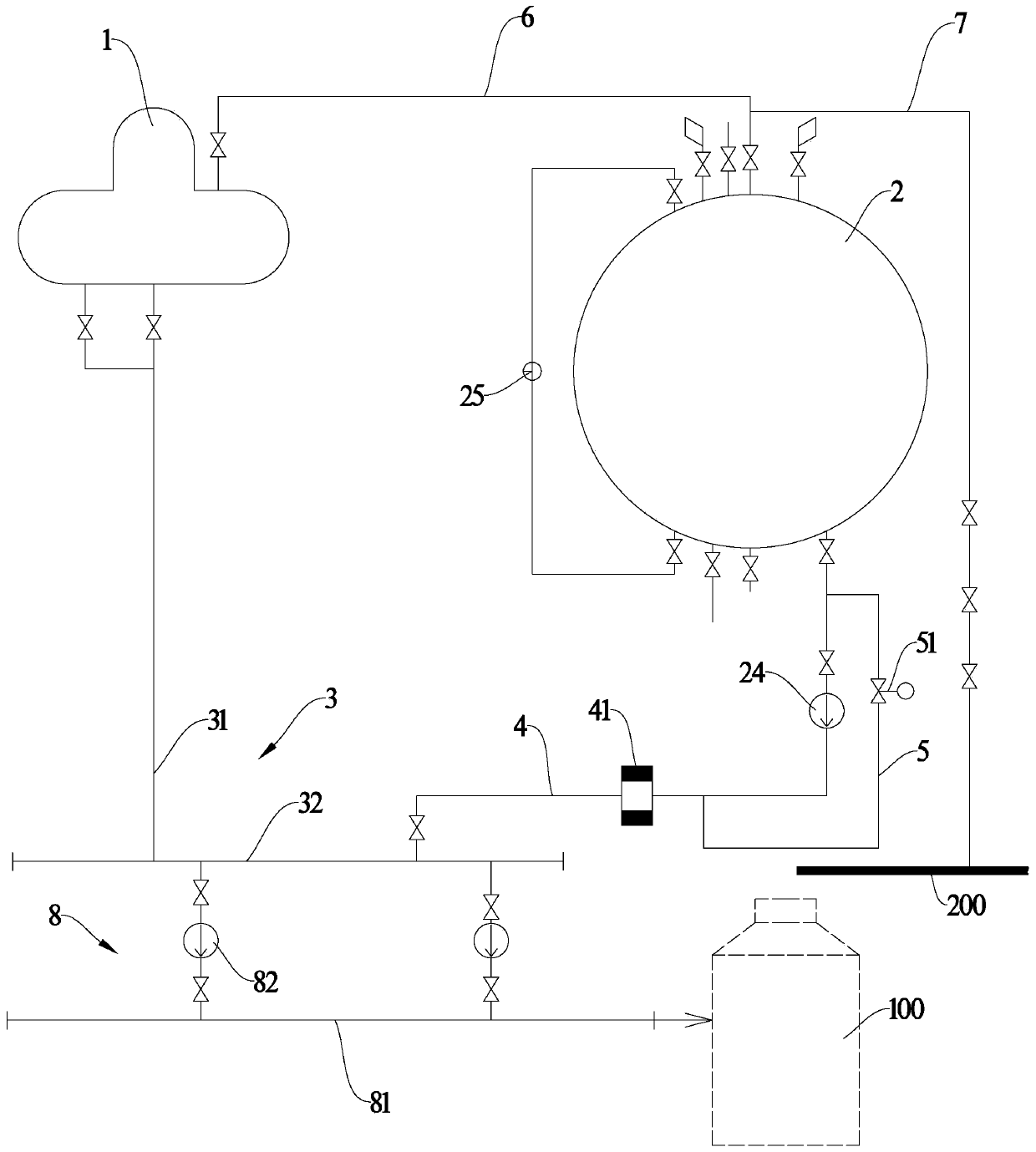

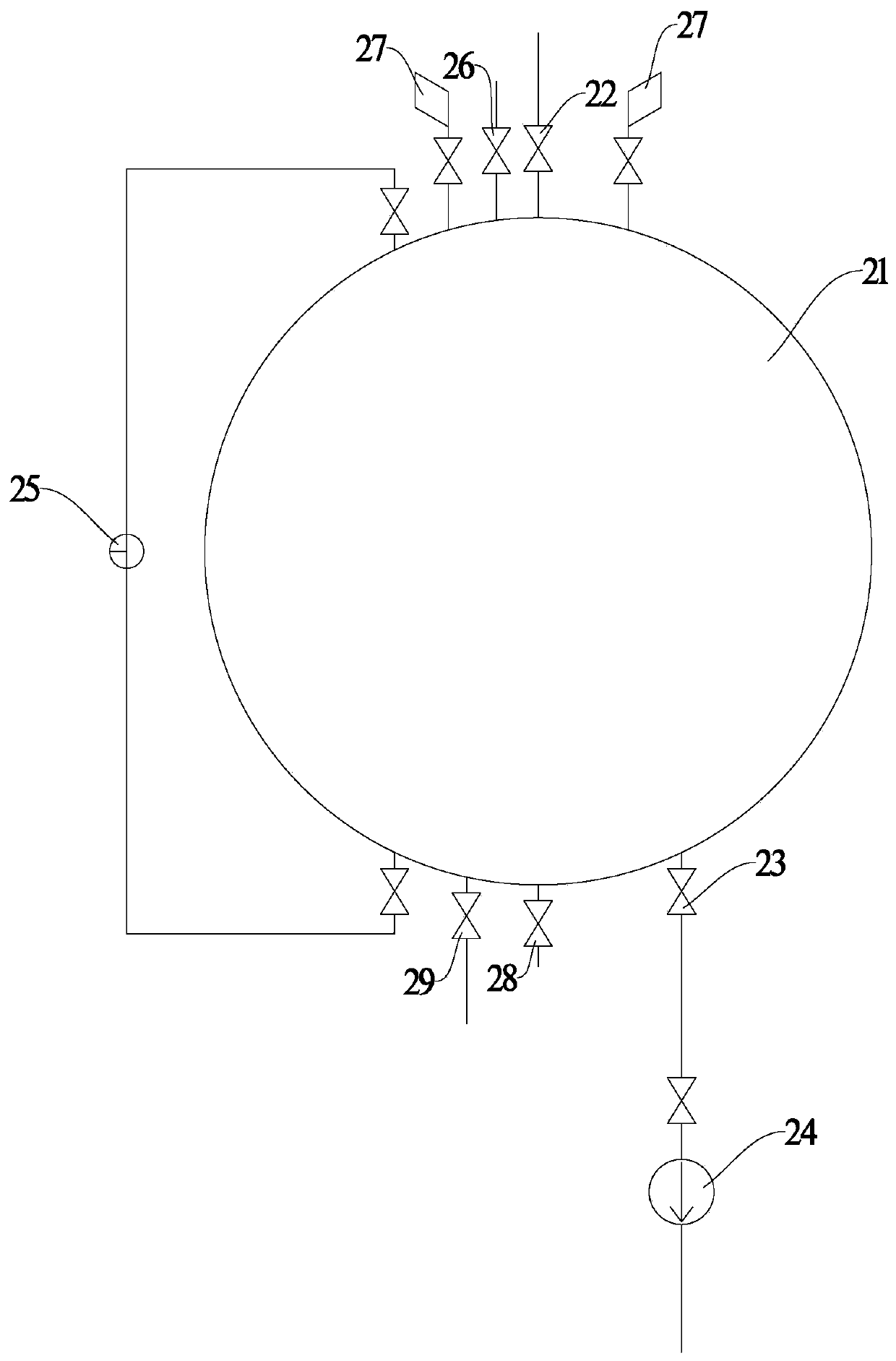

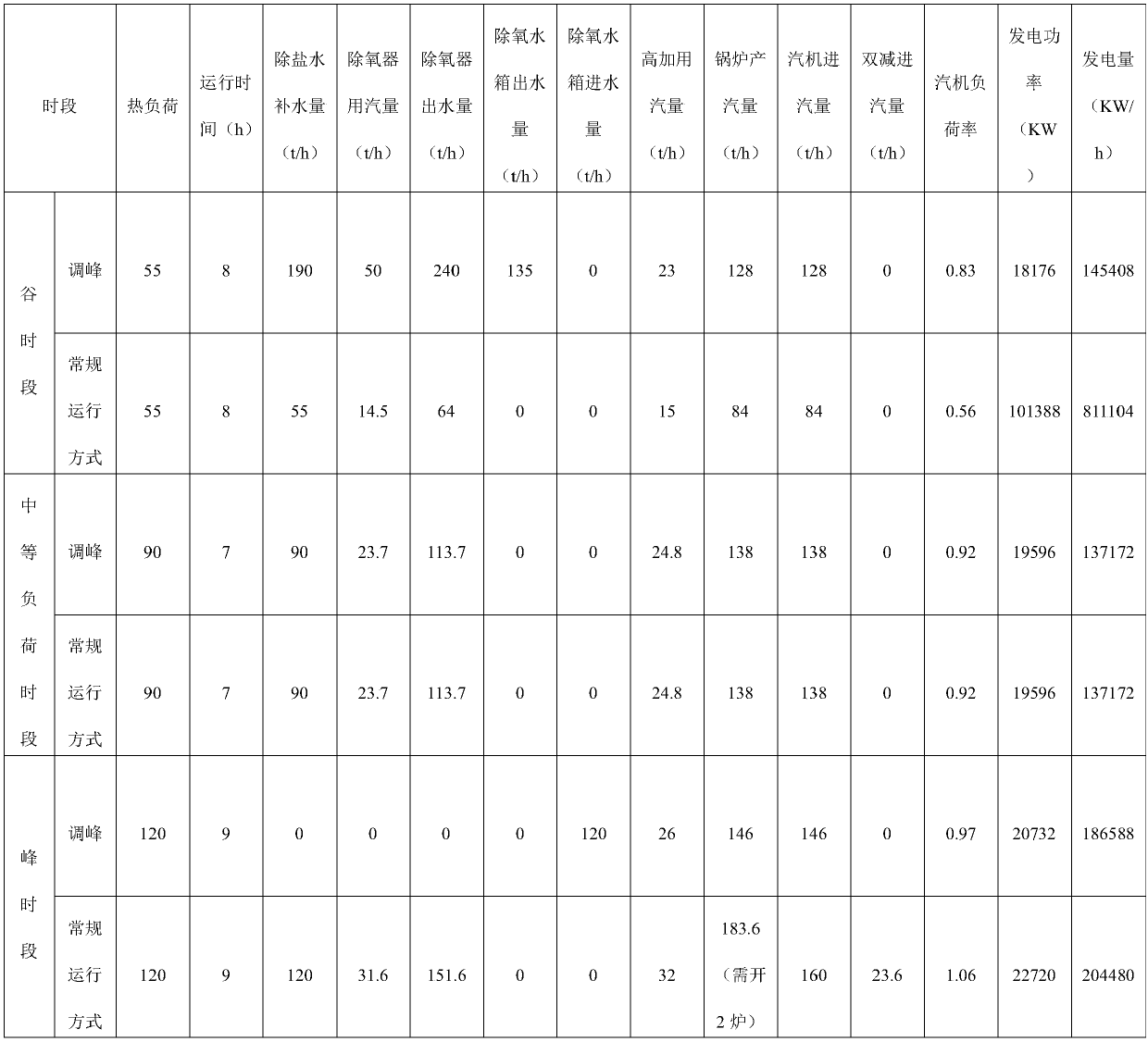

Power station energy storing and heating peak valley adjusting system and method

PendingCN110553247AIncrease steam consumptionIncrease loadLiquid degasificationFeed-water heatersEnvironmentally friendlyWater pipe

The invention provides a power station energy storing and heating peak valley adjusting system. The system comprises a deoxidizing device, a deoxidizing water tank, a deoxidizing device water supply pipeline, a water tank water supply pipeline, a by-pass adjusting pipeline, a steam balancing pipeline and a steam supplementing pipeline. The deoxidizing device is located at a high position. The lower end of the deoxidizing device is connected with the deoxidizing device water supply pipeline which is used for supplying water to a boiler. The upper end of the deoxidizing device is connected withthe steam balancing pipeline. The steam balancing pipeline is connected with the deoxidizing water tank and the steam supplementing pipeline. The steam supplementing pipeline is connected to a heatingfemale pipe. The deoxidizing water tank is located at the low position. The deoxidizing water tank comprises a tank body. A gas input valve is arranged at the upper end of the tank body and is connected with the steam balancing pipeline. A water supply valve is arranged at the lower end of the tank body. A hot water pump is connected to the water supply valve. The system has the advantages of being stable in operation, high in heating ability, high in energy source utilization rate, safe and environmentally friendly.

Owner:宁波正源电力有限公司

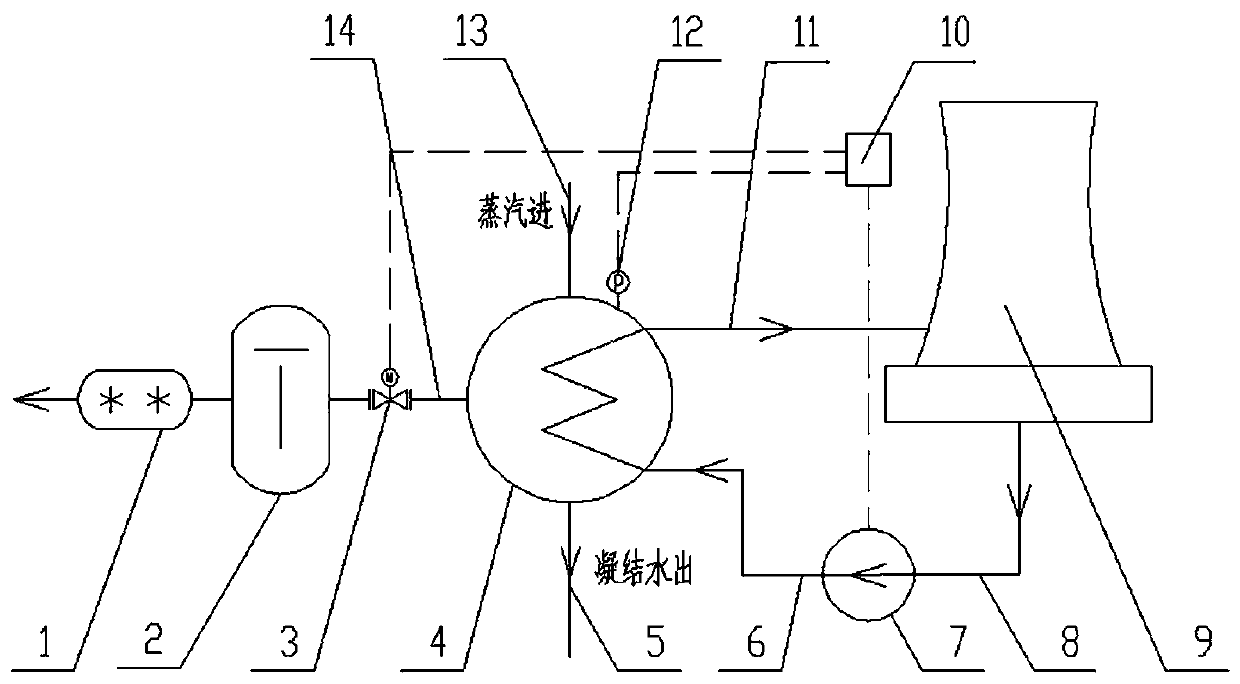

Condenser steam jet vacuum system

InactiveCN103321973AReduce lossImprove work performanceJet pumpsMachines/enginesCavitationEngineering

The invention discloses a condenser steam jet vacuum system which comprises a condenser pipeline connected with a condenser, a steam ejector set formed by at least a steam ejector I and a steam ejector II, and a condenser set formed by at least a condenser I and a condenser II. Power steam inlets of the steam ejector I and the steam ejector II are connected into power steam. Steam is used as media of the steam ejector I, and supersonic jet is produced through a power nozzle, so a head cavity is vaccumized to extract steam-gas mixtures in the condensers, the steam-gas mixtures exported from the condensers are mixed with the power steam and then are ejected into the condenser I through the steam ejector I to be processed in a condensed mode and finally are sucked in by the steam ejector II to be reprocessed. The condenser steam jet vacuum system is simple in structure and low in transformation cost, and can thoroughly solve the problem of unit efficiency reduction brought by vacuum pump cavitation.

Owner:上海赛迩福电力技术有限公司

A steel-plastic composite polyurethane movable guide vane vertical surface sealing device

ActiveCN105604768BSolve wear and tearImprove sealingHydro energy generationReaction enginesWater leakageResin-Based Composite

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

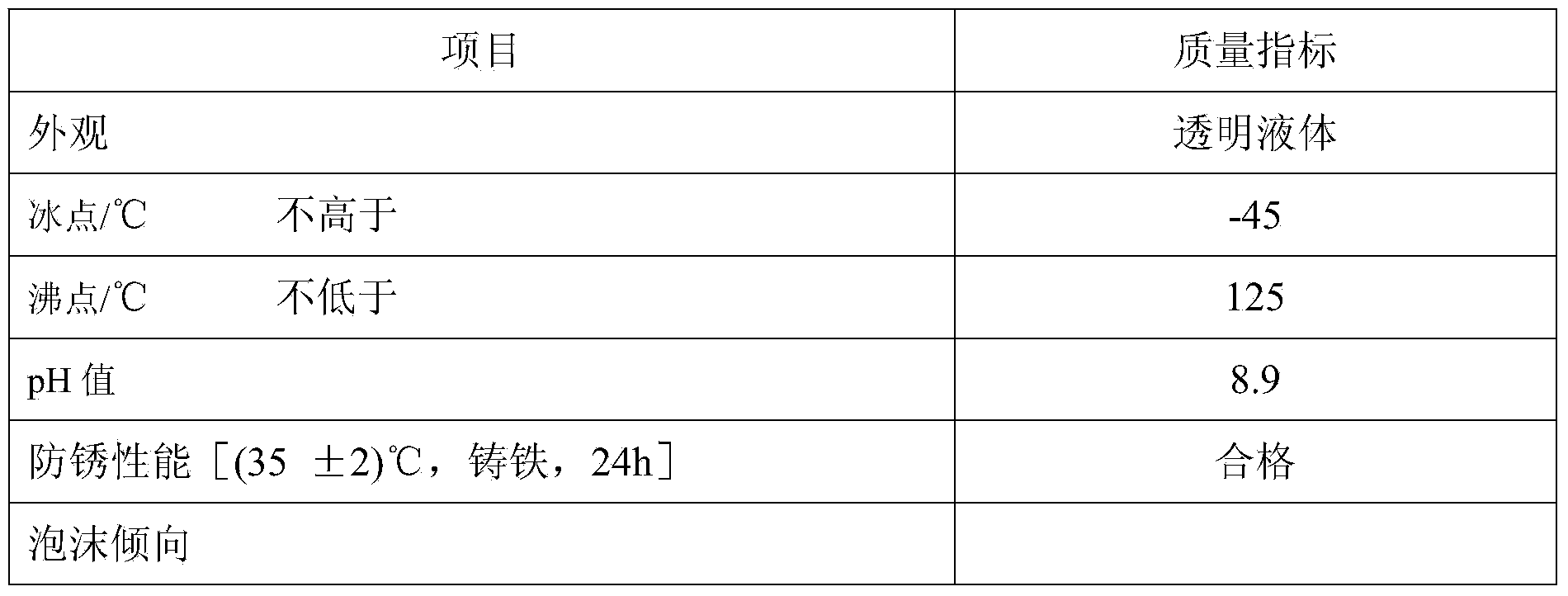

Fully formulated coolant for heavy-duty engine

ActiveCN103666400AImprove the protective effectExcellent corrosion and rust resistanceHeat-exchange elementsCavitationCooling effect

A fully formulated coolant for a heavy-duty engine adopts propylene glycol and ethylene glycol as basic liquids and compounds various composite additives including ethanol as an auxiliary, an inhibitor, an inhibition auxiliary, a rust inhibitor, deionized water and an antifoamer. The fully formulated coolant for the heavy-duty engine, disclosed by the invention, adopts an organic acid collaborative protection technique to solve the cavitation corrosion problem of a diesel engine cylinder so as to enhance protection capability, has excellent corrosion and rust resistance, storage stability, hard water resistance, cylinder cavitation corrosion protection and scale prevention, does not require a periodically compensated additive, has good thermostability and anti-foaming performance, is stable in form and outstanding in cooling effect, can prolong the service life, and can meet use requirements of a cooling system for a large-power and heavy-duty engine.

Owner:GUANGXI UNIV

Air conditioner, control method thereof, and computer readable storage medium

PendingCN110513922ASolve the problem of cavitationEliminate flashingMechanical apparatusSpace heating and ventilation safety systemsEngineeringCoolant pump

The invention discloses an air conditioner. The air conditioner comprises a compressor, a first heat exchanger, a coolant pump and a second heat exchanger, wherein the compressor, the first heat exchanger, the coolant pump and the second heat exchanger communicate with one another in sequence to form a coolant circulation loop; the air conditioner further comprises a flash evaporation bypass one-way valve; one end of the flash evaporation bypass one-way valve communicates with the outlet of the coolant pump; the other end of the flash evaporation bypass one-way valve communicates with the inlet of the first heat exchanger; when the flash evaporation bypass one-way valve is opened, the compressor is shut down; and the coolant pump, the flash evaporation bypass one-way valve and the first heat exchanger form an internal loop. The invention further discloses a control method of the air conditioner, and a computer readable storage medium. The air conditioner disclosed by the invention caneliminate the phenomenon of flash evaporation, caused by sudden reduction of the pressure of a coolant, of the air conditioner after the compressor is shut down and the coolant pump runs.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Heat energy circulating system of coating production line

ActiveCN101799204ASediment conveniencePrevent Negative Pressure ProblemsEnergy industryWater heatersPipingThermal energy

The invention relates to a heat energy circulating system of a coating production line, which comprises a heating water tank of a pre-treatment system of the coating production line and a drying box of a drying facility of the coating production line, wherein a stainless steel inner container and a combustor are fixed in a furnace body; the combustor is fixed to the lower part of the stainless steel inner container; an air outlet of a circulating calorifier is communicated with the furnace body; an atmosphere communicating vent opening into atmosphere directly is arranged at the top of the furnace body; a water outlet pipe and a return pipe are arranged on the stainless steel inner container; a hot-water circulating pump is arranged on the water outlet pipe; the water outlet pipe is communicated with hot-water inlets of the heating water tank of the pre-treatment system of the coating production line and the drying box of the drying facility of the coating production line; and hot-water outlets of the heating water tank of the pre-treatment system of the coating production line and the drying box of the drying facility of the coating production line are communicated with the return pipe. The heat energy circulating system has the advantages of completely eradicating the phenomenon of the negative pressure of a loop and a water outlet pipe and solving the problems of the cavitation of the water circulating pump and the water attack of the system along with good anti-explosion performance and convenient overhauling.

Owner:ZHEJIANG MINGQUAN INDAL COATING

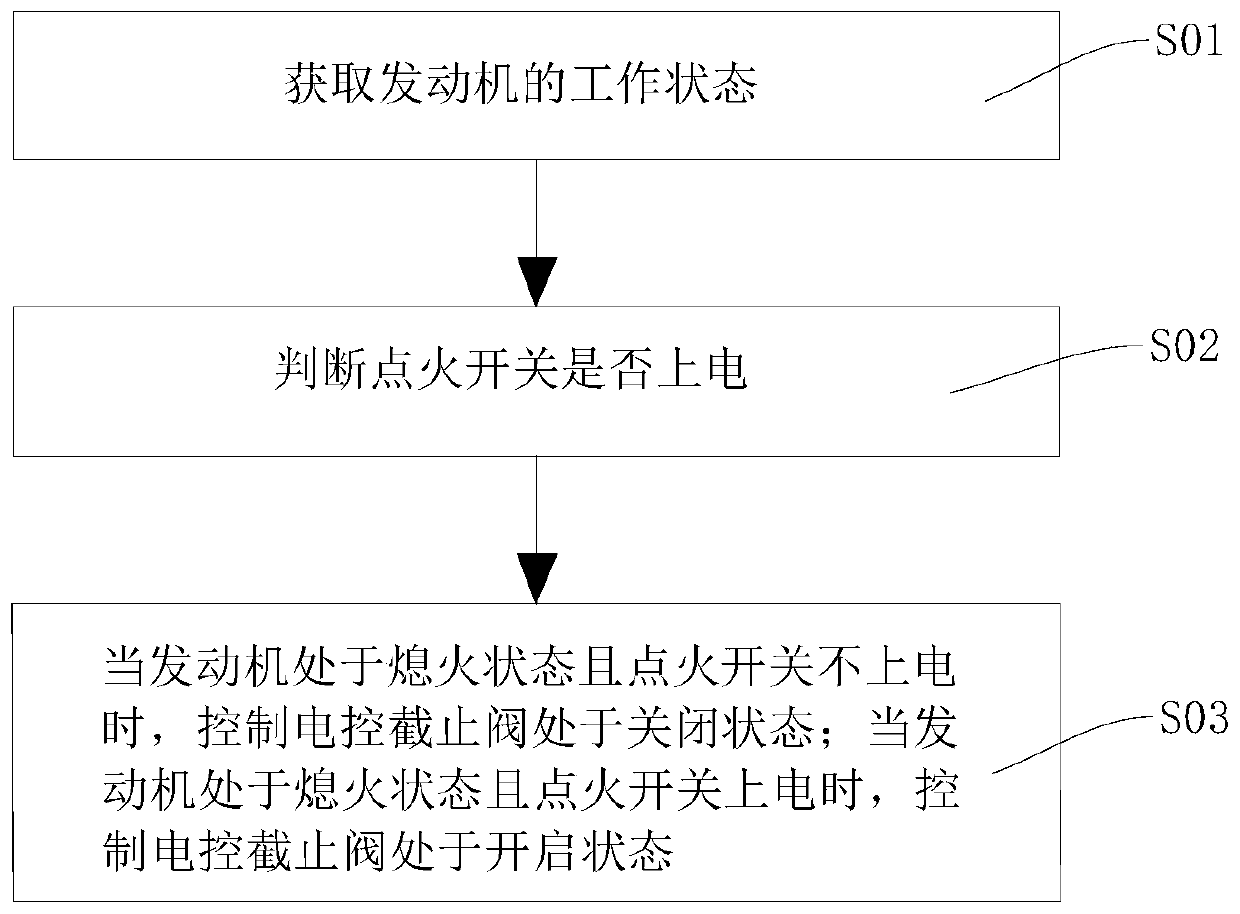

Hydraulic system, excavator and control method

PendingCN110939171AAvoid secondary pollutionCause secondary pollutionServomotorsSoil-shifting machines/dredgersThermodynamicsElectric control

The embodiment of the invention provides a hydraulic system, an excavator and a control method, and relates to the engineering equipment technology field. The hydraulic system comprises a controller,a power pump, an electric control stop valve, an oil inlet pipe and an oil tank. The electric control stop valve is arranged on a pipeline of the power pump and the oil tank, the oil inlet pipe is connected with the power pump, hydraulic oil in the oil tank is pumped into the oil inlet pipe through the power pump, and the oil inlet pipe is used for being connected with a breaking hammer so as to supply oil to the breaking hammer. When maintenance is needed, the oil tank can be separated from the pipeline only through closing the electric control stop valve, the hydraulic oil of a whole machinedoes not need to be pumped, secondary pollution to the hydraulic oil in a maintenance process can be effectively avoided, and maintenance is more convenient and fast. The controller is electrically connected with the electric control stop valve and is used for controlling the electric control stop valve so that opening and closing of the electric control stop valve are intelligently controlled through the controller, and fool-proof and mistake-proof problems in a use process of a user are solved.

Owner:SANY HEAVY MACHINERY

Oil cylinder core tube cavitation corrosion prevention system for crane and crane with same

ActiveCN103615440ASolve the problem of cavitationAvoid jitter failuresCranesFluid-pressure actuator componentsCavitationStreamflow

The invention relates to an oil cylinder core tube cavitation corrosion prevention system for a crane and the crane with the oil cylinder core tube cavitation corrosion prevention system. The oil cylinder core tube cavitation corrosion prevention system for the crane comprises a telescopic changeover valve, a cavitation corrosion prevention overflow valve, a first directional control valve, a second directional control valve, a primary oil cylinder and a secondary oil cylinder, wherein the cavitation corrosion prevention overflow valve comprises a first oil port and a second oil port, the first directional control valve comprises a first control oil port, a second control oil port, four working oil port and two working positions, the second directional control valve comprises four working oil ports and two working positions, the primary oil cylinder comprises a core tube cavity, a rod cavity and a rodless cavity, and the secondary oil cylinder comprises a rod cavity and a rodless cavity. According to the oil cylinder core tube cavitation corrosion prevention system for the crane, due to the facts that a core tube oil supplementation channel is added, and the flow of supplemented oil is reasonably matched, the core tube cavity can be kept to be in the constant pressure state all the time, and the problem that cavitation corrosion of the core tube cavity happens due to the fact that negative pressure exists in a core tube is effectively solved; in addition, the phenomenon that extension of a third arm, a fourth arm and a fifth arm delays can be avoided, and a shaking fault of a pipeline can be prevented from happening.

Owner:XUZHOU HEAVY MASCH CO LTD

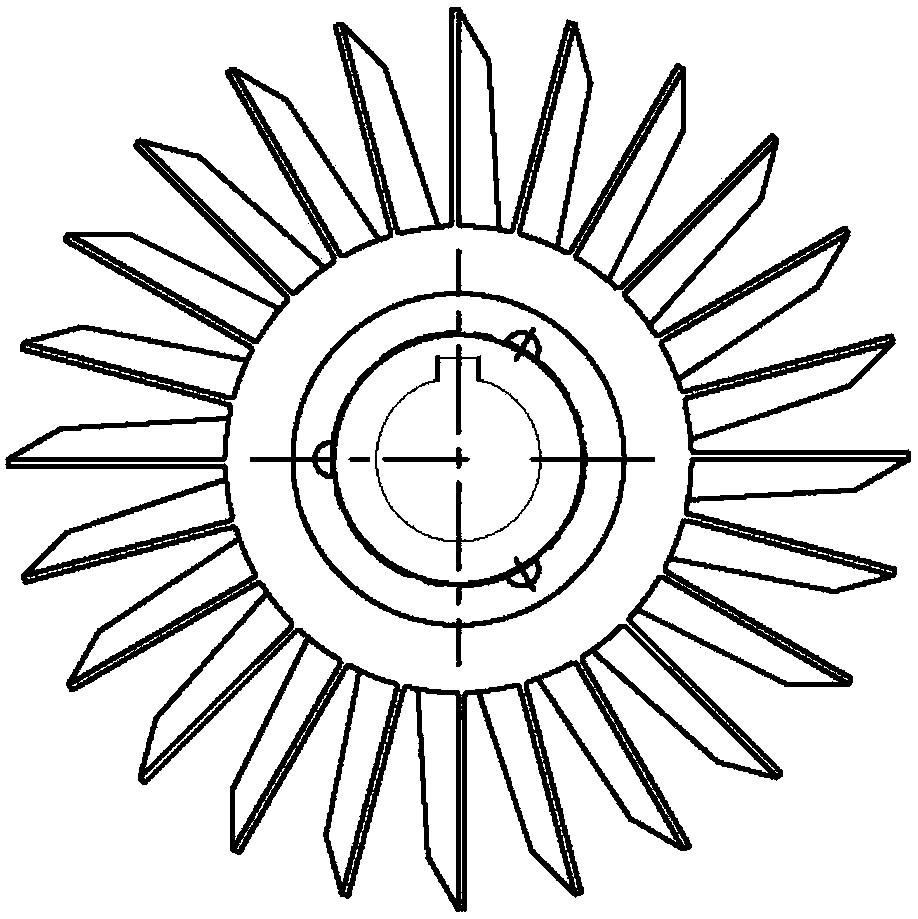

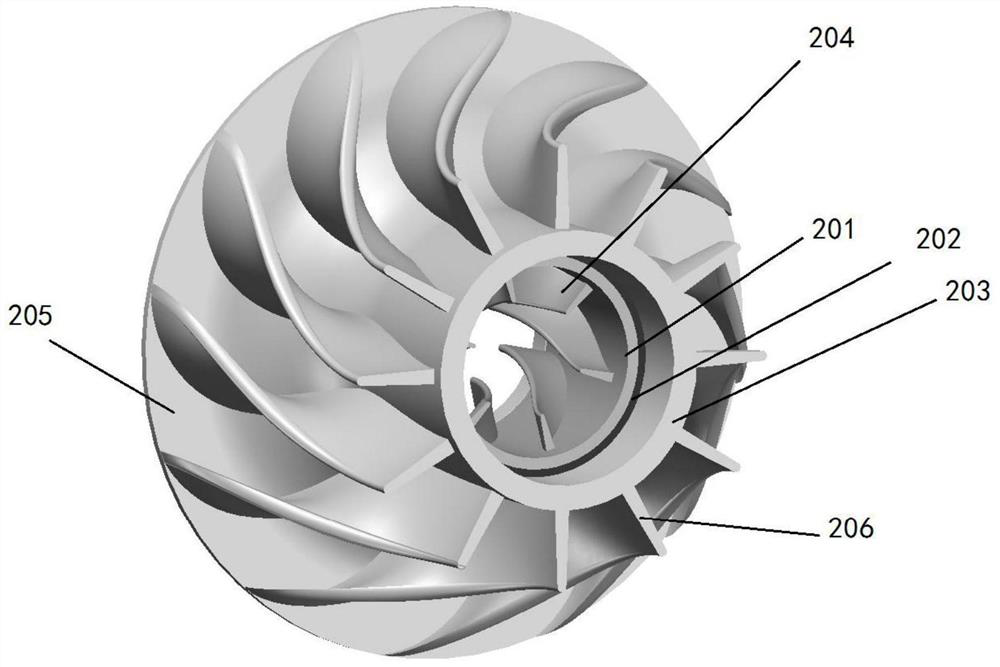

Axial flow impeller

An axial flow impeller comprises an impeller body which is provided with a guide blade. The guide blade and a rotating shaft of the axial flow impeller form an inclined angle, a transmission shaft connecting device is arranged on the impeller body, and the area of the guide blade is enlarged gradually from two ends of the impeller to the middle part of the impeller. The axial flow impeller fully utilizes circumference motion and fluid motion and utilizes eddy to buffer energy and mix fluid, thus generating higher pushing force and pressure. The axial flow impeller can replace the existing impellers of axial flow water pumps, axial flow fans, spraying devices, atomization devices, screw propellers and the like, saves more energy, lowers noise, and can realize higher rotating speed, higher pressure, longer service life and lower construction cost.

Owner:陈久斌

Cold end system of thermal power plant and controlling method of cold end system

PendingCN107621175AIncrease pressureRelieve pressureSteam/vapor condensersVacuum pumpingInlet channel

The invention relates to a cold end system of a thermal power plant and a controlling method of the cold end system. The cold end system is characterized in that the cold end system comprises a condenser, a circulating water outlet pipeline, a cooling tower, a circulating water inlet channel, a frequency conversion circulating pump and a circulating water inlet pipeline; one end of the circulatingwater outlet pipeline is connected to an outlet of the water side of the condenser, and the other end of the circulating water outlet pipeline is connected to an inlet of the cooling tower; the outlet of the cooling tower is connected with one end of the circulating water inlet channel, and the other end of the circulating water inlet channel is connected with an inlet of the frequency conversioncirculating pump; one end of the circulating water inlet pipeline is connected with an outlet of the frequency conversion circulating pump, and the other end of the circulating water inlet pipeline is connected with an inlet of the water side of the condenser; and a steam inlet pipeline and a condensed water outlet pipeline are connected to the condenser. According to the cold end system of the thermal power plant, design is reasonable, and conception is unique; and through comprehensive consideration of the cold end system of the thermal power plant and optimized design of the condenser, a circulating water pump, the cooling tower and a vacuum pumping system, pressure of the condenser can be effectively reduced, and standard coal consumption of power supply of a unit can be reduced.

Owner:HANGZHOU HUADIAN ENERGY ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com